Patents

Literature

95 results about "Carbon-based fuel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon-based fuel is any fuel principally from the oxidation or burning of carbon. Carbon-based fuels are of two main kinds, biofuels and fossil fuels. Whereas biofuels are derived from recent-growth organic matter and are typically harvested, as with logging of forests and cutting of corn, fossil fuels are of prehistoric origin and are extracted from the ground, the principal fossil fuels being oil, coal, and natural gas.

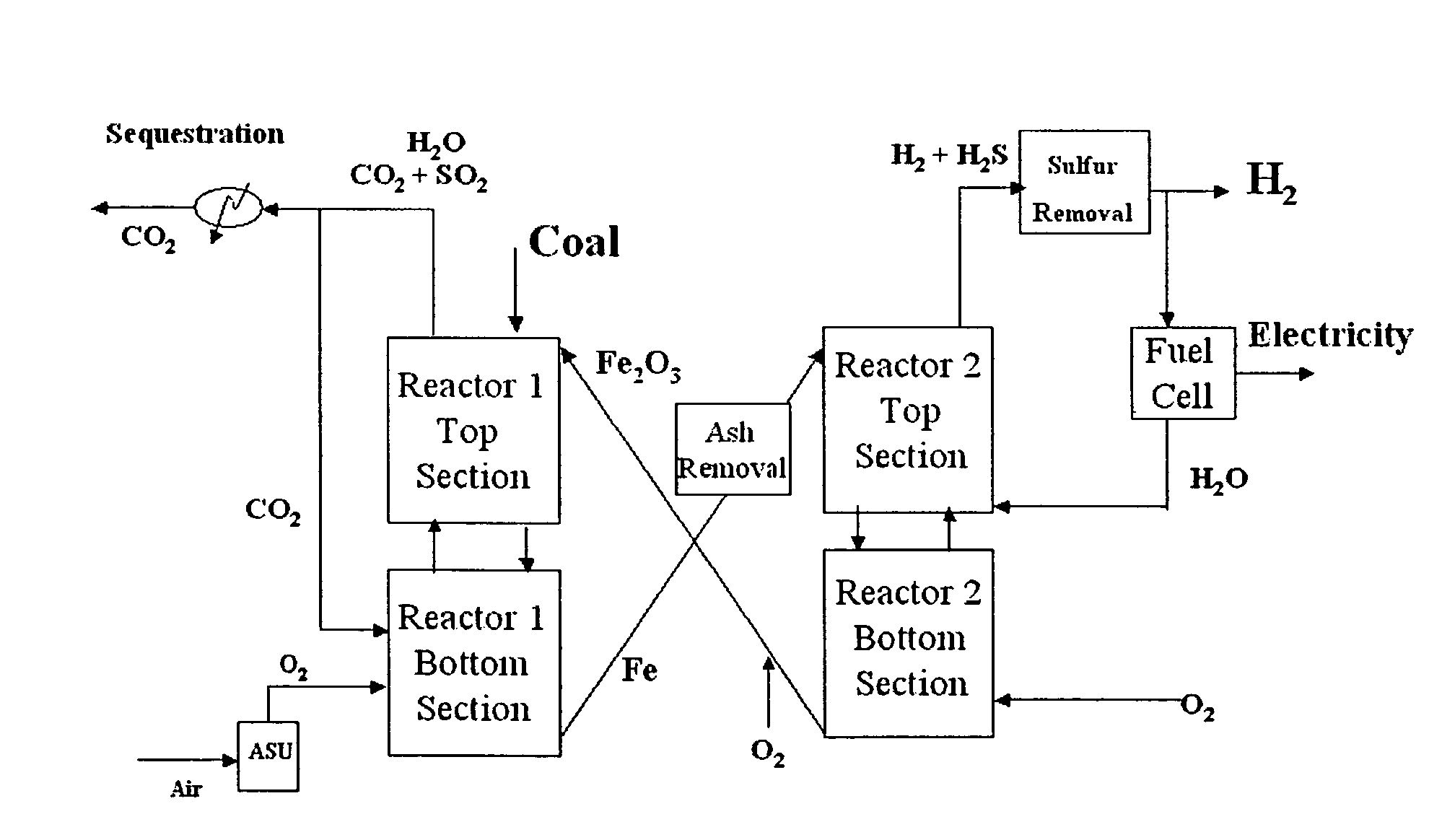

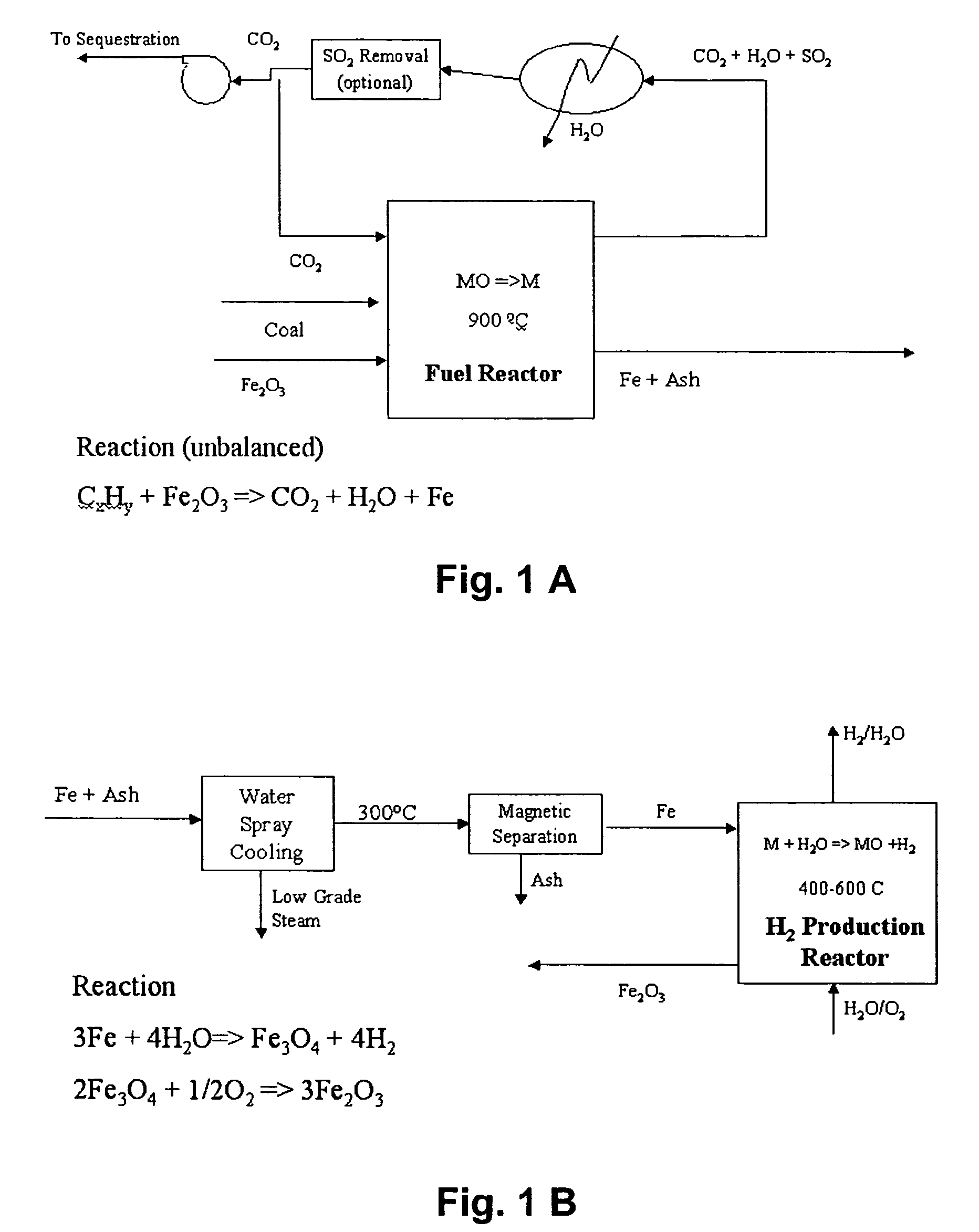

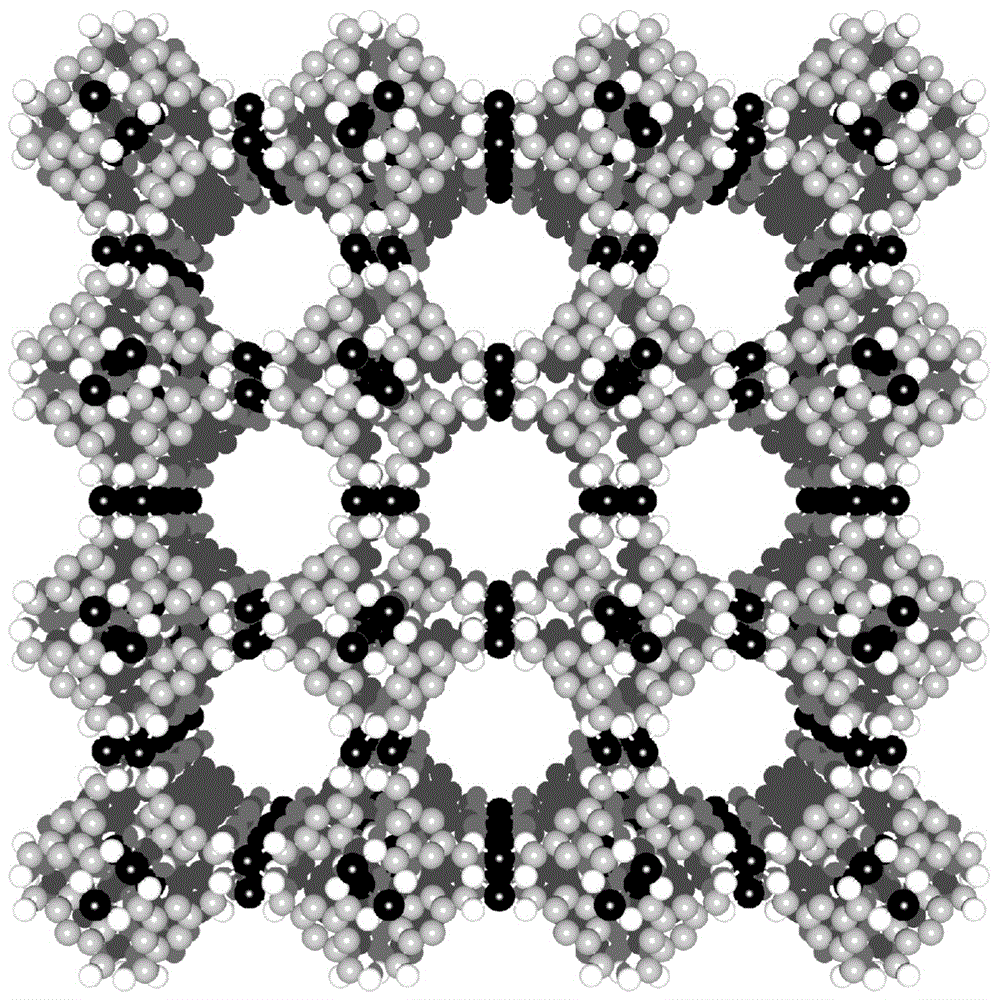

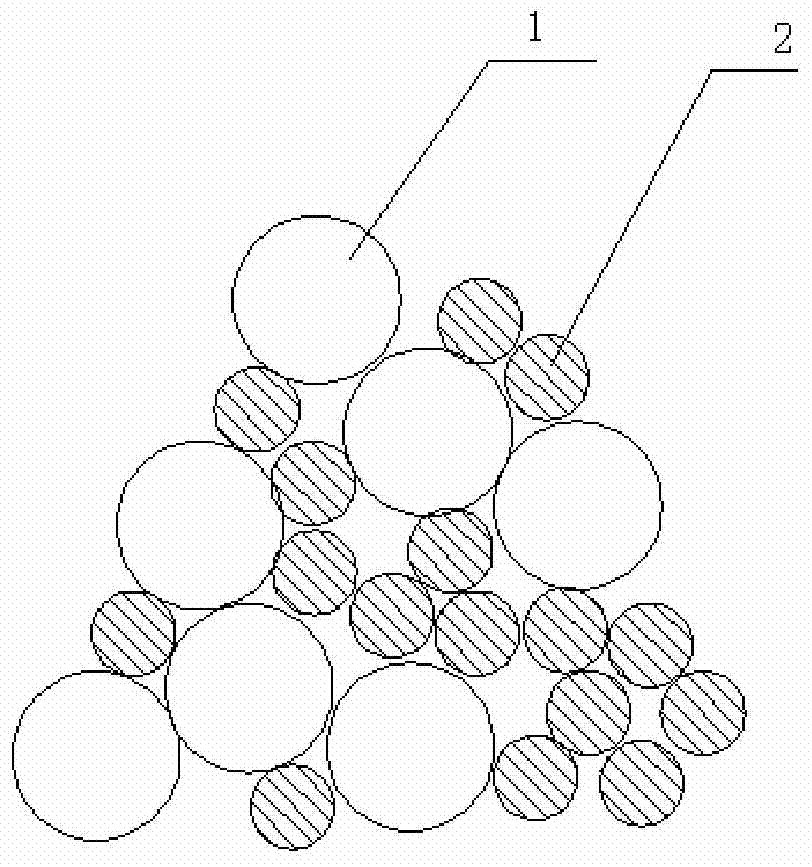

Combustion looping using composite oxygen carriers

ActiveUS20050175533A1Increase surface areaImprove energy conversion efficiencyHydrogen productionIndirect carbon-dioxide mitigationHydrogenCombustion

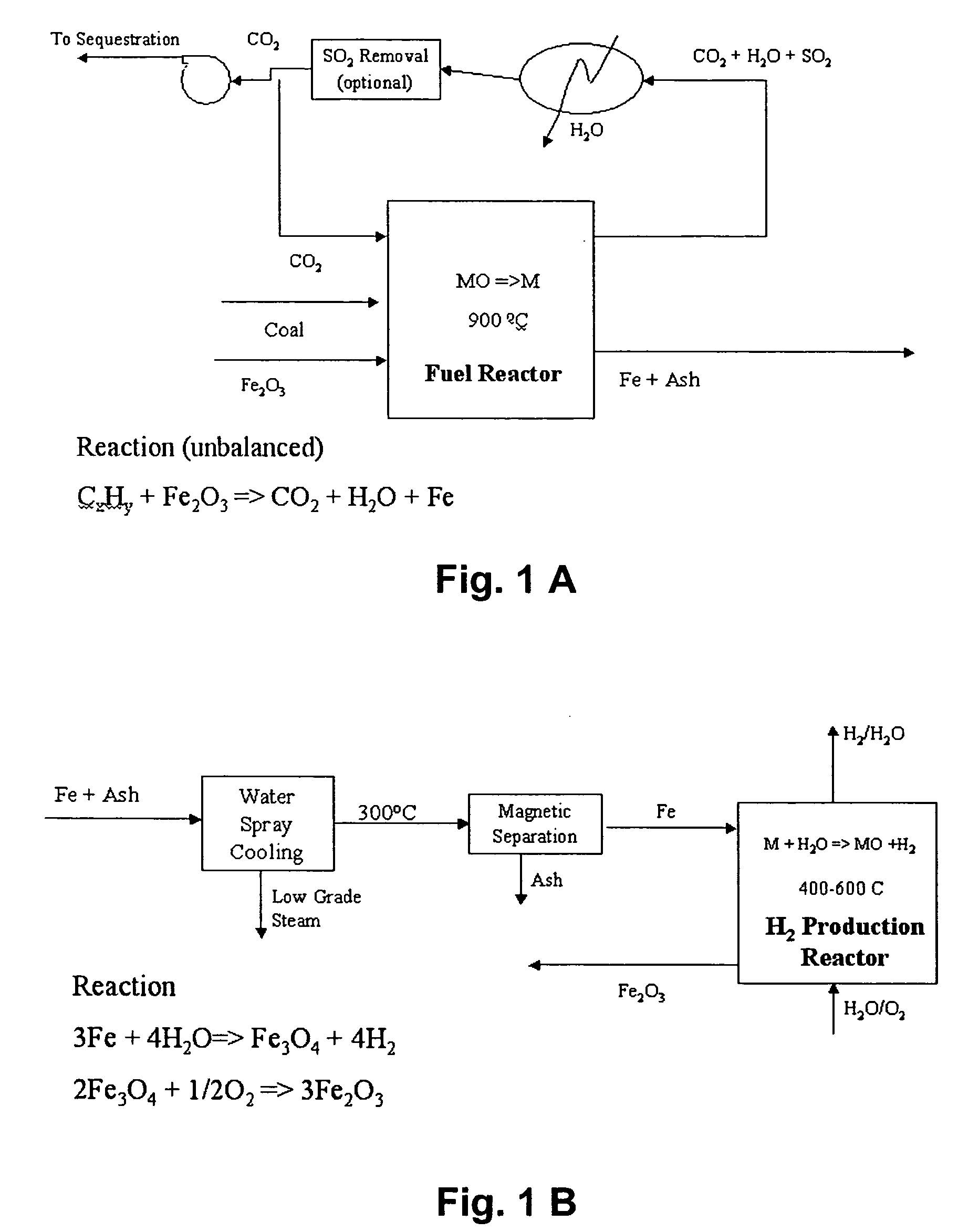

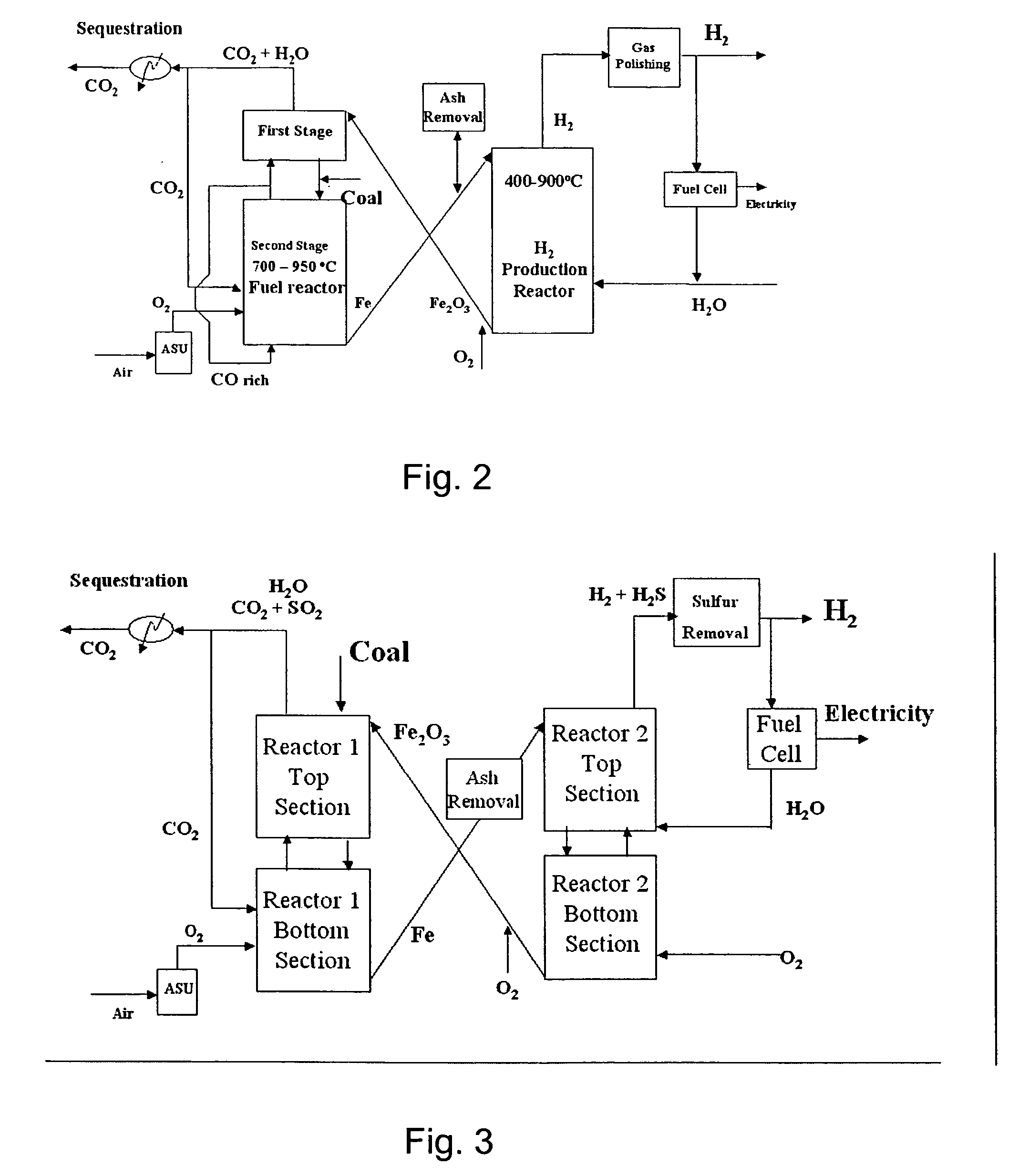

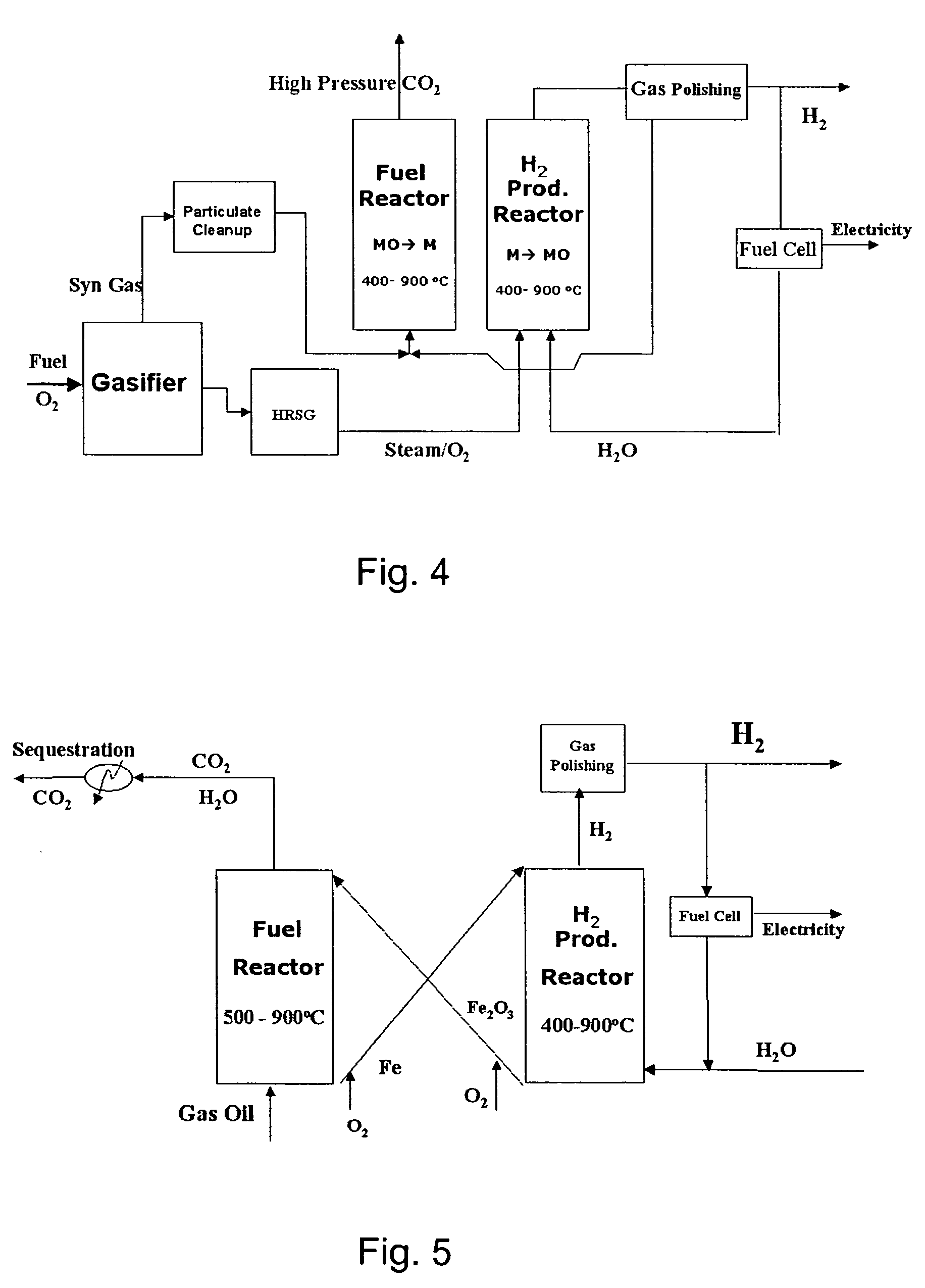

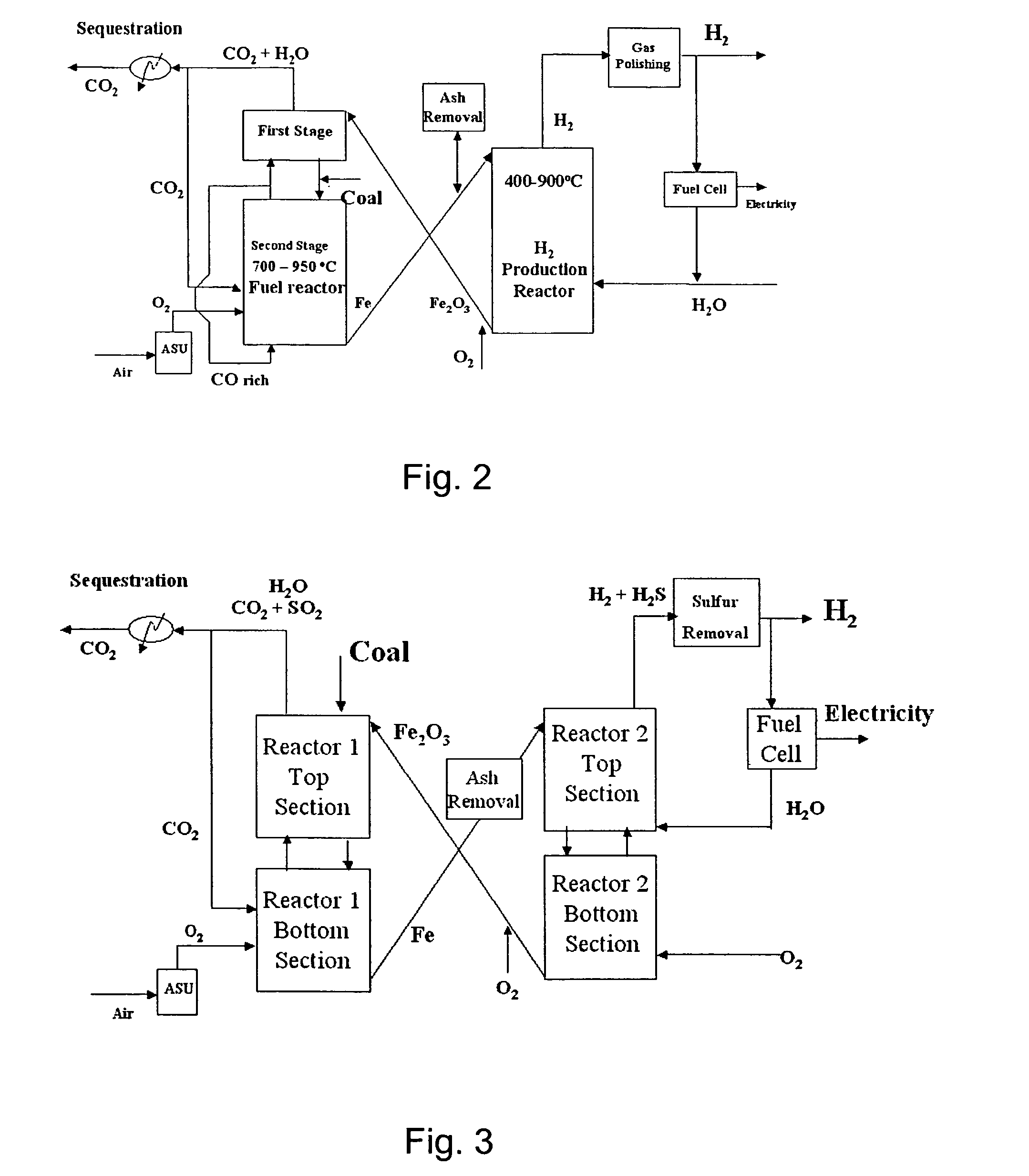

A method for producing hydrogen gas is provided and comprises reducing a metal oxide in a reduction reaction between a carbon-based fuel and a metal oxide to provide a reduced metal or metal oxide having a lower oxidation state, and oxidizing the reduced metal or metal oxide to produce hydrogen and a metal oxide having a higher oxidation state. The metal or metal oxide is provided in the form of a porous composite of a ceramic material containing the metal or metal oxide. The porous composite may comprise either a monolith, pellets, or particles.

Owner:OHIO STATE INNOVATION FOUND

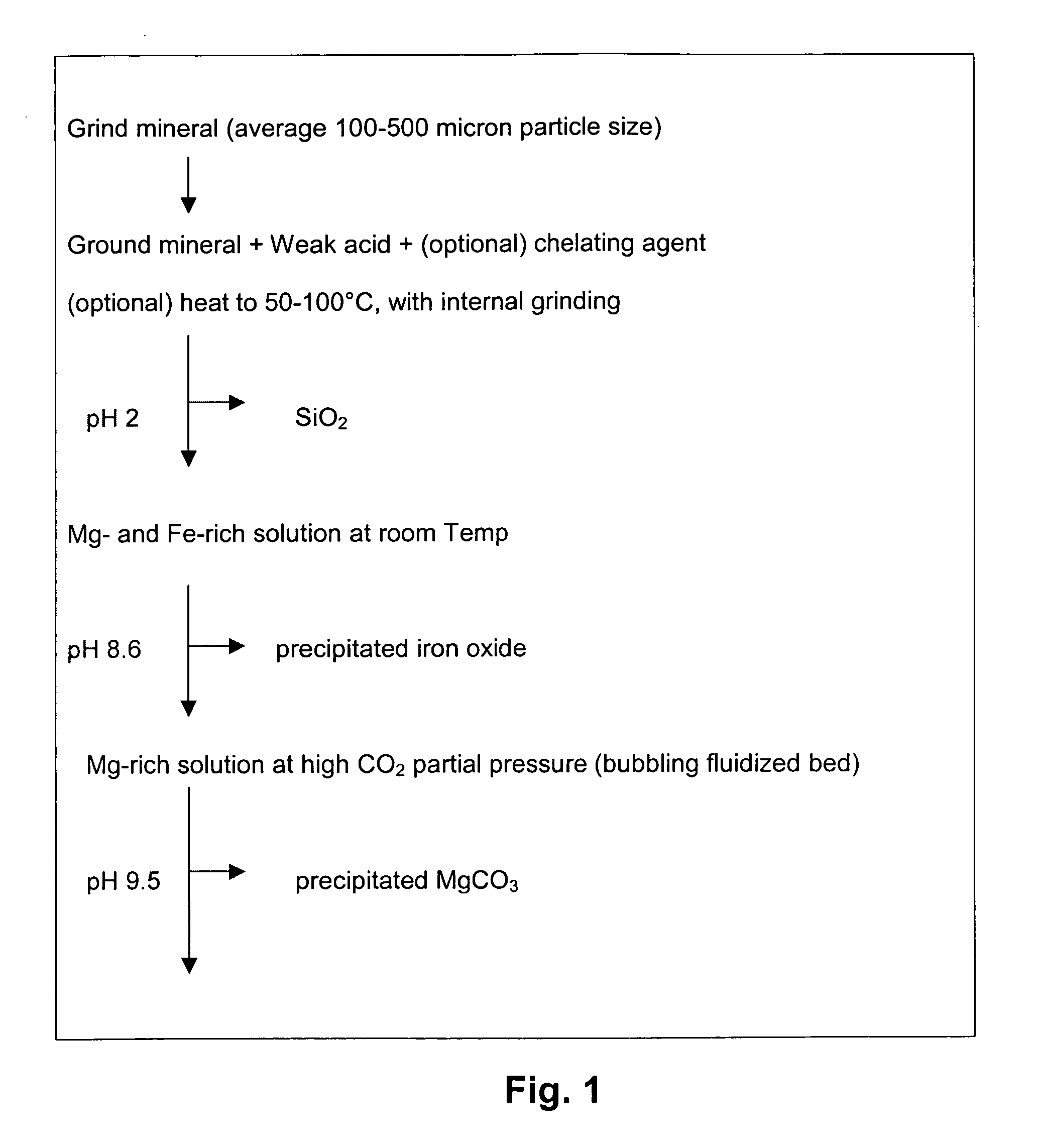

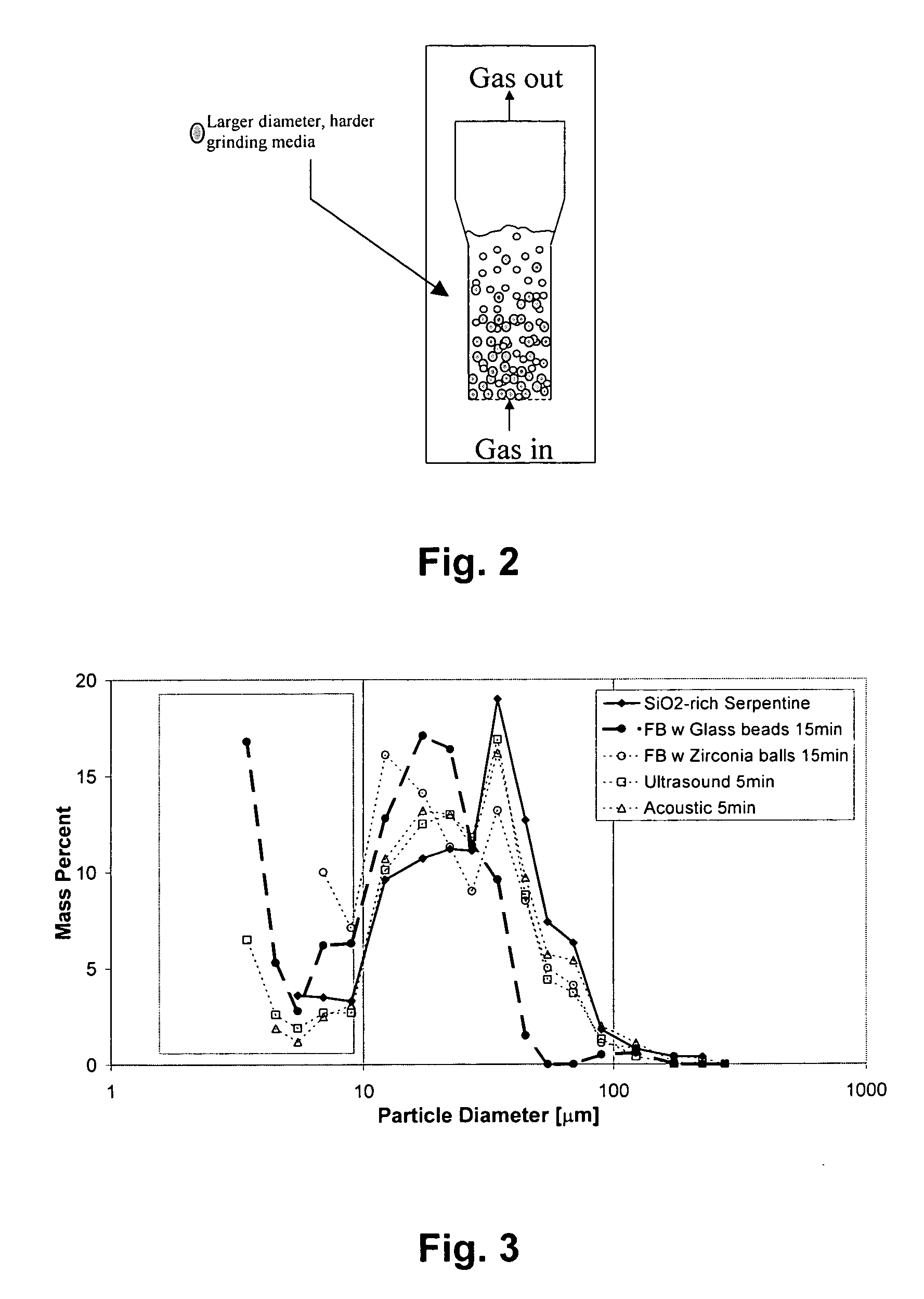

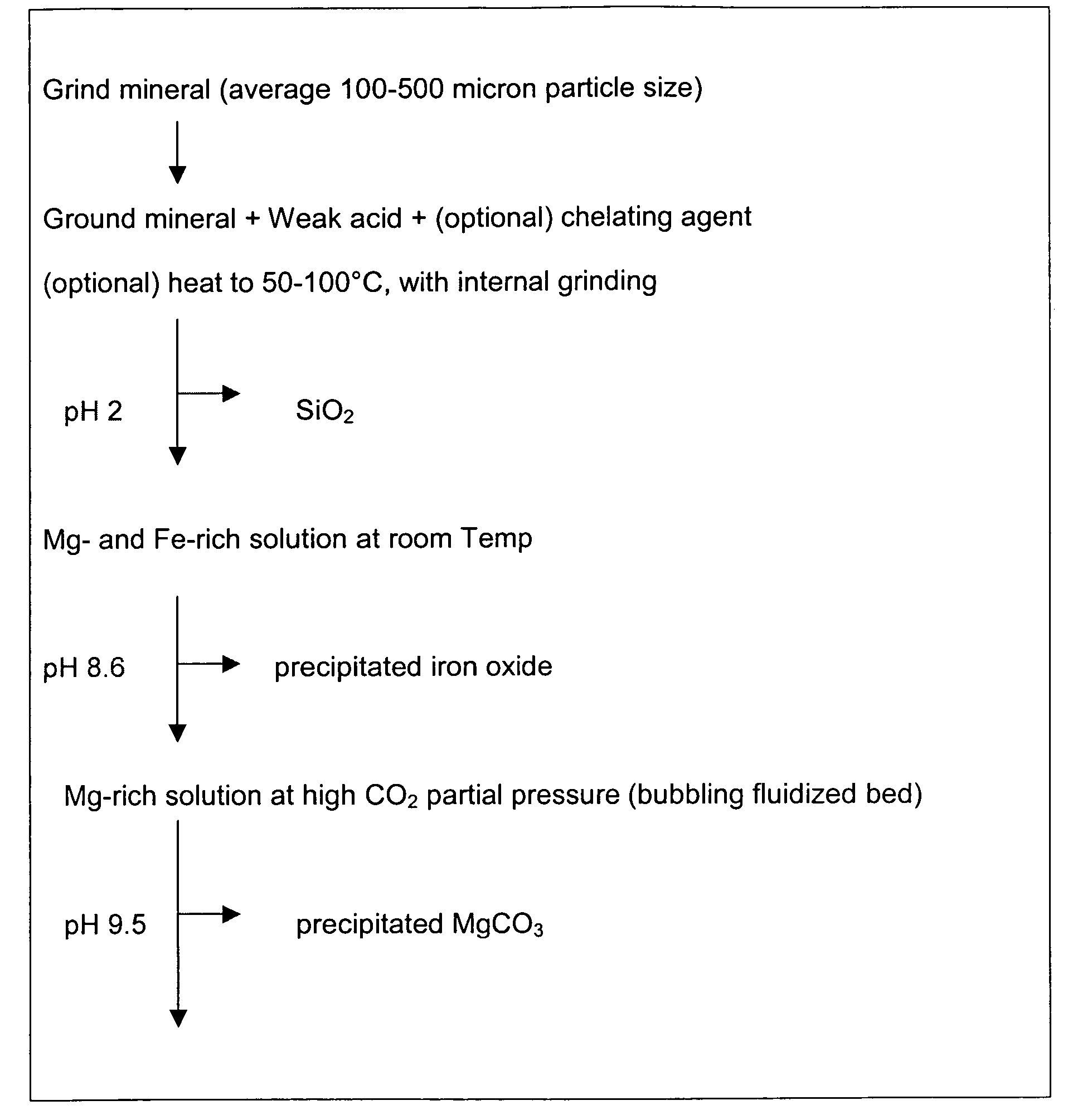

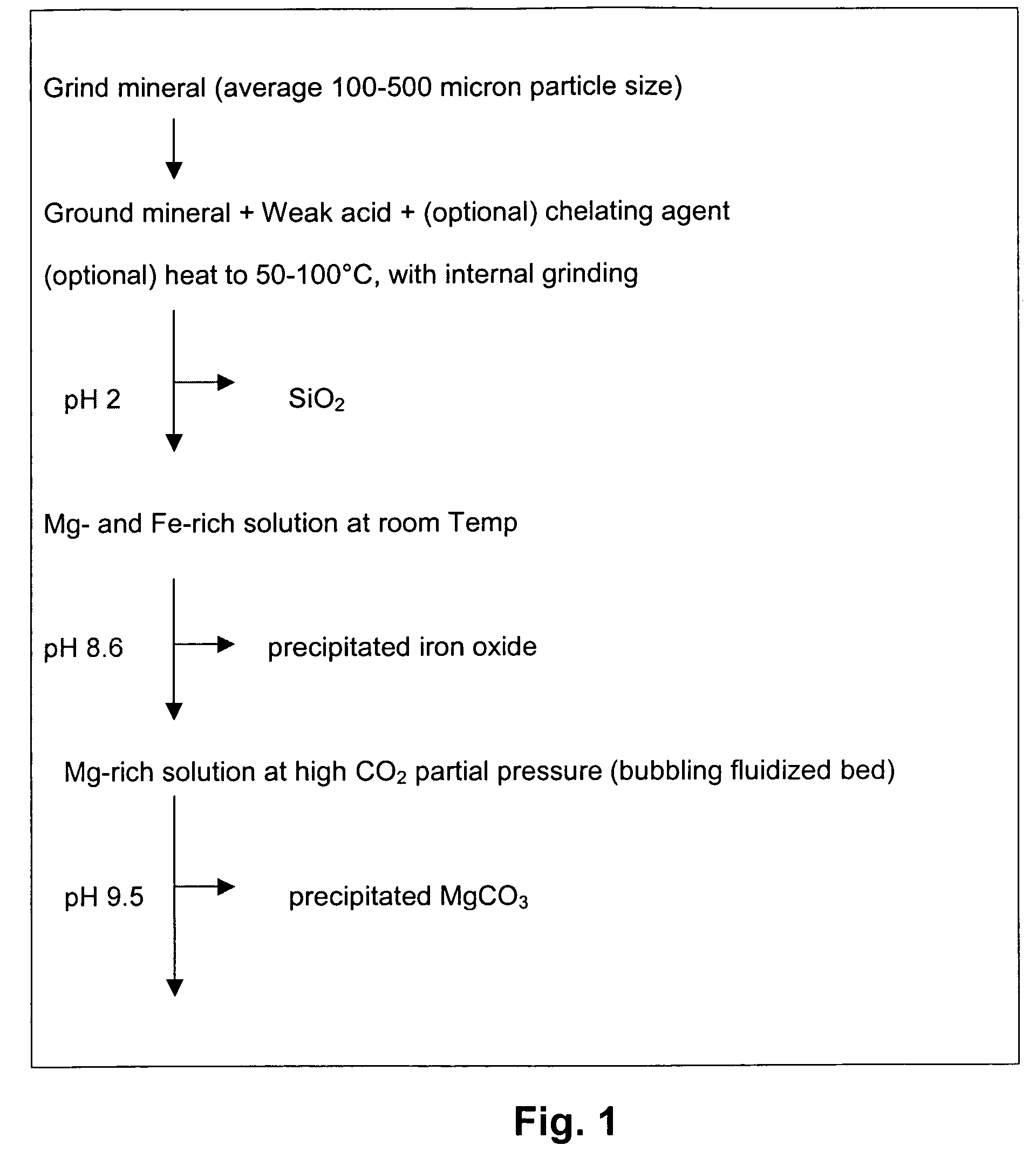

Carbon dioxide sequestration using alkaline earth metal-bearing minerals

ActiveUS20050180910A1High dissolution rateEfficient removalCalcium/strontium/barium carbonatesProductsParticulatesAlkaline earth metal

