Patents

Literature

61results about How to "No change in mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc-nickel seeping layer ferrous metal corrosion protection process

ActiveCN101319300AHigh hardnessImprove wear resistanceSolid state diffusion coatingAl powderRolling resistance

The invention discloses a process for resisting ferrous metal corrosion of a zinc nickel diffusion layer. The process comprises the steps of alkaline degreasing, shot blasting, heating diffusion layer, water washing dust removal and colorful closing according to the requirement of a customer, wherein in the heating diffusion layer step, the zinc nickel diffusion layer and a metal matrix are put in a sealed metallic container and heated; the zinc nickel diffusion layer is prepared by evenly mixing the following powders in mass proportion: 20 to 30 percent of Zn powder, 0.5 to 1.4 percent of Ni powder, 3 to 12 percent of Al powder, 2 to 6 percent of rare earth, 1 to 4 percent of NH4Cl ammonium chloride, the balance being Al2O3 powder. The diffusion layer has the advantages of high rigidity, good wear resistance, unchangeableness of original mechanical performances of products, high adhesion strength, bumping and rolling resistance, good solderability, moisture and heat resistance and acid and alkali resistance; the diffusion layer has uniform thickness and compactness, and appearances of finished products have good uniformity; and no three-waste emission occurs during the course of processing, so the process belongs to the clean production process and is environment-friendly.

Owner:CHONGQING DAYOU SURFACE TECH

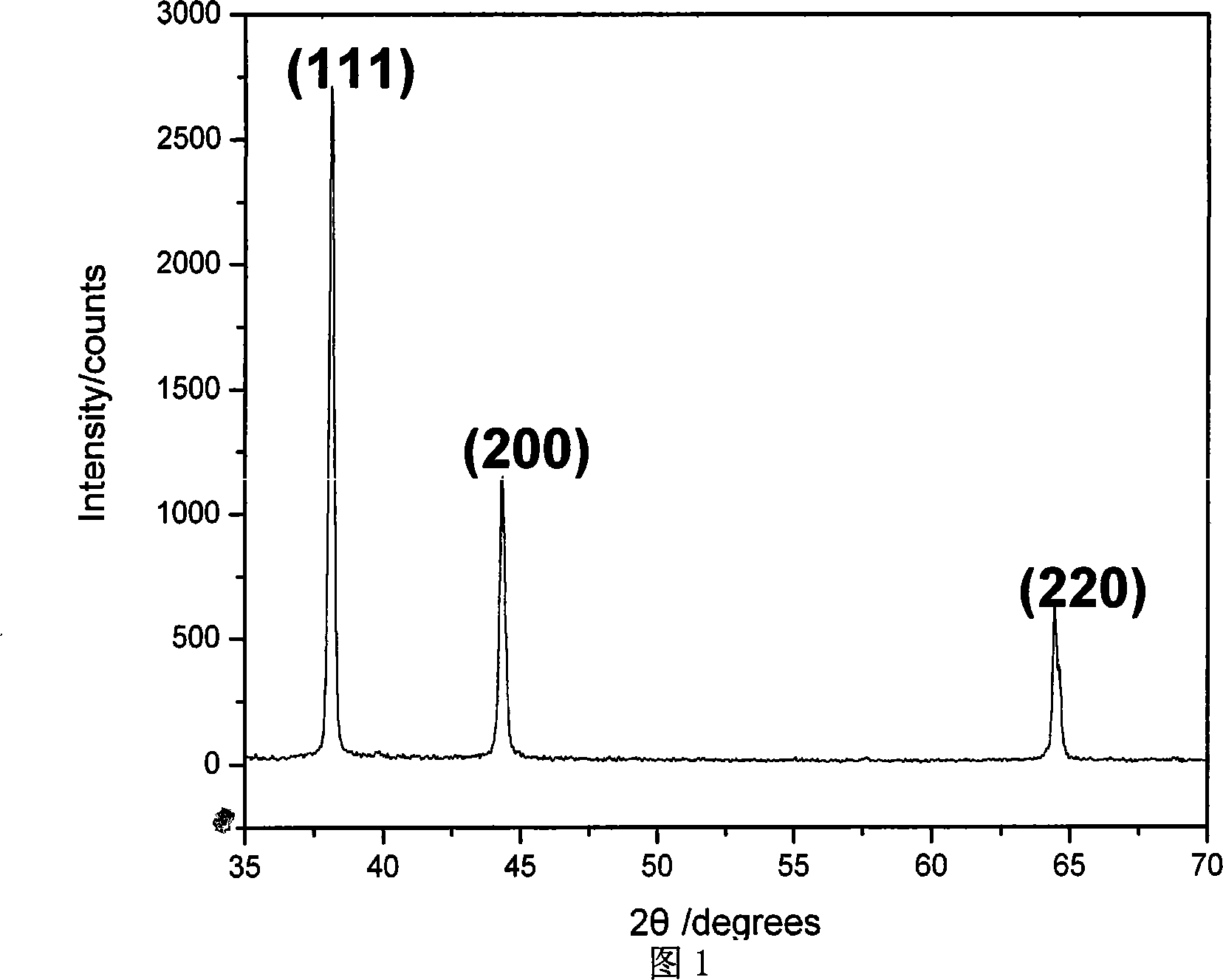

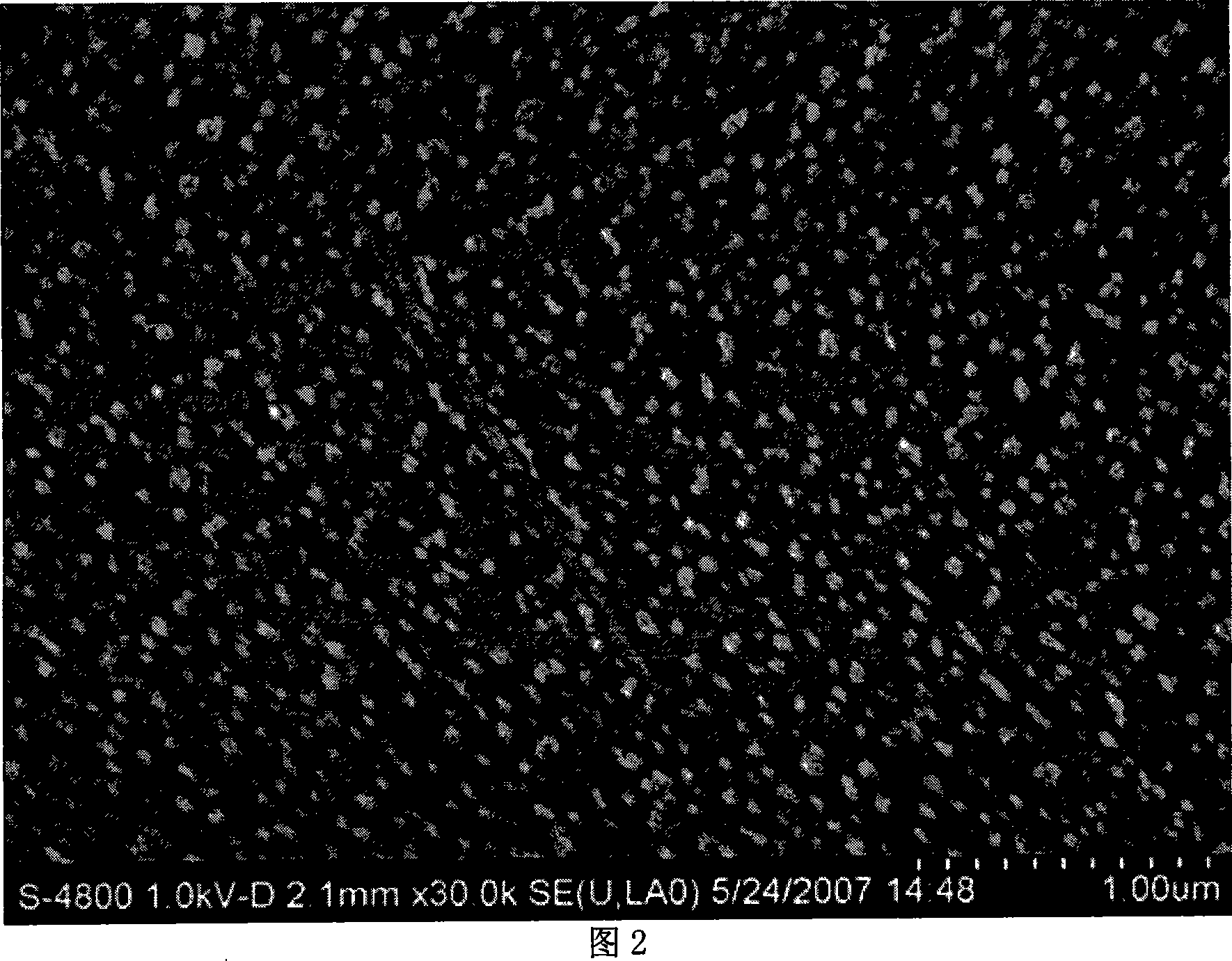

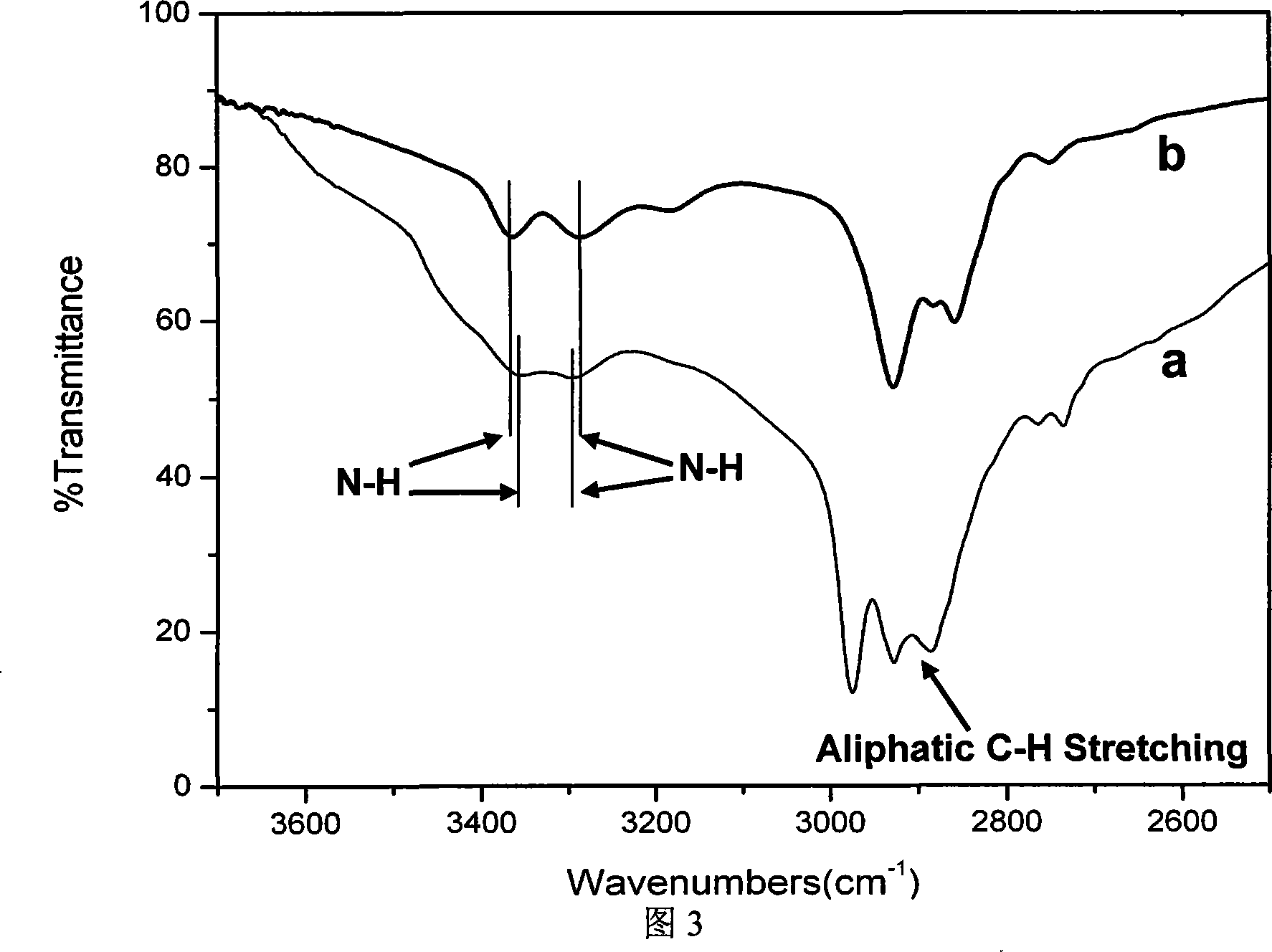

Nano silver composite antibacterial material using porous ceramics as carrier and preparation method thereof

InactiveCN101054218AHigh activityNo change in mechanical propertiesWater/sewage treatment using germicide/oligodynamic-processFiltration separationAlcoholSilanes

The invention relates to a nano-Ag compound antisepsis material using porous porcelain as the carrier and method for preparing same. In the method, coupling agent modified porous porcelain is dipped in 10-100nm nano-Ag sol for 12-24 hours, which is then taken out and washed with alcohol and the product is obtained after drying. The porous porcelain material is selected from the porous porcelain for filtering water, and the coupling agent is ramda-mercaptopropyl trimethoxy silane or ramda-aminopropyl triethoxy silane. The invention modifies the porous porcelain carrier with the coupling agent, fixes the nano-Ag in and on the surface of the porous porcelain in a chemical bonding way, which can reach the effects of uniform dispersion without changing the original mechanical properties of the porous porcelain, not easy fall-off in friction and impact condition and sterilization in continuance. The invention is characterized in small consumption of raw materials, simple processing, low production cost and short production period.

Owner:SHANDONG UNIV

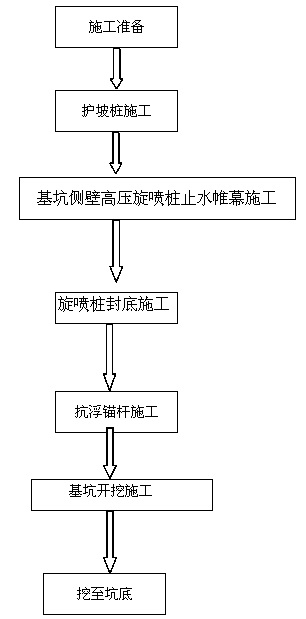

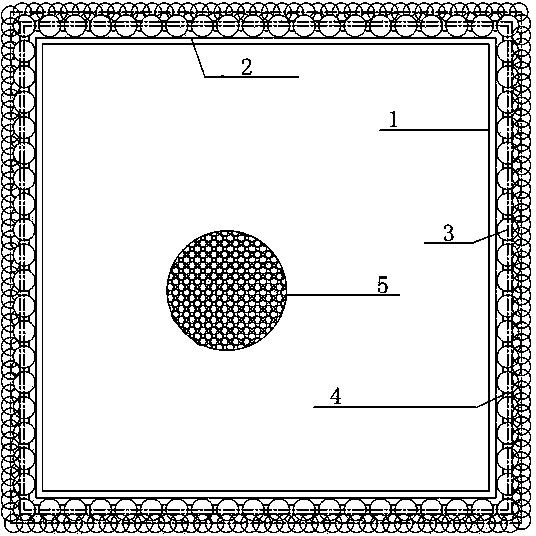

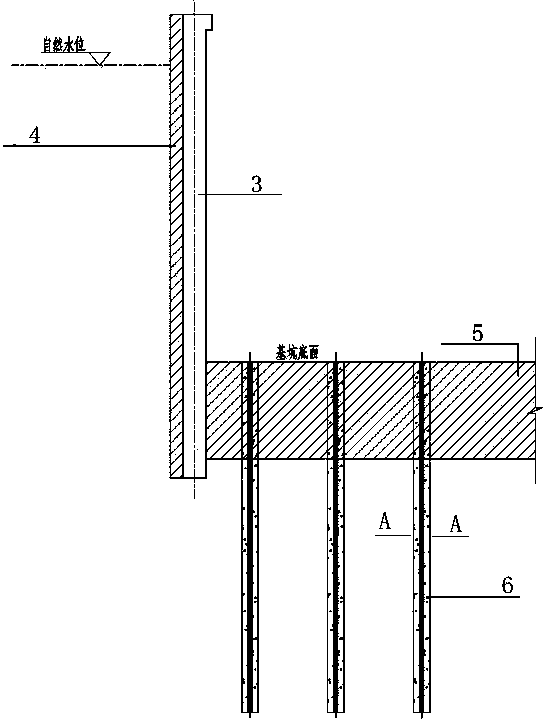

Top-down construction method for anchor rod and rotary jet grouting back cover deep foundation pit without precipitation operation

ActiveCN103993603AClosely connectedEffective water blocking systemExcavationsBulkheads/pilesWater tableEngineering

The invention belongs to the technical field of civil engineering and particularly relates to a top-down construction method for an anchor rod and rotary jet grouting back cover deep foundation pit without precipitation operation. The top-down construction method for the anchor rod and rotary jet grouting back cover deep foundation pit without precipitation operation particularly comprises the steps of construction preparation, construction of a water stop curtain of a high-pressure rotary jet grouting pile of the side wall of the foundation pit, construction of a rotary jet grouting pile back cover, construction of an anti-floating anchor rod, and excavation of the foundation pit. The water stop curtain of the high-pressure rotary jet grouting pile of the side wall of the foundation pit is connected with the jet grouting pile back cover, and the anti-floating anchor rod is connected with the rotary jet grouting pile back cover of the anchor rod. According to the top-down construction method, it can be ensured that a side wall support is closely connected with the rotary jet grouting pile back cover while the requirements for strength, stability and impermeability from construction of the water stop curtain of the high-pressure rotary jet grouting pile of the side wall of the foundation pit, the jet grouting pile back cover and the anti-floating anchor rod are met, the external anchorage section of the anti-floating anchor rod is located in the rotary jet grouting pile back cover, an effective water stop system can be formed in the deep foundation pit, and influence on construction from the underground water level does not need to be controlled.

