Patents

Literature

45results about How to "Does not reduce plasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corrosion resistant niobium-titanium alloy, and method for manufacturing plates and pipes with the same

InactiveCN102703757AImprove corrosion resistanceExpand the range of corrosion resistanceSolid solution strengtheningTitanium alloy

The invention relates to a corrosion resistant niobium-titanium alloy, and a method for manufacturing plates and pipes with the corrosion resistant niobium-titanium alloy, wherein the corrosion resistant niobium-titanium alloy contains the following components by weight: 0.1-4.9% o Nb, not more than 0.08% of C, not more than 0.03% of N, not more than 0.012% of H, not more than 0.1% of O, not morethan 0.1% of Fe, and the balance of Ti. In Ti-(0.8-6%) Nb alloy pipes disclosed by the invention, titanium is as a matrix; little niobium is added; mechanical property of the niobium is improved by asolid-solution strengthening way; shearing strength and tensile strength of the alloy are higher than pure titanium; the tensile strength is increased by 10-20%; good plasticity and formability are kept; cold working performance is excellent; the niobium is added to further increase corrosion resistance of titanium and enlarge corrosion resistant range of titanium, so that the corrosion resistantniobium-titanium alloy is a good easily-formed corrosion resistant material.

Owner:NINGXIA ORIENT TANTALUM IND

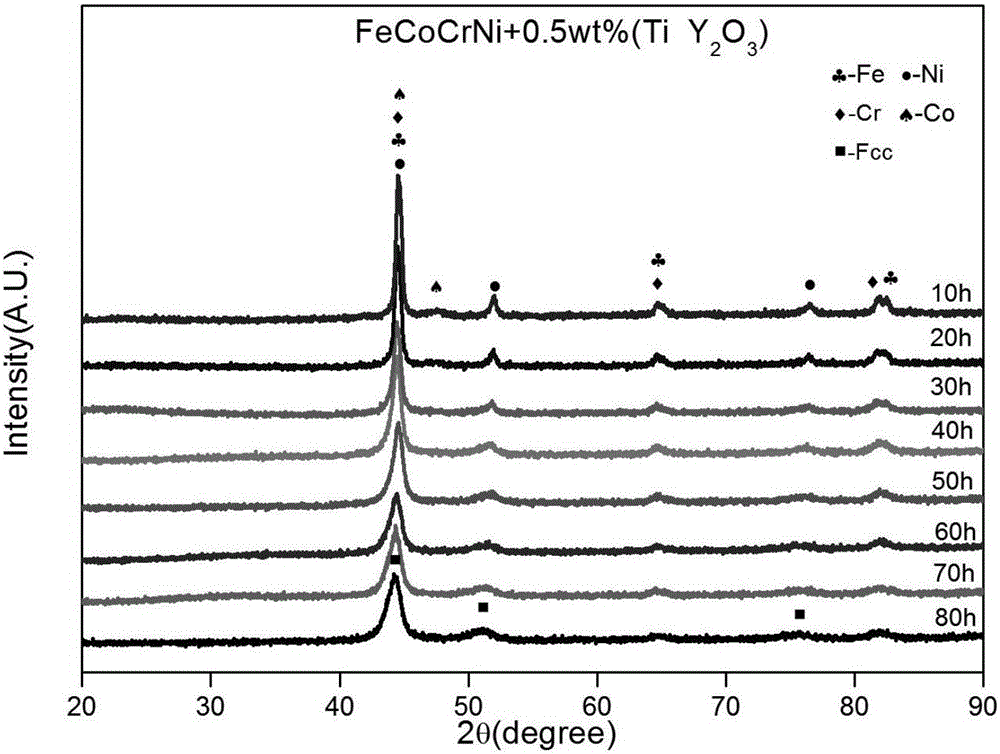

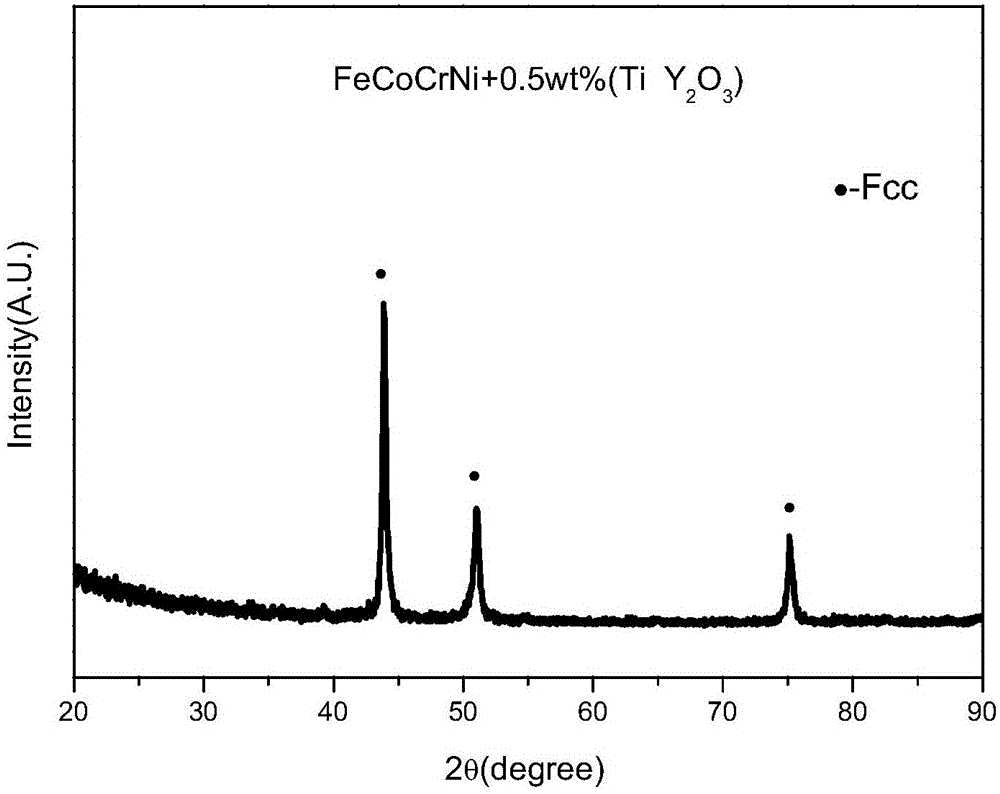

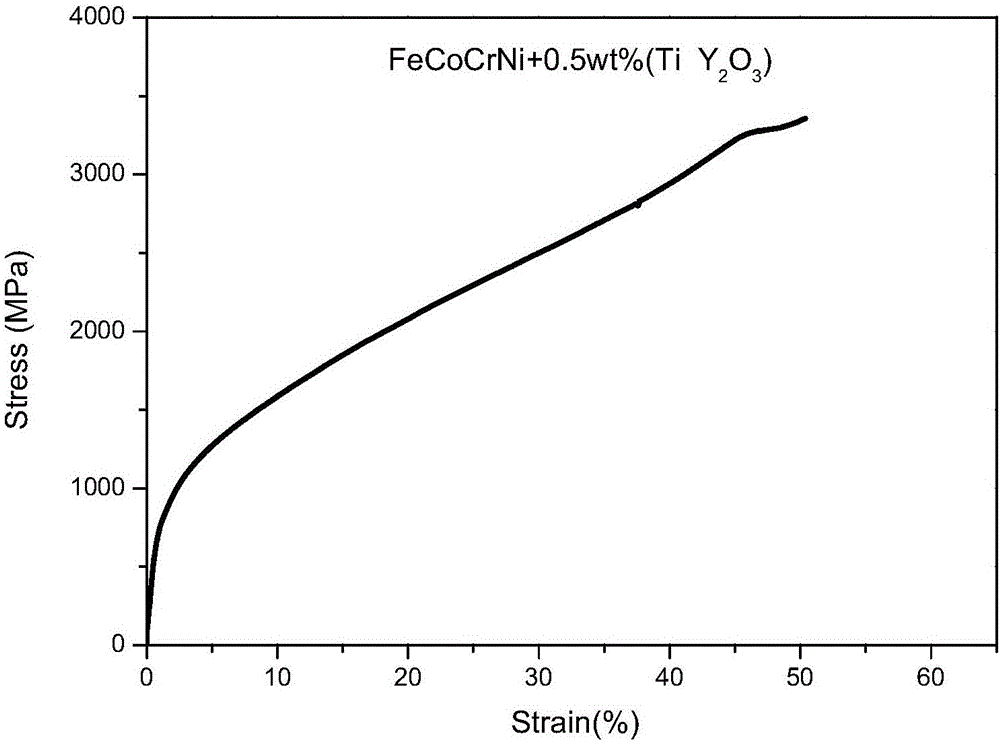

