Energy saving ribbed cavity floor slab

A cavity floor and dense rib technology, applied in the direction of floors, building materials, building components, etc., can solve rare and other problems, achieve the effect of improving heat preservation, improving comprehensive performance, and flexible setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

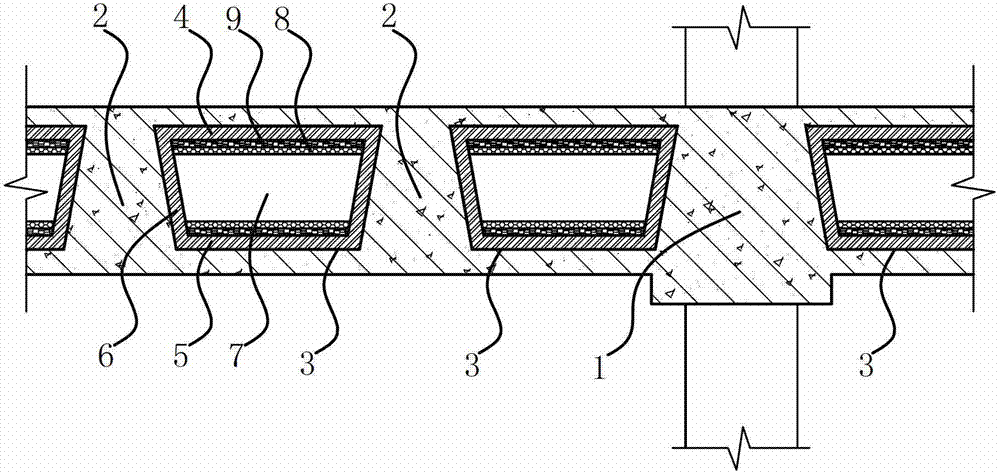

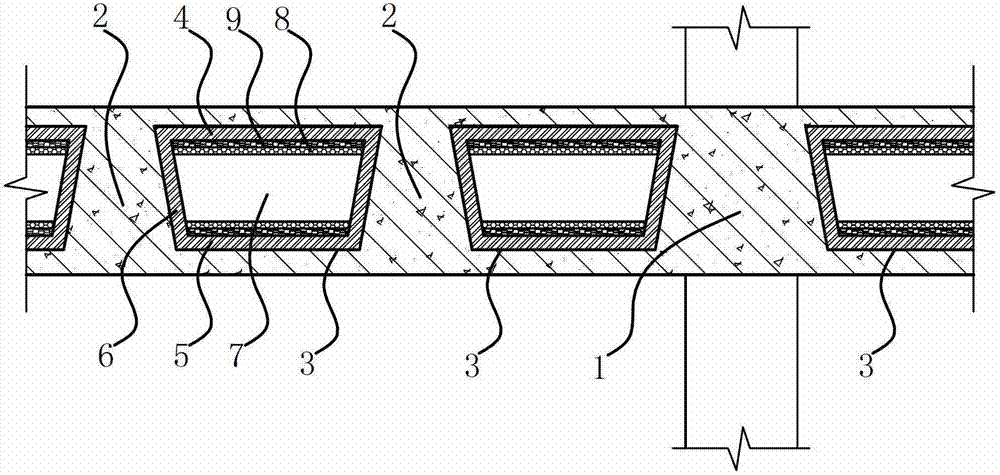

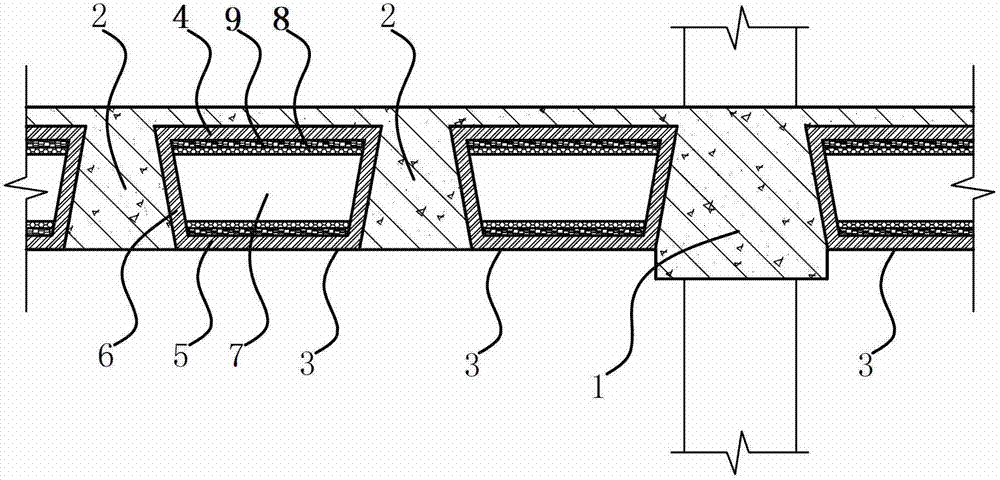

[0044] Below in conjunction with accompanying drawing, the present invention is further described: in each accompanying drawing, numbering is identical, and its description is identical. In the figure, 1 is the frame beam, 2 is the dense rib beam, 3 is the energy-saving cavity component, 4 is the upper plate, 5 is the lower plate, 6 is the wall plate, 7 is the cavity body, 8 is the insulation layer, and 9 is the heat insulation Layer, 10 is a splicing strip, 11 is a pick edge, 12 is a connector, 13 is a reinforcement, and 14 is a hanging point.

[0045] Such as figure 1 The shown energy-saving densely ribbed cavity floor slab includes frame beam 1, densely ribbed beam 2, and energy-saving cavity member 3 arranged between frame beam 1 and densely ribbed beam 2 or between densely ribbed beam 2 and densely ribbed beam 2, which is characterized in that The energy-saving cavity component 3 is enclosed by the upper plate 4, the lower plate 5 and the surrounding wall plates 6 to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com