One-dimensional nanometer fiber base Ni-GDC composite anode materials and preparation method thereof

A technology of nanofibers and composite anodes, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of anode performance attenuation, etc., and achieve large three-phase interface, good combination, and shape retention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

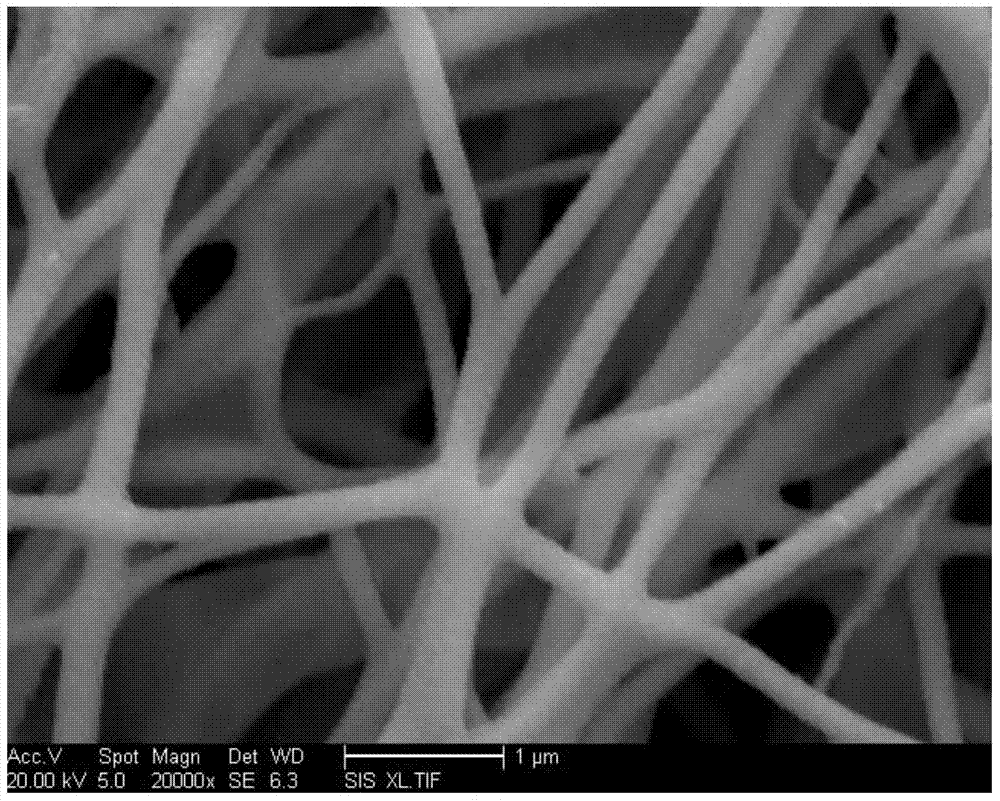

[0024] Embodiment 1: The one-dimensional nanofiber-based Ni-GDC composite anode material of this embodiment is to adhere Ni nanoparticles on the surface of GDC nanofibers; wherein the chemical formula of GDC is Ce 0.8 Gd 0.2 o 1.9 .