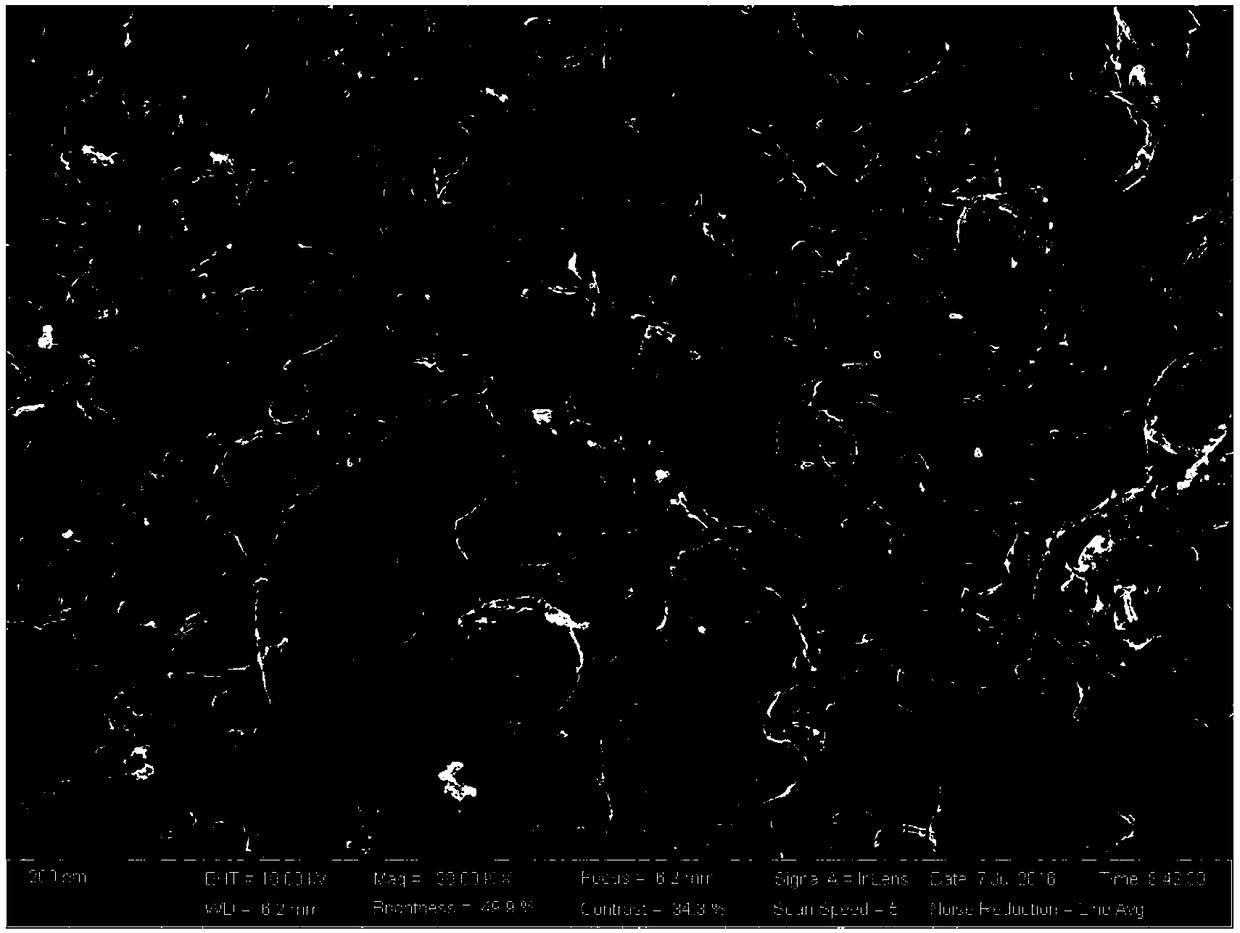

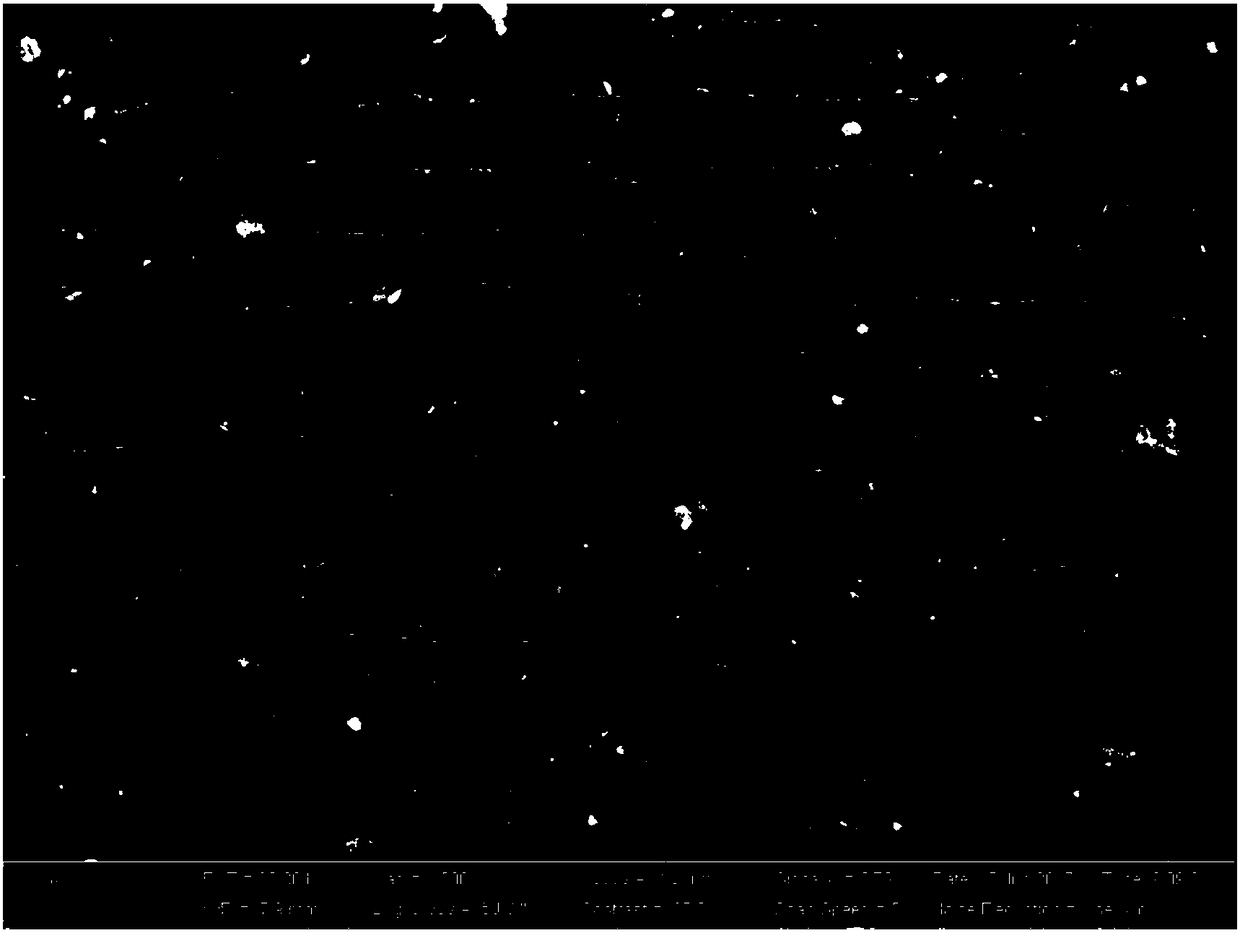

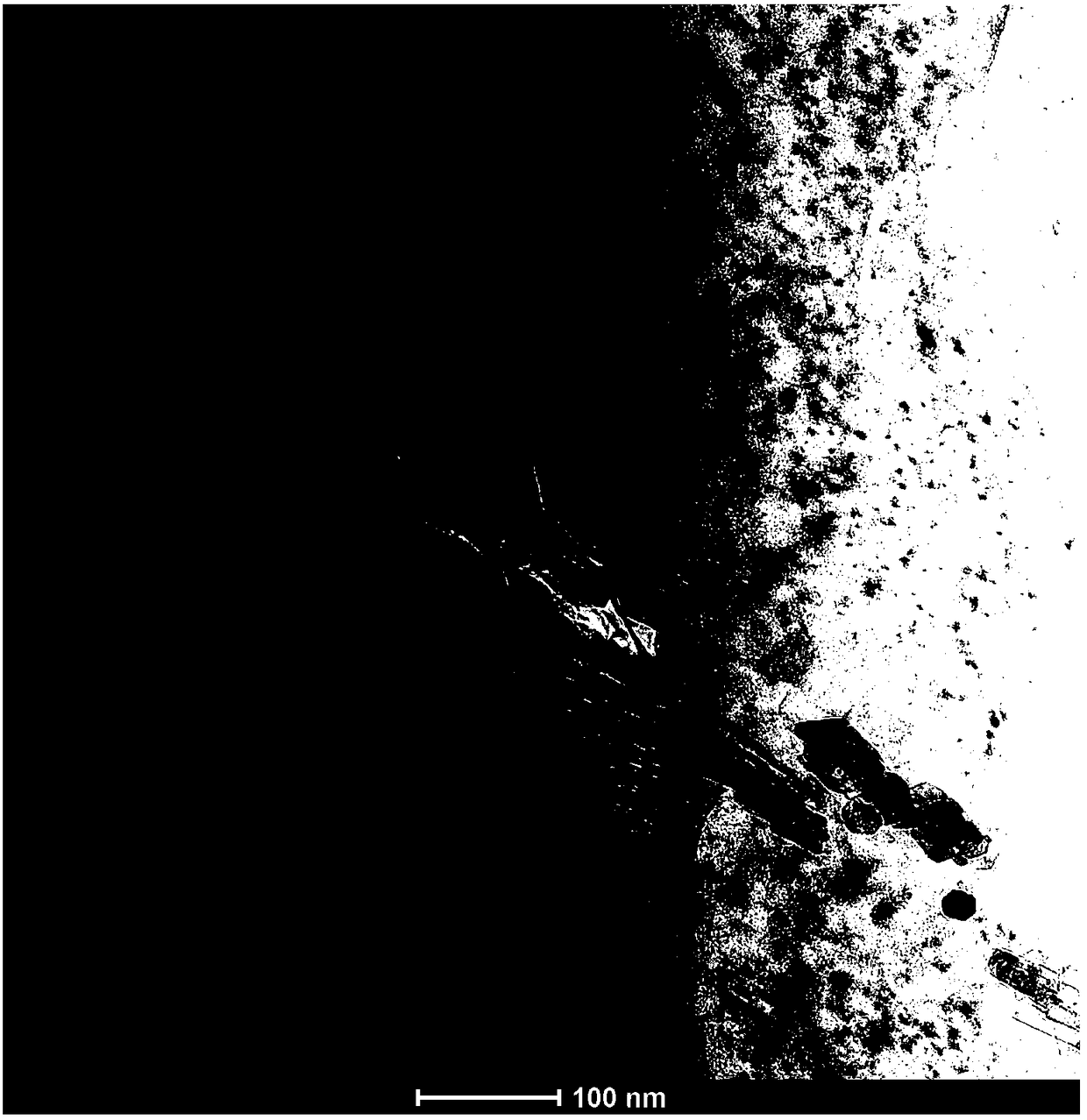

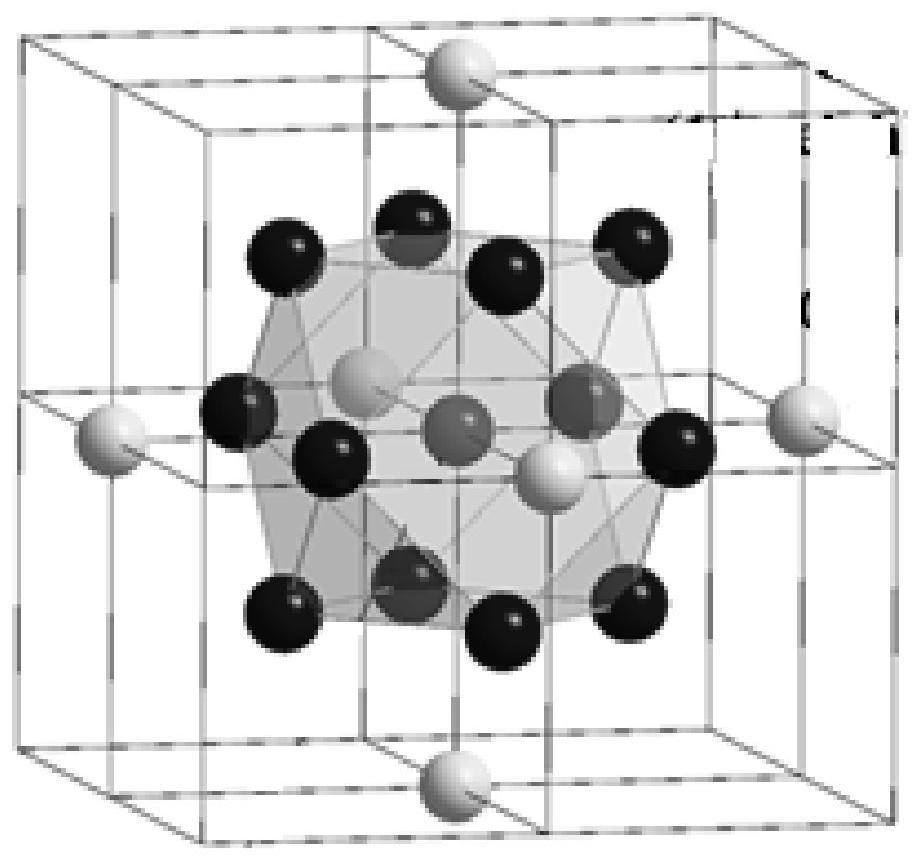

Oxide dispersion strengthened (ODS) high-entropy alloy and preparation method thereof

The invention provides oxide dispersion strengthened (ODS) high-entropy alloy and a preparation method thereof, and belongs to the field of structural metallic materials. Pure metal powder with a certain composition proportion and oxide particles of a certain content are mixed, and then ODS high-entropy alloy powder is prepared through a mechanical alloying method; and then the final ODS high-entropy alloy is obtained through a spark plasma sintering (SPS) method. The prepared ODS high-entropy alloy is mainly composed of a solid solution phase (95% or above) and a small amount of evenly-dispersed nanometer oxide particles, and has the excellent comprehensive mechanical property and good thermal stability; and the compressive strength of the FeCoNiCrAl-based ODS high-entropy alloy composed of the face-centered cubic structure (FCC) solid solution and the body-centered cubic structure (BCC) solid solution is higher than 3500 MPa, and compressive strain of the high-entropy alloy can reach 10%. The high-entropy alloy has high strength, high hardness, high corrosion resistance, high abrasion resistance, and excellent thermal stability and irradiation resistance, and has potential application prospects in the fields of aerospace, metallurgy, the chemical industry, electrical energy and the like.

