Temperature-control expansion plugging material for well drilling and preparation method thereof

A plugging material and drilling technology, which are applied in the directions of building thermal insulation materials, chemical instruments and methods, drilling compositions, etc., can solve problems such as being unsuitable for drilling plugging operations, affecting the effect of plugging, and reducing the strength of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

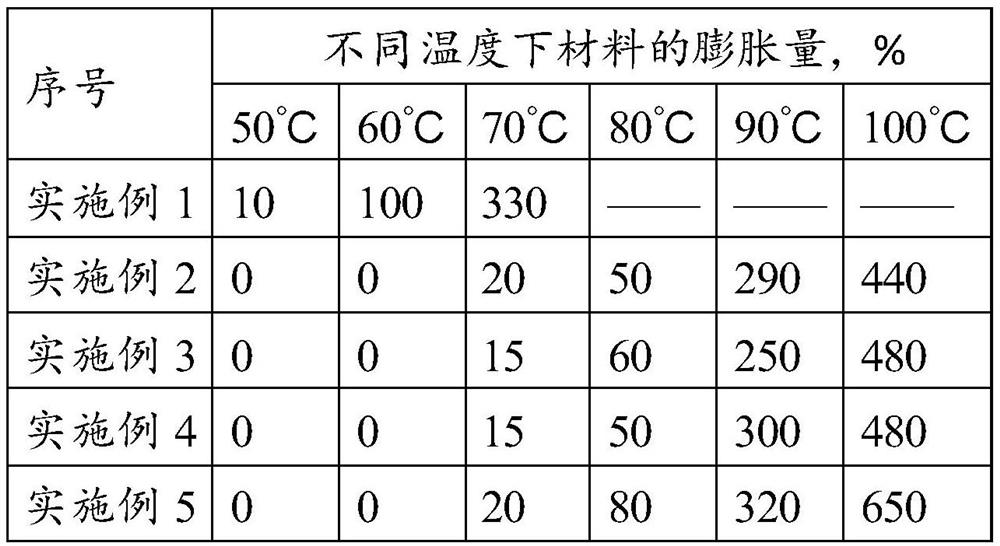

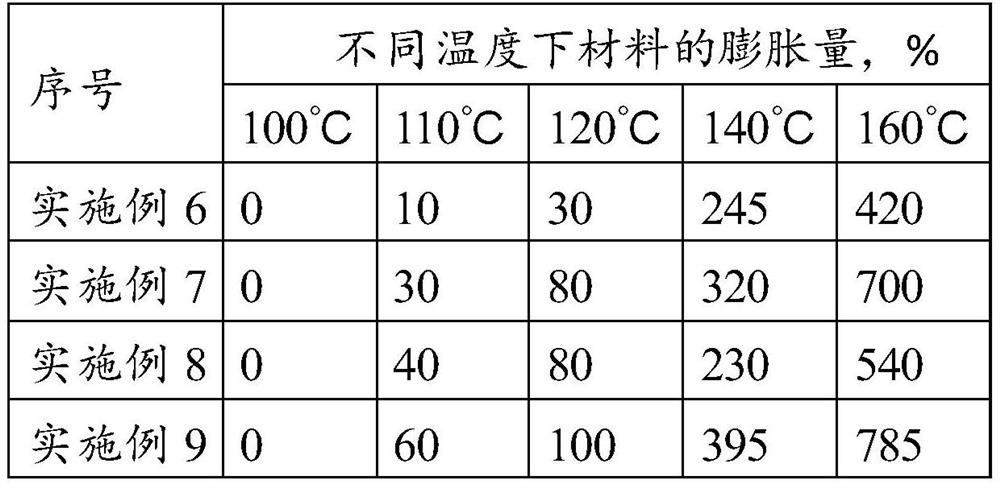

Examples

Embodiment 1

[0030] Take a polyurethane foam with a length of 500mm, a width of 400mm, a thickness of 10mm, and a pore diameter of 0.4mm (provided by Shuxin Sponge Factory, Xihe Town, Longquanyi District), and immerse it in molten 64# paraffin (provided by the E-Commerce Operation Department of Dakang Industrial Raw Materials, Linyi Mall) ), let the paraffin fully enter the polyurethane foam, and then place the paraffin-coated polyurethane foam on a flat press before the paraffin solidifies, and slowly pressurize to compress the polyurethane foam thickness to 3mm. After the paraffin is completely solidified, use scissors The cutting equipment cuts the compressed and shaped polyurethane foam into particles of different shapes with a side length of about 2-5mm to obtain a temperature-controlled expansion plugging material for drilling.

Embodiment 2

[0032] Get long 500mm, wide 400mm, thick 30mm, the polyurethane foam (provided by Shuxin Sponge Factory, Xihe Town, Longquanyi District) with a length of 500mm, wide 400mm, thick 30mm, and immerse it in melting 90# microcrystalline wax (Hebei Dongguang County Qinyuan Wax Products Factory) Provided), let the microcrystalline wax fully enter the polyurethane foam, and then place the polyurethane foam covered with the microcrystalline wax on a flat press before the microcrystalline wax solidifies, and pressurize slowly to compress the thickness of the polyurethane foam to 5mm. After the microcrystalline wax is completely solidified, use a shearing device to cut the compressed and shaped polyurethane foam into particles of different shapes with a side length of about 3-6 mm to obtain a temperature-controlled expansion plugging material for drilling.

Embodiment 3

[0034]Take a polyurethane foam with a length of 500mm, a width of 400mm, a thickness of 30mm, and a pore diameter of 0.8mm (provided by Shuxin Sponge Factory, Xihe Town, Longquanyi District), and immerse it in molten Fischer-Tropsch wax (provided by the E-Commerce Operation Department of Dakang Industrial Raw Materials, Linyi Mall) ), allow the Fischer-Tropsch wax to fully enter the polyurethane foam, then place the polyurethane foam coated with the Fischer-Tropsch wax on a flat press before the Fischer-Tropsch wax solidifies, pressurize slowly, and compress the thickness of the polyurethane foam to 5mm. After the wax is completely solidified, use a shearing device to cut the compressed and shaped polyurethane foam into particles of different shapes with a side length of about 3-6 mm to obtain a temperature-controlled expansion plugging material for drilling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com