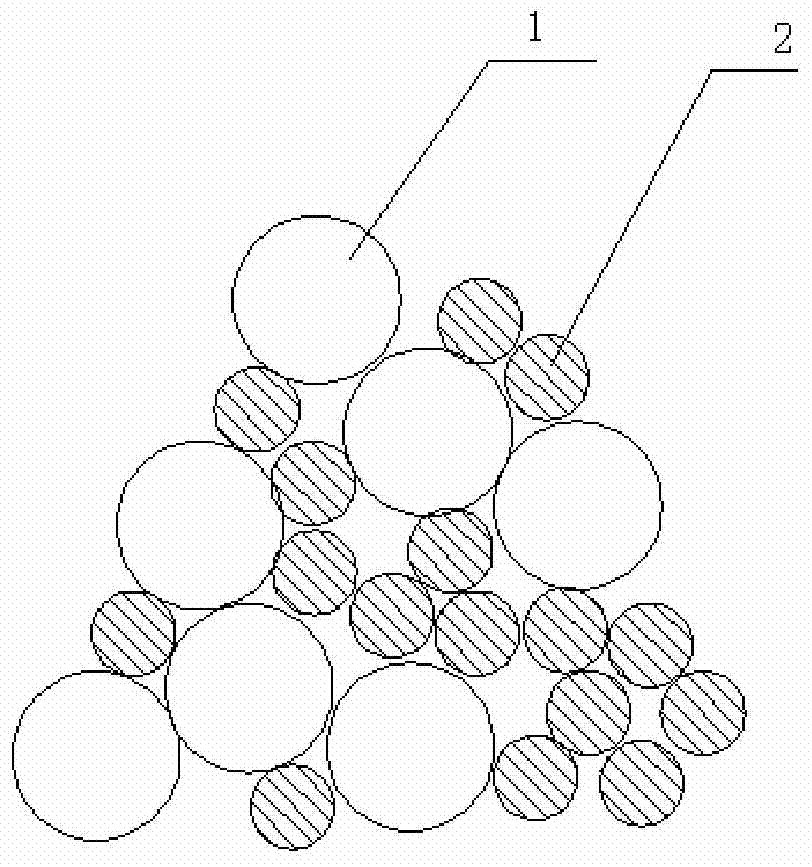

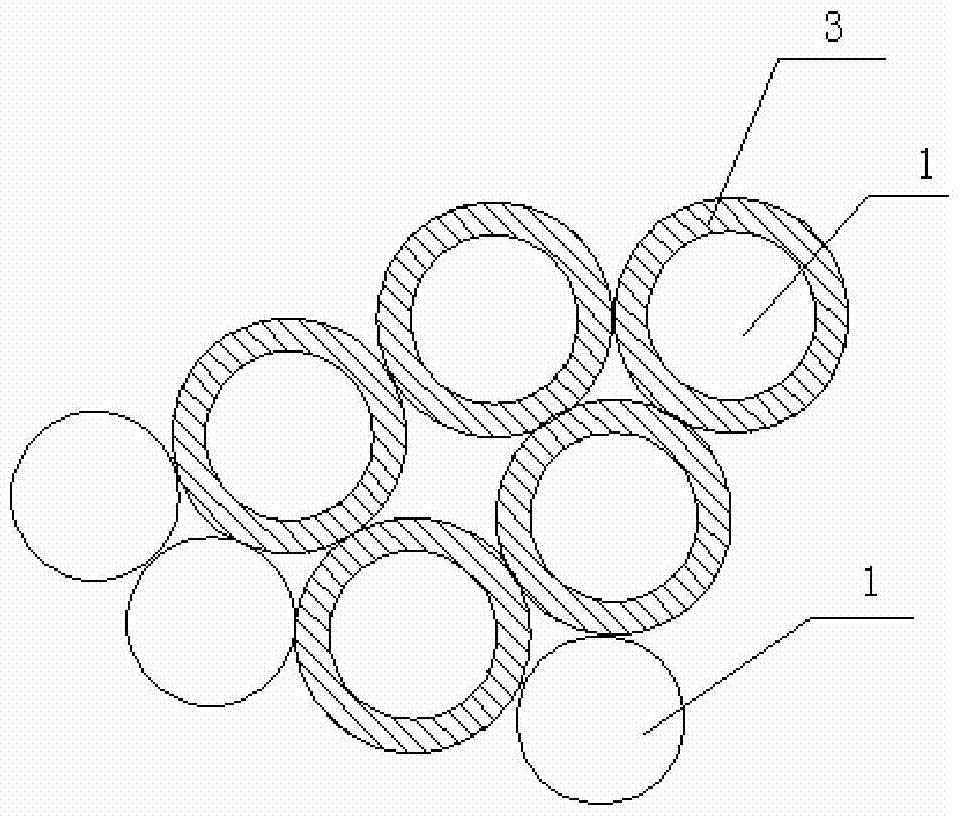

[0025] The schematic diagram of Ni-GDC cermet anode structure in the prior art is as figure 1 As shown, 1 is GDC and 2 is Ni particles. Although GDC as a scaffold maintains the dispersion and porosity of the Ni metal phase to a certain extent, it cannot meet the commercial requirements of an ideal anode using carbon-based materials as fuel. . Using carbon-based fuel, the structure mode of the existing Ni-GDC cermet anode causes obvious agglomeration of Ni, and the Ni particles agglomerate into large particles, which interrupts the electron conduction path and eventually leads to the failure of the anode performance. decay to failure. The schematic diagram of the structure of the one-dimensional nanofiber-based Ni-GDC composite anode material...

specific Embodiment approach 2

[0026] Embodiment 2: This embodiment differs from Embodiment 1 in that the mass ratio of GDC to Ni is 1: (0.3-0.7). Others are the same as the first embodiment.

[0027] The one-dimensional nanofiber-based Ni-GDC composite anode material of this embodiment is that Ni nanoparticles are adhered to the surface of GDC nanofibers, and the Ni particles present a continuous and uneven distribution form, which effectively reduces the degree of agglomeration of Ni particles and avoids The phenomenon that the three-phase interface is reduced, so as to achieve the purpose of improving the electrochemical performance of the anode.

specific Embodiment approach 3

[0028] Specific embodiment three: the preparation method of the one-dimensional nanofiber-based Ni-GDC composite anode material described in specific embodiment one is carried out according to the following steps:

[0029] 1. According to the chemical formula Ce 0.8 Gd 0.2 o 1.9 , respectively weigh cerium nitrate and gadolinium nitrate according to the molar ratio of Ce and Gd elements of 4:1, then add cerium nitrate and gadolinium nitrate to N,N-dimethylformamide, and magnetically stir at room temperature until Cerium nitrate and gadolinium nitrate are completely dissolved, then polyvinylpyrrolidone is added and stirred to obtain an electrospinning precursor solution, and then electrospinning is performed to obtain nanofibers;

[0030] 2. Sinter the nanofibers at a constant temperature of 280-300°C at a heating rate of 2-5°C / min for 2-3 hours, then continue to heat up to 500-1000°C at a heating rate of 2-5°C / min, and sinter at a constant temperature 2 to 3 hours to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com