Owner:UNIV OF SCI & TECH BEIJING

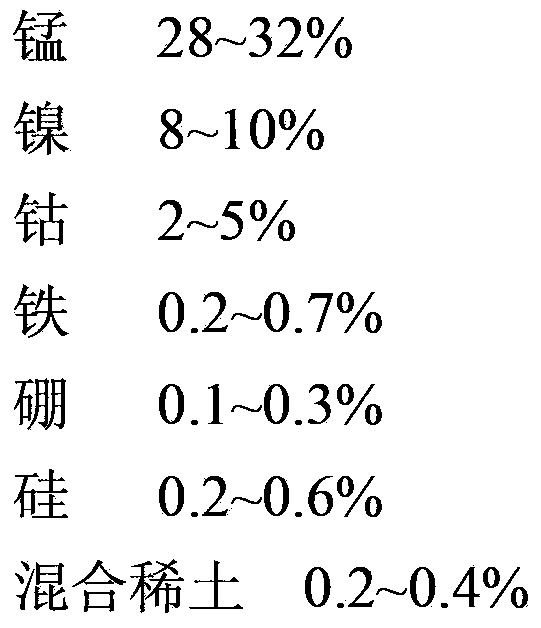

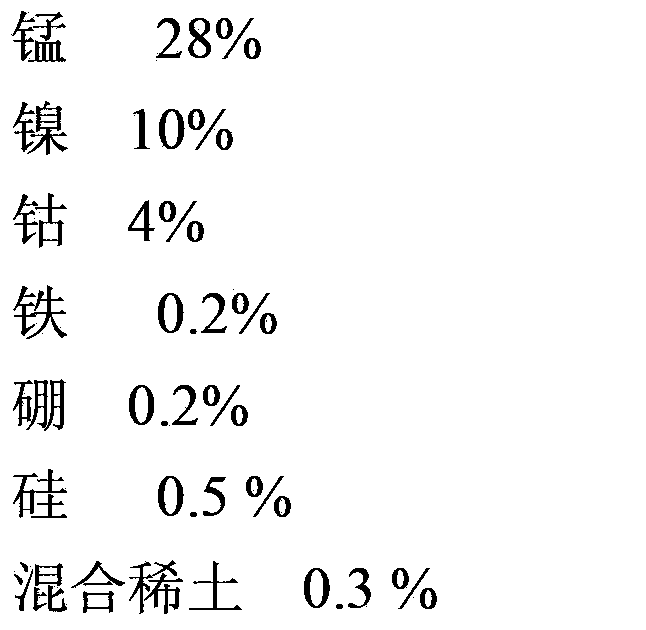

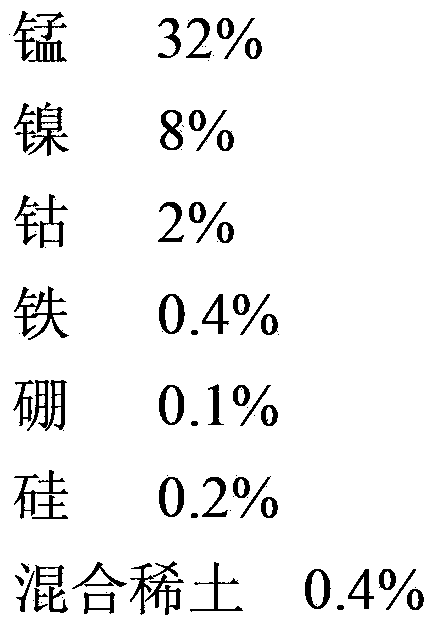

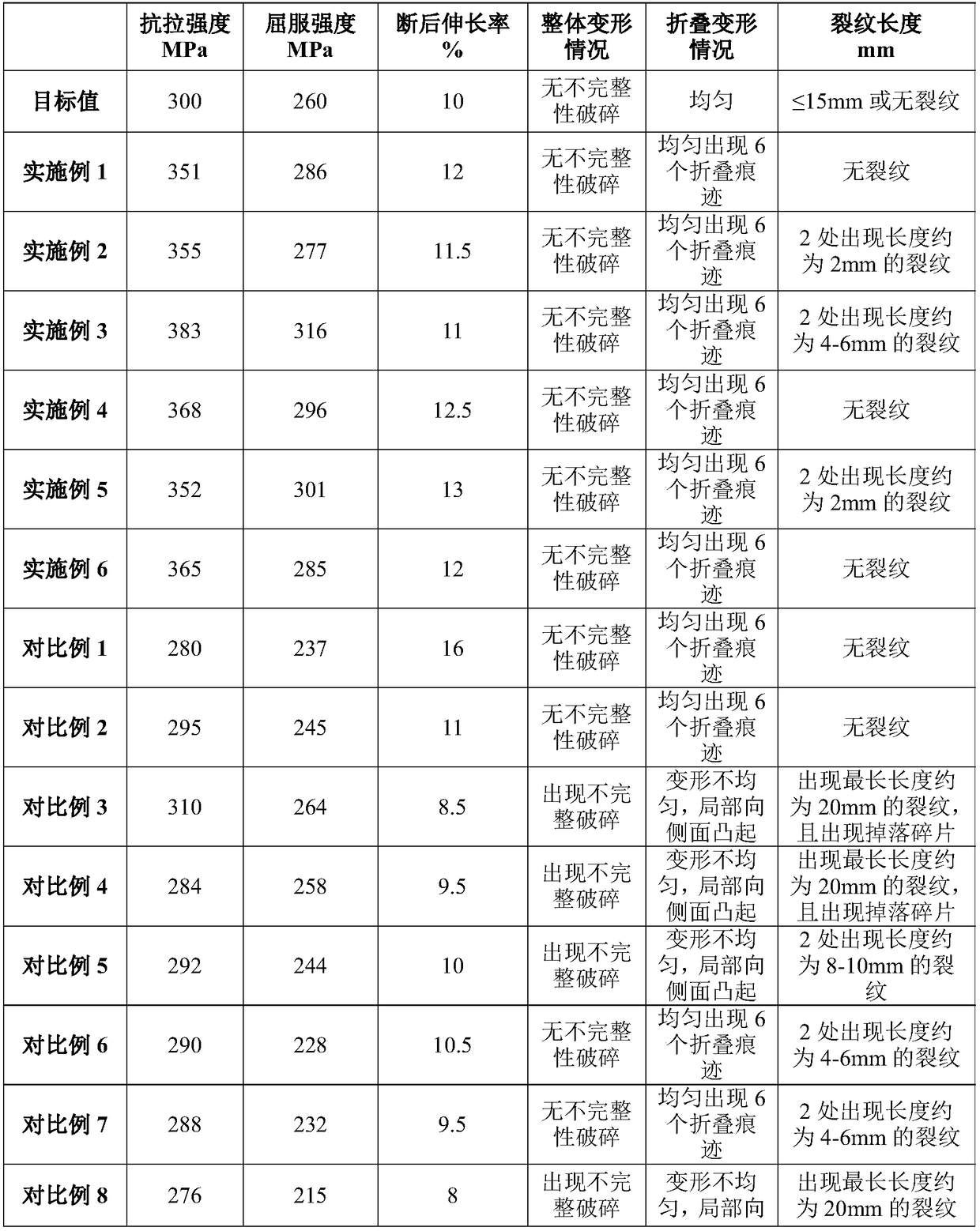

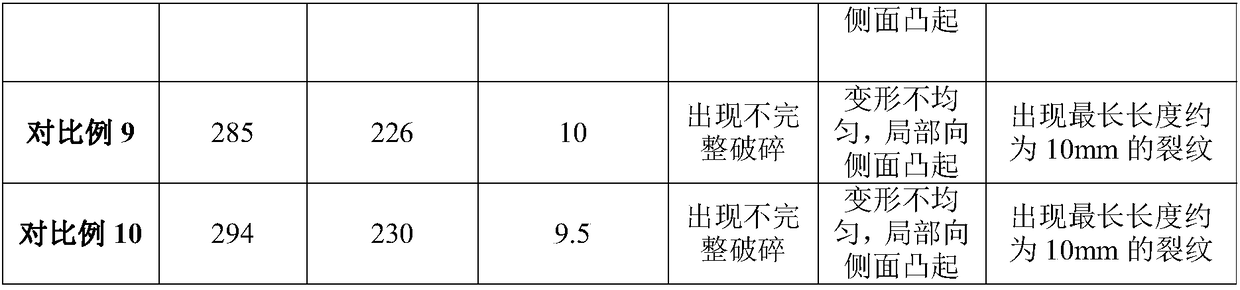

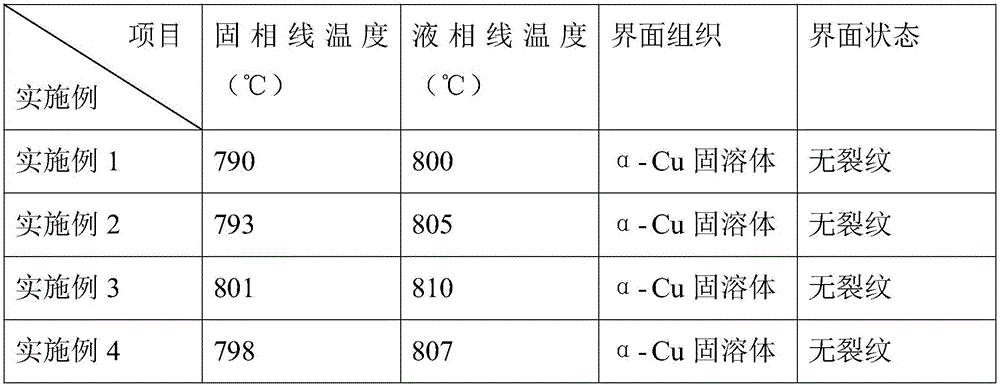

Copper-based solder and preparation method thereof

ActiveCN103358051ALower melting temperatureImprove wettabilityWelding/cutting media/materialsSoldering mediaCorrosionSmelting process

The invention discloses a method for preparing a copper-based solder. The method comprises the following steps: (1) burdening: preparing a furnace burden from copper, manganese, nickel, cobalt, silicon, a copper-ferrous intermediate alloy, a copper-boron intermediate alloy and a copper-mixed rare earth intermediate alloy serving as raw materials; (2) casting: putting the prepared furnace burden into the a corundum crucible according to the sequence of manganese, copper, nickel, cobalt, silicon, copper-boron intermediate alloy, copper-mixed rare earth intermediate alloy and copper-ferrous intermediate alloy, smelting by adopting medium-frequency induction, and cooling along with the furnace to obtain an alloy blank, wherein the smelting process is performed under the protection of argon gas; and (3) rolling: rolling the alloy blank with a cold-rolling mill to obtain the copper-based solder. The copper-based solder provided by the invention can be applied to an ODS (Oxide Dispersion Strengthened) high-temperature alloy welding joint, has high brazing process performance, heat resistance, corrosion resistance and machining process, and is low in cost.

Owner:SOUTH CHINA UNIV OF TECH

Production process of aluminum profile for automobile impact energy absorbing components and produced aluminum profile

The invention discloses a production process of an aluminum profile for automobile impact energy absorbing components and a produced aluminum profile, relates to the technical field of aluminum and aluminum alloy extrusion machining and heat treatment. The production process comprises the following steps that an aluminum alloy ingot is subjected to uniform annealing treatment, extrusion and quenching treatment, tensile treatment and aging treatment in sequence; then, the aluminum alloy ingot is cooled to 490-525 DEG C after the uniform annealing treatment, and extrusion is carried out again; and the aging treatment includes first, natural aging treatment and then secondary artificial aging treatment, the natural aging treatment time is carried out for 30-60 h, the heat preservation temperature of a first artificial aging stage is 100-120 DEG C, the heat preservation time is 2-3.5 h, the heat preservation temperature of a second artificial aging stage is 150-170 DEG C, and the heat preservation time is 8-12 h. By reasonably designing parameters of extrusion process and heat treatment process, the production process can improve tensile mechanical properties simultaneously without reducing the plasticity, so that the aluminum profile has better compression performance.

Owner:SHANDONG NANSHAN ALUMINUM +3

Method for preparing carbon nanotube reinforced magnesium-based composites of layered structure

InactiveCN108179294AHigh yield strengthHigh strengthElectrophoretic coatingsMagnesium matrix compositeNanotube

The invention provides a method for preparing carbon nanotube reinforced magnesium-based composites of a layered structure, and belongs to the technical field of magnesium-based composites. The problem that the strength and plasticity of pure magnesium matrix can not be considered simultaneously is solved. According to the method provided by the invention, the elongation of materials is maintainedto a certain extent while the strength is improved. The method provided by the invention comprises the step 1 of taking a magnesium foil of which the surface oxides are removed as a cathode, a stainless steel plate as an anode, immersing the cathode and the anode into electrophoretic liquid for electrophoretic deposition, and then drying the magnesium foil and the stainless steel plate to obtaincarbon nanotube / magnesium layered elements; the step 2 of stacking the carbon nanotube / magnesium layered elements obtained in the step 1, and then performing vacuum hot-pressing sintering to obtain the carbon nanotube reinforced magnesium-based composites of the layered structure. The carbon nanotube reinforced magnesium-based composites prepared with the method provided by the invention are applied to aerospace.

Owner:HARBIN INST OF TECH

Copper alloy for conditioner pipe

Disclosed is a copper alloy for air-conditioner pipes, which comprises the following components (by weight percentage): Cu 99.9%, P 0.001-0.099%, 0.001-0.099% of mixed rare earth metal (Re) mainly including lightweight rare-earth elements such as La and Ce. The content of P is preferably 0.015-0.040% and 0.004-0.012%. The invention can improve the metal's corrosion resistance and increase the operating life for the air-conditioner pipes.

Owner:ZHEJIANG HAILIANG

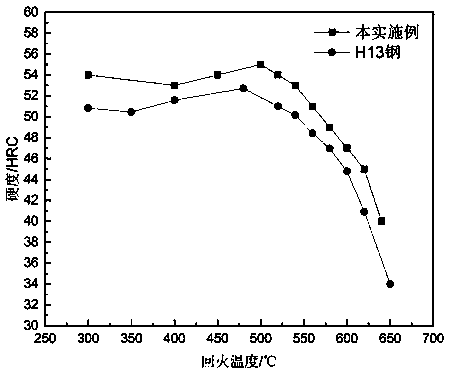

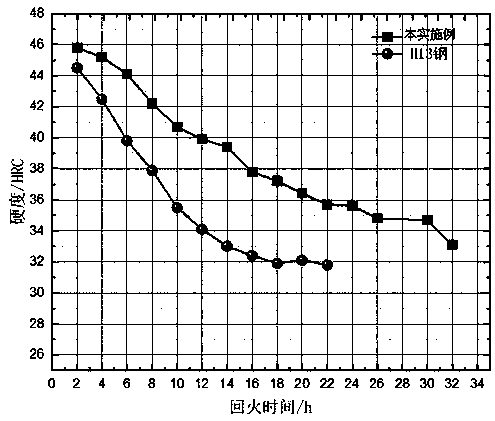

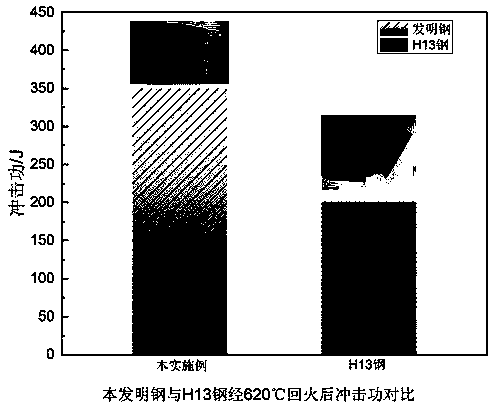

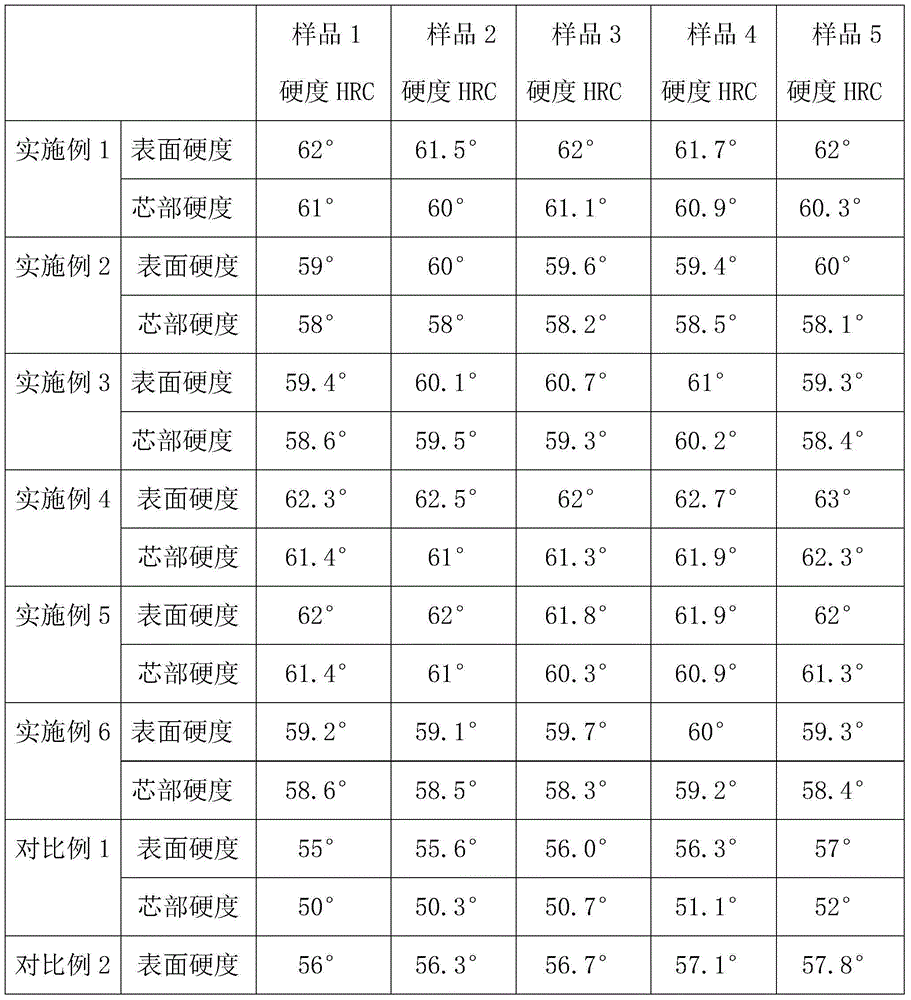

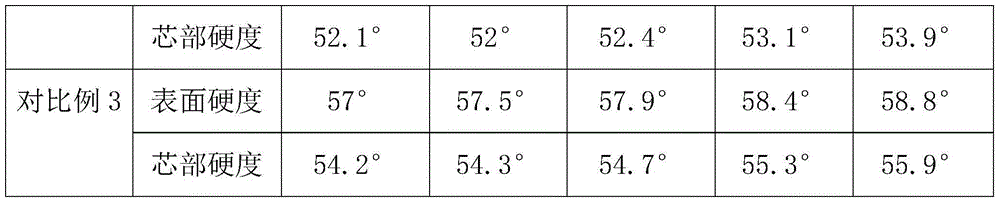

High-manganese low-chromium type hot work die steel and preparation method thereof

The invention relates to high-manganese low-chromium type hot work die steel and a preparation method of the high-manganese low-chromium type hot work die steel, and belongs to the technical field ofhot work die steel. The high-manganese low-chromium type hot work die steel is prepared from, by mass, 0.35-0.45% of C, 0.50-1.20% of Si, 0.60-1.20% of Mn, 3.75-4.50% of Cr, 0.80-1.20% of Mo, 0.30-0.60% of V, 0.50-5.50% of Co, 0.80-3.00% of Ni, less than 0.02% of P, less than 0.02% of S and the balance Fe and inevitable impurities. The high-manganese low-chromium type hot work die steel is prepared through the processes of material preparation, smelting, casting, electroslag remelting, high temperature homogenization treatment, forging, annealing and heat treatment. Compared with existing H13hot work die steel, the high-manganese low-chromium type hot work die steel has higher toughness and higher heat stability.