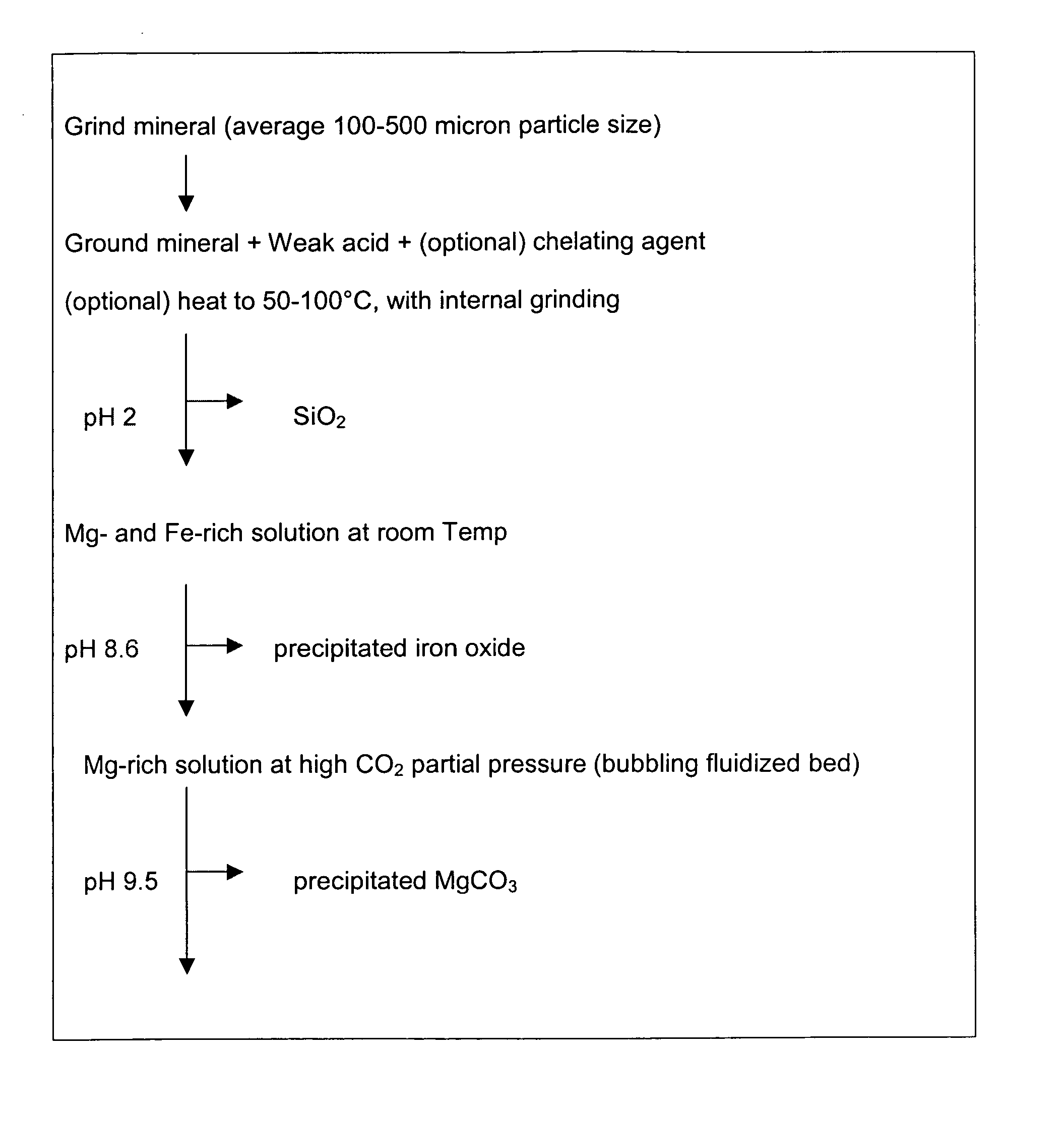

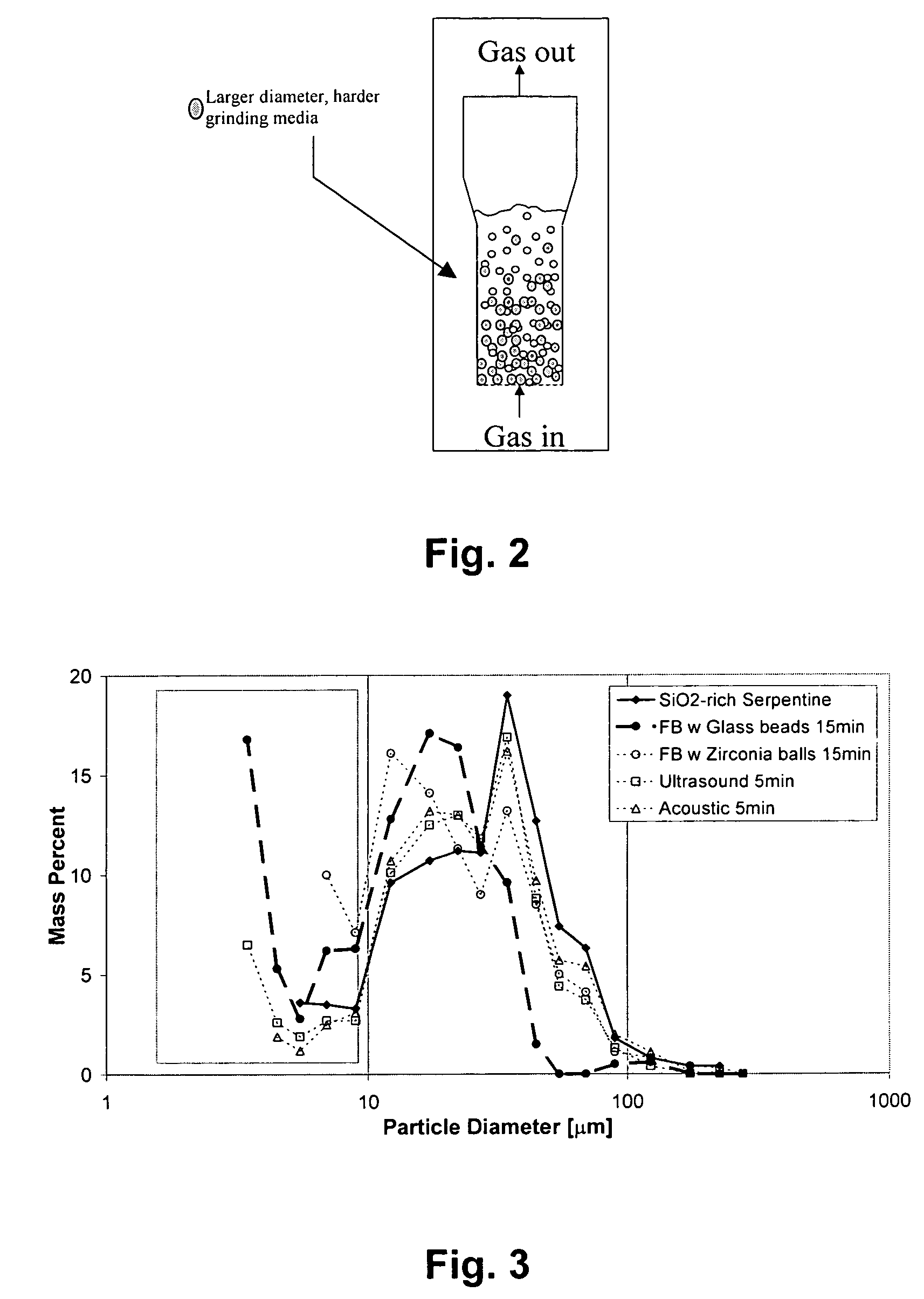

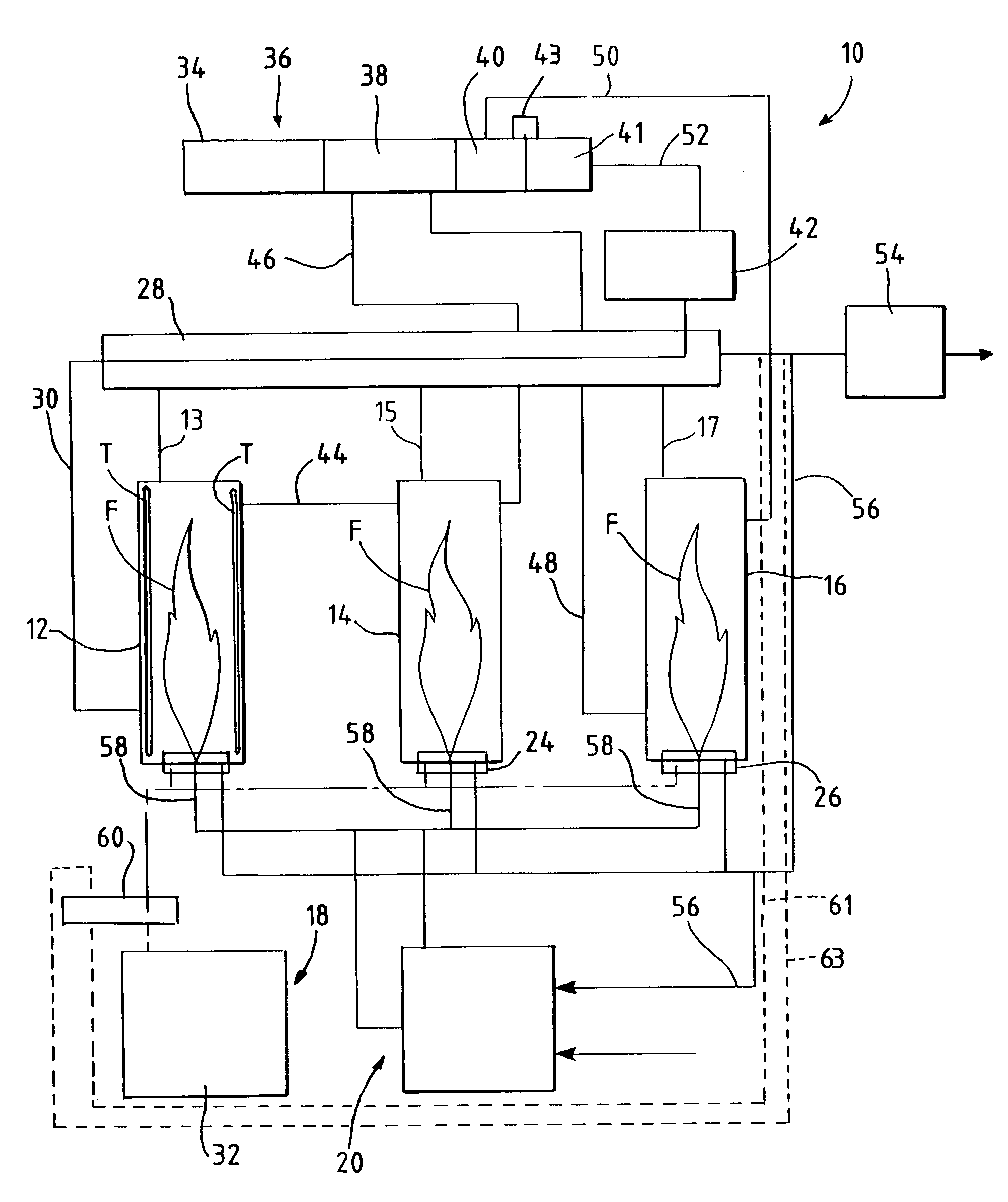

A method for mineral sequestration of pollutant gases resulting from the combustion of carbon-based fuels such as carbon and sulfur dioxides is provided and includes, providing a particulate magnesium-containing mineral and exposing the magnesium-containing mineral to a weak acid to dissolve magnesium from the mineral and form a magnesium-containing solution. The surface of the particulate magnesium-containing mineral is physically activated to expose and dissolve additional magnesium into the solution. Pollutant gases such as carbon dioxide are mixed with the magnesium-containing solution. When the pH of the magnesium-containing solution is increased, solid magnesium carbonate is formed.

Owner:THE OHIO STATES UNIV

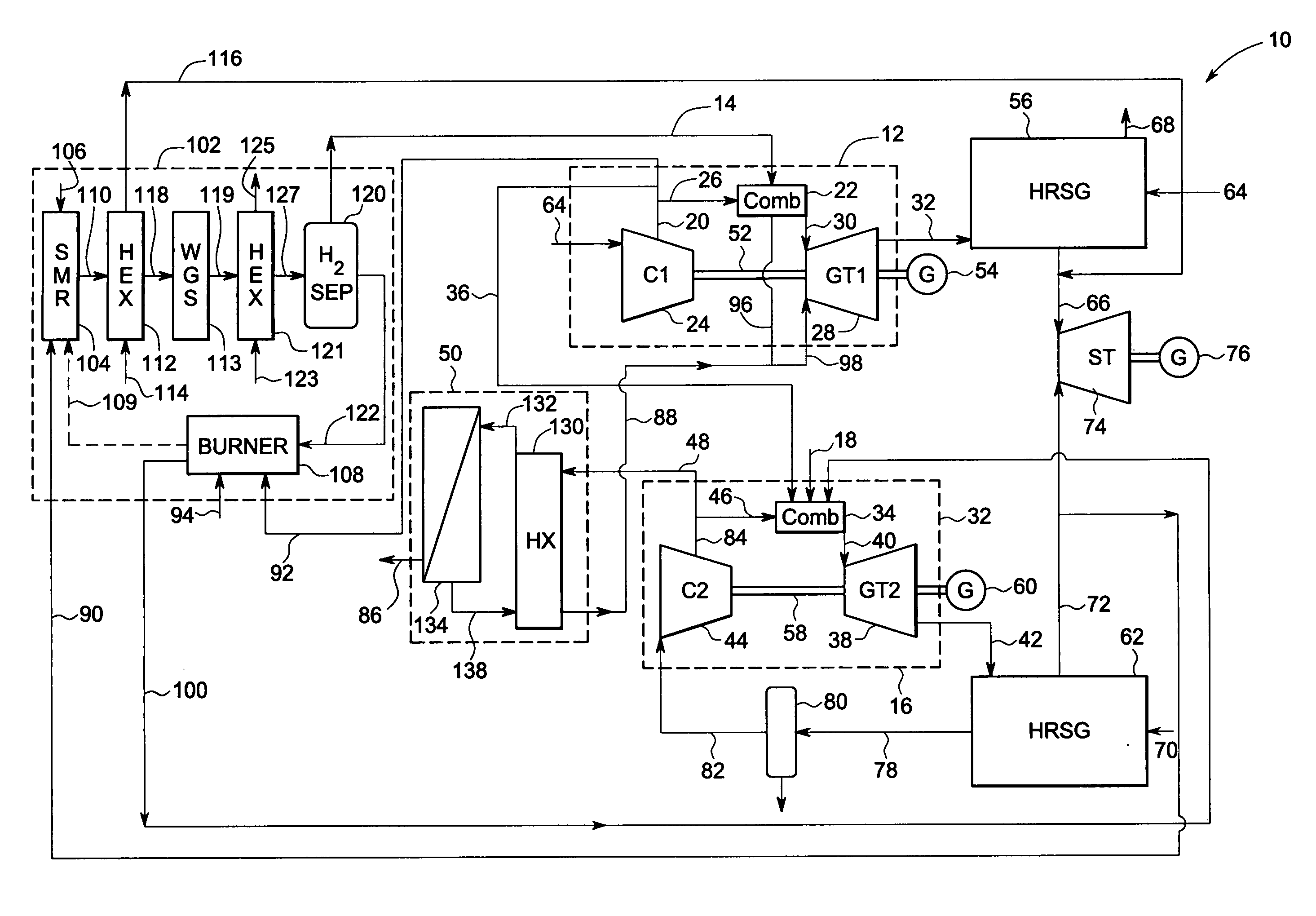

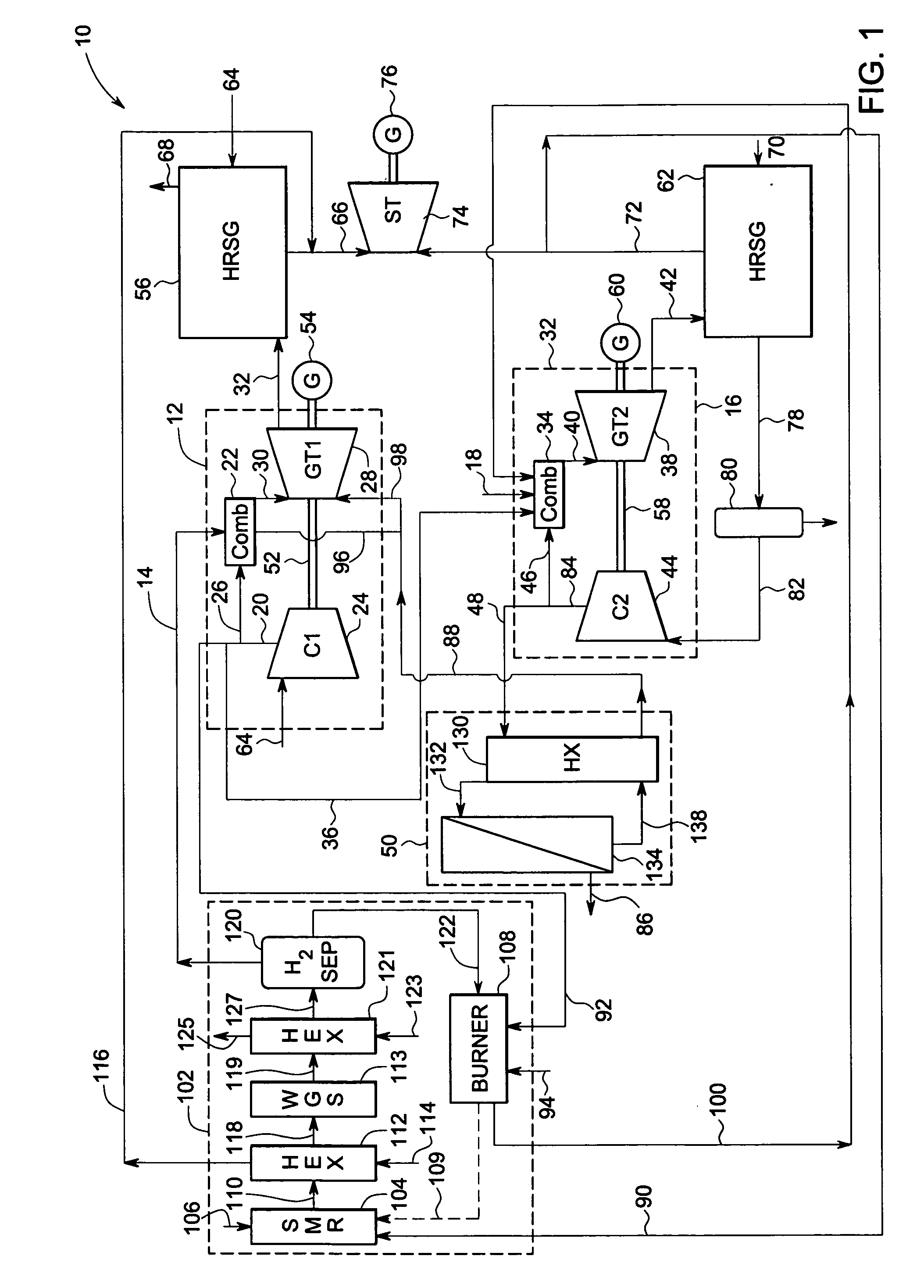

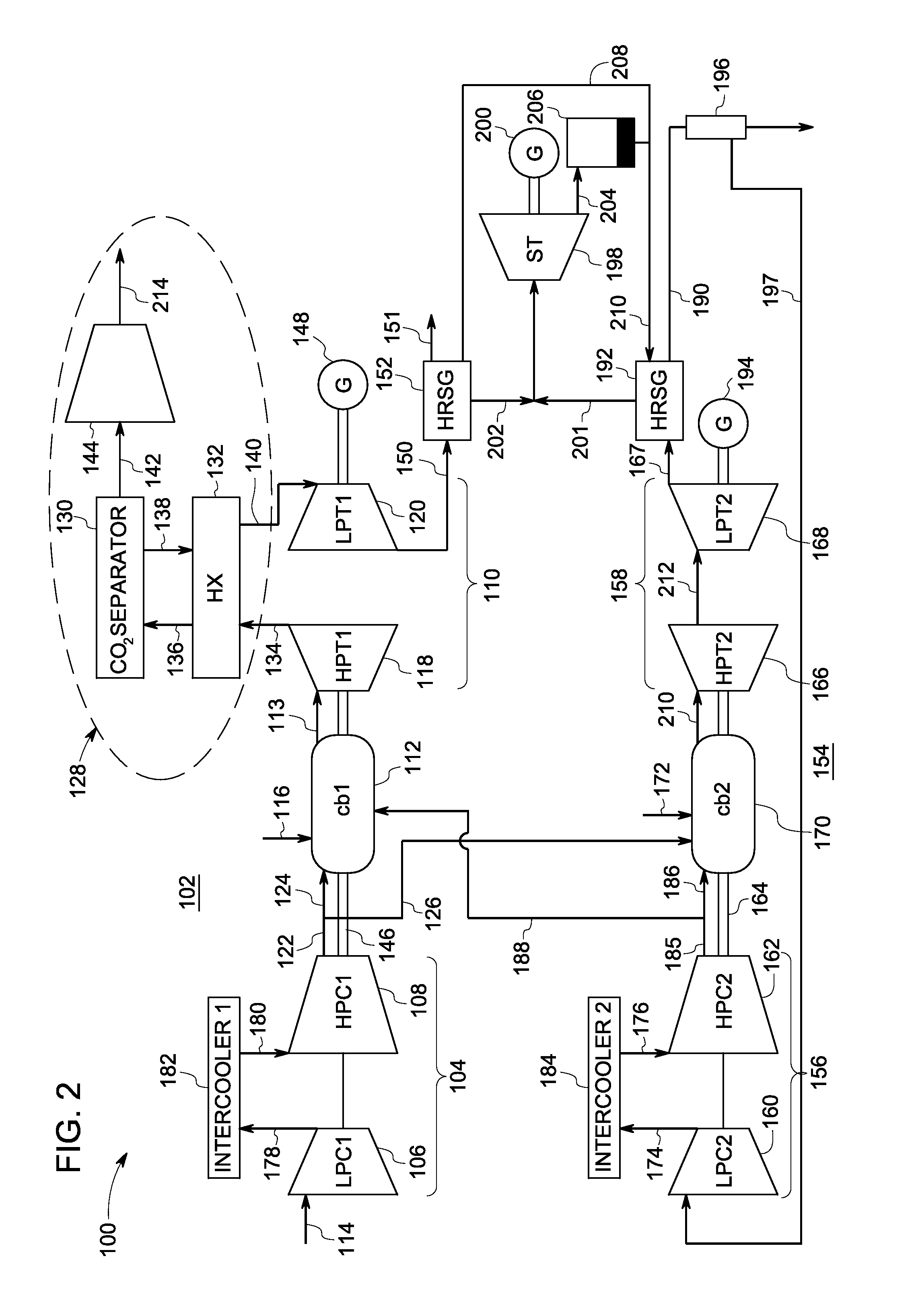

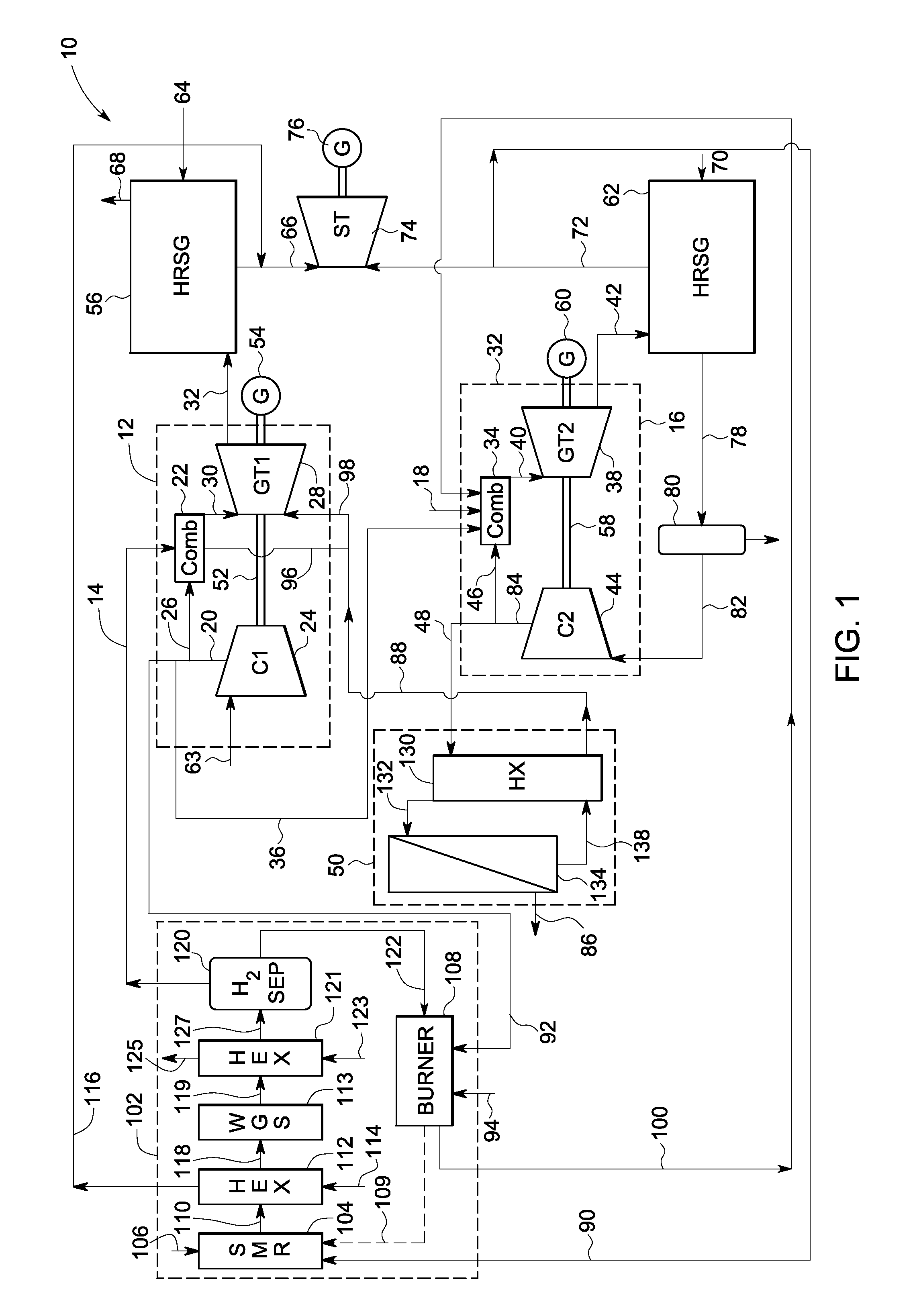

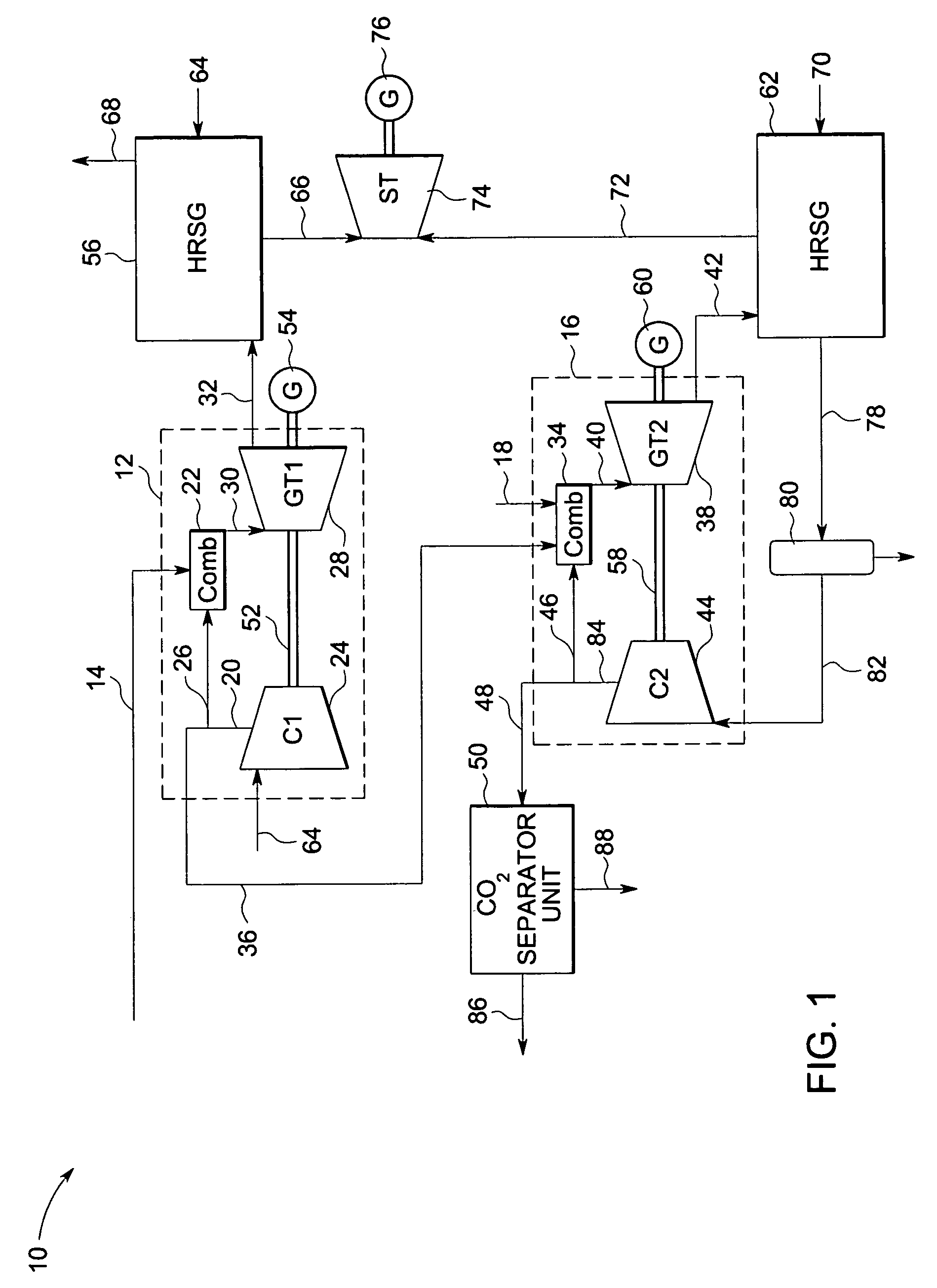

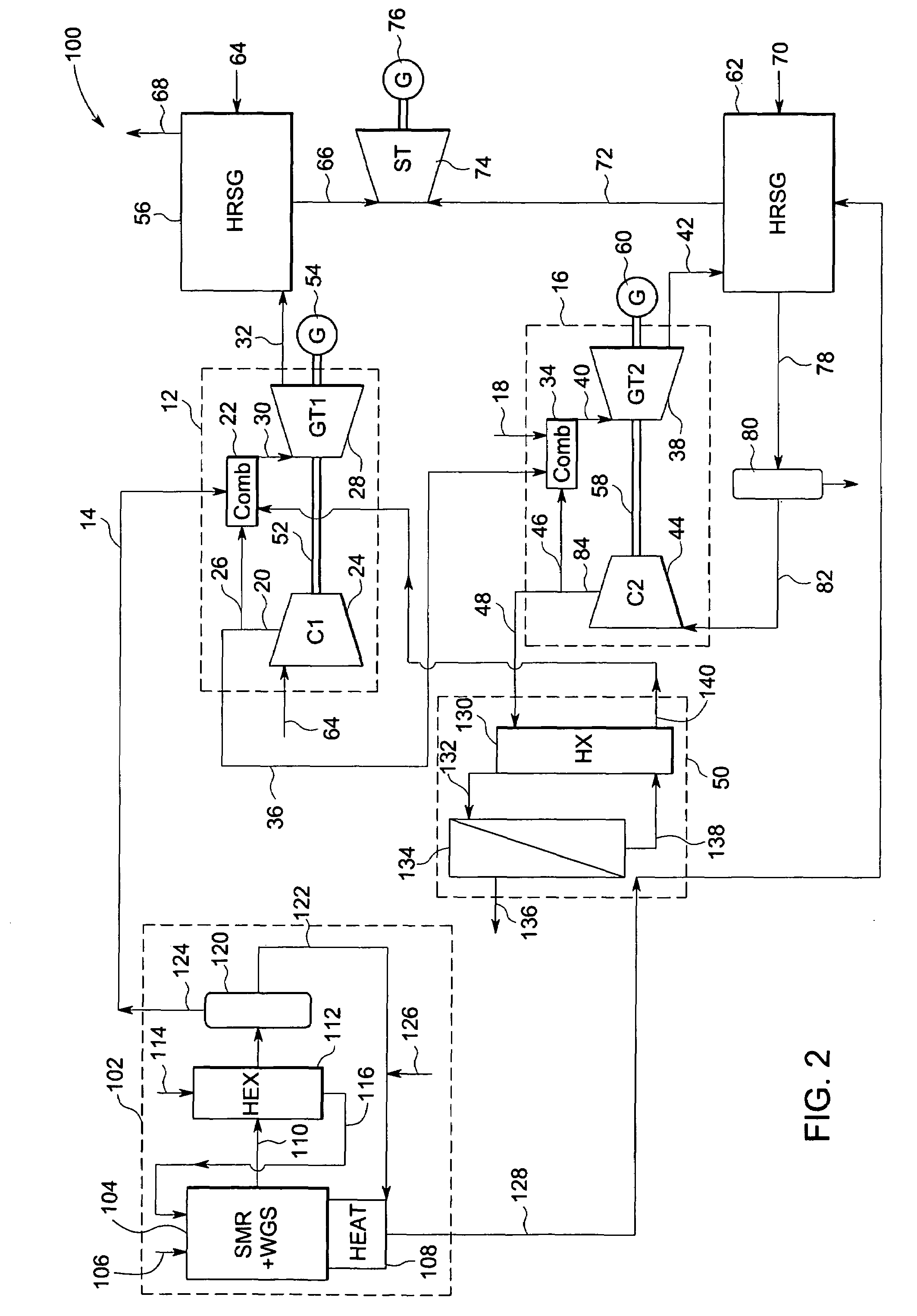

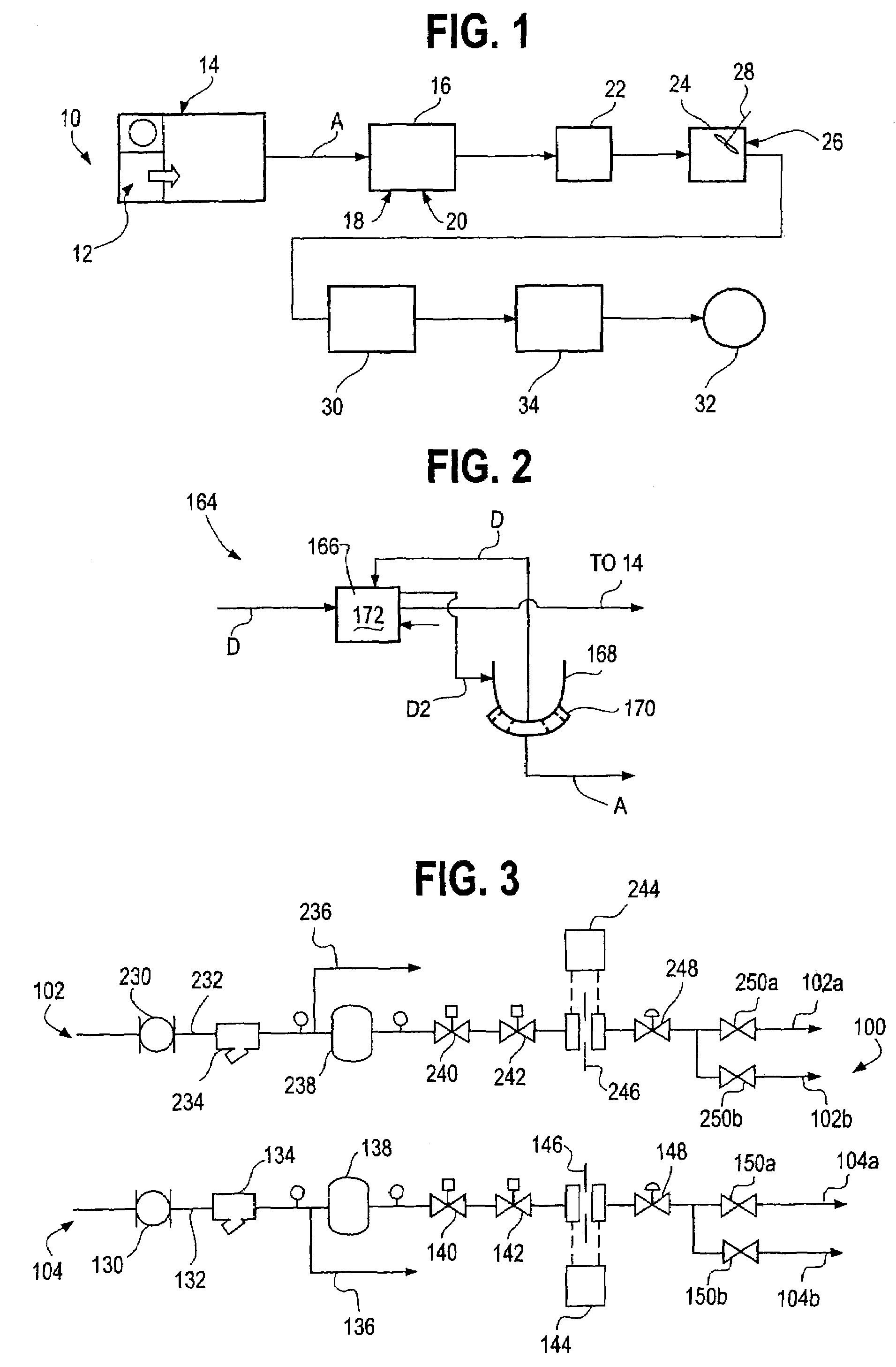

Systems and methods for power generation and hydrogen production with carbon dioxide isolation