Owner:中冶沈勘工程技术有限公司

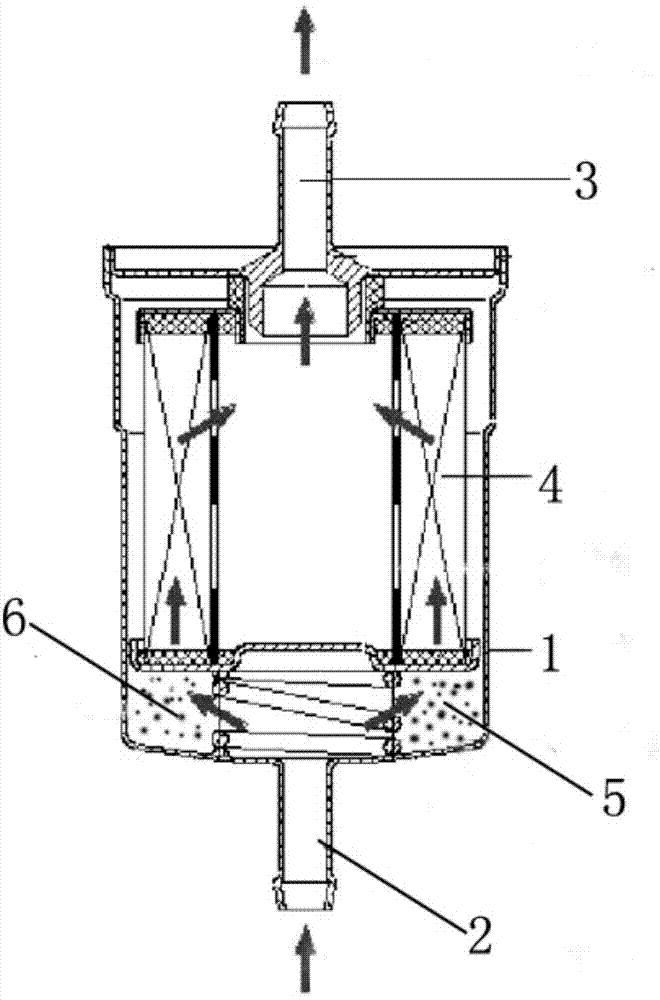

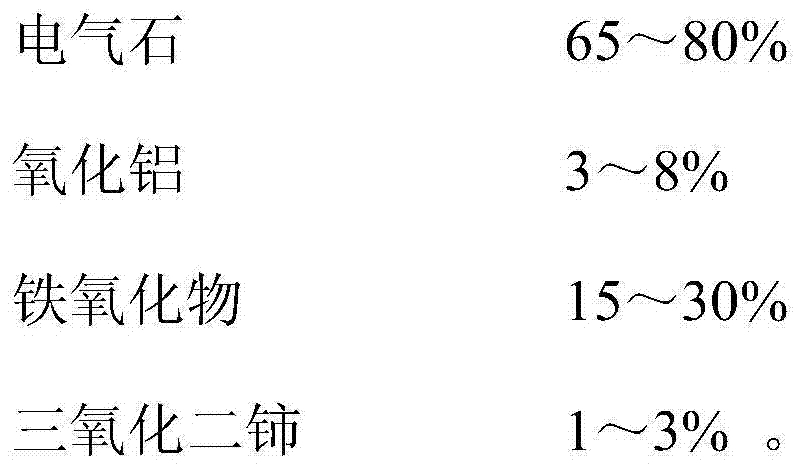

Vehicular internal combustion engine fuel-borne catalyst and application thereof

InactiveCN104845682AImprove combustion efficiencyHigh calorific valueInternal combustion piston enginesCombustion-air/fuel-air treatmentGasolineInternal combustion engine

The invention discloses a vehicular internal combustion engine fuel-borne catalyst and application thereof. The vehicular internal combustion engine fuel-borne catalyst comprises, by mass percent, 65-80% of tourmaline, 3-8% of aluminum oxide, 15-30% of iron oxide and 1-3% of dicerium trioxide. The vehicular internal combustion engine fuel-borne catalyst has the advantages of safety, reliability, simplicity in application, no physicochemical damage to an engine, no influence on a vehicular structure, a circuit, an oil circuit and mechanical properties, capability of achieving remarkable energy-saving and emission-reducing effects, lower vehicular maintenance cost, higher power, low use cost and long service life and can be applied to various diesel vehicles, gasoline vehicles, LPG (liquefied petroleum gas) vehicles and the like.

Owner:余任文

Low-alloy super-strength steel and heat treatment technique for the same

InactiveCN101078088ANo change in mechanical propertiesImprove hardenabilityBearing componentsHeat treatment process controlMartensiteUltimate tensile strength

A kind of low alloy martensite steel with high strength, the character of it is the component range as following, quality percent: C0.3-0.6,Mn0.8-2.0,i0.1-0.4,r0.8-2.0,o0.1-0.4,l1.0-2.5,S<0.0l,P<0.01, the other is Fe. The steel will be stabilized after quenching and backfire at low temperature. The low alloy steel in this patent, can own very high strength and certain tenacity after a simple heat treatment, as a result the cost of it is lower.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Black ceramic and method for enhancing blackness of black ceramic

PendingCN106495746ADoes not affect blacknessReduce reflectionMechanical propertyToxic industrial waste

The invention provides a method for enhancing blackness of a black ceramic. The method is characterized in that an antireflection film (AR film) is arranged on a black ceramic substrate layer. According to method for enhancing blackness of a black ceramic, the surface of the black ceramic substrate layer is not destroyed, and the original high-gloss mirror surface effect of the black ceramic substrate layer is retained; according to method for enhancing blackness, the mechanical property of the black ceramic substrate layer is not changed, and vacuum coating is only performed on the surface of the black ceramic substrate layer; the method for enhancing blackness is applicable to black ceramic substrate layers of all materials, and the blackness can be further enhanced on the basis of the original blackness of the black body; if the blackness of the black ceramic is inappropriate, the AR film can be removed, and a new AR film can be coated again; the black ceramic body can be used repeatedly, thereby lowering the cost; the method for enhancing blackness is simple to operate, involves no three industrial wastes in the process, and is green and environment-friendly; the AR film is colorless and transparent and realizes pure blackness enhancing; and after being coated with the hard AR film, the black ceramic substrate layer is scratch-resistant, thereby being durable in use.

Owner:CHAOZHOU THREE CIRCLE GRP

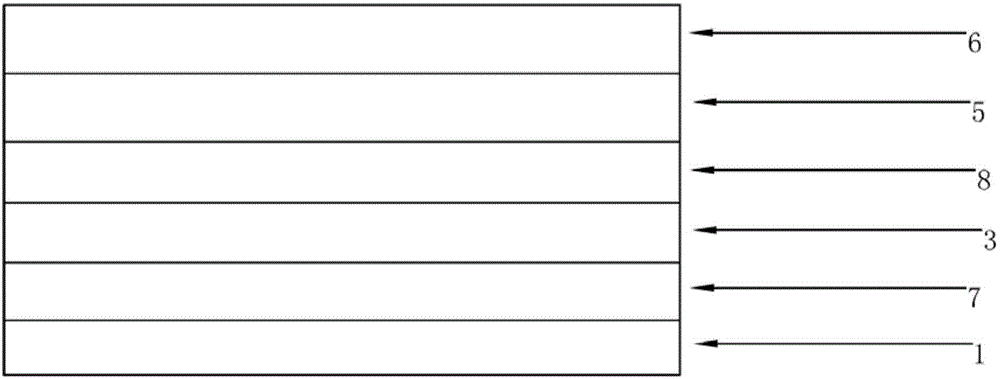

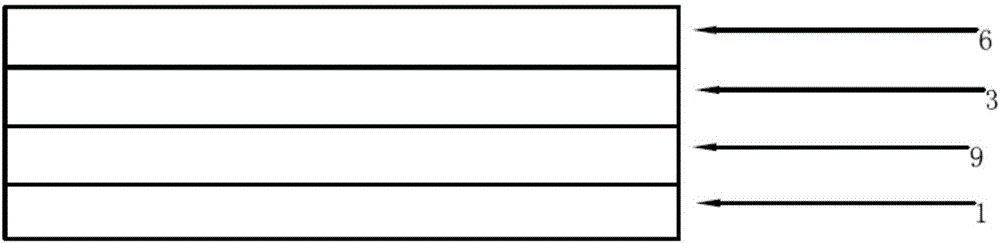

Spray-free metal-like color master batch

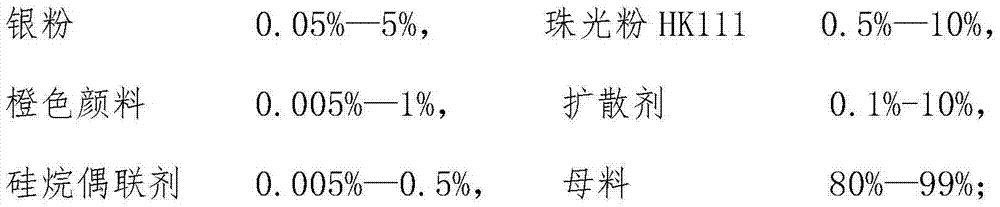

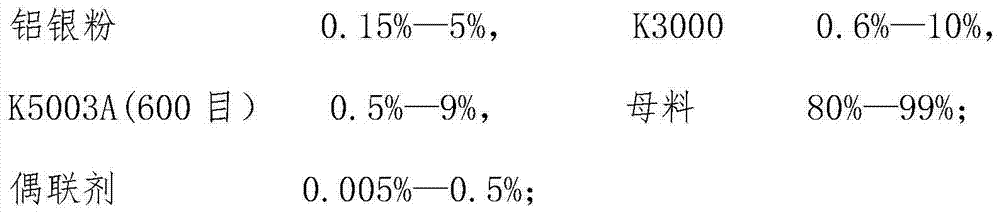

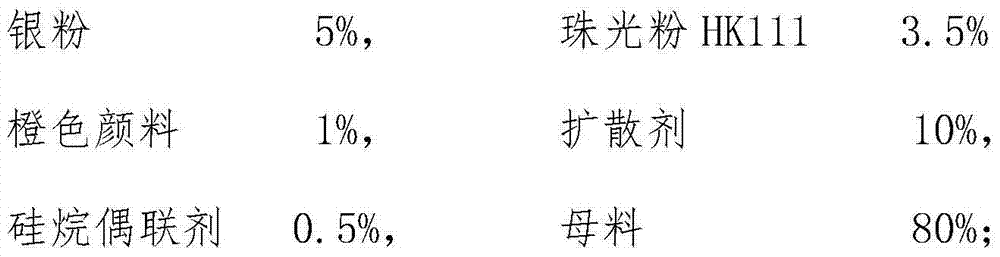

The invention relates to a spray-free metal-like color master batch which is composed of aluminum powder, pearl powder HK111, orange pigment, diffusant, silane coupling agent and master batch. The resin and gold / aluminum powder are organically combined and pretreated, so that the plastic product has the glossiness which is not less than metals. The spray-free metal-like color master batch has the advantages of excellent dispersity, excellent high temperature resistance, higher corrosion resistance and one-step forming, does not change the mechanical properties of the resin, does not influence the processability of the resin, greatly shortens the production cycle of the enterprise, lowers the production cost, and can substitute steel with plastics in deed.

Owner:LIANGCAI DYE ZHONGSHAN IND

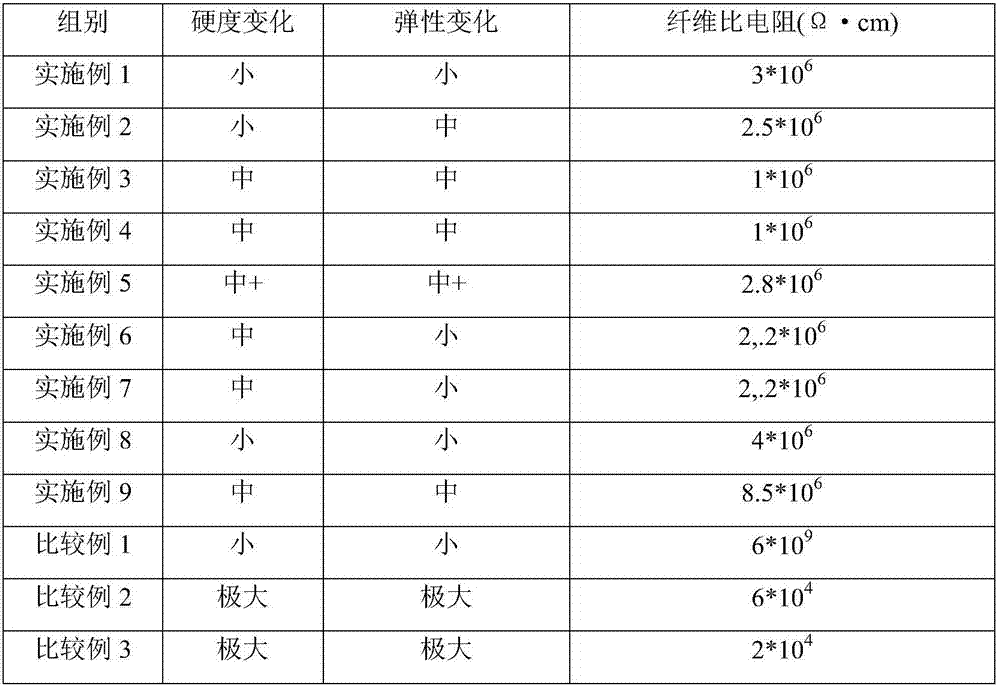

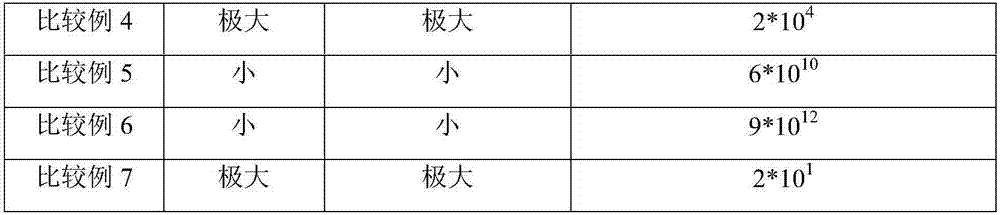

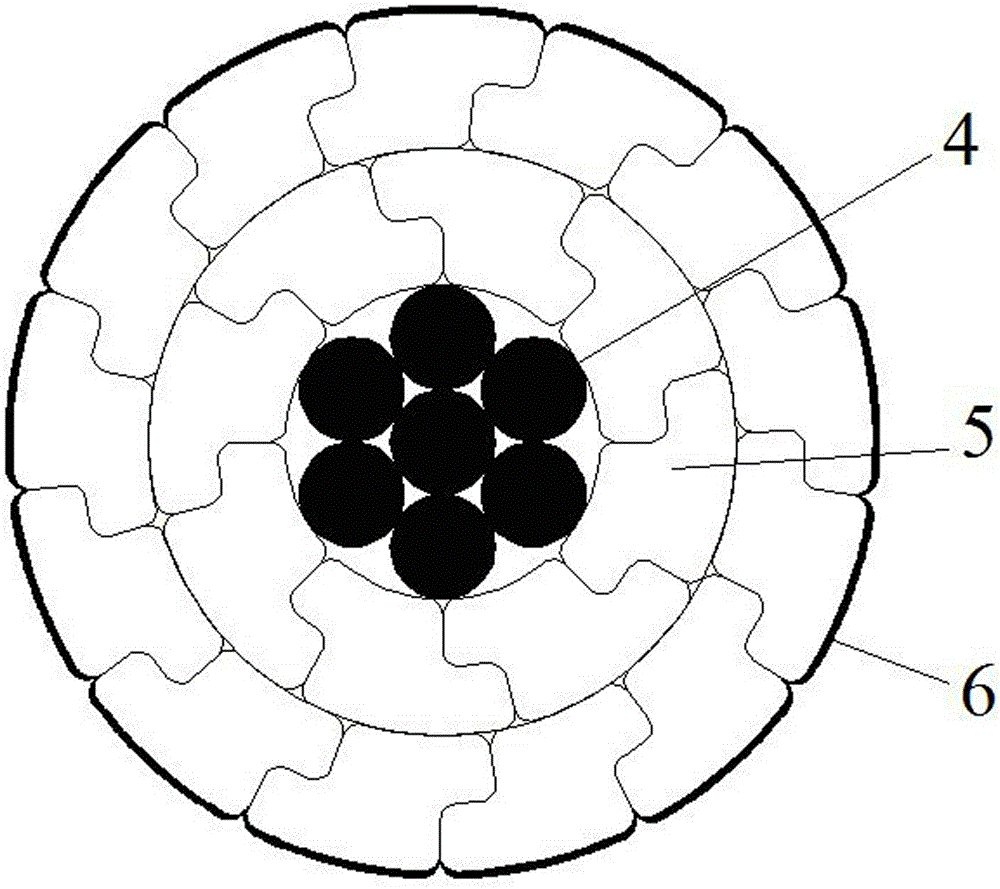

Conductive fiber for pen, preparation method of conductive fiber, capacitive pen and touch device

ActiveCN107881769AExtended service lifeImprove conductivityAnimal fibresInput/output processes for data processingCapacitanceCarbon nanomaterials

The invention provides a conductive fiber for a pen, a preparation method of the conductive fiber, a capacitive pen and a touch device. The conductive fiber for the pen comprises a fiber matrix for the pen; a graphene material with micron-sized thickness is attached to the surface of the fiber matrix. The preparation method comprises the steps of dipping the fiber matrix into a graphene material water solution, after that, taking out for standing, and then air-drying or drying; dipping the fiber matrix treated through the above steps into an enhancer water solution, and taking out for rinsingand air-drying or drying. The conductive fiber provided by the embodiment of the invention utilizes electrical conductivity of carbon nanomaterials so as to be well applied to the touch device, is particularly suitable for being applied to the capacitive pen, and is combined with a traditional Chinese writing brush so as to carry out DIY improvement on the traditional Chinese writing brush for realizing the application of the traditional Chinese writing brush on the touch device, so that the problems of poor use experience and short service life of a capacitive Chinese writing brush prepared by other conductive fibers are solved.

Owner:山东省圣泉生物质石墨烯研究院

Dyeing and finishing method for improving dyeing performance of kapok fibers and dyed kapok fibers

The invention provides a dyeing and finishing method for improving dyeing performance of kapok fibers and relates to the technical field of textile dyeing and finishing.According to the dyeing and finishing method, firstly, plasma surface modification treatment is conducted on the kapok fibers, then chitosan quaternary ammonium salt is adopted for cationic modification treatment on the kapok fibers, and then dyeing is conducted.The dyeing and finishing method is simple in technology, use of chemicals is reduced, pollution is reduced, cost is low, damage to the kapok fibers is reduced, dyeing performance of the kapok fibers is improved, heat preservation, antibacterial performance and other good performance of fibers are maintained, and mechanical properties of the kapok fibers are not changed.The invention further provides dyed kapok fibers which are good in dyeing performance and mechanical property.

