Patents

Literature

33results about How to "Add three-phase interface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

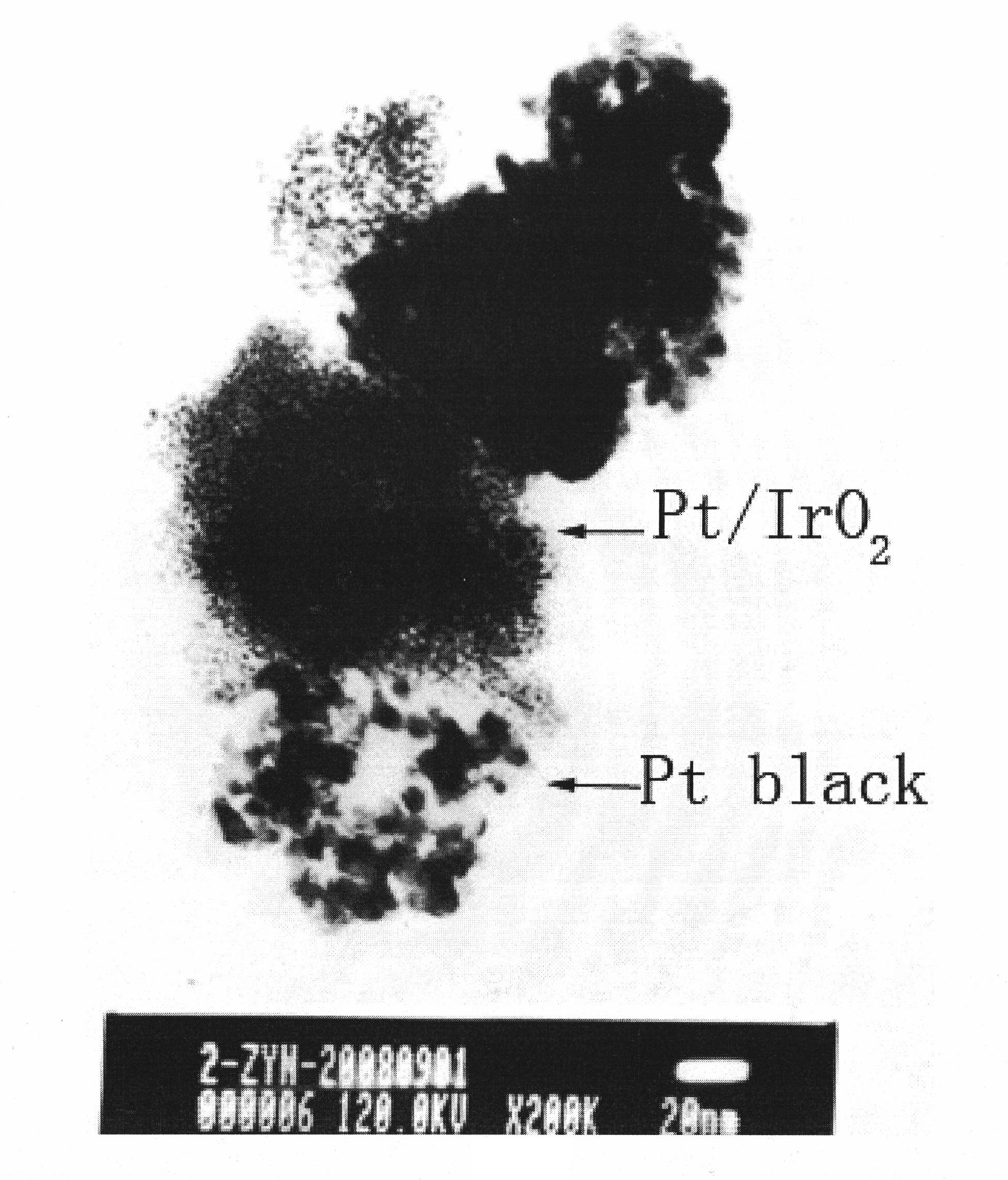

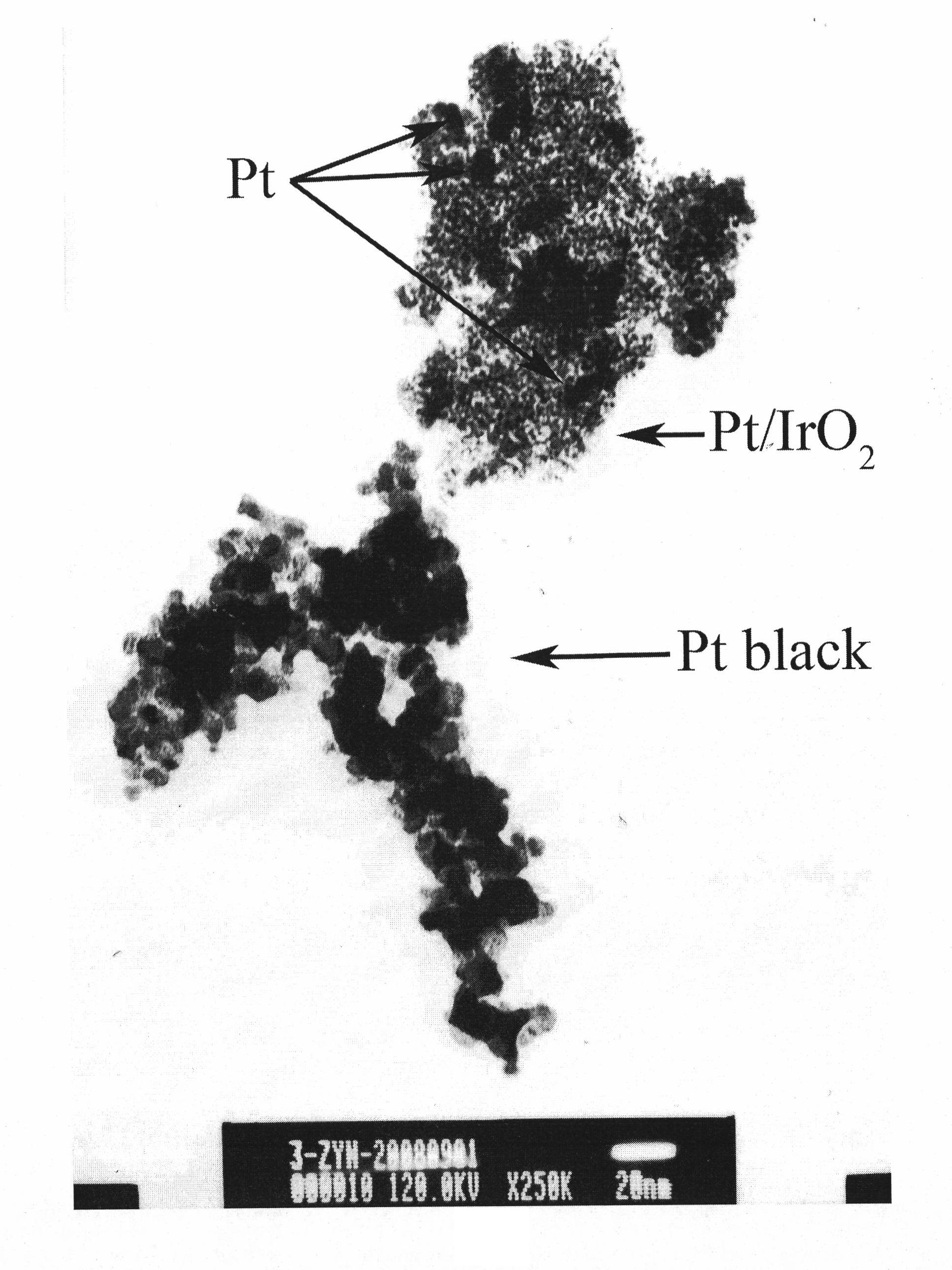

