Patents

Literature

48results about How to "Increased diffusion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

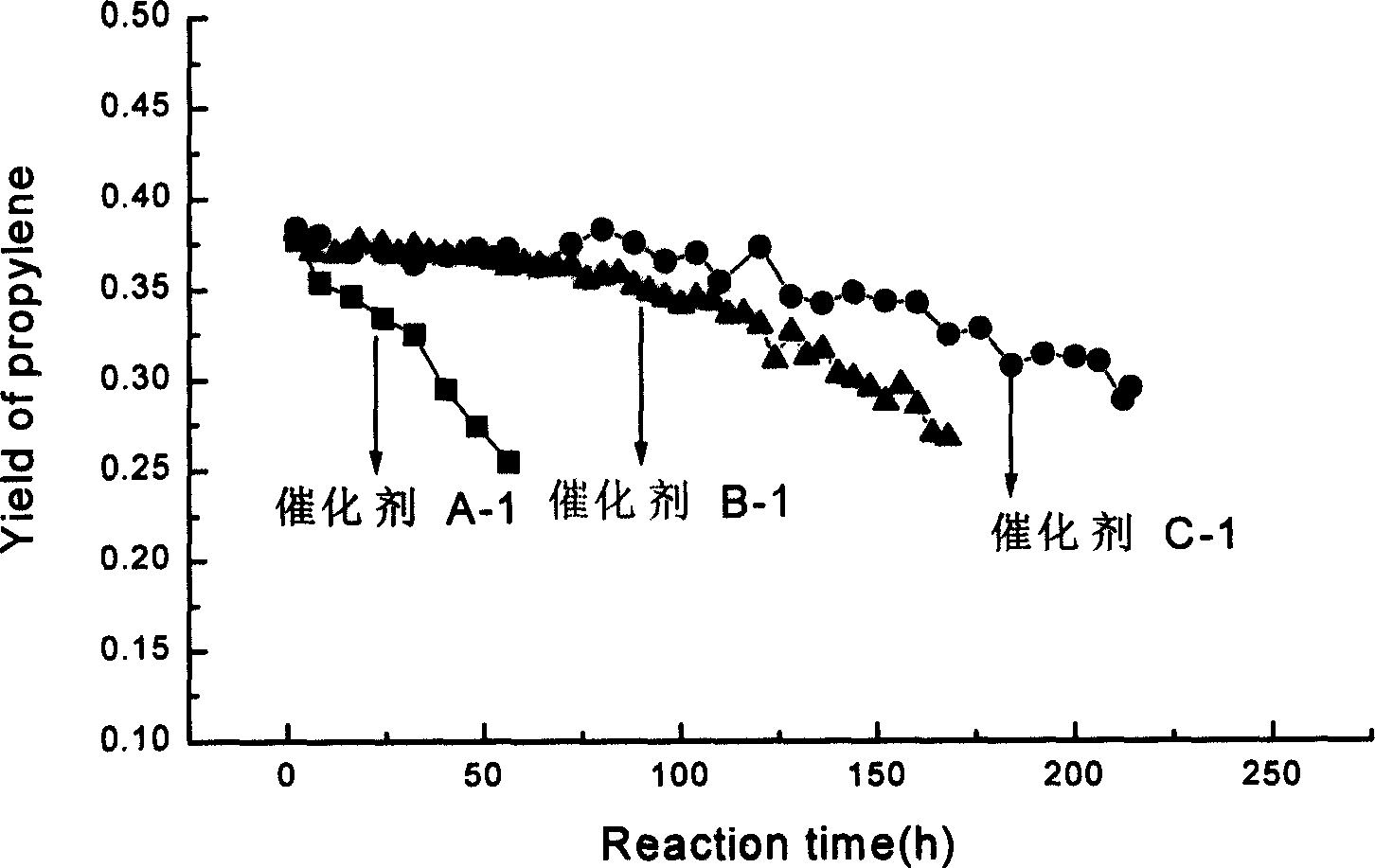

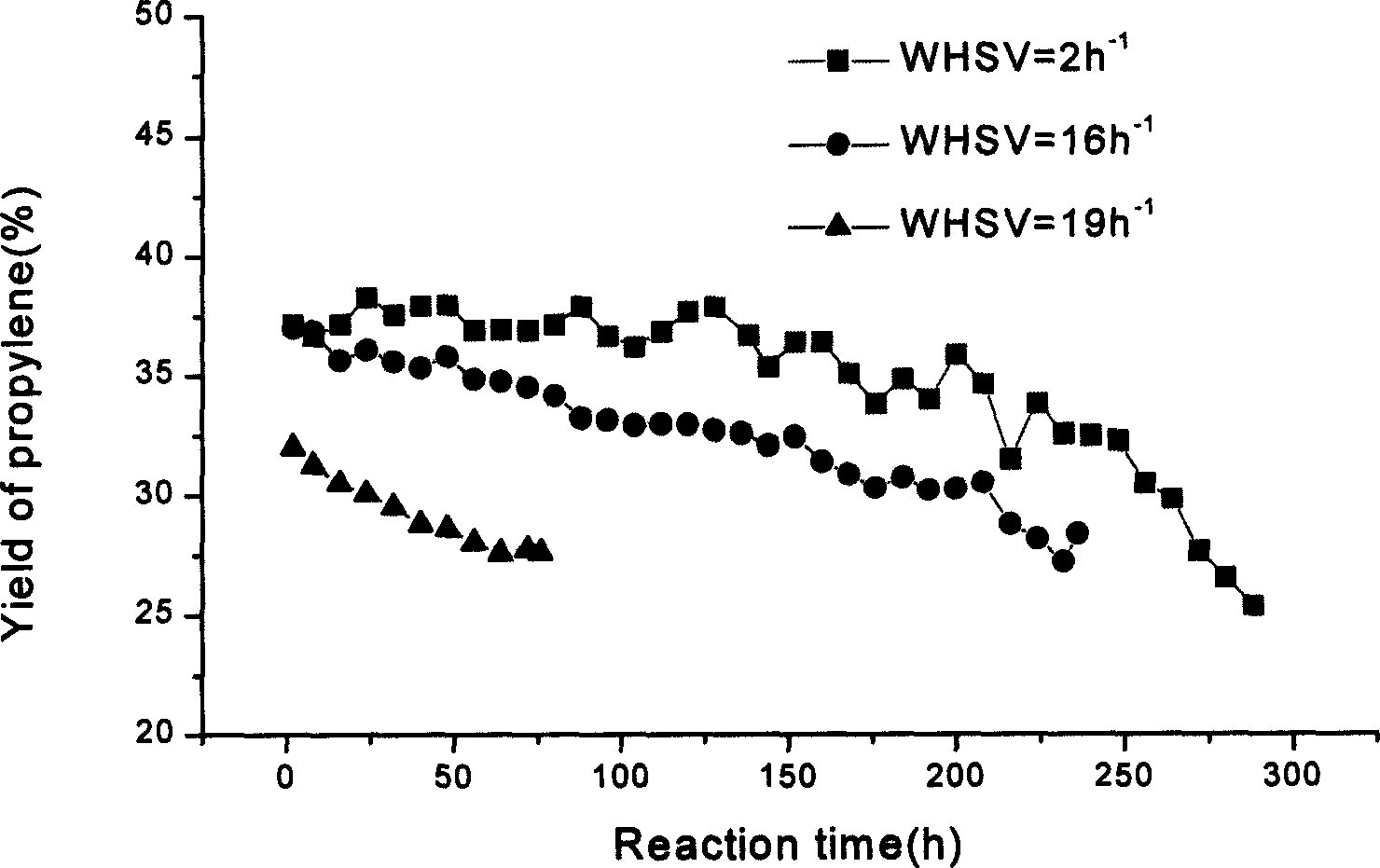

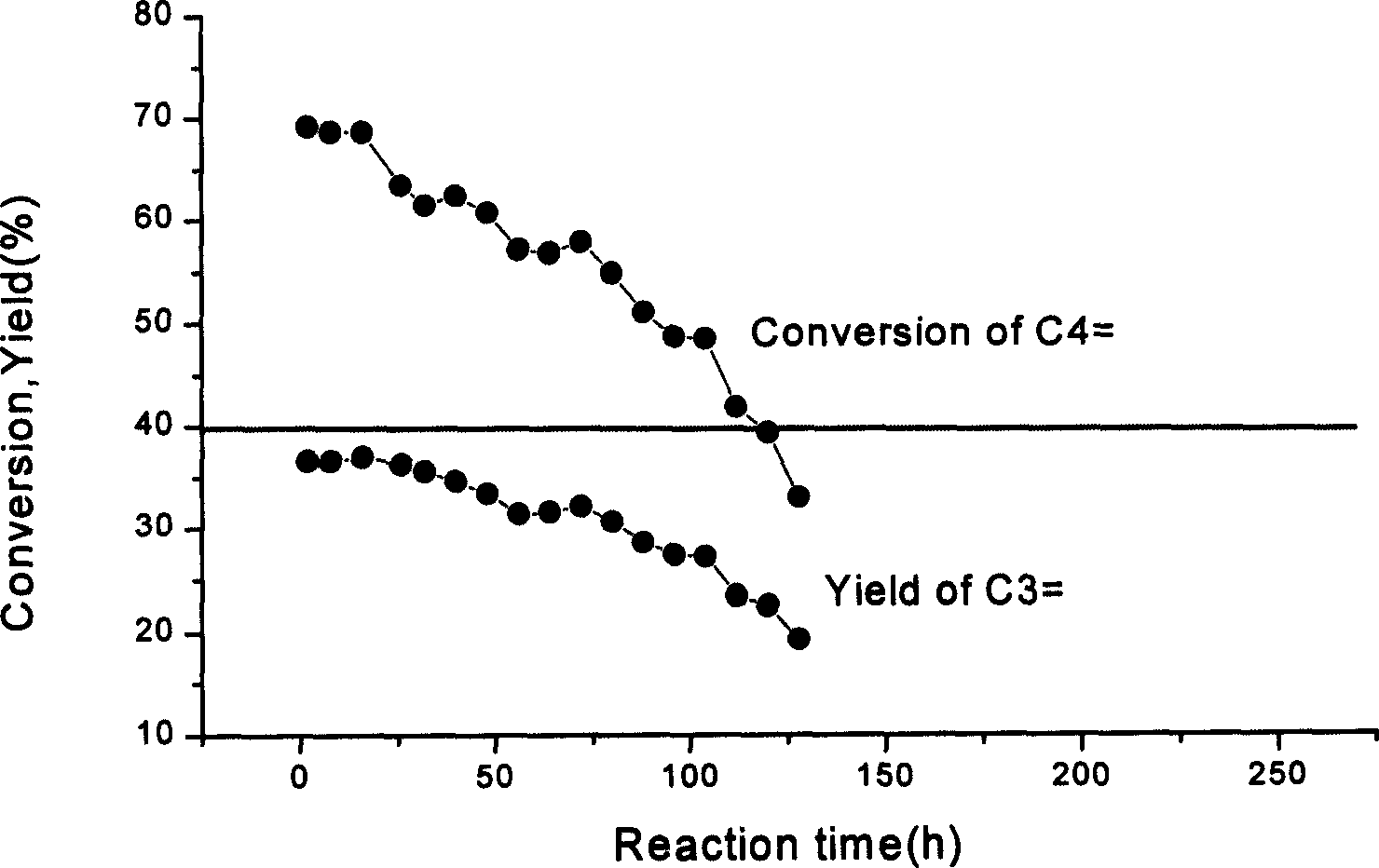

Method for producing propene for C4 and more olefin catalytic cracking

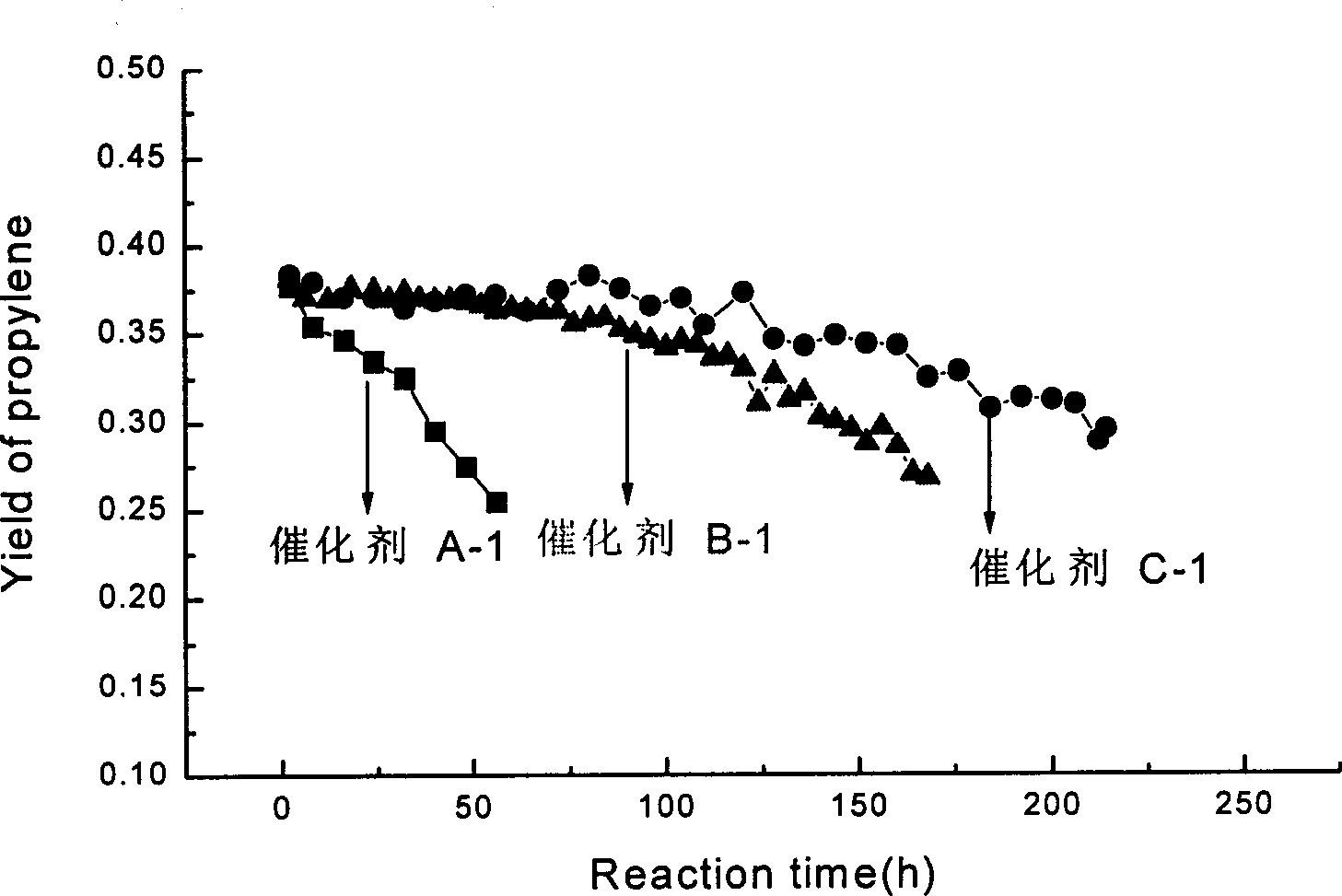

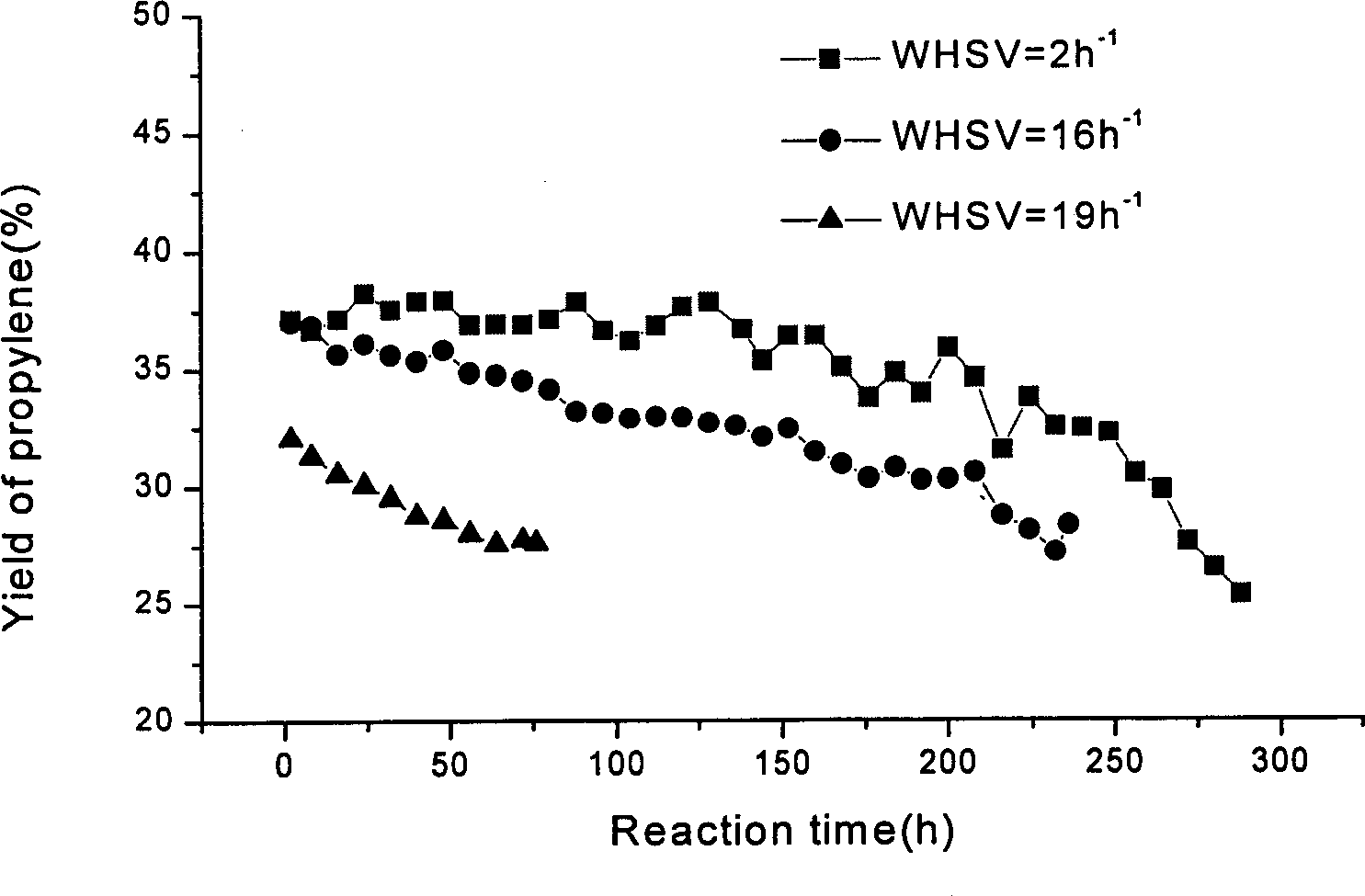

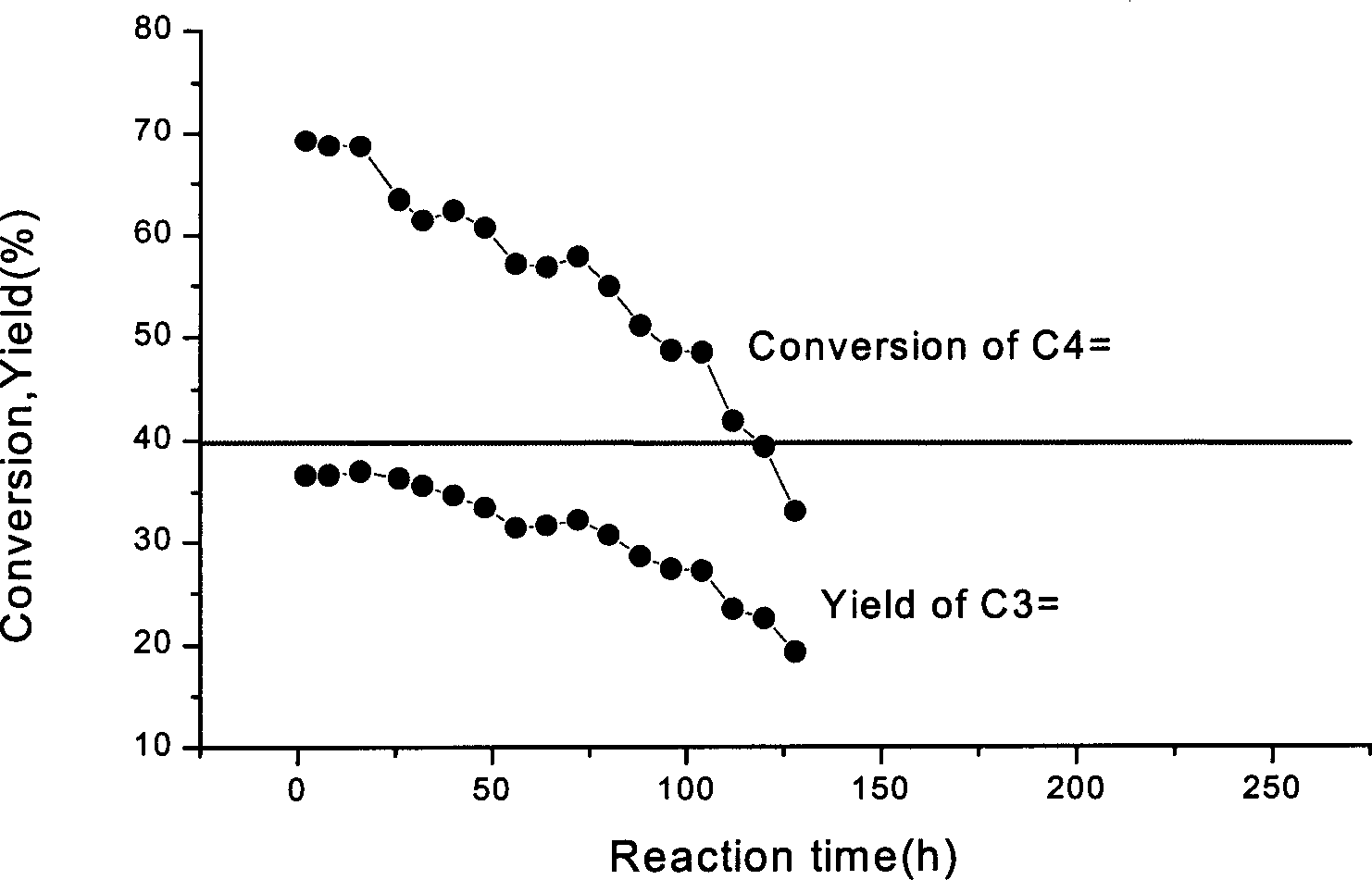

ActiveCN1611472AIncreased diffusion resistanceSize diffusion resistanceChemical recyclingHydrocarbon by hydrocarbon crackingMolecular sieveAluminium

The invention relates to a kind of method for manufacturing propylene by catalytic cracking alkene of no less than tetra carbon, which mainly solves the short catalyst regeneration period problem and the stability problems uninvolved in previous technique. The invention uses minor crystalline grain and molecular sieve with high silicon-aluminium ratio as the catalyst for catalytic cracking with alkene that no less than tetra carbon to manufacture propylene. According to the technique scheme that described above, the invention can solve the problems mentioned above excellently, and can be used in industrial production of manufacturing propylene by catalytic cracking with alkene.