Owner:YANCHENG INST OF TECH

Flame-retardant system for acetate cloth tape

InactiveCN103045122AImprove flame retardant performanceAdd lessNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceZinc borate

The invention relates to a flame-retardant system for an acetate cloth tape, which is provided with a halogen-free flame retardant system with environmental-friendliness and high flame retardant efficiency. The halogen-free flame retardant system has excellent compatibility with a rubber pressure sensitive adhesive, does not change mechanical performance of the acetate cloth tape and simultaneously improves heat resistance of the acetate cloth tape. The flame-retardant system does no harm to the environment and a human body; the specific gravity of the halogen-free flame retardant system in the rubber pressure sensitive adhesive is between 10 percent and 20 percent; the halogen-free flame retardant system is a mixture consisting of a halogen-free inrumescent flame retardant (IFR), metal hydrate and superfine zinc borate powder. By the synergistic effect of the flame-retardant system, the flame retardance of a flame retardant is improved, the addition quantity of the flame retardant is reduced, the flame retardant effect which is the same with that obtained when a great quantity of single flame retardant is added is achieved, and the flame-retardant acetate cloth tape has the advantages of resistance to high temperature, resistance to high pressure, insulation, flame retardance and the like, is soft and docile, has tear property and can be used for various electronic components.

Owner:新丰杰力电工材料有限公司

Synthesis method of polyether ester plasticizer

The present invention discloses a method for preparation of a novel polyether ester green plasticizer from adipic acid, C4-C6 dihydric alcohols, and ether-bond-containing C4-C6 dihydric alcohols as main raw materials by addition of a catalyst for three-step esterification, neutralization, water washing, bleaching, reduced pressure distillation, and purification, wherein the catalyst is n-tetrabutyl titanate, stannous octoate and stannous chloride. The designed preparation process is simple and efficient, and rich in source of raw materials. The designed novel polyether ester exhibits better durability, and anti-migration property, and large-scale industrial production can be performed.

Owner:TIANJIN UNIV OF SCI & TECH

Deslagging agent used for smelting cast iron and preparation method thereof

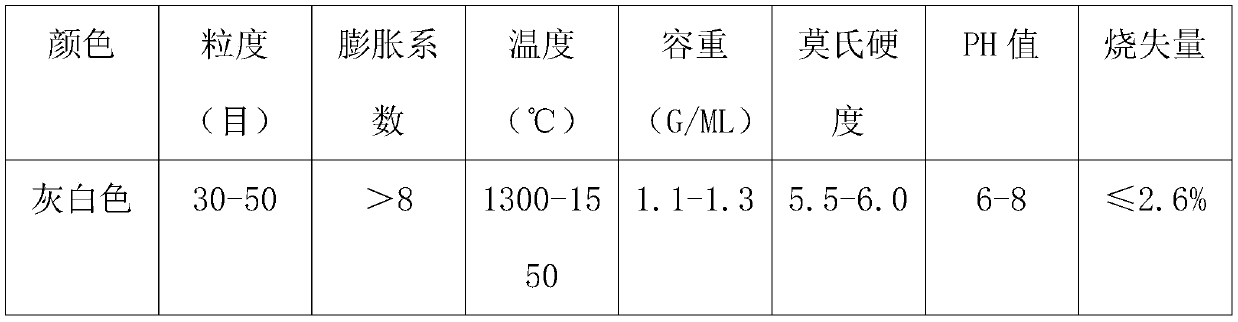

The invention discloses a deslagging agent used for smelting cast iron and a preparation method thereof. The deslagging agent comprises, by weight, 70%-75.2% of silicon dioxide, 12.1%-15.9% of aluminum oxide, 0.5%-1.9% of ferric oxide, 1.2%-3.22% of sodium oxide, 1.9%-3.84% of potassium oxide, 0.9%-1.48% of calcium oxide, 0.47%-1.46% of magnesium oxide, and the balance iron and inevitable impurities. The deslagging agent used for smelting the cast iron mainly comprises SiO2 and Al2O3 and can instantly expand when sharply heated to the temperature of 1100DEG C or over so as to form a viscous active material of a porous structure, so that molten iron, slag in the molten iron, and impurities can adhere together to be gathered; the deslagging agent has a low heat conductivity coefficient so that heat conduction and thermal radiation on the surface of the molten iron can be effectively reduced, and a heat preservation effect is achieved; and the problems, such as corrosive pits, white spotsand wrinkles, which occur frequently during cast iron machining are solved while the defects are overcome.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

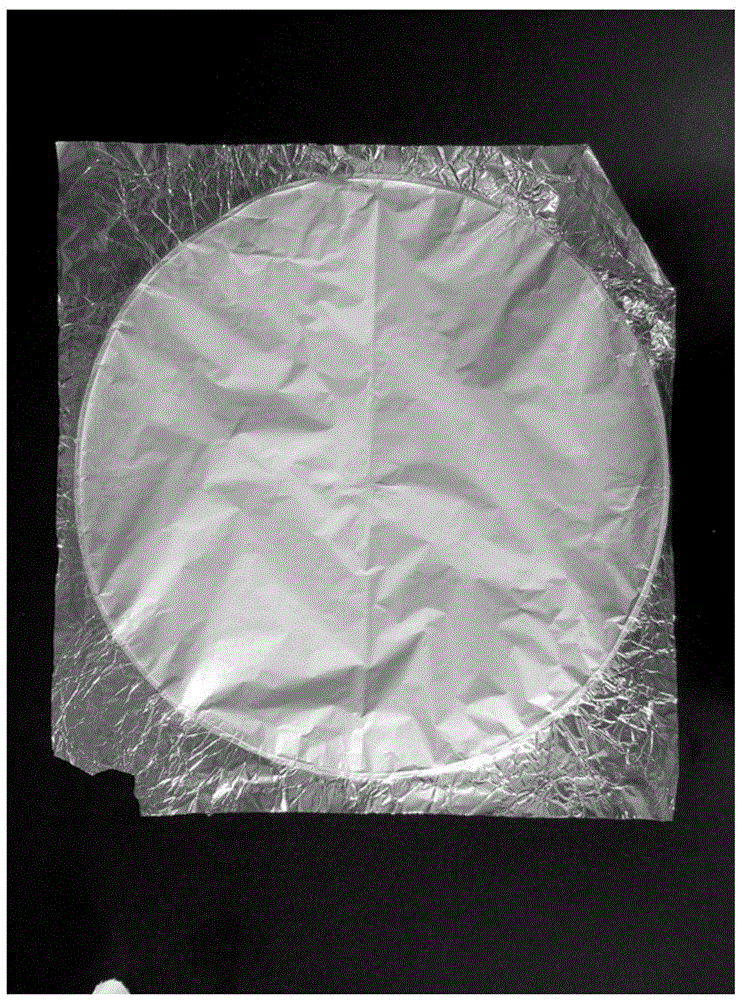

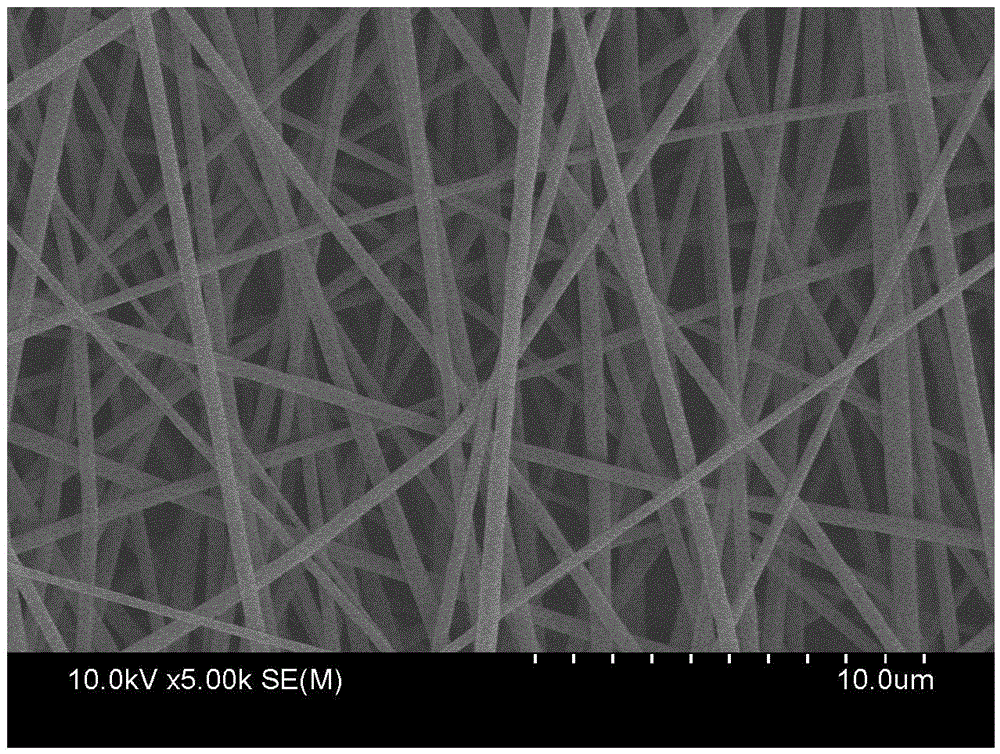

Method for enabling nano-micron porous luminescent fibers to be attached to surface of non-woven fabric treated with flash evaporation method

ActiveCN105568551AFunction increaseChange mechanical propertiesElectro-spinningCoatingsFiberElectrospinning

The invention belongs to the technical fields of electrostatic spinning and flash evaporation spinning and discloses a method for enabling nano-micron porous luminescent fibers to be attached to the surface of non-woven fabric treated with a flash evaporation method. According to the method, the nano-micron porous luminescent fibers are manufactured with an electrostatic spinning method and are attached to the surface of the non-woven fabric treated with the flash evaporation method. Composition comprises the non-woven fabric treated with the flash evaporation method and the nano-micron porous luminescent fibers prepared through electrostatic spinning. The composition is prepared according to the steps as follows: treatment of the non-woven fabric with the flash evaporation method, electrostatic spinning and fixing of the nano-micron porous luminescent fibers. Compared with the prior art, the method can increase the functions of the non-woven fabric treated with the flash evaporation method without changing the mechanical performance of the non-woven fabric, and the mechanical performance of the nano-micron porous luminescent fibers is also greatly improved.

Owner:TIANJIN POLYTECHNIC UNIV

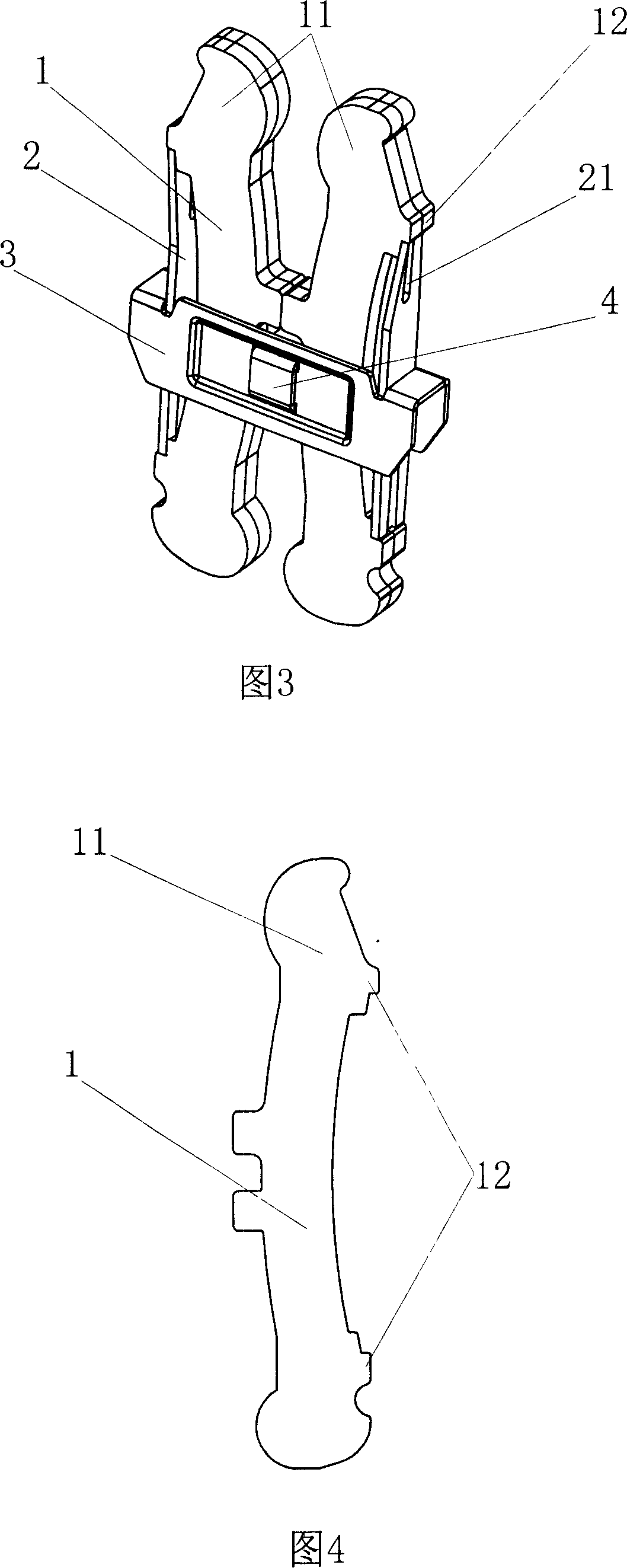

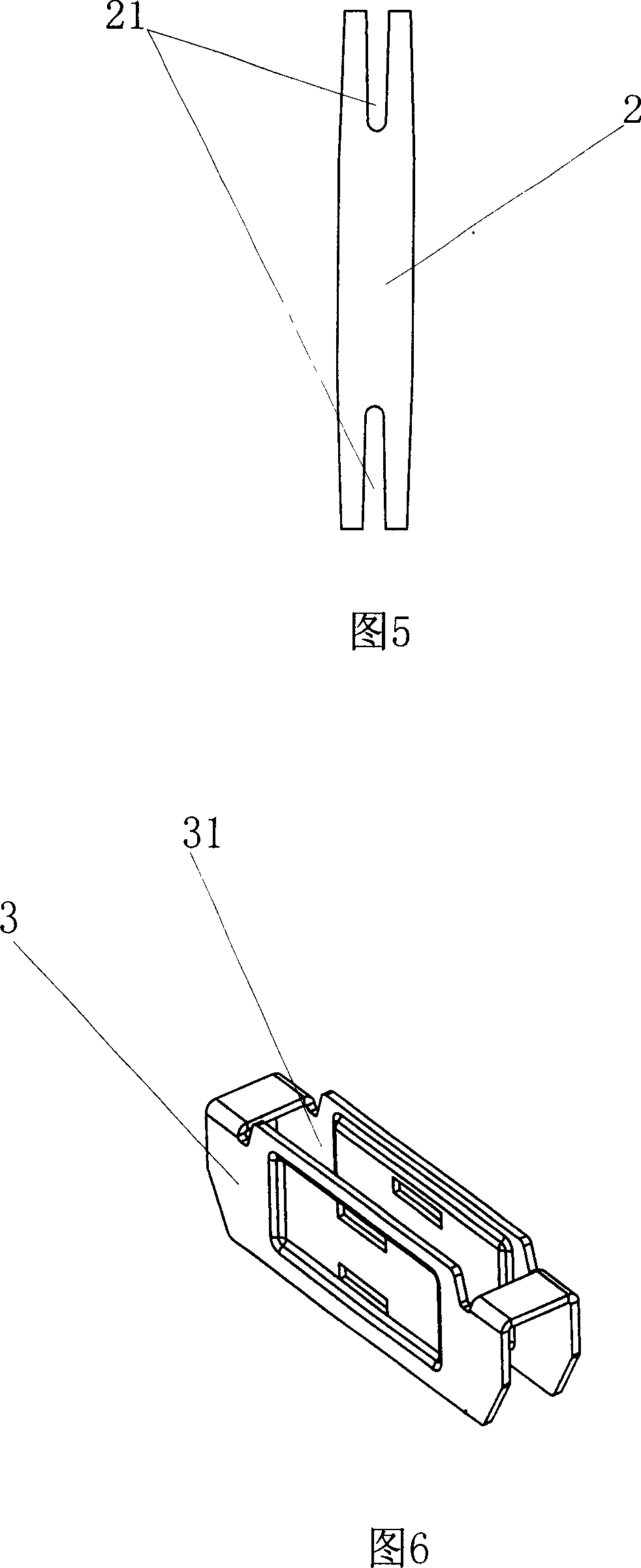

Contact unit for connector

InactiveCN101005172AReduce contact areaLow thermal conductivityCoupling contact membersContactorWork performance

The contactor unit includes two pair of stylus or more, pressure spring, and lugs setup symmetrically on outside the touch claws at two ends of each stylus. The pressure spring is linear spring. There are comby openings at two ends of linear spring. One pressure spring is setup at each outside end of the stylus. Two ends of each pressure spring are pressed against two lugs at same side of the stylus so as to constitute elastic component of the stylus unit. A spring bracket is socket jointed to middle part of the stylus unit. A plug socket for the stylus and pressure spring to be inserted is setup on the spring bracket along long direction. Position limited fit is formed between inner wall of the plug socket and the pressure spring. Being setup at the middle of the spring bracket, a bolt forms positioning fit together with the stylus. Features are: reasonable structure, compact, and stable working performance of the contactor unit.

