Once forming stamping method of double-parabolic plate with consistent thickness

A technology of hyperbolic plates and dies, which is applied in the field of metal pressing, can solve the problems of changing the mechanical properties of plates, making it difficult to form large-scale processing and production, and greatly affecting the processing methods, so as to save employment and production costs, and reduce processing and forming Time, to achieve the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The solution of the present invention will now be described by taking the one-time die processing method for the flow guide plate of a 60.5-meter marine engineering ship as an example. It includes the following steps:

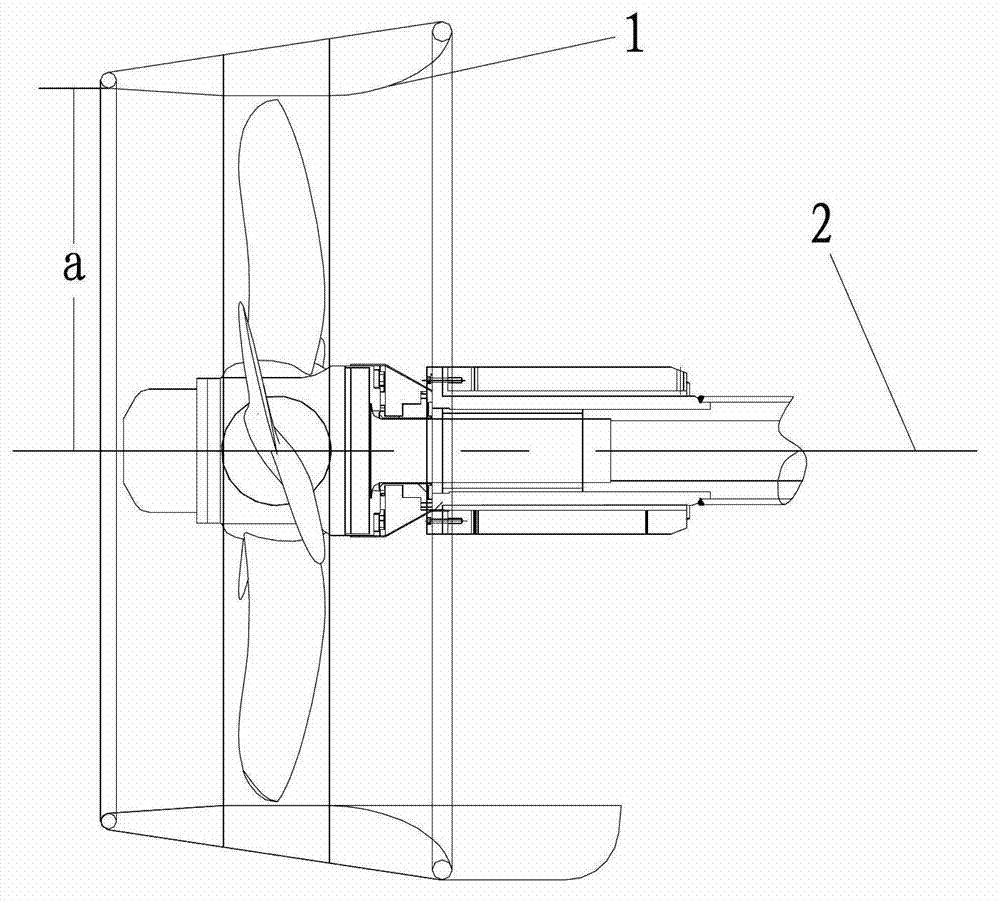

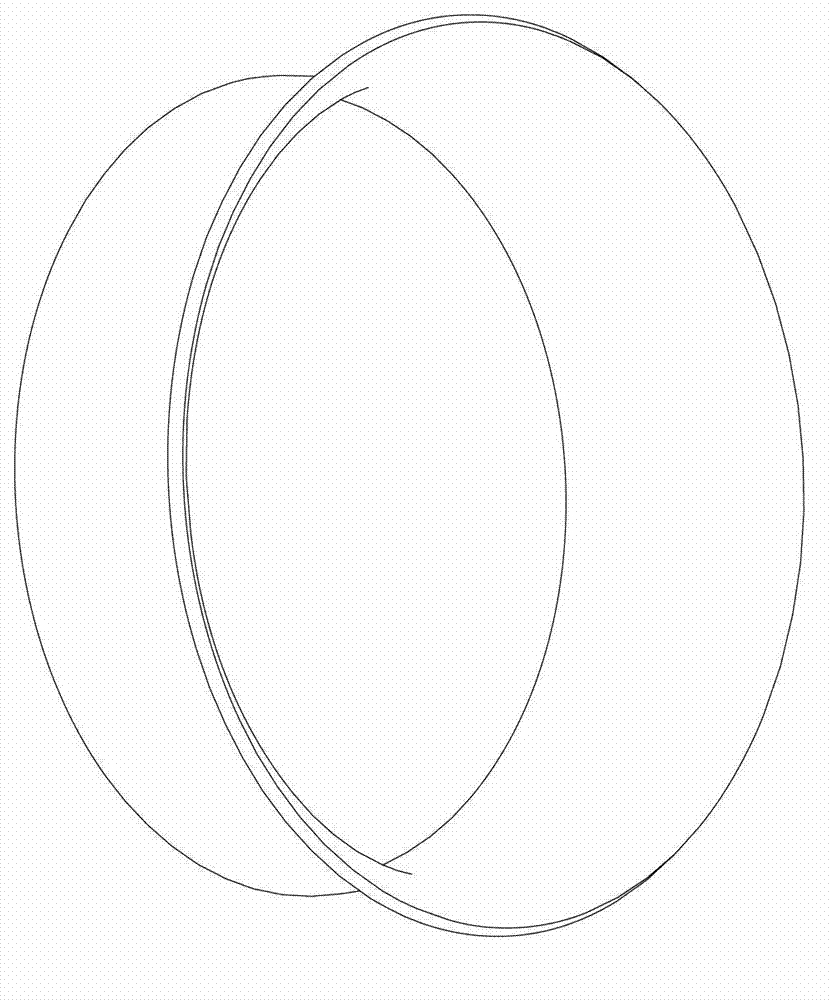

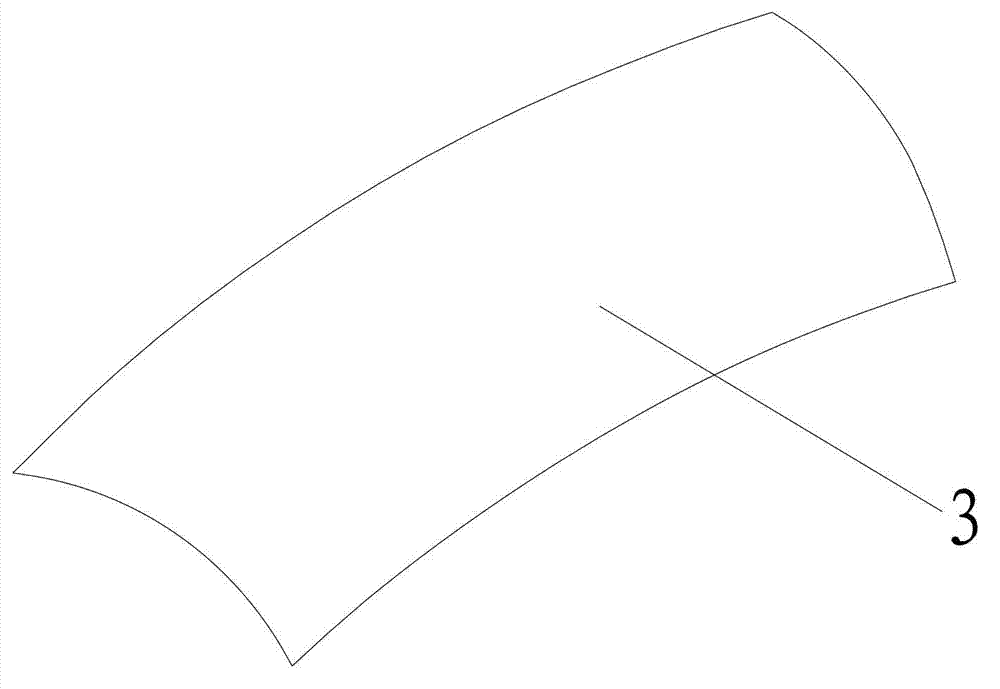

[0037] A. If figure 1 , figure 2 and image 3 As shown in , the linear analysis of the inlet plate of the air deflector is carried out, and the contour line 1 of the air deflector is centered on the centerline 2 of the axis and rotated with a as the radius of rotation to obtain the surface of the lower die surface of the air deflector air deflector Three-dimensional curved surface model, according to the division of the plate seam of the plate, select a 1 / 6 full circle part of the plate as the lower die surface 3 of the target plate for compression molding;

[0038] B. If Figure 4 and Figure 5 As shown in , according to the stress angle, stress area and operation difficulty of the target plate, the machining reference plane is selected, and the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plate thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com