Method for preparing loaded carbon-based anode catalysts for fuel batteries and application of loaded carbon-based anode catalysts

A fuel cell and load-type technology, which is applied in the preparation and application field of load-type carbon-based fuel cell anode catalysts, can solve the problems of reducing the catalytic effect, and achieve the effect of good dispersion and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

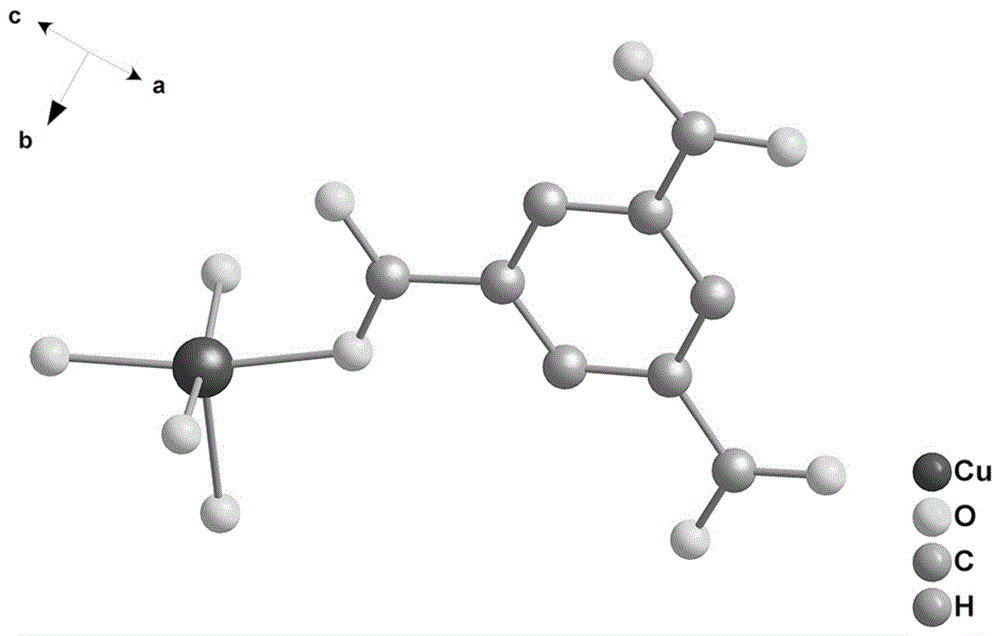

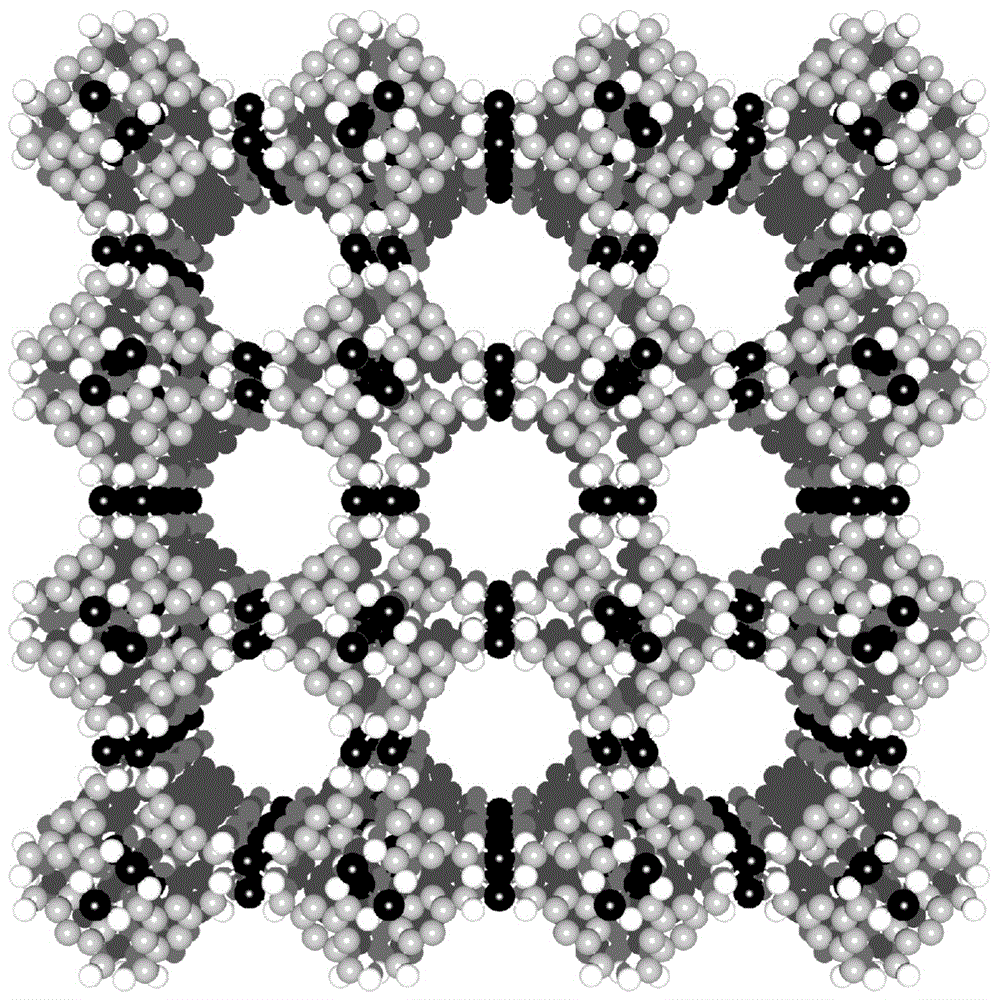

[0031]Accurately weigh 215mg of trimesic acid and 125mg of copper acetate, measure 25ml of N,N-dimethylformamide (DMF), 25ml of ethanol and 25ml of deionized water with a graduated cylinder, put them into a 100ml beaker, and stir them mechanically for 120min , the stirring speed is 750r / min. After the reaction, transfer the mixed system to a centrifuge tube and centrifuge three times. Add N,N-dimethylformamide to wash in the first centrifugation, and then add ethanol solution twice to wash. After the product was filtered, it was dried in a vacuum oven at 80°C for 120 min to obtain a blue powder microcrystalline sample.