Owner:潘敏

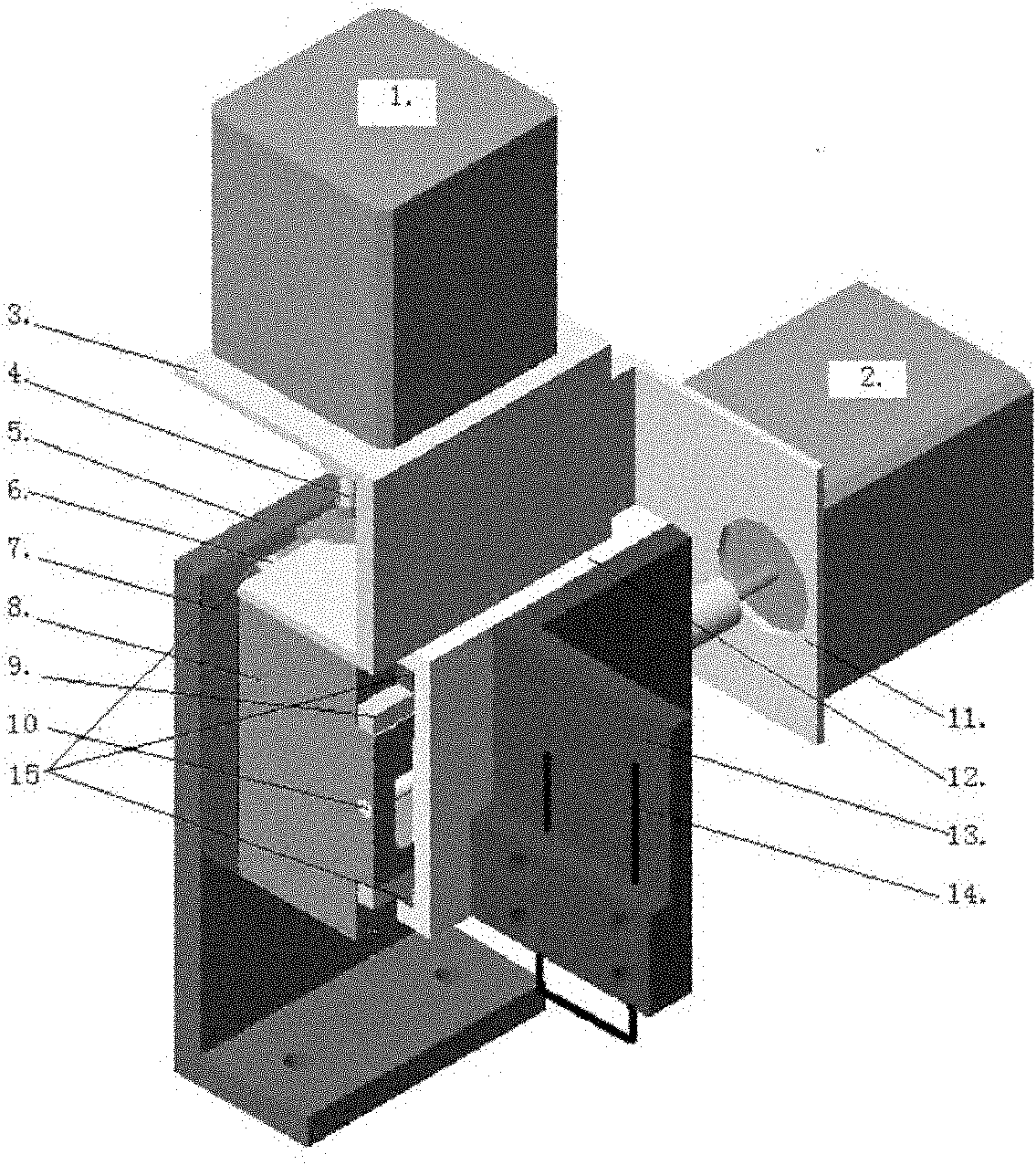

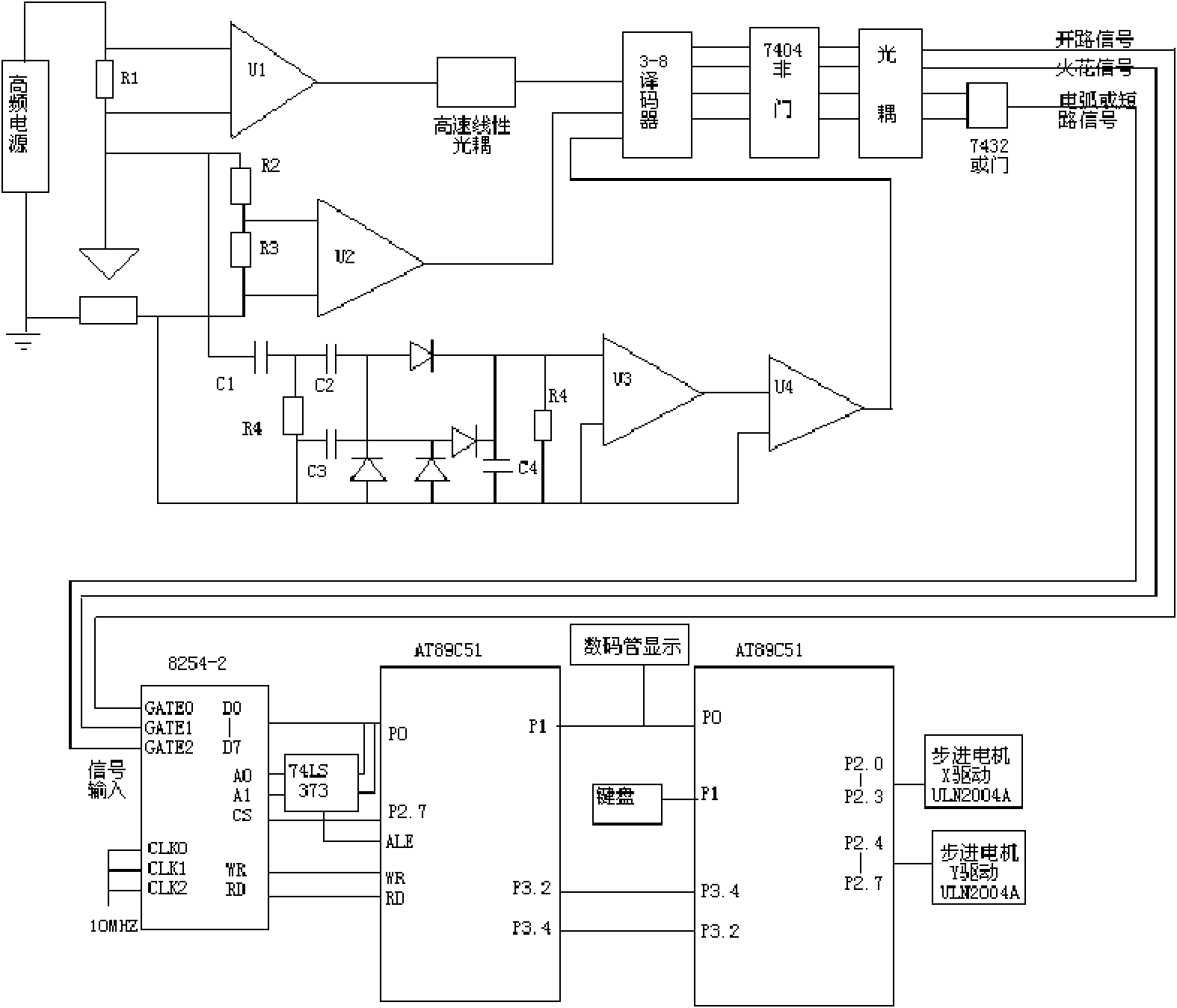

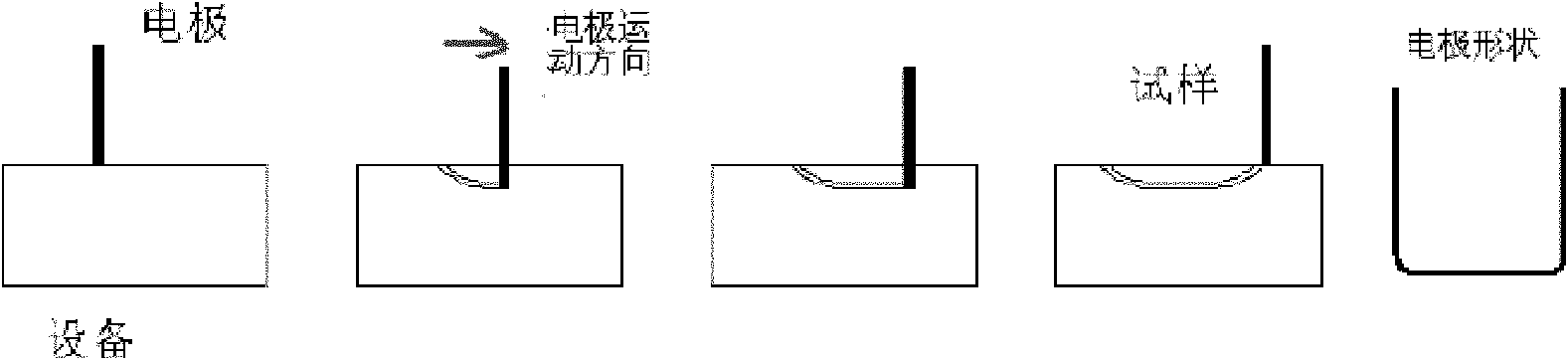

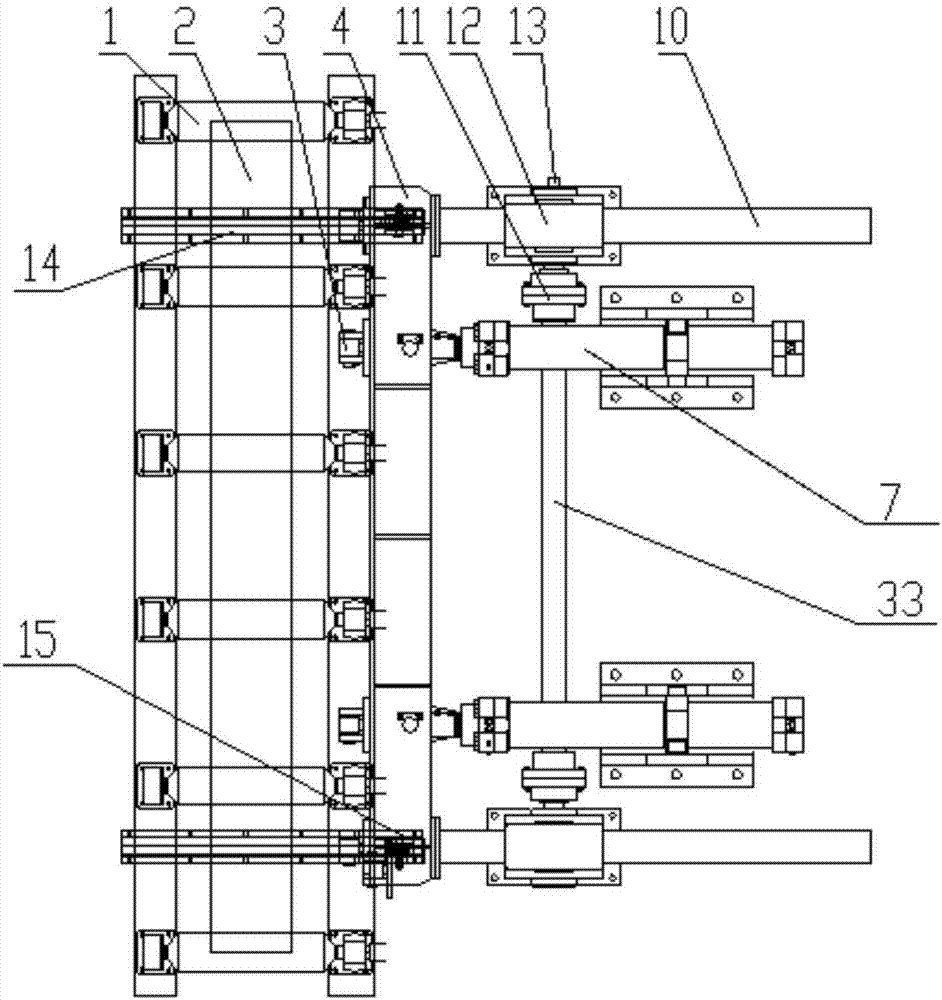

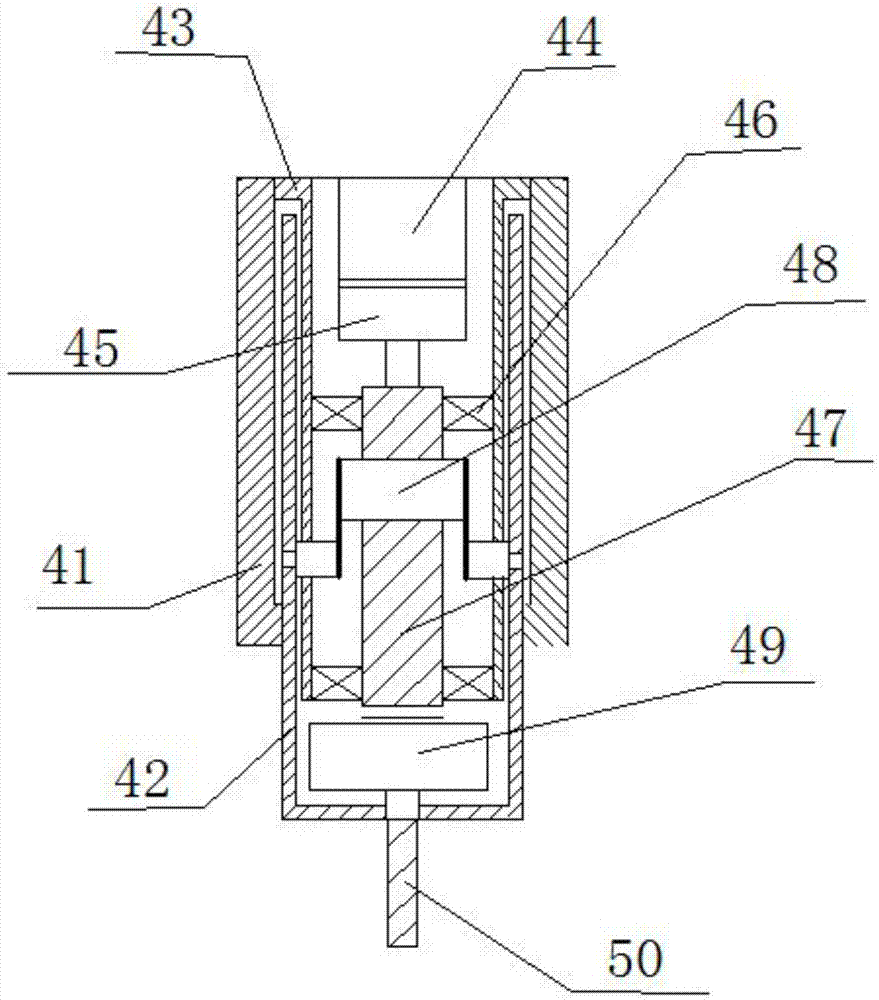

Microsample sampling system based on sinker EDM (Electric Discharge Machining) principle

InactiveCN102419266ANo change in mechanical propertiesWithdrawing sample devicesMicrocontrollerElectric discharge

The invention provides a microsample sampling system based on a sinker EDM (Electric Discharge Machining) principle. The microsample sampling system comprises a sinker EDM power supply, an electrode, a mechanical stroke mechanism, a single detecting unit and a singlechip control unit, wherein the sinker EDM power supply is used for providing pulse voltage for the electrode, the mechanical stroke mechanism is used for controlling the movement of the electrode, the signal detecting unit comprises a current signal detecting module, a voltage signal detecting module and a high-frequency signal detecting module, the singlechip control unit comprises a communication module and a driving module of a stepping motor, and the signals detected by the signal detecting unit are input into the singlechip control unit to be processed. The microsample sampling system in the invention can be used for cutting off a microsample block from in-service equipment by using a sinker EDM technology; meanwhile, the equipment is damaged slightly, the mechanical property of the cut sample is not changed, and a surface heat affected layer is less than 10 microns.

Owner:EAST CHINA UNIV OF SCI & TECH +2

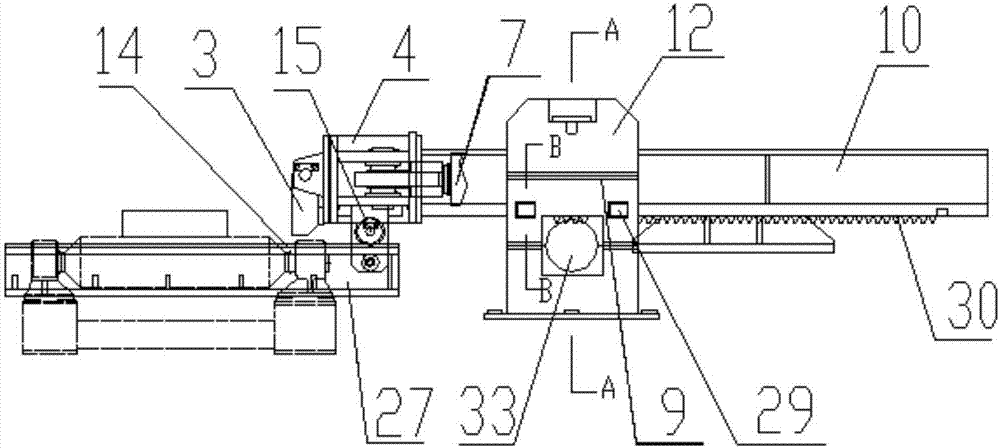

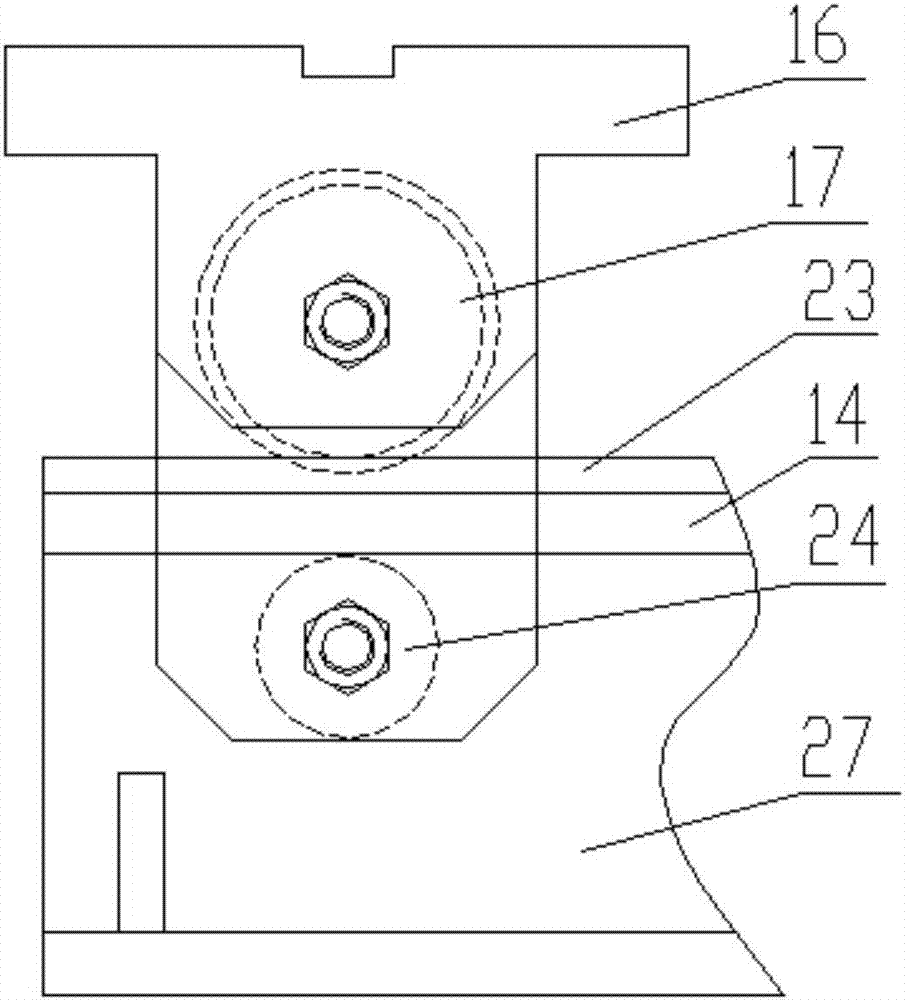

Compact type cross beam type hydraulic pusher

PendingCN107289785AChange mechanical propertiesCompact structureCharge manipulationHydraulic cylinderLinear motion

The invention provides a compact type cross beam type hydraulic pusher which comprises a push head, a cross beam, guide rail beams, fixed wheel groups, mechanical synchronizing devices and hydraulic cylinders. The fixed wheel groups are clamped and fixed to the guide rail beams through double-rim wheels and hook wheels, so that the fixed wheel groups can but make linear motion in the direction of the guide rail beam. Each mechanical synchronizing device comprises a rack guide rod, a gear box and a coupler; each rack guide rod is clamped in the middle position by an upper pressing wheel, lower supporting wheels and pressing wheels on the left side and the right side in one corresponding gear box, and thus can but make linear motion through the limitation of a gear between the corresponding lower supporting rollers; the gear in each box body is connected with a synchronizing shaft depending on a key; the ends of the synchronizing shafts in the two box bodies are connected with the couplers correspondingly; and mechanical synchronization of the two rack guide rods is realized. The compact type cross beam type hydraulic pusher is compact in structure, small in floor area and light in weight, the mechanical property of an existing pusher is not changed, the compact type cross beam type hydraulic pusher is simple in structure and convenient to mount and maintain, and is more stable and reliable, the mechanical synchronization is realized, and thus the production efficiency is improved.