Owner:KUNMING UNIV OF SCI & TECH

Wear-resistant alloy steel, alloy grinding ball and preparation method of wear-resistant alloy steel

The invention discloses wear-resistant alloy steel, an alloy grinding ball and a preparation method of the wear-resistant alloy steel, and relates to the technical field of metallurgy, aiming at solving the problem that an alloy grinding ball which is good in ductility and good in wear resistance cannot be prepared by a rolling process in the prior art. The main technical scheme of the invention is as follows: the wear-resistant alloy steel consists of the following substances in percentage by weight: 0.90-1.00% of carbon, 0.35-0.45% of silicon, 0.50-0.60% of manganese, 1.1-1.3% of chromium, 0.25-0.35% of molybdenum, 0.07-0.09% of boron, 0.3-0.5% of rare earth, 0-0.016% of sulfur, 0-0.015% of phosphor, 0-0.06% of copper and the balance of iron and inevitable impurities. The invention prepares the wear-resistant alloy steel and the alloy grinding ball which are high in ductility and wear-resistant mainly by virtue of a rolling process.

Owner:清原满族自治县三方耐磨材料有限公司

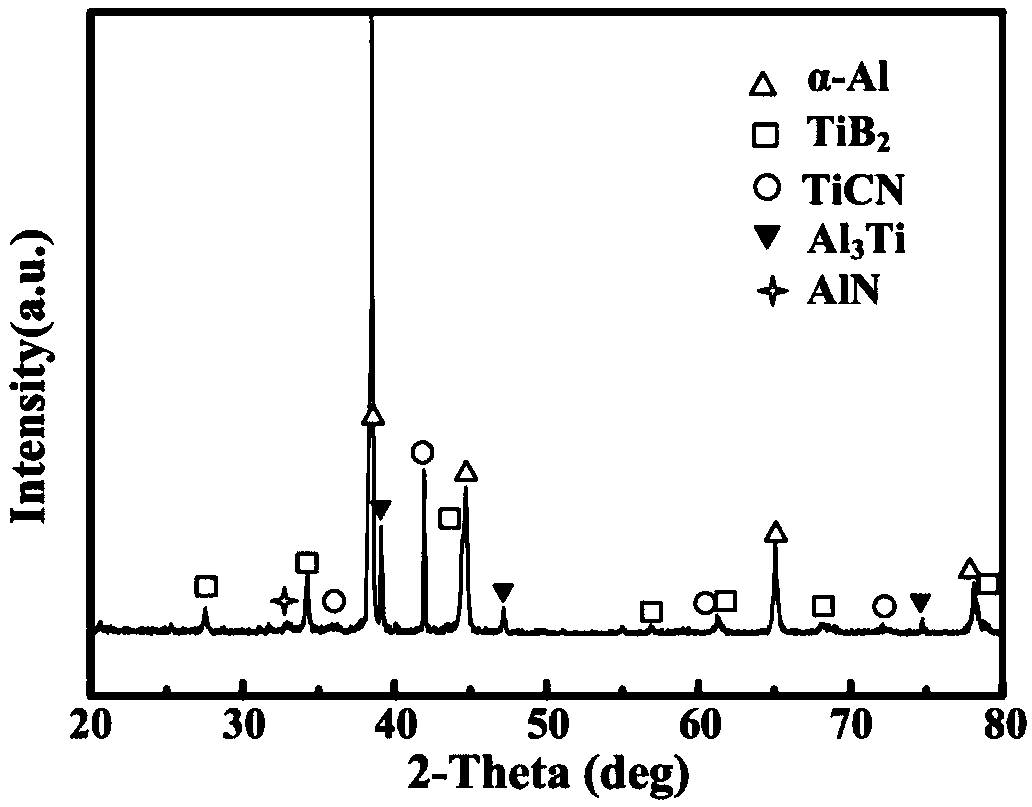

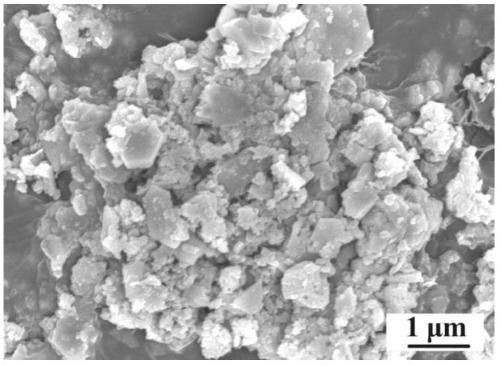

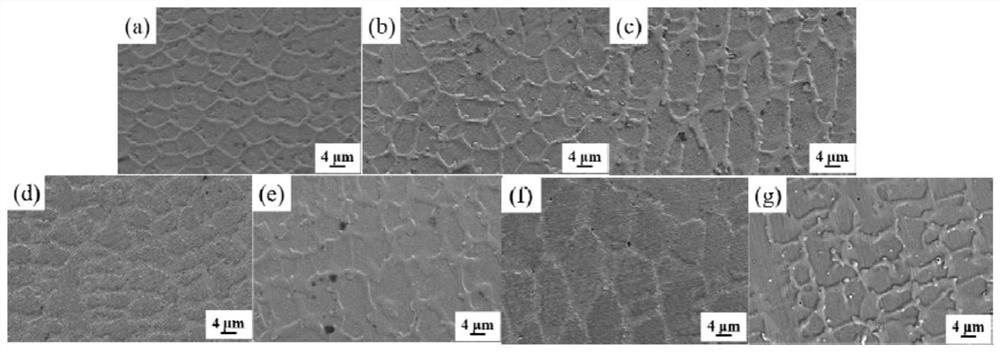

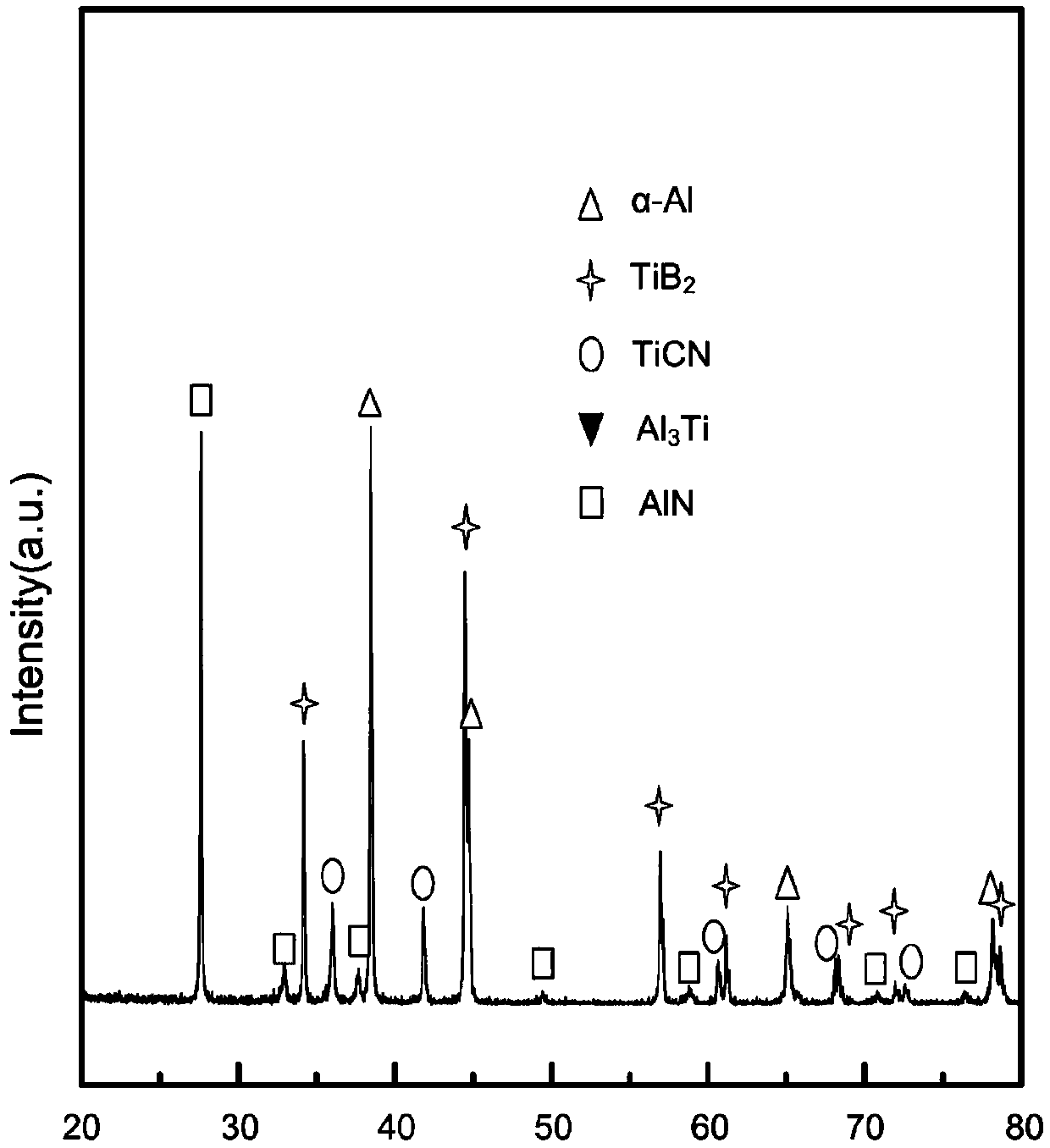

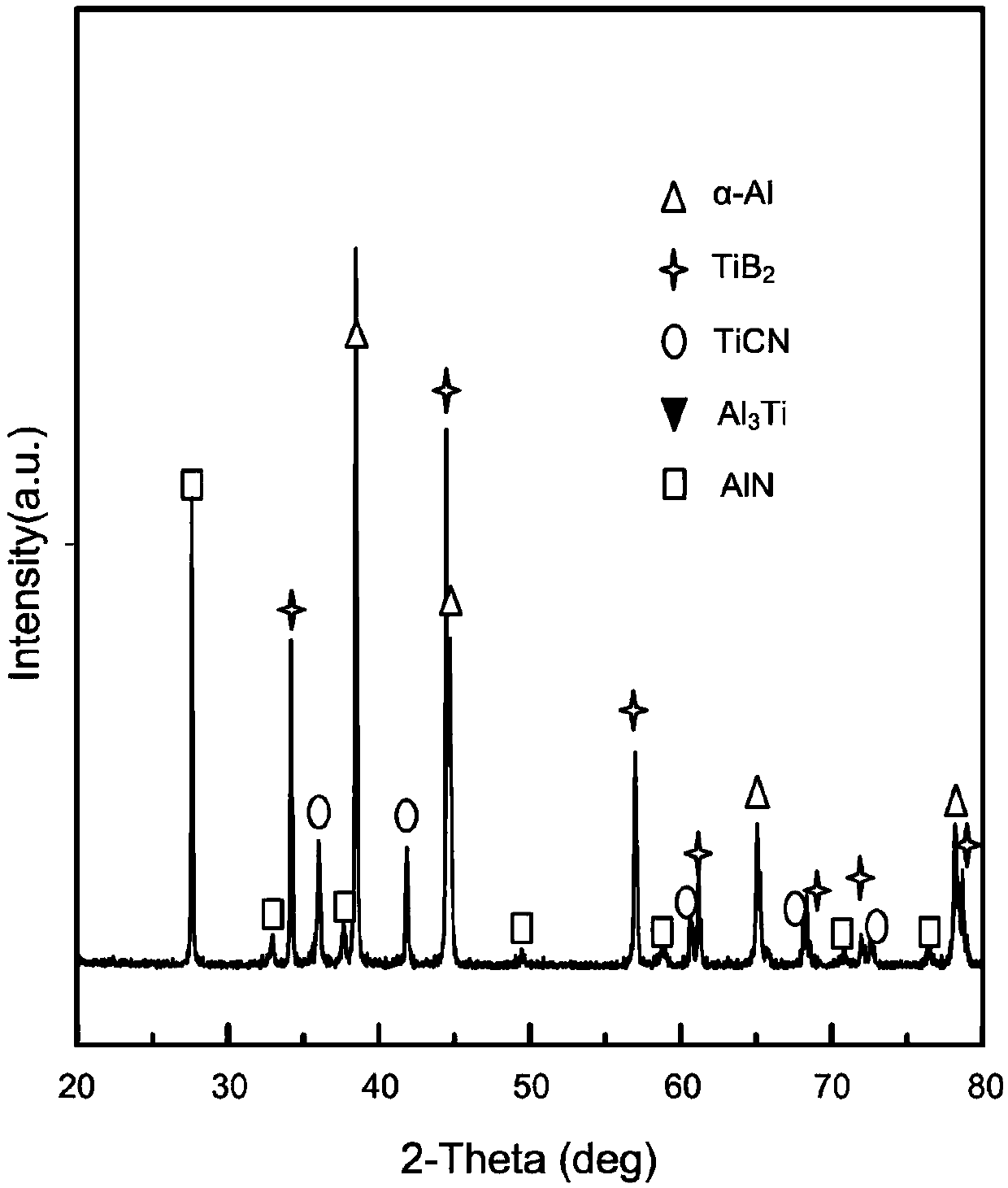

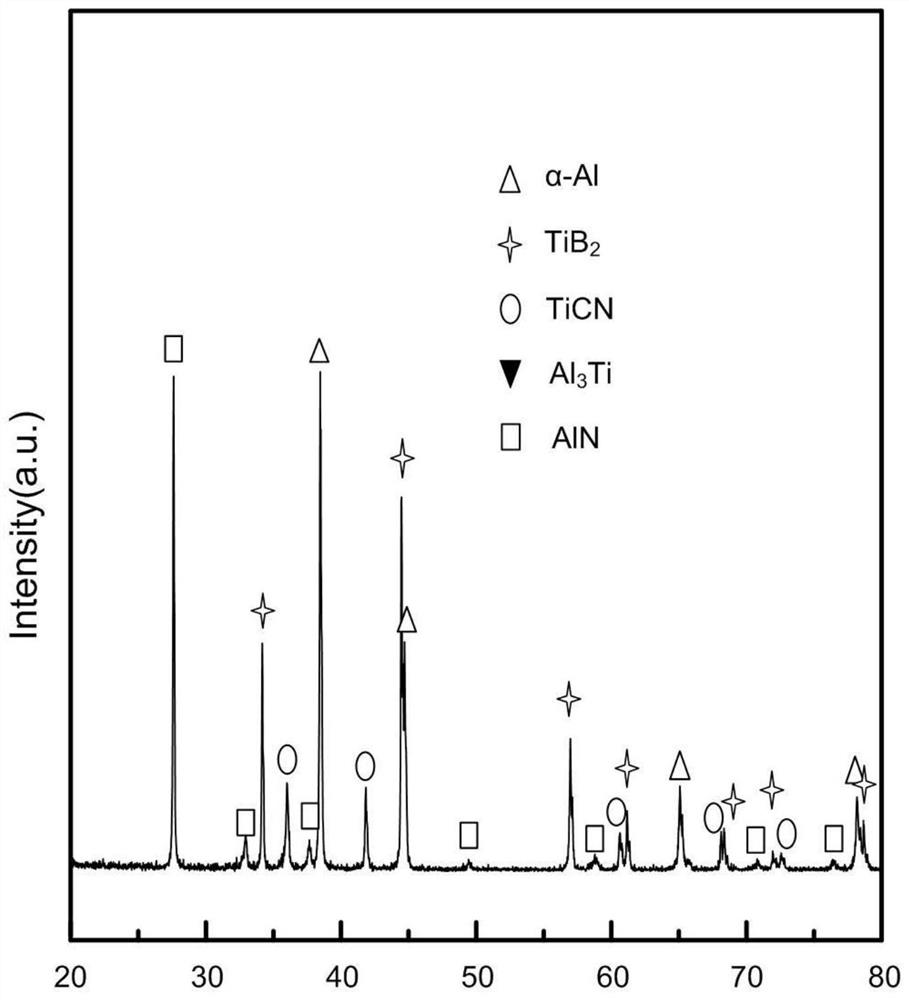

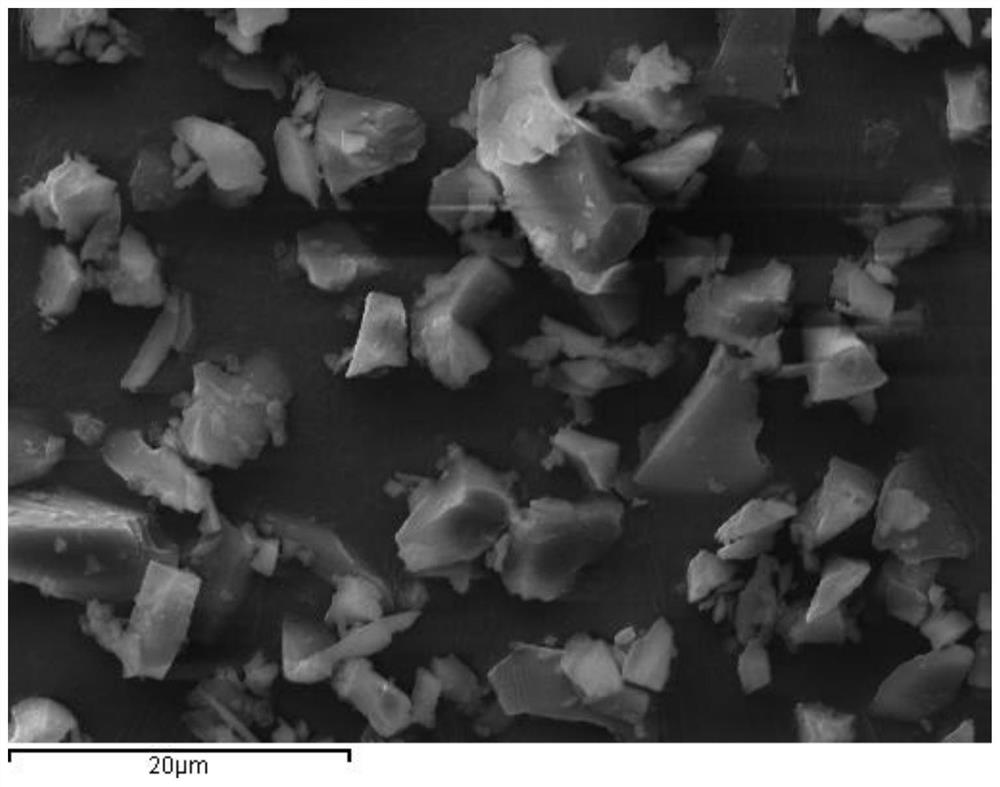

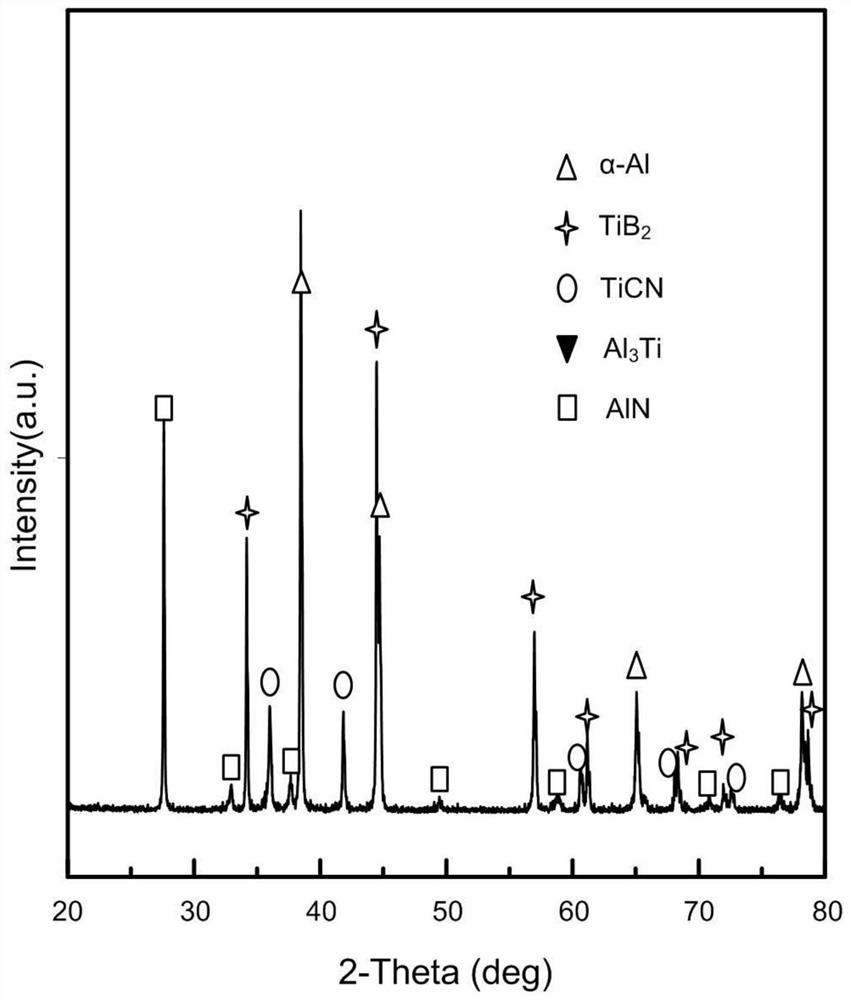

Multi-scale ceramic particle mixed high elastic modulus high strength aluminum alloy and preparation method thereof

The invention discloses a multi-scale ceramic particle mixed high elastic modulus high strength aluminum alloy. The chemical composition and weight percentage of the multi-scale ceramic particle mixedhigh elastic modulus high strength aluminum alloy are as follows: 6.5-10% of Si, 0.3-0.7% of Mg, 2-8% of SiC, 0.1-0.6% of TiCN, AlN and TiB2 and the balance Al. The invention further provides a preparation method of the multi-scale ceramic particle mixed high elastic modulus high strength aluminum alloy, Al powder, Ti powder and BN and B4C powder are subjected to sintering and situ endogenous preparation to generate nano-sized TiCN particles and sub-micron-sized TiB2 and AlN particles, micron SiC ceramic particles are added additionally, and the high elastic modulus high strength aluminum alloy is prepared. The content of TiCN, AlN and TiB2 particles and SiC particles is optimized, the superposition effect of nano-sized ceramic particles and micron-sized ceramic particles in aluminum matrix is achieved, and the mechanical properties of the aluminum alloy are improved.

Owner:JILIN UNIV

Silver-free brass solder alloy