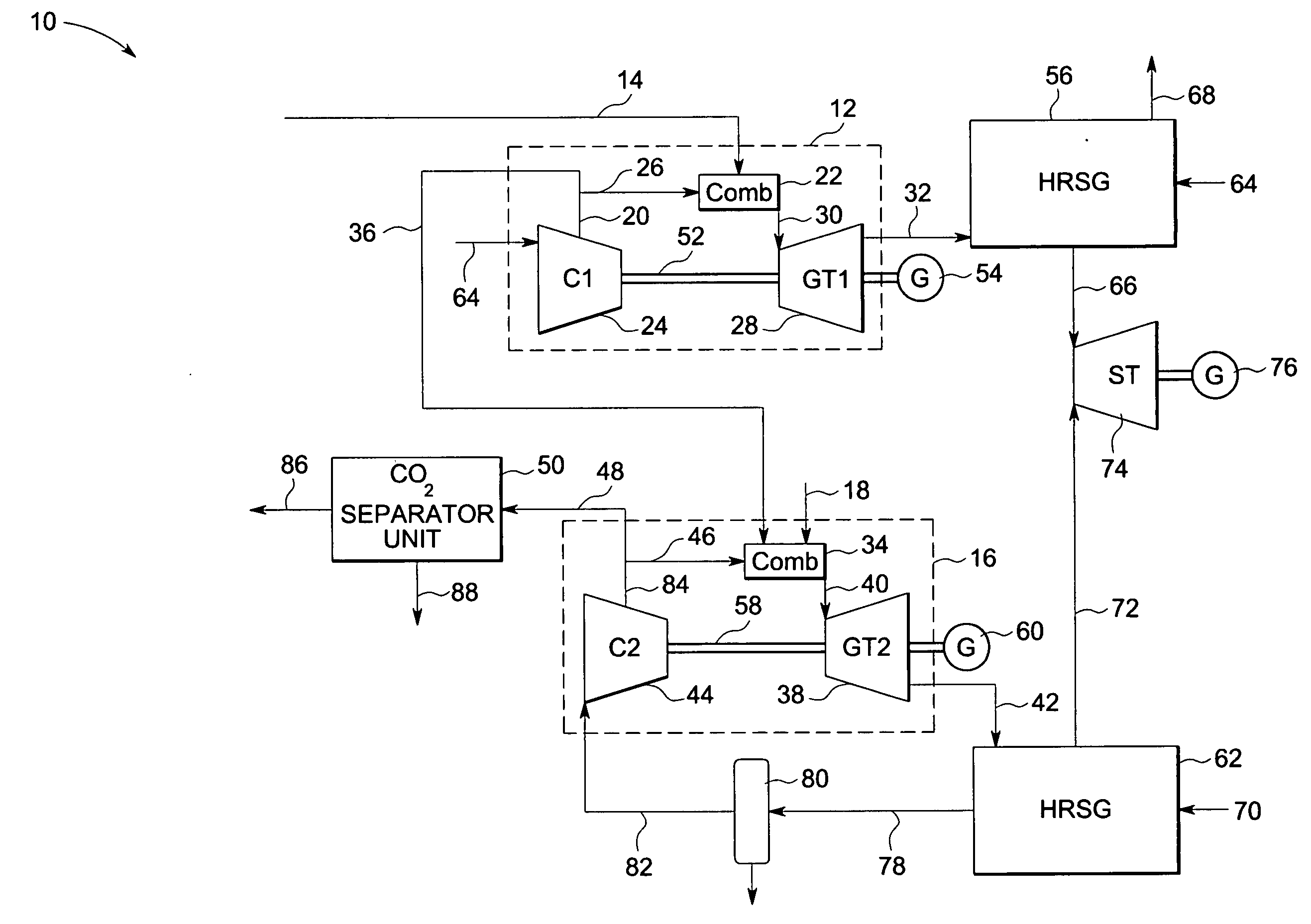

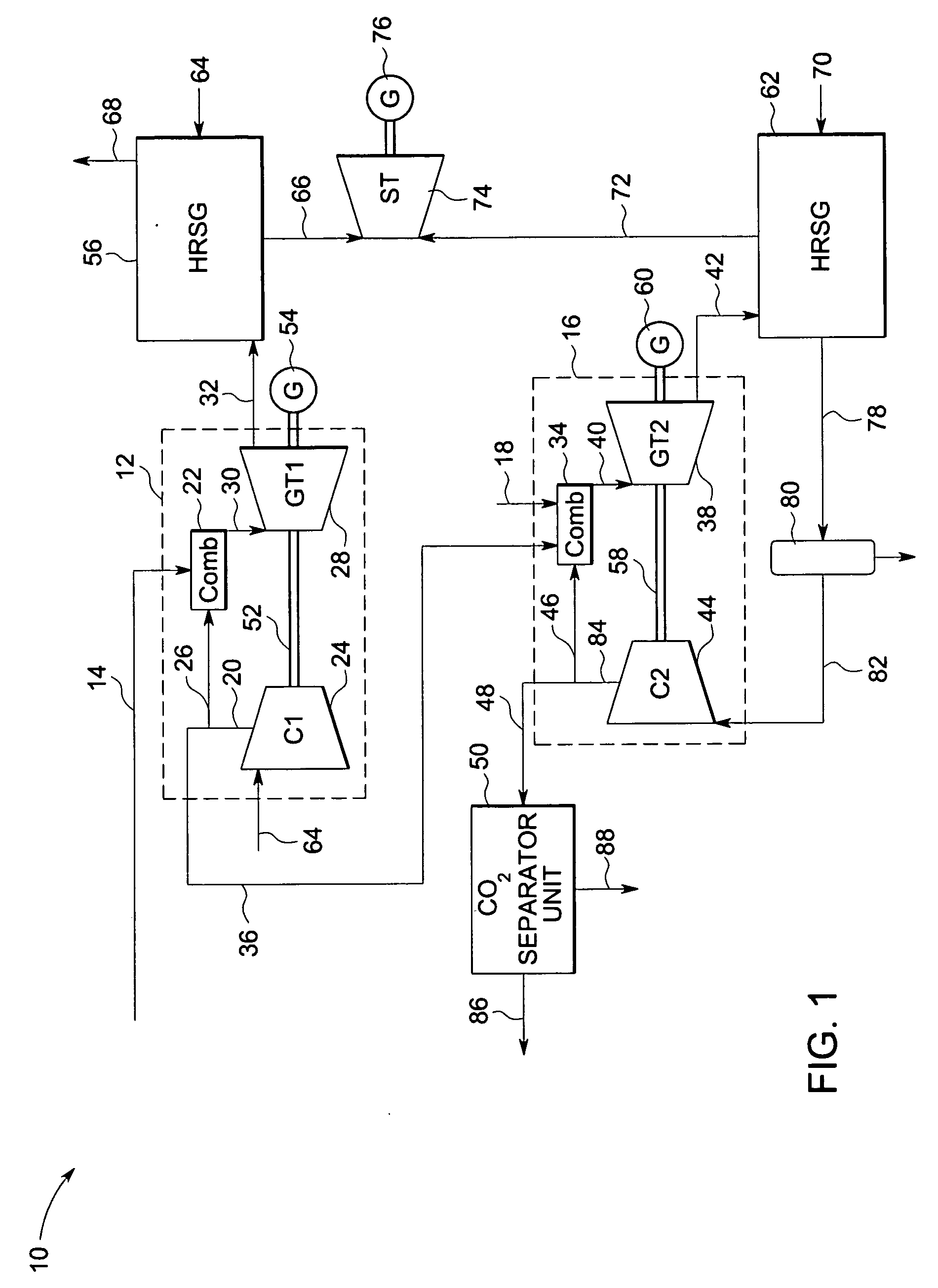

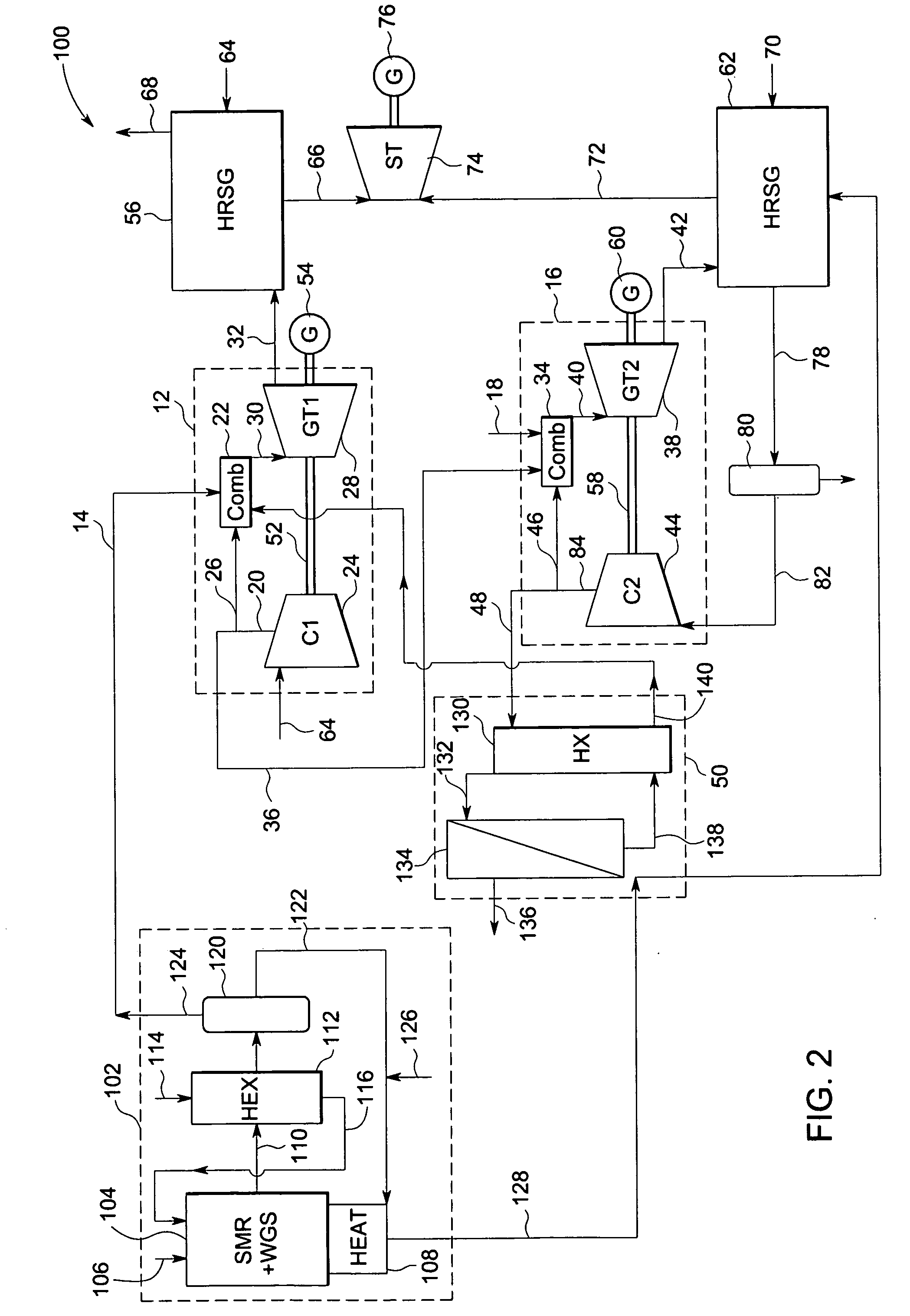

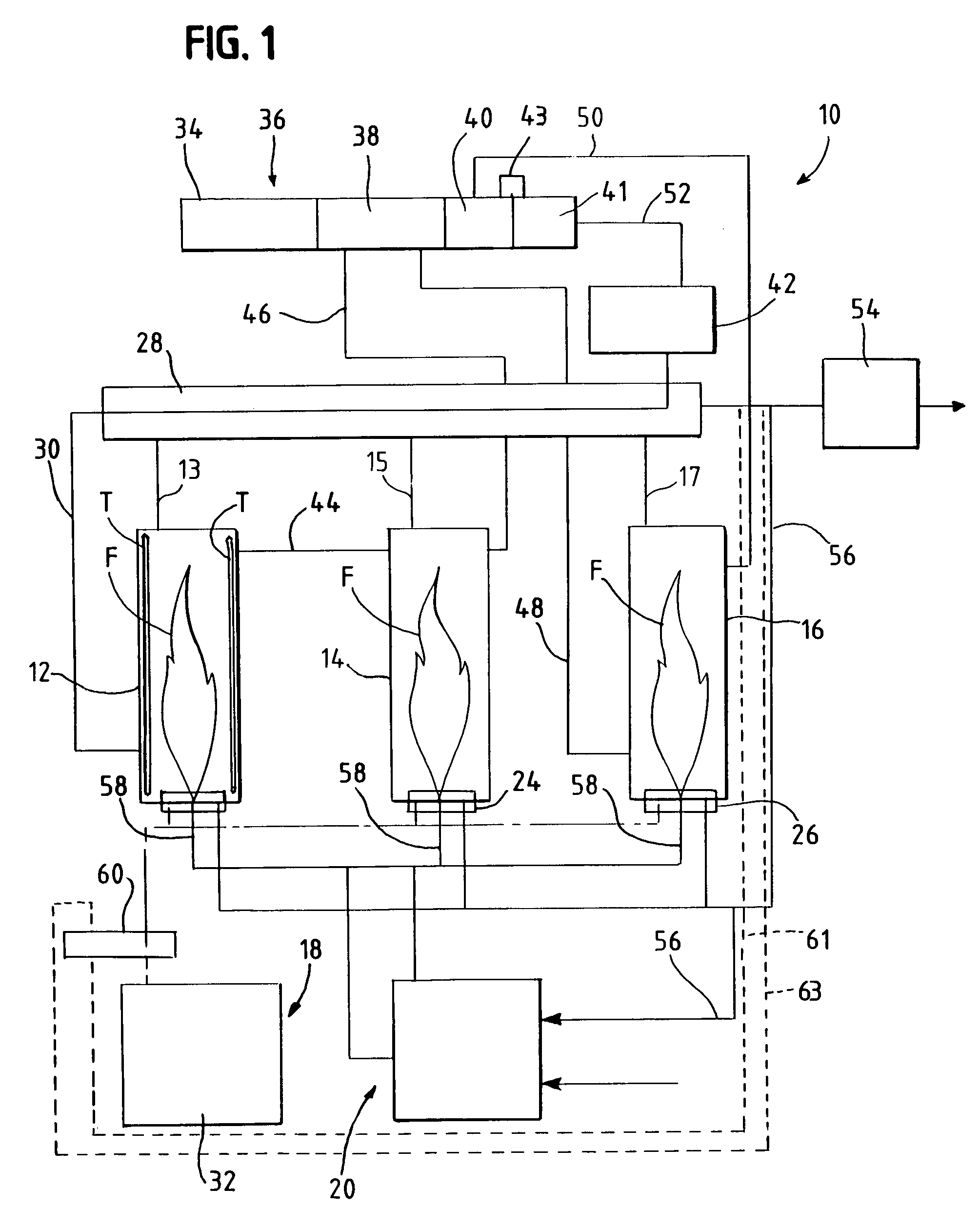

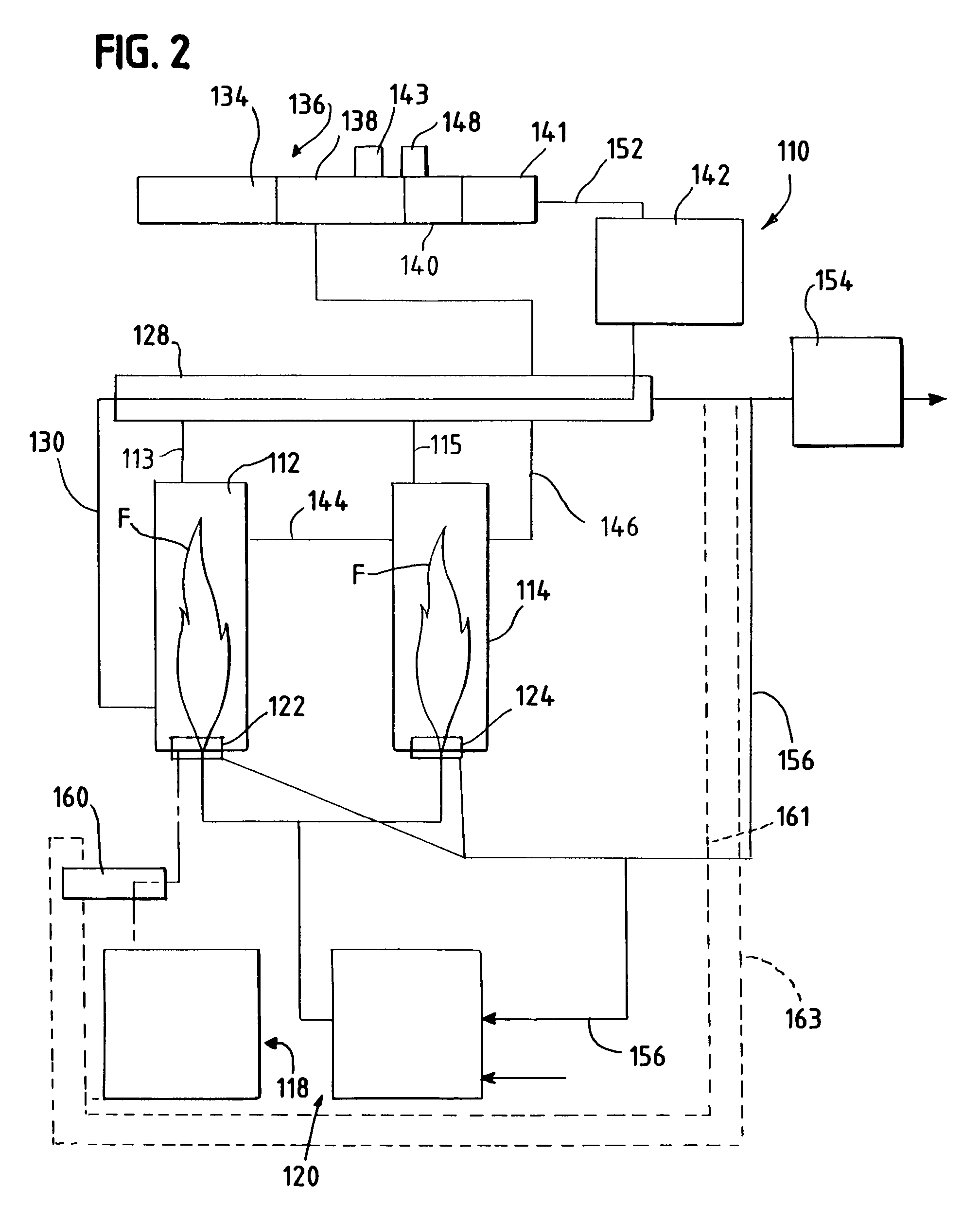

A power generation system includes a first gas turbine system. The first turbine system includes a first combustion chamber configured to combust a first fuel stream of primarily hydrogen that is substantially free of carbon-based fuels, a first compressor configured to supply a first portion of compressed oxidant to the first combustion chamber and a first turbine configured to receive a first discharge from the first combustion chamber and generate a first exhaust and electrical energy. The power generation system further includes a second gas turbine system. The second turbine system includes a second combustion chamber configured to combust a second fuel stream to generate a second discharge, wherein the first compressor of the first gas turbine system is configured to supply a second portion of compressed oxidant to the second combustion chamber and a second turbine configured to receive the second discharge from the second combustion chamber to generate a second exhaust and electrical energy. A second compressor is configured to receive the second exhaust comprising carbon dioxide and to discharge a recycle stream to the second combustion chamber and a split stream to a separator system adapted to recover carbon dioxide. The power generation system also includes a hydrogen generation system configured to receive a third fuel and steam to generate the first fuel and a third exhaust gas, wherein the third exhaust gas is recycled into the second combustion chamber.