Owner:CHINA PETROLEUM & CHEM CORP +1

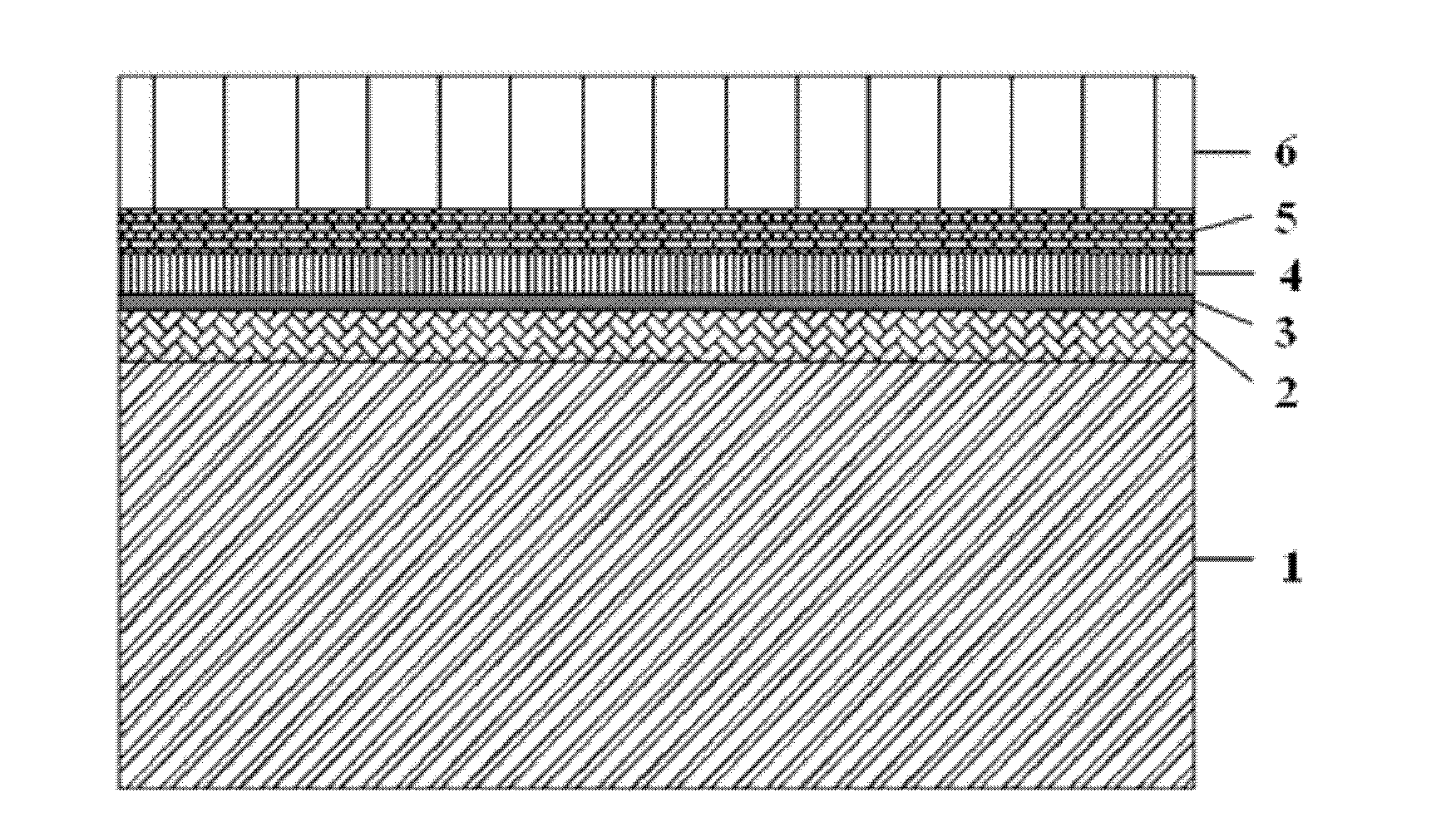

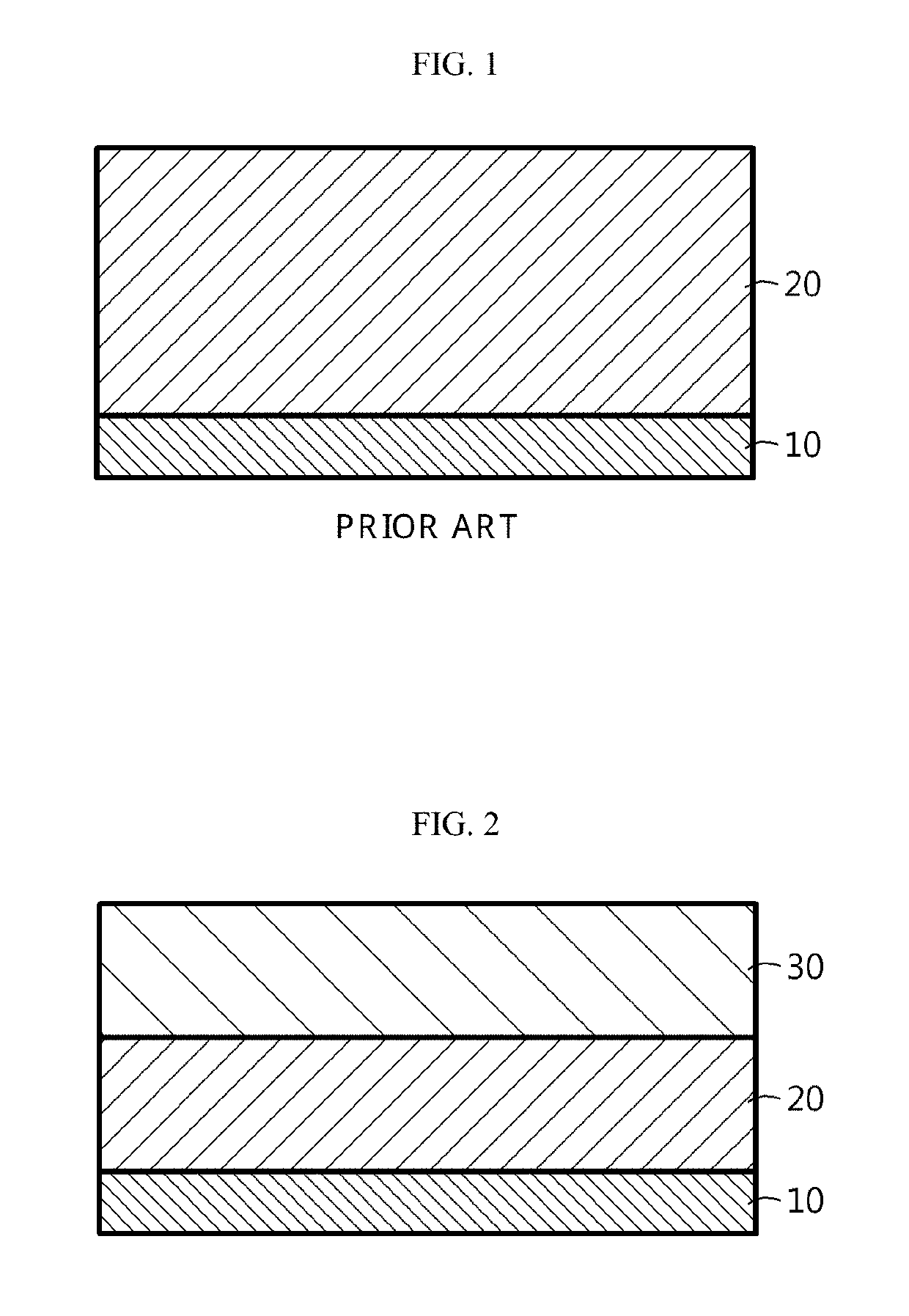

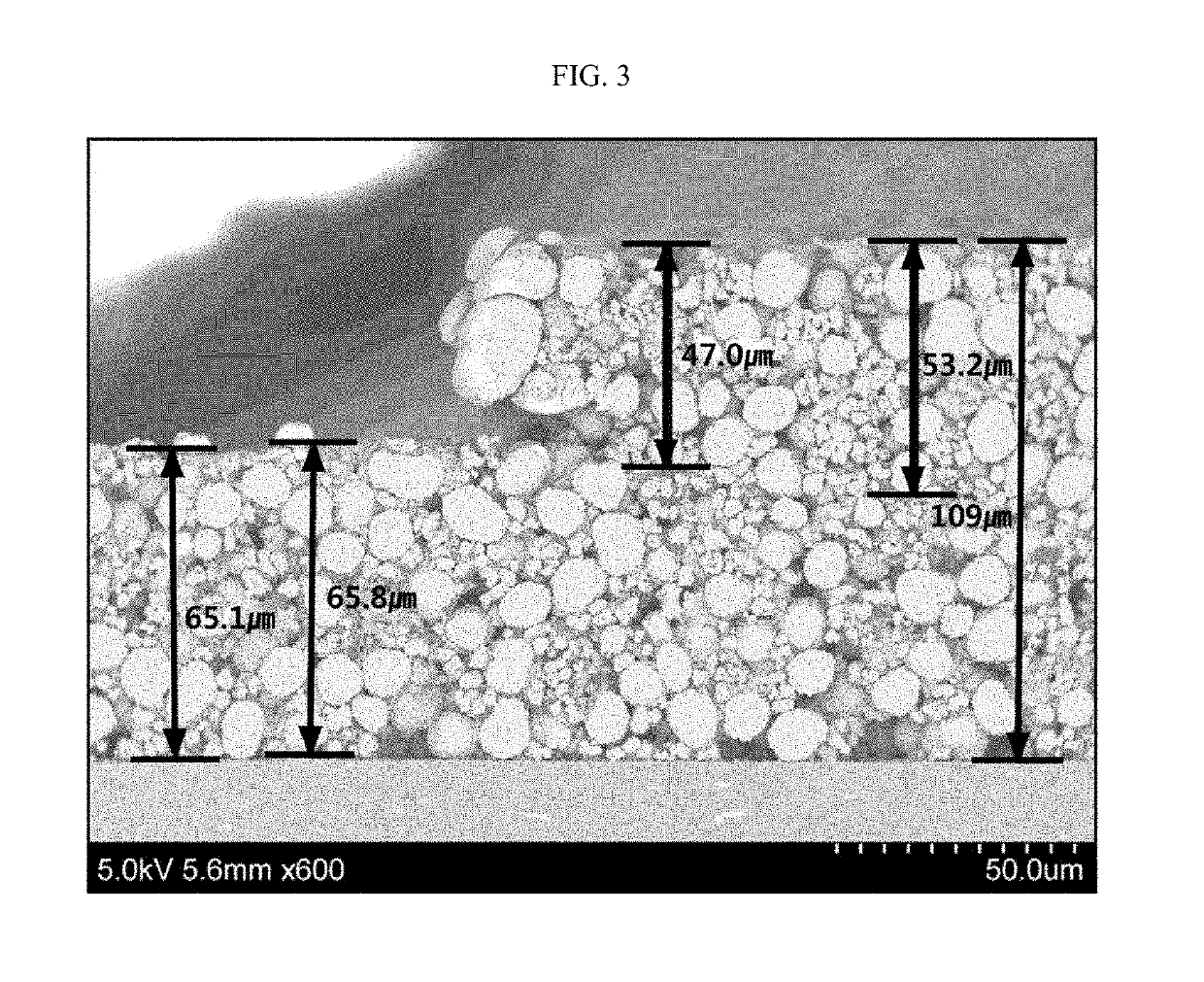

Thermal barrier coating system

InactiveCN102423935AIncreased ability to moderate thermal mismatchReduce thermal stressCeramic layered productsThermal insulationCeramic coating

The invention discloses a thermal barrier coating system, which comprises a base body, a bonding layer and a multilayer ceramic coating, wherein the multilayer ceramic coating is formed on the bonding layer and comprises a reinforcing layer, a transition layer and a toughness enhancing thermal insulation layer which are sequentially formed on the bonding layer, and vertical cracks are arranged on the toughness enhancing thermal insulation layer. In the thermal barrier coating system, the ceramic coating is provided with the toughness enhancing thermal insulation layer with the sufficient vertical cracks, the ceramic coating has the characteristic of high stress toughness through the existence of the vertical cracks, the thermal mismatch relieving capability of the ceramic layer is enhanced, and the thermal stress in the ceramic layer is reduced, so the characteristics of efficient thermal barrier and long service life are obtained. The reinforcing layer is prepared near an interface easy to generate unsticking, the oxygen atom diffusion resistance can be enhanced, in addition, the layer separation invalidation position is transferred from the interface to a position inside the ceramic layer far away from a thermal growth oxide layer (TGO), simultaneously, the transition layer is formed between the toughness enhancing thermal insulation layer and the reinforcing layer, the thermal mismatch stress can be effectively reduced, and the thermal barrier coating system has the characteristic that the service life is long.

Owner:XI AN JIAOTONG UNIV

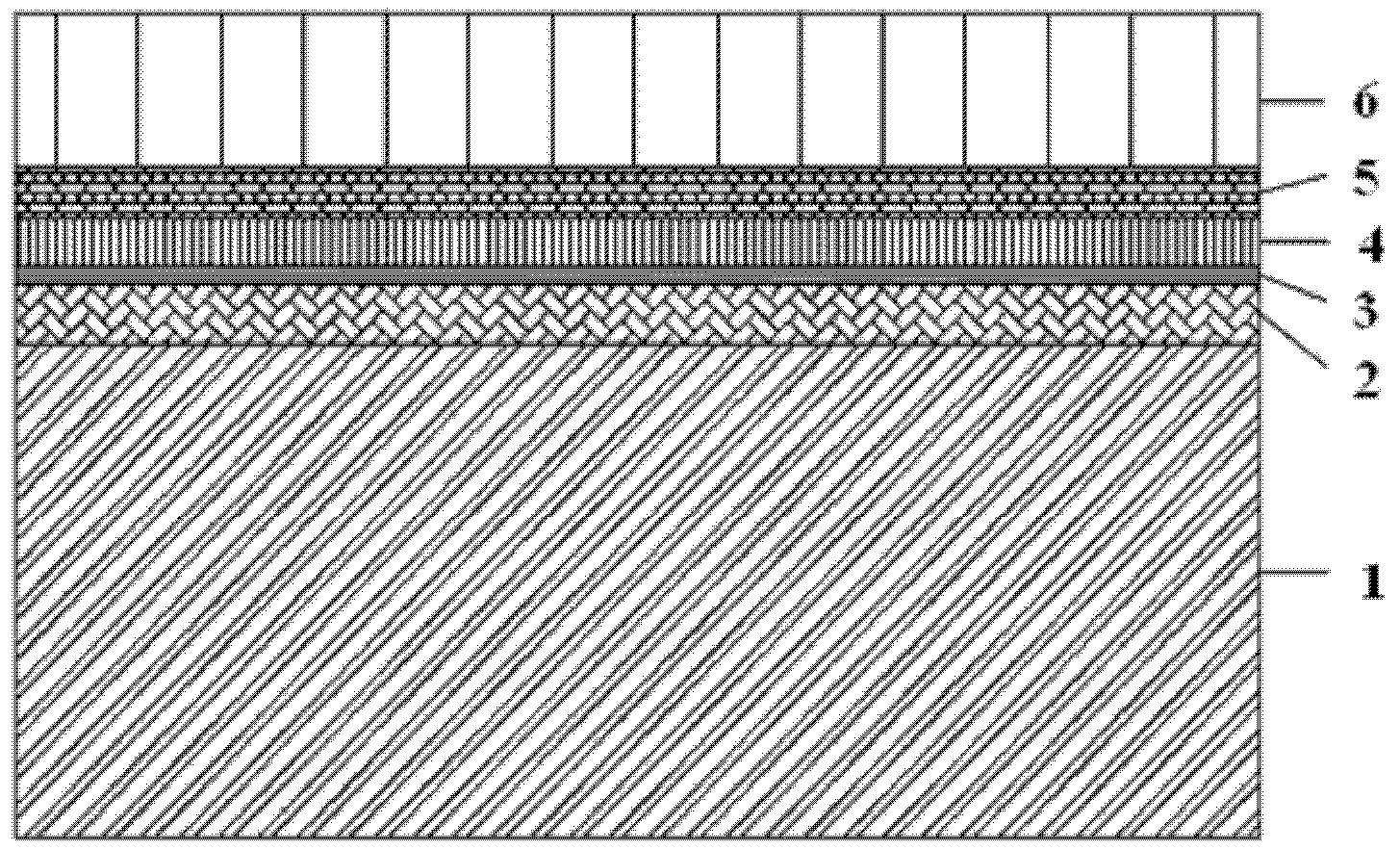

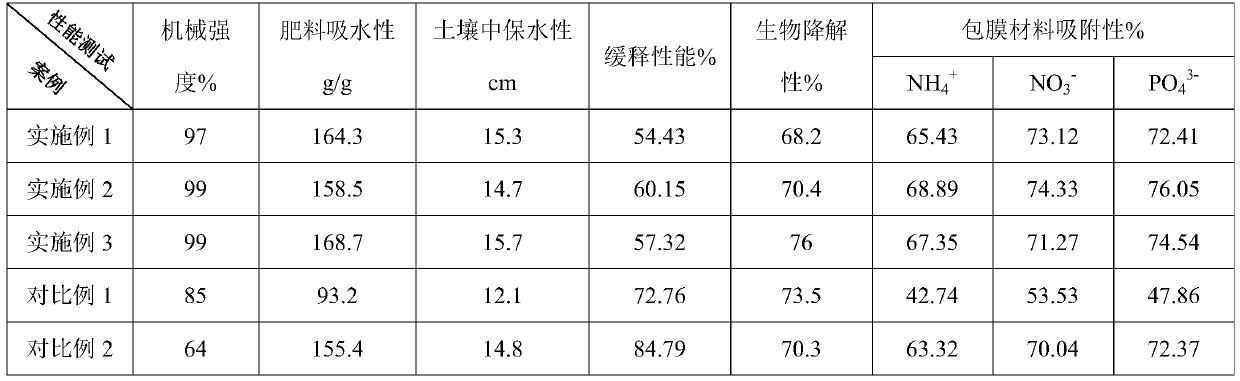

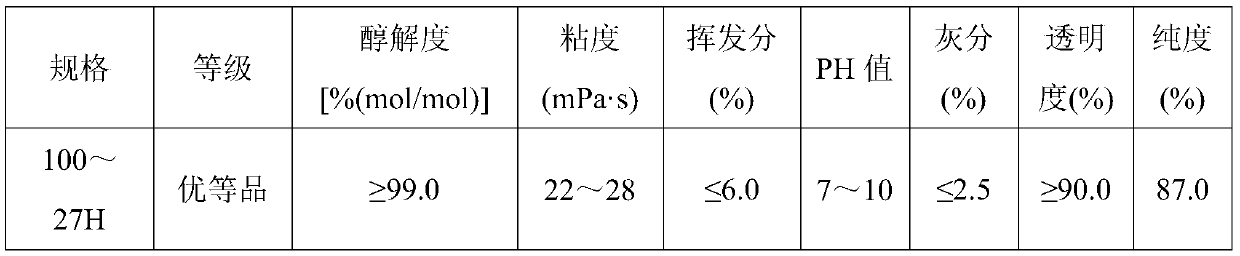

Method for preparing coated straw fiber-based water-retaining slow-release fertilizer