Owner:中重科技(天津)股份有限公司

Once forming stamping method of double-parabolic plate with consistent thickness

The invention relates to a once forming stamping method of a double-parabolic plate with consistent thickness. The forming stamping method includes the following steps that A, establishing a three-dimensional curve surface model of an upper mould surface of the double-parabolic plate; B, selecting a process base surface on the three-dimensional curve surface model; C, carrying out lofting treatments, obtaining data of the upper mould surface, the data of the upper mould surface is served as a mould dummy plate and a periphery plate linetype of the upper mould; D, adding thickness of the plate to obtain a lower mould surface curve surface model, and carrying out lofting treatments, obtaining the data of the lower mould surface linetype, and the data of the lower mould surface linetype is served as the mould dummy plate and the periphery plate linetype of the lower mould; E, obtaining the mould dummy plates and the periphery plate linetypes of the upper mould and the lower mould to manufacture the upper mould and the lower mould according to the step C and the step D; F, finishing the once forming stamping manufacture of the upper mould and the lower mould by a press driven. The once forming stamping method of the double-parabolic plate with consistent thickness is simple in step, short in elapsed time, high in accuracy, capable of achieving easily large-scale mass manufacturing production.

Owner:GUANGXIN SHIPBUILDING & HEAVY IND

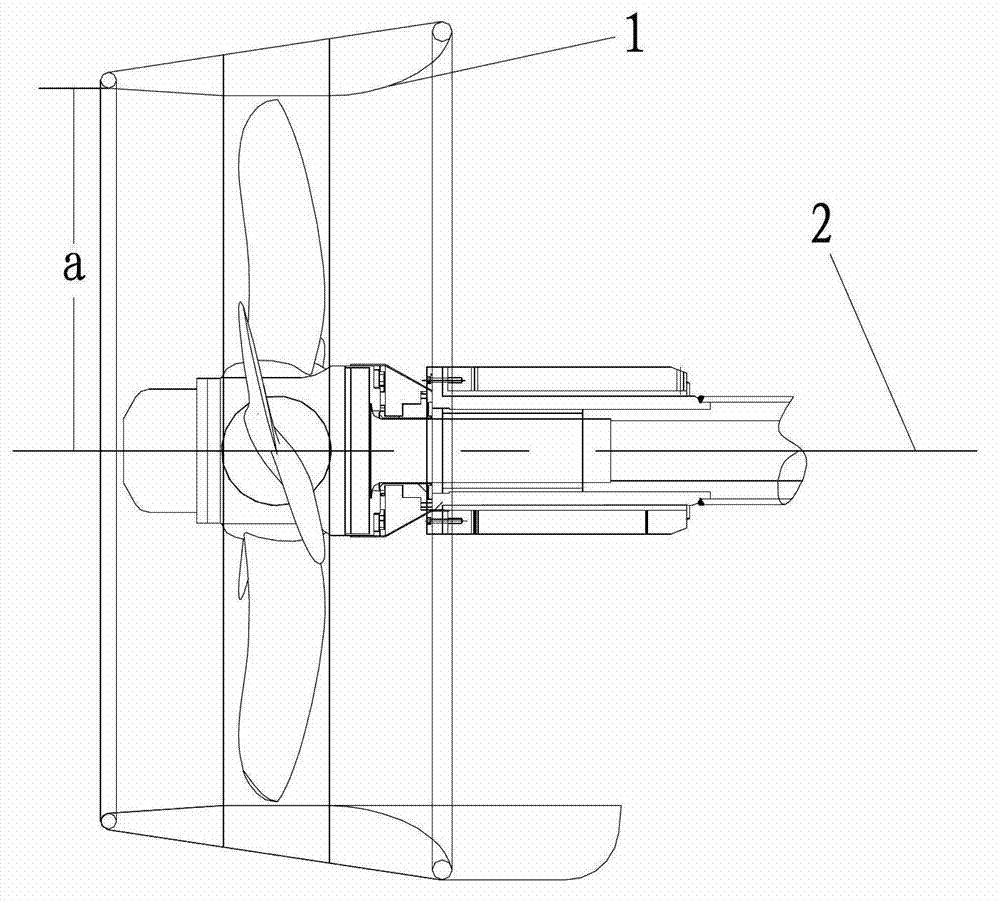

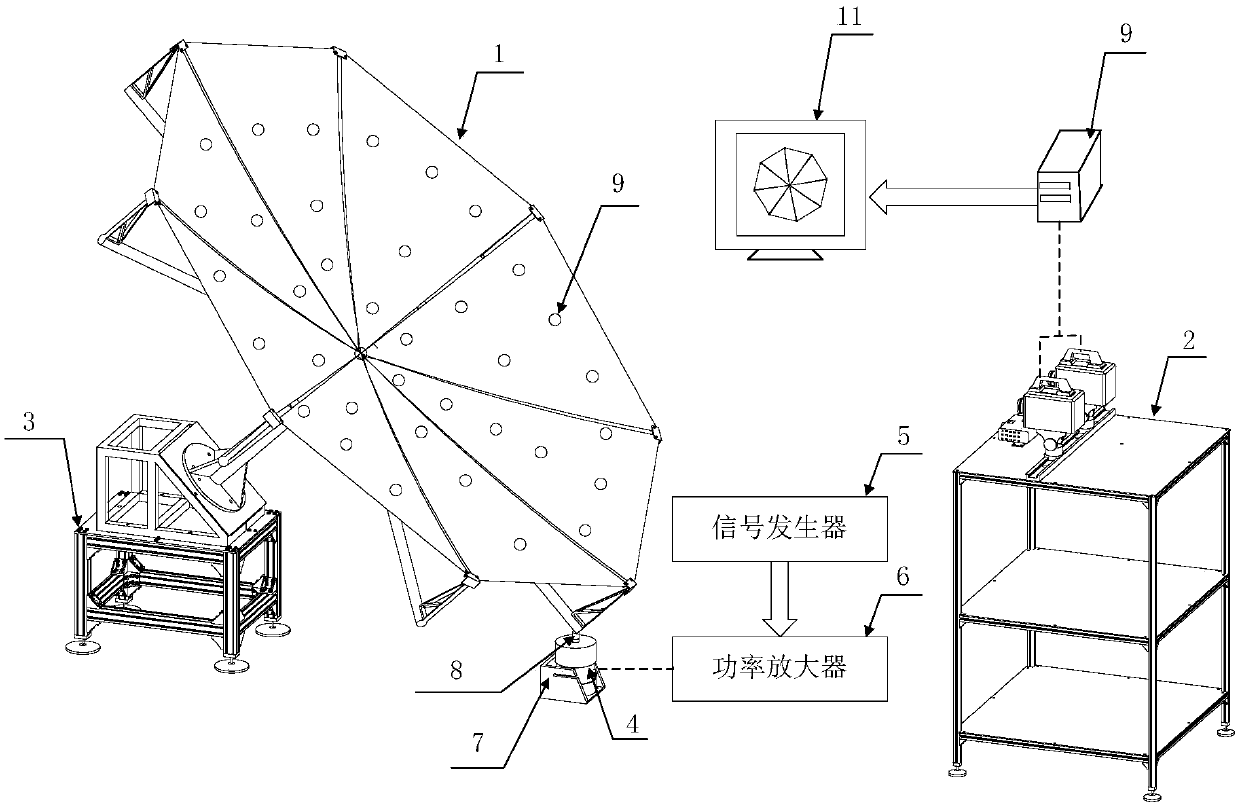

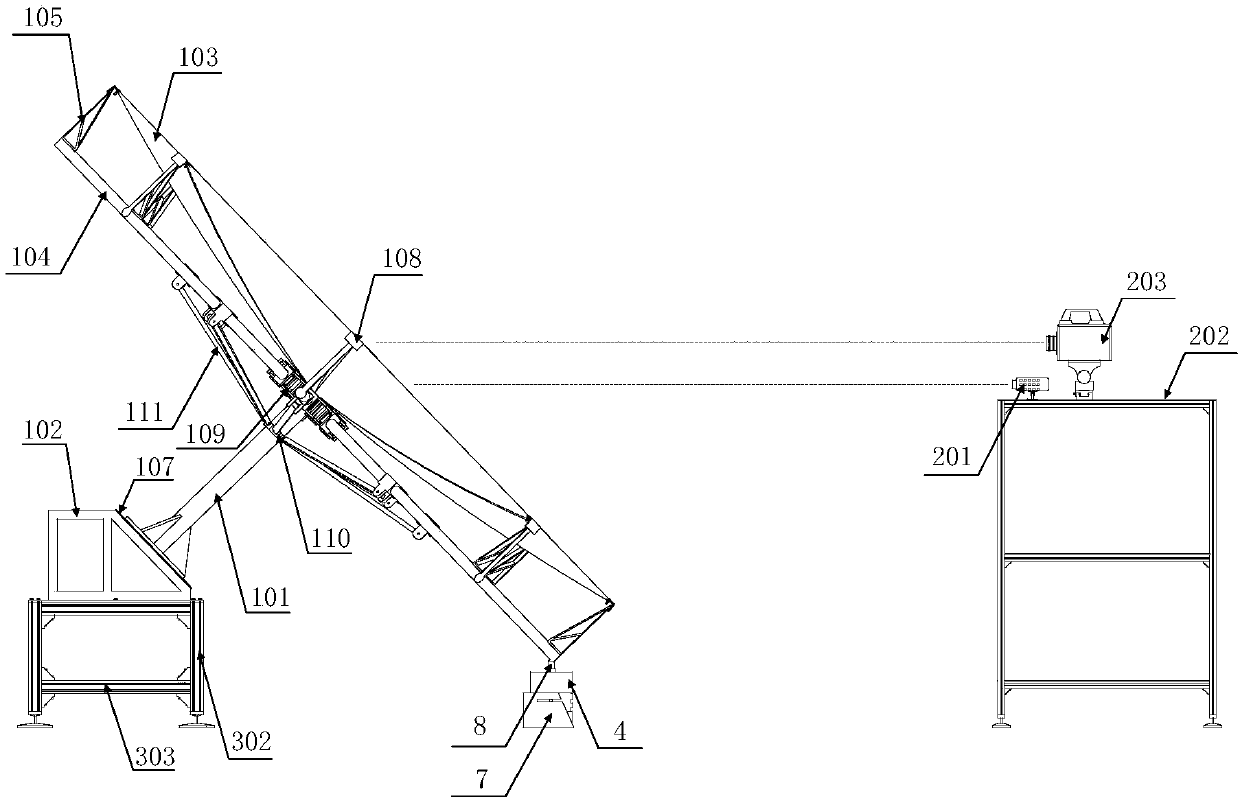

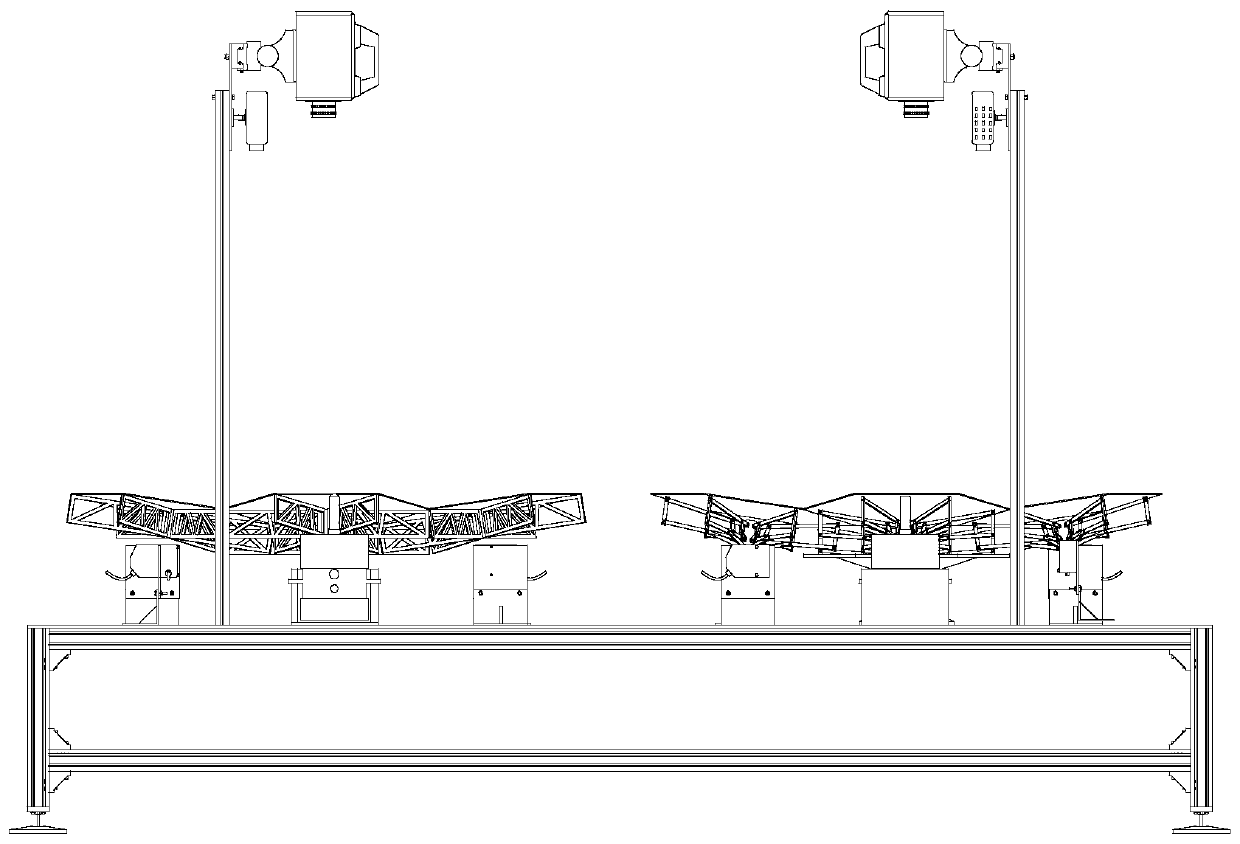

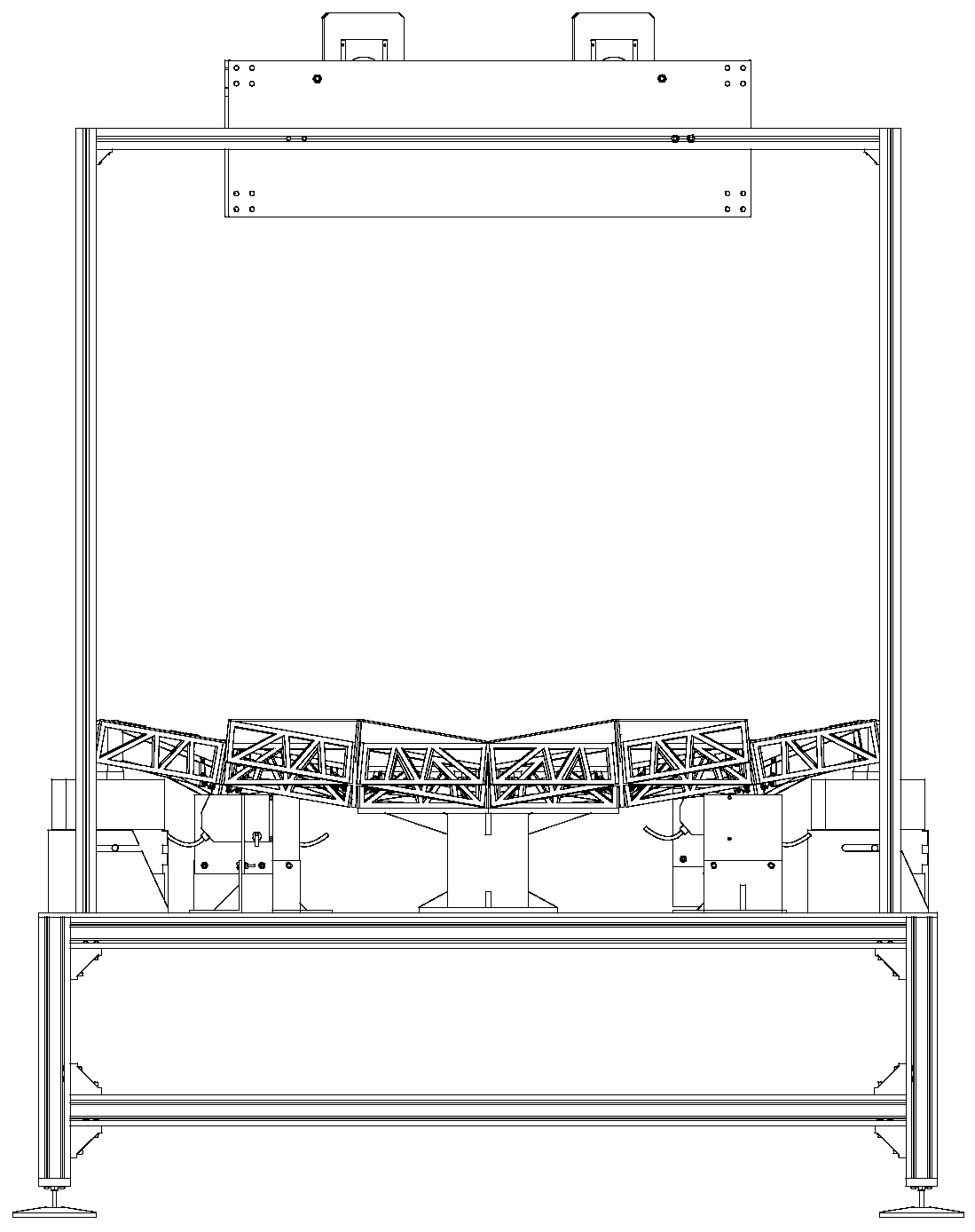

Umbrella-shaped reflector vibration measurement device and method

PendingCN108709627AReduce weightNo change in structureSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansCamera lensVibration measurement

The invention discloses an umbrella-shaped reflector vibration measurement device and method. The device comprises an umbrella-shaped reflector, a vibration excitation mechanism and a vision detectionmechanism. The umbrella-shaped reflector is provided with a reflective film, the vibration excitation mechanism is connected with the umbrella-shaped reflector and used for stimulating the umbrella-shaped reflector to vibrate, and the vision detection mechanism comprises a projector, a binocular vision system and an operating platform. The projector and the binocular vision system are arranged onthe operating platform, a lens of the projector faces the center of the reflective film and is used for projecting mark points to the surface of the reflective film, and the binocular vision system is used for detecting mark point areas on the surface of the reflective film. By noncontact vision detection, the mark points are projected to the surface of the reflective film through the projector;reflective film matching characteristics of the mark points are recognized by the binocular vision system, and accordingly vibration information is processed and analyzed to reflect dynamic morphologyof the reflective film in real time.