Owner:GENERAL ELECTRIC CO

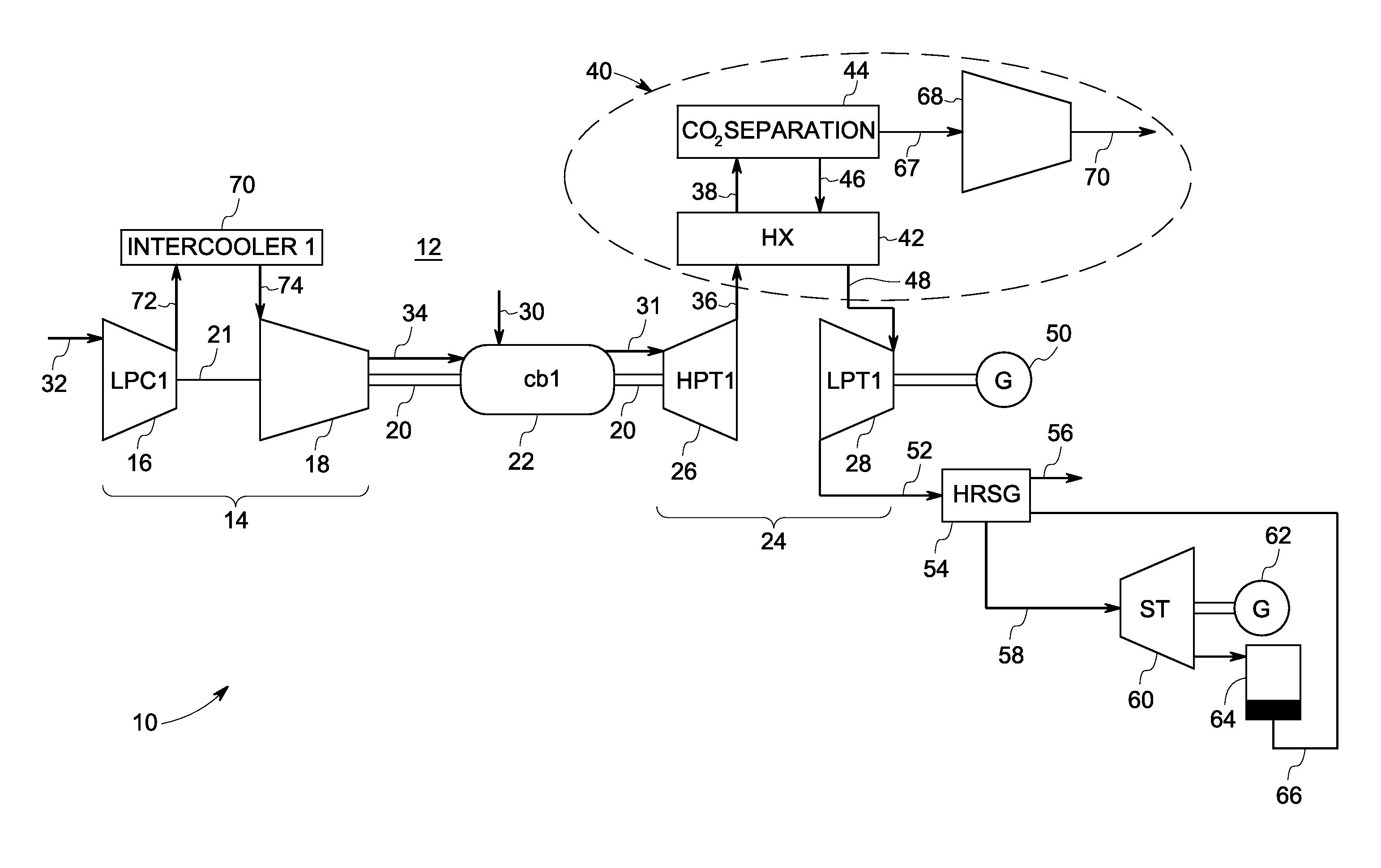

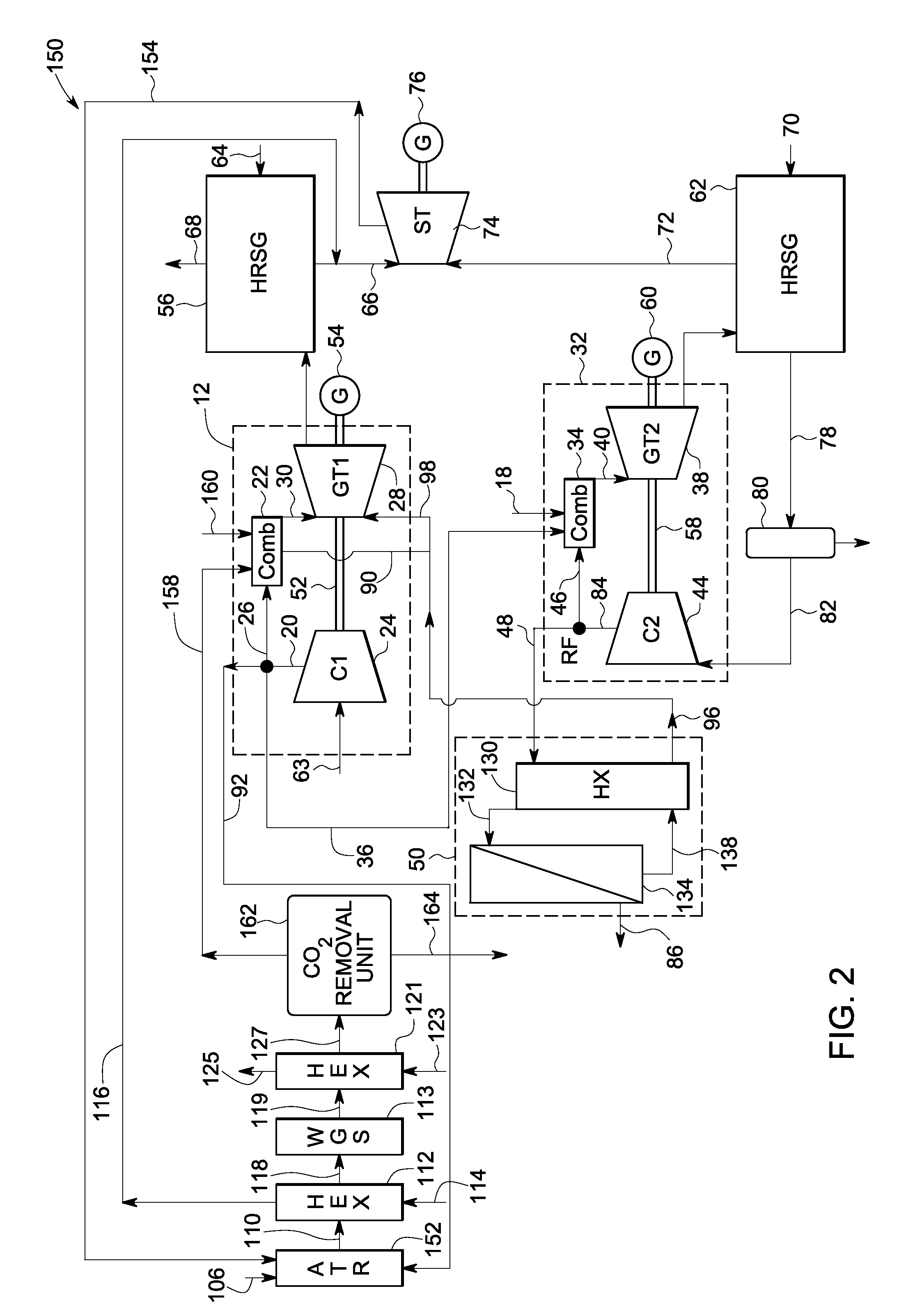

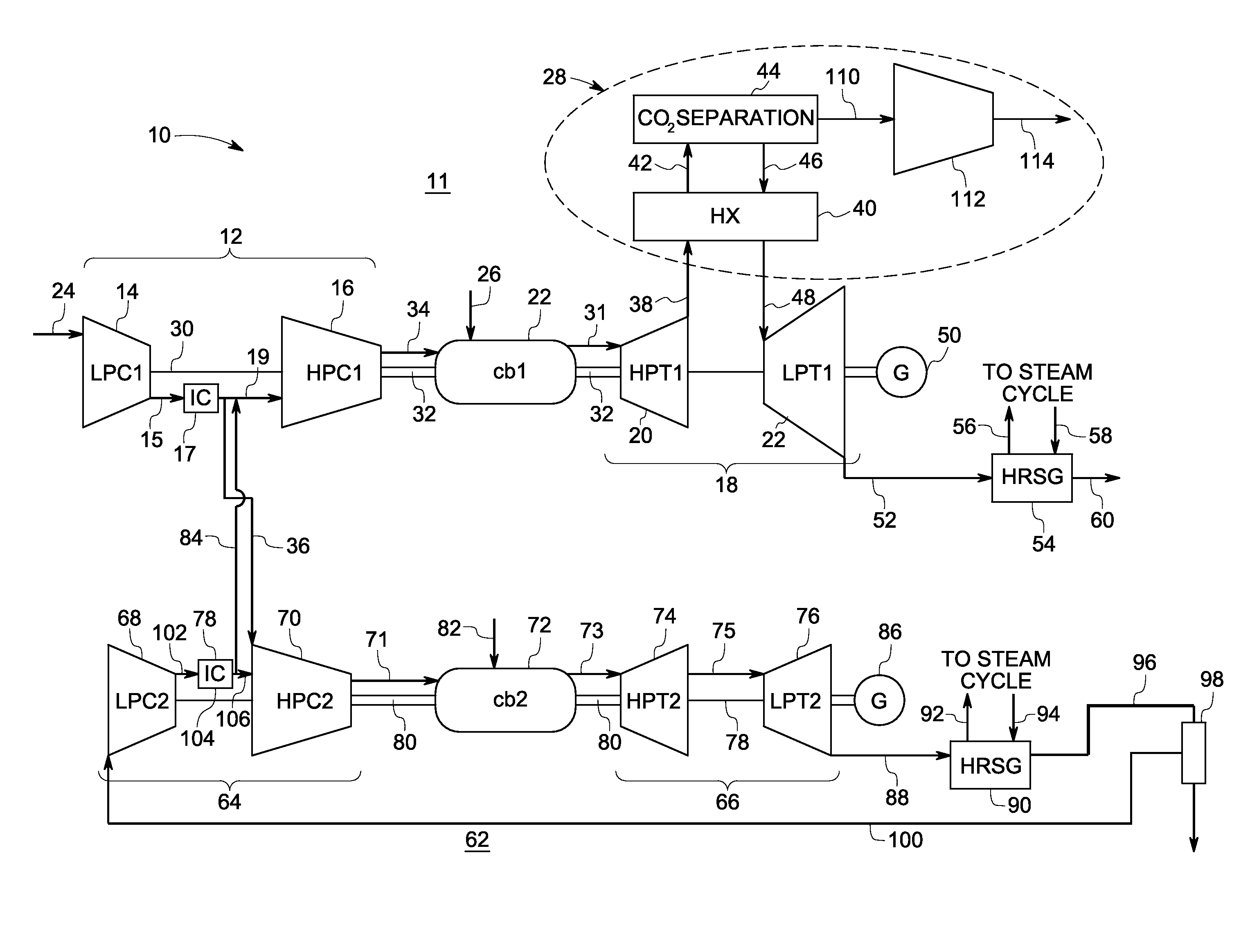

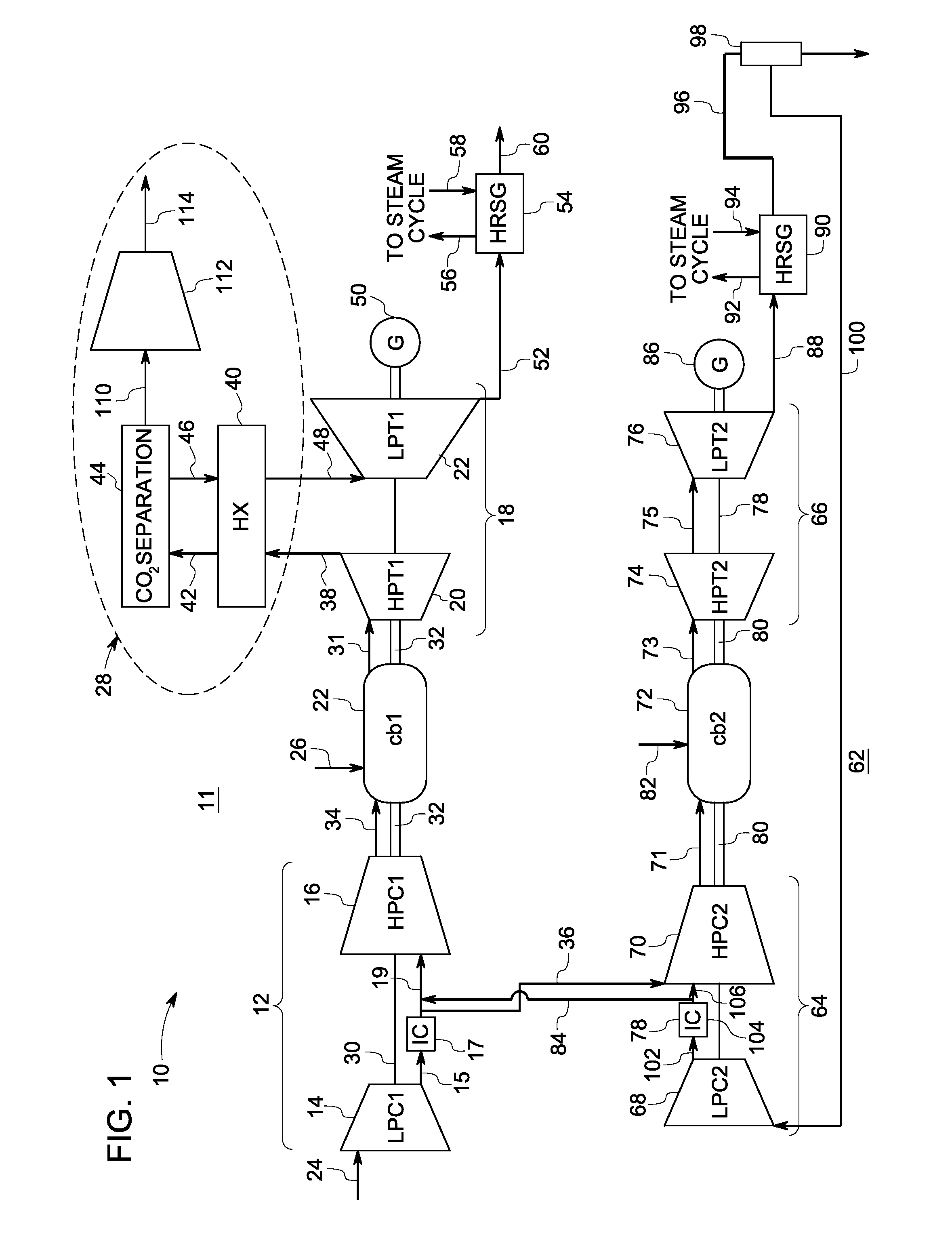

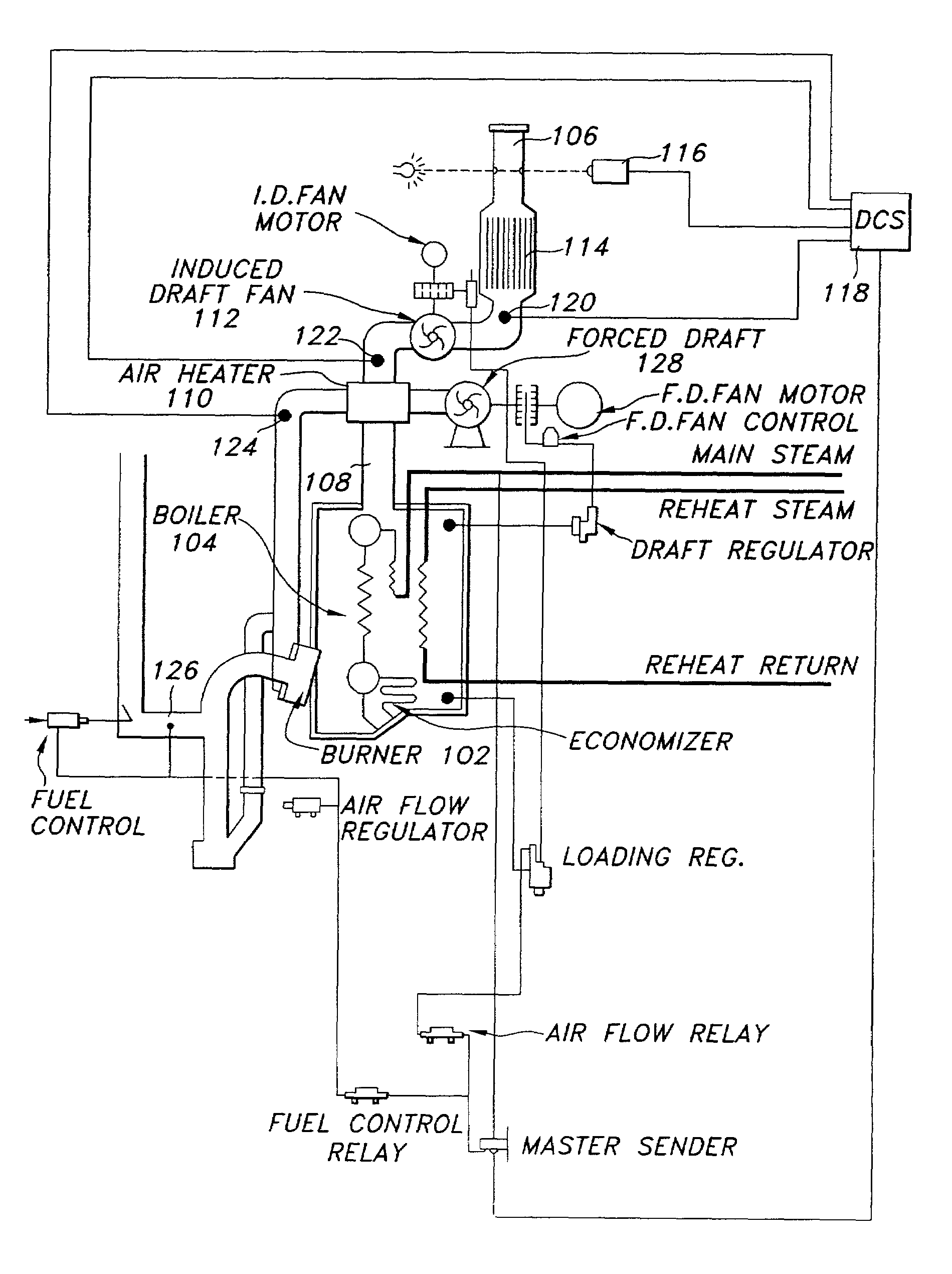

Systems and methods for power generation with carbon dioxide isolation

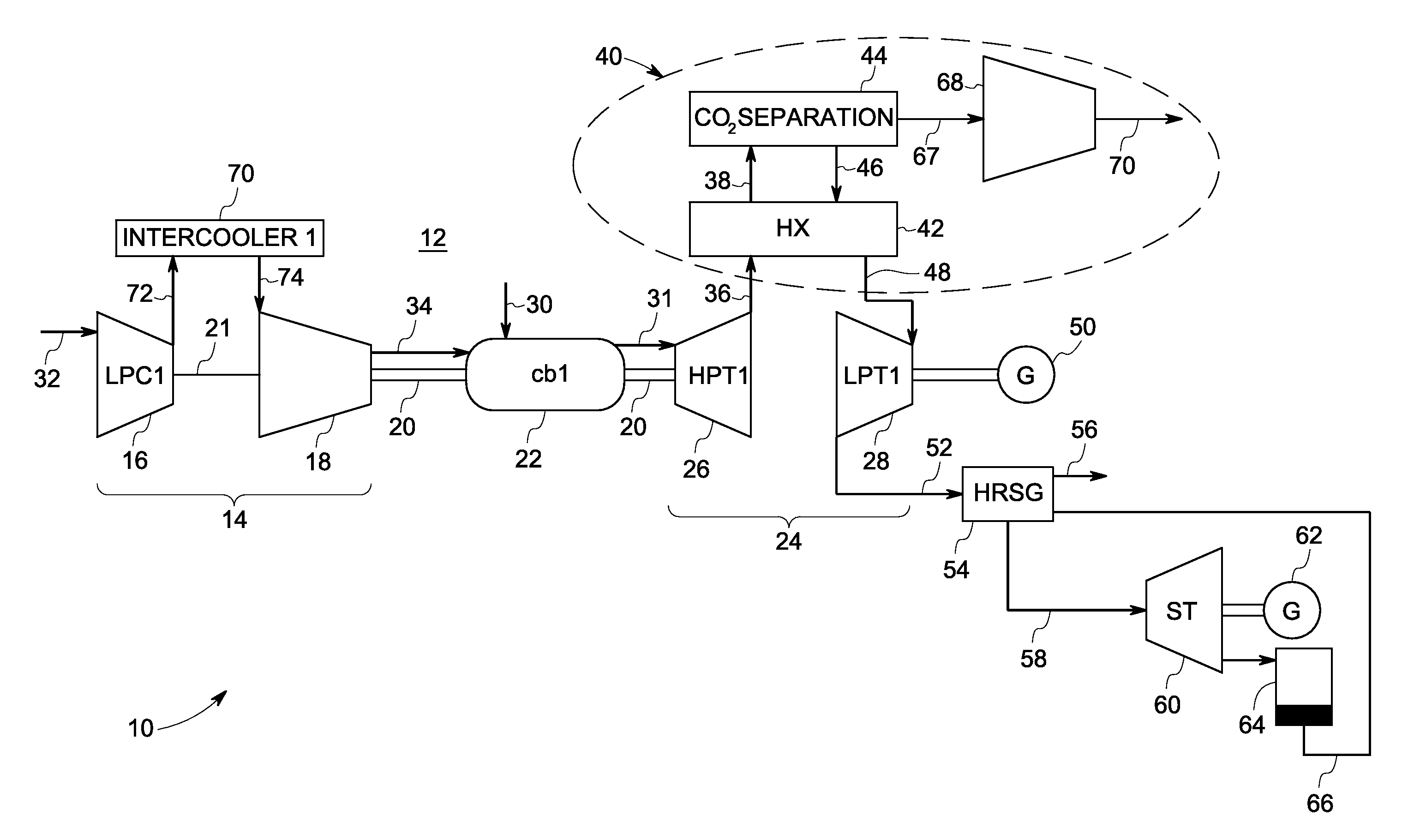

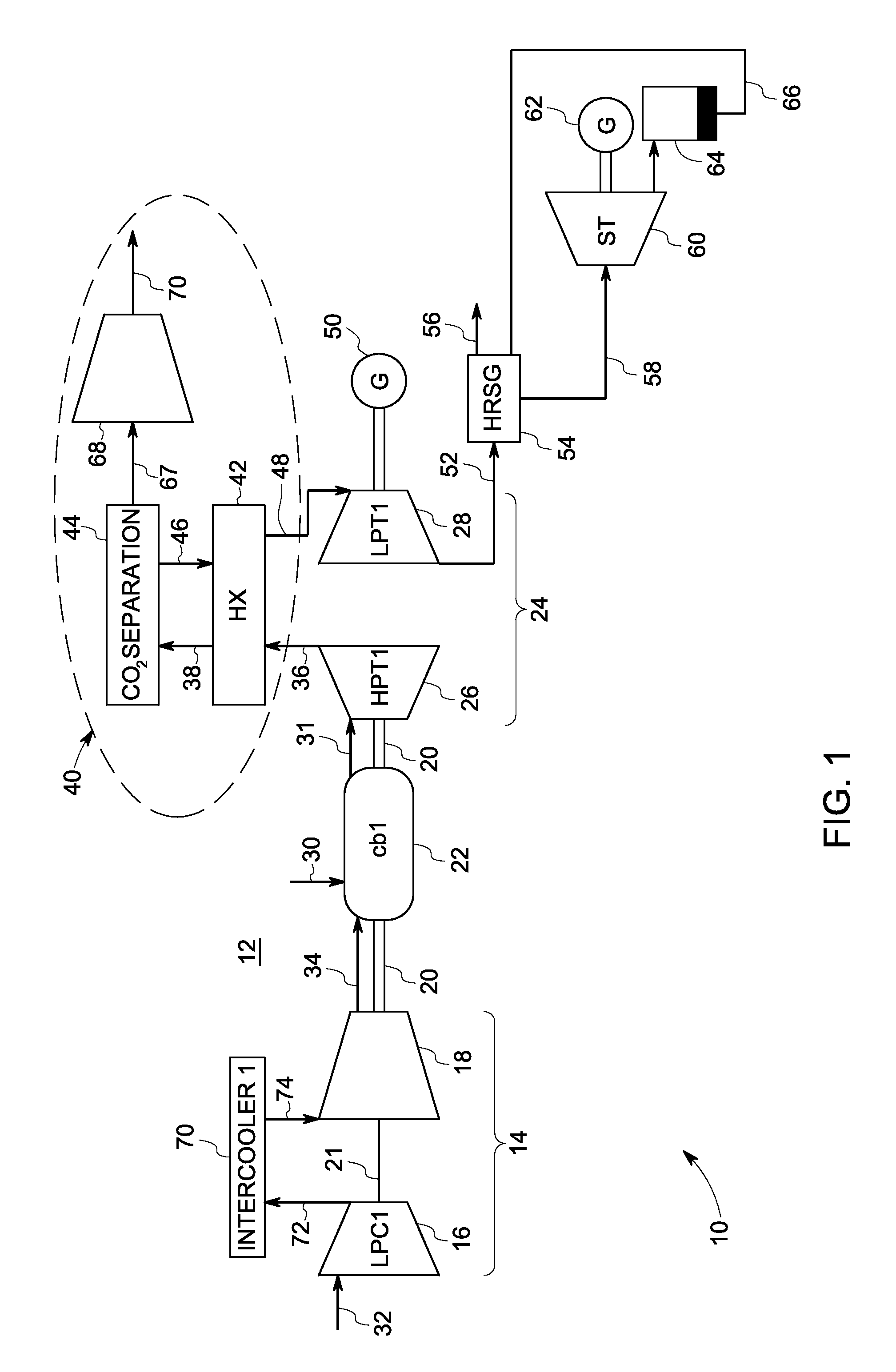

InactiveUS20080104939A1Dispersed particle separationGas turbine plantsCombustion chamberHigh pressure

A power generation system includes at least one turbine system. The turbine system includes a compressor section comprising at least one stage, configured to supply a compressed oxidant and a combustion chamber configured to combust the compressed oxidant and a fuel stream comprising carbon-based fuels and to generate a hot flue gas. The turbine system further includes an expander section having an inlet for receiving the hot flue gas comprising at least two stages. The two stages include a high-pressure expander configured to generate an expanded exhaust gas rich in CO2. The high-pressure expander fluidly coupled to a low-pressure expander configured to generate a final exhaust and electrical energy. A CO2 separation system is fluidly coupled to the high-pressure expander for receiving the expanded exhaust gas from the high-pressure expander and providing a CO2 lean gas that is then fed to the low-pressure expander.

Owner:GENERAL ELECTRIC CO

Systems and methods for power generation with carbon dioxide isolation

A power generation system includes at least one turbine system. The turbine system includes a compressor section comprising at least one stage, configured to supply a compressed oxidant and a combustion chamber configured to combust the compressed oxidant and a fuel stream comprising carbon-based fuels and to generate a hot flue gas. The turbine system further includes an expander section having an inlet for receiving the hot flue gas comprising at least two stages. The two stages include a high-pressure expander configured to generate an expanded exhaust gas rich in CO2. The high-pressure expander fluidly coupled to a low-pressure expander configured to generate a final exhaust and electrical energy. A CO2 separation system is fluidly coupled to the high-pressure expander for receiving the expanded exhaust gas from the high-pressure expander and providing a CO2 lean gas that is then fed to the low-pressure expander.

Owner:GENERAL ELECTRIC CO

Systems and methods for power generation and hydrogen production with carbon dioxide isolation

Owner:GENERAL ELECTRIC CO

Combustion looping using composite oxygen carriers

ActiveUS7767191B2Increase surface areaImprove energy conversion efficiencyHydrogen productionIndirect carbon-dioxide mitigationHydrogenCombustion

A method for producing hydrogen gas is provided and comprises reducing a metal oxide in a reduction reaction between a carbon-based fuel and a metal oxide to provide a reduced metal or metal oxide having a lower oxidation state, and oxidizing the reduced metal or metal oxide to produce hydrogen and a metal oxide having a higher oxidation state. The metal or metal oxide is provided in the form of a porous composite of a ceramic material containing the metal or metal oxide. The porous composite may comprise either a monolith, pellets, or particles.

Owner:OHIO STATE INNOVATION FOUND

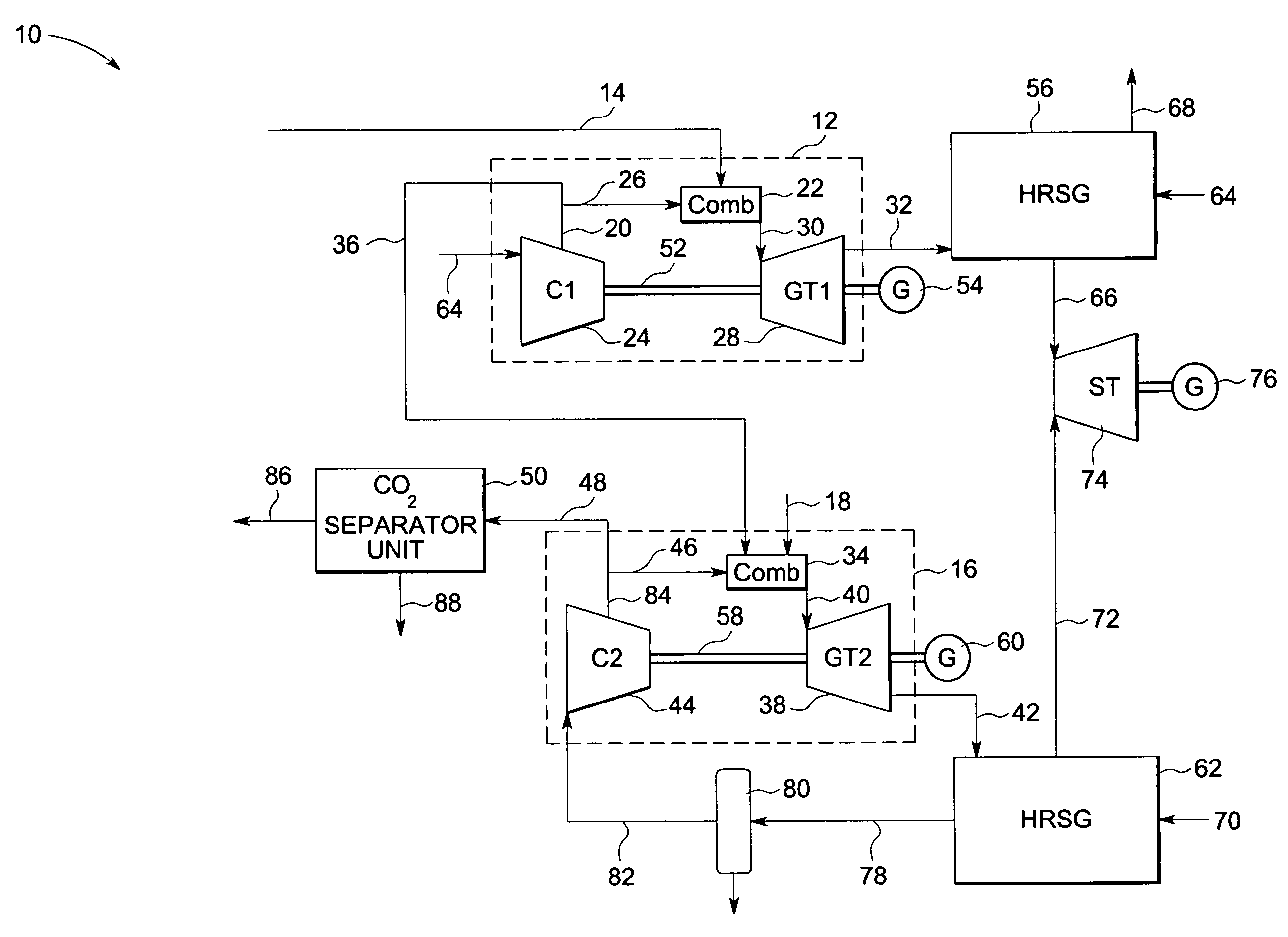

Systems and methods for power generation with carbon dioxide isolation

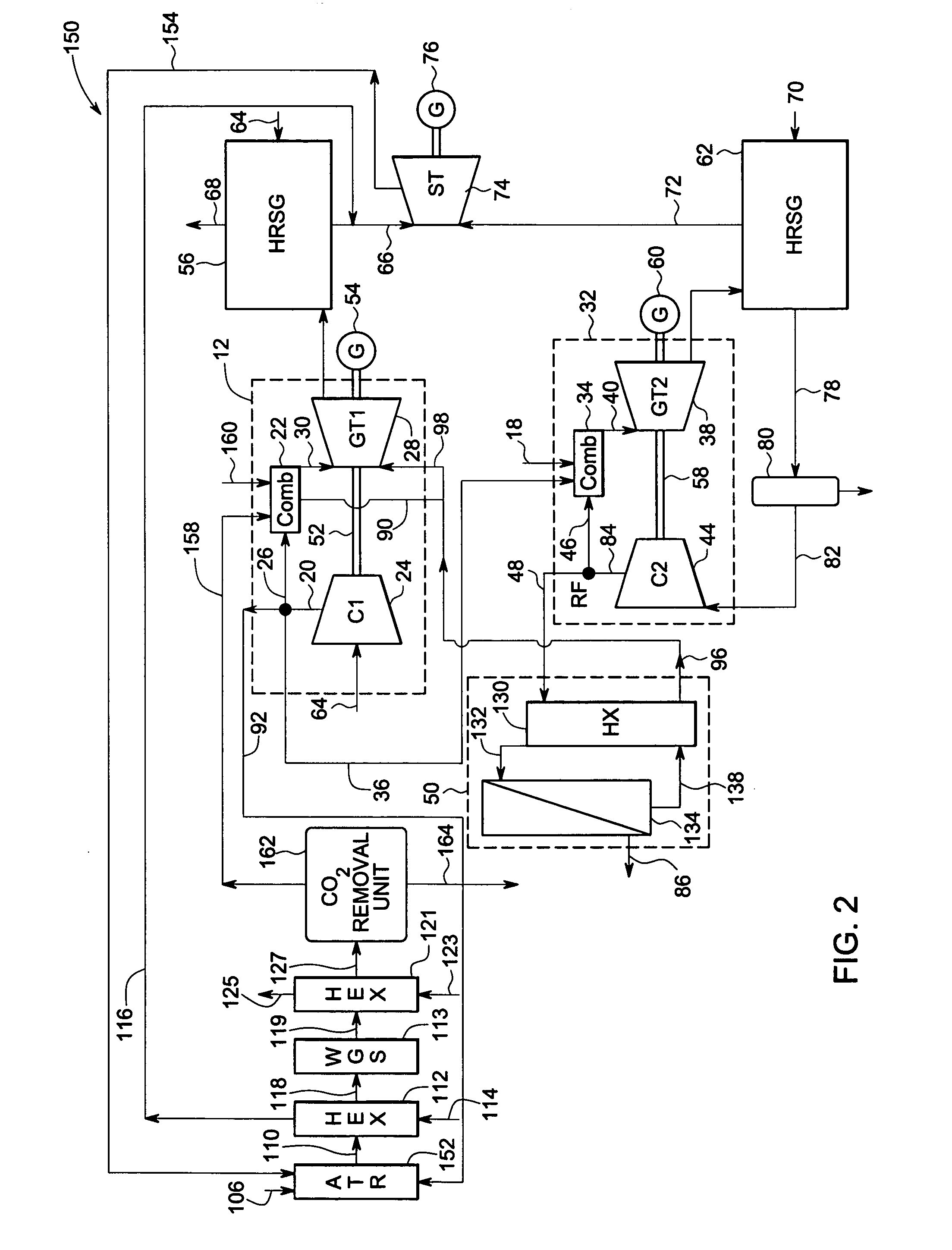

A power generation system and method includes a first gas turbine system comprising a first combustion chamber configured to combust a first fuel stream of primarily hydrogen that is substantially free of carbon-based fuels. The first gas turbine system also includes a first compressor configured to supply a first portion of compressed oxidant to the first combustion chamber and a first turbine configured to receive a first discharge from the first combustion chamber and generate a first exhaust and electrical energy. The power generation system further includes a second gas turbine system comprising a second combustion chamber configured to combust a second fuel stream to generate a second discharge. The first compressor of the first gas turbine system is configured to supply a second portion of compressed oxidant to the second combustion chamber. The second turbine system also includes a second turbine configured to receive the second discharge from the second combustion chamber to generate a second exhaust and electrical energy and a second compressor configured to receive the second discharge comprising carbon dioxide. The second compressor is also configured to discharge a recycle stream to the second combustion chamber and a split stream to a separator system adapted to recover carbon dioxide.

Owner:GENERAL ELECTRIC CO

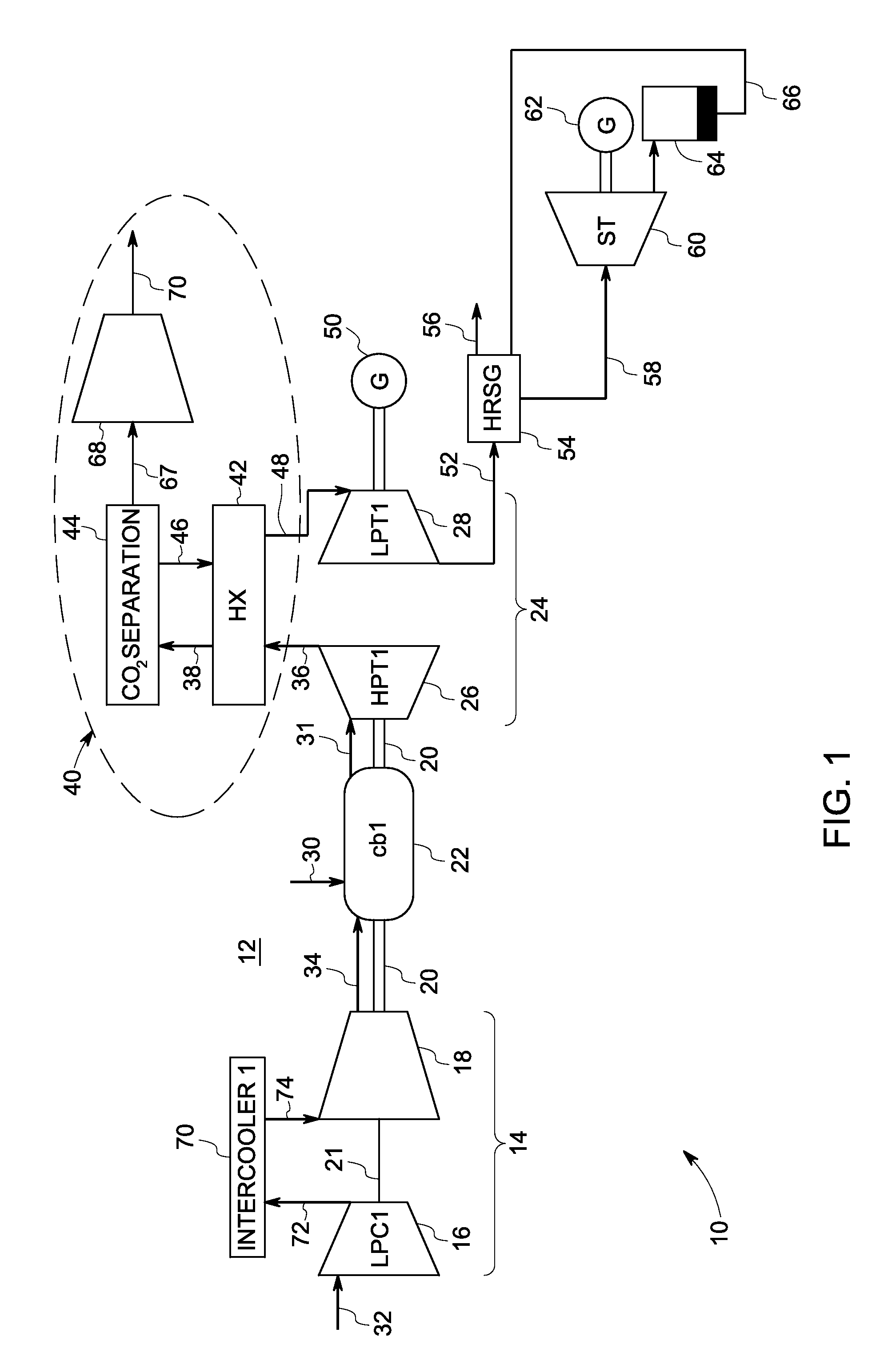

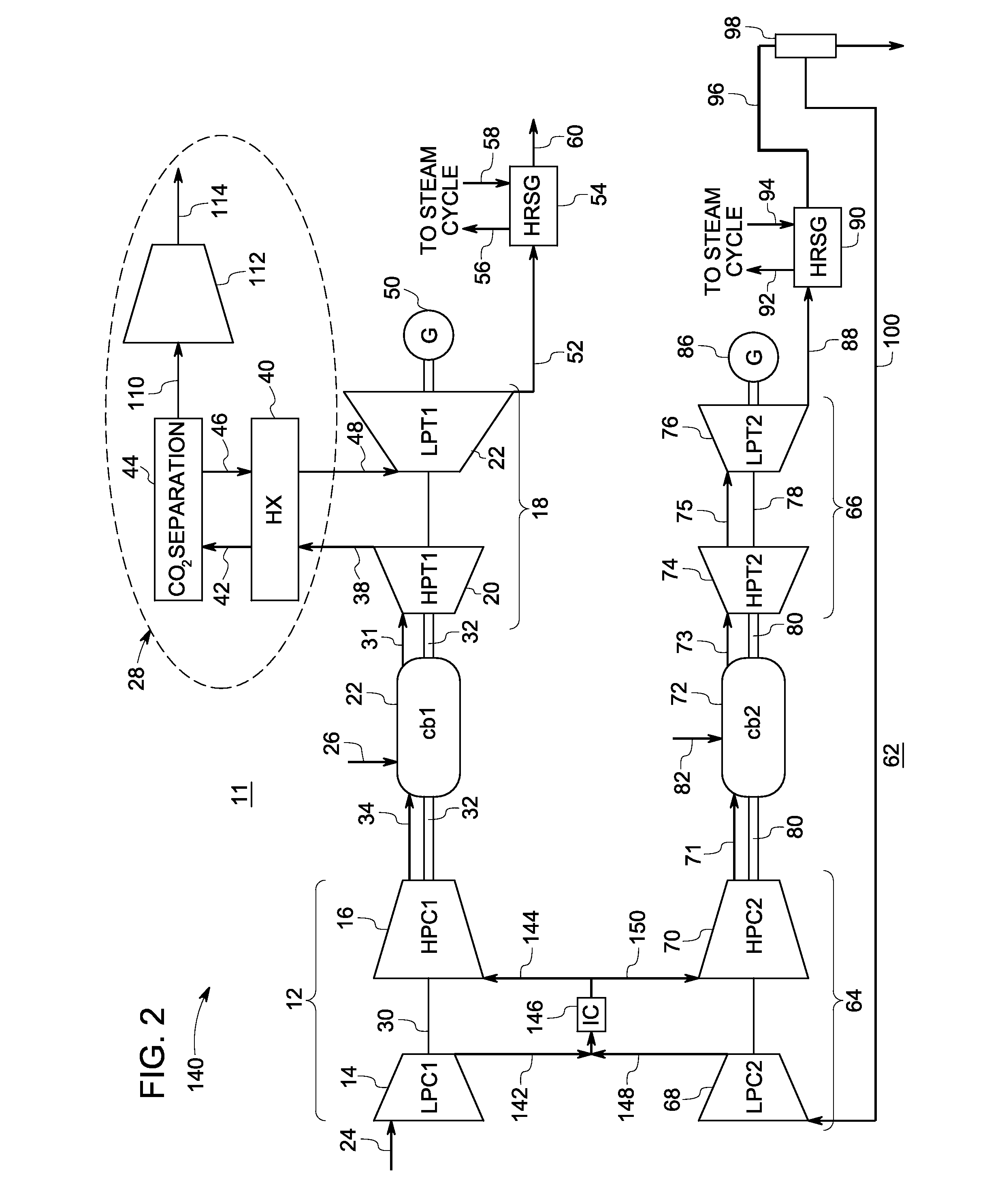

Systems and methods for power generation with carbon dioxide isolation

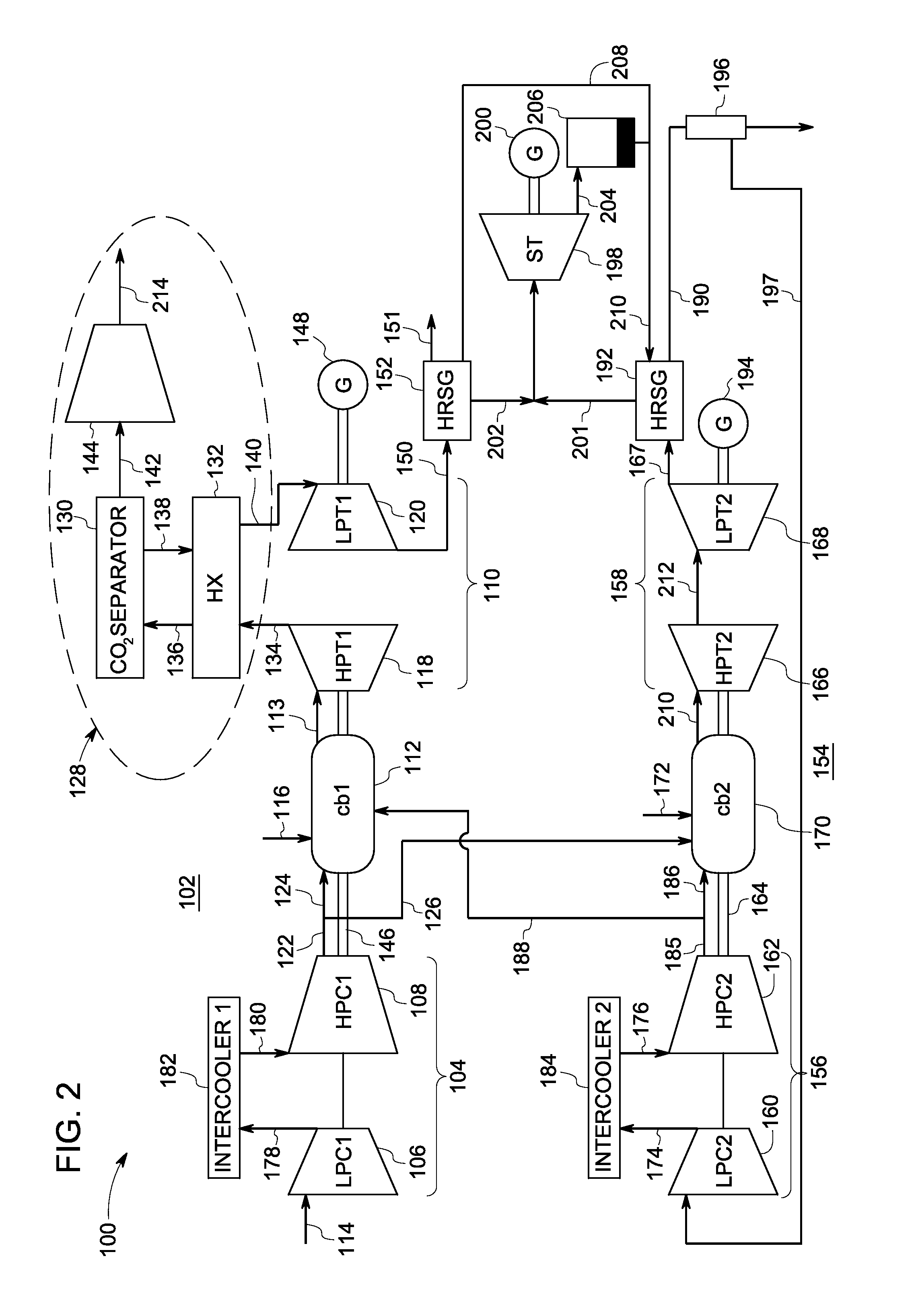

A power generation system includes a first turbine system. The first turbine system includes a first compressor section comprising at least two stages. The two stages includes a first low pressure compressor fluidly coupled to a first high pressure compressor configured to supply a first portion of compressed oxidant and a second portion of compressed oxidant A first combustion chamber is configured to combust said first portion of compressed oxidant and a first fuel stream comprising carbon-based fuels and to generate a first hot flue gas. The first turbine system further includes a first expander section having an inlet for receiving said first hot flue gas and generating a first expanded exhaust gas rich in CO2. The first high-pressure expander is fluidly coupled to a first low-pressure expander configured to generate a first exhaust and electrical energy. A CO2 separation system is fluidly coupled to the high-pressure expander for receiving said first expanded exhaust gas from said first high-pressure expander and provide a CO2 lean gas that is then fed to said first low-pressure expander. The power generation system also includes a second turbine system including a second compressor section comprising at least two stages. The two stages includes a second low-pressure compressor fluidly coupled to a second high pressure compressor, wherein said high pressure compressor is configured to receive said second portion of compressed oxidant. A second combustion chamber is configured to combust a second fuel stream comprising carbon-based fuels and to generate a second hot flue gas and a second expander section is configured to receive said second hot flue gas and to generate a second final exhaust and electrical energy. The second compressor section is configured to receive said second final exhaust comprising carbon dioxide and to discharge a recycle stream from said second high pressure compressor to said second combustion chamber and a split stream from said second low-pressure compressor to said first high pressure compressor.

Owner:GENERAL ELECTRIC CO

Systems and methods for power generation with carbon dioxide isolation

Owner:GENERAL ELECTRIC CO

High flash point additives for treating carbon-based fuels

Owner:LIQUID MINERALS GRP LTD

High flash point additives for treating carbon-based fuels

A simple method is disclosed to produce oil soluble nano particle size additives with significantly higher flash points to improve the safety aspects of these products especially when used in, around, and near high temperature combustion equipment.