InactiveCN110272314AIncreased diffusion resistanceImprove the sustained release effectAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersFertilizerSodium carboxymethylcellulose

The invention discloses a method for preparing a coated straw fiber-based water-retaining slow-release fertilizer. According to the method, a straw cellulose polysaccharide chain is used as a framework; acrylic acid and acrylamide substances generated by a reaction of acrylic acid and urea are grafted to a cellulose main chain; then crosslinking is carried out by a cross-linking agent to form a polymer with a three-dimensional network structure; meanwhile, the polymer with the three-dimensional network structure and polyvinyl alcohol interpenetrate through each other to form high-water-absorbing resin with a semi-interpenetrating network structure; then the high-water-absorbing resin with the semi-interpenetrating network structure coats fertilizer particles; and a mixed solution of polyvinyl alcohol, sodium alginate and carboxymethyl cellulose forms a membrane by crosslinking to coat the outermost layer of the fertilizer particles to obtain the coated straw fiber-based water-retaining slow-release fertilizer. The fertilizer disclosed by the invention has good mechanical properties and water absorption performance, has excellent slow release effects on the fertilizer, reduces nutrient loss, improves the utilization rate of the fertilizer, reduces maintenance cost of farmland in the later period, and improves the yield and quality of crops. The method provided by the invention has the advantages that the operation method is simple and convenient, cost is low, the additional value of straw application is improved, and the new idea of straw resourceful utilization is further expanded.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

Lithium-air battery structure

ActiveCN104716405AAvoid erosionPromotes the electrochemical reduction reactionFuel and secondary cellsCell electrodesElectrochemical responseLithium–air battery

The invention relates to a lithium-air battery structure, including a lithium negative electrode, a porous diaphragm and a positive electrode which are sequentially laminated, an electrically conductive porous function layer is arranged between the lithium negative electrode and the porous diaphragm, the electrically conductive porous function layer is an electrically conductive porous carbon material layer or a composite layer of an electrically conductive porous carbon material and catalytic components, and mass ratio of electrically conductive porous carbon material to other functional components is 20:1 to 2:1. By the electrochemical reaction of the conductive porous functional layer and dissolved diffused oxygen or reactive oxygen species, the dissolved diffused oxygen or reactive oxygen species can be effectively consumed, the corrosion and damage to the lithium negative electrode can be reduced, and substantial improvement of the battery stability can be facilitated.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for producing propene for C4 and more olefin catalytic cracking

InactiveCN1274645CIncreased diffusion resistanceSize diffusion resistanceChemical recyclingHydrocarbon by hydrocarbon crackingMolecular sievePeriod problem

The invention relates to a kind of method for manufacturing propylene by catalytic cracking alkene of no less than tetra carbon, which mainly solves the short catalyst regeneration period problem and the stability problems uninvolved in previous technique. The invention uses minor crystalline grain and molecular sieve with high silicon-aluminium ratio as the catalyst for catalytic cracking with alkene that no less than tetra carbon to manufacture propylene. According to the technique scheme that described above, the invention can solve the problems mentioned above excellently, and can be used in industrial production of manufacturing propylene by catalytic cracking with alkene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Foliage fertilizer for longan tree and production method of foliage fertilizer

InactiveCN105254432APromote growth and developmentImprove stress resistanceFertilizer mixturesDiseaseSophocarpidine

The invention belongs to the field of agricultural fertilizer, relates to a foliage fertilizer, in particular to a foliage fertilizer for a longan tree and a production method of the foliage fertilizer. The foliage fertilizer is prepared from the following raw materials in parts by weight: 7 to 10 parts of biochemical fulvic acid potassium, 12 to 15 parts of urea, 5 to 7 parts of washing powder, 7 to 13 parts of monopotassium phosphate, 8 to 14 parts of amino acid-chelated copper and boron, 6 to 13 parts of sucrose-complexed manganese and calcium, 8 to 12 parts of diaminoferric xanthohumate, 1 to 2.5 parts of sophocarpidine, 14 to 20 parts of magnesium sulfate and 6 to 10 parts of zinc sulfate. The foliage fertilizer prepared by the production method disclosed by the invention is good in fertilizer efficiency, is rich in multiple medium trace elements required by the longan tree, and meets nutritional requirements of longan; after application, the foliage fertilizer has a significant prevention effect for physiological yellow coloring, small leaf, mottled leaf, roll leaf and the lime of the fruit tree; by using the foliage fertilizer, toot system development of the fruit tree can be promoted, disease invasion is prevented, and disease resistance, drought resistance and cold resistance of crops are improved; the foliage fertilizer has effects of improving the growth speed of longan, promoting fruiting and swelling, improving the yield and the quality of longan, improving the resistance of the fruit tree and sterilizing.

Owner:DAXIN SCI & TECH INFORMATION RES INST

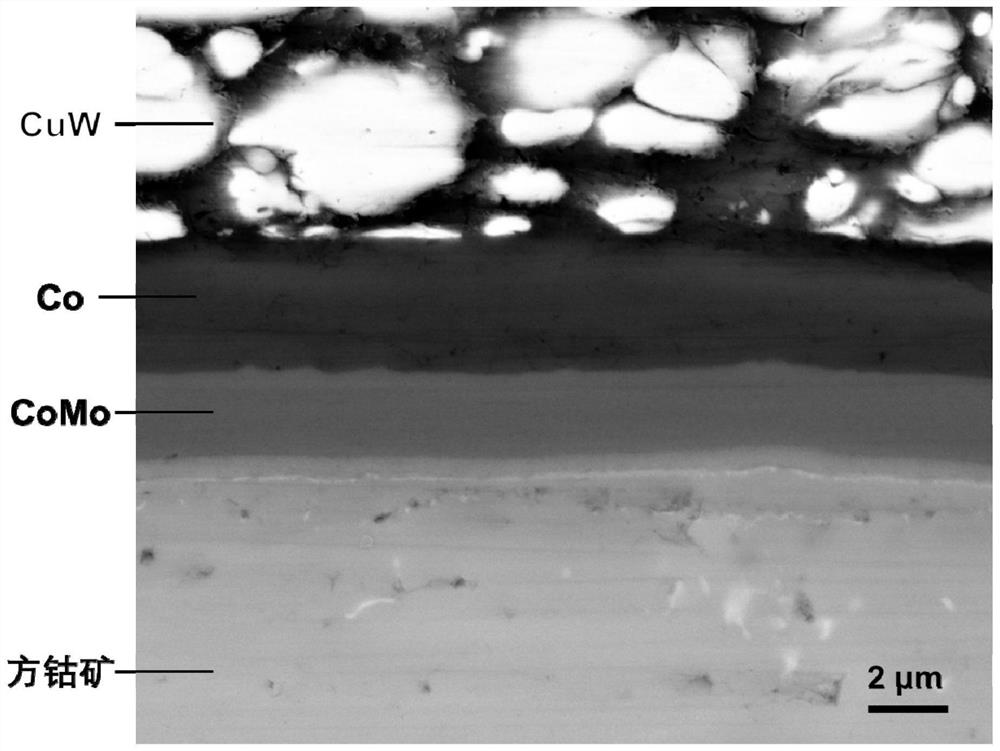

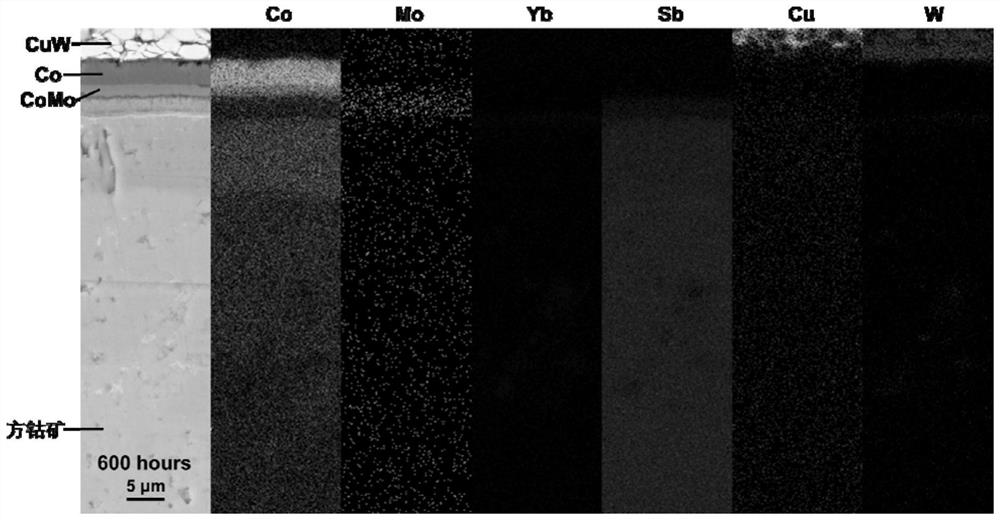

Method for connecting skutterudite thermoelectric material and electrode by using high-thermal-stability alloy composite intermediate layer

ActiveCN112276275ABarrier interdiffusionReduce contact resistivityThermoelectric device manufacture/treatmentSoldering apparatusHeat stabilityAlloy composite

The invention relates to a method for connecting a skutterudite thermoelectric material and an electrode by using a high-thermal-stability alloy composite intermediate layer, in particular to the method for connecting the skutterudite thermoelectric material and the electrode. The method aims to solve the problems of poor thermal stability and large contact resistance of a joint obtained by the existing skutterudite thermoelectric material welding method. The method comprises the following steps of 1, cleaning the skutterudite thermoelectric material and the electrode; and 2, preparing the intermediate connecting layer and a diffusion barrier layer by using an electroplating or physical vapor deposition method, and carrying out diffusion welding, wherein the intermediate connecting layer is made of Co, Fe or Ni, and the diffusion barrier layer is made of CoMo, CoW, FeMo or FeW. According to the method, the joint obtained by utilizing the intermediate connecting layer and the diffusionbarrier layer has low contact resistivity, and the thermal stability of the joint is high. The method is suitable for connecting the skutterudite thermoelectric material and the electrode.

Owner:HARBIN INST OF TECH

Sustained-release solid chlorine dioxide preparation and preparation method and application method thereof

InactiveCN105746575AReduce evaporation rateRelease safe and effectiveBiocideFood preservationChlorine dioxideRoom temperature

The invention provides a sustained-release solid chlorine dioxide preparation.The sustained-release solid chlorine dioxide preparation comprises, by weight, 0.5%-25% of one or a mixture of liquid chlorine dioxide and a chlorine dioxide water solution, 20%-70% of sustained-release agents, 5%-40% of hygroscopic agents and 0.1%-3% of essence.The sustained-release solid chlorine dioxide preparation is prepared according to the steps of gradually adding the sustained-release agents into the hygroscopic agents at 5-15 DEG C, adding the liquid chlorine dioxide after sufficient soluble inflation, uniformly stirring and placing in a room temperature environment for sufficient hardening.The sustained-release solid chlorine dioxide preparation which is prepared from the highly water-soluble materials is soluble to water easily and used for cleaning, soaking or being sprayed on objects needing disinfection quite conveniently.The sustained-release solid chlorine dioxide preparation is simple in technology, low in price, safe and effective to use, capable of releasing chlorine dioxide gas in a sustained manner and long in effective service life.

Owner:艾子义

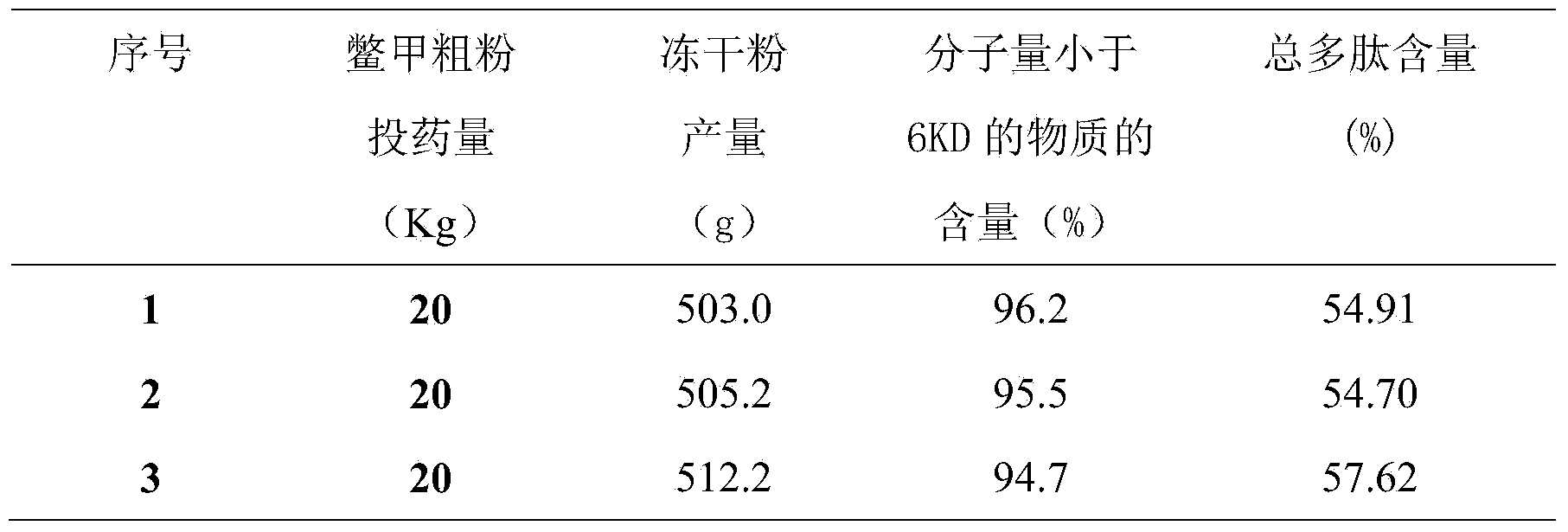

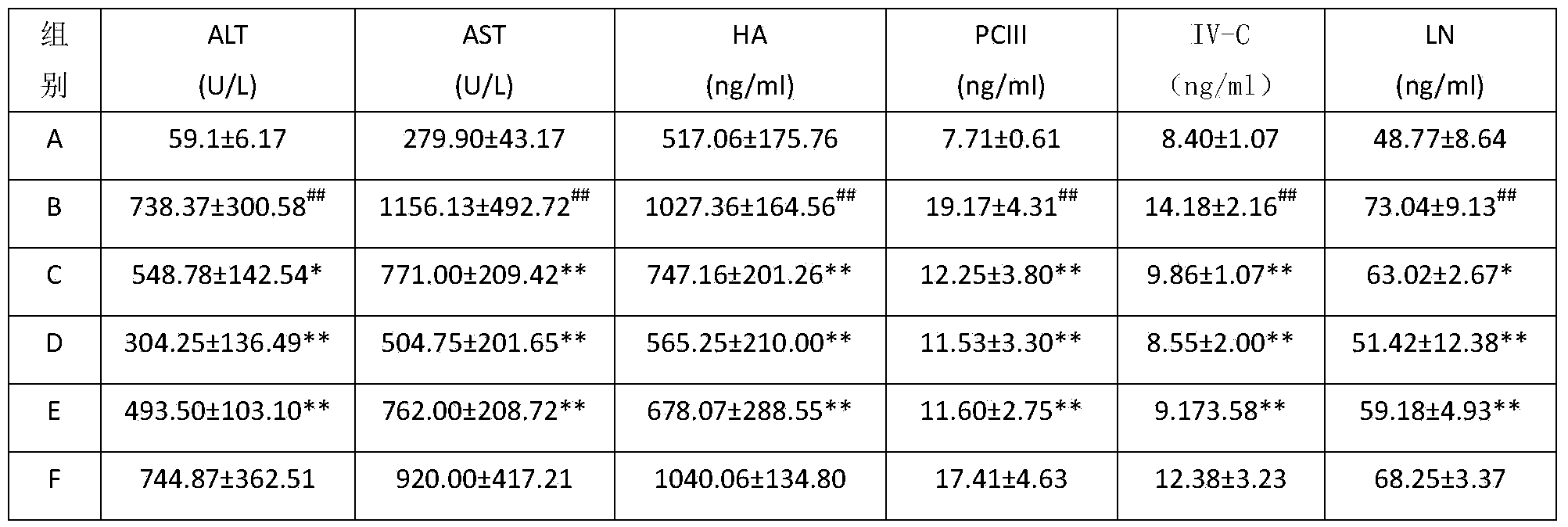

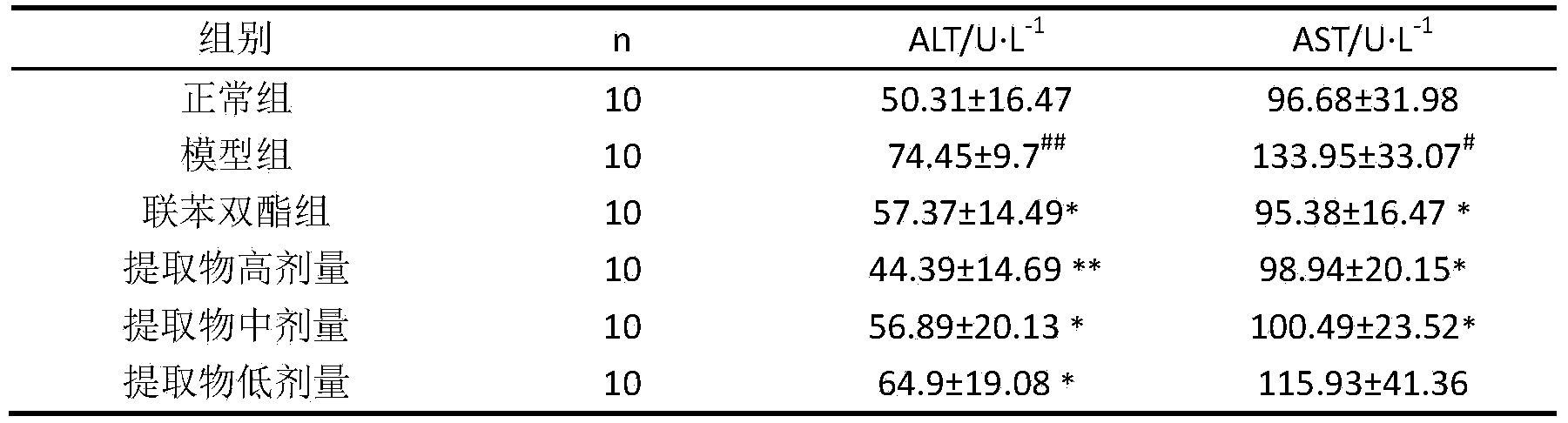

Preparation method and application of turtle shell active polypeptide extractive

ActiveCN103705907ATime consumingExtension of timePeptide/protein ingredientsDigestive systemFreeze-dryingDistilled water

The invention belongs to the technical field of preparation of traditional Chinese medicine extractives, and particularly discloses a preparation method and application of a turtle shell active polypeptide extractive. The preparation method particularly comprises the following steps of decocting a turtle shell by using water for extraction; diluting an extracting solution by using distilled water till the concentration corresponding to contain 4-8 g / 100 mL of turtle shell medicinal materials; respectively carrying out microfiltration and multistage ultrafiltration to obtain ultrafiltrate, carrying out vacuum concentration, and freeze-drying to obtain freeze-dried powder with molecular weight less than 6 KD. The preparation method disclosed by the invention can be used for preparing the active polypeptide substance part of the turtle shell by adopting a multistage membrane separation method, and can transit to industrialization on process parameters through a pilot scale test; the prepared turtle shell active polypeptide extractive has a liver protection effect and can be used for preparing a drug or health-care food used for preventing or treating liver fibrosis and alcoholic liver injury.

