Flexible MEMS resistance reducing covering and method of manufacturing the same

A manufacturing method and flexible technology, applied in the manufacture of microstructure devices, impedance networks, gaseous chemical plating, etc., can solve the problems of high power consumption, cavitation noise and shortened voyage, and achieve good drag reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

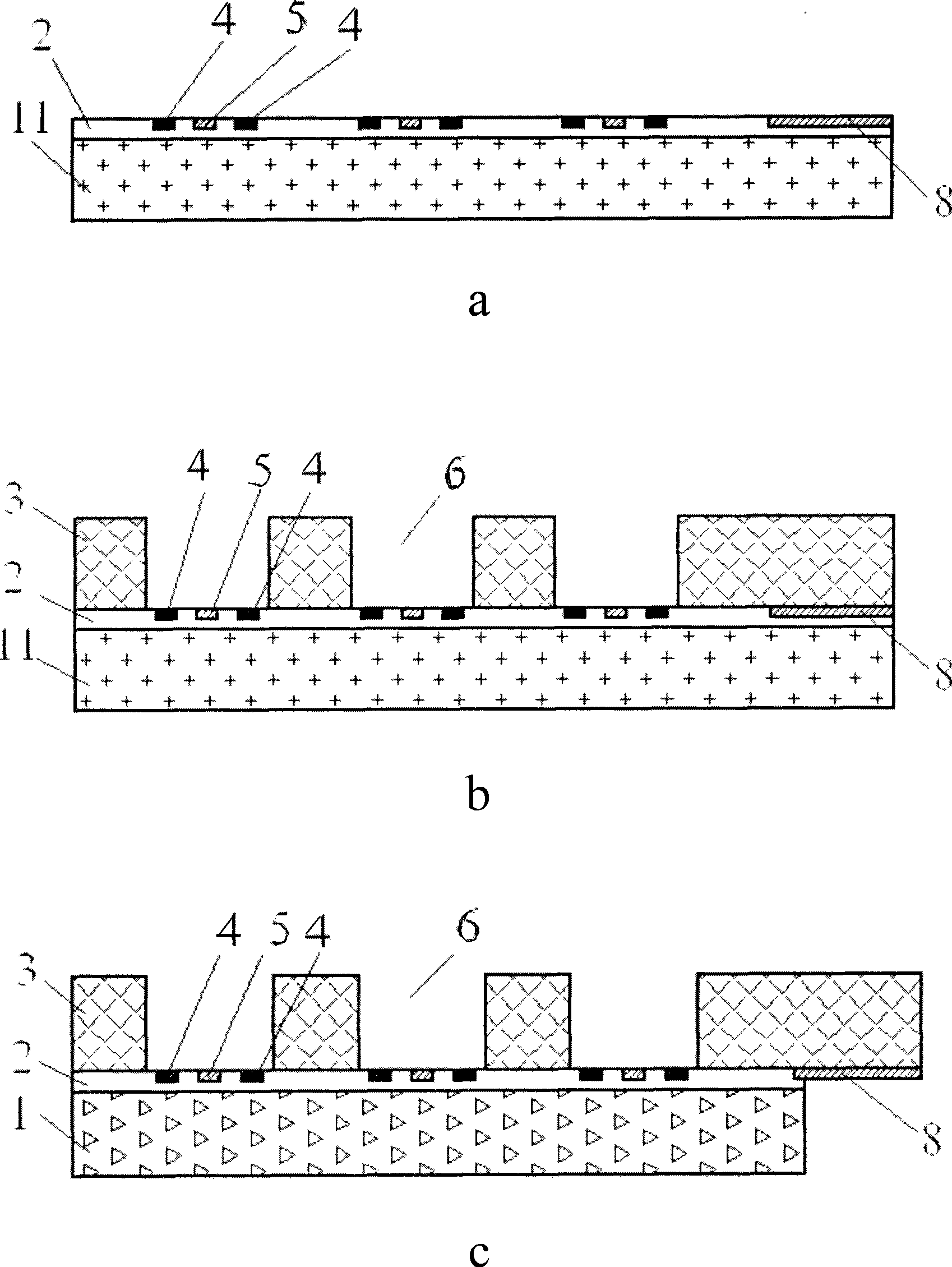

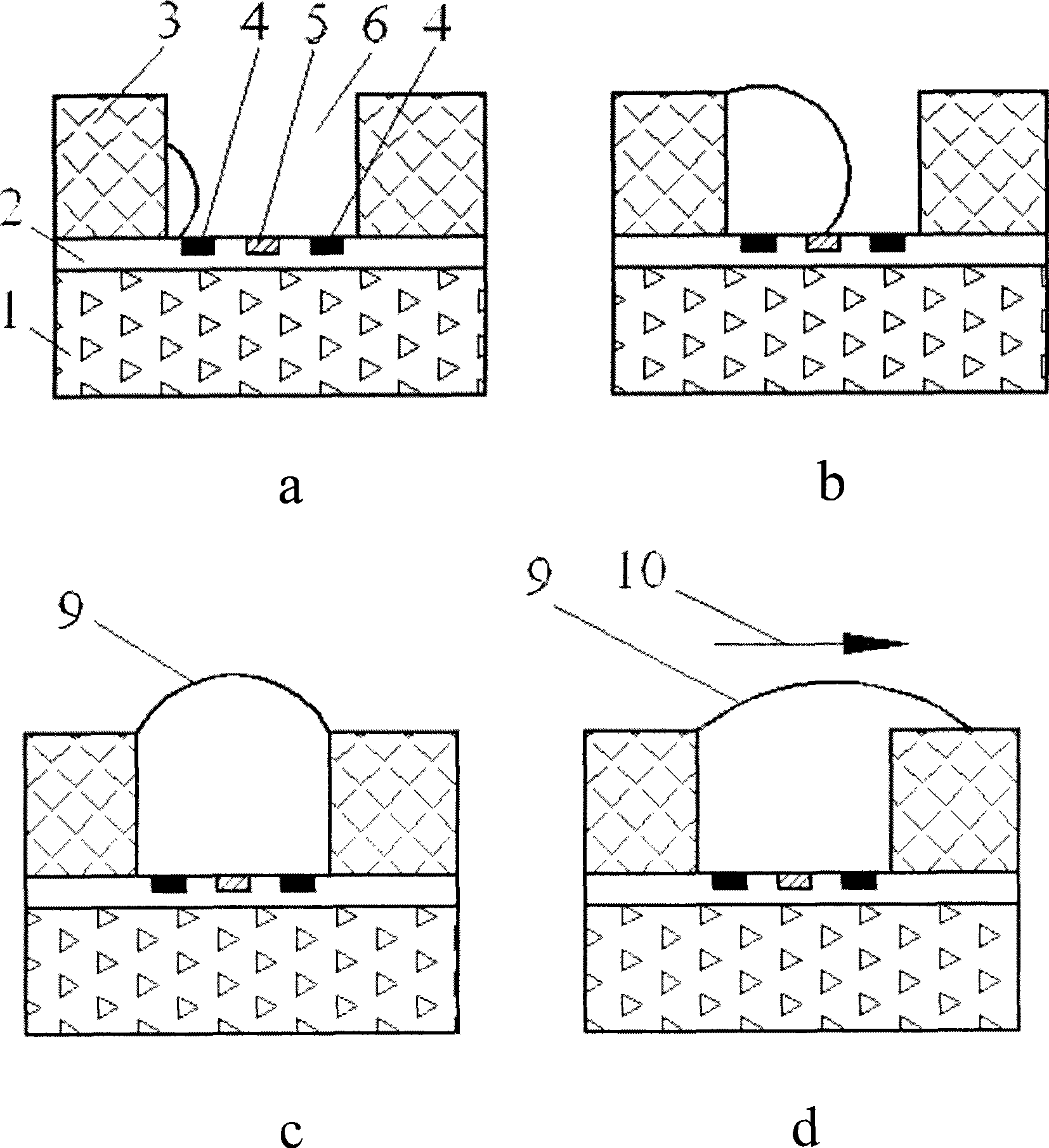

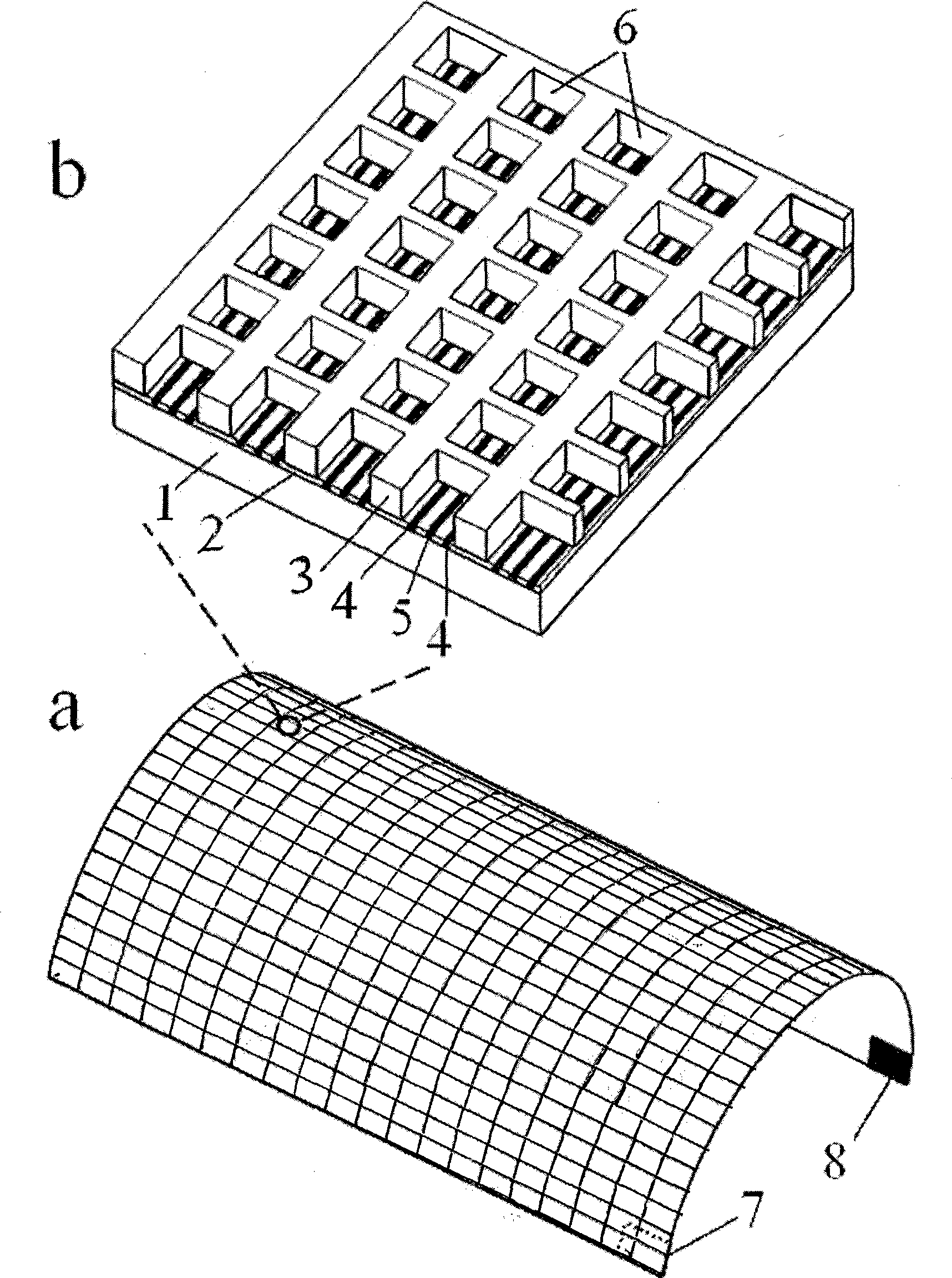

[0042] Based on the comprehensive analysis of the two drag reduction technologies of bubble injection and supercavitation film, the present invention proposes a new drag reduction principle: drag reduction by resident microbubbles. Bubbles are not injected into the fluid boundary layer, but are controlled to stably attach and reside on the surface of the water surface and the outer wall of the underwater vehicle. A large number of attached micro-bubbles isolate most of the water-solid interface, and the liquid-solid interface becomes liquid. - The air interface, so that the surface frictional resistance of the vehicle during travel is significantly reduced. Combined with flexible MEMS technology, a flexible film structure is made to obtain a drag-reducing skin suitable for water surface and underwater vehicles.

[0043] The following are examples of the present invention, and the implementation of the present invention will be described in conjunction with the accompanying dra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com