InactiveCN106736015ALower melting temperatureImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaRare-earth elementIndium

The invention provides a silver-free brass solder alloy. The silver-free brass solder alloy is prepared from the following raw materials in percentage by weight: 50 to 56 percent of copper, 0.5 to 3 percent of tin, 0.06 to 0.4 percent of indium, 1 to 4 percent of nickel, 0.004 to 0.02 percent of rare earth elements, 2 to 6 percent of manganese, and the balance of zinc, wherein the rare earth elements are two of La, Pr, Er, Dy or Nd. The silver-free brass solder alloy does not contain silver or cadmium and has the advantage of high activity; a melting point of a traditional brass solder can be reduced.

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

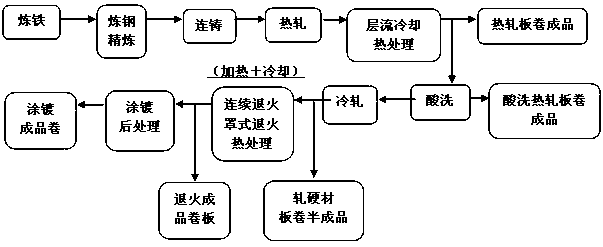

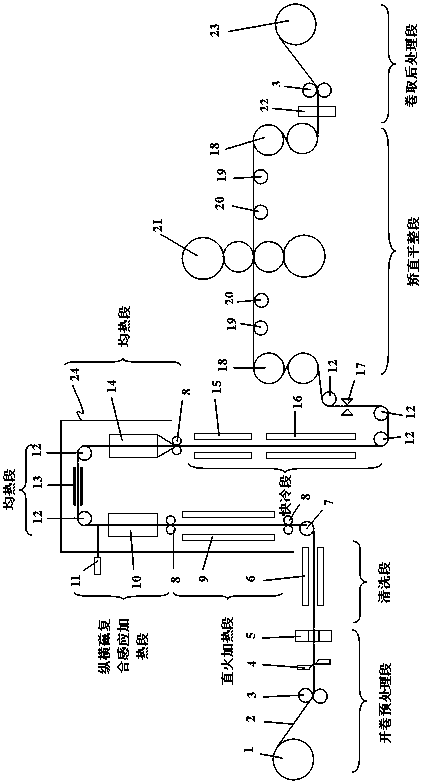

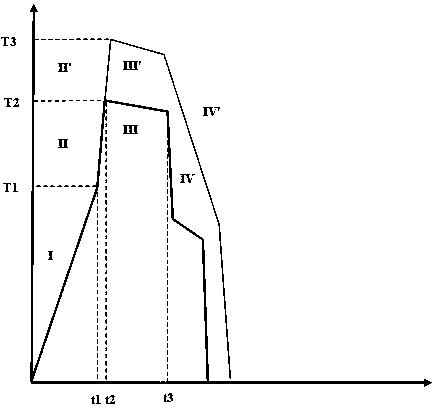

Compact type fine-grain high-strength plate strip steel production line flexible manufacturing method

InactiveCN108220566AReduce scratchesSmall footprintFurnace typesIncreasing energy efficiencyMagnetic heatingProduction line

The invention discloses a compact type fine-grain high-strength plate strip steel production line flexible manufacturing method. The method comprises an uncoiling pretreatment zone, a cleaning zone, adirect fire heating zone, a longitudinal-transverse magnetic compound induction heating zone, a rapid soaking zone, a rapid cooling zone, a tension straightening leveling zone and an aftertreatment coiling zone. In the direct fire heating zone, an operation plate strip is heated in the section from the initial temperature to the largest 600-700 DEG C. In the longitudinal-transverse magnetic compound induction heating zone, a longitudinal and transverse magnetic compound induction heating furnace composed of longitudinal magnetic flux induction heating and transverse magnetic flux induction heating forms a high-temperature rapid heating zone, wherein longitudinal magnetic heating is responsible for heating in the temperature section of 600-700 DEG C, and transverse magnetic heating is responsible for heating in the temperature section of 600-1200 DEG C; and two kinds of initial temperature for starting the two kinds of heating are flexibly combined according to the steel kind and the production heating capability, rapid heating in the recrystallization high-temperature zone interval of plate strips is achieved, the heating speed is 50-1000 DEG C / s; and soaking time of the rapid soaking zone is 0-40 s, the rapid cooling zone rapidly cools the plate strips, and the average cooling speed is 50-1000 DEG C / s.