Owner:HUBEI UNIV OF CHINESE MEDICINE

Preparation method of macroporous alumina support

ActiveCN103055949AHigh specific surface areaConcentrated hole distributionCatalyst carriersAluminium saltsSaw dust

The invention discloses a preparation method of a macroporous alumina support. The method is characterized by taking sawdust produced in the wood processing industry as a pore-enlarging agent, enabling the sawdust to adsorb an inorganic aluminium salt solution after carbonizing treatment, and kneading, forming, drying and roasting the sawdust and an alumina precursor after drying the sawdust, thus obtaining the macroporous alumina support. The alumina support obtained by the method is larger in specific surface area, more concentrated in pore size distribution and high in mechanical strength, also contains part of macropores with sizes more than 100nm, is suitable for preparing heavy / residual oil hydrogenation catalysts, and is favorable for removing macromolecular impurities in heavy / residual oil and delaying the increase of diffusion resistance in heavy / residual oil hydrogenation, thus being favorable for maintaining the activities of the hydrogenation catalysts and lengthening the running period.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nano sunscreen agent, preparation method, and application thereof

ActiveCN108210347AImprove light protection efficiencyImprove photostabilityCosmetic preparationsToilet preparationsSunscreen agentsNuclear chemistry

The invention discloses a nano sunscreen agent, a preparation method, and an application thereof. The nano sunscreen agent includes a zeolite imidazate framework structure material and an organic sunscreen agent which is sealed in the framework material. The zeolite imidazate framework structure material coats the surface of the organic sunscreen agent. The nano sunscreen agent has gentle synthesis conditions and short reaction time, can effectively inhibit contact between the organic sunscreen agent and skin and reduce direct contact between the organic sunscreen agent and an active oxygen substance, ROS, generated after photo-activation and skin, so that a series of phototoxicities caused by transdermal absorption of the nano sunscreen agent is prevented. The product is a novel nano sunscreen agent material.

Owner:JIANGSU PROVINCE HOSPITAL THE FIRST AFFILIATED HOSPITAL WITH NANJING MEDICAL UNIV

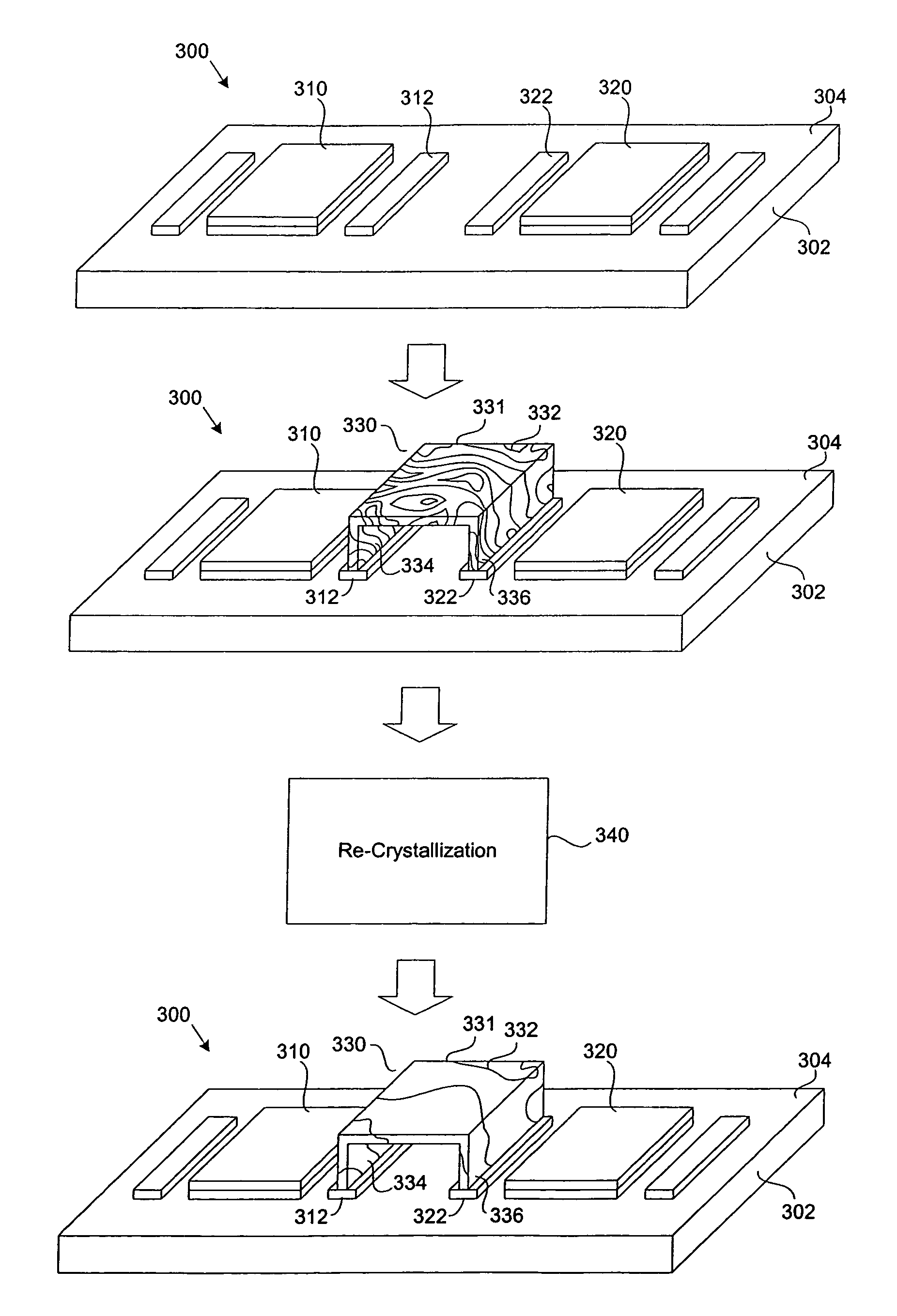

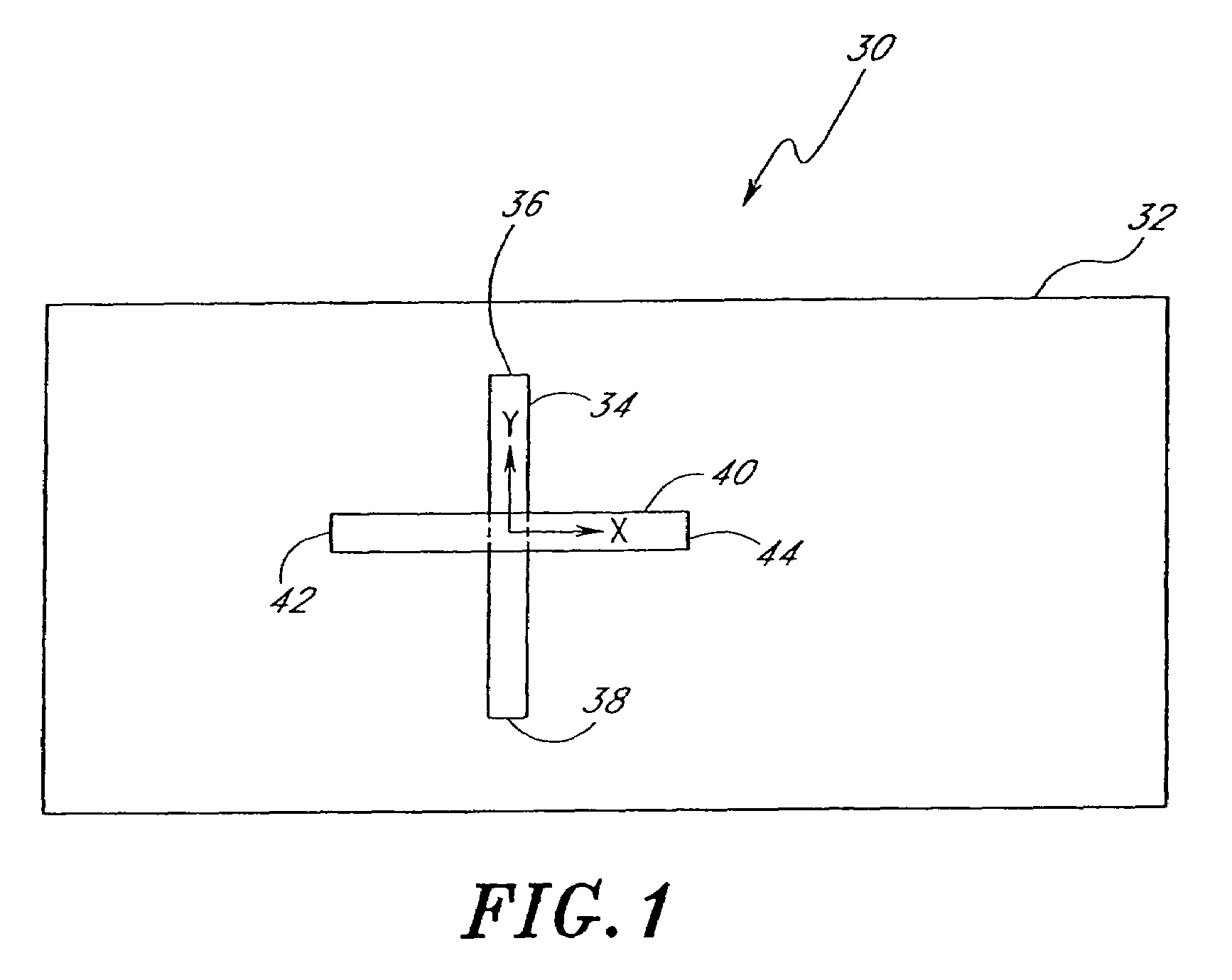

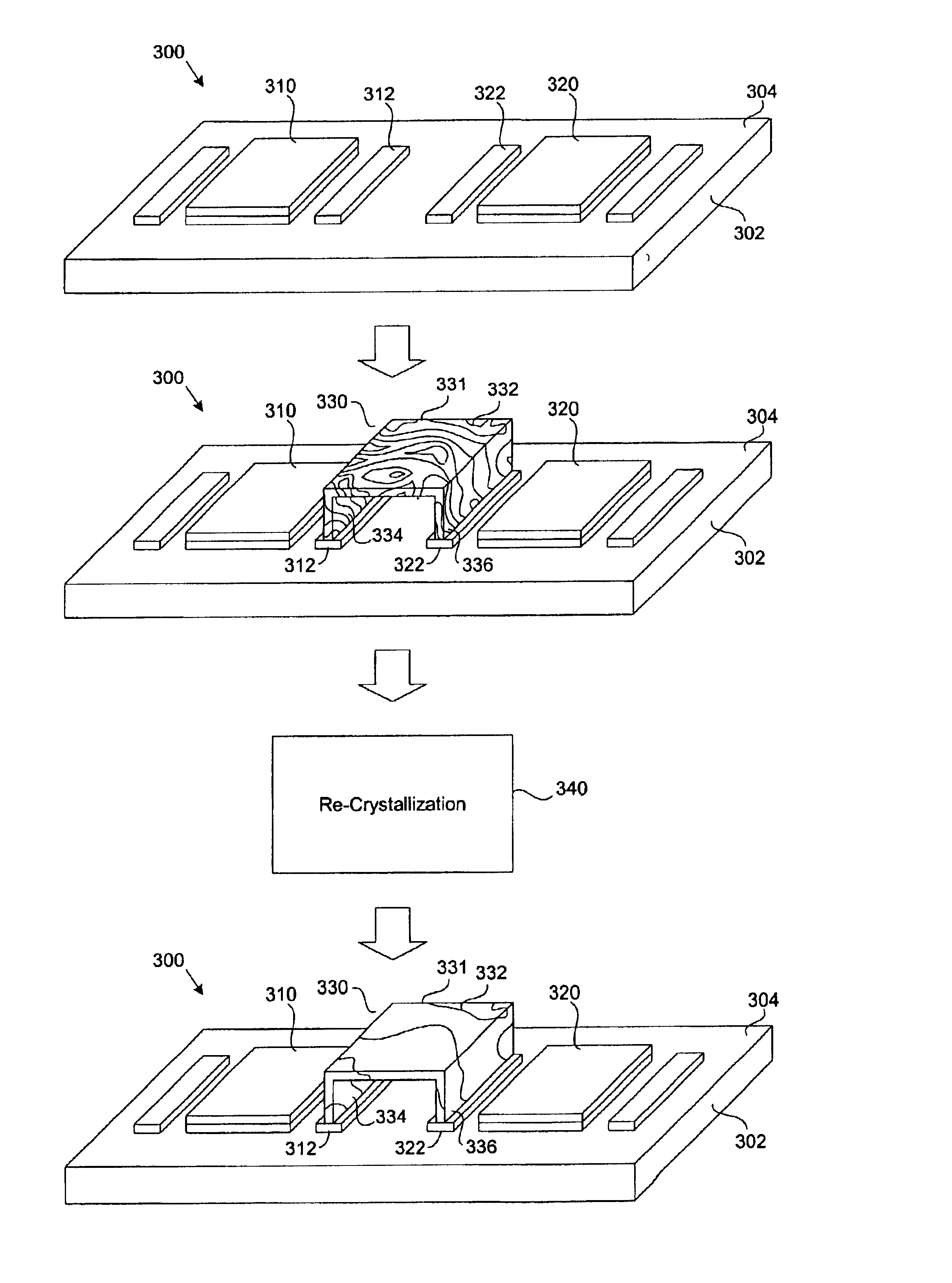

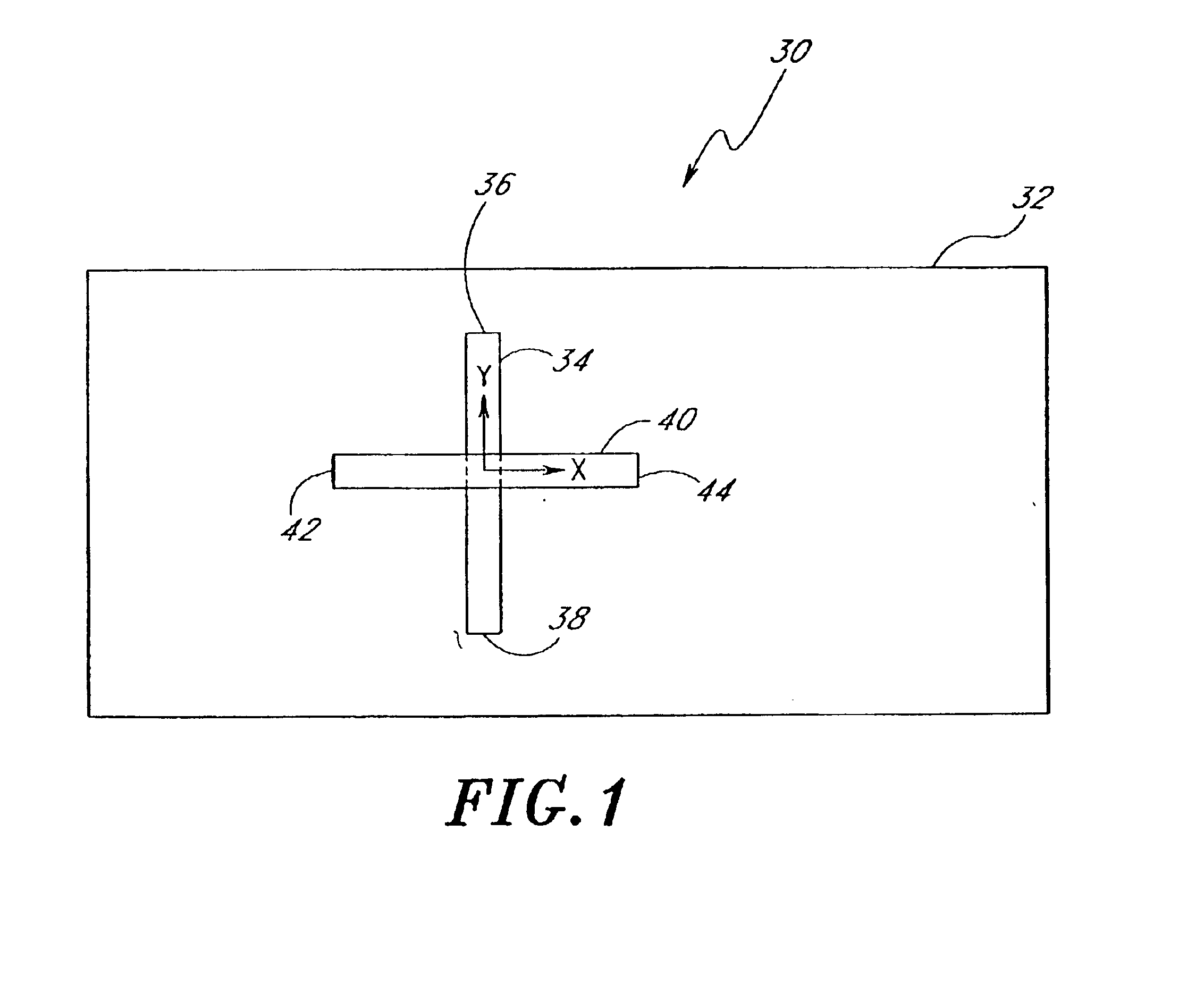

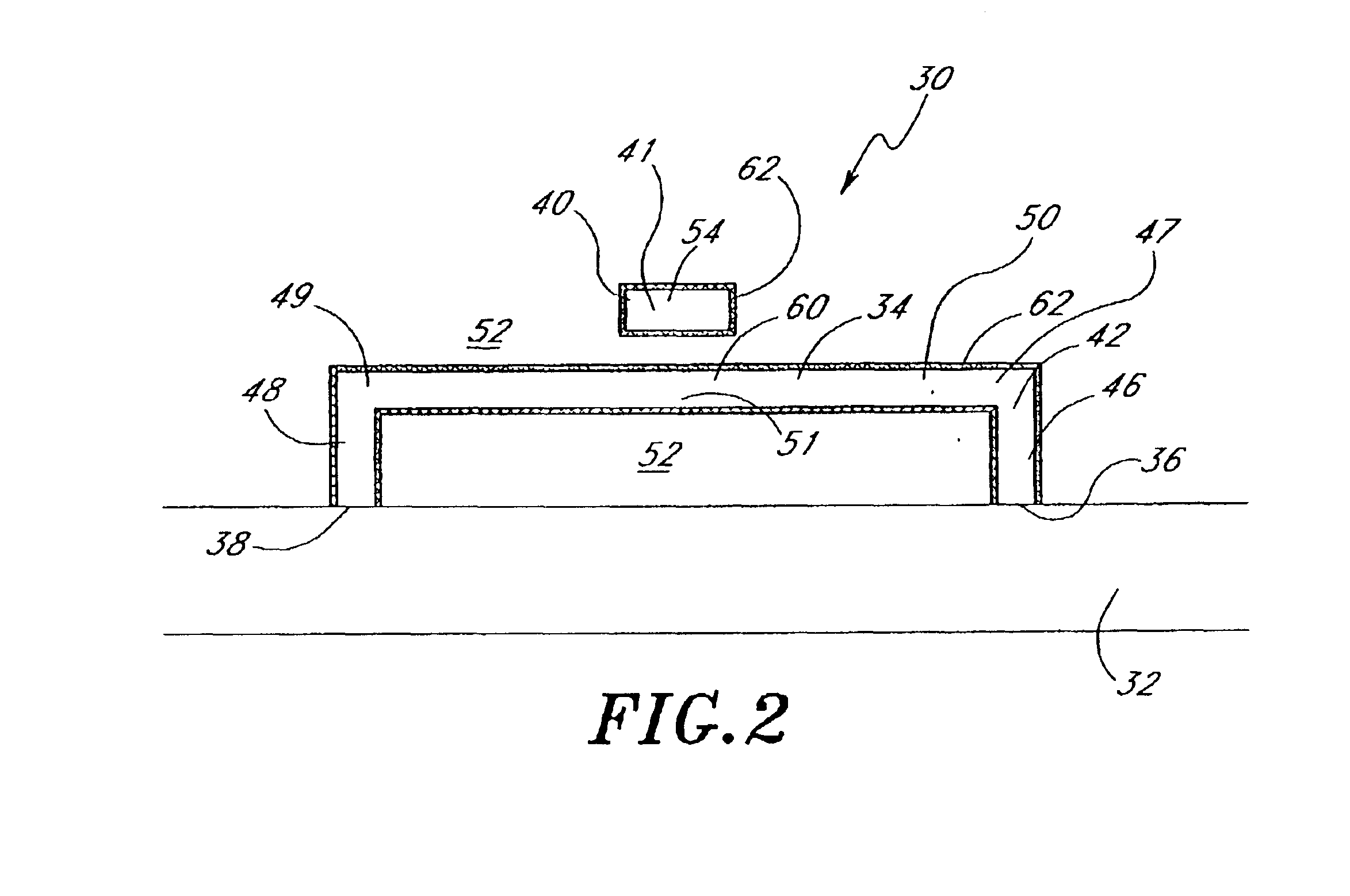

Coating of copper and silver air bridge structures to improve electromigration resistance and other applications

InactiveUS7075166B1Improve electrical performanceIncrease resistanceSemiconductor/solid-state device detailsSolid-state devicesCapacitanceAir bridge

An improved electrical interconnect for an integrated circuit and methods for providing the same are disclosed. The electrical interconnect includes an air bridge extending through a gaseous medium so as to reduce the capacitance of the interconnect. The air bridge is supported at a first and second end such that the air bridge is suspended above the substrate. The air bridge comprises a highly conductive material, such as silver, so as to provide the air bridge with a reduced resistivity. To inhibit gaseous medium from contaminating the air bridge, the air bridge further comprises an adherent coating interposed between the air bridge and the gaseous medium. A method of forming the electrical interconnect is also disclosed, wherein, prior to forming the adherent coating, the conductive material is processed so as to form fewer grain boundaries, which enhances the electrical properties of the air bridge.