Owner:SOUTH CHINA UNIV OF TECH

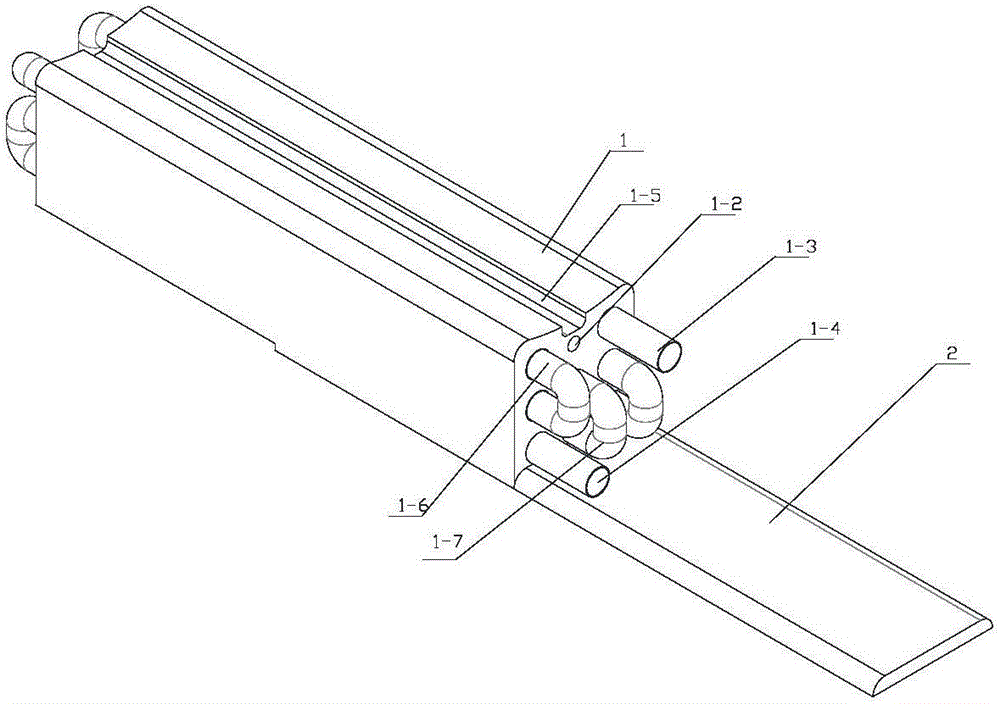

Welding line inner protecting device of stainless steel pipe making machine

InactiveCN106001873AIncrease temperatureNo change in mechanical propertiesWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingShielding gas

The invention relates to the technical field of welding, in particular to a welding line inner protecting device of a stainless steel pipe making machine. The device comprises a protecting device body; the protecting device body is provided with inert gas inlets, cooling water inlet guide pipes, cooling water outlet guide pipes, an inert gas acting groove, through holes, a pipe fitting and a horizontal connecting bar; the inert gas inlets, the cooling water inlet guide pipes, the cooling water outlet guide pipes and the through holes, corresponding in position, are respectively arranged in ports of two sides of the protecting device body; even through holes are provided; the same one pipe fitting is connected between two adjacent through holes; the inert gas acting groove is transversely formed in the upper end surface of the protecting device body; the lower end of the protecting device body is connected with the horizontal connecting bar; the horizontal connecting bar is connected with a machine tool; and the cooling water inlet guide pipes are higher than the cooling water outlet guide pipes in position. The device is low in dosage of protective gas, can adapt to the welding line inner protection of steel pipes with different diameters, can achieve a support effect on materials on two sides of welding lines on the inner walls of the steel pipes, prevents deformation, and can quickly reduce the temperature of the inner walls of the welding lines.

Owner:重庆巨源不锈钢制品有限公司

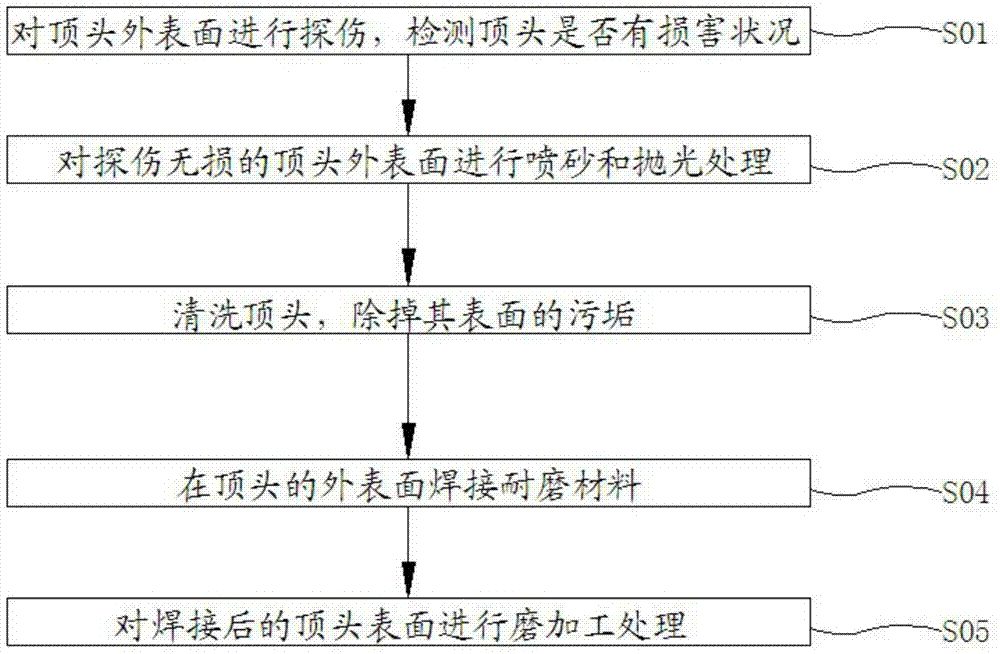

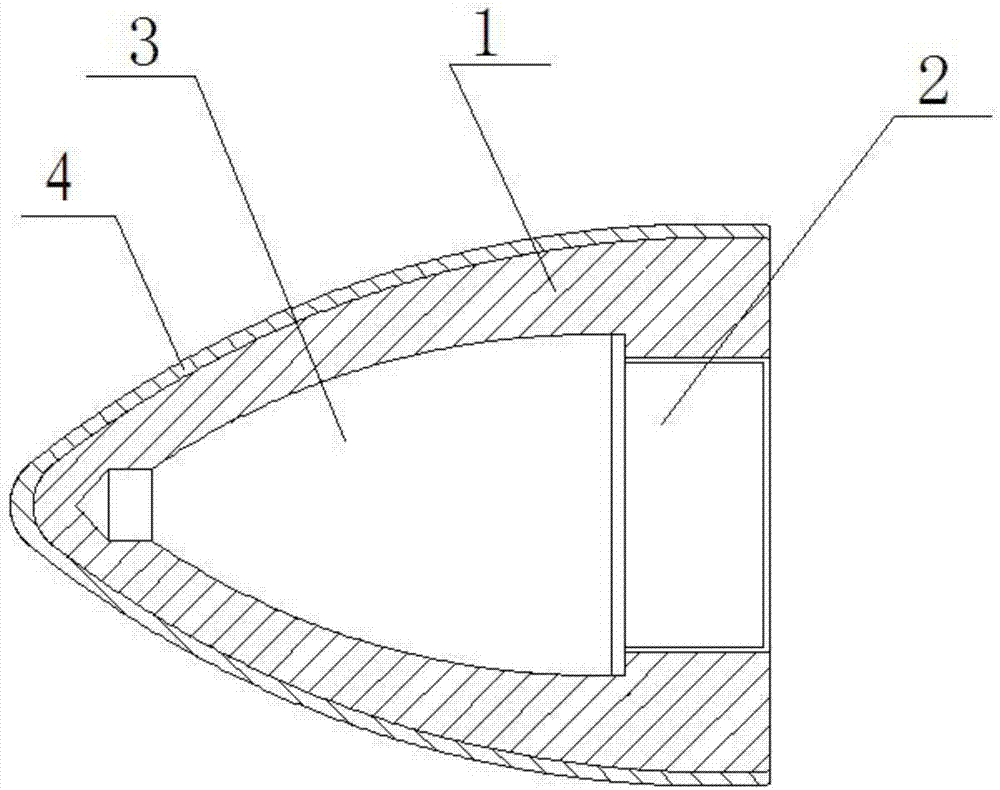

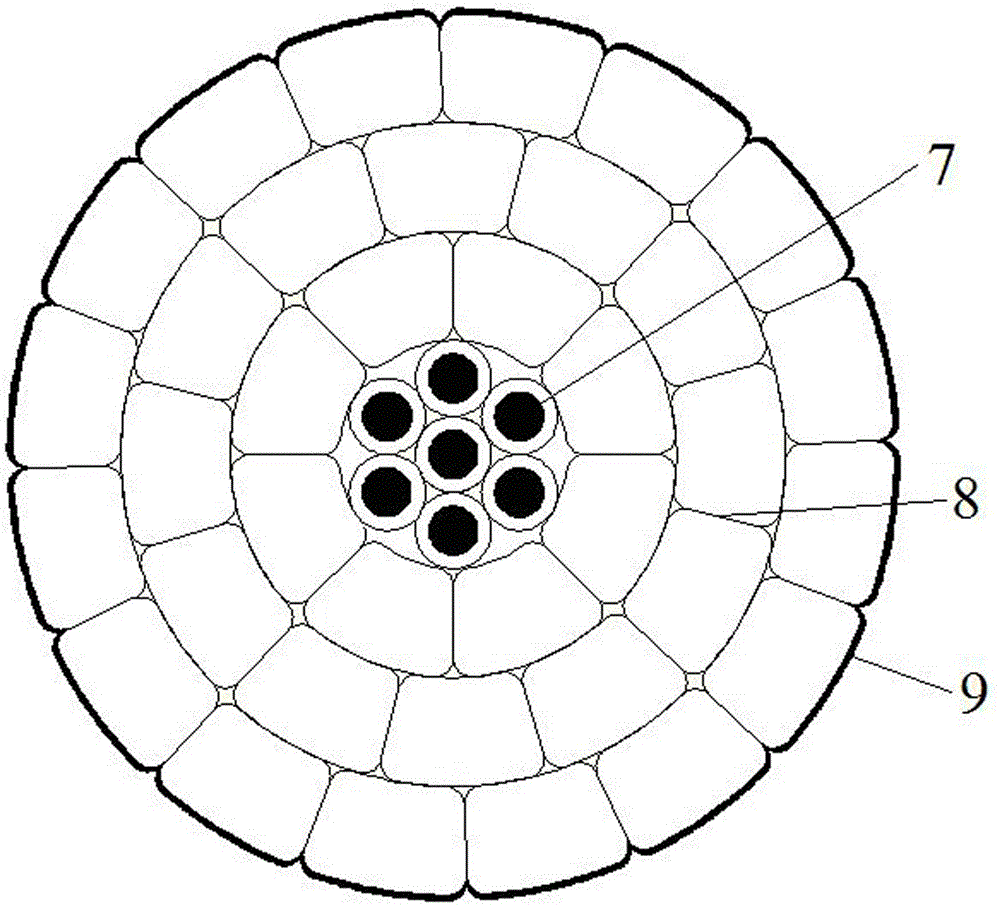

Strengthening method of surface of piercing plug of seamless steel tube rolling mill

InactiveCN103769794ANo change in mechanical propertiesGuaranteed high temperature strengthMandrelsMetal rolling arrangementsAbrasive blastingAlloy

The invention relates to the field of seamless steel tube manufacturing, in particular to a strengthening method of the surface of a piercing plug of a seamless steel tube rolling mill. The strengthening method comprises the following steps that 1 flaw detection is conducted on the outer surface of the plug to detect whether the plug is damaged or not; 2 abrasive blasting processing and polishing processing are conducted on the outer surface of the plug which is confirmed not damaged through flaw detection; 3 the plug with abrasive blasting processing and polishing processing conducted is cleaned so as to remove dirt on the surface of the plug; 4 an abrasion-resistant layer is welded onto the outer surface, with the dirt removed, of the plug; 5 grinding is conducted on the welded surface of the plug. The strengthening method of the surface of the piercing plug of the seamless steel tube rolling mill has the advantages that according to the technology, welding strengthening is conducted on the surface of the plug on the basis that the comprehensive mechanical performance of a common plug is not influenced, the welding material is formed by adding hard alloy phase into a cobalt base, the surface of the plug is strengthened in a welding mode, metallurgical bonding of the super abrasion-resistant layer and a base of the plug is guaranteed, the mechanical performance of a plug body is not changed and after a strengthened part is abraded due to use, the part can be repaired multiple times.

Owner:烟台开发区蓝鲸金属修复有限公司

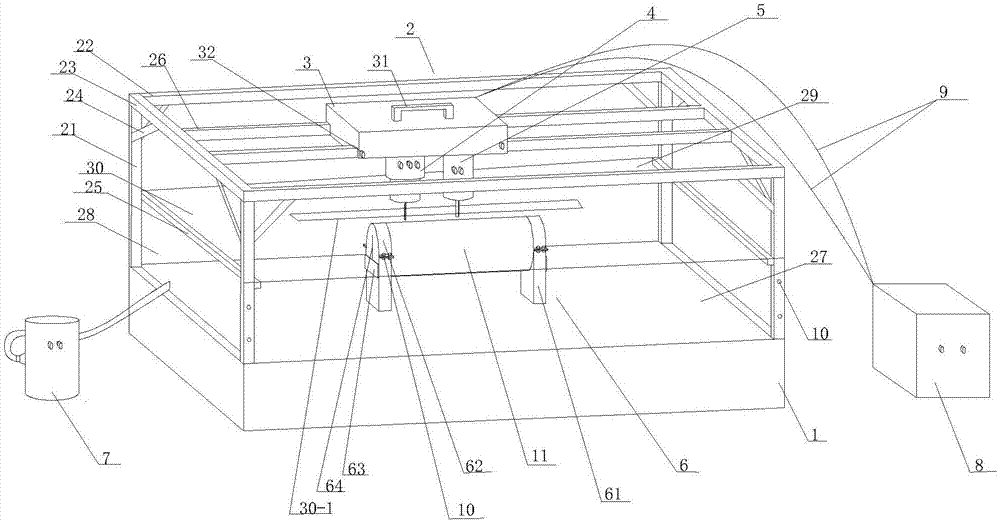

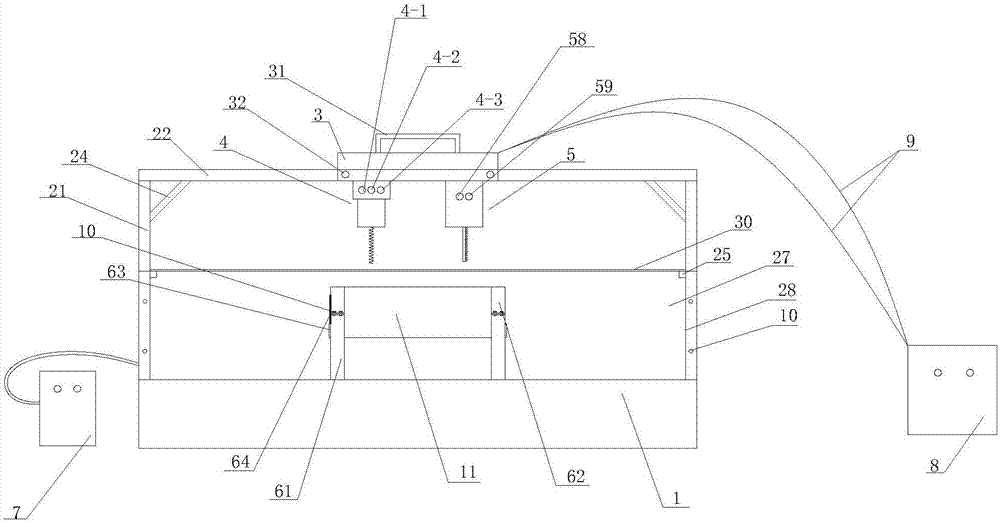

Apparatus for forming penetrating cracks in rock sample and operation method thereof

ActiveCN107290192AEliminate the effects ofNo change in mechanical propertiesPreparing sample for investigationGlass coverClassical mechanics

The invention discloses an apparatus for forming penetrating cracks in a rock sample and an operation method thereof. The apparatus includes a pedestal, a support structure, a workbench, a drilling device, a cutting device, a sample fixing device, a dust removal device, and a power source. The support structure is fixed on the pedestal and includes four vertical columns, two crossbeams, two linking beams, two support rods, two slide rails, a front glass board, side glass boards, a rear glass board and a glass cover board. The four vertical columns are vertically fixed on the pedestal. The two crossbeams and two linking beams are fixedly connected to form a rectangular frame which is fixed on the upper ends of the vertical columns. Each support rod is fixed on the middle parts of two vertical columns. The two support rods are symmetrically disposed and are located on the same horizontal plane. The apparatus can effectively increase the precision and efficiency of forming the penetrating cracks in the rock sample, so that subsequent test on the rock sample is convenient to carry out. In addition, the production process also includes dry-type dust removal, so that the apparatus does not change the original mechanical properties of rock and is free of influence on surrounding environment and body health.