Owner:BAOSHAN IRON & STEEL CO LTD

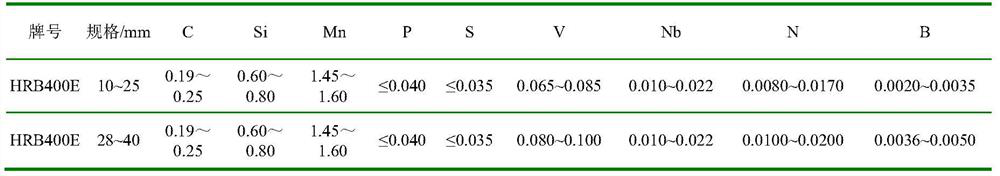

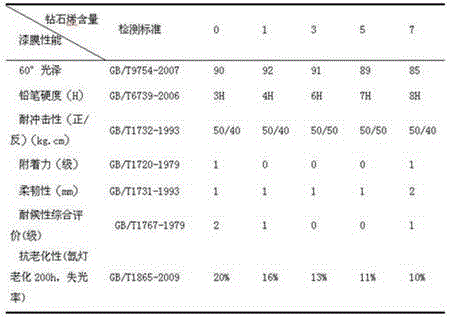

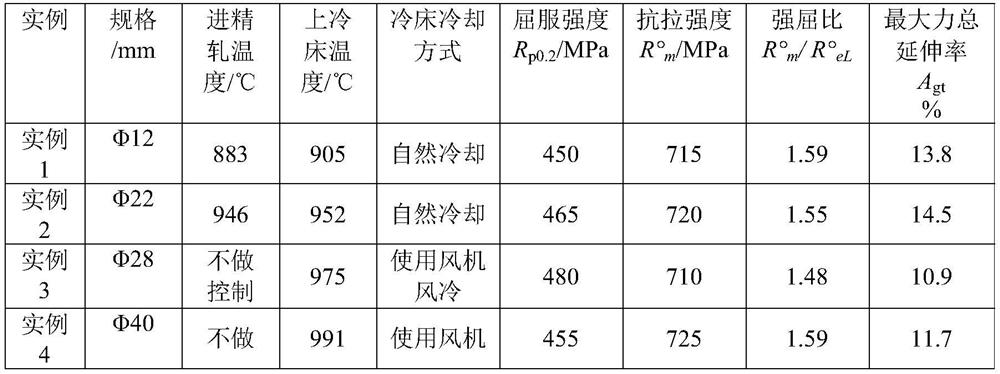

HRB400E ordinary-speed hot-rolled ribbed steel bar with tensile strength of 700 Mpa or above and production method thereof

ActiveCN113444968AImprove hardenabilityHigh tensile strengthTemperature control deviceMetal rolling arrangementsMolten steelRebar

The invention provides an HRB400E ordinary-speed hot-rolled ribbed steel bar with the tensile strength of 700 Mpa or above and a production method thereof. The production method of the HRB400E ordinary-speed hot-rolled ribbed steel bar with the tensile strength of 700 Mpa or above comprises the following process stages which are sequentially carried out: blast furnace molten iron smelting, molten iron desulfurization pretreatment, converter molten steel smelting, LF refining, square billet continuous casting, hot continuous rolling and fixed-length shearing; and the HRB400E ordinary-speed hot-rolled ribbed steel bar is prepared from the following components in percentages by weight: 0.19 to 0.25 percent of C, 0.60 to 0.80 percent of Si, 1.45 to 1.60 percent of Mn, less than or equal to 0.040 percent of P, less than or equal to 0.035 percent of S, 0.065 to 0.10 percent of V, 0.010 to 0.022 percent of Nb, 0.008 to 0.020 percent of N and 0.0020 to 0.0050 percent of B. By means of the method, the tensile strength of the HRB400E straight hot-rolled ribbed steel bar with the specification of phi 10-40 mm can be improved to 700 Mpa or above, the yield ratio R degree m / R degree eL is larger than or equal to 1.45, and a hot-rolled ribbed steel bar product with the anti-seismic property better than that of the conventional HRB400E is obtained.

Owner:广西柳钢华创科技研发有限公司 +1

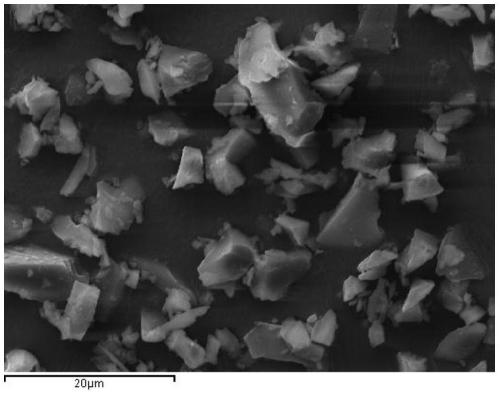

Double-scale ceramic particle hybrid high-elastic modulus high-strength aluminum alloy and preparing method thereof

The invention discloses a double-scale ceramic particle hybrid high-elastic modulus high-strength aluminum alloy. The double-scale ceramic particle hybrid high-elastic modulus high-strength aluminum alloy is characterized in that the double-scale ceramic particle hybrid high-elastic modulus high-strength aluminum alloy comprises chemical compositions including, by mass, 6.5%-10% of Si, 0.3%-0.7% of Mg, 0.1%-0.5% of TiB2, 2%-8% of SiC and the balance Al. The invention also provides a preparing method of the double-scale ceramic particle hybrid high-elastic modulus high-strength aluminum alloy.Al powder, Ti powder and B powder are sintered for in-situ endogeny of nano-scale TiB2 particles, micron-SiC ceramic particles are externally added to prepare the high-elastic modulus high-strength aluminum alloy, the contents of the nano-TiB2 and micron-SiC ceramic particles are optimized, the superposition effect of nano-sized ceramic particles and micron-sized ceramic particles in an aluminum matrix is realized, and the mechanical properties of the aluminum alloy are improved.

Owner:JILIN UNIV

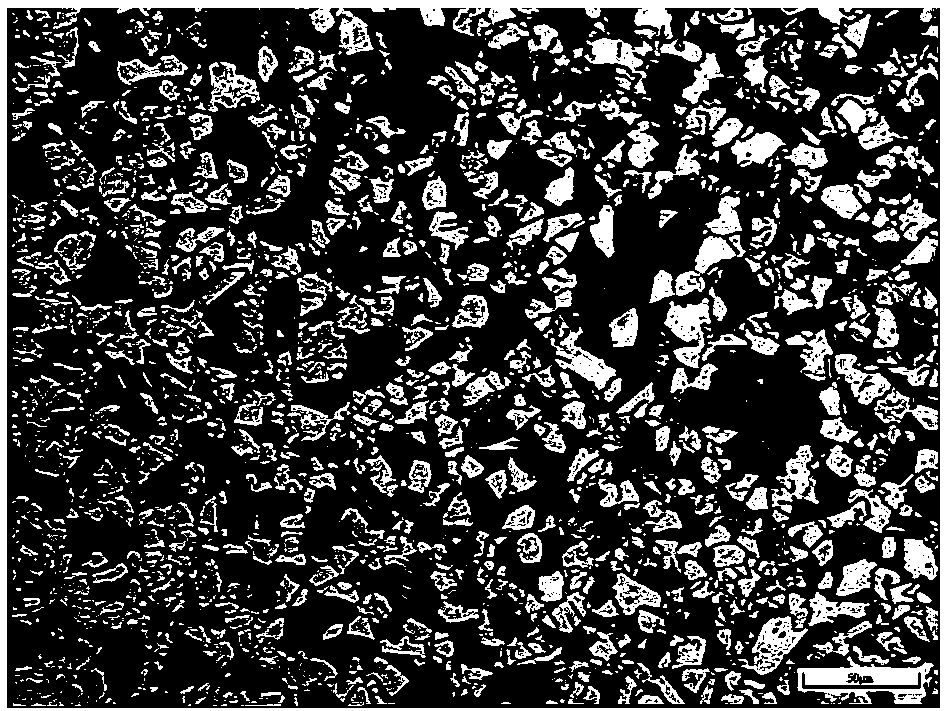

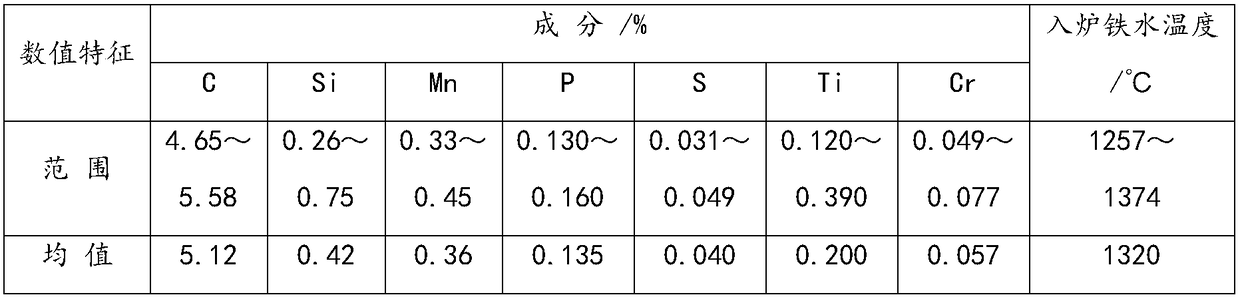

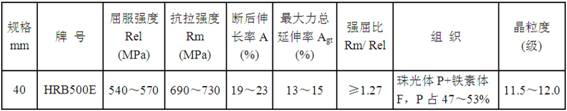

Production method of phi 36-40 mm HRB500E twisted steel

The invention provides a production method of phi 36-40 mm HRB500E twisted steel. The production method comprises the following steps: after molten iron, waste steel and slag are added in a converterfor smelting, steel is discharged through pushing off the slag; molten steel is deoxidized and alloyed for continuous casting in a LF refining furnace after refining; and an obtained steel blank is rolled to obtain the phi 36-40 mm HRB500E twisted steel, wherein finished molten steel comprises the following components in percentage weight: 0.22-0.25% of C, 0.60-0.70% of Si, 1.50-1.60% of Mn+Cr, Pnot more than 0.045%, S not more than 0.045%, 0.11-0.13% of V, and the balance of iron and inevitable impurities. In the method, through adjustment and control of such condition parameters as production flow steps and temperature and such factors as N and V element contents in the steel, the finished steel with high mechanical property and high stability can be obtained.