Owner:MICRON TECH INC

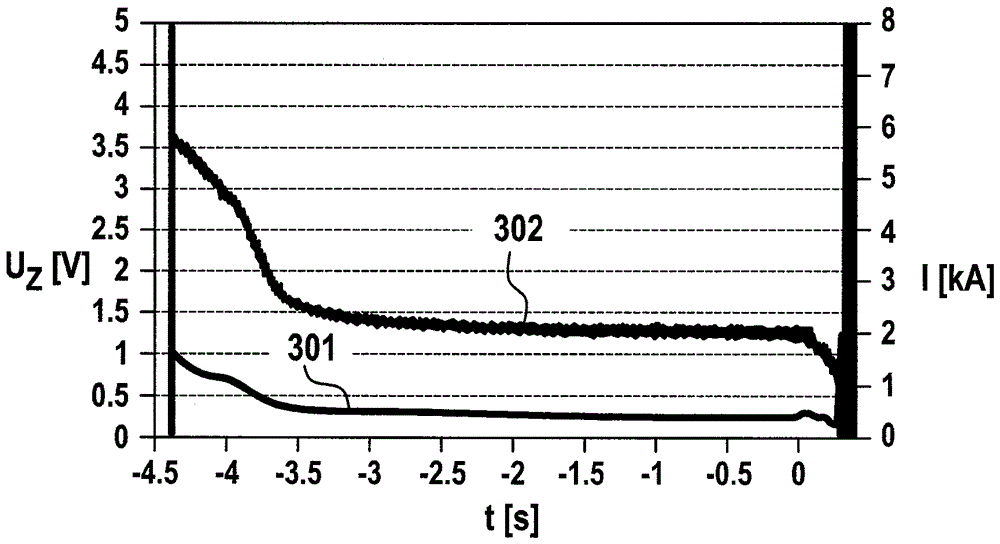

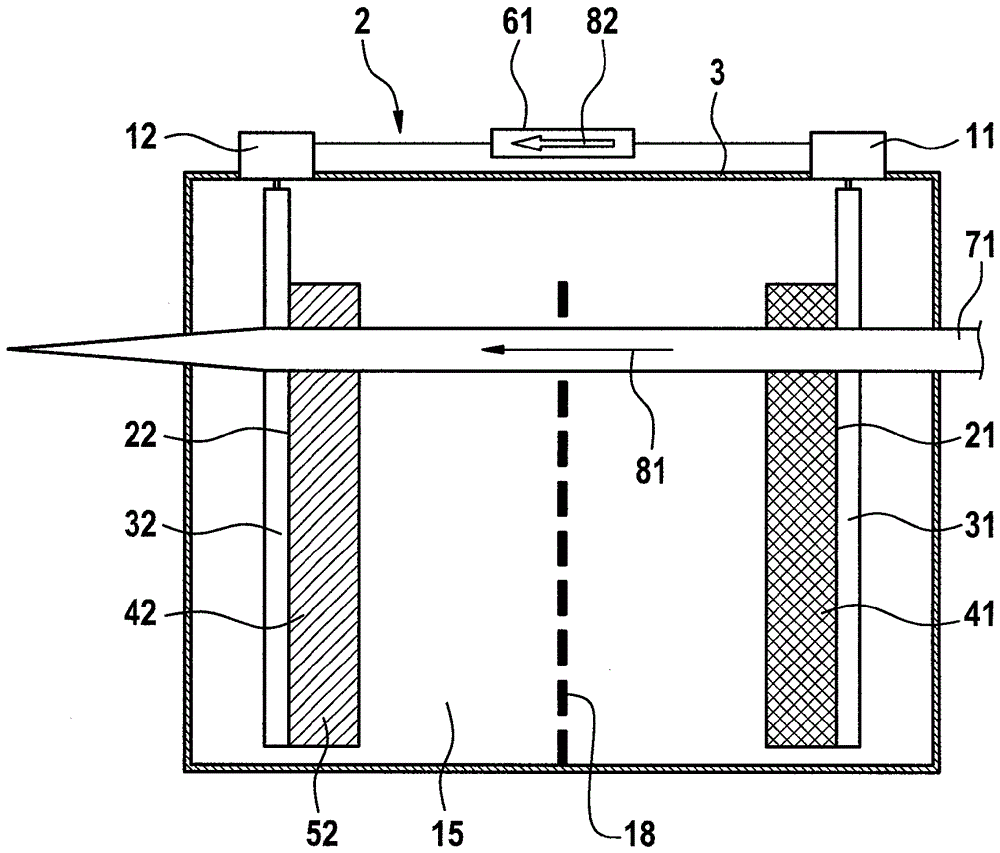

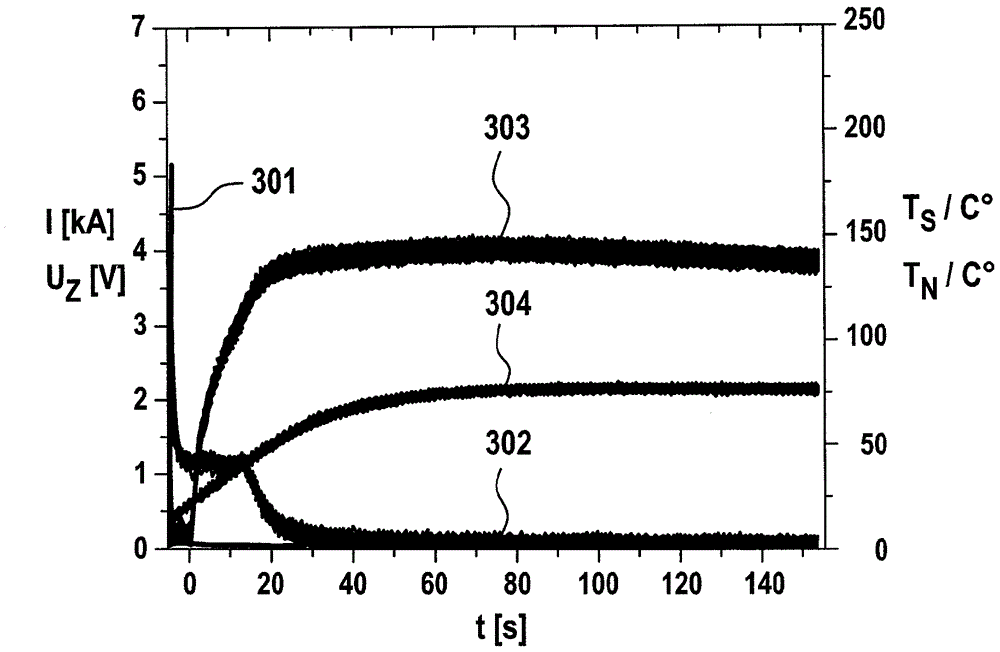

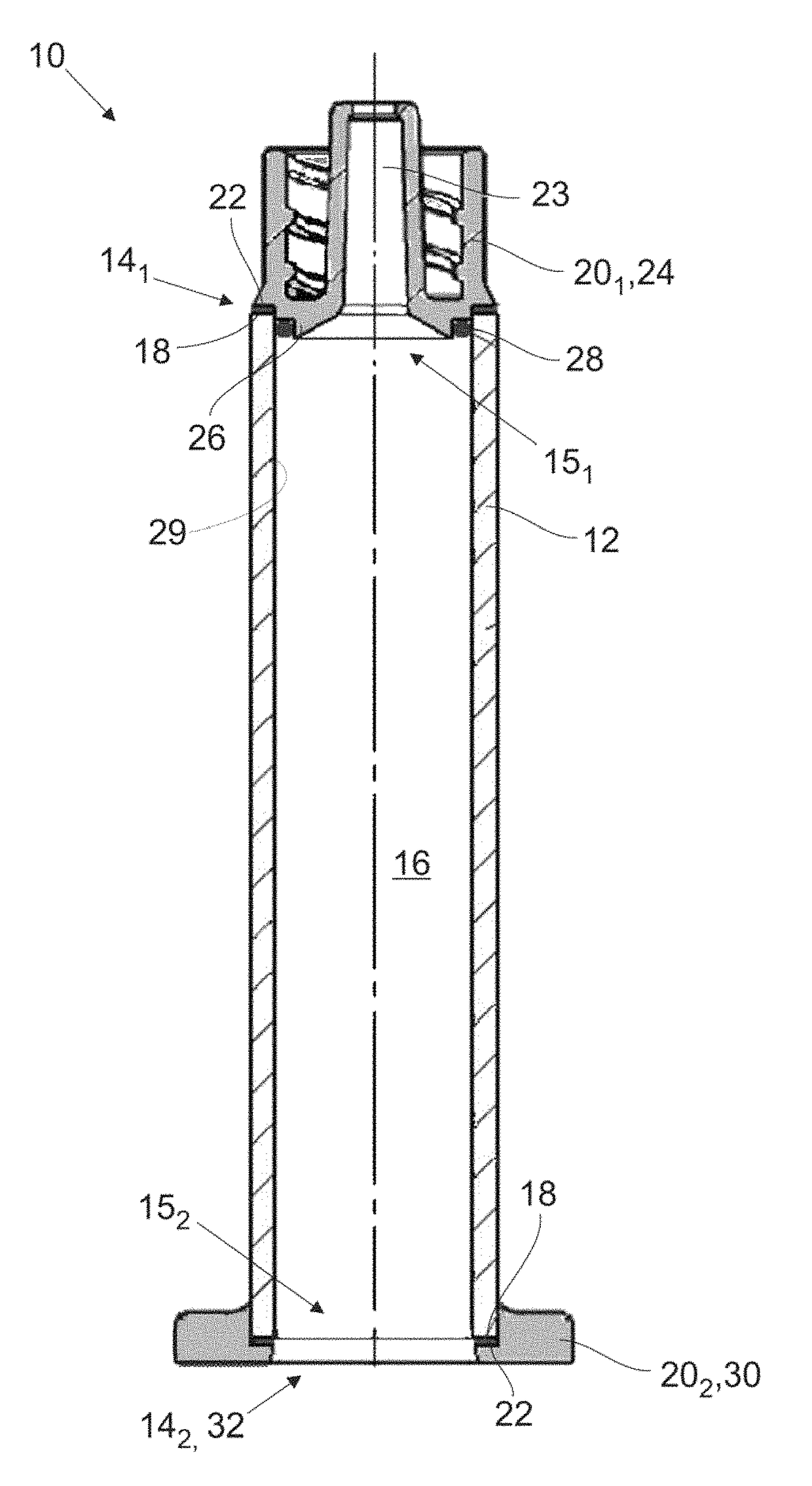

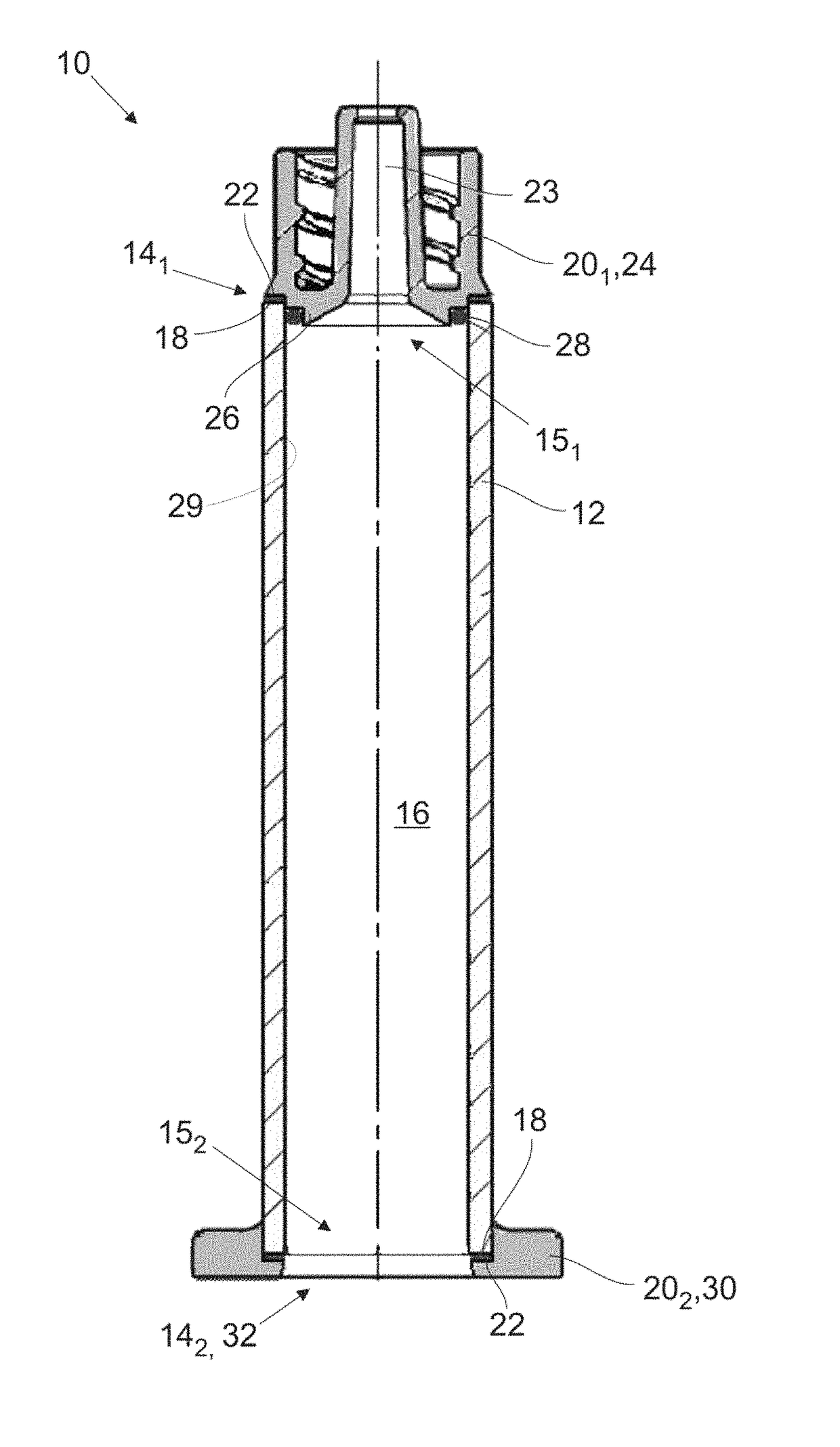

Method for producing a lithium ion battery and lithium ion battery

InactiveCN106848178AReduced risk of short circuitsReduce the risk of uncontrolled heatingFinal product manufactureCells structural combinationSolubilityElectrolyte composition

Owner:LITHIUM ENERGY & POWER GMBH & CO KG

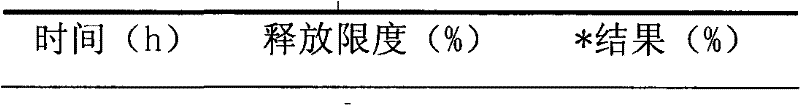

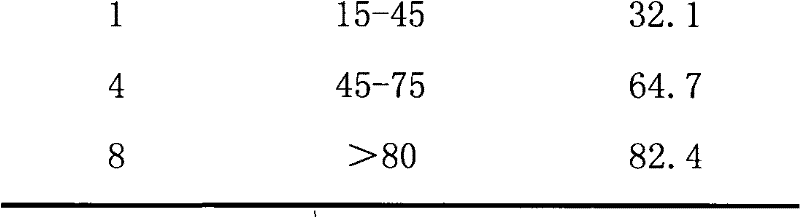

Loxoprofen sodium matrix sustained-release tablet

ActiveCN102525989AIncreased diffusion resistanceReduced Diffusion ResistanceOrganic active ingredientsAntipyreticSustained Release TabletLoxoprofen

The invention relates to a novel matrix sustained-release tablet containing loxoprofen sodium, in particular to a locoprofen sodium matrix sustained-release tablet with a regulation layer, which is capable of stably releasing for 8 hours, good in releasing effect, simple in process and low in cost.

Owner:北京天衡药物研究院有限公司

Method for preparing IPN structure PMMA-PU high-transparency composite board through ultrasonic assistance

The invention discloses a method for preparing an IPN structure PMMA-PU high-transparency composite board through ultrasonic assistance, and belongs to the field of composites. The method comprises the following steps that 1, raw materials (monomers, an initiator / catalyst, a cross-linking agent, a chain extender and the like) of polymethyl methacrylate (PMMA) and polyurethane (PU) are mechanically mixed to be uniform, and the materials are poured into a polytetrafluoroethylene mold after being subjected to vacuum degassing; 2, a sealing pressing head is placed on the mold to apply constant pressure; 3, the mold is placed in a temperature-adjustable low-frequency ultrasonic container, a sequential polymerization reaction is carried out under the action of ultrasonic waves, and the high-transparency interpenetrating polymer network (IPN) structure PMMA-PU composite board is prepared. The action of ultrasonic assistance is adopted, and the prepared IPN structure PMMA-PU composite board has the advantages of being low in microphase separation degree, high in transparency and the like and is expected to be applied to light bulletproof transparent materials.

Owner:NANCHANG HANGKONG UNIVERSITY

Slow release type solid aromatic and preparation method thereof

InactiveCN104031742AFix stability issuesResolution timeEssential-oils/perfumesNano silicon dioxidePolyvinylpyrrolidone

The invention discloses a slow release type solid aromatic. The slow release type solid aromatic comprises the following components in percentage by mass: 40-46% of nanosilicon dioxide hollow spheres, 40-46% of essence, 4-10% of starch, 0.5-3% of superfine silica powder, 2.5-4% of polyvinylpyrrolidone and 1-3% of talcum powder, wherein particle size of each nanosilicon dioxide hollow sphere is 300-500nm. The invention also provides a preparation method of the slow release type solid aromatic. The preparation method of the slow release type solid aromatic comprises the steps of uniformly mixing nanosilicon dioxide hollow spheres, essence and auxiliaries, and carrying out direct compression, so that the slow release type solid aromatic is obtained. The slow release type solid aromatic has the advantages of uniform and slow fragrance release, long scent lasting time, no toxicity, no harm and high essence load capacity and can be widely applied to the fields of daily chemicals, textiles, leathers, coating and the like.