Owner:HUNAN UNIV OF SCI & TECH

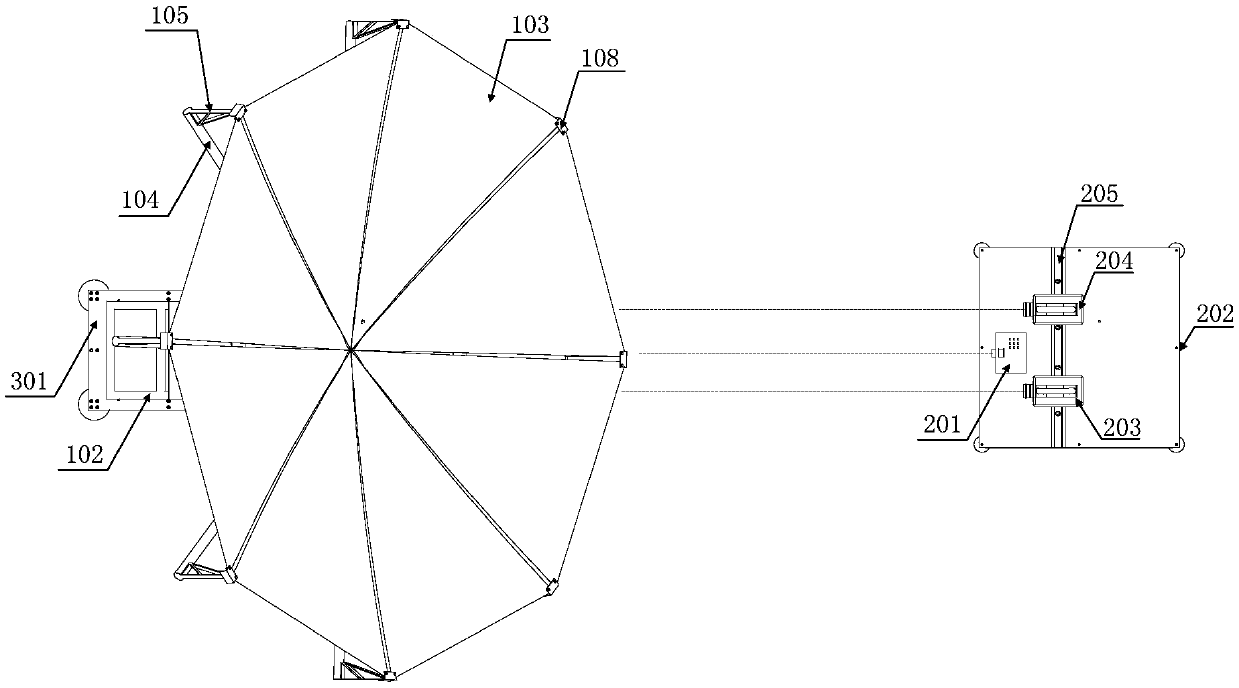

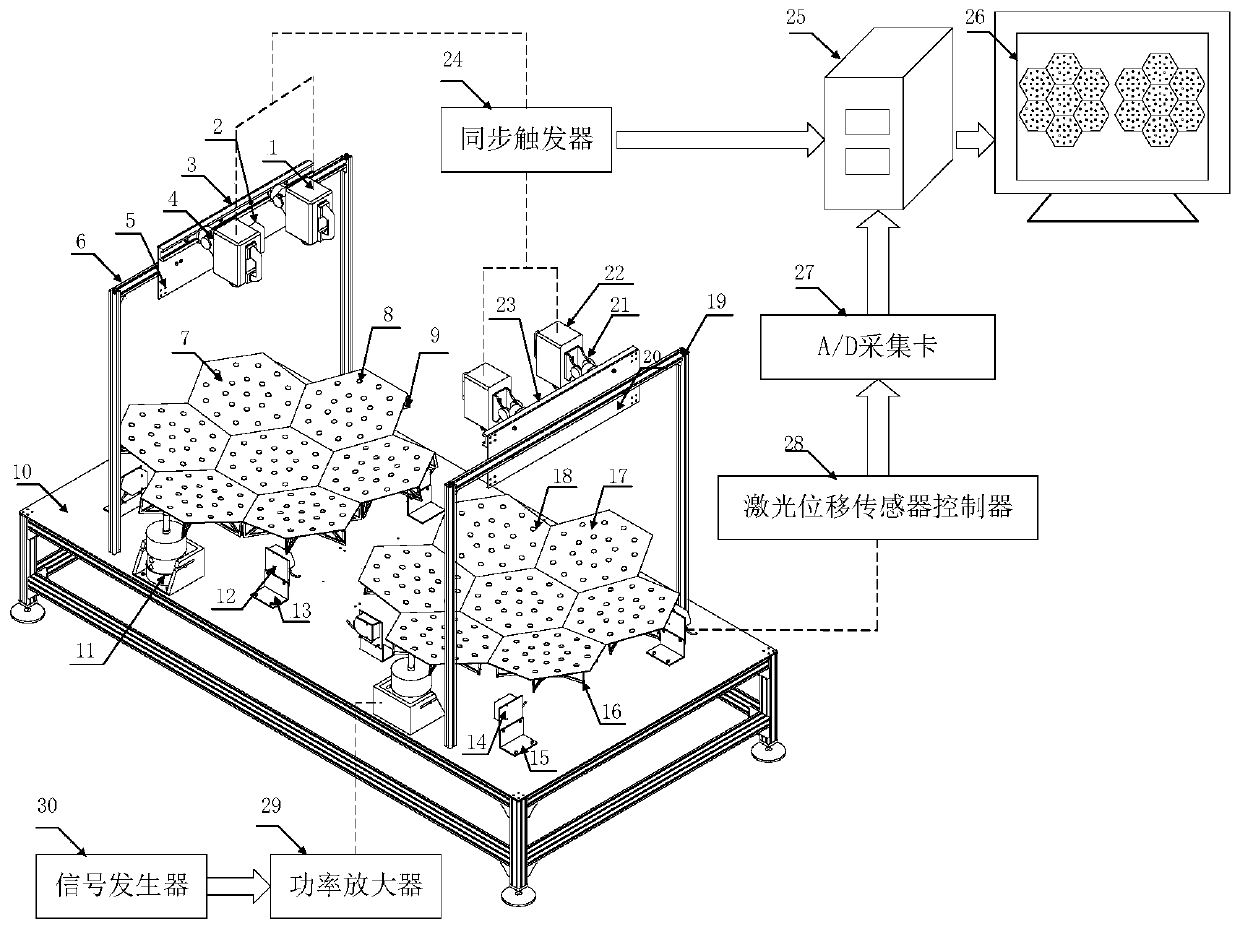

Reflection surface vibration detecting device for umbrella antenna and method

PendingCN110095242AAccurate measurementUniform image contrastVibration testingSatelliteVibration detection

The invention discloses a reflection surface vibration detecting device for an umbrella antenna and a method. The device comprises an antenna body part, a vibration detection part and a driving excitation part; the antenna body part comprises a rigid satellite antenna and a flexible satellite antenna, wherein the rigid satellite antenna and the flexible satellite antenna are symmetrically arrangedat two sides of an experiment table; a vibration exciter is directly connected with the reflection surface of the antenna so as to excite the vibration of the reflection surface; a projection point on the surface of a flexible plate is recognized through a laser-projection non-contact type visual detection mode; the vibration information of the projection point is collected; a laser displacementsensor is used in an assisted manner to synchronously detect the back surface of the flexible plate; the composite vibration information of two paths of detection modes is obtained; the vibration information of the two experimental objects is compared with each other, and the vibration difference of the two experimental objects is analyzed; and a visualization technology is introduced to display the dynamic forms of the two experimental objects on a display, so that experimental results are more direct.

Owner:SOUTH CHINA UNIV OF TECH

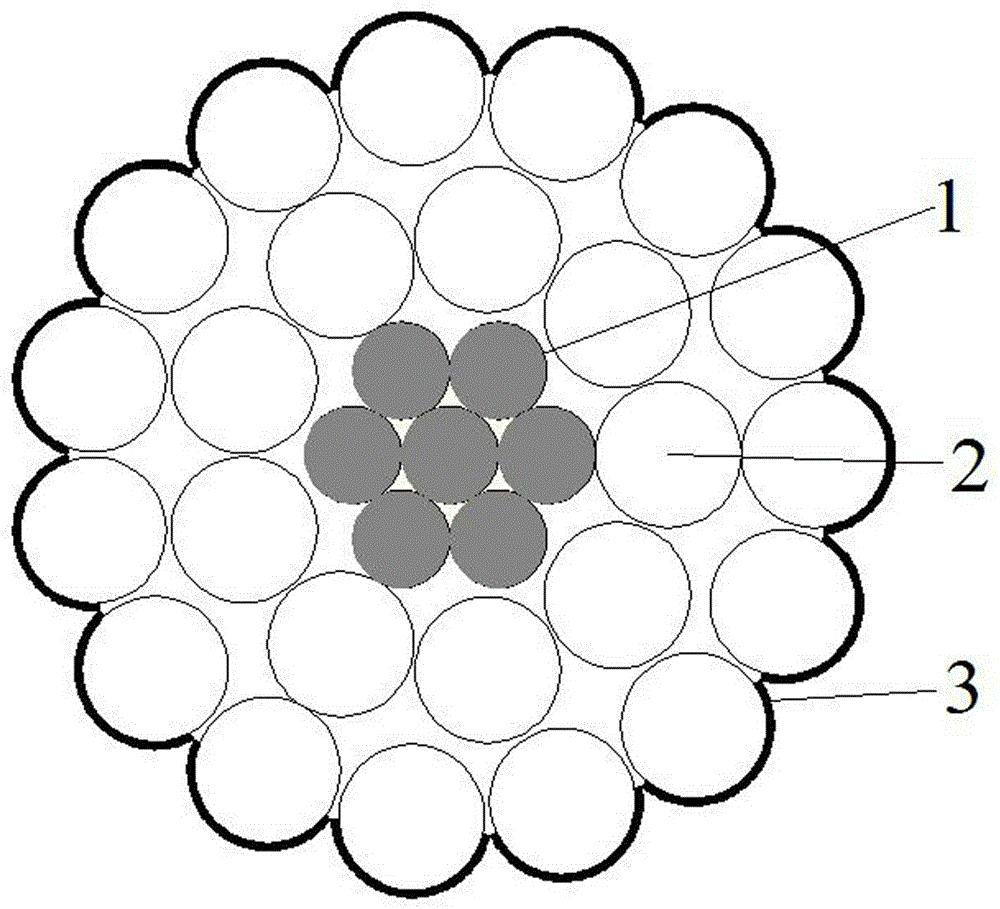

Surface-treated cooled wire

InactiveCN104835553ANo differentiationHigh chemical inertnessNon-insulated conductorsCarrying capacityElectrical conductor

The inventions relates to a surface-treated cooled wire and to the field of overhead conductors, and specifically to a novel cooled wire with a surface coated with high-radiation lowly-endothermic coating. The surface-treated cooled wire comprises central reinforcing cores, conductors, and an outermost coating. The conductors are stranded on the outer side of the central reinforcing cores and are coated with the outermost coating. The outermost coating is a high-radiation lowly-endothermic coating layer and is a fluorocarbon coating containing fluorocarbon element. The surface-treated cooled wire is easy to manufacture, low in cost increase, decreased in used temperature, and resistant to weather and corrosion. The outermost coating forms a permanent layer with high-radiation lowly-endothermic coating on the surface of the surface-treated cooled wire. Compared with a wire with same specification, the novel surface-treated cooled wire is decreased in surface temperature by 5 to 20 degrees centigrade in the case of same current-carrying capacity. As a result, line energy loss in a transmission process is reduced and low-carbon economy is achieved.

Owner:JIANGSU ZHONGTIAN TECH CO LTD

High-frequency electromagnetic induction straight hot press heating plate

PendingCN111203945AEven distribution of coilsHeating evenlyPlywood pressesLaminationPhysicsSteel plates

The invention discloses a high-frequency electromagnetic induction straight hot press heating plate. The high-frequency electromagnetic induction straight hot press heating plate comprises a steel plate and a high-temperature electromagnetic wire; a row of wire holes penetrating through the steel plate are formed in the positions, parallel to the upper surface and the lower surface, of the middleof the steel plate and are distributed at equal intervals, and the distance between centers of every two adjacent wire holes is 5-10 cm; when the distance between centers of every two adjacent wire holes is 5-8 cm, the high-temperature electromagnetic wire is threaded through the wire hole according to the principle that the current direction of every two adjacent holes is consistent as much as possible, and the two ends of the high-temperature electromagnetic wire are connected with a high-frequency heating power source and a controller. According to the high-frequency electromagnetic induction straight hot press heating plate, through the wire hole forming mode, the self structure of the steel plate is not changed as much as possible, and it is ensured that the mechanical property of thesteel plate is not changed; and meanwhile, it can be ensured that electromagnetic energy is absorbed by the steel plate sufficiently and converted into heat energy, the whole steel plate is uniform in heating, and an existing flat hot pressing plate is transformed advantageously.

Owner:湖南宏润科技发展有限公司

Zinc-nickel seeping layer ferrous metal corrosion protection process

ActiveCN101319300BHigh hardnessImprove wear resistanceSolid state diffusion coatingAl powderRolling resistance

The invention discloses a process for resisting ferrous metal corrosion of a zinc nickel diffusion layer. The process comprises the steps of alkaline degreasing, shot blasting, heating diffusion layer, water washing dust removal and colorful closing according to the requirement of a customer, wherein in the heating diffusion layer step, the zinc nickel diffusion layer and a metal matrix are put in a sealed metallic container and heated; the zinc nickel diffusion layer is prepared by evenly mixing the following powders in mass proportion: 20 to 30 percent of Zn powder, 0.5 to 1.4 percent of Nipowder, 3 to 12 percent of Al powder, 2 to 6 percent of rare earth, 1 to 4 percent of NH4Cl ammonium chloride, the balance being Al2O3 powder. The diffusion layer has the advantages of high rigidity,good wear resistance, unchangeableness of original mechanical performances of products, high adhesion strength, bumping and rolling resistance, good solderability, moisture and heat resistance and acid and alkali resistance; the diffusion layer has uniform thickness and compactness, and appearances of finished products have good uniformity; and no three-waste emission occurs during the course of processing, so the process belongs to the clean production process and is environment-friendly.

Owner:CHONGQING DAYOU SURFACE TECH

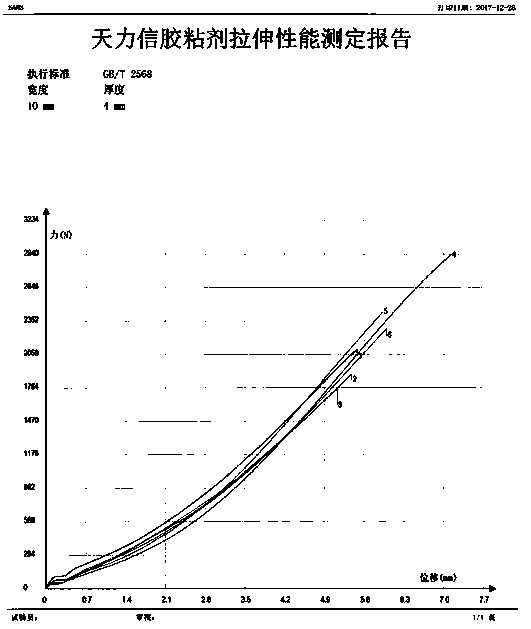

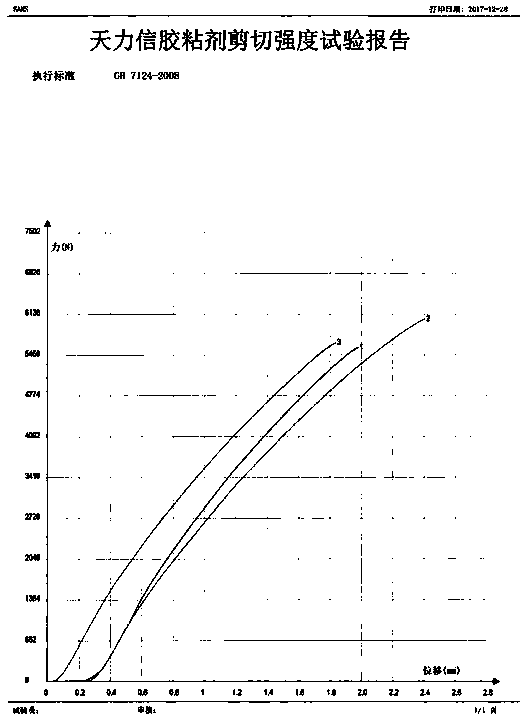

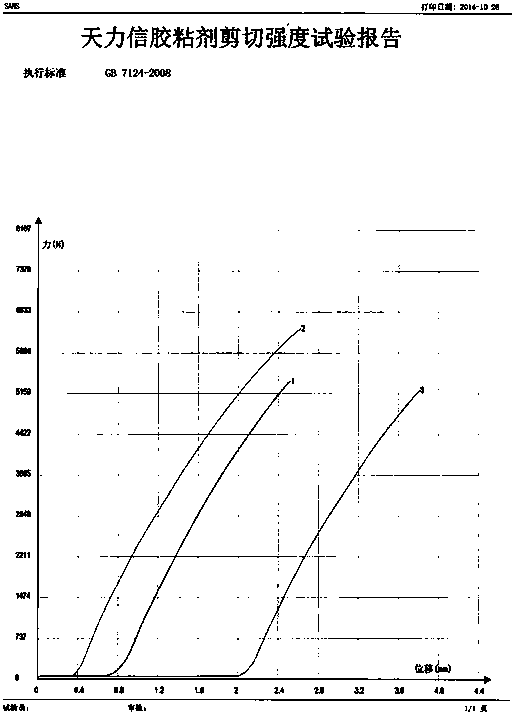

Carbon fiber impregnating adhesive and preparation method thereof

InactiveCN108727998AHigh viscosityImprove thixotropyNon-macromolecular adhesive additivesFilm/foil adhesives without carriersEpoxyFiber

The invention belongs to the technical field of preparation and application of building materials and in particular discloses a carbon fiber impregnating adhesive. The carbon fiber impregnating adhesive is prepared from a component A and a component B, wherein the component A and the component B are mixed according to the mixing ratio of 4 to 1 based on weight; the component A is prepared from thefollowing components in parts by weight: 90 to 110 parts of epoxy resin, 5 to 25 parts of diluting agent, 10 to 30 parts of toughening agent, 0.5 to 1.5 parts of de-foaming agent, 2 to 6 parts of gaseous silicon and 6 to 26 parts of activated calcium powder; the component B is prepared from the following components in parts by weight: 25 to 45 parts of curing agent, 1 to 5 parts of accelerant, 0.5 to 1.5 parts of coupling agent and 0.125 to 0.75 part of color paste. The carbon fiber impregnating adhesive disclosed by the invention has the beneficial effects that less activated calcium powderis added into the component A, so that the viscosity and thixotropy of the carbon fiber impregnating adhesive are increased; the adhesion performance is enhanced and the mechanical property of an adhesive body is not changed; the carbon fiber impregnating adhesive has high strength and excellent wetting property and permeability; a cured adhesive layer has good physical and mechanical properties,is tough and elastic and has excellent anti-ageing performance, acid and alkali resistance and water resistance; the carbon fiber impregnating adhesive does not contain a volatile solvent and is suitable for reinforcing and repairing a concrete structure by various fiber sheet materials.

