Time-limit-free passive combined heat removal system with integrated heat release trap

A heat removal system and passive technology, applied in the field of passive safety systems, can solve the problems of increasing the volume of the nuclear power plant containment and construction costs, and achieve the effects of low maintenance costs, simplified system layout, and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

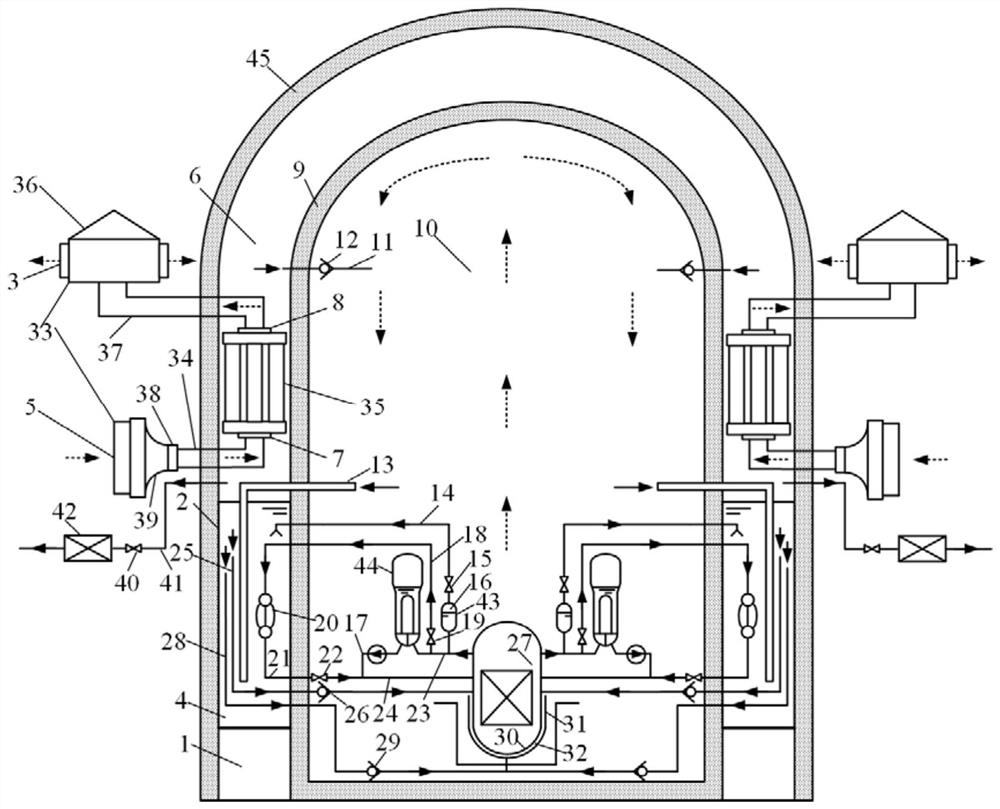

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030]Because different passive systems in the existing passive safety system design schemes of nuclear power plants have their own cooling water tanks / heat sinks, this is not conducive to the simplification of system equipment in the containment, and does not make full use of the space inside the containment. In addition, the existing containment passive heat removal system is mainly used to alleviate the second pressure peak in the containment under breach accident conditions, but there is no effective solution for the relief of the first pressure peak. Based on the large available space in the interlayer of the double-layer concrete containment vessel, the present invention arranges an integrated heat release trap in the air space of the interlayer, which can provide cooling water sources for multiple passive safety systems, thereby...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com