Owner:SHANGHAI INST OF TECH

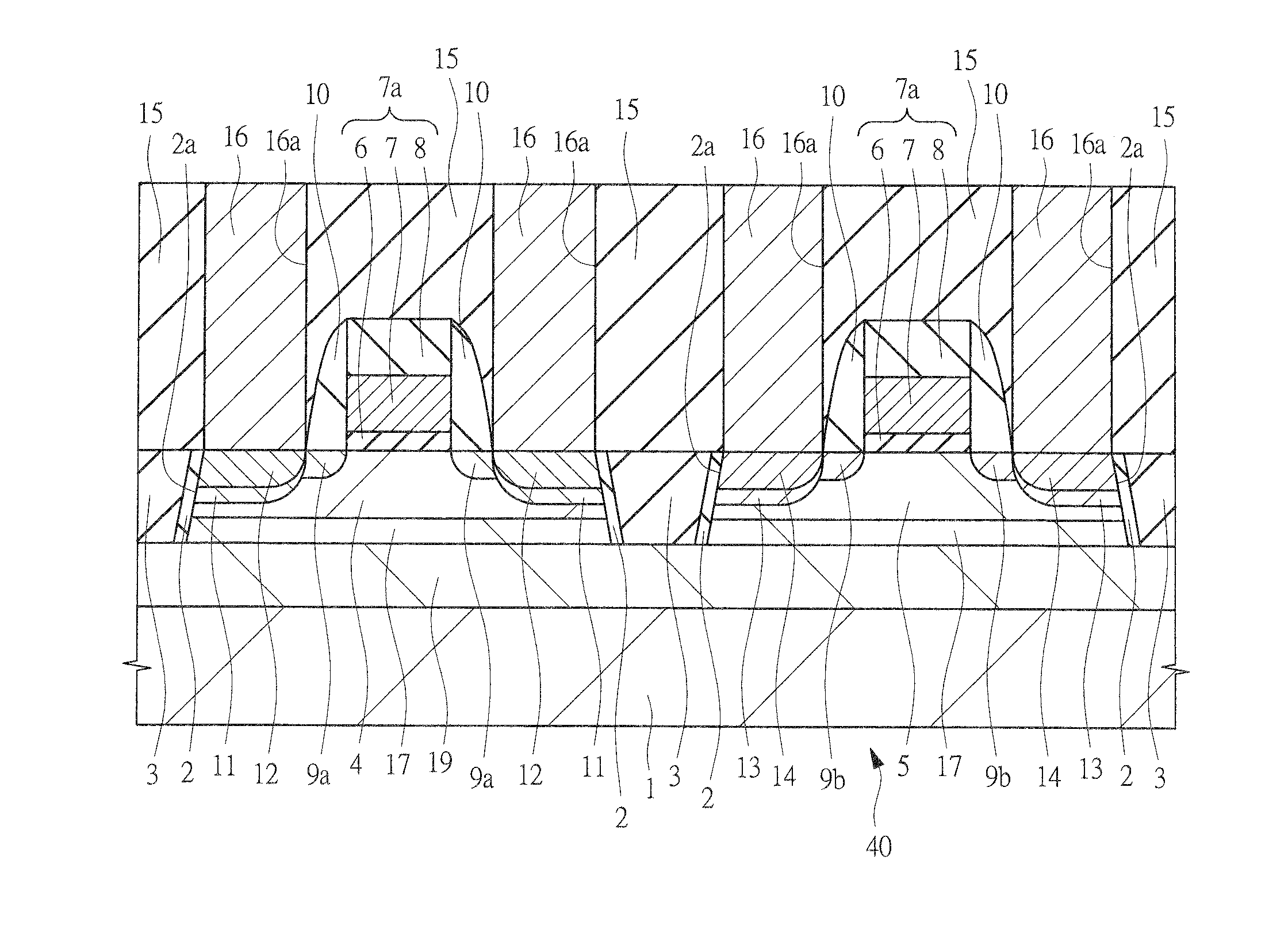

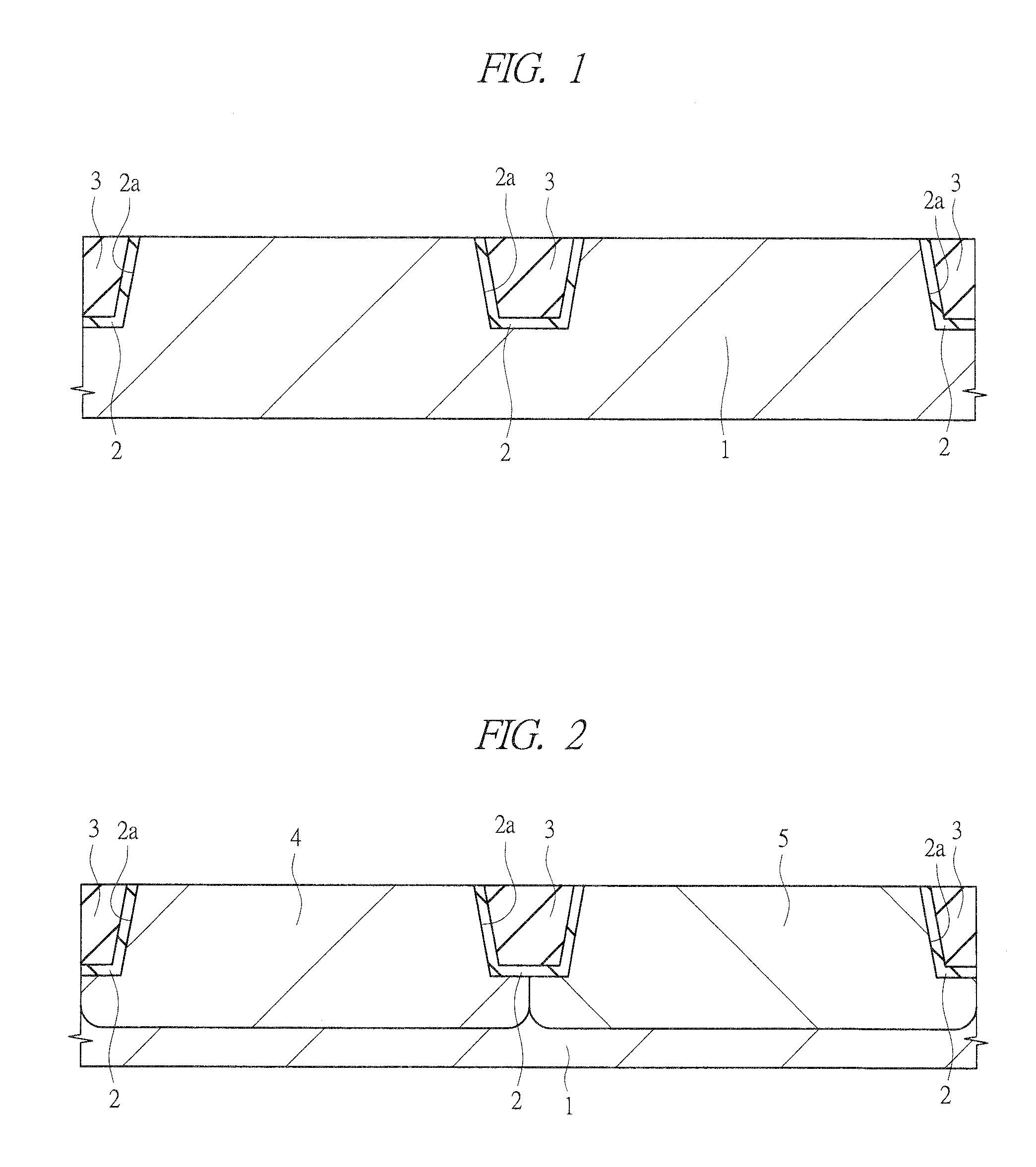

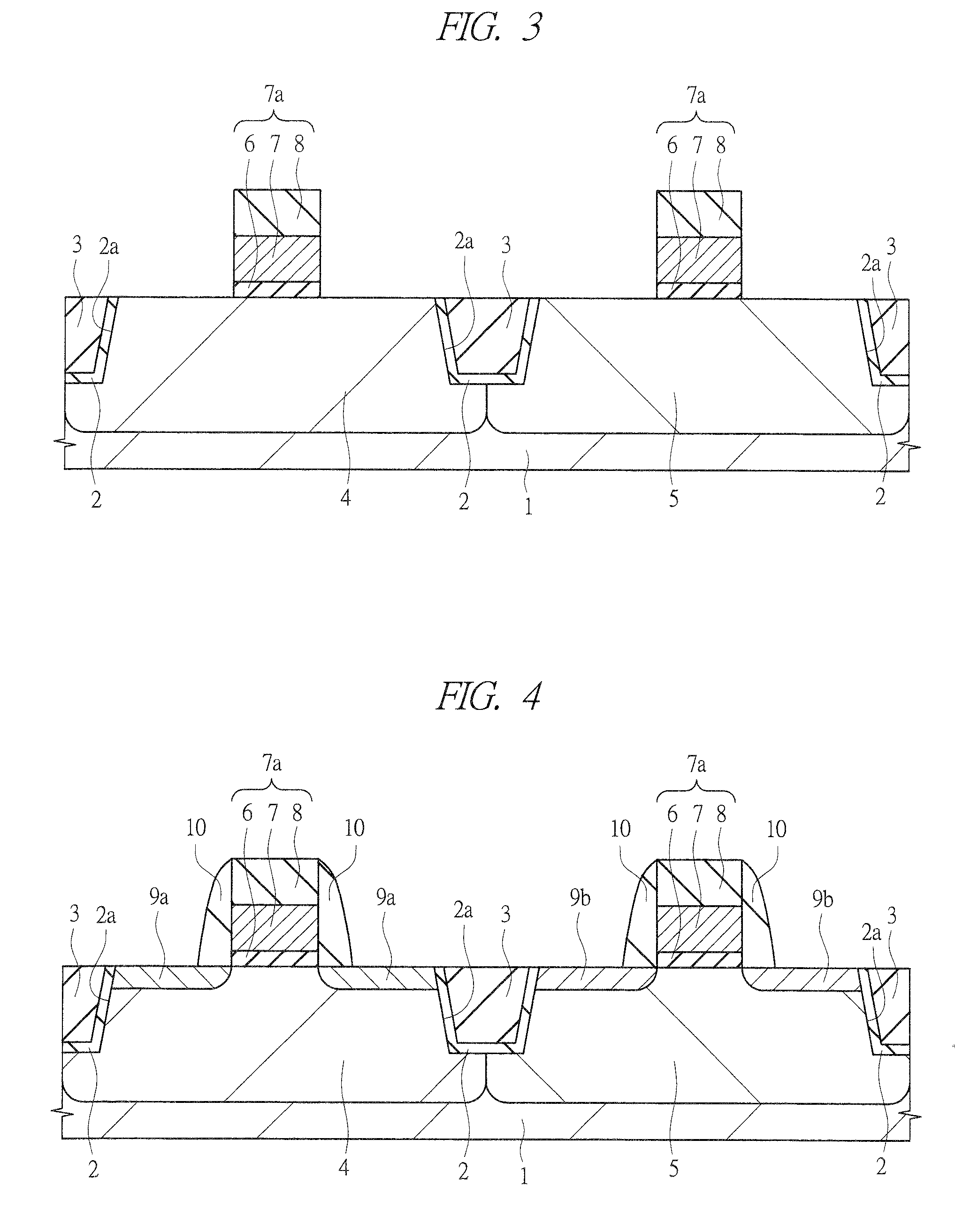

Semiconductor device and manufacturing method thereof

InactiveUS20100140711A1Increased diffusion resistanceImprove performanceTransistorSolid-state devicesDislocationNitrogen

Generation of dislocation and increase of diffusion resistance at edge portions of source / drain regions in a CMIS are prevented. When source / drain regions in a CMIS are formed, argon is implanted to a P-well layer as a dislocation-suppressing element and nitrogen is implanted to an N-well layer as a dislocation-suppressing element before an ion implantation of impurities to a silicon substrate. In this manner, by separately implanting dislocation-suppressing elements suitable for each of the P-well layer and the N-well layer as well as suppressing the generation of dislocation, increase of diffusion resistance can be suppressed, yield can be improved, and the reliability of devices can be increased.

Owner:RENESAS ELECTRONICS CORP

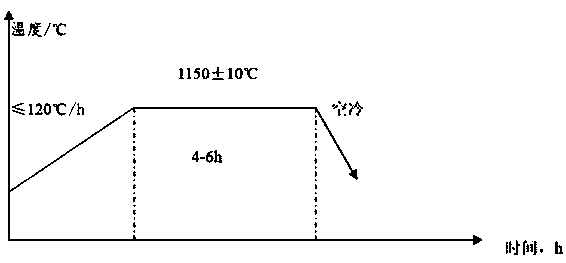

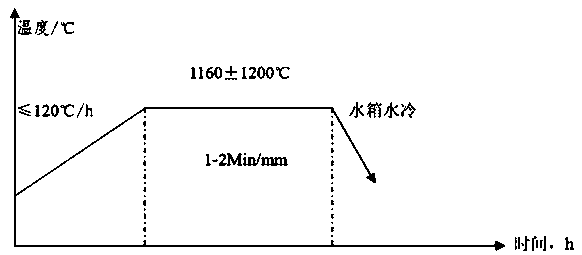

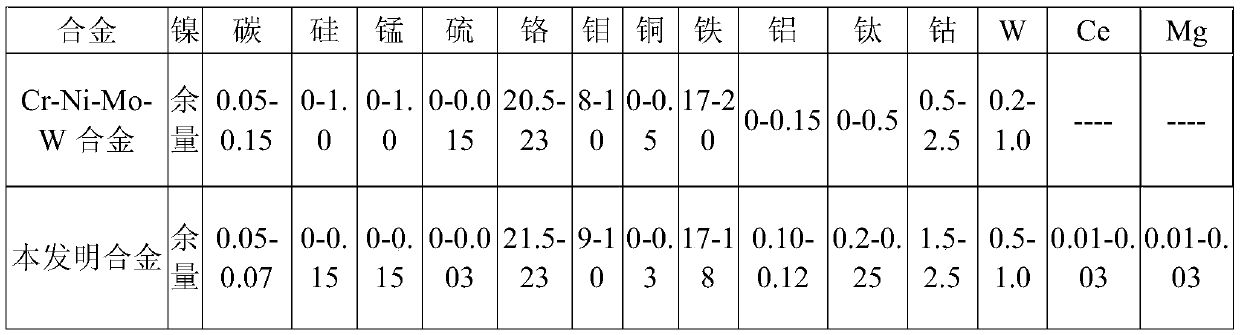

Manufacturing method for alloys with excellent durability performance under high temperature and high pressure conditions

ActiveCN109988927AManufacturing method of alloy with excellent durabilityImprove high temperature strengthAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial strength using tensile/compressive forcesRare earthHigh pressure

The invention provides a manufacturing method for alloys with excellent durability performance under high temperature and high pressure conditions. The manufacturing method for the alloys with the excellent durability performance under the high temperature and high pressure conditions comprises the following steps of (1) raw material preparation, (2) vacuum smelting, (3) electroslag remelting, (4)forging, (5) heat treatment, and (6) durability performance testing, sampling, peeling, inspection, packaging and storage, wherein the step 2 comprises the steps of (2.1) charging, (2.2) melting, (2.3) refining, (2.4) pouring, and the manufacture of the alloys with the excellent durability performance under the high temperature and high pressure conditions is completed. On the one hand, the manufacturing method optimizes the design of alloy elements, moreover, the traditional vacuum degassing and desulphurization technology is combined, and the desulphurization and degassing effect of using Ni-Mg and rare earth is especially increased; and on the other hand, the heat treatment process of a Cr-Ni-Mo-W alloy is optimized, and high end Cr-Ni-Mo-W alloy steel with a lasting life of more than500 hours is successfully manufactured under the conditions of 815 DEG C high temperature and 110 MPa high pressure.

Owner:江苏汉青特种合金有限公司

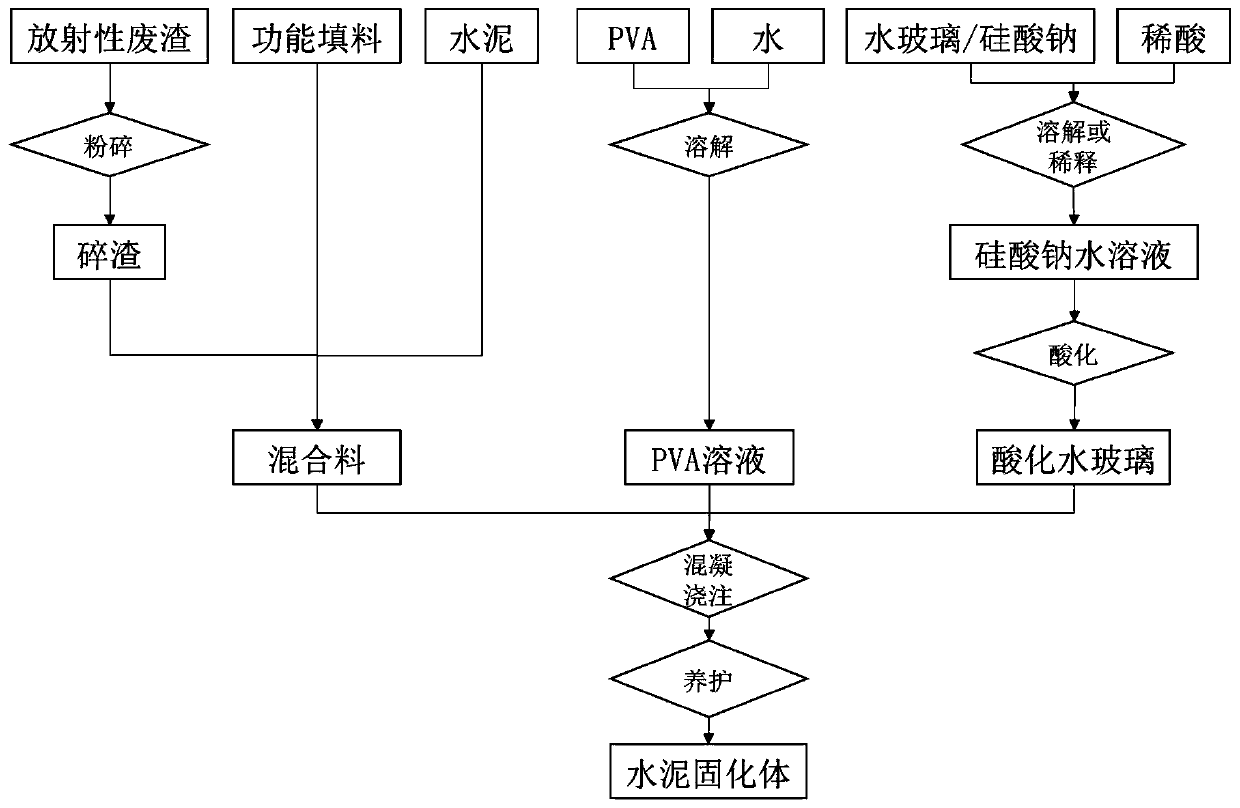

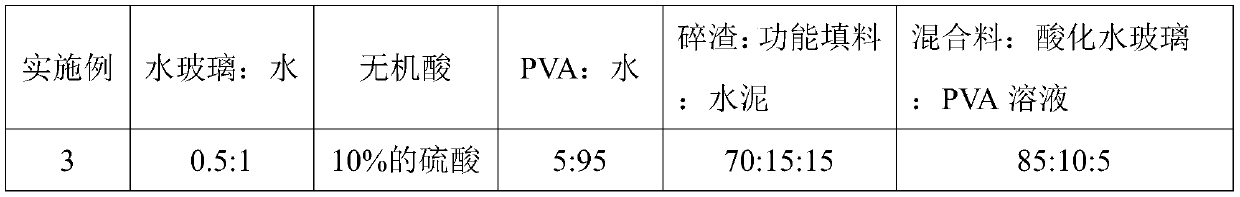

Solidification method of radioactive waste residues

The invention provides a solidification method of radioactive waste residues. The solidification method comprises the following steps: S1, crushing the radioactive waste residues to be treated into crushed residues; S2, uniformly mixing the crushed residues with a functional filler and cement to obtain a mixture; S3, adding water into sodium silicate or water glass to obtain a sodium silicate aqueous solution, and then adding inorganic acid to obtain acidified water glass; S4, adding PVA into water at a preset temperature, and dissolving to obtain a PVA solution; and S5, uniformly mixing the mixture with the acidified sodium silicate and the PVA solution to obtain a castable, and then pouring and maintaining the castable to obtain a cement solidified body waste residue bag. By utilizing the curing and film-forming effects of PVA and the filling effect of active silica gel in acidified sodium silicate, the strength and water resistance of a solidified body are remarkably improved, and the porosity of the solidified body is reduced, so that the ion diffusion resistance is increased, and the diffusion and exudation rate of nuclide ions is remarkably reduced.

