Plating of high-volume-fraction silicon carbide particle reinforced aluminum-based composite and preparation method thereof

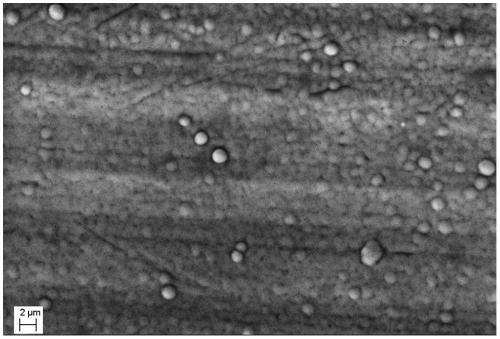

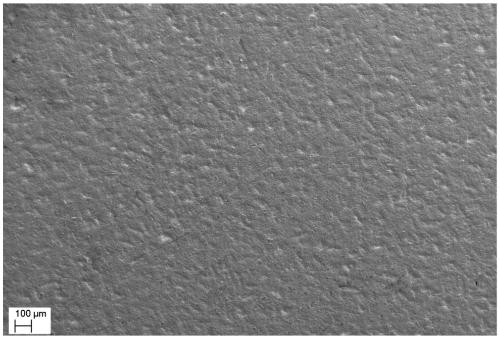

A technology of silicon carbide particles and high volume fraction, applied in metal material coating process, liquid chemical plating, coating, etc., can solve the problems of poor microscopic continuity of the coating, and achieve improved protection ability, high wear resistance and corrosion resistance Good performance and continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0068] 1) Wipe the surface of the high volume SiCp / Al composite material with absolute ethanol;

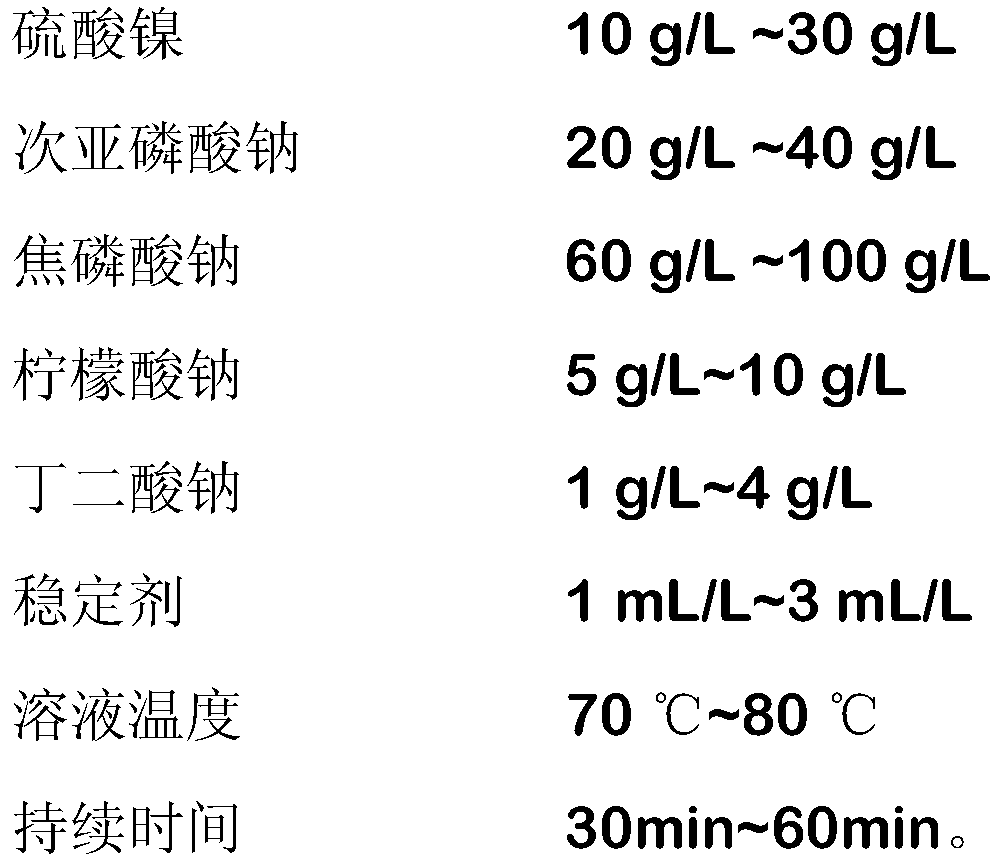

[0069] 2) The surface of the high volume SiCp / Al composite material obtained in step 1) is chemically degreased, and the formula and operating conditions of the chemical degreasing solution are as follows:

[0070]

[0071]

[0072] After the chemical degreasing is completed, the high volume SiCp / Al composite material is taken out of the solution;

[0073] 3) washing the residual solution on the surface of the high volume SiCp / Al composite material obtained in step 2) with water;

[0074] 4) Light-emitting the surface of the high-volume SiCp / Al composite material obtained in step 3), the formula and operating conditions of the light-emitting solution are as follows:

[0075] Nitric acid 500g / L

[0076] Solution temperature room temperature

[0077] Duration 30s

[0078] After the light emission is completed, the high-volume SiCp / Al composite material is taken out of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com