Owner:SHOUGANG SHUICHENG IRON & STEEL GRP

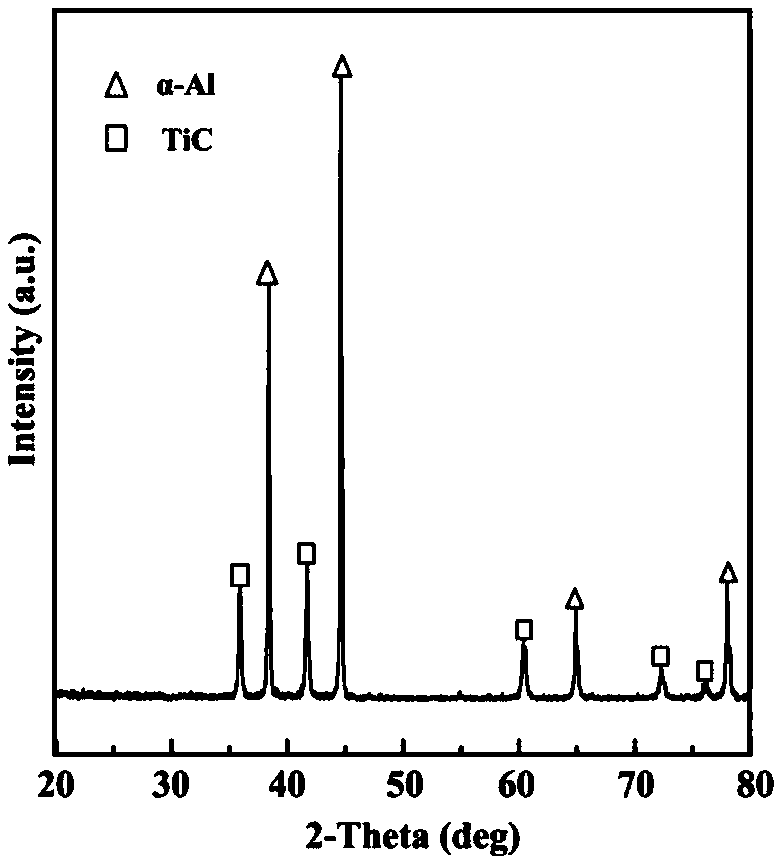

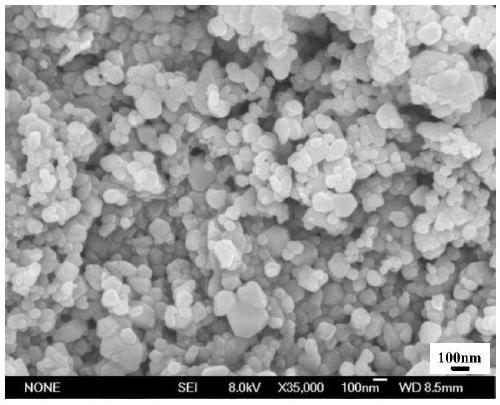

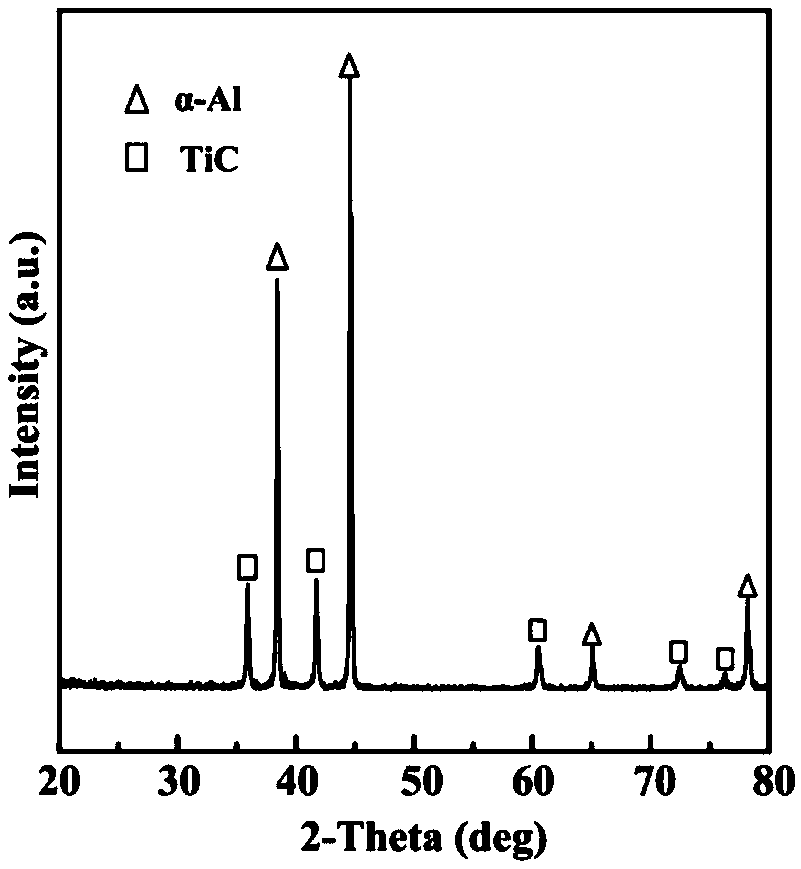

Preparation method of bidirectional perpendicular controlled-rolling trace TiC reinforced Al-Cu-Mg alloy plate

The invention discloses a preparation method of a bidirectional perpendicular controlled-rolling trace TiC reinforced Al-Cu-Mg alloy plate. The preparation method comprises the steps that 1, TiC-Al intermediate alloy is prepared through an endogenous preparation method; 2, Al-Cu-Mg alloy melt is prepared; 3, the TiC-Al intermediate alloy is pre-heated and then pressed into the Al-Cu-Mg alloy melt,so that the addition of TiC ceramic particles is 0.1-0.6%, by weight, of the total amount of Al-Cu-Mg alloy melt; 4, a slag remover is added, after stirring and heat preservation are conducted, the melt surface dross is removed; 5, after the melt is cast into a steel mold, TiC reinforced Al-Cu-Mg alloy ingot is obtained; 6, the TiC reinforced Al-Cu-Mg alloy ingot is cut into a cuboid alloy block,and the surface oxidation film of the alloy block is removed by grinding; and 7, after the alloy block is subjected to homogenization treatment, second rolling, solidification, water quenching and the aging treatment are conducted after first rolling and annealing, and the TiC reinforced Al-Cu-Mg alloy plate is obtained.

Owner:JILIN UNIV

Production method of HRB500E fine-grain high-strength anti-seismic anti-corrosion reinforcing steel bar

InactiveCN112779460ACorrosion resistantImprove corrosion resistanceMetal rolling arrangementsAlloyShock resistance

The invention discloses a production method of an HRB500E fine-grain high-strength anti-seismic anti-corrosion reinforcing steel bar. The method comprises the following steps of converter smelting, deoxidizing alloying, LF refining, square billet continuous casting, steel billet heating, rolling and cooling in sequence to produce the fine-grain high-strength anti-seismic anti-corrosion reinforcing steel bar which is stable in quality, excellent in plasticity and toughness, greater than 1.27 in yield ratio and 11.5-12.0 in ferrite grain size. The Cr, V and Ni composite microalloying process is adopted, converter smelting and LF external refining are matched, the rolling technology for controlling the inner diameter and negative deviation of the reinforcing steel bar at low temperature is adopted, finishing is combined, formation and precipitation of a fine and dispersed microalloy carbon (nitrogen) compound second phase are promoted, the steel strength is improved, meanwhile, the plasticity and toughness are remarkably improved, mechanical connection is further facilitated, reasonable matching of high strength, obdurability, low strain timeliness, shock resistance and corrosion resistance of the reinforcing steel bar is achieved, and the method can be applied to the fields of main stream hydropower station flood discharge tunnel engineering, expressway road and bridge engineering and the like.

Owner:WUKUN STEEL

Laser additive manufacturing process for TC4 titanium alloy

InactiveCN108274001AHigh strengthReduce plasticityAdditive manufacturing apparatusIncreasing energy efficiencyTitanium alloyUltimate tensile strength

The invention discloses a laser additive manufacturing process for TC4 titanium alloy, and the laser additive manufacturing process greatly enhances the strength of TC4 titanium alloy without reducingthe plasticity. According to the laser additive manufacturing process disclosed by the invention, TC4 titanium alloy powder is molten and solidified by adopting laser, and afterwards low-temperatureinert gas treatment is immediately implemented in order to generate lots of defects.

Owner:佛山市领卓科技有限公司

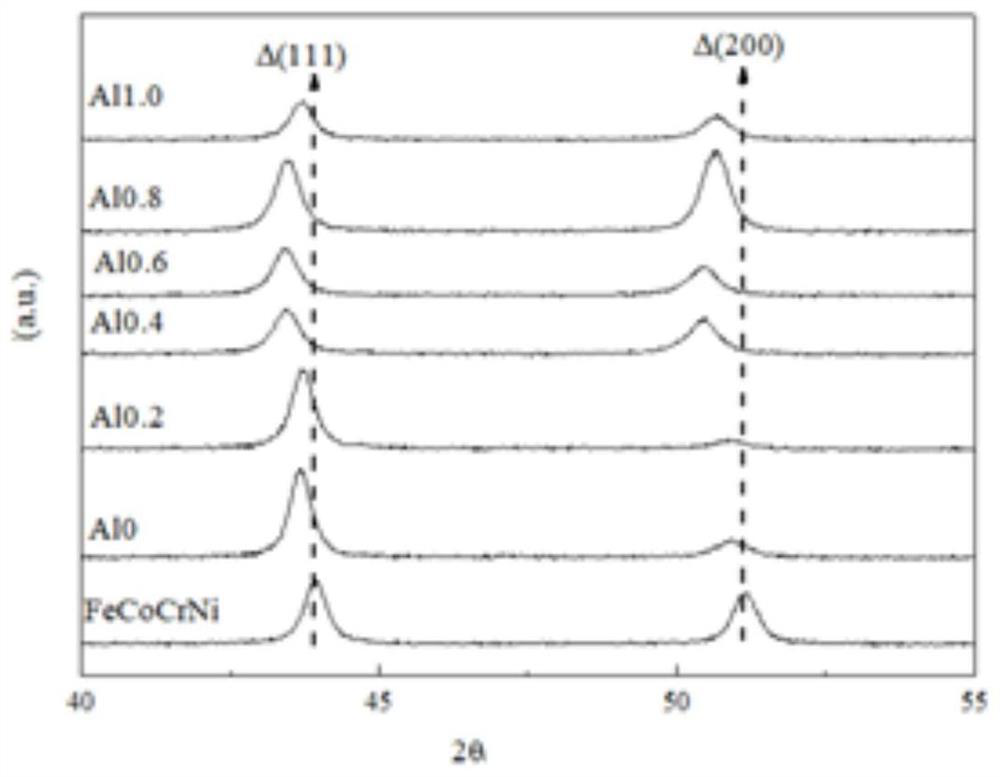

Strong-acid-erosion-resistant high-entropy alloy coating for repairing stirring paddle blade of phosphoric acid reaction tank and preparation method of high-entropy alloy coating

PendingCN114807720AHigh hardnessImprove toughnessMetallic material coating processesO-Phosphoric AcidHigh entropy alloys

The invention discloses a strong-acid-erosion-resistant high-entropy alloy coating for repairing a stirring paddle blade of a phosphoric acid reaction tank, which is characterized in that Fe, Co and Ni are adopted as solvent atoms to replace Fe and Ni at the atomic position of a shell layer on the basis of 904L stainless steel with the trademark of 00Cr20Ni25Mo4. 5Cu, so that a cluster model formula [Cr-Fe4Co4Ni4] Cr2.6Mo0.4 is constructed, Al is added at the atomic connecting position to obtain an ordered-phase coherent high-entropy alloy formula [Cr-Fe4Co4Ni4] Cr2.6-xAlxMo0.4, and x is equal to 0-1. According to the method, a cluster and connecting atom model design theory is introduced, chemical components of 904 stainless steel are analyzed, cluster type [Cr-Fe4Co4Ni4] Cr2.6Mo0.4 high-entropy alloy components similar to the chemical components of the 904 stainless steel are constructed, Al atoms are added to the connecting atom positions, the [Cr-Fe4Co4Ni4] Cr2.6-xAlxMo0.4 high-entropy alloy subjected to ordered phase coherent precipitation is further constructed, and the high-entropy alloy coating is prepared through a broadband laser cladding technology. The hardness and the erosion corrosion resistance of the alloy are improved.

Owner:GUIZHOU UNIV

Manufacturing technology of arc-shaped molybdenum plate for long-service-life heat shield

A manufacturing technology of an arc-shaped molybdenum plate for a long-service-life heat shield specifically comprises the steps of preparing powder A which is of a rhenium-doped nanometer aluminum oxide structure, preparing nanometer lanthanum oxide, preparing the molybdenum plate, preparing a molybdenum blank through the molybdenum plate, and pressing the molybdenum blanket to obtain the targeted arc-shaped molybdenum plate. According to the manufacturing technology, the outward dispersing and oxidizing capacity of molybdenum is reduced through compound elements, so that the oxidizing resistance of molybdenum can be improved, and the service life can be prolonged by more than 30%; in addition, powder metallurgy and mechanical rolling are combined, so that the relative density of the manufactured arc-shaped molybdenum plate is high, and the plasticity is improved, and as a result, cracks can be avoided; an uniform fine grain structure is obtained, and thus physical performance and the mechanical performance can be improved.

Owner:LUOYANG KEWEI MOLYBDENUM & TUNGSTEN

High-strength steel bar and method for controlling power strength of concrete civil defense structure through high-strength steel bars

The invention relates to a high-strength steel bar. The high-strength steel bar comprises, by weight, 0.19-0.29% of C, 0.45-0.85% of Si, 1.25-1.75% of Mn, 0.08-0.28% of combined elements including V, Ti and Nb, 0.01-0.07% of Cr, 0.01-0.07% of Ni, 0-0.05% of Cu, 0-0.01% of Mo, 0.025% of P or less, 0.025% of S or less, 0.01-0.15% of N and the balance Fe and unavoidable impurities. The yield strength and tensile strength of the high-strength steel bar can be improved, the plasticity is not lowered, and the yield strength can reach 600 MPa or higher. The high-strength steel bars are applied to a civil defense structure, the power strength value of the civil defense structure is set as the product of the tensile strength value of the high-strength steel bars and the steel bar strength comprehensive adjustment coefficient, and the steel bar strength comprehensive adjustment coefficient is 1.05-1.1.

Owner:TIANSHUN GROUP

High-strength steel bar and method for controlling width of crack of concrete structural component through high-strength steel bar

The invention discloses a high-strength steel bar. The high-strength steel bar comprises, by weight, 0.2-0.28% of C, 0.5-0.8% of Si, 1.4-1.6% of Mn, 0.1-0.25% of a composite component of V, Ti and Nb, 0.01-0.05% of Cr, 0.01-0.05% of Ni, 0.01-0.05% of Cu, 0-0.01% of Mo, smaller than or equal to 0.025% of P, smaller than or equal to 0.025% of S, 0.008-0.015% of N, and the balance Fe and inevitable impurities. The composite component of V, Ti and Nb is the composition of V and at least one of Ti and Nb. According to the high-strength steel bar, the yield strength and the tensile strength can be improved while plasticity is not reduced. The yield strength can reach the level of 600 MPa or more, and when the high-strength steel bar is used in a concrete structural component under the one-grade environment, the maximum crack width limit value of the high-strength steel bar can be more than 0.3 mm.

Owner:TIANSHUN GROUP

High-strength steel bar and method for controlling minimum reinforcement ratio of concrete plate flexural member through high-strength steel bars

InactiveCN105088074AHigh yield strengthHigh tensile strengthConstruction materialHigh strength steel

The invention discloses a high-strength steel bar. The high-strength steel bar comprises 0.18-0.28% of C, 0.45-0.85% of Si, 1.35-1.65% of Mn, 0.09-0.26% of combined elements of V+Ti+Nb, 0.01-0.06% of Cr, 0.01-0.06% of Ni, 0-0.05% of Cu, 0-0.01% of Mo, 0.025% of P or less, 0.025% of S or less, 0.005-0.015% of N and the balance Fe and unavoidable impurities. The yield strength and tensile strength are improved, the plasticity is not lowered, and the yield strength can reach 600 MPa or more, so that when the high-strength steel bar is applied to a concrete plate flexural member, the minimum reinforcement ratio of the concrete plate flexural member is set as the larger value between 0.15 and 45ft / fy.