Owner:LIQUID MINERALS GRP LTD

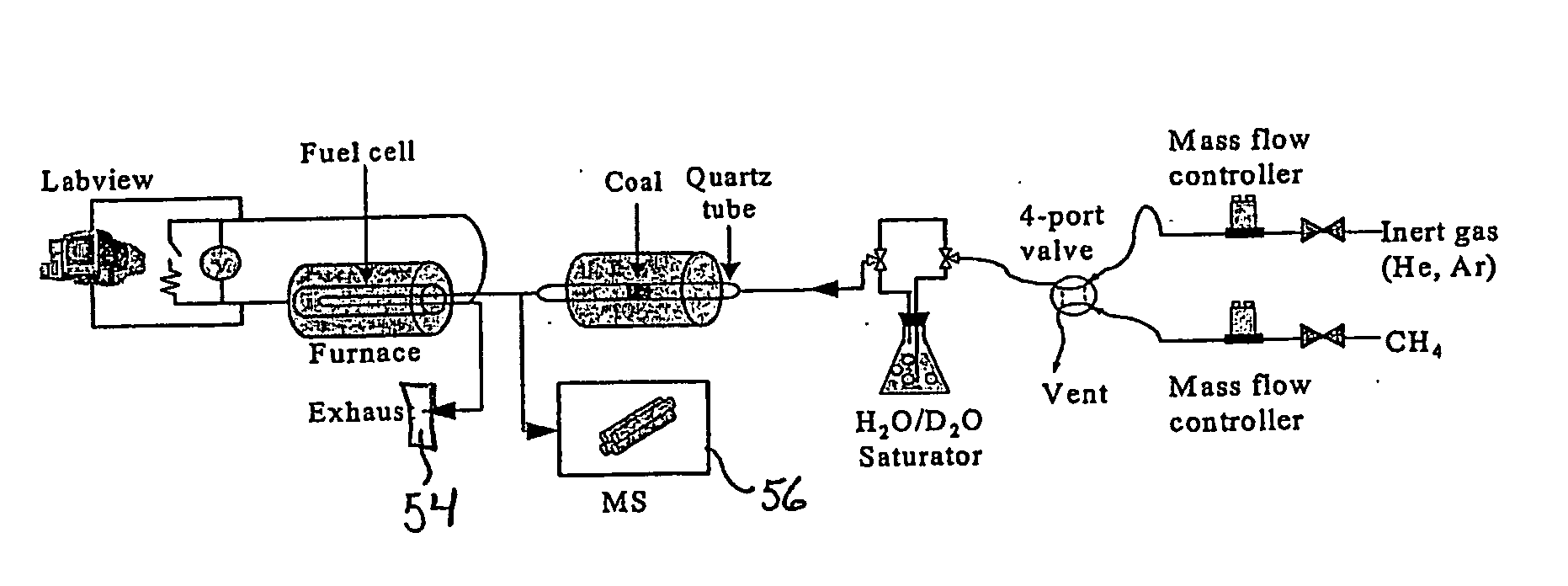

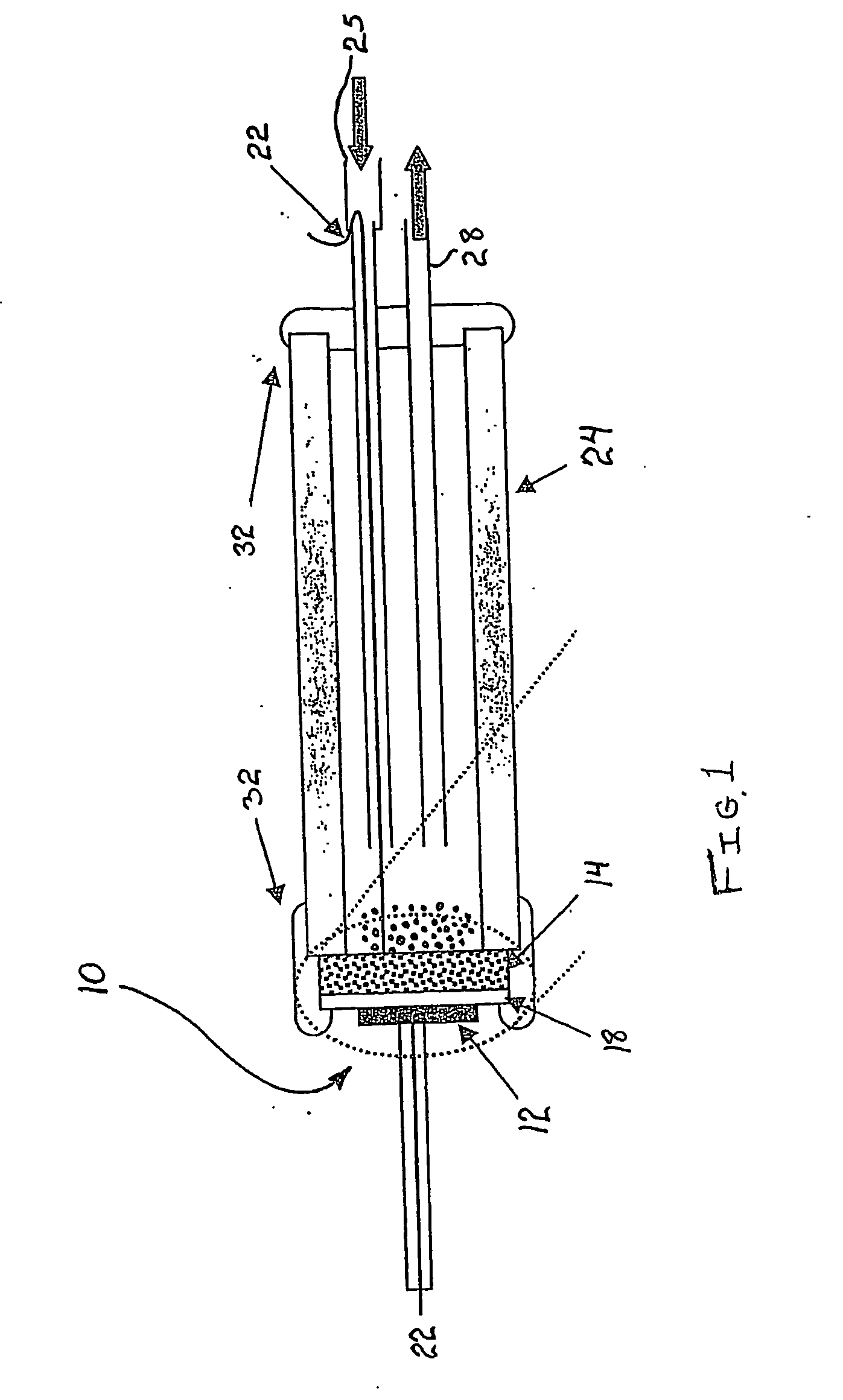

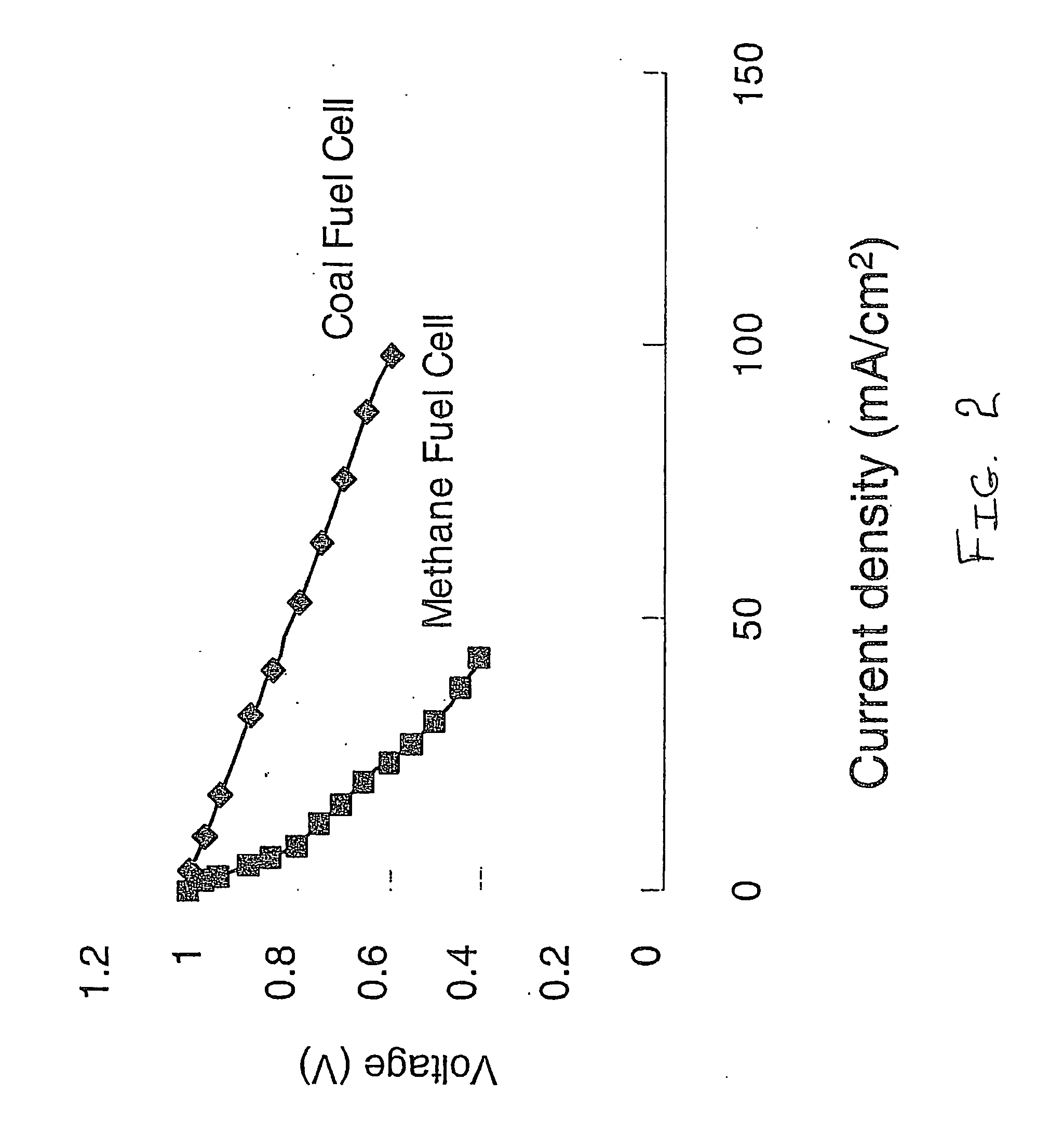

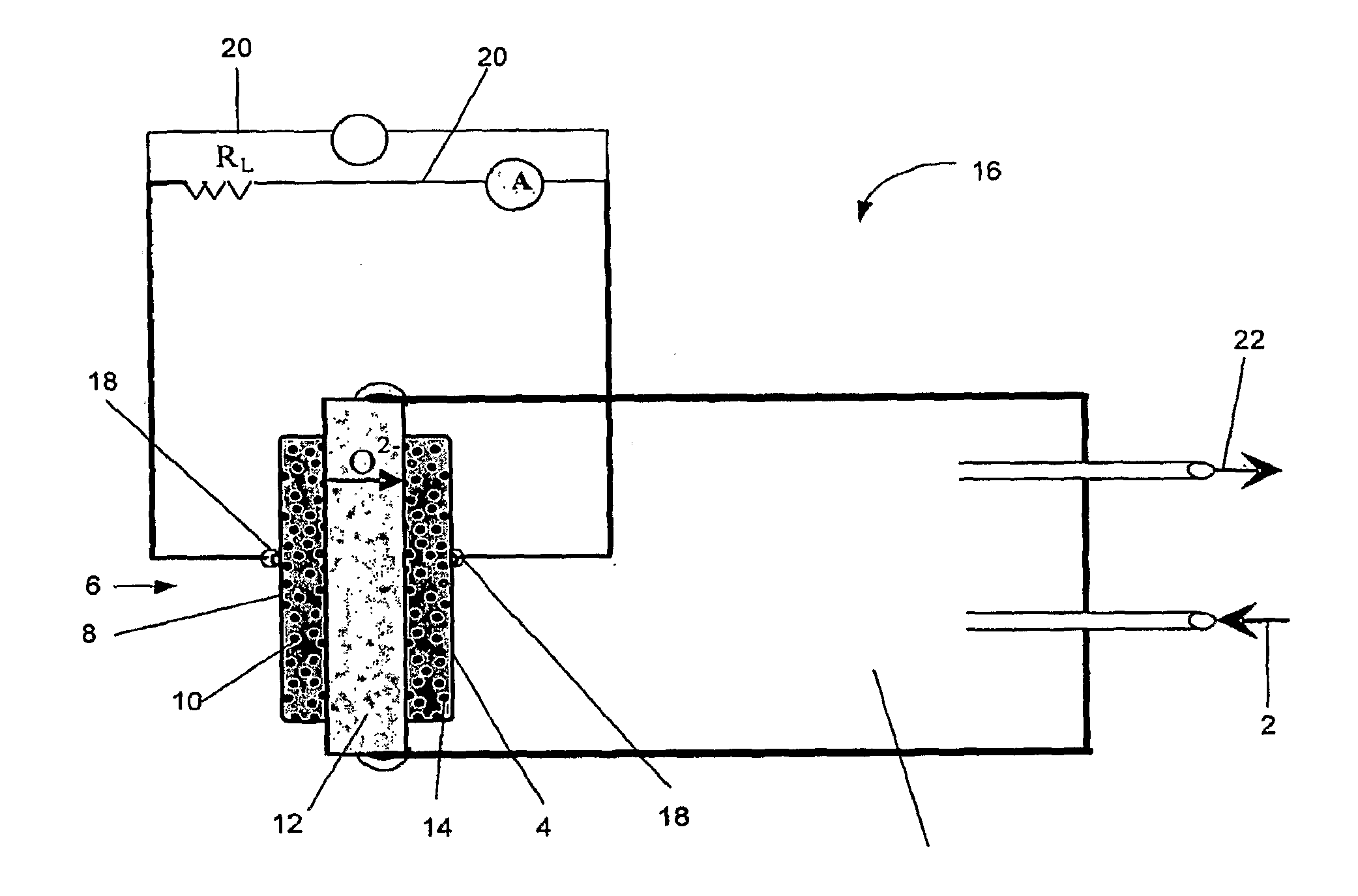

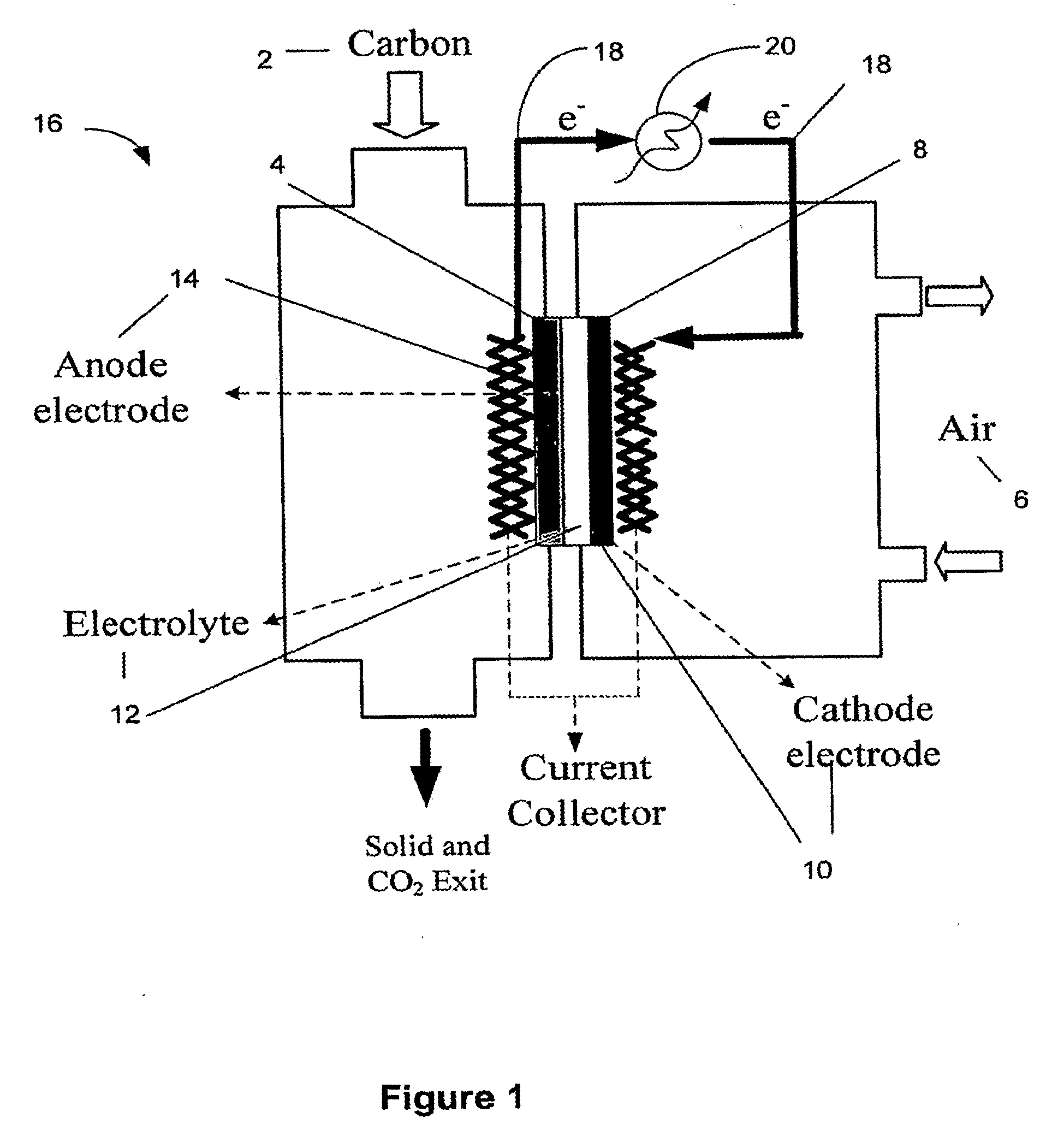

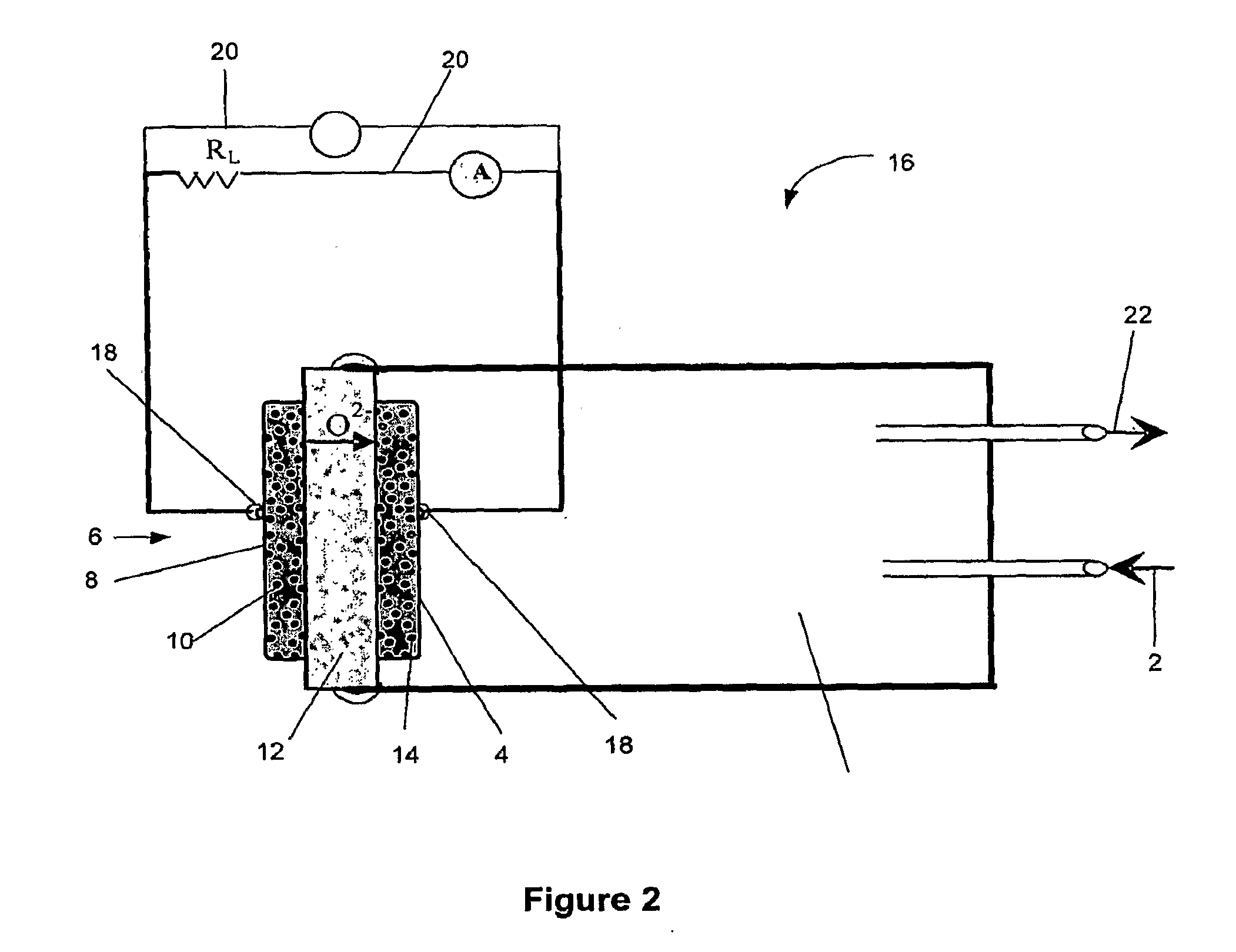

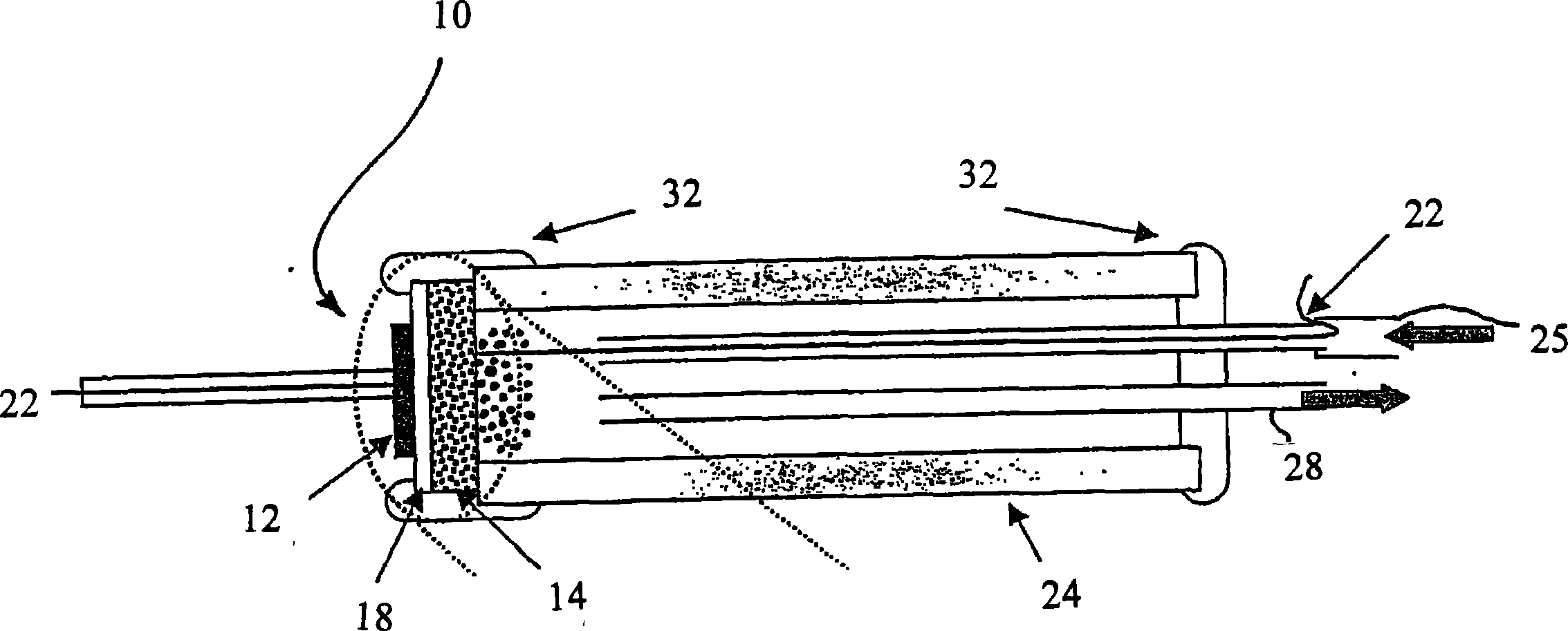

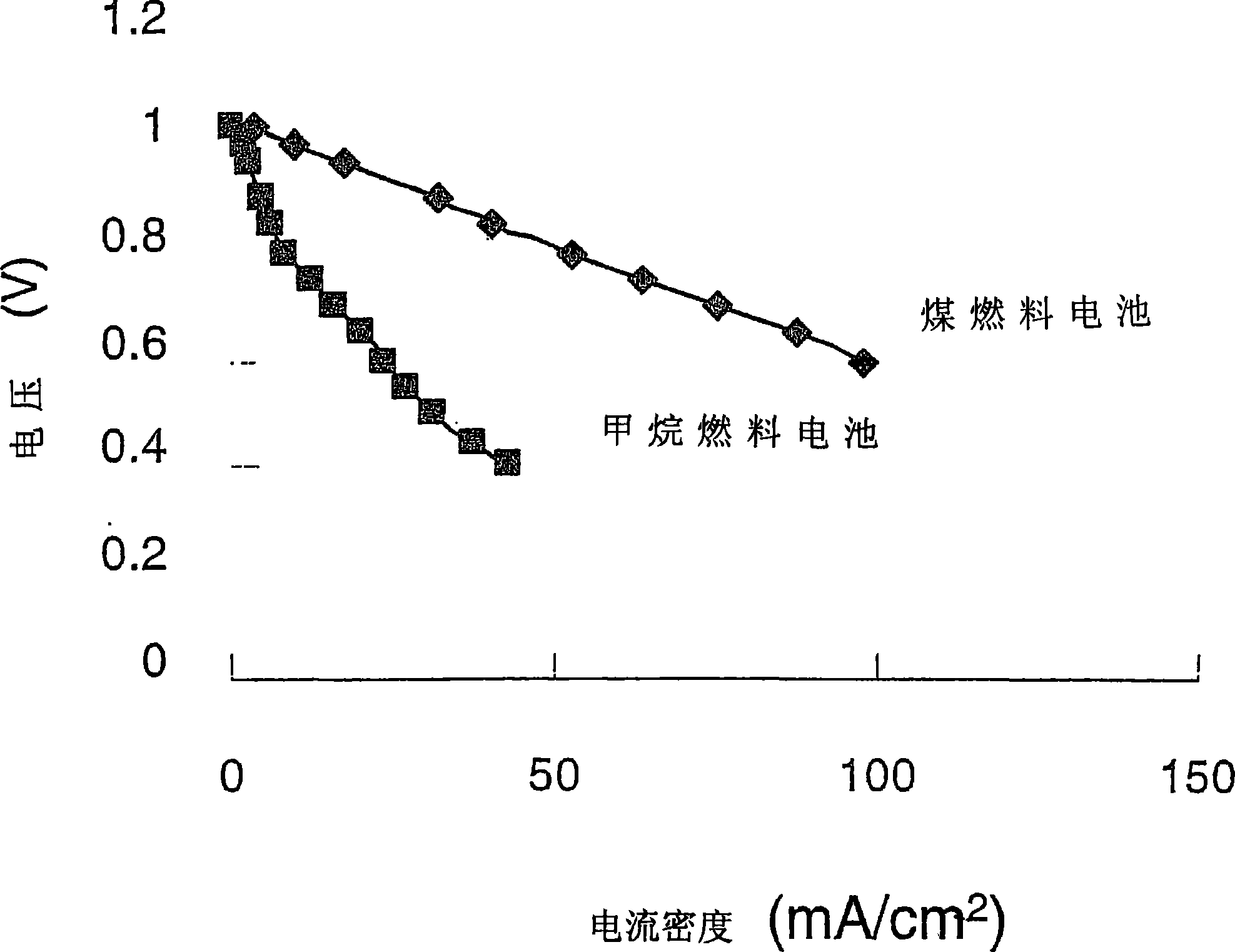

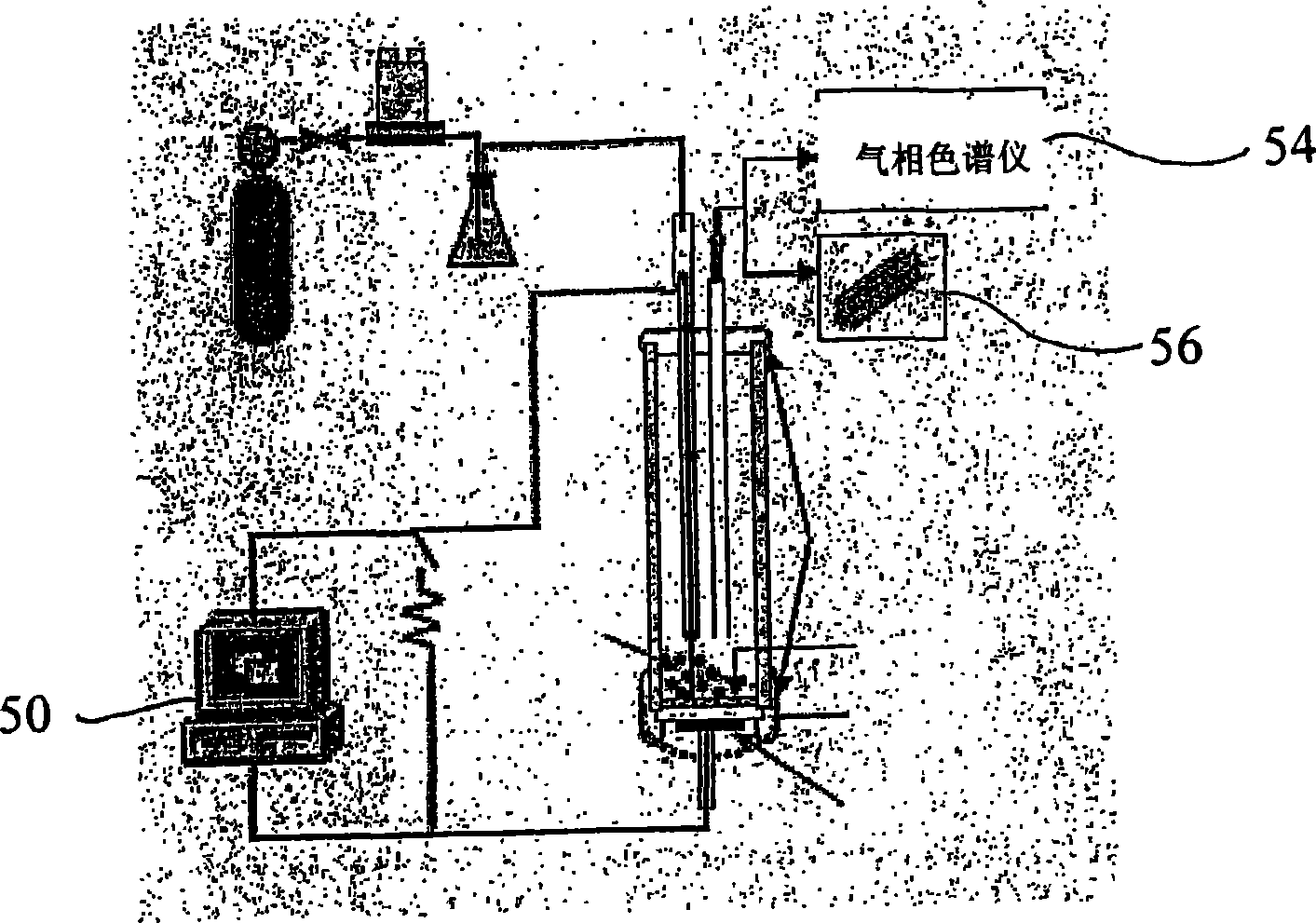

Carbon-Based Fuel Cell

ActiveUS20070212584A1Promote oxygen productionEasy to produceFuel and primary cellsReactant parameters controlFuel cellsSulfur

A direct-electrochemical-oxidation fuel cell and method for generating electrical energy from a solid-state organic fuel. The fuel cell includes a cathode provided with an electrochemical-reduction catalyst that promotes formation of oxygen ions from an oxygen-containing source at the cathode, an anode provided with an electrochemical-oxidation catalyst that promotes direct electrochemical oxidation of the solid-state organic fuel in the presence of the oxygen ions to produce electrical energy, and a solid-oxide electrolyte disposed to transmit the oxygen ions from the cathode to the anode. The electrochemical oxidation catalyst can optionally include a sulfur resistant material.

Owner:AKRON UNIV OF

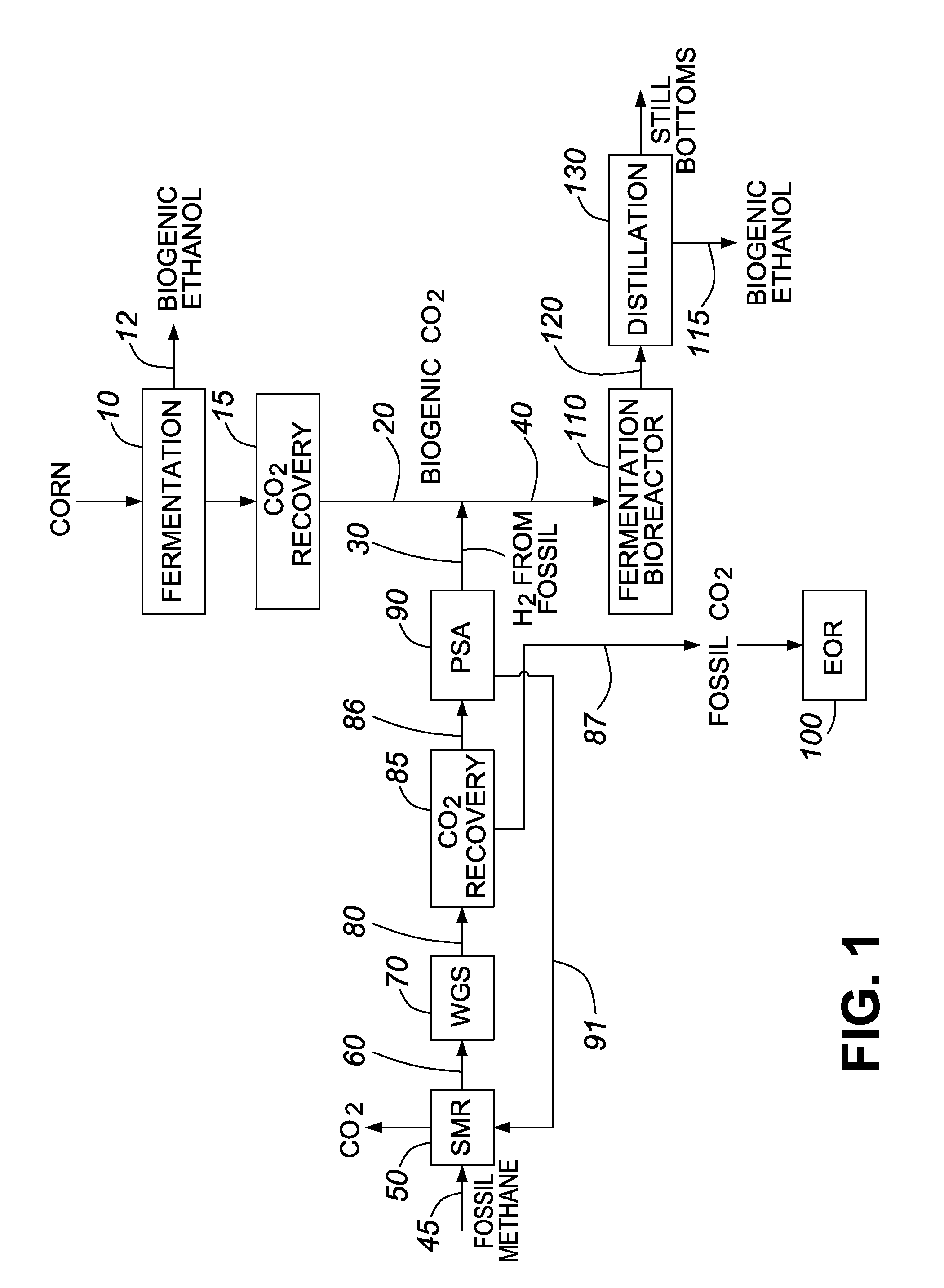

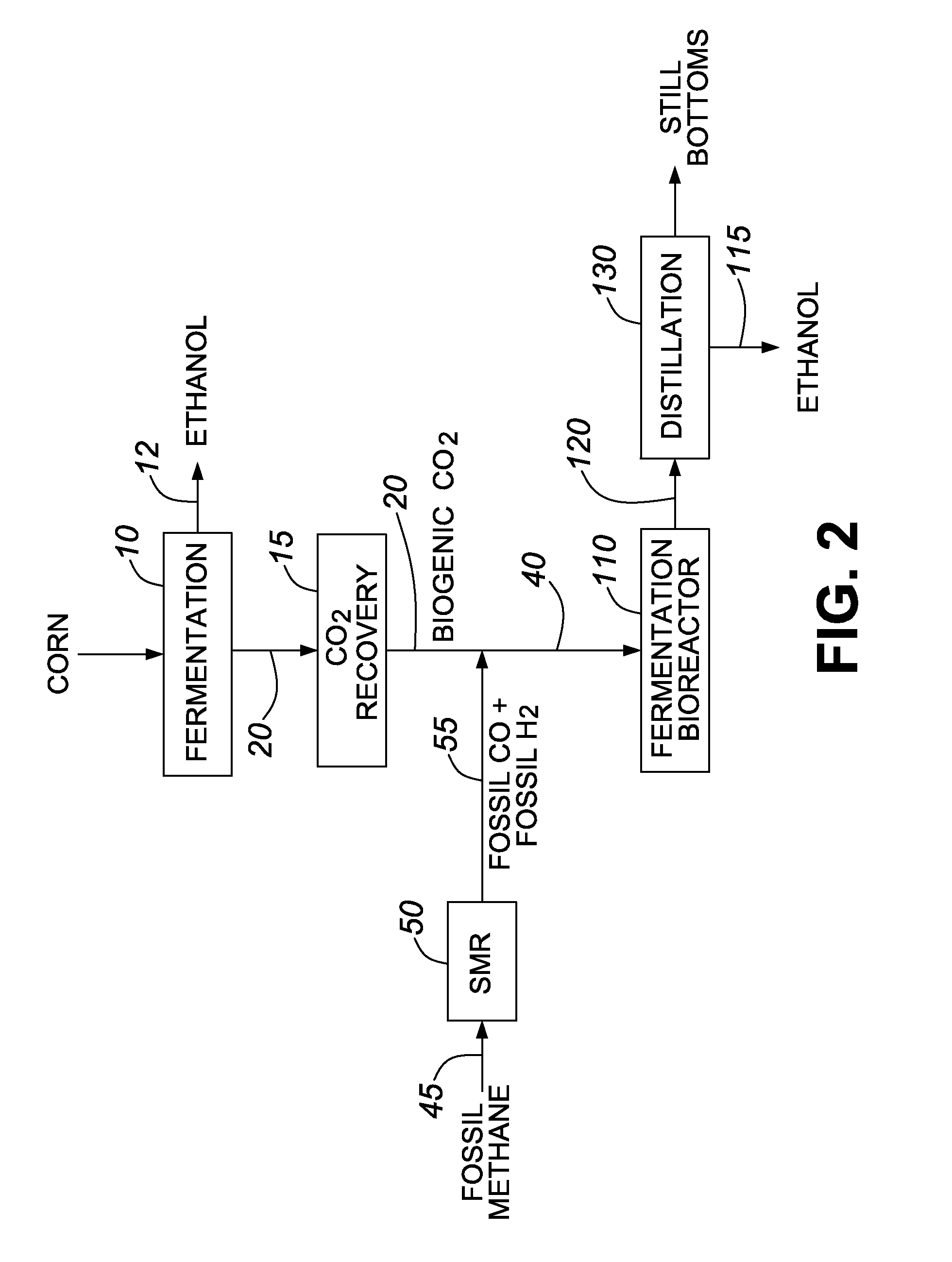

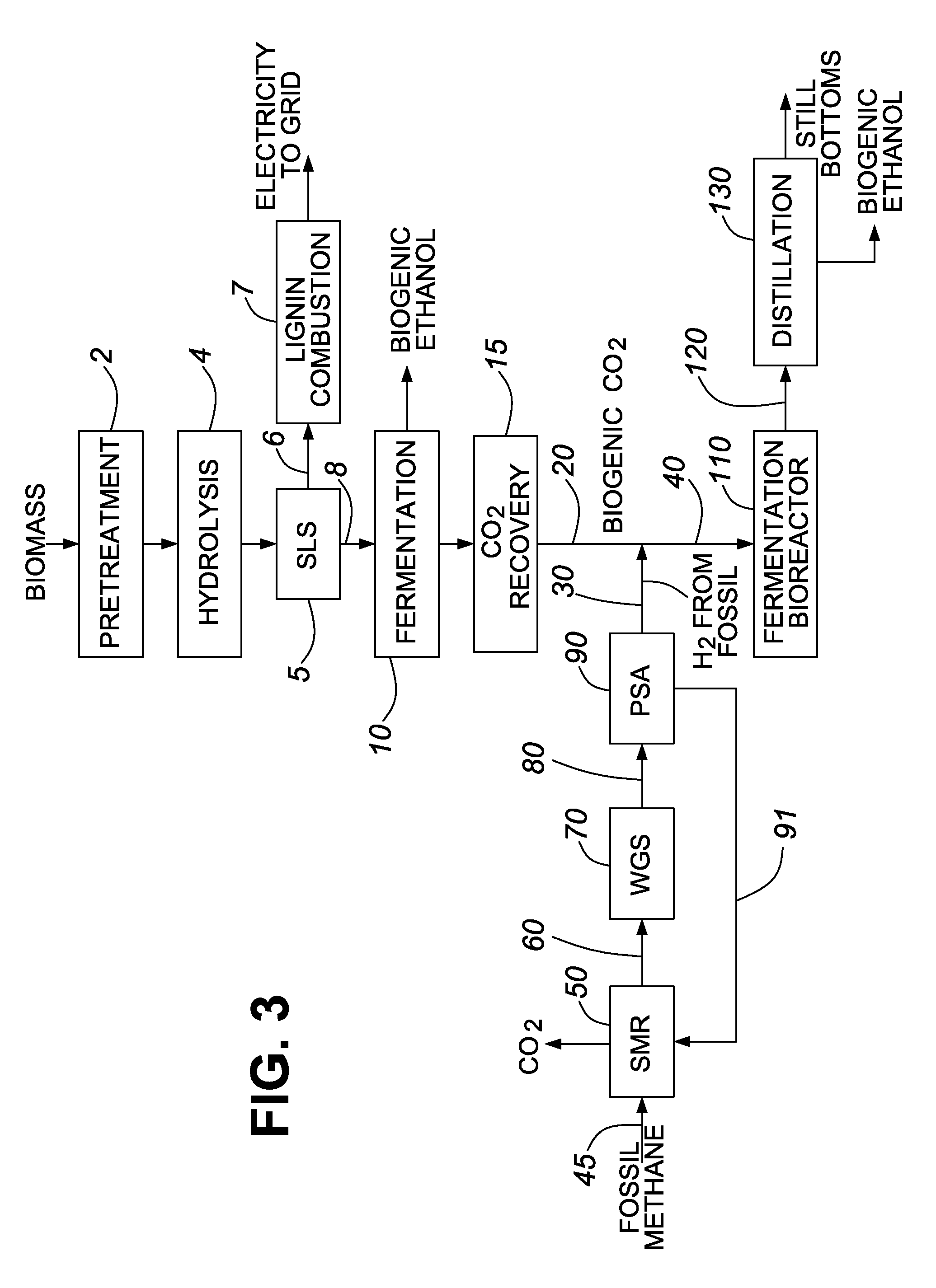

Process for using biogenic carbon dioxide derived from non-fossil organic material

ActiveUS9108894B1Improve production yieldProduce moreCarbon compoundsBiofuelsEnergy productsHydrogen

The present disclosure provides a process for forming a biogenic carbon-based fuel or a fuel intermediate from biogenic carbon dioxide and hydrogen. The hydrogen is sourced from a process that produces hydrogen and fossil carbon dioxide from a fossil-fuel hydrocarbon and separates the fossil carbon dioxide from the hydrogen. The process may further comprise carrying out or arranging for one or more parties to carry out at least one step that contributes to a reduction in the GHG emissions of the biogenic carbon-based fuel, or a fuel made from the fuel intermediate, of at least 20% relative to a gasoline baseline. In various embodiments this includes (a) introducing the fossil carbon dioxide underground, and / or (b) using a biogenic carbon-based product selected from a chemical and energy product produced from the non-fossil organic material to displace the use or production of a corresponding fossil-based product. Methods of using the present invention to enable fuel credit generation are also described.