Owner:NANJING TELESUN S & T IND

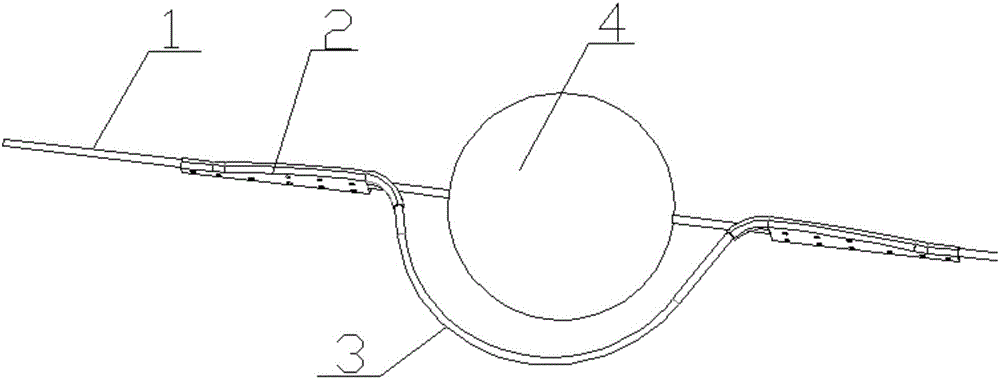

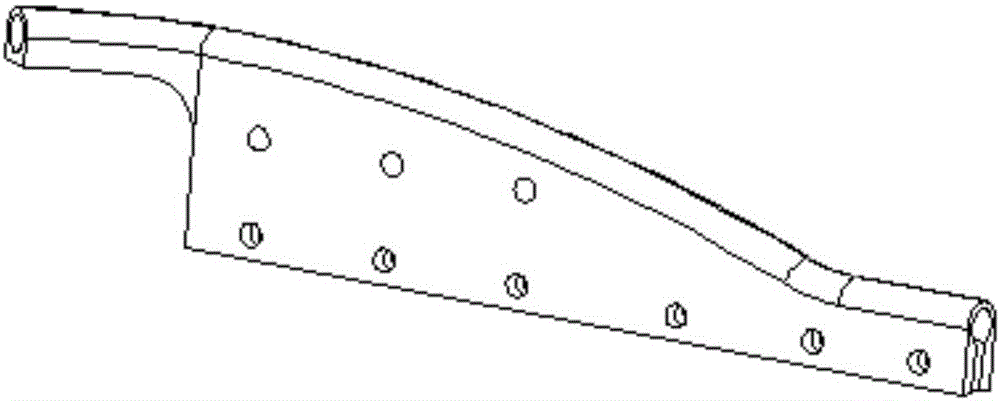

Guide rail device and device for enabling inspection robot to directly pass through navigation mark ball

InactiveCN106374408ANo change in mechanical propertiesNo change in electrical characteristicsOverhead installationApparatus for overhead lines/cablesEngineeringMarine navigation

The invention discloses a guide rail device and a device for enabling an inspection robot to directly pass through a navigation mark ball. The guide rail device comprises a guide rail and two guiding elements, wherein the two guiding elements are symmetrically arranged on two sides of the navigation mark ball along the moving direction of the inspection robot; the guide rail is positioned on the left side or right side of the navigation mark ball and is parallel to a ground wire, and two ends of the guide rail are connected with the tail ends of the guiding elements respectively. The efficiency for crossing the navigation mark ball by the robot is improved, and the robot does not need to perform complex obstacle crossing actions.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +2

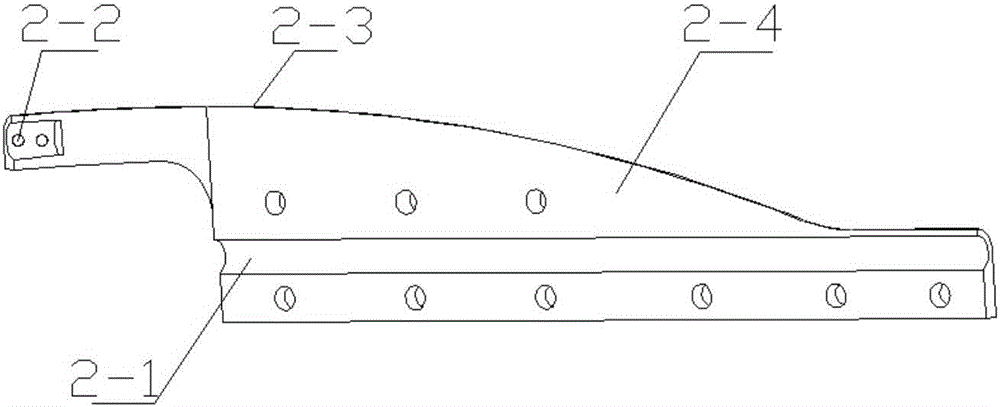

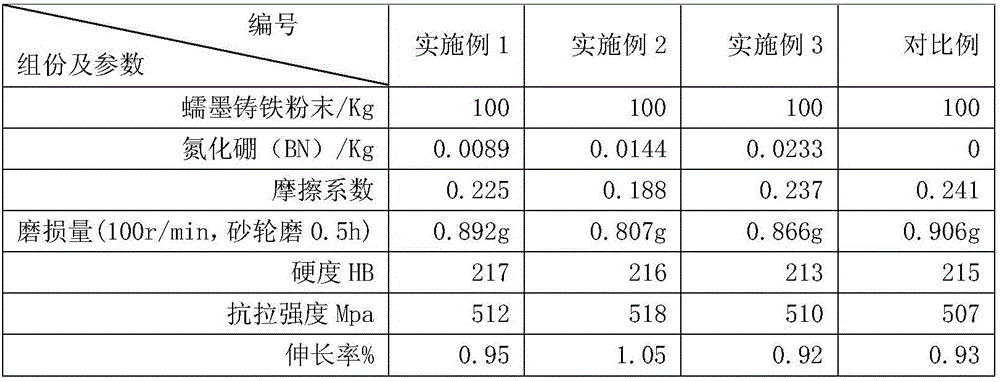

Easy-to-machine vermicular graphite cast iron

The invention provides easy-to-machine vermicular graphite cast iron and belongs to the technical field of cast iron materials. The easy-to-machine vermicular graphite cast iron is mainly prepared by adding cubic boron nitride (BN) powder into molten iron of conventional vermicular graphite cast iron, so that BN can be uniformly distributed in the easy-to-machine vermicular graphite, the easy-to-machine vermicular graphite can possess the self-lubricating property, and the mechanical property of the easy-to-machine vermicular graphite can remain unchanged when the cutting machinability is improved on the basis that the natural hardness and tensile strength properties of the easy-to-machine vermicular graphite are kept. Accordingly, the easy-to-machine vermicular graphite cast iron can be economically and efficiently machined by cutting.

Owner:GUANGXI UNIV

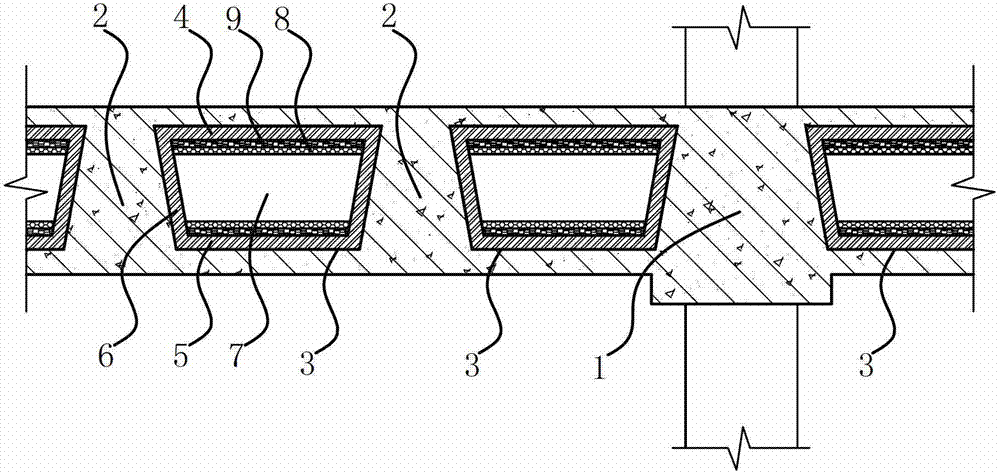

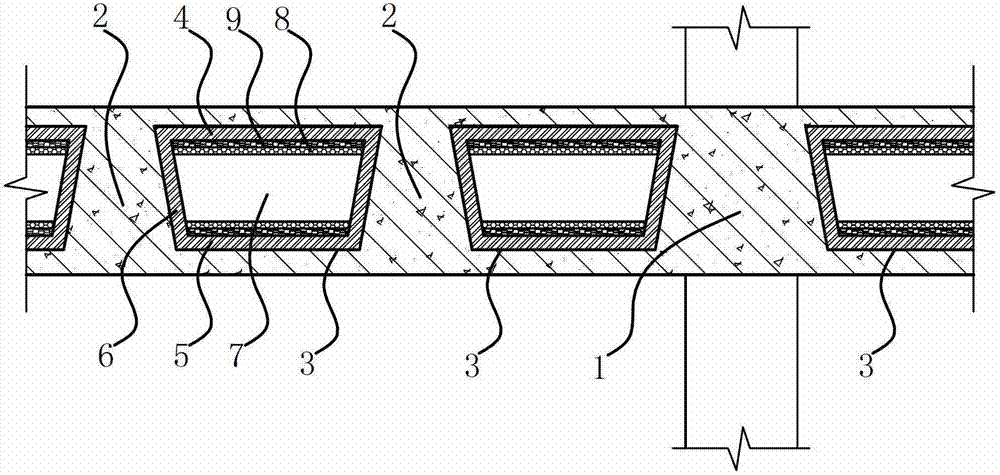

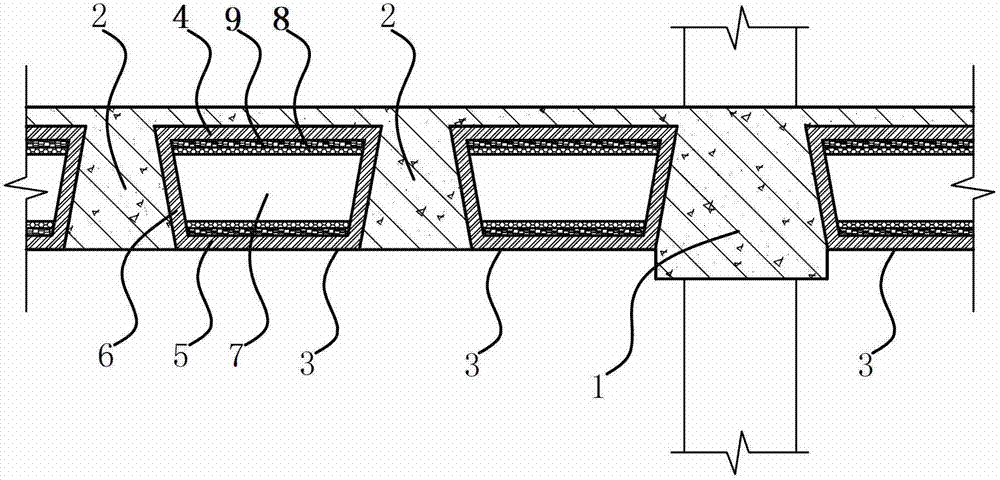

Energy saving ribbed cavity floor slab

InactiveCN102966209AChange mechanical propertiesImprove insulation effectConstruction materialFloorsFloor slabInsulation layer

An energy saving ribbed cavity floor slab comprises frame beams, ribbed beams and an energy-saving cavity components arranged between each frame beam and each ribbed beam or every two ribbed beams, and is characterized in that each energy-saving cavity component is a cavity body, which is formed by an upper board, a lower board and periphery wall boards; and at least one surface of the cavity body is provided with an insulation layer or / and a heat insulation layer. According to the invention, the mechanics performance of the cavity floor slab is not changed; the cavity floor slab has an own heat insulation processing function, so as to greatly improve the heat insulation and sound insulation performance. The heat insulation layer is embedded in the closed cavity, therefore the weatherability of the cavity is good, and besides, the heat insulation layer is flexibly arranged, cavity floor slabs with different heat insulation coefficients can be designed; each cavity component is specially arranged on a warping edge provided with the heat insulation layer, and the whole floor slab has a broken bridge type heat insulation effect via carrying out heat insulation process of the ribbed beams or the frame beams. The comprehensive performance of the cavity floor slab is improved, and the effect on energy conservation of buildings is qualitatively improved.

Owner:HUBEI SYNTHETIC SPACE TECH CO LTD

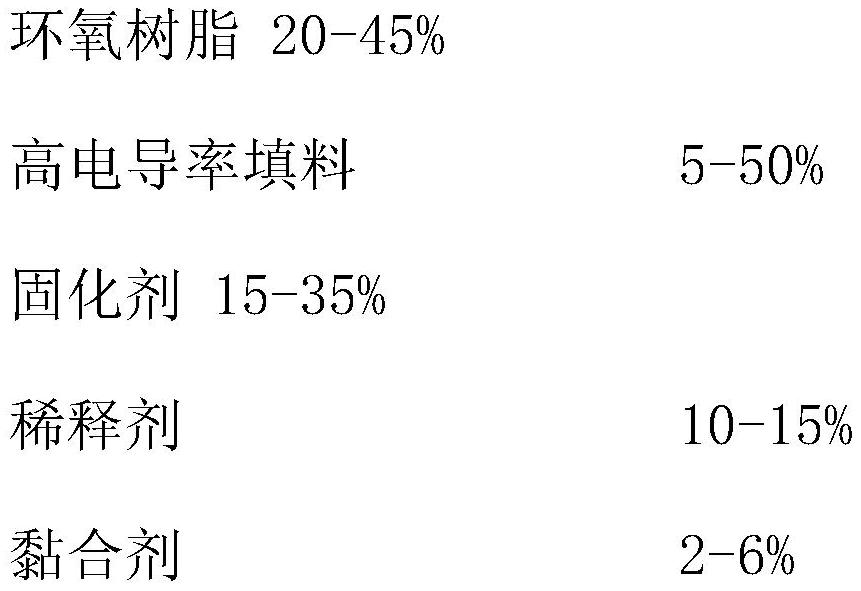

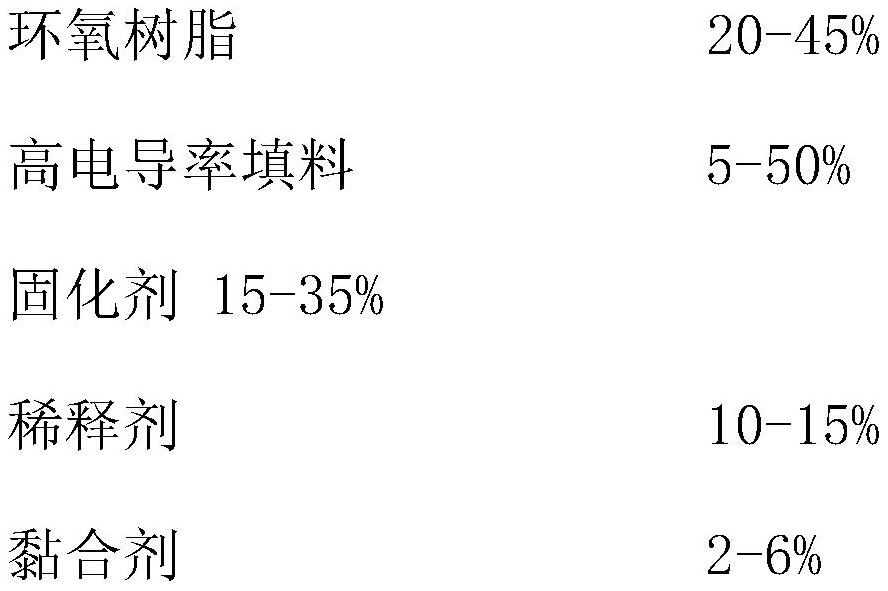

Preparation method of surface conductivity gradient coating for direct current GIL epoxy resin insulator

PendingCN113793739AGood adhesionOptimizing Surface Electric FieldNon-conductive material with dispersed conductive materialInsulatorsEpoxySurface charges

The invention discloses a preparation method of a surface conductivity gradient coating for a direct-current GIL epoxy resin insulator, and the method comprises the following steps: dividing the surface of the insulator into N parts from a high-voltage electrode to a ground electrode, and then sequentially coating high-conductivity coatings on the surface of the insulator from the high-voltage electrode to the ground electrode according to the conductivity from high to low, and through curing, forming the gradient distribution insulator with gradually reduced conductivity. The bonding between the surface coating and the epoxy resin insulator is firmer. A normal-temperature liquid epoxy resin material which is the same as an insulator substrate material is adopted as a matrix of the coating, so that the adhesion between the coating and an epoxy resin insulator can be ensured; the method can be used for regulating and controlling the surface charge distribution of the GIL epoxy resin insulator under the direct-current voltage, optimizing the surface electric field distribution and improving the surface electric strength. The coating provided by the invention is simple and feasible in preparation scheme, relatively low in cost and wide in application prospect.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com