Owner:TIANSHUN GROUP

Method for preparing high-elasticity-modulus high-strength aluminum alloy through mixing of polyphase ceramic particles

The invention relates to a method for preparing a high-elasticity-modulus high-strength aluminum alloy through mixing of polyphase ceramic particles. The method specifically comprises following stepsof firstly, preparing of an Al-Ti-B4C-BN system in-situ endogenous ceramic particle reinforcer; secondly, pretreatment of SiC ceramic particles; thirdly, compound reinforcement of an Al-Si-Mg alloy through multiple particles; and fourthly, casting forming and heat treatment of the reinforced Al-Si-Mg alloy. According to the method, through directly-added micron SiC ceramic particles, the rigidityand elasticity modulus of the aluminum alloy can be obviously improved, the polyphase mixed ceramic particles can further reinforce the aluminum alloy through the coordinative effect of different manners of grain refinement and strengthening, Orovan reinforcement, precipitation phase strengthening and the like, the ceramic particle dispersion effect is better, the reinforcing process is simple andconvenient, operability is high, the method is suitable for industrial batched production, and practical value and potential are giant.

Owner:JILIN UNIV

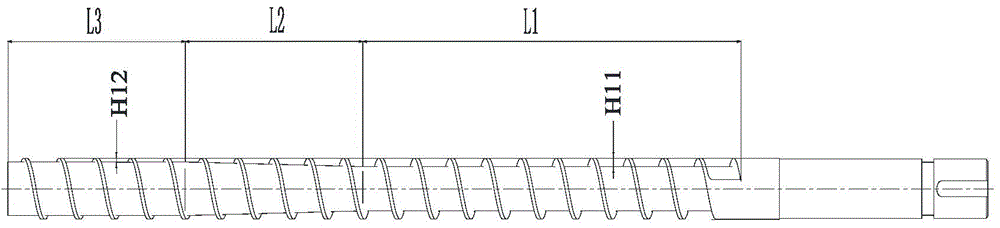

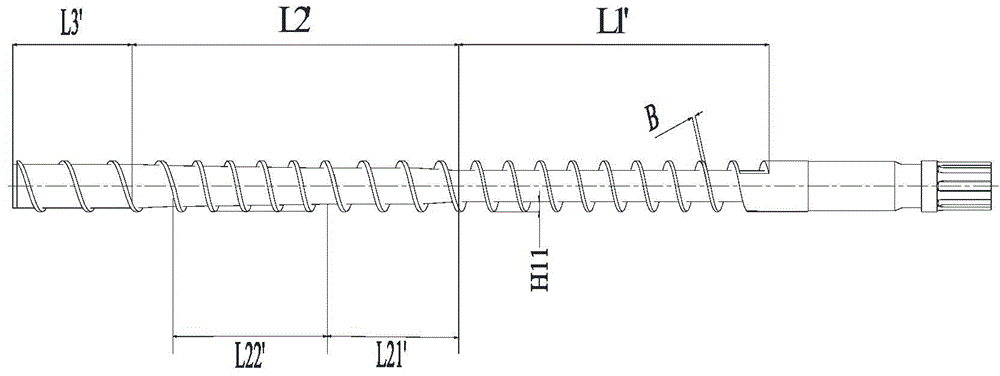

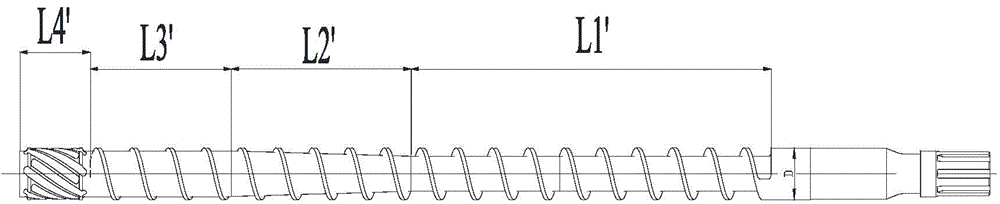

Injection molding machine and glue melting threaded rod thereof

The invention provides an injection molding machine and a glue melting threaded rod thereof. A thread part of the glue melting threaded rod comprises a feeding section and a plasticizing section. The plasticizing section is composed of four different variable-diameter and variable-distance compression sections. The whole glue melting threaded rod is provided with auxiliary external thread screw flights as barriers. A main external threaded groove of the plasticizing section is divided into a solid phase groove and a liquid phase groove, the solid phase groove gets shallower gradually, and the liquid phase groove gets deeper gradually. When plastic enters from the feeding section to the solid phase groove, after the solid phase groove is gently compressed and plasticized, a melt crosses gaps of the auxiliary external thread screw flights to be sheared and plasticized sufficiently, enters the variable-distance large-pitch liquid phase groove, and then is delivered into a storage space of a charging barrel in a small-damp and high-efficiency mode. Meanwhile, a vortex is formed, vortex flowing along the section of the liquid phase groove is generated, the melt is uniformly mixed, heat exchange between the melt and the charging barrel is more sufficient, and the uniform-temperature high-quality melt is generated. The injection molding machine is stable in production process, and both the plasticizing capacity and the melt quality are improved.

Owner:震雄机械(深圳)有限公司

A method for preparing high-elastic modulus and high-strength aluminum alloys by mixing multi-phase ceramic particles

The invention relates to a method for preparing a high-elastic-modulus high-strength aluminum alloy by mixing multiphase ceramic particles, which specifically comprises the following steps: (1) Al-Ti-B 4 Preparation of in-situ endogenous ceramic particle reinforcement in C‑BN system; (2) pretreatment of SiC ceramic particles; (3) composite strengthening of Al‑Si‑Mg alloy with various particles; (4) strengthened Al‑Si‑Mg alloy Casting and heat treatment of Mg alloy. In the method of the invention, the directly added micron-sized SiC ceramic particles can significantly increase the rigidity and elastic modulus of the aluminum alloy. Multi-phase mixed ceramic particles can work synergistically through different methods such as grain refinement strengthening, Orowan strengthening, and precipitated phase strengthening to further strengthen the aluminum alloy, and the dispersion effect of ceramic particles is better. The strengthening process is simple and convenient, and the operability Strong, suitable for industrial batch production, with great practical value and potential.

Owner:JILIN UNIV

A kind of copper base solder and preparation method thereof

ActiveCN103358051BEasy to processReduced processing performanceWelding/cutting media/materialsSoldering mediaRare earthManganese

The invention discloses a method for preparing a copper-based solder. The method comprises the following steps: (1) burdening: preparing a furnace burden from copper, manganese, nickel, cobalt, silicon, a copper-ferrous intermediate alloy, a copper-boron intermediate alloy and a copper-mixed rare earth intermediate alloy serving as raw materials; (2) casting: putting the prepared furnace burden into the a corundum crucible according to the sequence of manganese, copper, nickel, cobalt, silicon, copper-boron intermediate alloy, copper-mixed rare earth intermediate alloy and copper-ferrous intermediate alloy, smelting by adopting medium-frequency induction, and cooling along with the furnace to obtain an alloy blank, wherein the smelting process is performed under the protection of argon gas; and (3) rolling: rolling the alloy blank with a cold-rolling mill to obtain the copper-based solder. The copper-based solder provided by the invention can be applied to an ODS (Oxide Dispersion Strengthened) high-temperature alloy welding joint, has high brazing process performance, heat resistance, corrosion resistance and machining process, and is low in cost.

Owner:SOUTH CHINA UNIV OF TECH

Corrosion resistant niobium-titanium alloy, and method for manufacturing plates and pipes with the same

InactiveCN102703757BImprove corrosion resistanceExpand the range of corrosion resistanceSolid solution strengtheningTitanium alloy

The invention relates to a corrosion resistant niobium-titanium alloy, and a method for manufacturing plates and pipes with the corrosion resistant niobium-titanium alloy, wherein the corrosion resistant niobium-titanium alloy contains the following components by weight: 0.1-4.9% o Nb, not more than 0.08% of C, not more than 0.03% of N, not more than 0.012% of H, not more than 0.1% of O, not more than 0.1% of Fe, and the balance of Ti. In Ti-(0.8-6%) Nb alloy pipes disclosed by the invention, titanium is as a matrix; little niobium is added; mechanical property of the niobium is improved by a solid-solution strengthening way; shearing strength and tensile strength of the alloy are higher than pure titanium; the tensile strength is increased by 10-20%; good plasticity and formability are kept; cold working performance is excellent; the niobium is added to further increase corrosion resistance of titanium and enlarge corrosion resistant range of titanium, so that the corrosion resistant niobium-titanium alloy is a good easily-formed corrosion resistant material.

Owner:NINGXIA ORIENT TANTALUM IND

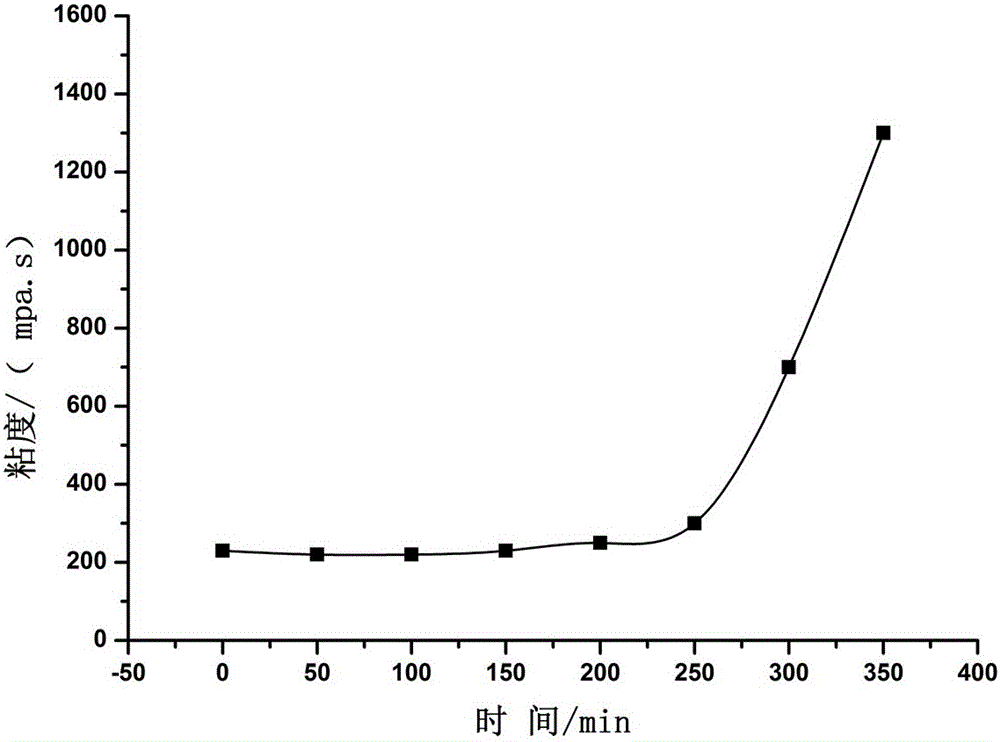

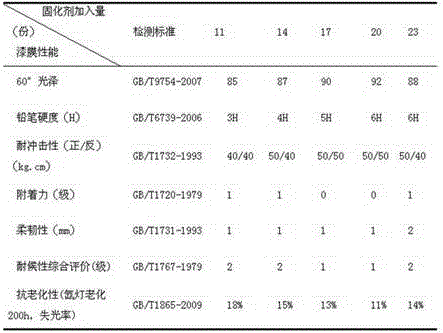

Nano diamond alkene containing novel aqueous varnish and preparation method thereof

InactiveCN106634375AImproves paint film strength and flexibilityGood chemical stabilityCoatingsSolventIon

The invention belongs to the field of water varnish, and in particular relates to nano diamond alkene containing novel aqueous varnish and a preparation method thereof. The nano diamond alkene containing novel aqueous varnish is prepared from the following raw materials in parts by weight: a first component, including 50-70 parts of a hydroxied acrylate emulsion, 0.5-7 parts of nano diamond alkene, 5-15 parts of deionized water, 0.1-0.6 part of a dispersing agent, 0.01-0.1 part of an anti-settling agent, 0.01-0.1 part of a defoaming agent, 0.2-1 part of a leveling agent, 2-4 parts of a coalescing agent, 0.3-2 parts of a thickening agent and 0.1-0.3 part of a pH adjusting agent; a second component, 15-25 parts of a curing agent and 1-3 parts of a cosolvent. The nano diamond alkene containing novel aqueous varnish is capable of solving the problems that conventional water vanish is relatively poor in weather resistance, scratch resistance, distinctness of image, and the like, is greatly excellent in glossiness, hardness, impact resistance, flexibility and weather resistance when being compared with those of conventional vanish, and is relatively good in environmental friendliness.

Owner:HENAN YUXING MICRON DIAMOND CO LTD

HRB400E ordinary-speed hot-rolled ribbed steel bar with tensile strength of 700 Mpa or above

ActiveCN114717477AImprove hardenabilityHigh tensile strengthTemperature control deviceMetal rolling arrangementsEarthquake resistanceRebar

The invention provides an HRB400E ordinary speed hot rolling ribbed steel bar with the tensile strength of 700 Mpa or above. The HRB400E ordinary speed hot rolling ribbed steel bar comprises the following components in percentage by weight: 0.19%-0.25% of C, 0.60%-0.80% of Si, 1.45%-1.60% of Mn, less than or equal to 0.040% of P, less than or equal to 0.035% of S, 0.065%-0.10% of V, 0.010%-0.022% of Nb, 0.008%-0.020% of N and 0.0020%-0.0050% of B. By means of the method, the tensile strength of the HRB400E straight hot-rolled ribbed steel bar with the specification of phi 10-40 mm can be improved to 700 Mpa or above, the yield ratio R degree m / R degree eL is larger than or equal to 1.45, and a hot-rolled ribbed steel bar product with the anti-seismic property better than that of the conventional HRB400E is obtained.

Owner:GUANGXI LIUGANG HUACHUANG TECH R & D CO LTD +1

Laser additive manufacturing technology of 6061 aluminum alloy

InactiveCN108500265AHigh strengthReduce plasticityAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyUltimate tensile strength

The invention discloses a laser additive manufacturing technology of a 6061 aluminum alloy. Plasticity is not reduced while the strength of the 6061 aluminum alloy is greatly improved. 6061 aluminum alloy powder is molten and solidified through lasers, and then, low-temperature inert gas treatment is instantly conducted to generate a large number of dislocation defects, so that the strength is improved.

Owner:长沙大衡智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com