Owner:IOGEN CORPORATION

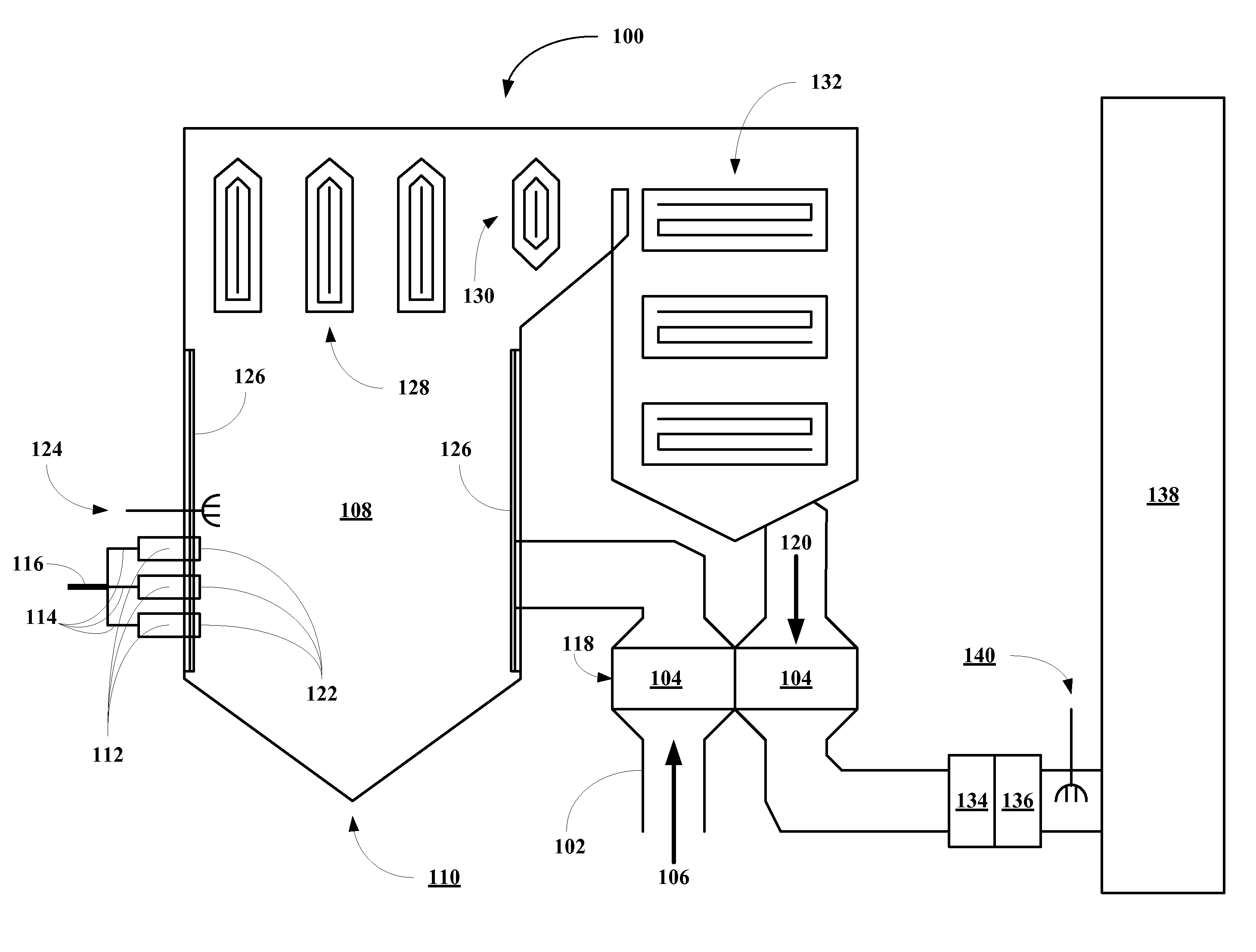

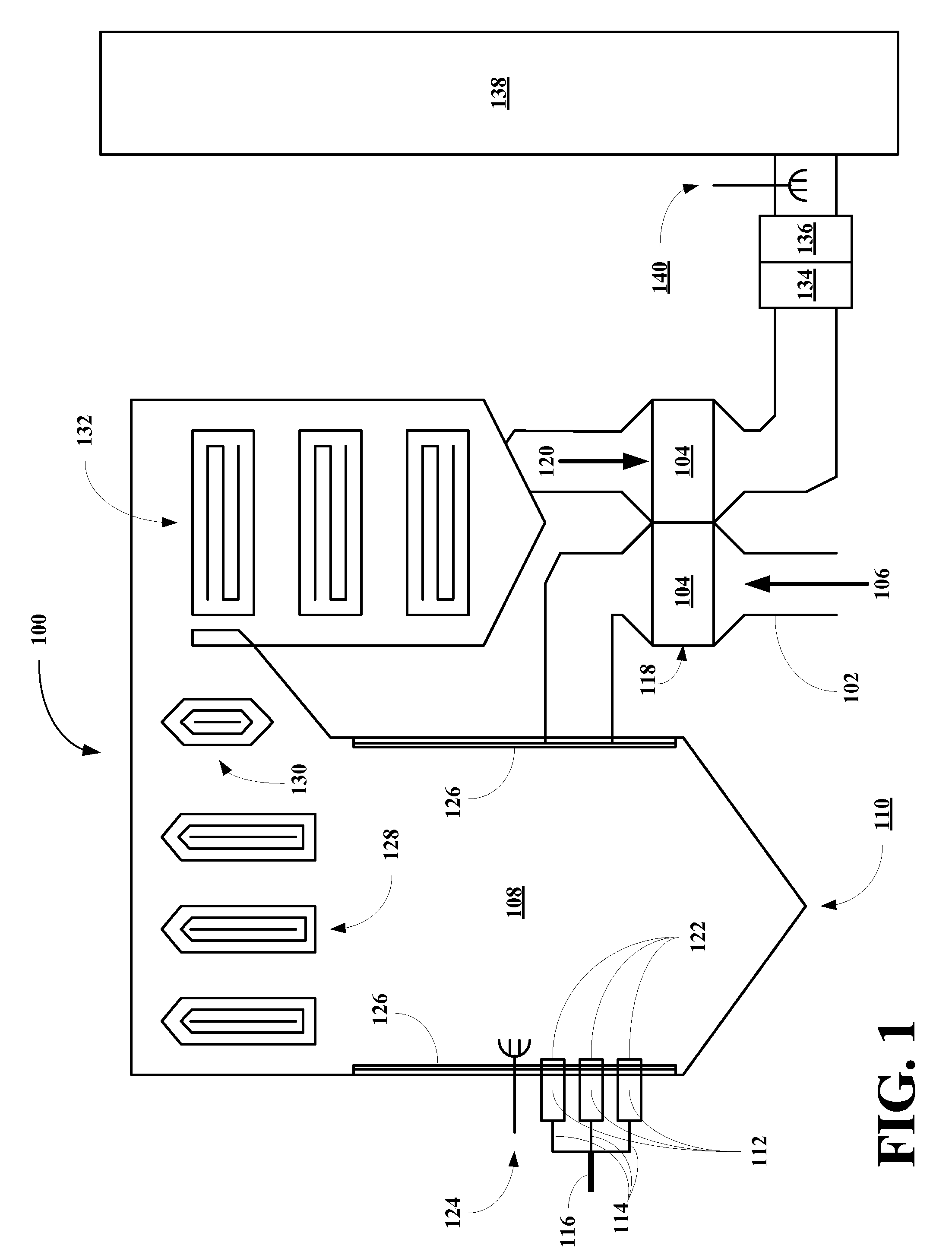

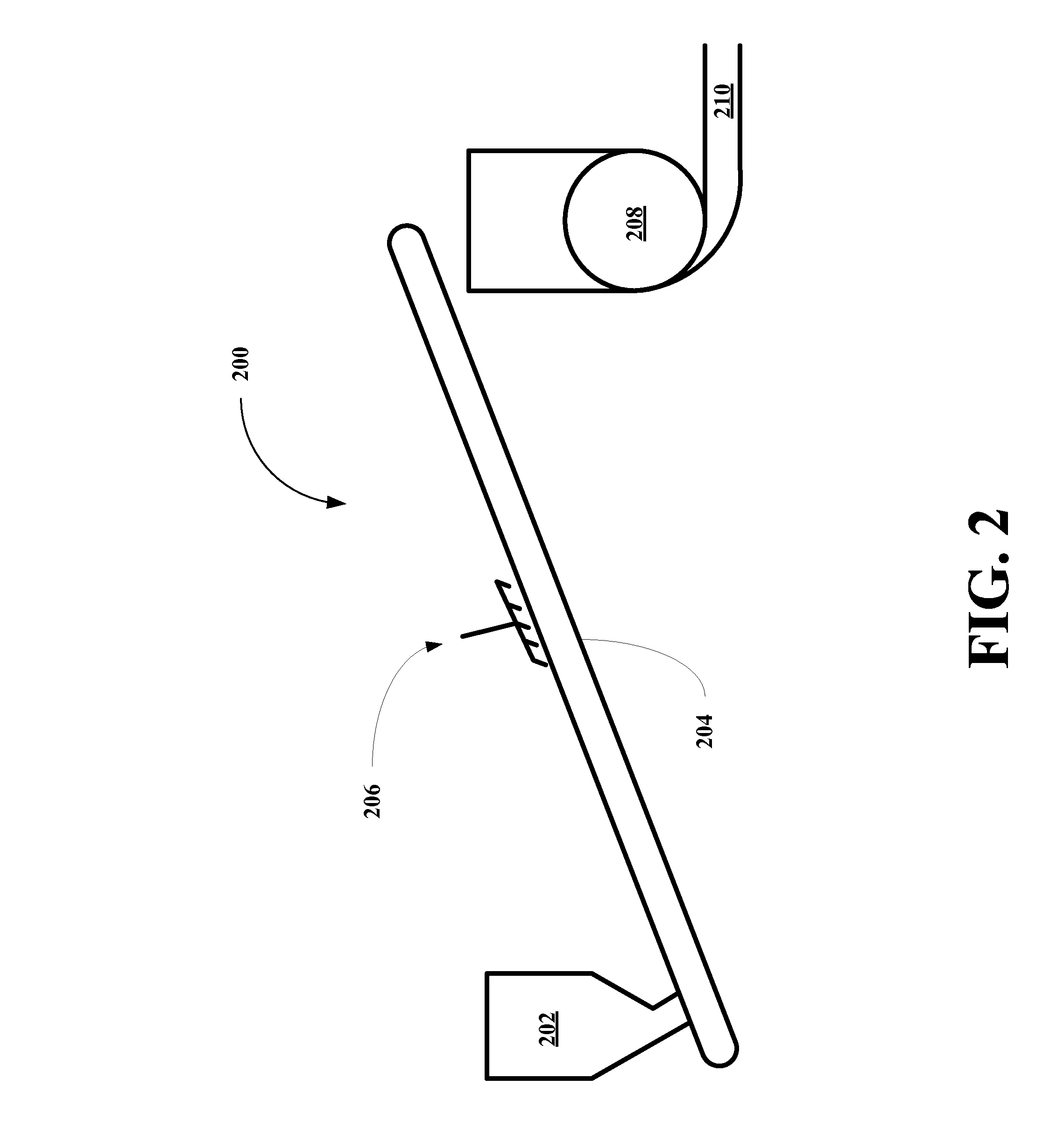

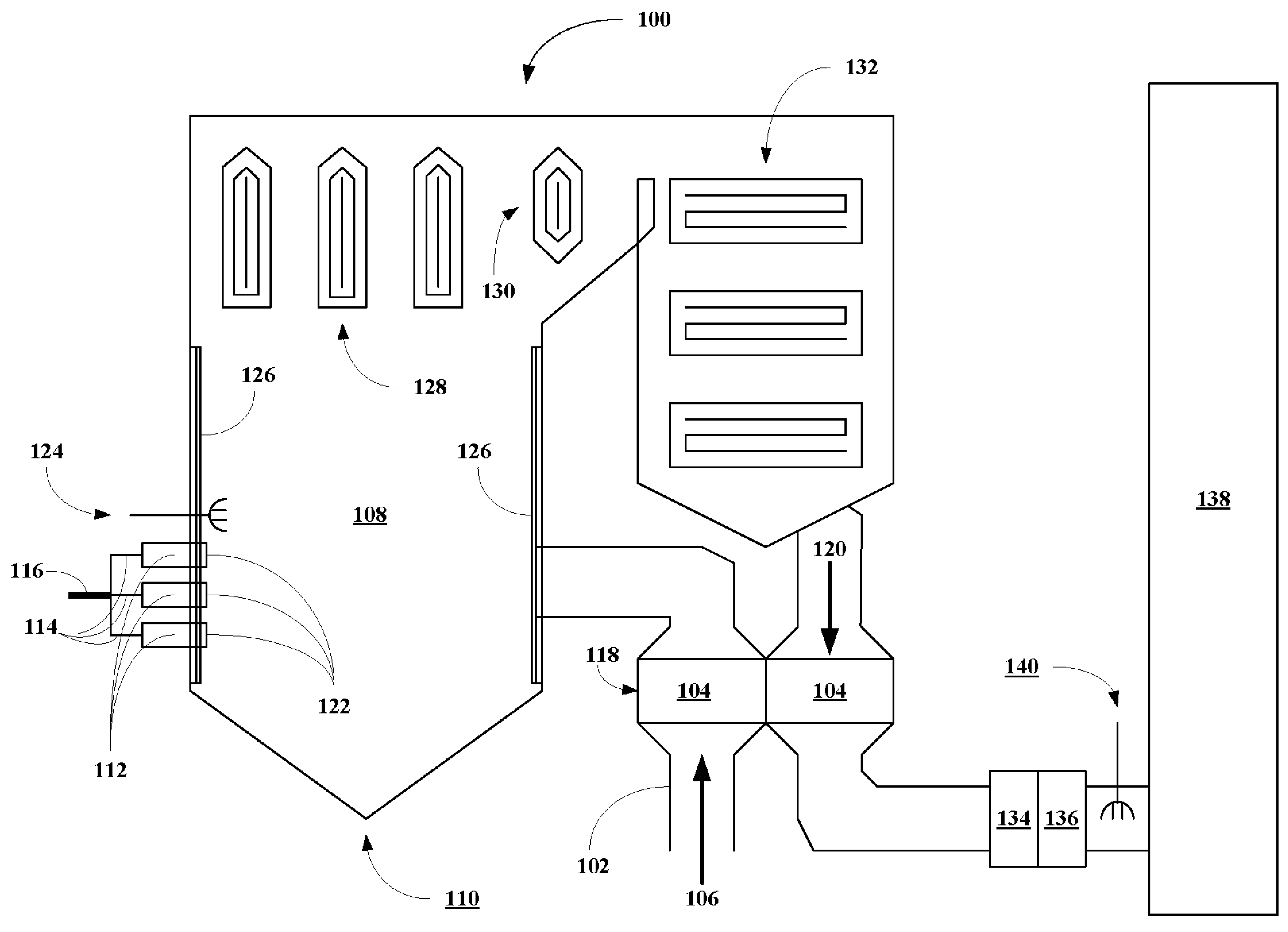

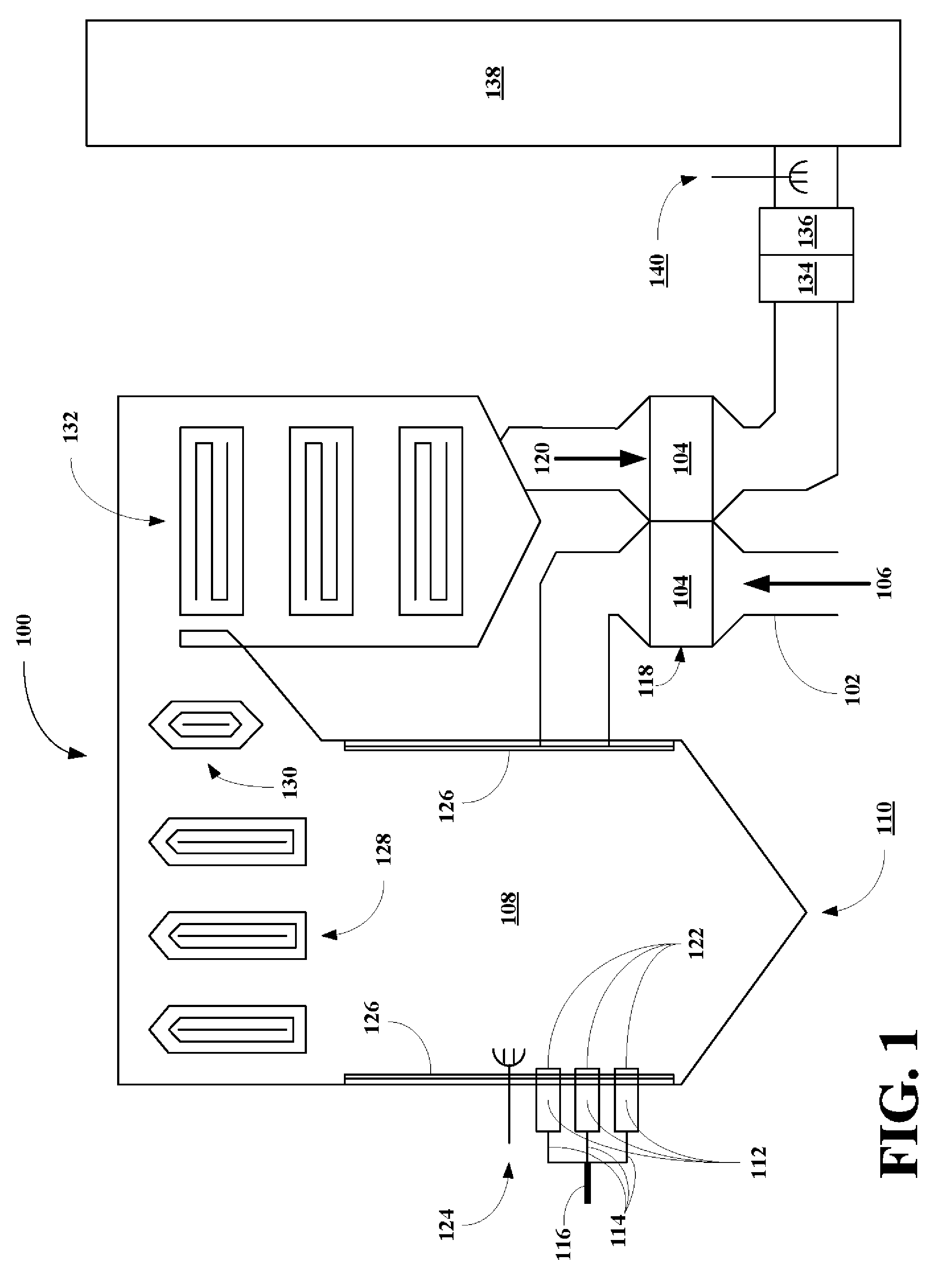

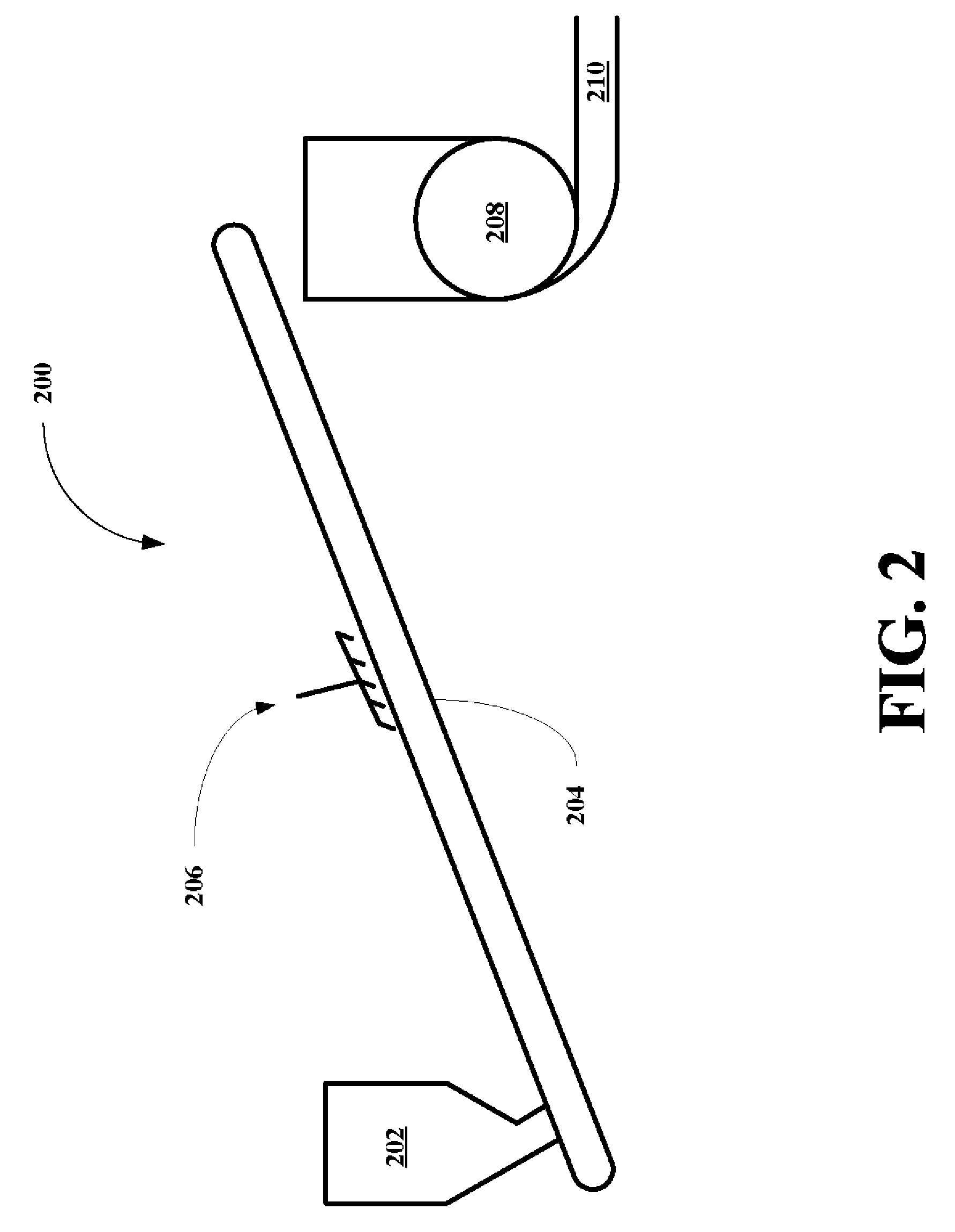

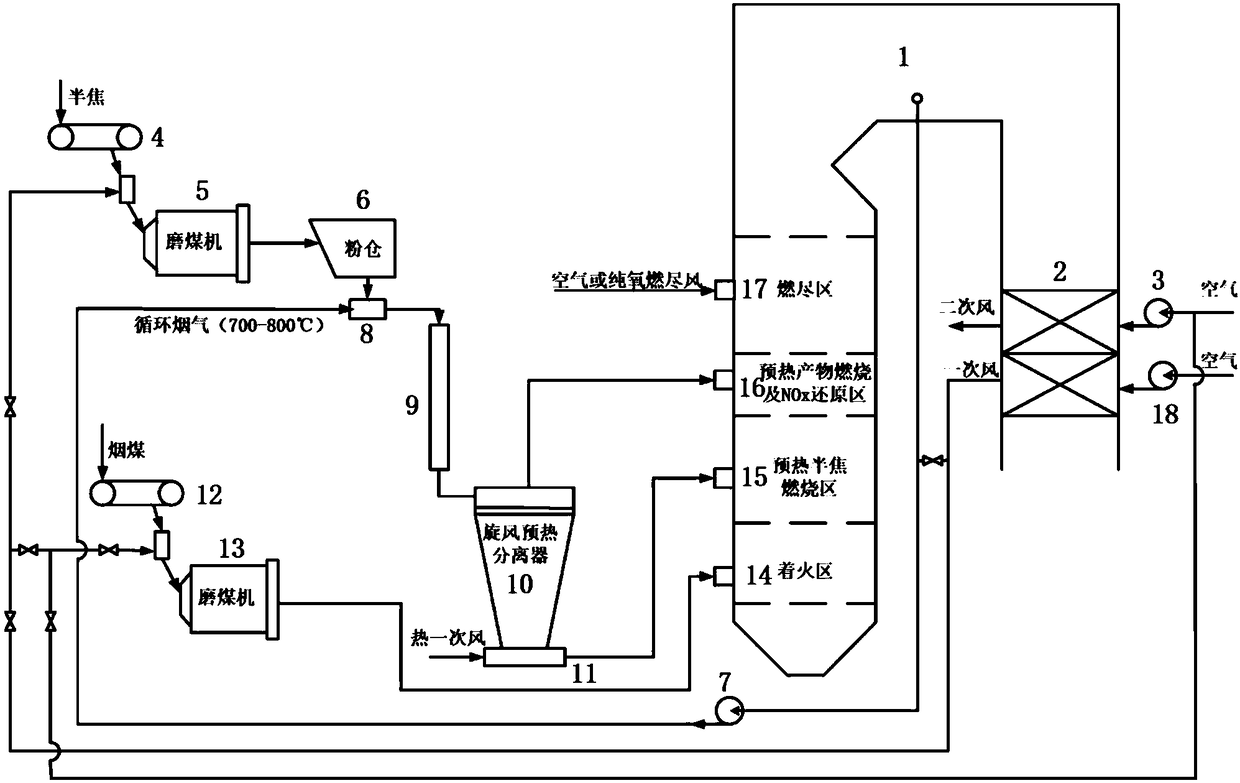

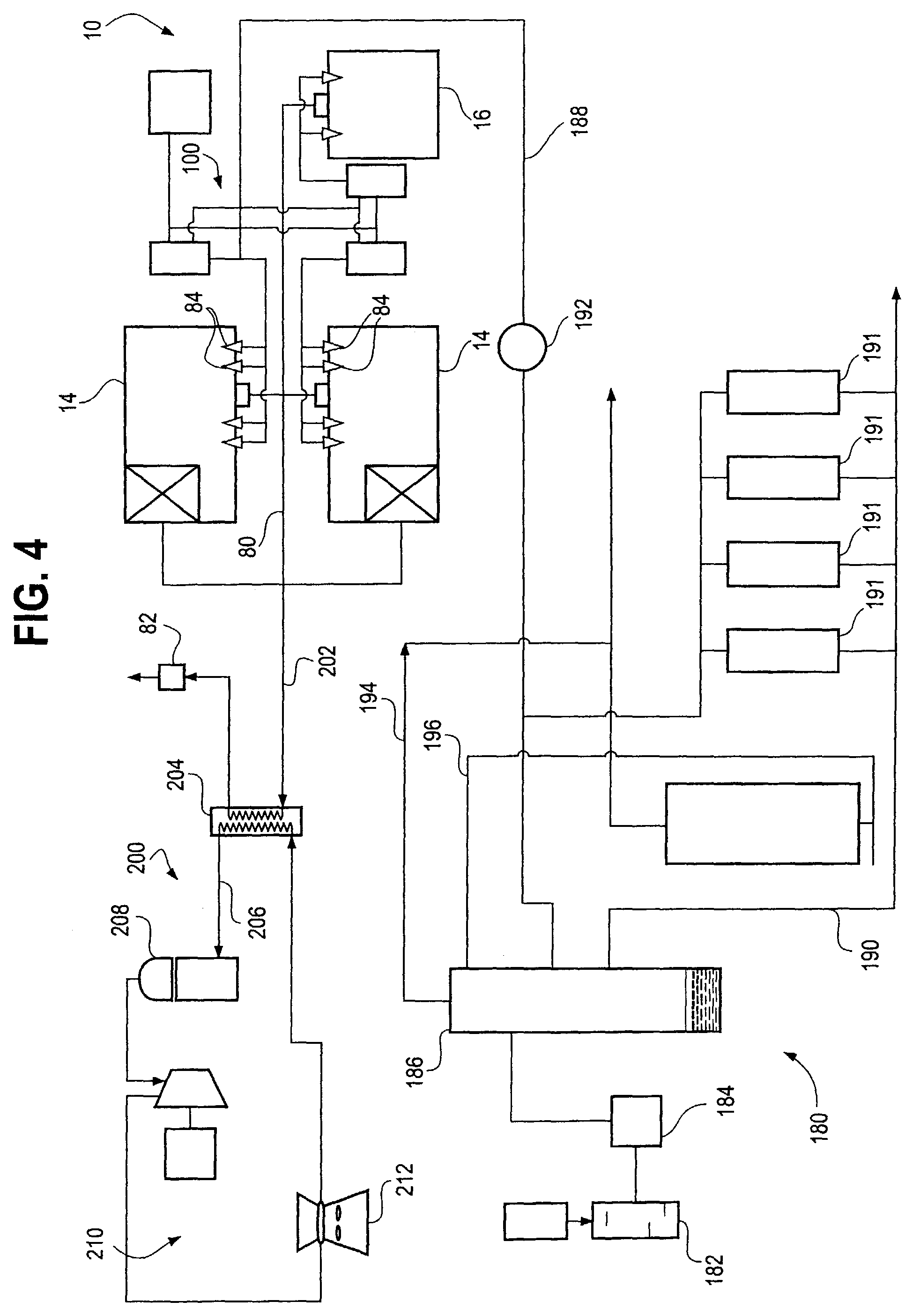

Low NOx hybrid combustion system and method for preheating semi-coke by high-temperature flue gas of power station boiler

ActiveCN108151008AIncrease temperatureFire guaranteeGas treatmentDispersed particle separationCycloneCombustion system

The invention relates to a low NOx hybrid combustion system and method for preheating semi-coke by high-temperature flue gas of a power station boiler. According to the hybrid combustion system and method, a preheating pipeline and a cyclone preheating separator are adopted, the semi-coke is directly preheated through the high-temperature flue gas, so that the temperature of the semi-coke sprayedinto a hearth is remarkably improved; meanwhile, a stable ignition region for combustion of bituminous coal is arranged at the lower part of the hearth, so that ignition and flame stabilization of combustion of ultra-low volatile semi-coke fuel are facilitated, and the large proportion (larger than or equal to 45%) blending combustion of the semi-coke fuel of the power station boiler is achieved;a preheating product with the relatively strong reducibility is produced while the semi-coke is preheated, the preheating product is directly sprayed into the middle part of the hearth through a combustor, a NOx reduction zone is formed on the upper part of a preheating semi-coke combustion zone, so that emission of NOx is greatly reduced, and low NOx combustion of ultra-low volatile carbon-basedfuel is effectively realized; and air or pure oxygen over fire air is injected into the upper part of a combustion region of the hearth so that the fuel can be completely combusted, and the carbon content of the fly ash and the NOx emission can be effectively reduced.

Owner:XI AN JIAOTONG UNIV

Carbon dioxide sequestration using alkaline earth metal-bearing minerals

ActiveUS7722842B2High dissolution rateEfficient removalCalcium/strontium/barium carbonatesProductsParticulatesAlkaline earth metal

A method for mineral sequestration of pollutant gases resulting from the combustion of carbon-based fuels such as carbon and sulfur dioxides is provided and includes, providing a particulate magnesium-containing mineral and exposing the magnesium-containing mineral to a weak acid to dissolve magnesium from the mineral and form a magnesium-containing solution. The surface of the particulate magnesium-containing mineral is physically activated to expose and dissolve additional magnesium into the solution. Pollutant gases such as carbon dioxide are mixed with the magnesium-containing solution. When the pH of the magnesium-containing solution is increased, solid magnesium carbonate is formed.

Owner:THE OHIO STATES UNIV

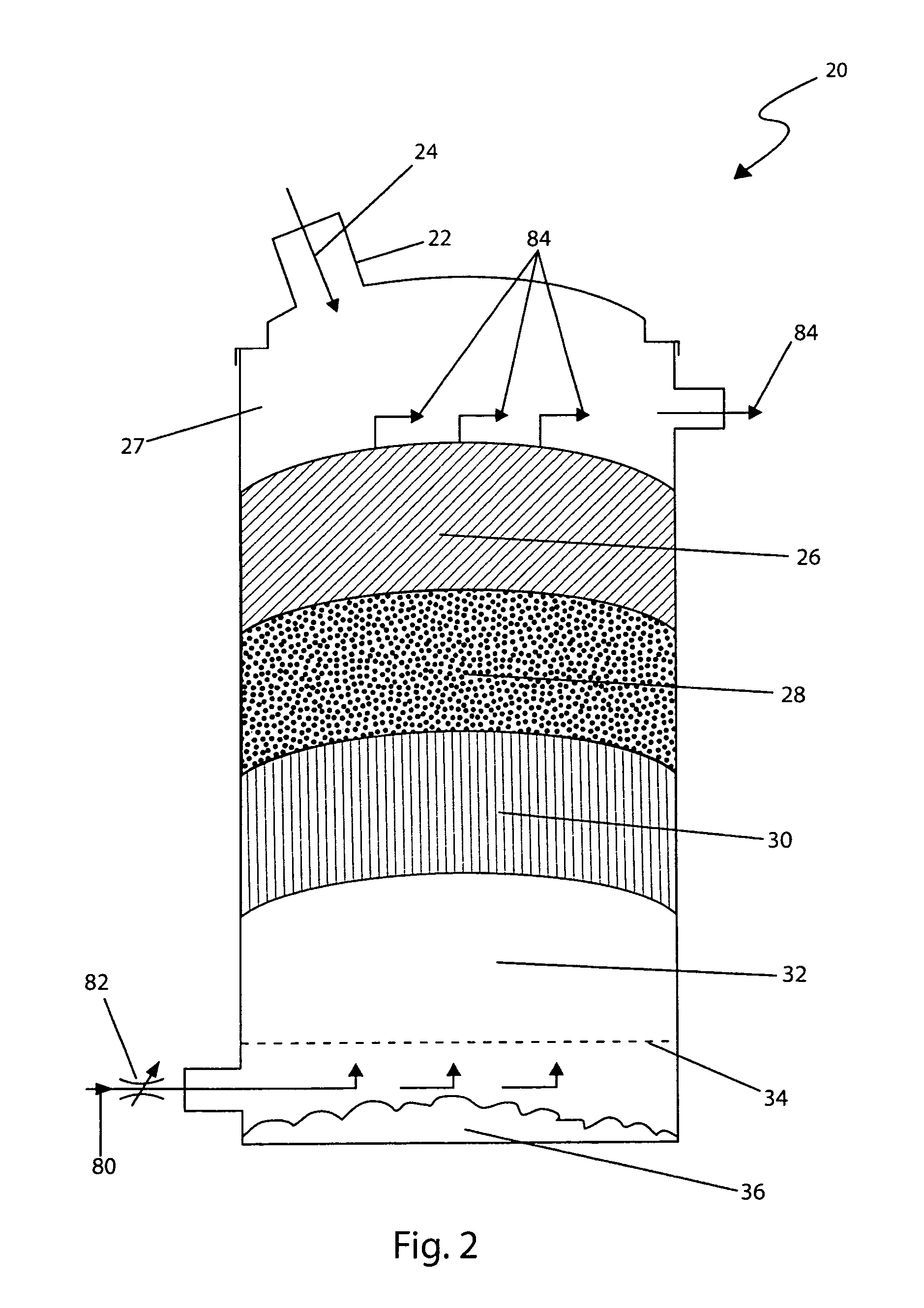

Module-based oxy-fuel boiler

InactiveUS7516620B2Avoid introducingFluidized bed combustionSteam useCombustion systemEnergy transfer

Owner:JUPITER OXYGEN CORP

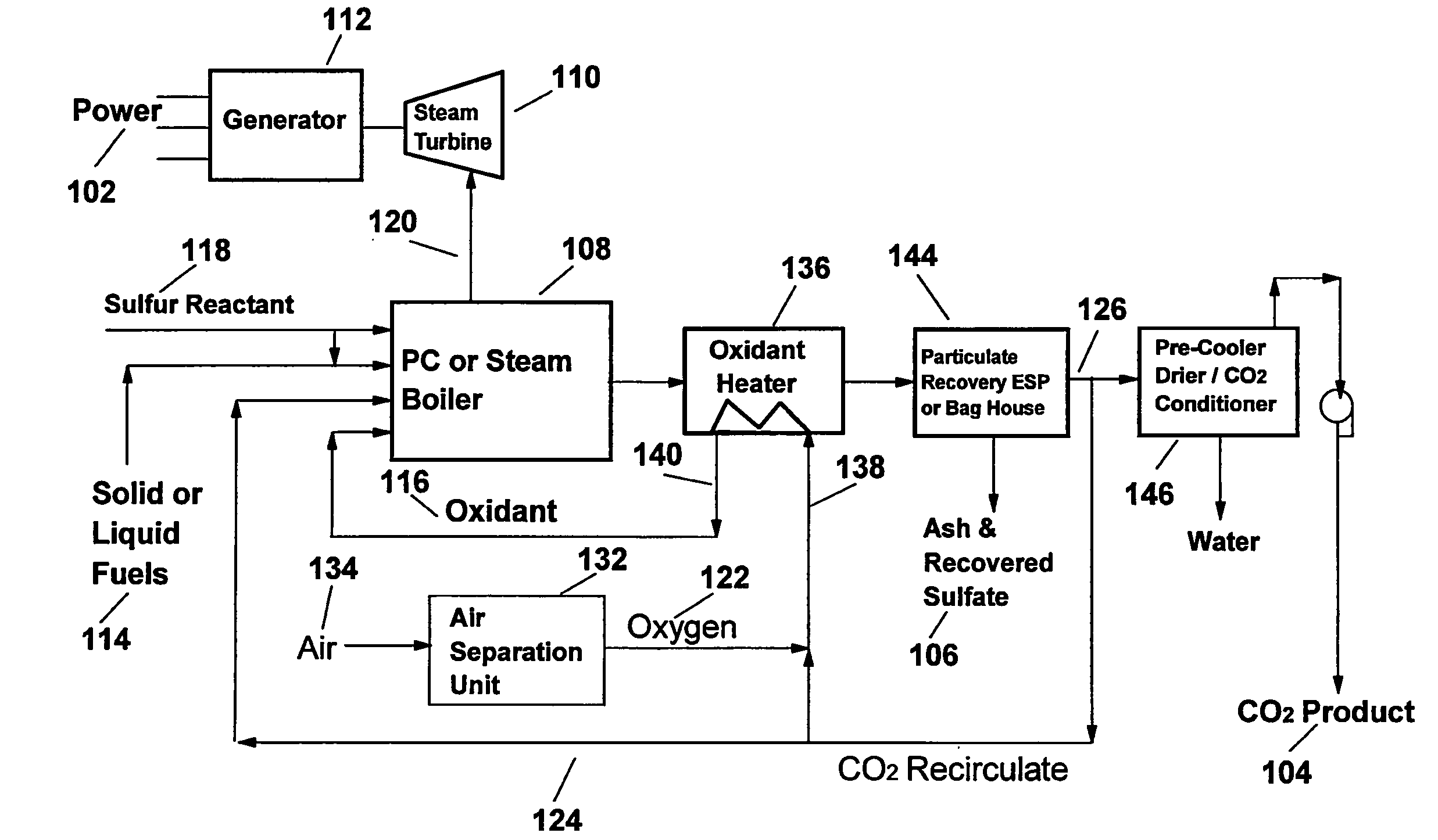

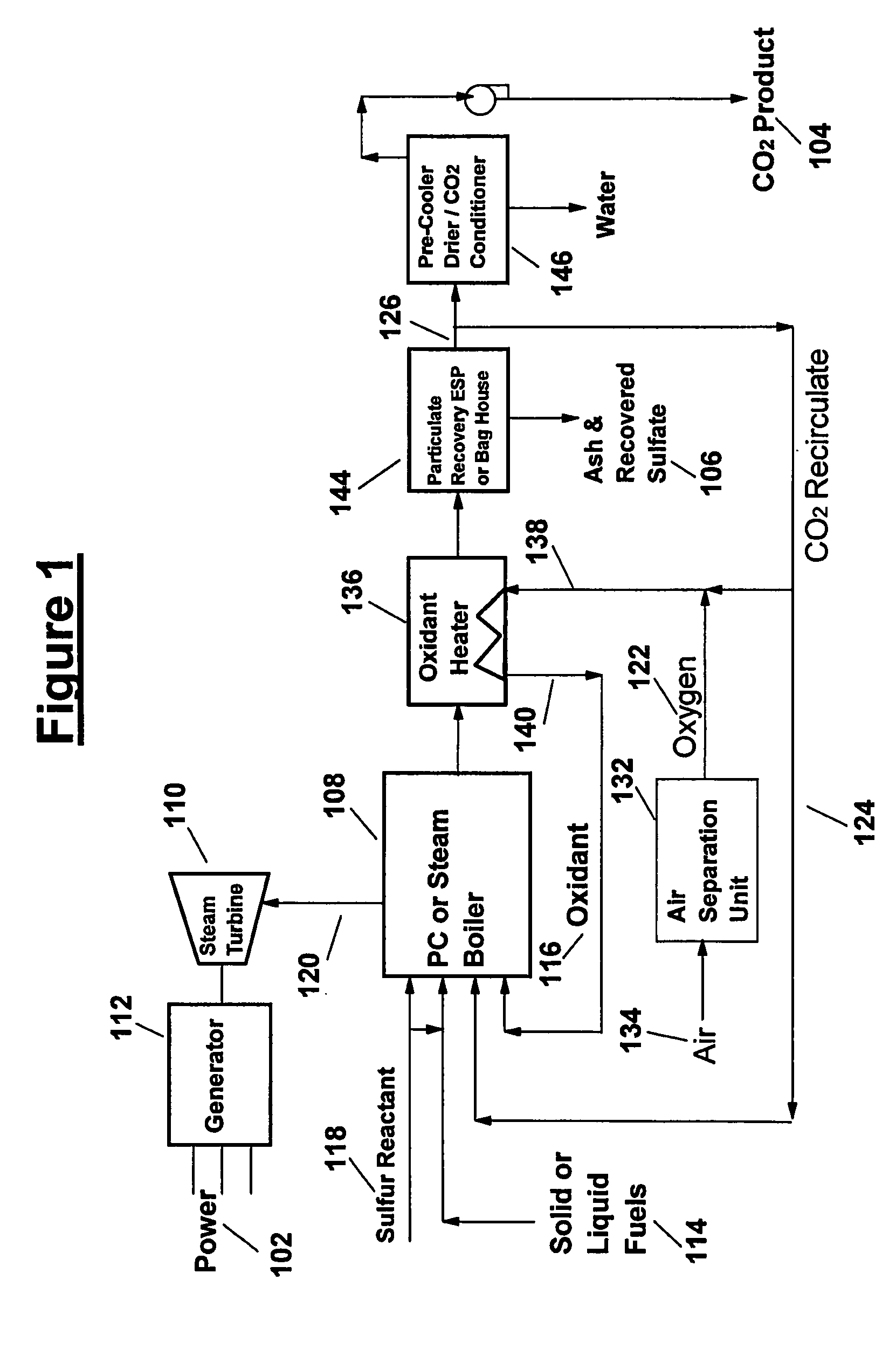

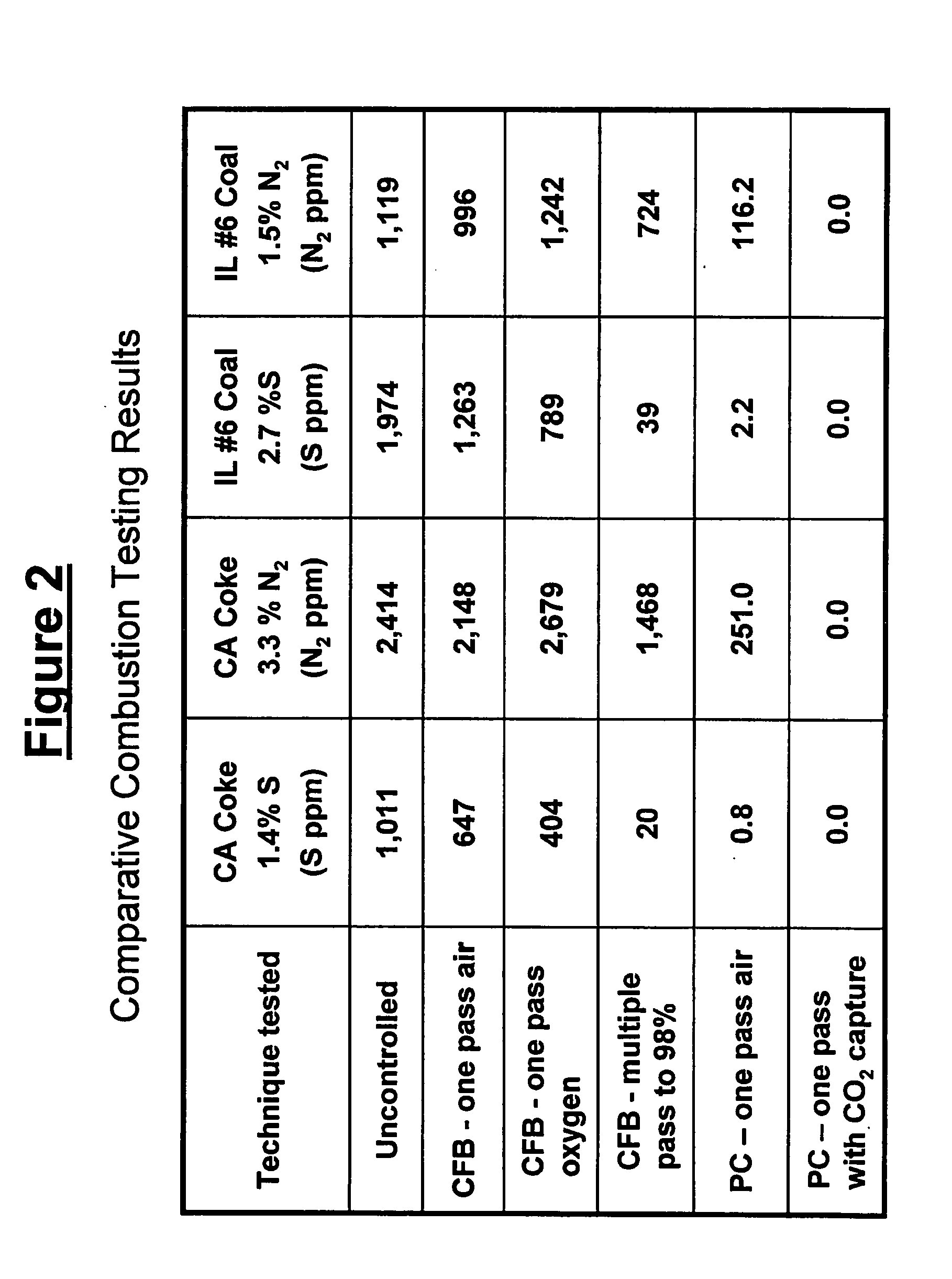

Coal/Coke/Heavy Residual Oil Boiler With Sulfur And Carbon Dioxide Capture And Recovery

A pulverized coal / coke (PC) boiler combusts carbon-based fuel with substantially pure oxygen and a flue gas recirculation stream (containing predominately carbon dioxide) at varied ratios to achieve a desired boiler temperature profile while producing captured sulfur, a high purity captured CO2 and electric power. The boiler includes at least one of (a) a mechanism for admixing a pulverized solid carbon-based fuel with an alkali metal salt and (b) injecting alkali metal salt into the boiler combustion zone containing a pulverized solid carbon-based fuel.