Owner:NANHUA UNIV

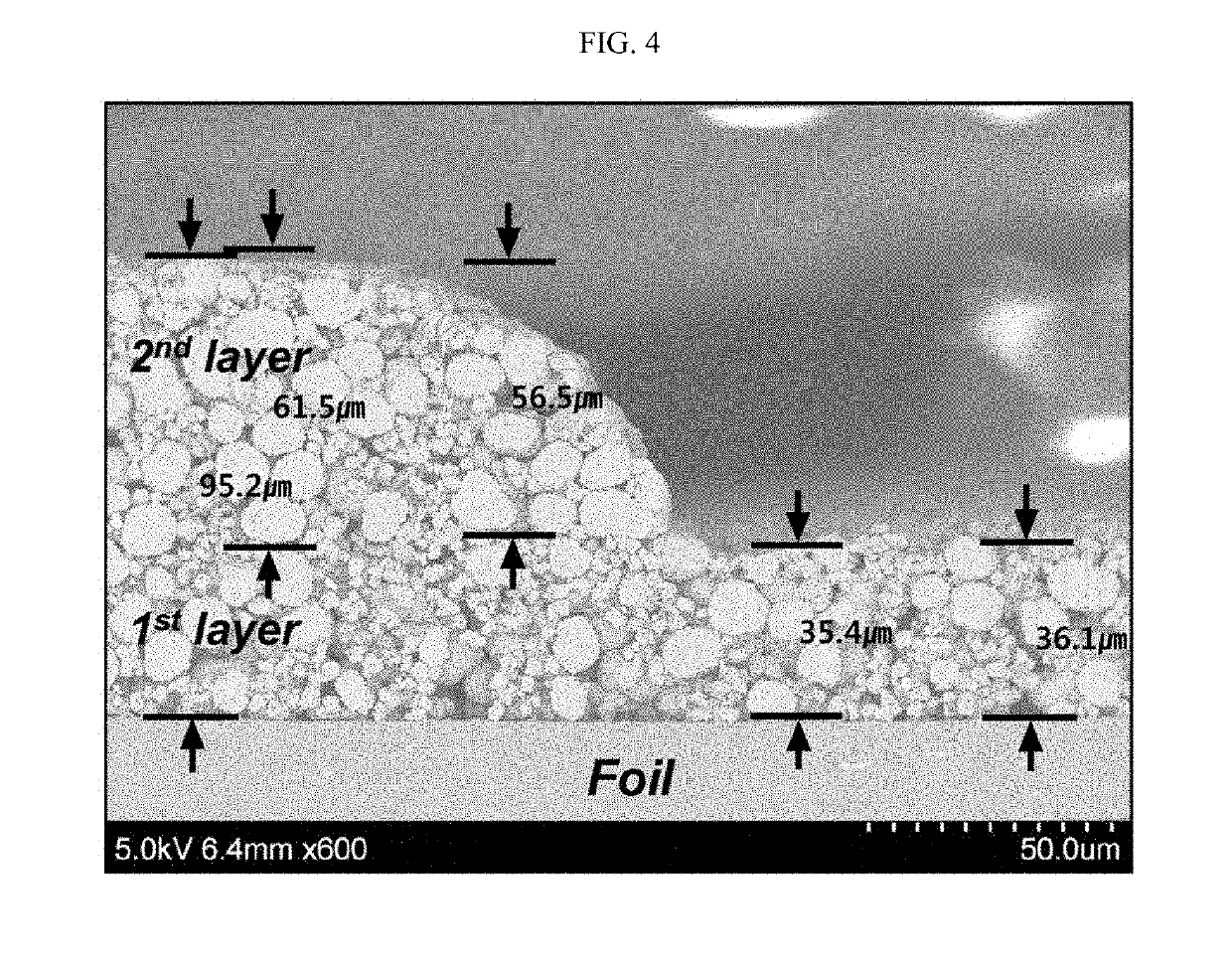

Positive Electrode For Lithium Secondary Battery And Method For Manufacturing The Same

ActiveUS20190312259A1Improve high temperature storage performanceIncreased diffusion resistanceElectrode thermal treatmentFinal product manufactureLithiumEngineering

A positive electrode for a lithium secondary battery includes a positive electrode current collector; a lower positive electrode active material layer disposed on at least one surface of the positive electrode current collector; and an upper positive electrode active material layer disposed on the lower positive electrode active material layer, wherein the lower positive electrode active material layer includes 90% or more of a sphere-type carbonaceous conductive material as a conductive material, the upper positive electrode active material layer includes 90% or more of a needle-type carbonaceous conductive material as a conductive material, and the content of the conductive material contained in the lower positive electrode active material layer is larger than the content of the conductive material contained in the upper positive electrode active material layer.

Owner:LG ENERGY SOLUTION LTD

Preparation method of macroporous alumina support

ActiveCN103055949BKeep aliveExtended operating cycleCatalyst carriersDiffusion resistanceResidual oil

The invention discloses a preparation method of a macroporous alumina support. The method is characterized by taking sawdust produced in the wood processing industry as a pore-enlarging agent, enabling the sawdust to adsorb an inorganic aluminium salt solution after carbonizing treatment, and kneading, forming, drying and roasting the sawdust and an alumina precursor after drying the sawdust, thus obtaining the macroporous alumina support. The alumina support obtained by the method is larger in specific surface area, more concentrated in pore size distribution and high in mechanical strength, also contains part of macropores with sizes more than 100nm, is suitable for preparing heavy / residual oil hydrogenation catalysts, and is favorable for removing macromolecular impurities in heavy / residual oil and delaying the increase of diffusion resistance in heavy / residual oil hydrogenation, thus being favorable for maintaining the activities of the hydrogenation catalysts and lengthening the running period.

Owner:CHINA PETROLEUM & CHEM CORP +1

Coating of copper and silver air bridge structures to improve electromigration resistance and other applications

InactiveUS7049219B1Reduce electromigrationReduce solubilitySemiconductor/solid-state device detailsSolid-state devicesCapacitanceAir bridge

An improved electrical interconnect for an integrated circuit and methods for providing the same are disclosed. The electrical interconnect includes an air bridge extending through a gaseous medium so as to reduce the capacitance of the interconnect. The air bridge is supported at a first and second end such that the air bridge is suspended above the substrate. The air bridge comprises a highly conductive material, such as silver, so as to provide the air bridge with a reduced resistivity. To inhibit gaseous medium from contaminating the air bridge, the air bridge further comprises an adherent coating interposed between the air bridge and the gaseous medium. A method of forming the electrical interconnect is also disclosed, wherein, prior to forming the adherent coating, the conductive material is processed so as to form fewer grain boundaries, which enhances the electrical properties of the air bridge.

Owner:MICRON TECH INC

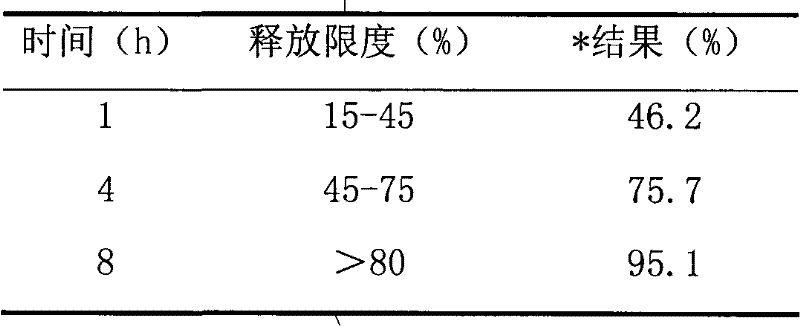

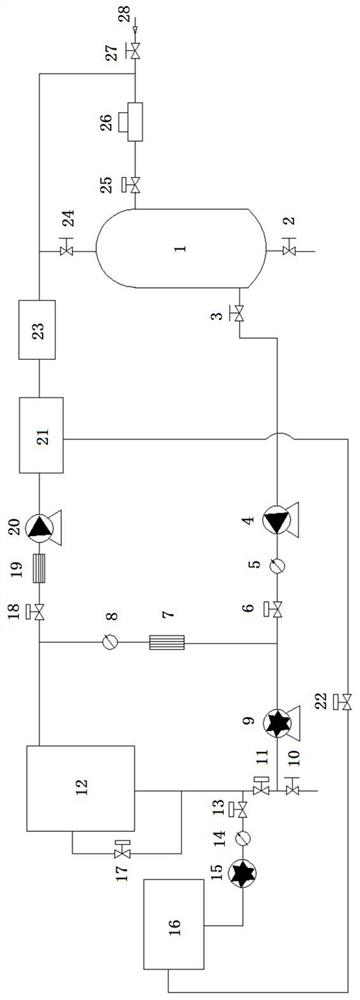

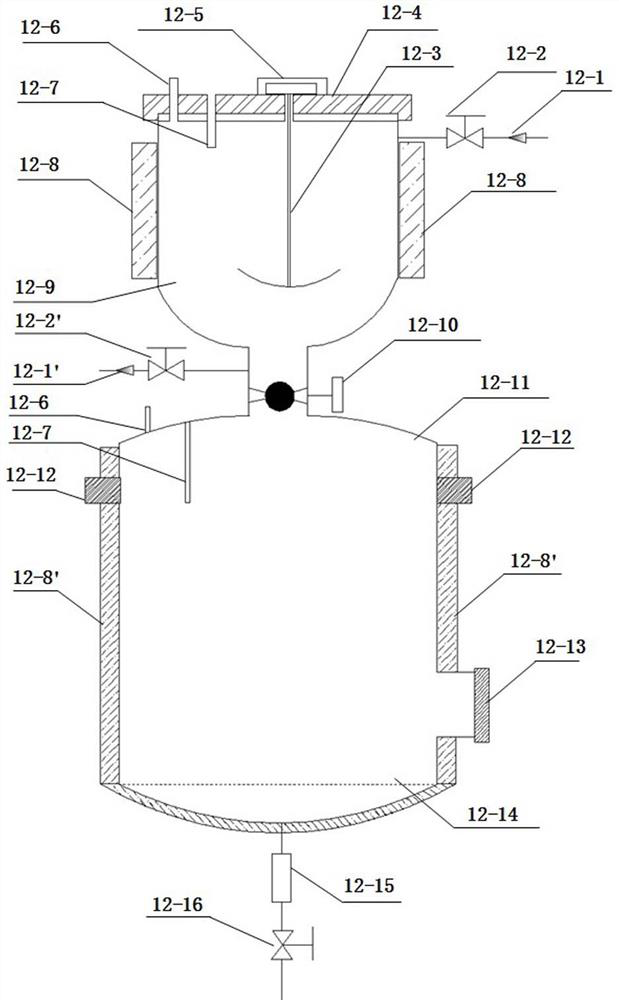

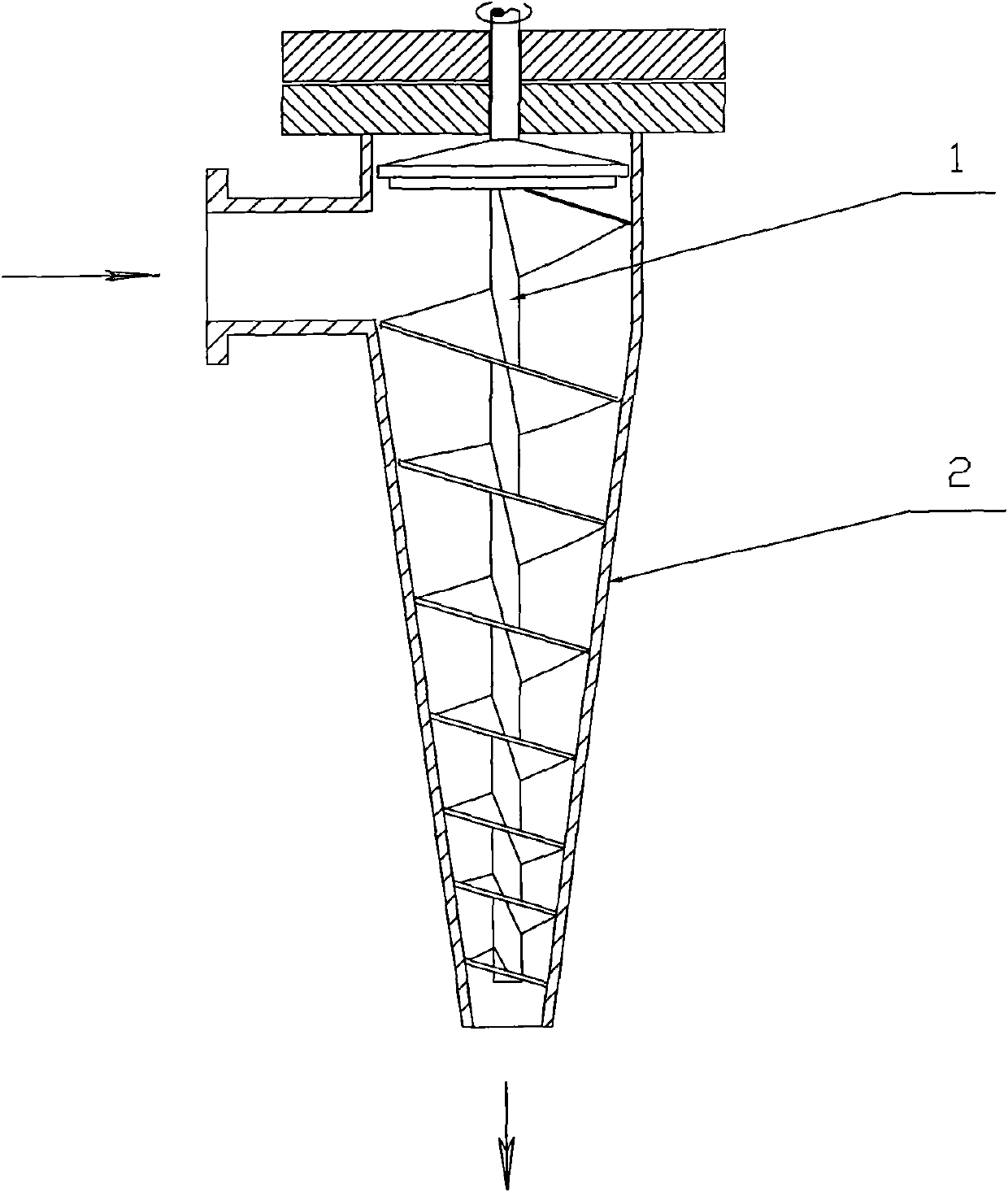

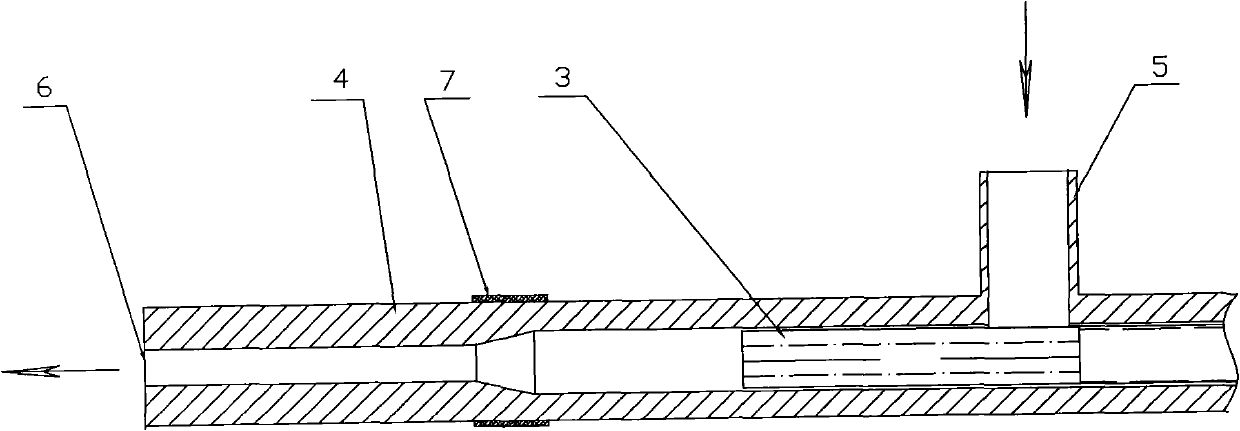

Multifunctional supercritical fluid processor for materials

ActiveCN111604009AUniform and efficient processingFacilitated DiffusionPressure vessels for chemical processBulk chemical productionProcess engineeringEnvironmental engineering

The invention discloses a multifunctional supercritical fluid processor for materials. The system comprises a high-temperature and high-pressure fluid puffing processing system provided with a high-temperature and high-pressure fluid treatment area and a fluid puffing buffer area, an auxiliary medium pressurization system, a carbon dioxide medium pressurization system, a circulation treatment system, a carbon dioxide separation and recovery system and an auxiliary medium separation and recovery system. The high-temperature and high-pressure fluid treatment area, the fluid puffing buffer area and the quick-opening valve connected with the fluid puffing buffer area can effectively realize processing treatment on materials in different modes such as puffing, foaming and fragmentation according to process requirements, so that the functional diversity and the application range of the equipment are expanded; the auxiliary medium pressurization system can conveniently carry out independent or step-by-step puffing and other processing on a material mixed with a fluid medium in any proportion, pretreatment of the material before processing can be achieved, and the medium polarity of the carbon dioxide fluid in the processing process can be regulated and controlled in real time. The method has the advantages of wide adaptability, diversified processing modes, high efficiency, simplicityand convenience in operation, ecological environmental protection and the like.

Owner:SUZHOU UNIV

Production process of biomass carbon-based briquetted coal for replacing fossil fuel

The invention discloses biomass carbon-based briquetted coal for replacing fossil fuel. The biomass carbon-based briquetted coal for replacing fossil fuel, based on 100 mass parts of agricultural and forest biomass raw material, comprises the following auxiliary materials: 0.01 to 0.05 mass percent of swelling agent, 0.001 to 0.005 mass percent of potassium permanganate oxidizer and 0.1 to 0.5 percent of calcium lignosulphonate organic binder. The production process comprises: crushing, drying, mixing and stirring the raw materials; subjecting the stirred raw materials to primary prepressing and secondary compression forming, and performing moisture regain preventing treatment; and finally, packaging finished product. Besides high density, convenience for storage and transport, high combustibility, high combustion performance, high heat efficiency, the biomass carbon-based briquetted coal produced by the process also has the advantages of generating less ash, hardly generating SO2 andNOx during combustion, avoiding environment pollution and the like. The carbon-based fuel disclosed by the invention is prepared from widely available raw materials and is environment-friendly, and the environmental-protection benefit of the carbon-based fuel is very obvious.

Owner:周之海

Two-component epoxy anticorrosive coating

InactiveCN110396346AImprove anti-corrosion performanceImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsSolventSoybean oil

The invention discloses a two-component epoxy anticorrosive coating, and belongs to the technical field of polymer anticorrosive materials. The coating is prepared by the following steps: sequentiallyweighing the following components in parts by weight: 40-60 parts of mixed epoxy resin, 30-40 parts of a solvent, 4-8 parts of a dispersing agent, 5-8 parts of a levelling agent, 4-8 parts of a coupling agent, 10-12 parts of epoxidized soybean oil and 20-35 parts of an additive; mixing the mixed epoxy resin and the solvent in a stirrer, adding the dispersing agent, the levelling agent, the coupling agent, the epoxidized soybean oil and the additive into the stirrer, performing mixing under stirring for 30-40 minutes under the conditions that the temperature is 40-50 DEG C and the rotating speed is 300-400 r / min to obtain an A component; weighing 12-20 parts of a curing agent to obtain a B component; and separately packaging the A component and the B component to obtain the two-component epoxy anticorrosive coating. The epoxy anticorrosive coating prepared by the technical solution of the invention has the characteristic of excellent corrosion resistance, and has wide prospects in development of technical industry of high polymer anticorrosive materials.

Owner:蓝海利

Zein-based nanometer sunscreen agent, and preparation method and application thereof

ActiveCN108815007AImprove light protection efficiencyImprove photostabilityCosmetic preparationsToilet preparationsSunscreen agentsLight activation

The invention discloses a zein-based nanometer sunscreen agent, and a preparation method and an application thereof. The nanometer sunscreen agent comprises zein and an organic sunscreen agent encapsulated by the zein, and the surface of the organic sunscreen agent is coated with the zein. The nanometer sunscreen agent has the advantages of mild synthesis conditions, short reaction time, effectiveness in inhibition of direct contact of the organic sunscreen agent with skins, reduction of direct contact of the organic sunscreen agent and reactive oxygen species (ROS) generated after light activation with skins, and inhibition of a series of phototoxicity caused by transdermal absorption, and is a novel nanometer sunscreen agent material.