Embodiment 2

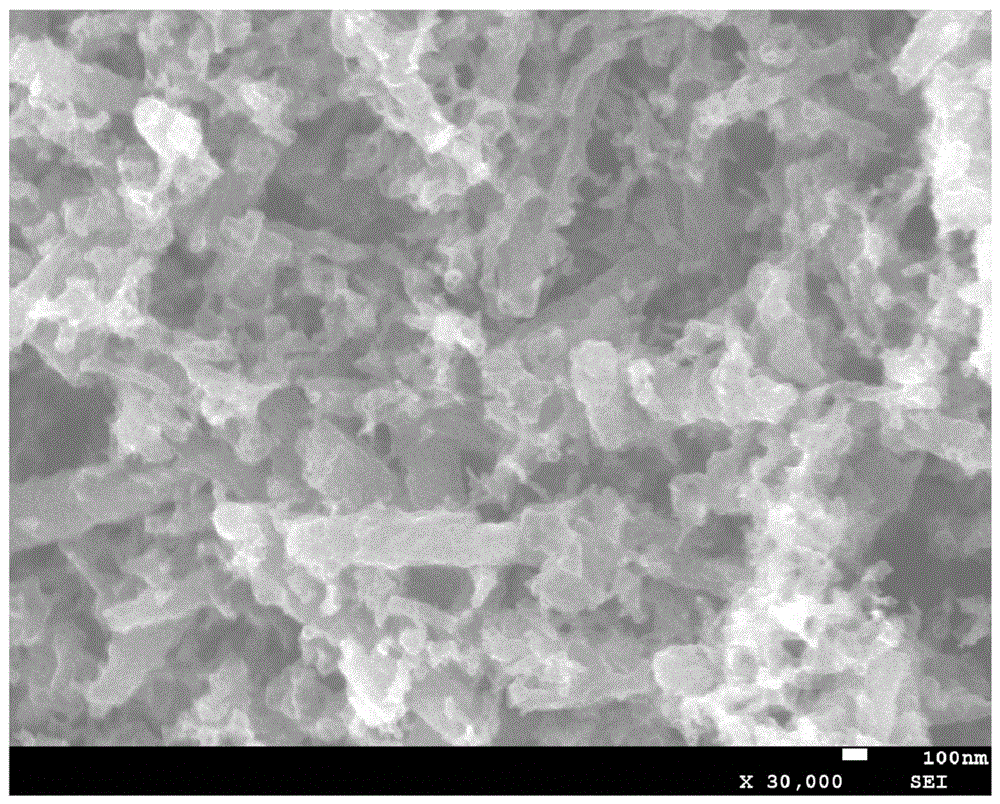

[0033] (1) Put the porous crystalline metal-organic framework material obtained in Example 1 (blue powdery microcrystalline sample) into a tube furnace, feed nitrogen gas as a protective atmosphere, and heat up to 550°C with a heating rate of 15°C / min, the calcination time is 360min.

[0034] (2) Transfer the sample prepared in the above steps to a hydrothermal reaction kettle, and use 2mol / l hydrochloric acid solution to etch the metal component (the metal component in the skeleton of the crystalline material) under the condition of stirring at 60°C. After filtration and vacuum drying, a black powder sample was obtained.

[0035] (3) After the obtained black powdery product is carbonized again, the degree of graphitization is increased and the conductivity is enhanced. The re-carbonization temperature was 900°C, the calcination time was 360min, and the heating rate was 15°C / min.

[0036] (4) Take 10 mg of carbon-based carrier material, add 0.4 ml of chloroplatinic acid sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com