Owner:PLASMA POWER PROD

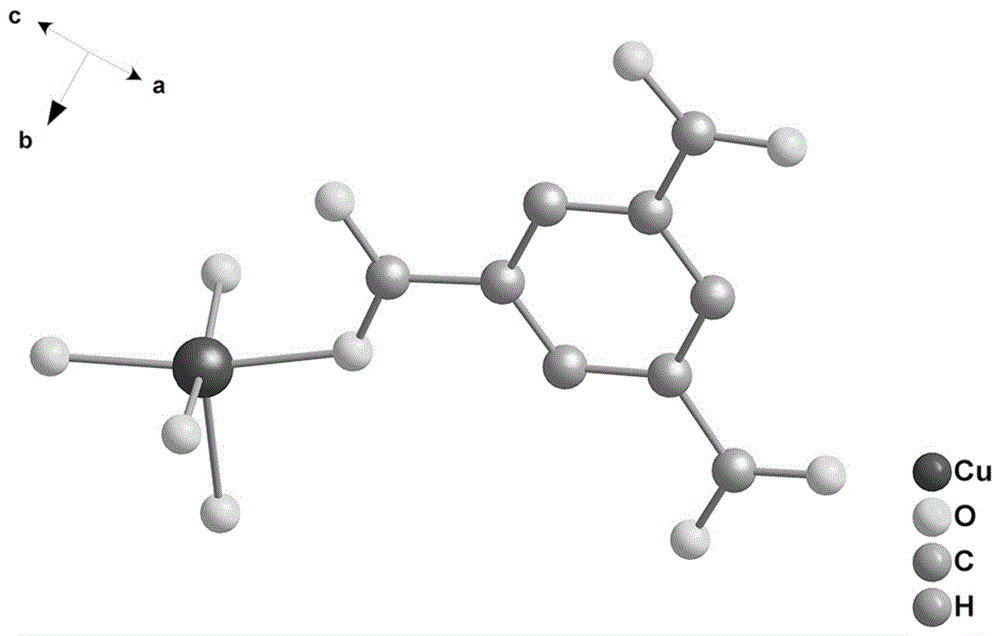

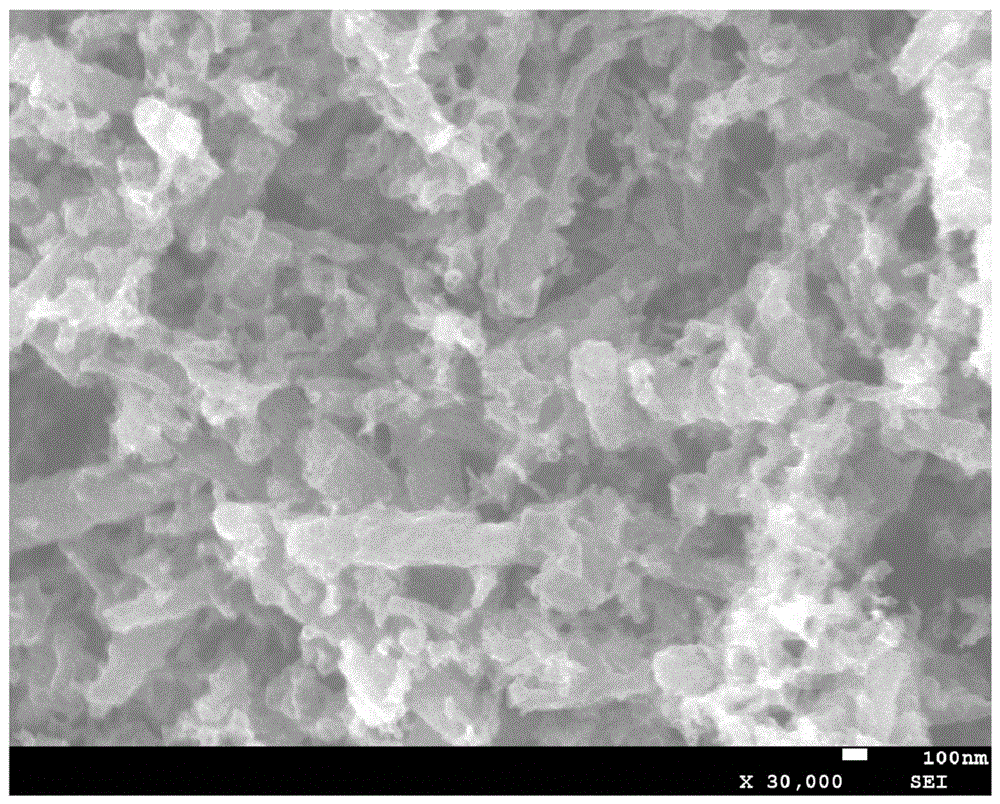

Method for preparing loaded carbon-based anode catalysts for fuel batteries and application of loaded carbon-based anode catalysts

The invention belongs to a loaded carbon-based anode catalyst material for fuel batteries, and discloses a method for preparing loaded carbon-based anode catalysts for fuel batteries. Mesoporous carbon-based carriers are prepared on the basis of porous crystalline-state metal organic framework materials, and precious metal Pt is loaded by the mesoporous carbon-based carriers, so that catalyst materials can be prepared by the aid of the method. The loaded carbon-based anode catalysts are prepared by the aid of two-step preparation technologies. The method includes carrying self-assembly on an organic ligand trimesic acid and copper acetate in mixed solution of N, N-dimethylformamide, ethyl alcohol and water to obtain the porous metal organic framework materials; carrying out a series of carbonization and acid etching treatment to obtain mesoporous carbon materials; loading nano-particles of the precious metal platinum (Pt) on the mesoporous carbon materials by the aid of ultrasonic-assisted technologies; preparing the catalyst materials with the uniformly distributed Pt nano-particles with uniform particle sizes and the diameters of 2-3 nm. The types of loaded precious metal and the loading capacity can be adjusted. The method has the advantage that the catalysts are stable and superior in catalytic activity when used for electrically catalytically oxidizing methanol and can be used as candidate materials for anode catalysts for the direct methanol fuel batteries and the like.

Owner:CHINA THREE GORGES UNIV

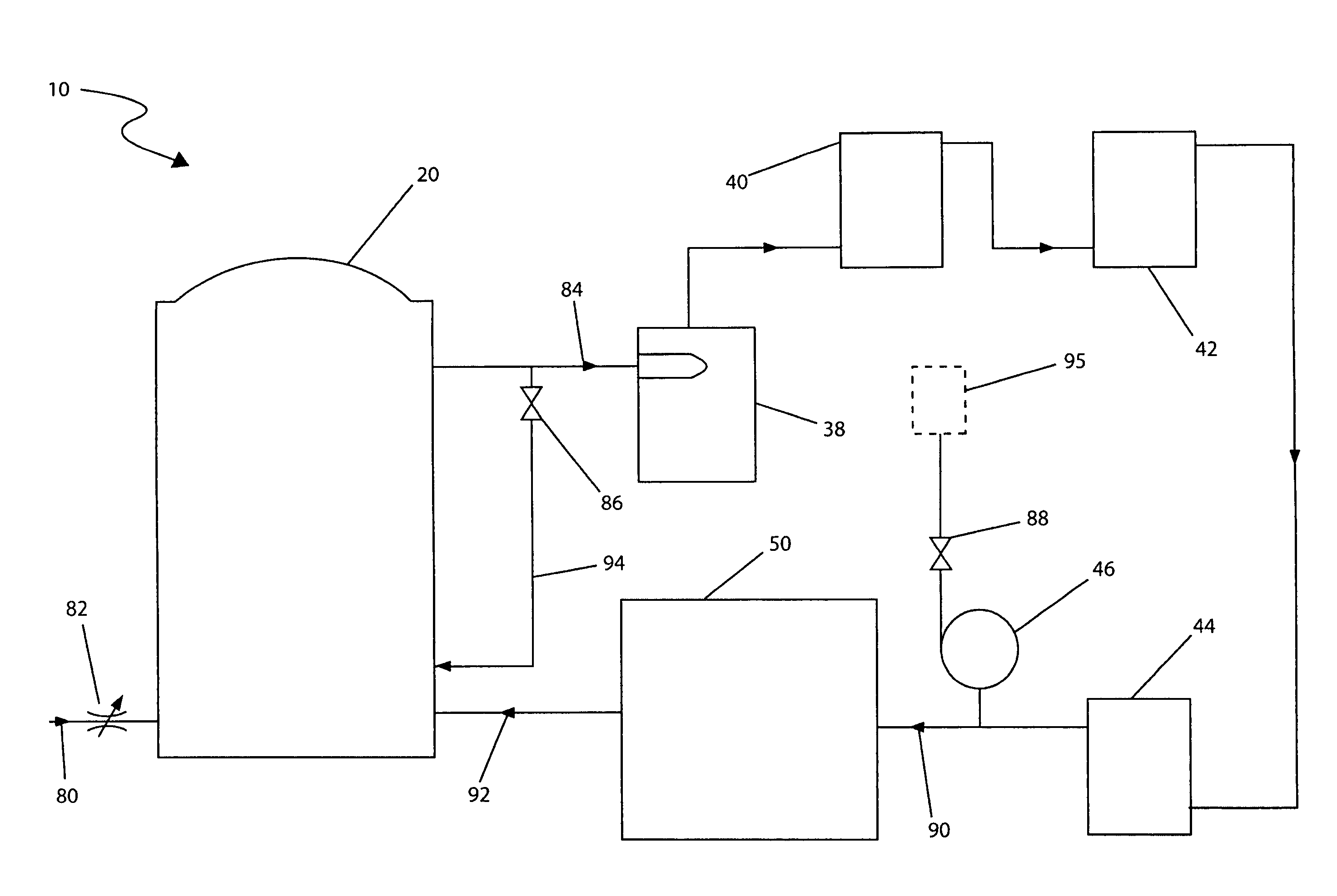

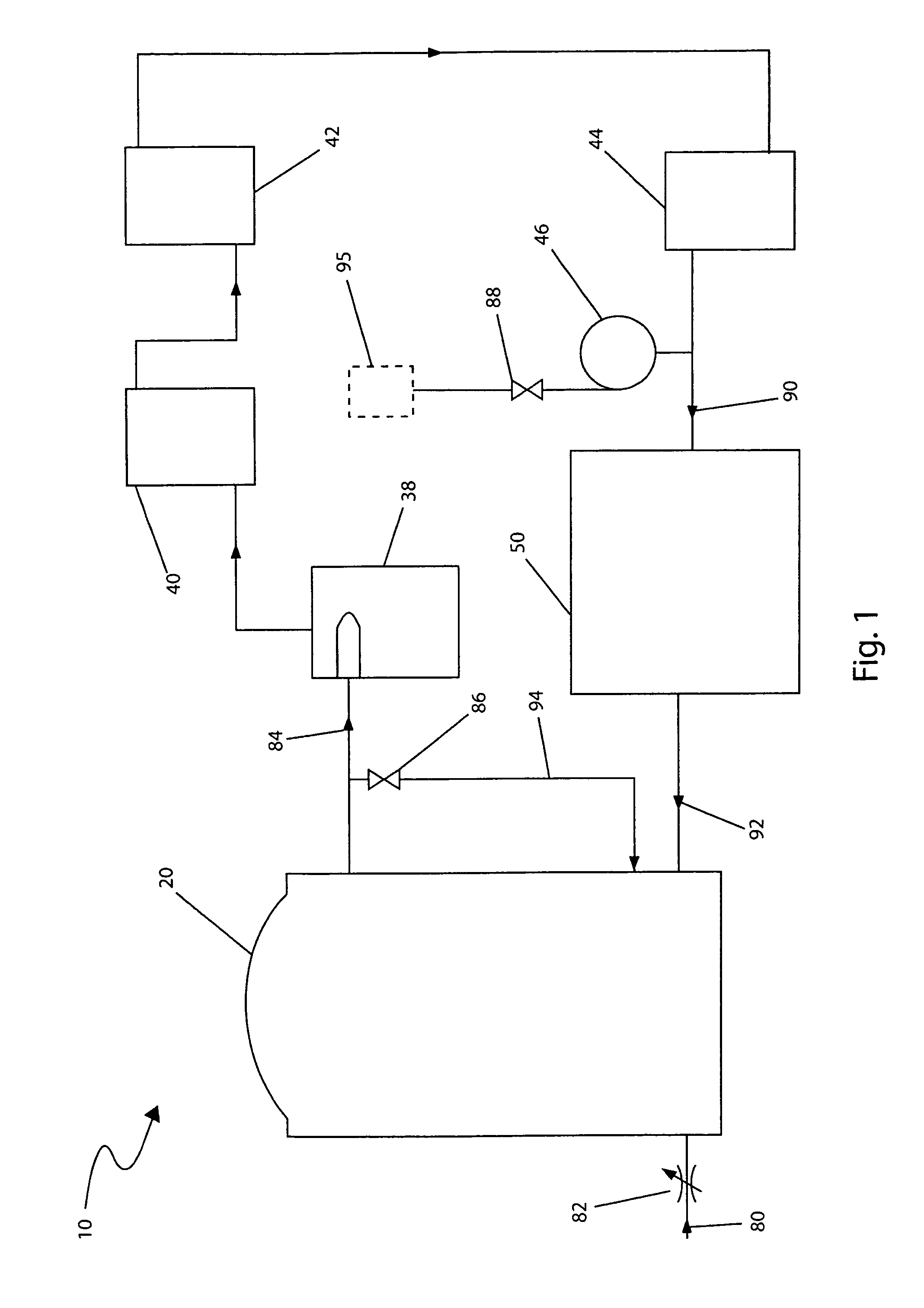

Method and system for recycling flue gas

InactiveUS8246700B1Improve reaction speedQuantity minimizationMultiple metal hydridesEnergy inputForming gasChemical reaction

An improved process to reduce emissions converts carbon dioxide from the flue gas exhaust from heat or power generators, into synthetic gas which is in-turn reintroduced back into the generator as fuel, is herein disclosed. Hot flue and exhaust gases from power generators, which contain carbon dioxide, would be blown into a gasification reactor, which contains coal, wood chips or other carbon based fuels substances. The process utilizes gasification technology to create a thermochemical reaction between the carbon dioxide and the fuel via a high temperature and no-oxygen atmosphere to produce synthetic gas. The synthetic gas includes carbon monoxide and hydrogen which is then fed back into a heat or power generator as fuel. The process may include two (2) or more reactors, thereby allowing one (1) reactor to be loaded or unloaded while synthetic gas continues to be produced by the other reactor. The synthetic gas may also be further converted into vehicle fuels and other useful chemicals.

Owner:KUTSIN LEONID

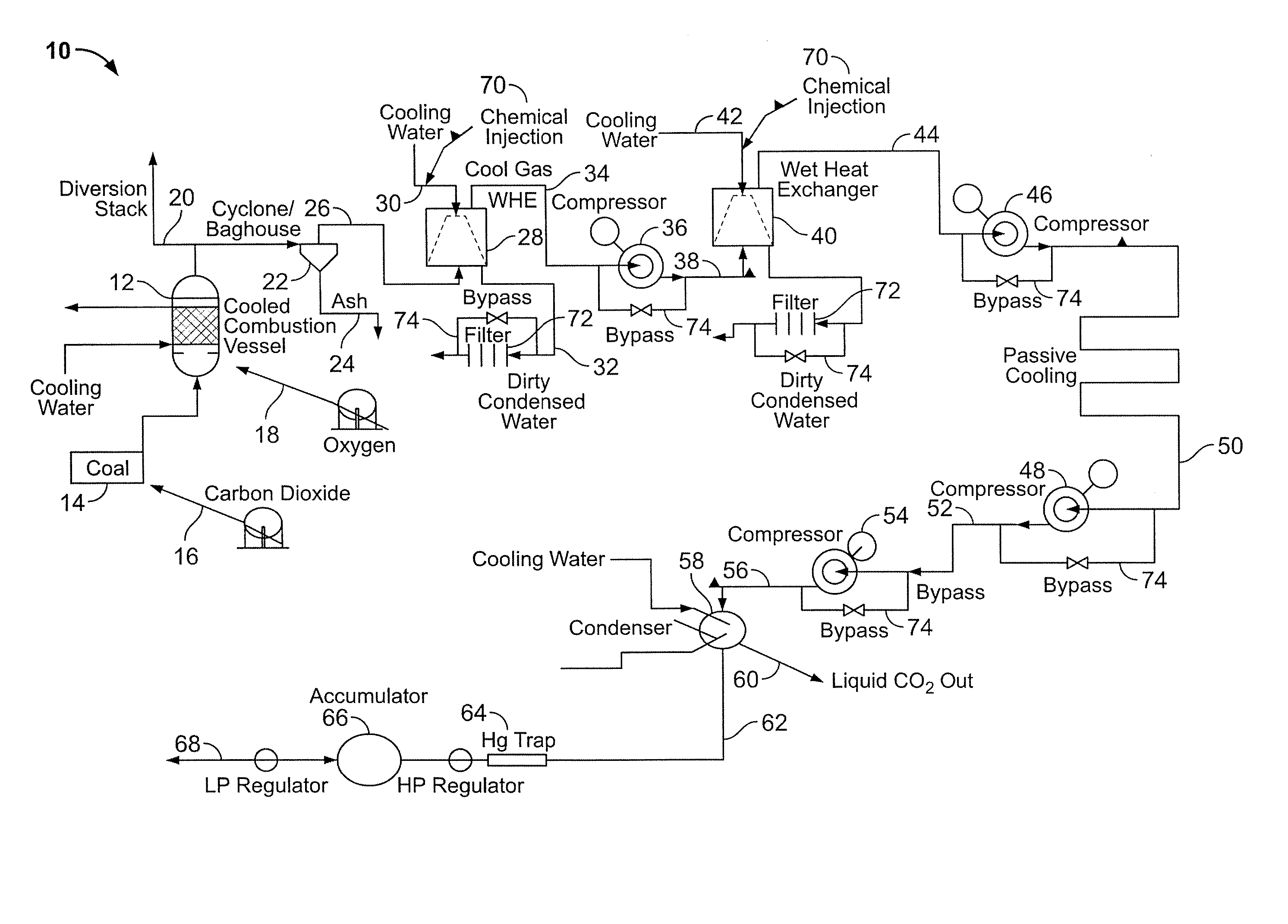

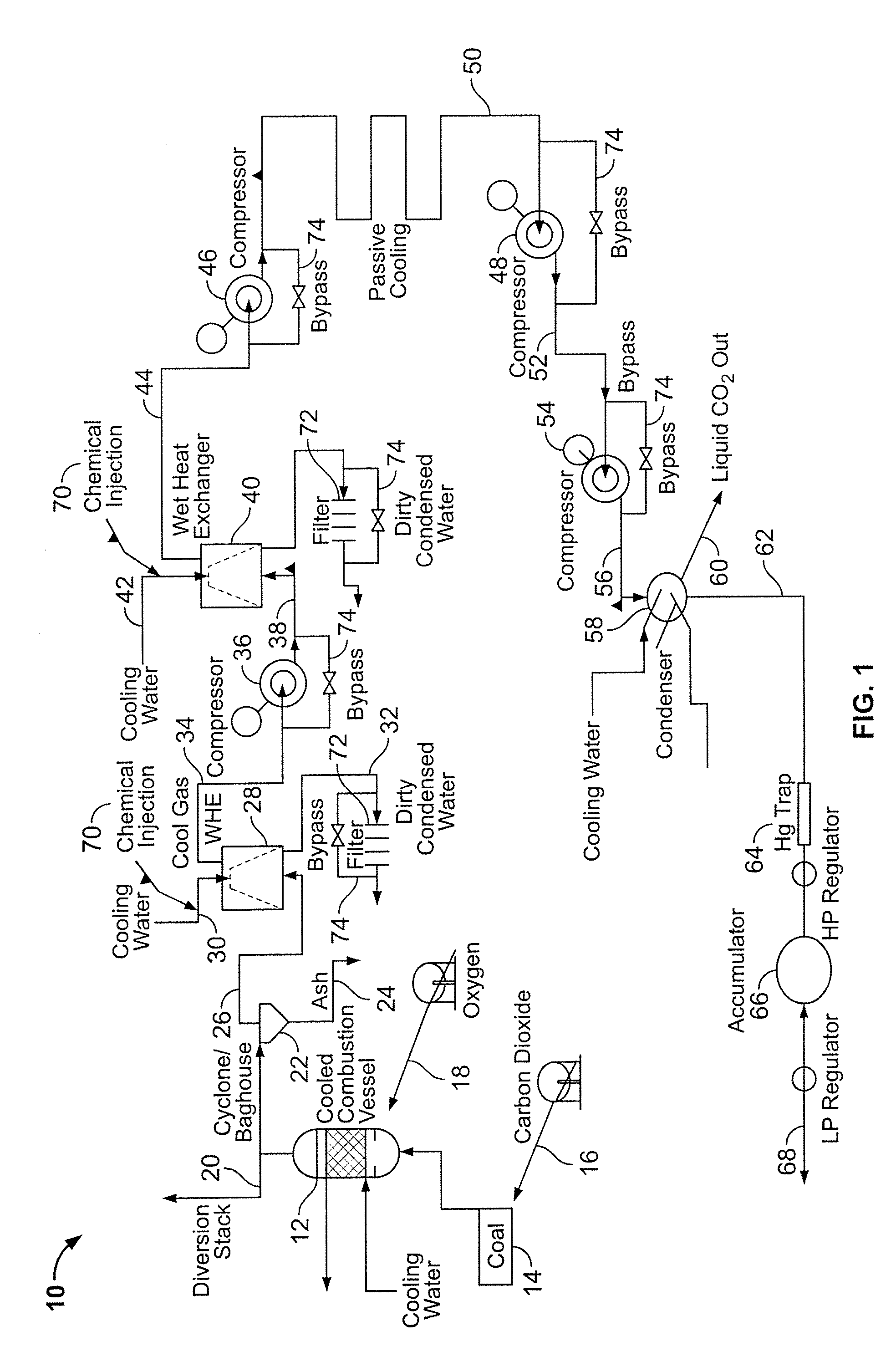

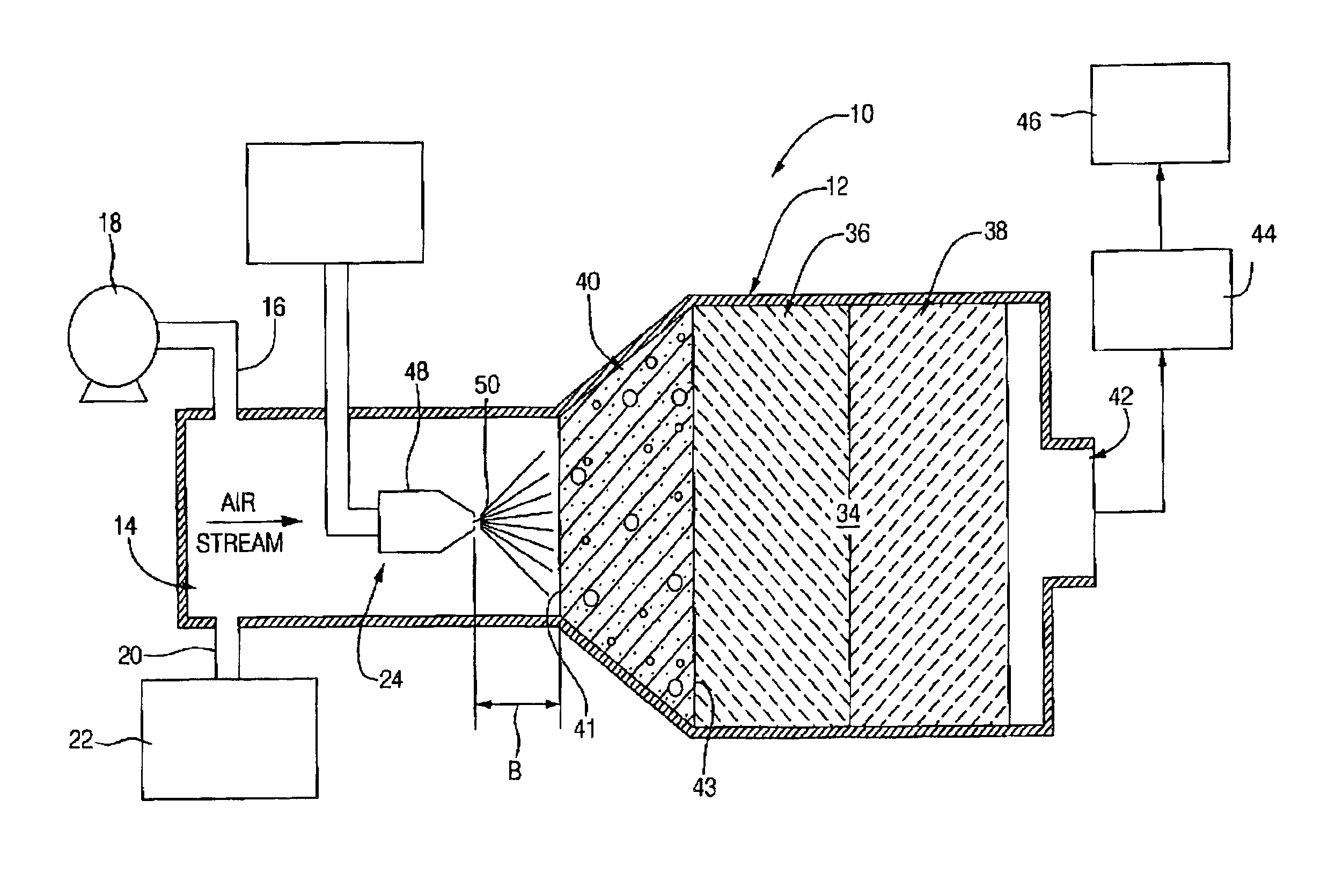

Oxy-fuel combustion with integrated pollution control

ActiveUS20070207419A1Avoid introducingReduce gas volumeBurnersLiquid degasificationCarbon-based fuelPollution

An oxygen fueled integrated pollutant removal and combustion system includes a combustion system and an integrated pollutant removal system. The combustion system includes a furnace having at least one burner that is configured to substantially prevent the introduction of air. An oxygen supply supplies oxygen at a predetermine purity greater than 21 percent and a carbon based fuel supply supplies a carbon based fuel. Oxygen and fuel are fed into the furnace in controlled proportion to each other and combustion is controlled to produce a flame temperature in excess of 3000 degrees F. and a flue gas stream containing CO2 and other gases. The flue gas stream is substantially void of non-fuel borne nitrogen containing combustion produced gaseous compounds. The integrated pollutant removal system includes at least one direct contact heat exchanger for bringing the flue gas into intimated contact with a cooling liquid to produce a pollutant-laden liquid stream and a stripped flue gas stream and at least one compressor for receiving and compressing the stripped flue gas stream.

Owner:JUPITER OXYGEN CORP

Method for oxy-fuel combustion

InactiveUS7282171B2Improve efficiencyLess fuelSolid waste disposalMaintainance of heating chambersCombustion systemNitrogen

An oxygen fueled combustion system includes a furnace having at least one burner, an oxygen supply for supplying oxygen having a predetermined purity, and a carbon based fuel supply for supplying a carbon based fuel. The oxygen and the carbon based fuel are fed into the furnace in a stoichiometric proportion to one another to limit an excess of either the oxygen or the carbon based fuel to less than 5 percent over the stoichiometric proportion. The combustion of the carbon based fuel provides a flame temperature in excess of 4500° F. The exhaust gas stream from the furnace has substantially zero nitrogen-containing combustion produced gaseous compounds from the oxidizing agent and reduced green-house gases. Substantially less carbon based fuel is required than conventional combustion systems without a loss of energy output.

Owner:JUPITER OXYGEN CORP

High efficiency combustion catalyst

The combustion catalyst for carbon-base fuel is prepared through compounding the main material and the auxiliary material into matrix, and dissolving the matrix in solvent. The main material includes alkyl alcohol ether, alkyl ester, olefin and aromatic compound; and the auxiliary material includes phosphate ester, chlorohydrocarbon, alkyl alcohol amide, metal compound and small amount of nitrogen, silicon and oxygen containing organic compound. When it is used, the combustion catalyst is mixed with carbon-base fuel through spraying or stirring. It promotes combustion by means of increasing the free radicals in the system, and can raise the combustion strength and efficiency and reach the aims of saving energy, raising efficiency, reducing pollution, etc.

Owner:北京金源化学集团有限公司

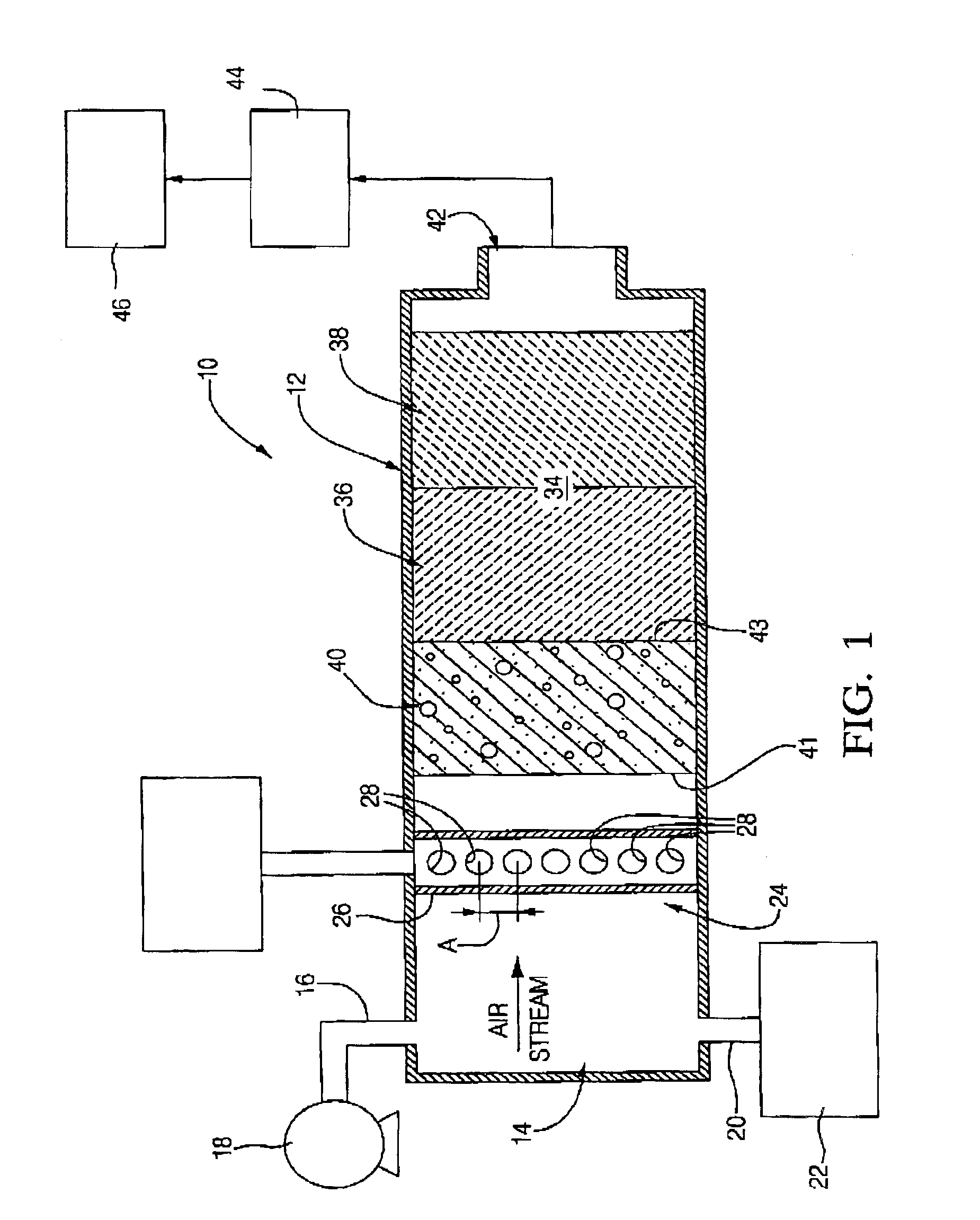

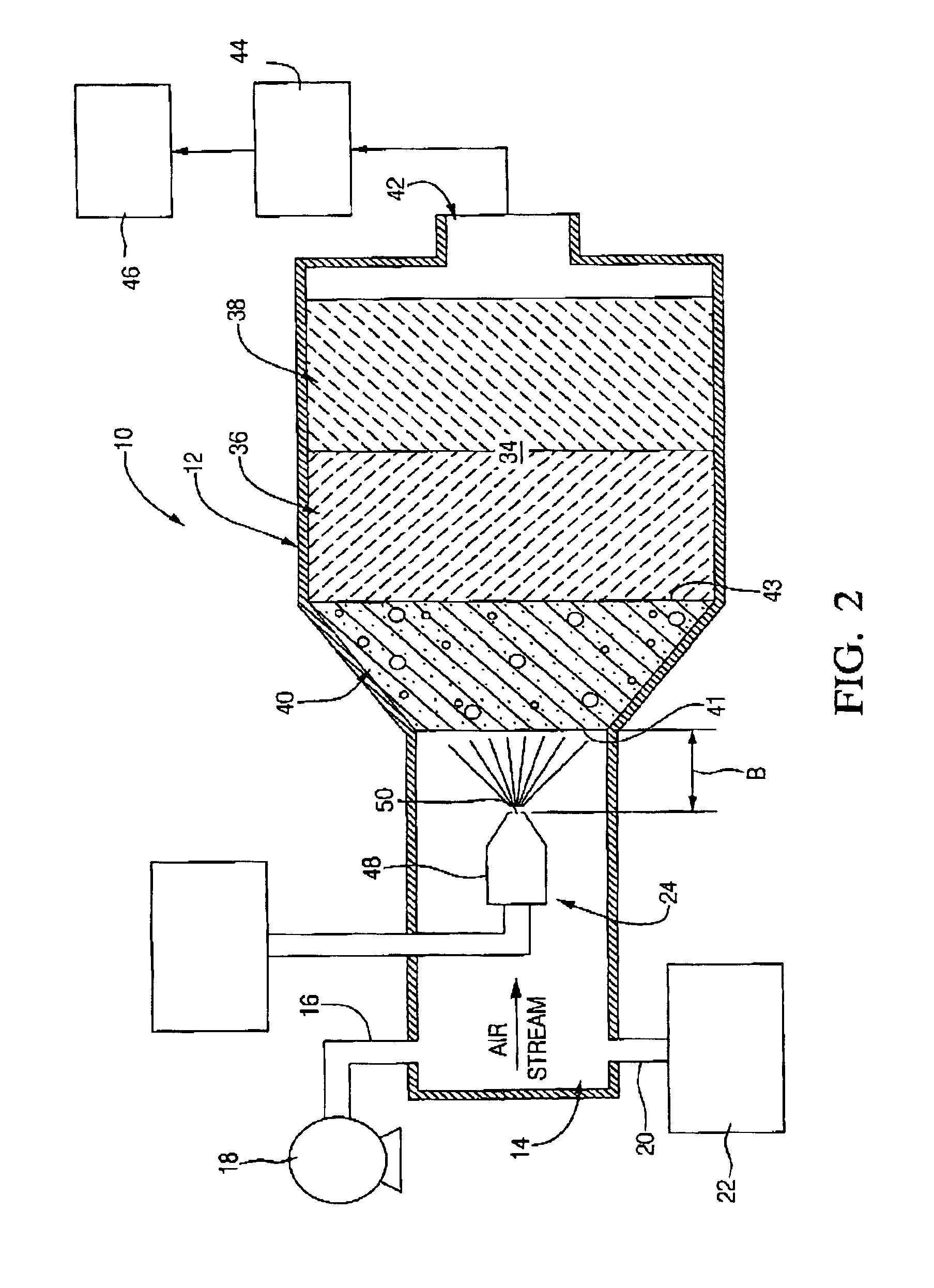

Reactor system including auto ignition and carbon suppression foam

A reactor system including a reactor housing having an inlet portion defined at one end of the housing and having a discharge opening formed in the housing at an opposite end. An air intake charge line is connected to the housing for charging air into the inlet portion. A steam charge line is connected to the housing for charging steam into the inlet portion. A fuel injector is positioned in the housing for injecting fuel into the stream of air and steam flowing through the housing. A fuel charge line is connected to the fuel injector for charging a carbon-based fuel into the injector. A catalyst bed is carried in the housing and positioned downstream of the fuel injector and at least a portion of the catalyst bed includes a catalyst for promoting the reformation of the carbon-based fuel to produce hydrogen. An auto-ignition suppression and carbon-suppression foam is carried in the housing and positioned between the catalyst bed and the fuel injector.

