Method for preparing IPN structure PMMA-PU high-transparency composite board through ultrasonic assistance

A high-transparency, ultrasonic-assisted technology, applied in the field of composite materials, can solve the problem of poor light transmission of plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Prepare 100 g of PMMA monomer solution, take 94.5 g of MMA monomer, add 5.0 g of cross-linking agent TMPTMA and 0.5 g of initiator AIBN, stir mechanically for 5 min, and set aside.

[0028] Prepare 100 g of PU monomer solution, take 34.8 g of isophorone diisocyanate IPDI, add 56.8 g of polypropylene glycol PPG, 7.7 g of chain extender BDO and 0.7 g of catalyst DBTDL, stir mechanically for 5 min, and set aside.

[0029] Use 250-mesh and 2000-mesh emery paper to coarsely grind and finely grind the sample, and use liquid paraffin and ultrafine silica powder to prepare an abrasive paste, and polish it on the surface of the flannelette to obtain a transparent glass with a thickness of about 3.5 mm. Composite panels, such as figure 2 shown. The optical performance of the composite board was tested by a photoelectric haze meter, and its transparency was 91.6%.

Embodiment 2

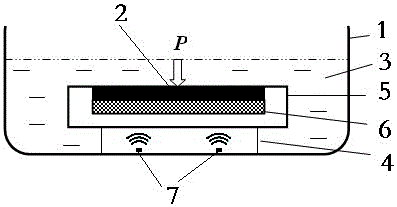

[0031] The PMMA and PU monomer solution in Example 1 are mechanically mixed, vacuum degassed, poured into a polytetrafluoroethylene mold, and the mixed solution is sealed by the upper pressure head of the mold, applying a constant pressure P=120 MPa, 50 degrees Celsius Under prepolymerization for 2 h. The mold was immersed in the water in the temperature-regulated low-frequency ultrasonic container, the water temperature was 60 degrees Celsius, the temperature was kept at 5 h, the temperature was raised to 70 degrees Celsius for 5 hours, the temperature was raised to 80 degrees Celsius for 5 hours, the temperature was raised to 95 degrees Celsius for 2 hours, and the PMMA with IPN structure was prepared. -PU transparent composite board.

[0032]Use 250-mesh and 2000-mesh emery paper to coarsely grind and finely grind the sample, and use liquid paraffin and ultrafine silica powder to prepare an abrasive paste, and polish it on the surface of the flannelette to obtain a transpar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparency | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com