Owner:JIANGSU PROVINCE HOSPITAL THE FIRST AFFILIATED HOSPITAL WITH NANJING MEDICAL UNIV

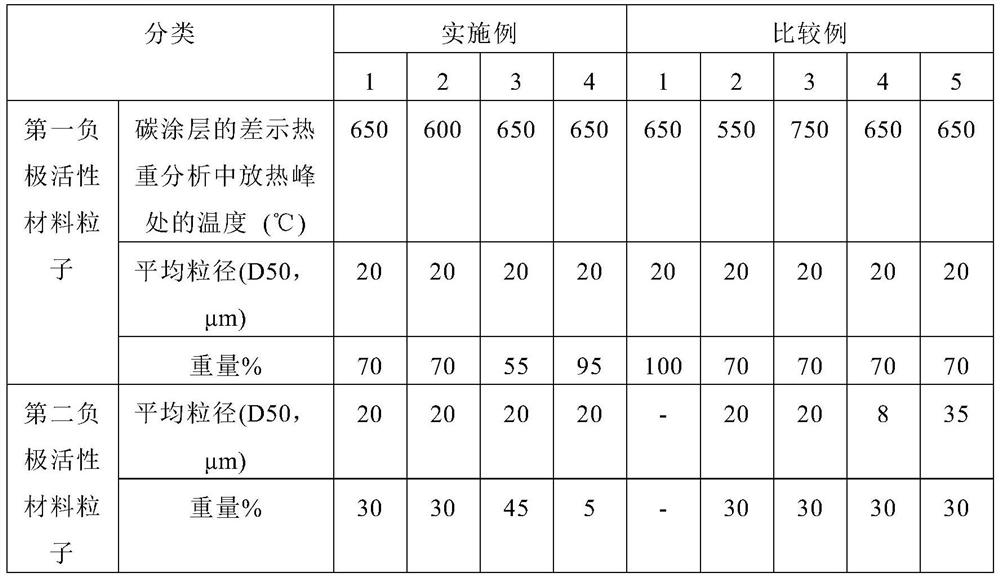

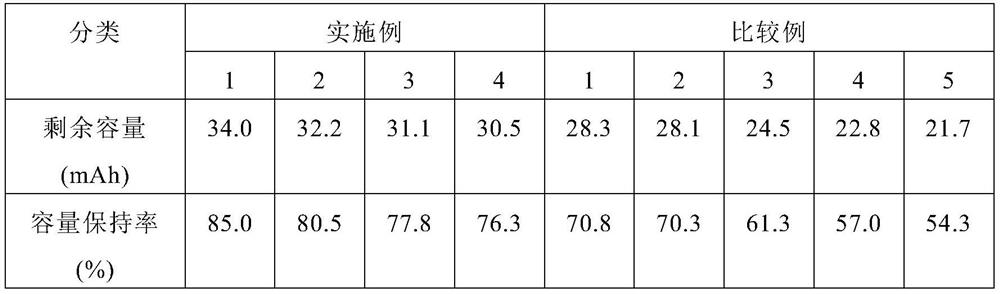

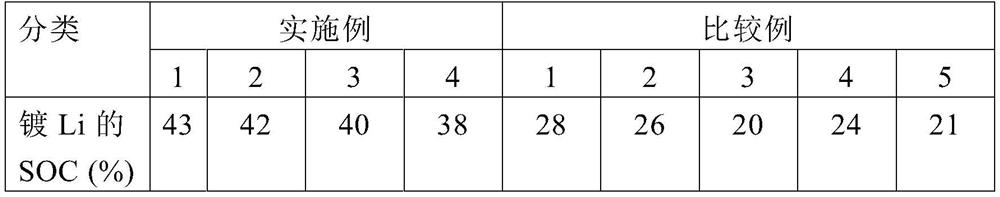

Negative electrode active material for lithium secondary battery, manufacturing method therefor, lithium secondary battery negative electrode comprising same, and lithium secondary battery

The present invention provides a negative electrode active material for a lithium secondary battery, the negative electrode active material comprising: first negative electrode active material particles comprising first artificial graphite particles, and a carbon coating layer which is formed on the first artificial graphite particles and comprises hard carbon; and second negative electrode activematerial particles comprising second artificial graphite particles, wherein the difference in average particle diameter (D50) between the first negative electrode active material particles and the second negative electrode active material particles is at most 5 um, and the temperature at a heat radiation peak during a differential thermogravimetric analysis of the carbon coating layer is 580 DEGto 690 DEG.

Owner:LG ENERGY SOLUTION LTD

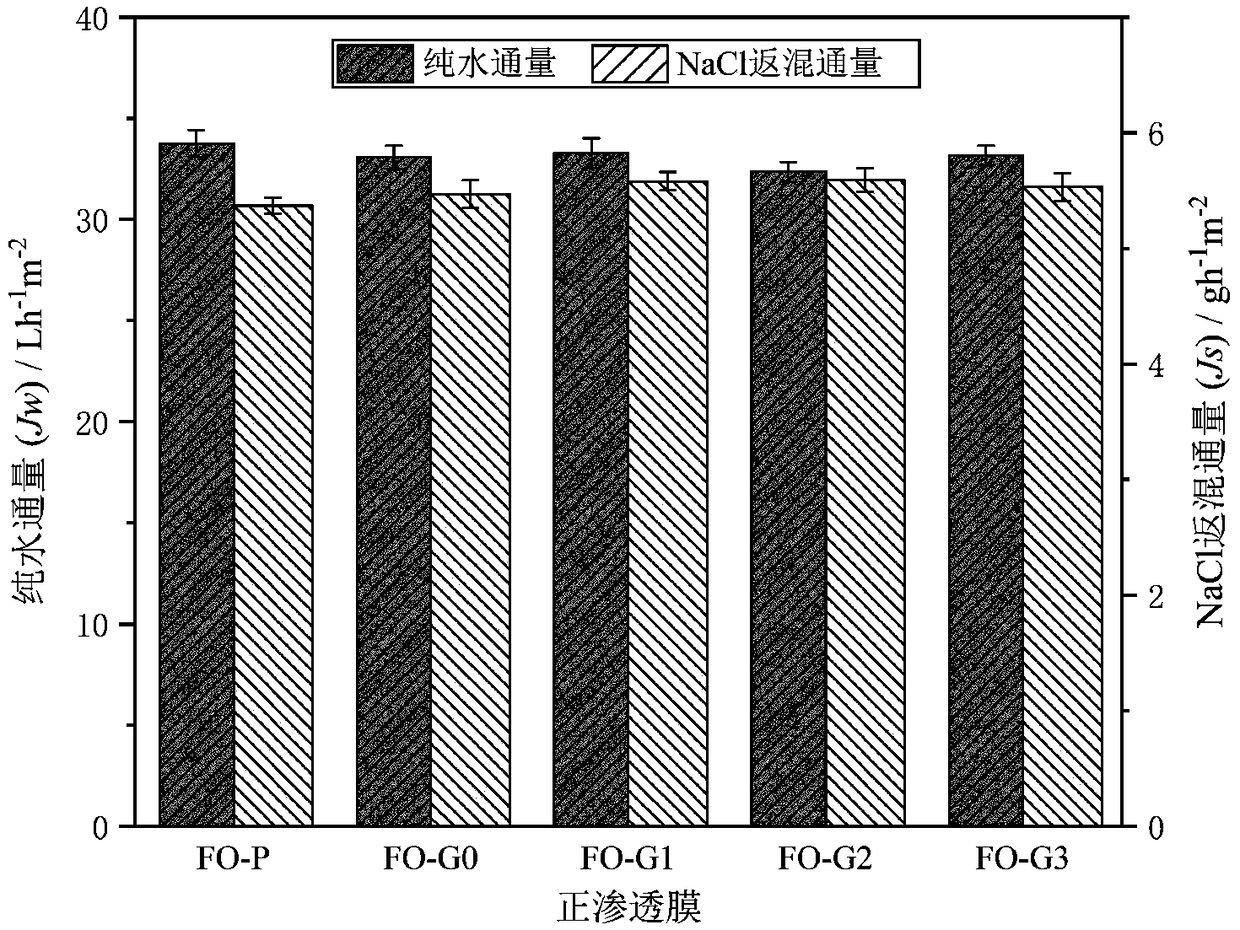

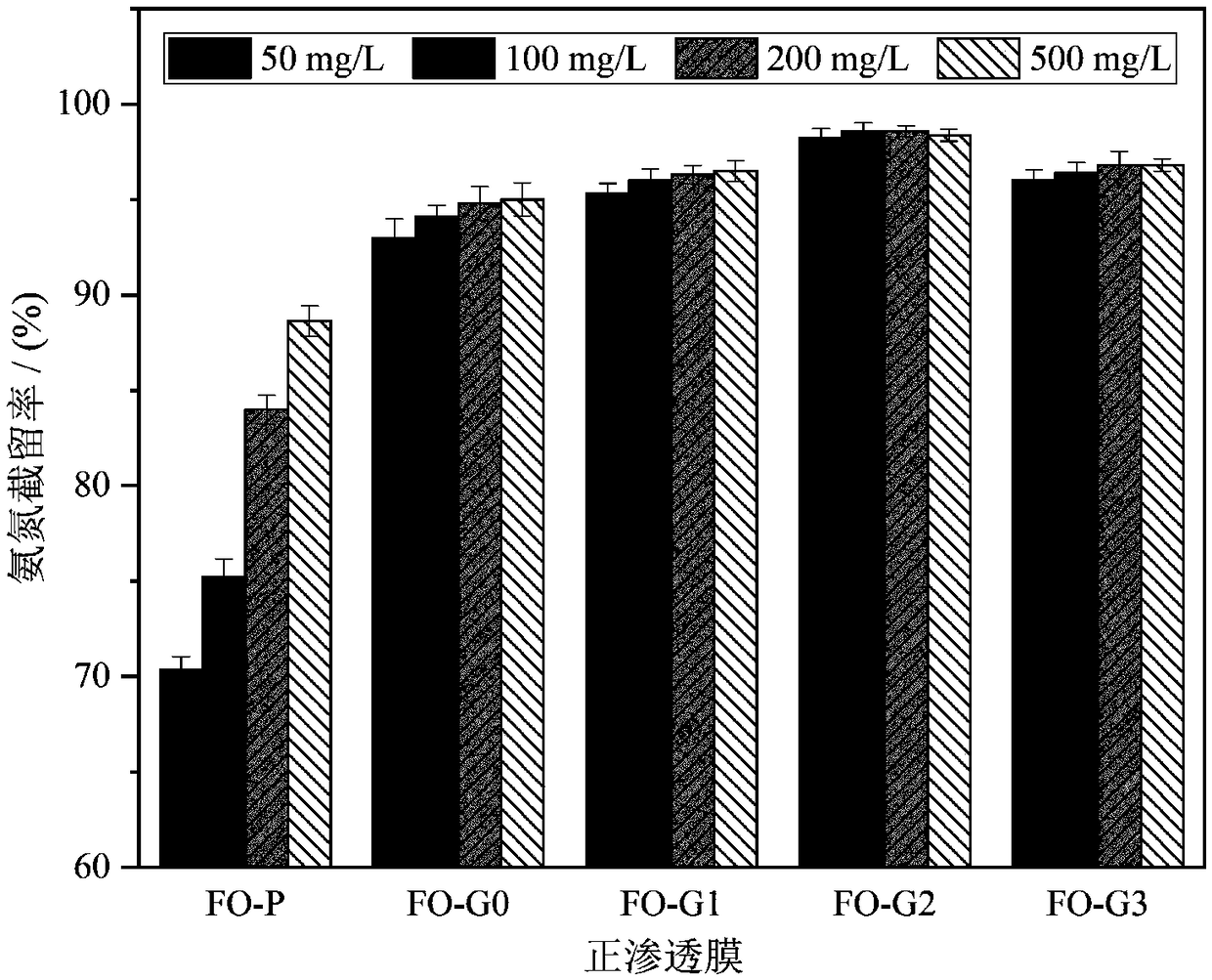

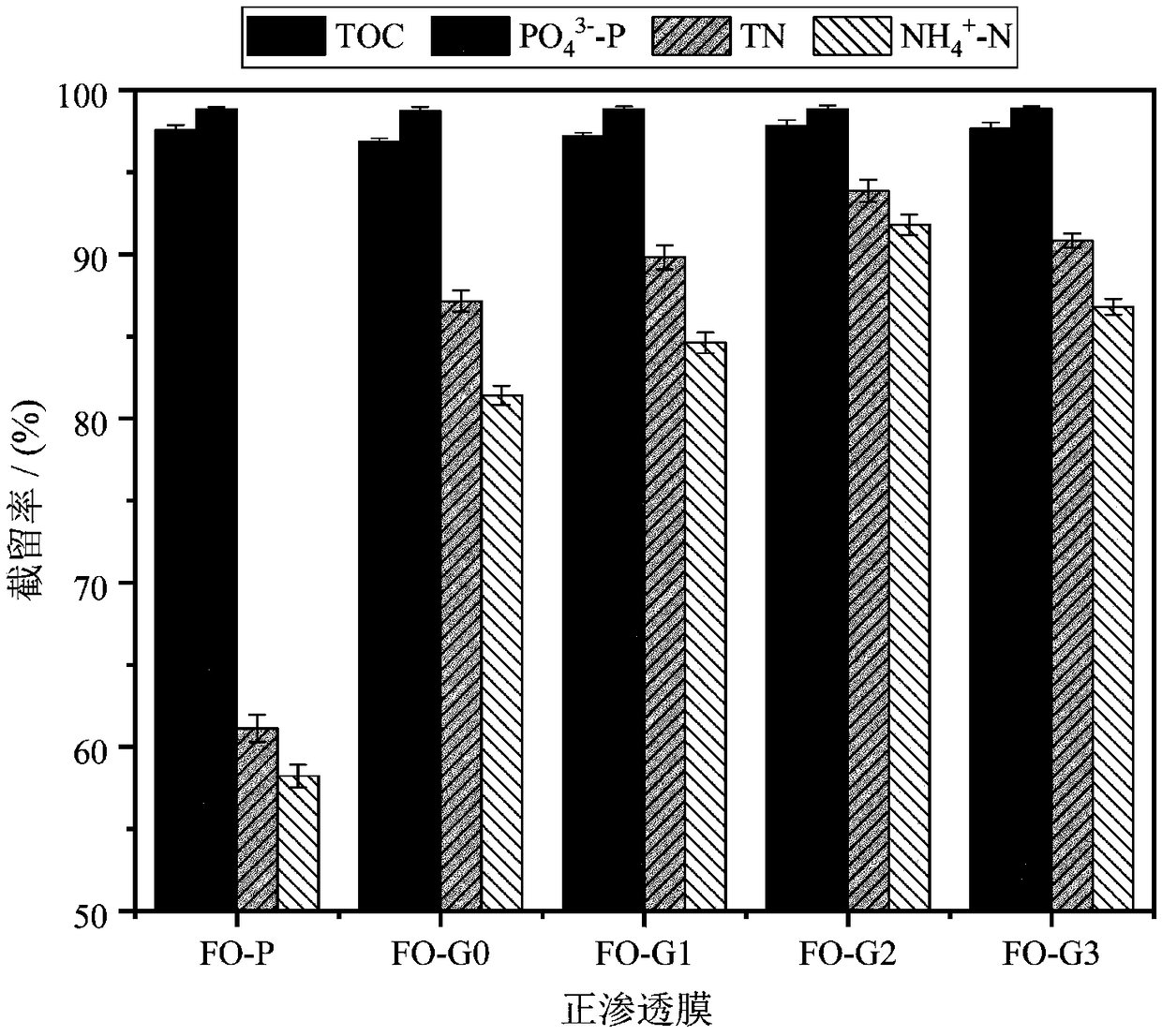

Positive osmosis membrane capable of trapping ammonia nitrogen and resisting membrane pollution, preparation method and applications thereof

InactiveCN109289561AImprove hydrophilicityImprove positive chargeSemi-permeable membranesMembranesDendrimerConcentration polarization

The invention discloses a positive osmosis membrane capable of trapping ammonia nitrogen and resisting membrane pollution, a preparation method and applications thereof, wherein the positive osmosis membrane is a polyamide amine dendrimer surface grafted composite membrane, the base layer of the composite membrane is sulfonated polyethersulfone, and the separation layer is polyamide. The specificpreparation steps comprise: 1, preparation of sulfonated polyethersulfone base membrane; 2, preparation of polyamide composite membrane; and 3, preparation of polyamide amine dendrimer surface graftedcomposite membrane. According to the present invention, the positive osmosis membrane prepared by the method can be used for concentrating domestic sewage; the sulfonated polyethersulfone in the prepared positive osmosis membrane can significantly increase the hydrophilicity of the support layer to reduce the concentration polarization in the membrane, such that the water flux of the membrane issubstantially improved; and the polyamide amine dendrimer grafted on the polyamide active layer surface can improve the repulsive force of the membrane to ammonia nitrogen and the hydrophilicity of the membrane surface, such that the ammonia nitrogen trapping ability and the pollution resistance of the grafted membrane can be improved.

Owner:HARBIN INST OF TECH

Liquid slow releasing compound fertilizer

InactiveCN1277786CImprove effective utilizationPlay a combined effectFertilizer mixturesDiffusion resistanceWater soluble

The delay-released liquid fertilizer consists of water soluble compounds of N, P, K, Fe, ZN, Mn, etc. as well as sodium polyacrylate, polyactylamide or other polymer material. It contains nutritious elements and rich water, and has high diffusion resistance in soil of retaining in the applied position reaching the delay-releasing effect. The present invention raises the utilization of nutritious elements and has outstanding comprehensive of multiple-component nutritious elements. The present invention is favorable to improving alkaline soil, increasing greatly the yield of crops and raising the commodity rate of agricultural product, and has wide application range.

Owner:BAIYIN CITY TECH DEV SERVICE CENT +1

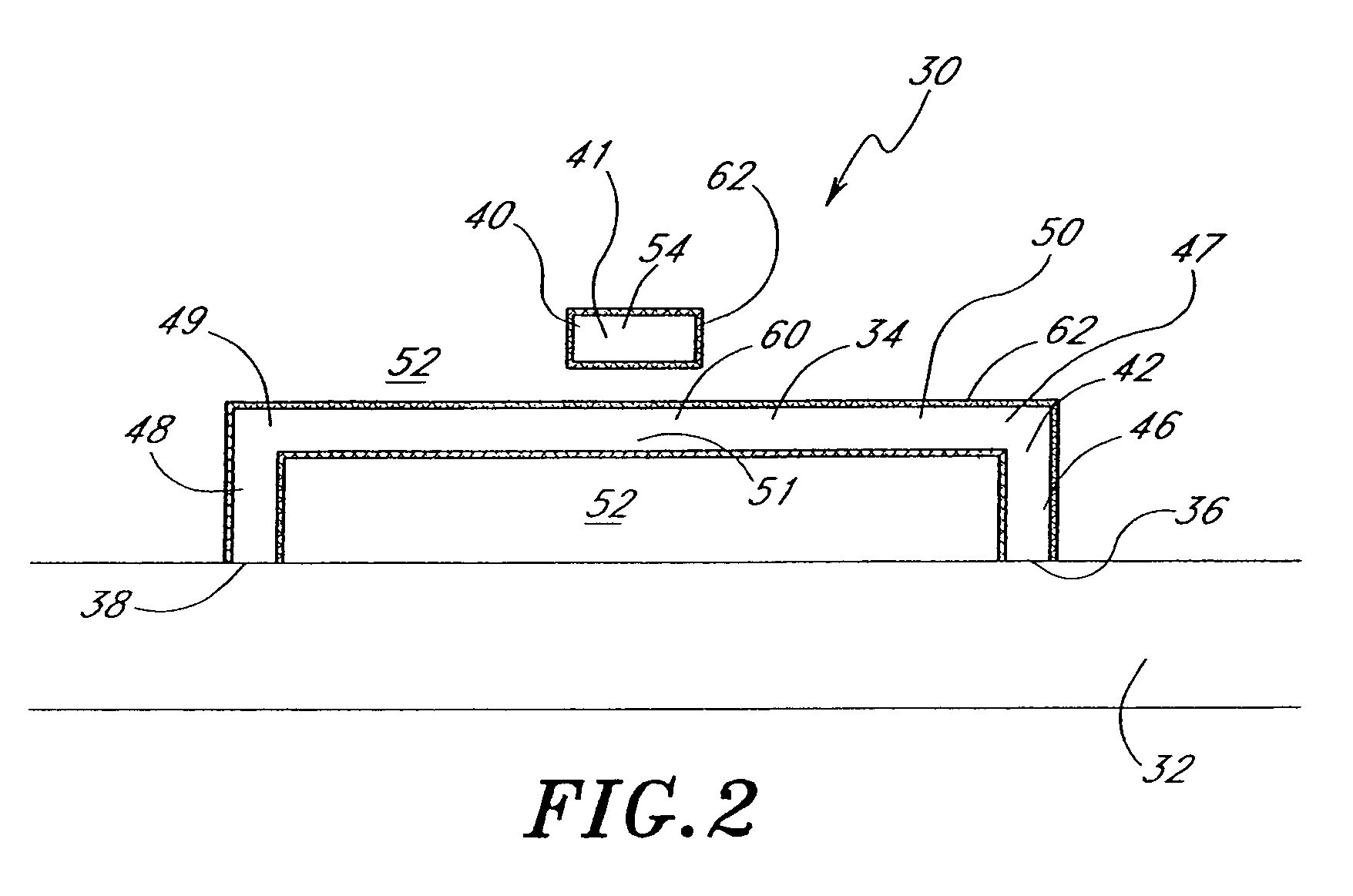

Multi-component container

ActiveUS10098812B2Increased diffusion resistanceIncrease inertiaInfusion syringesPharmaceutical containersThermoplasticPlastic materials

A container for storing and / or applying a substance is provided. The container includes a glass body having a substantially hollow cylindrical shape and enclosing a cavity, as well as a distal end with a first opening and a proximal end with a second opening. One or more connecting elements are attached to the glass body at the distal end and are made of a plastic material. The plastic material is a thermoplastic or thermosetting plastic material and the glass body and the or each connecting element are connected to each other by use of a joint. The connecting element arranged at the distal end includes a passage channel communicating with the first opening. The first and second openings are enclosed by end faces and immediately adjacent surfaces of the glass body and the connecting element(s) is / are attached to the glass body via the end faces and the immediately adjacent surfaces.

Owner:SCHOTT PHARMA SCHWEIZ AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com