Owner:GENERAL MOTORS COMPANY

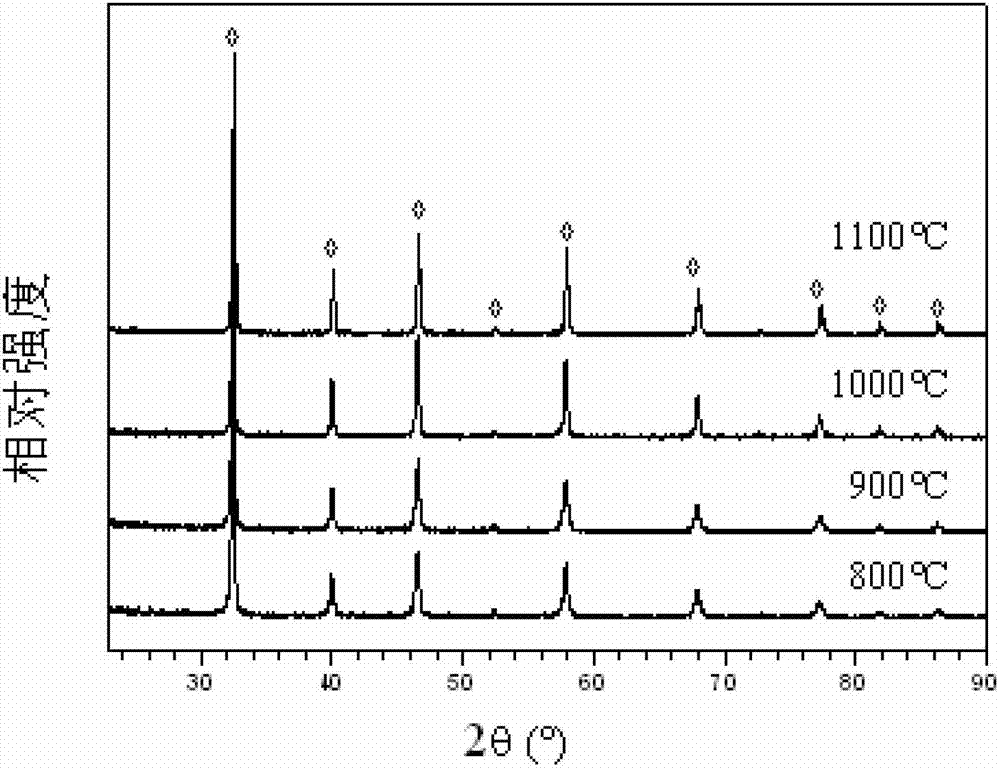

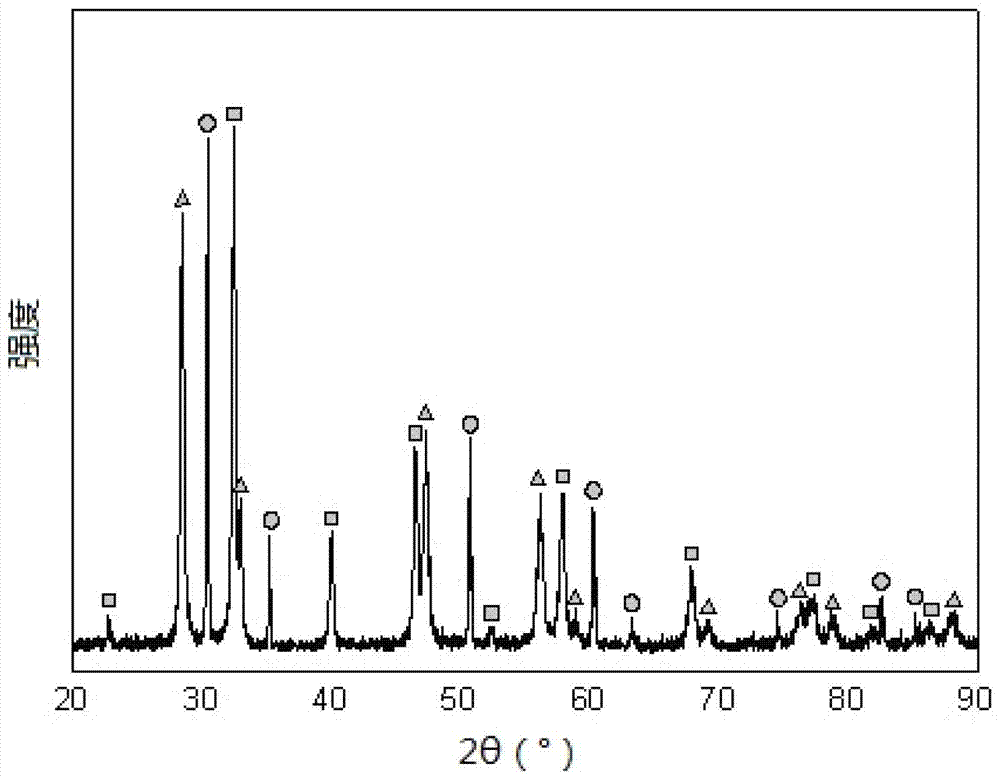

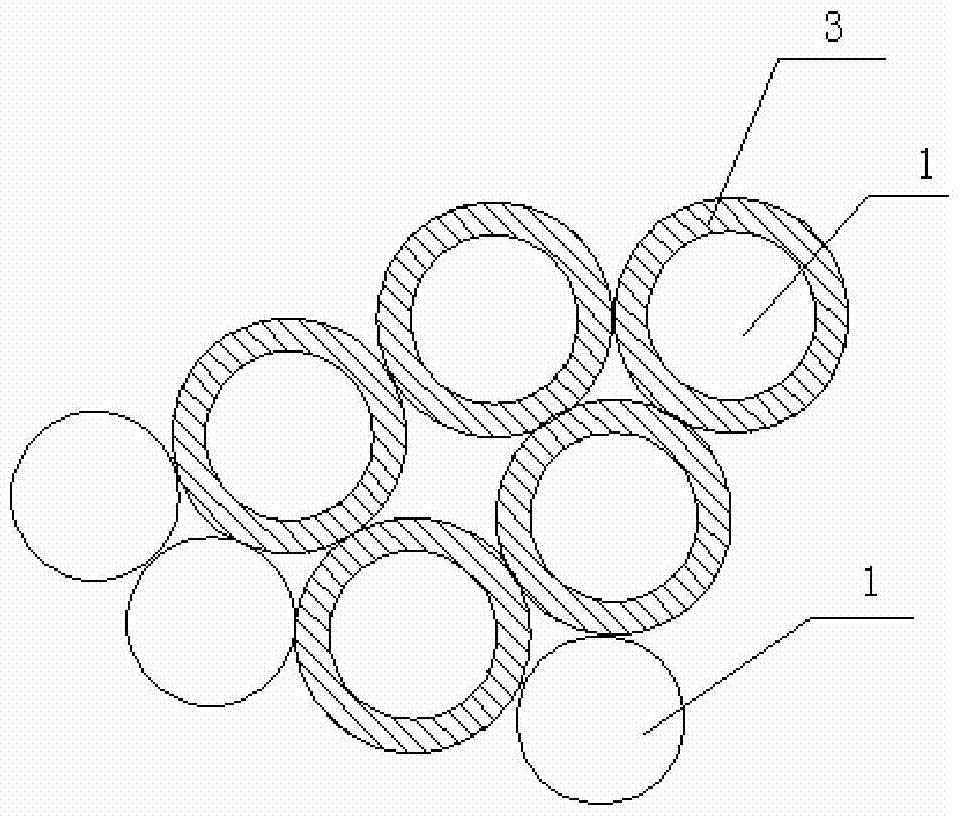

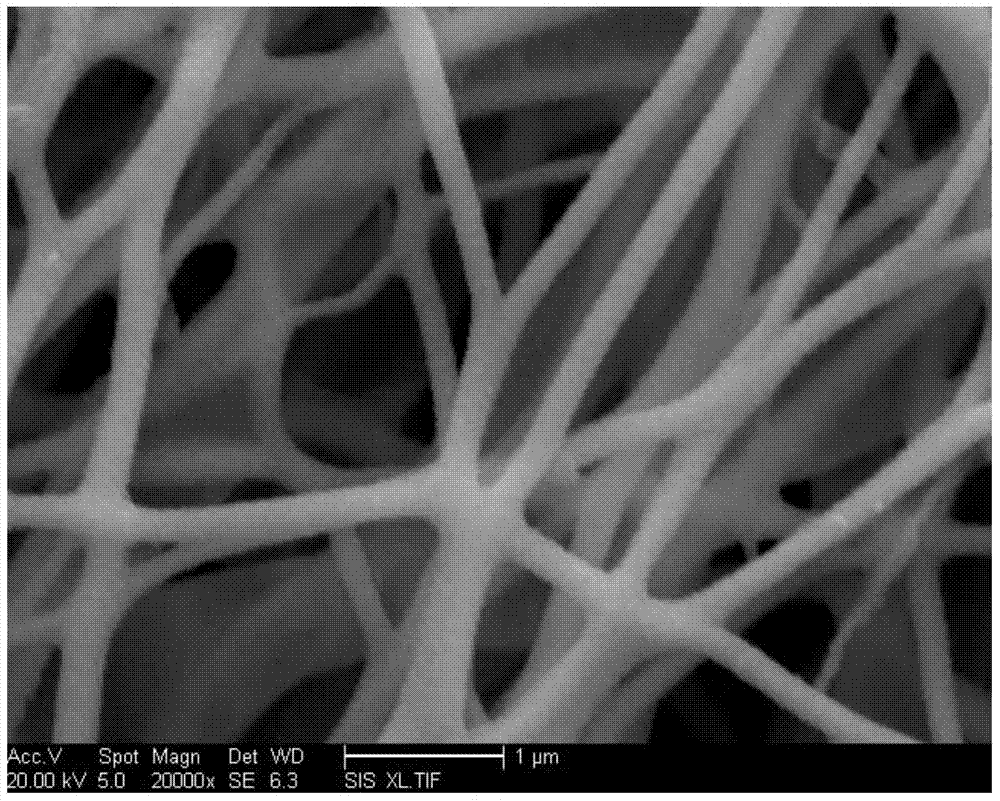

One-dimensional nano fibrous lanthanum strontium titanate (LST) anode material, preparation method thereof, composite anode utilizing anode material and preparation method of composite anode

ActiveCN103117404ASuitable electron conductivityImprove electronic conductivityCell electrodesSolid electrolyte fuel cellsStrontium titanateFiber

The invention relates to a preparation method of a one-dimensional fibrous lanthanum strontium titanate (LST) anode material, and relates to an anode material, a composite anode and a preparation method. The invention aims at solving the problems of reasonability in selection of the anode material and insufficiency in preparation technique that when a solid oxide fuel cell (SOFC) utilizes carbon-based fuel, the reduction of a three-phase interface caused by the carbon precipitation phenomenon and the clustering phenomenon of nickel after being deactivated by sulfur compounds on a nickel-based anode influences the working performances of the electrode. The one-dimensional fibrous LST anode material is LaxS(r1-x)TiO3 and obtained by preparing one-dimensional nano fibers through an electrostatic spinning technique and then sintering the one-dimensional nano fibers. The one-dimensional fibers are made into anode slurry to be coated on an electrolyte, cathode or anode supporting body, and a one-dimensional fibrous LST-based LST-GDC composite anode is prepared by adopting a method for combining the electrostatic spinning technique and dipping electrolyte precursor solution. The composite anode can be used in a low-medium-temperature solid oxide fuel cell.

Owner:HARBIN INST OF TECH

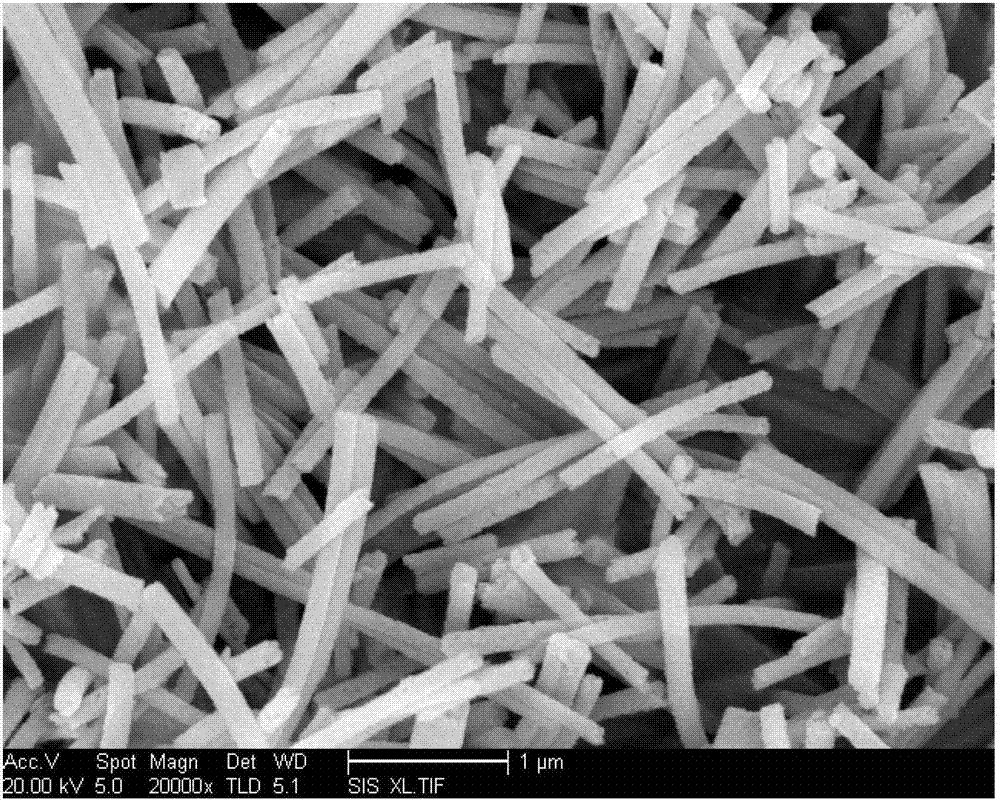

One-dimensional nanometer fiber base Ni-GDC composite anode materials and preparation method thereof

The invention discloses one-dimensional nanometer fiber base Ni-GDC composite anode materials and a preparation method thereof, and relates to middle-low temperature solid oxide fuel cell anode materials and the preparation method thereof. The one-dimensional nanometer fiber base Ni-GDC composite anode materials and the preparation method thereof are used for solving the problem that anode performance of a nickel base anode degrades, wherein the problem is caused by the nickel united phenomenon generated when carbon-base fuel is used by the nickel base anode on the high-temperature cell working condition. According to the one-dimensional nanometer fiber base Ni-GDC composite anode materials and the preparation method thereof, GDC nanometer fibers are prepared through the electrostatic spinning technology and the calcination method, nickel is plated on the surface of the GDC nanometer fibers, and the one-dimensional nanometer fiber base Ni-GDC composite anode materials are obtained. According to the one-dimensional nanometer fiber base Ni-GDC composite anode materials, the nickel particles plated on the surface of the GDC ceramic fibers are good in dispersibility, the nickel and ceramics have good associative property, the nickel united degree can be effectively reduced by the electrode manufactured by the one-dimensional nanometer fiber base Ni-GDC composite anode, and the one-dimensional nanometer fiber base Ni-GDC composite anode materials and the preparation method thereof can be applied to the field of middle-low temperature solid oxide fuel batteries.

Owner:HARBIN INST OF TECH

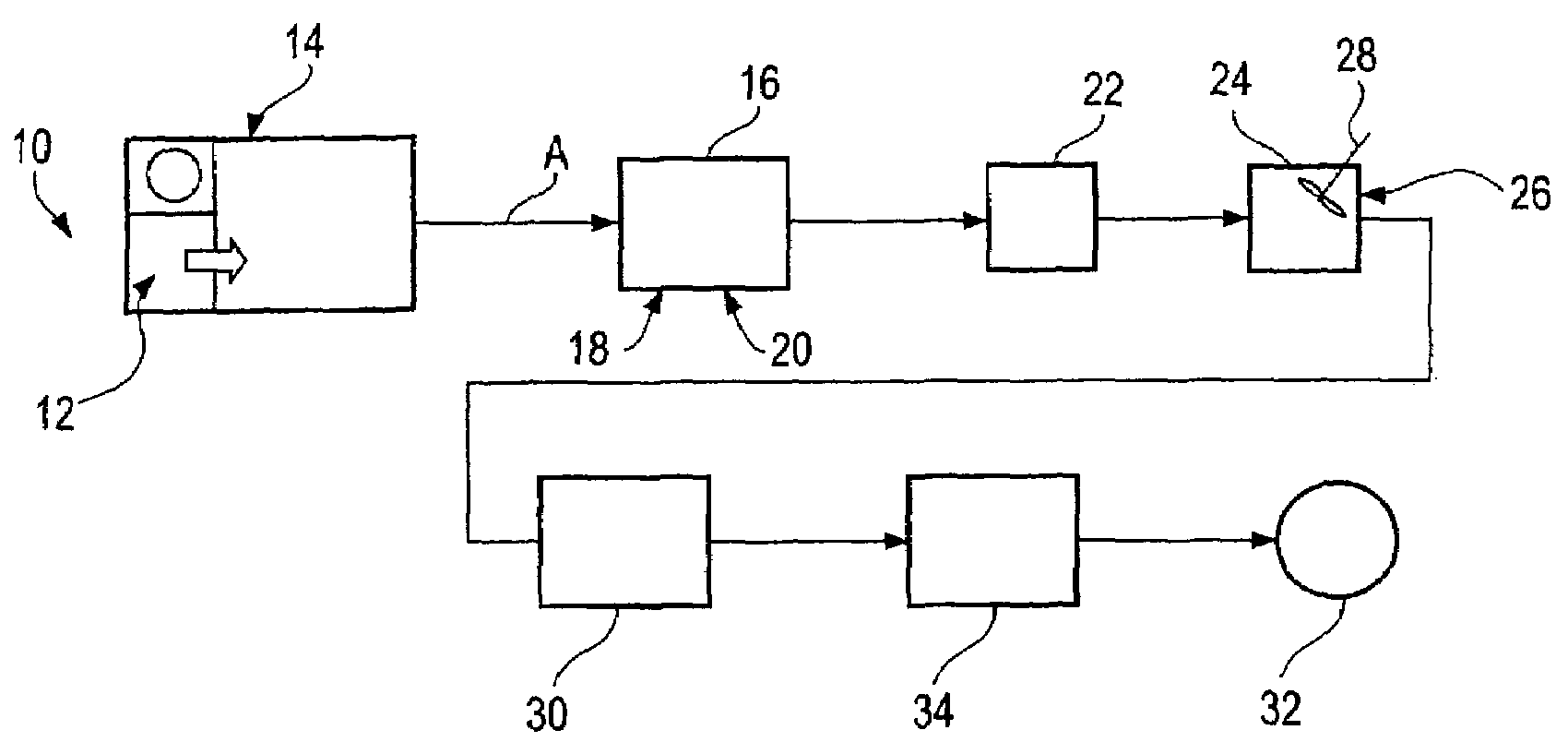

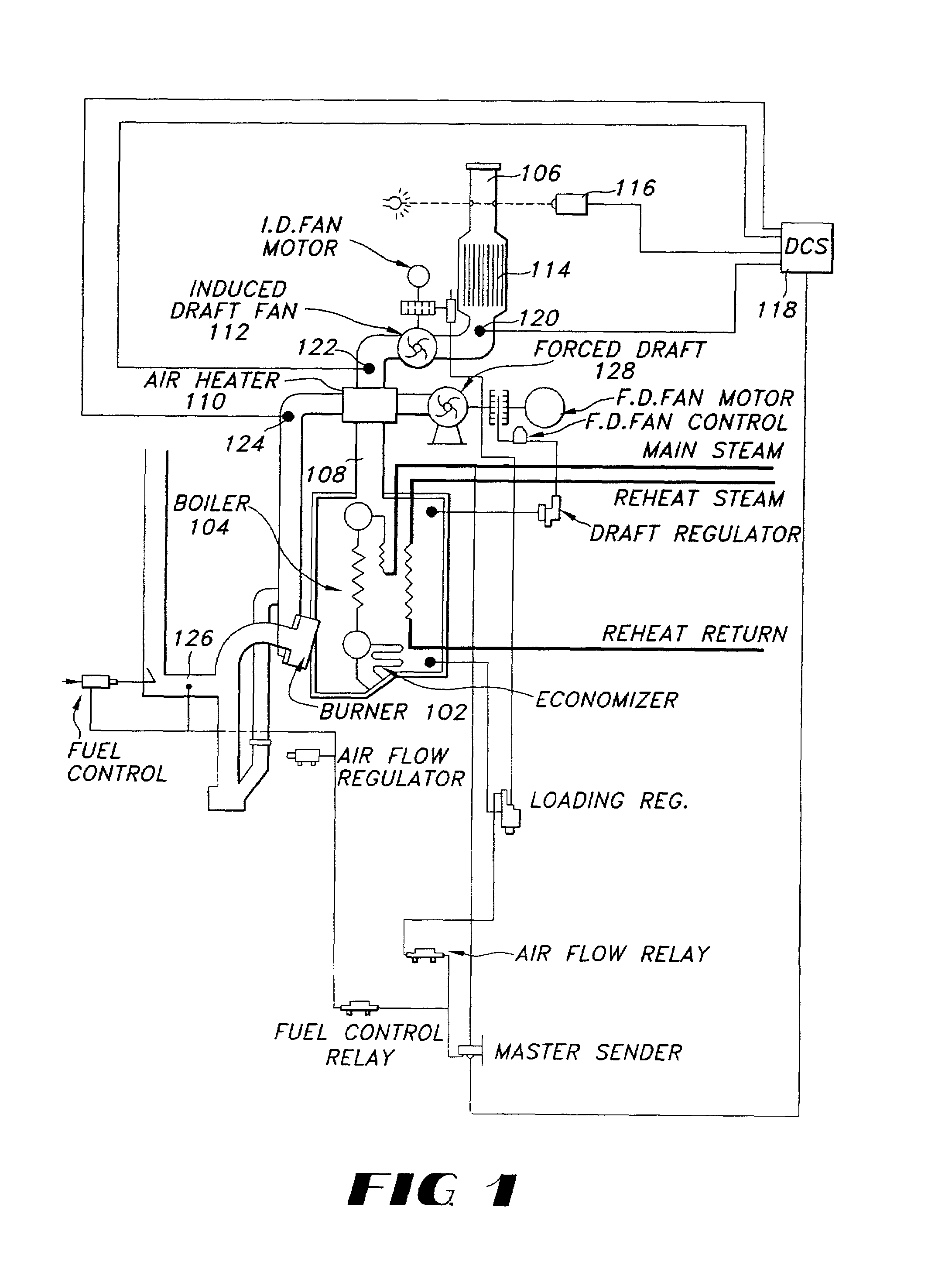

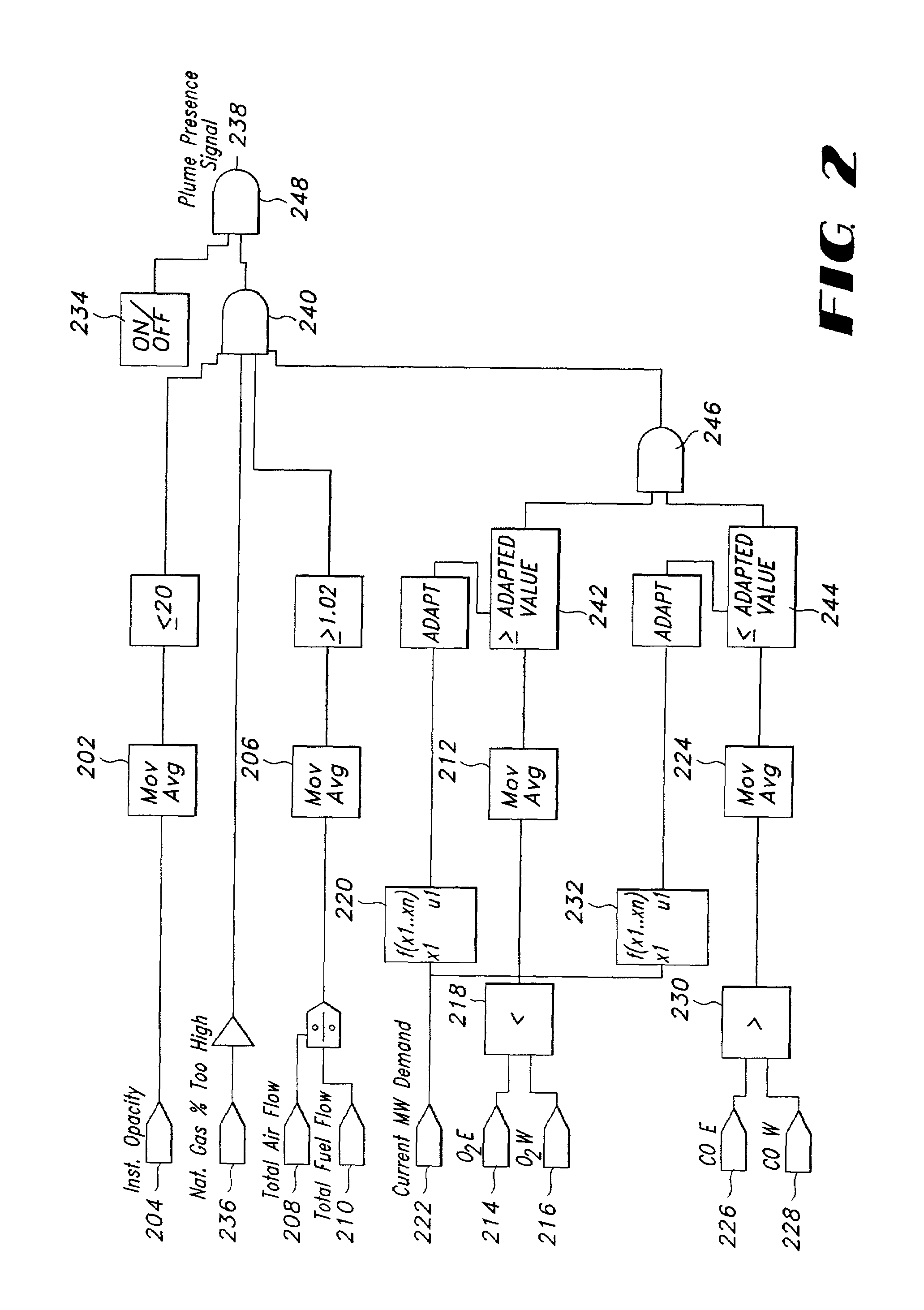

Systems and methods for determining the existence of a visible plume from the chimney of a facility burning carbon-based fuels

Excess oxygen in the combustion process of a facility that bums carbon-based fuels may cause a visible plume in the atmosphere at the stack of the facility. Traditional optical based opacity monitors may be unable to detect this plume or the plume may form at a location downstream from the opacity monitor toward the stack. The present invention discloses methods to utilize common combustion control variables to detect and signal the presence of a visible plume of exhaust gasses. Also disclosed are systems that detect the visible plume and provide a signal so that the combustion process may be manually or automatically adjusted to reduce or eliminate the visible plume.

Owner:FLORIDA POWER & LIGHT

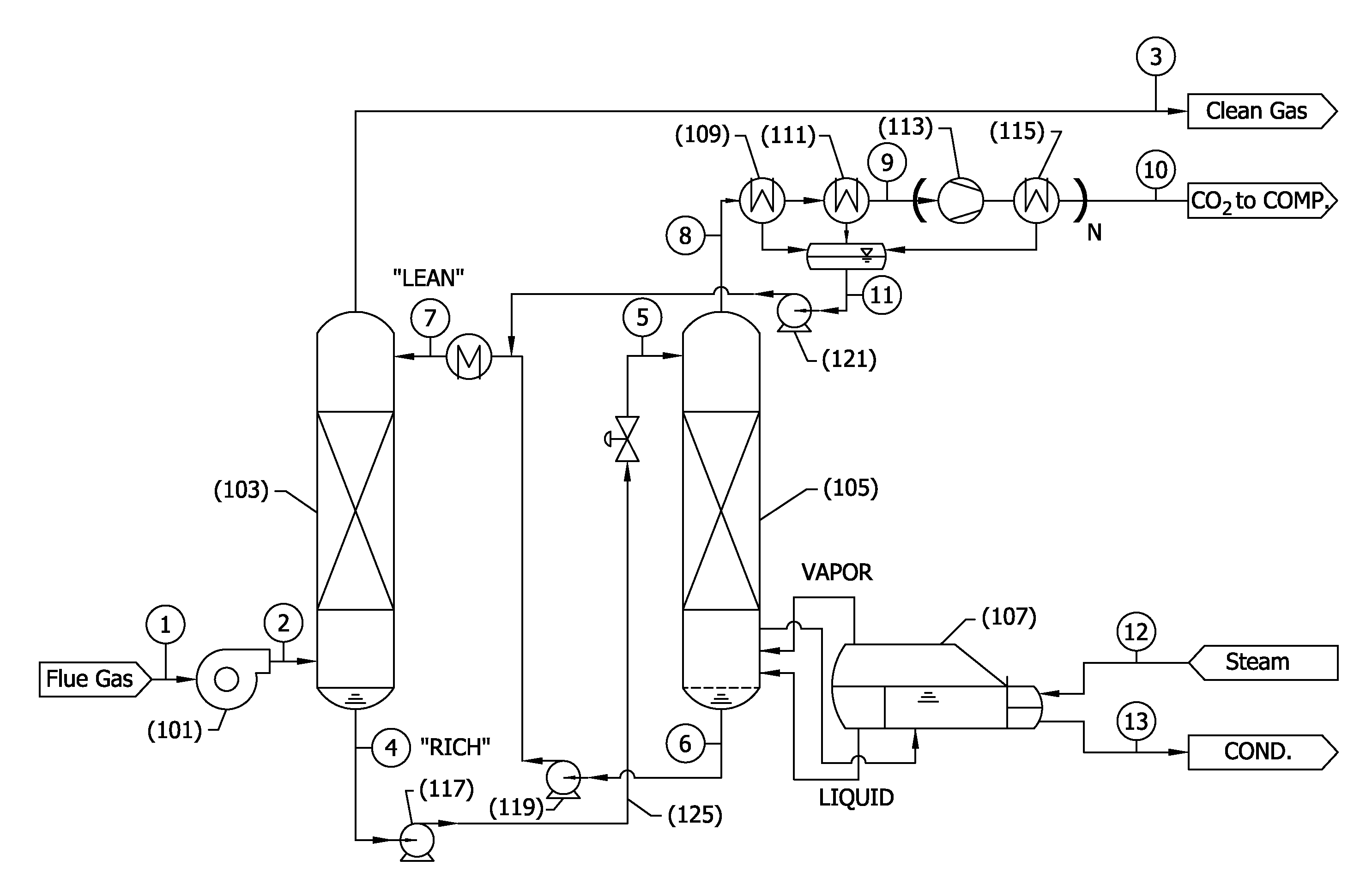

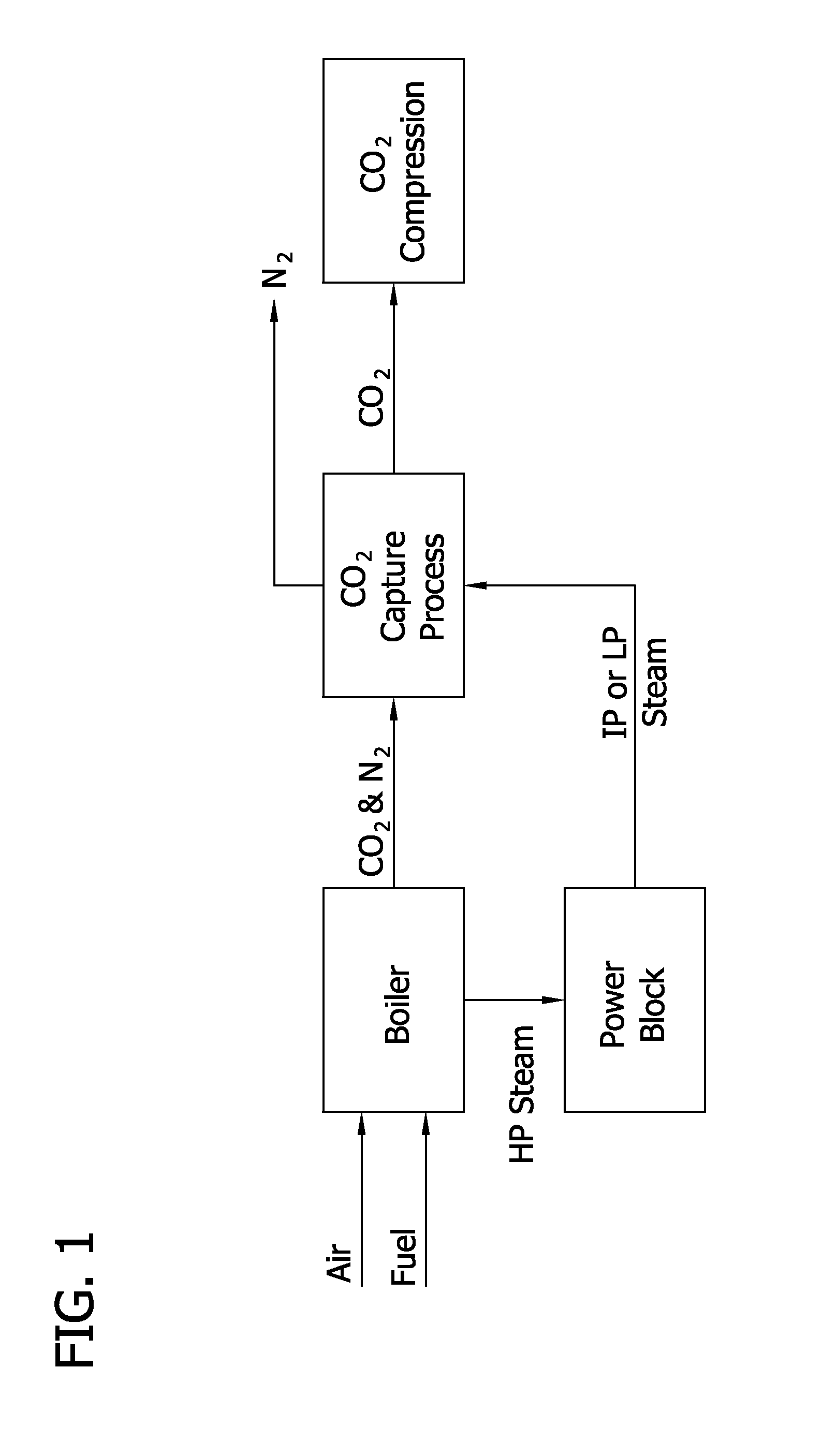

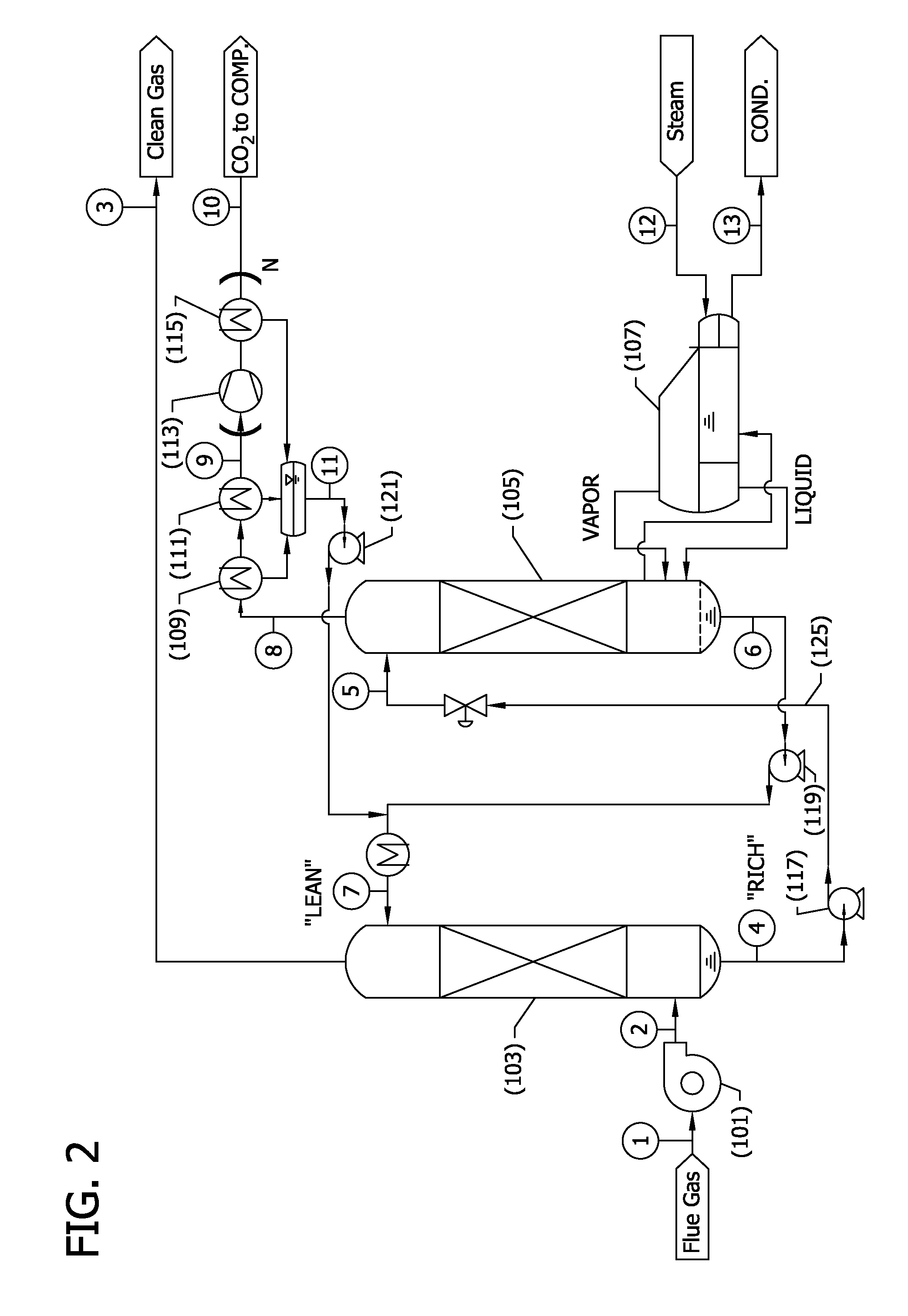

Processes and methods for low energy carbon dioxide capture

The present invention generally relates to processes and methods for the capture of carbon dioxide from gases that are produced by various industrial processes including the capture of CO2 from flue gases after the combustion of carbon-based fuels.

Owner:CO2 SOLUTION

Carbon-based fuel cell

A direct-electrochemical-oxidation fuel cell and method for generating electrical energy from a solid-state organic fuel. The fuel cell includes a cathode provided with an electrochemical-reduction catalyst that promotes formation of oxygen ions from an oxygen containing source at the cathode, an anode provided with an electrochemical-oxidation catalyst that promotes direct electrochemical oxidation of the solid-state organic fuel in the presence of the oxygen ions to produce electrical energy, and a solid-oxide electrolyte disposed to transmit the oxygen ions from the cathode to the anode. The electrochemical oxidation catalyst can optionally include a sulfur resistant material.

Owner:THE UNIVERSITY OF AKRON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com