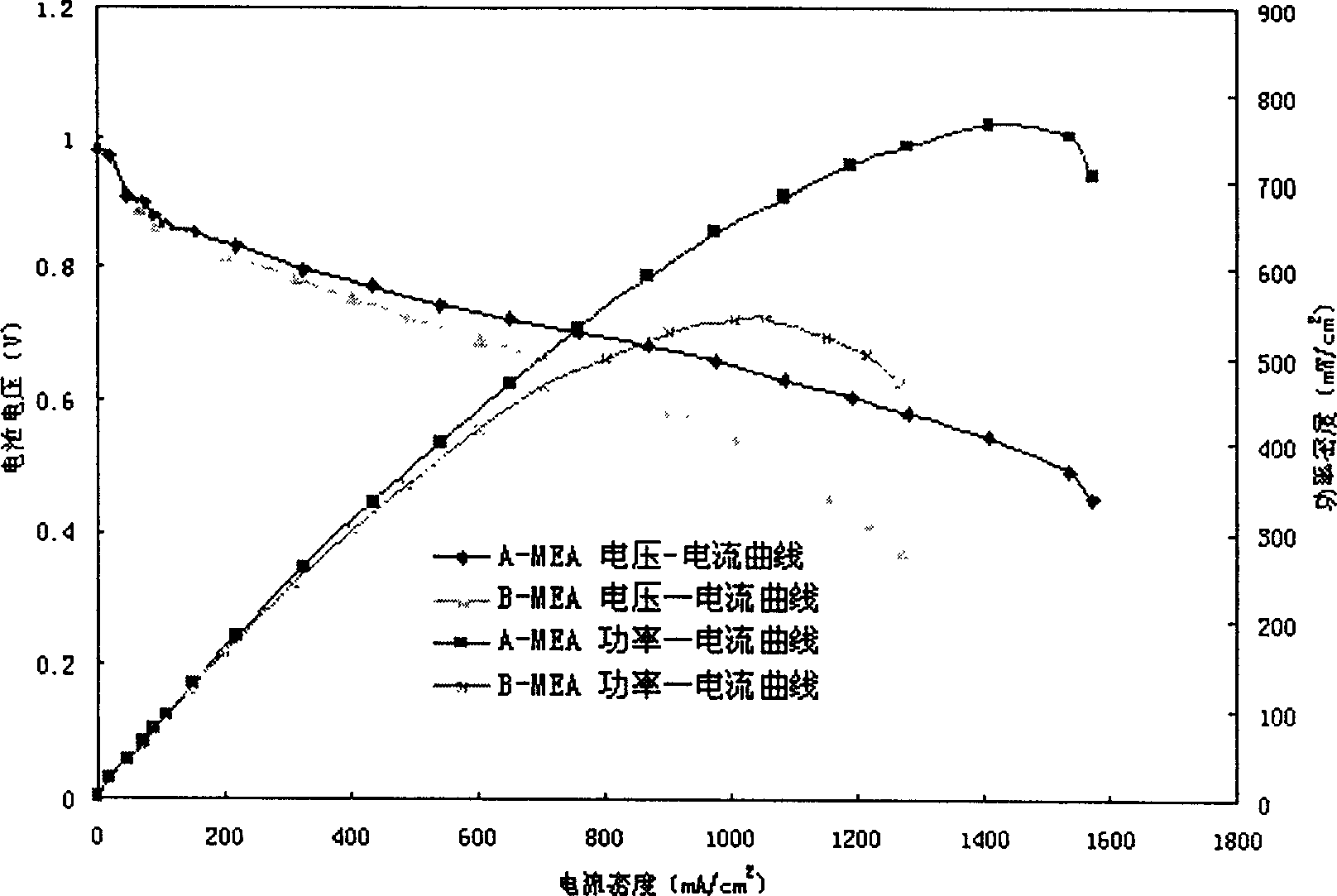

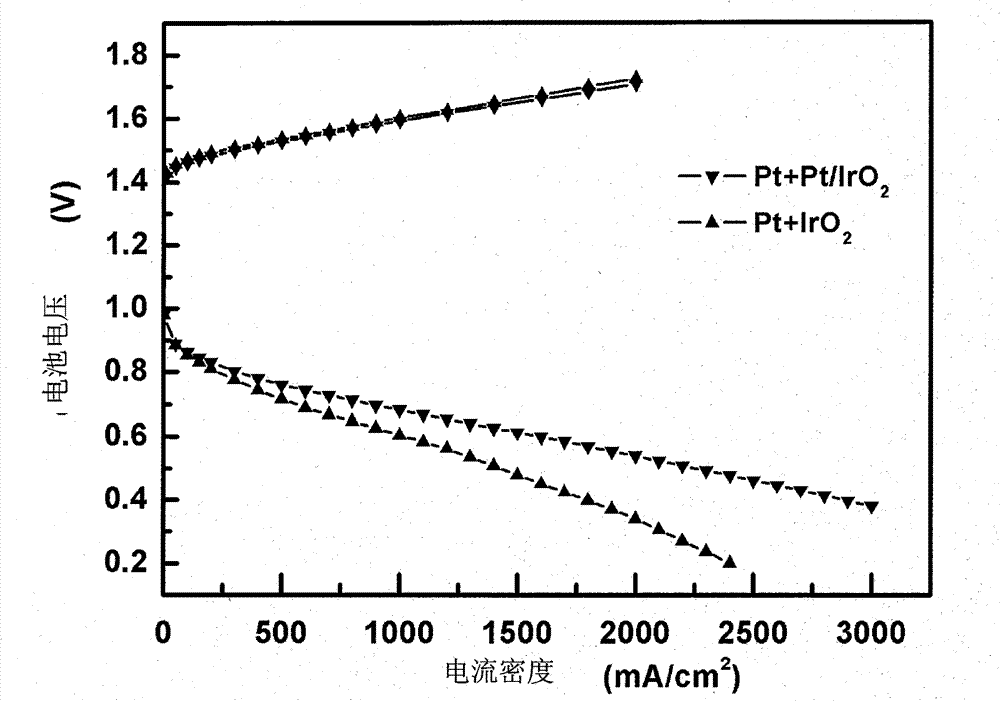

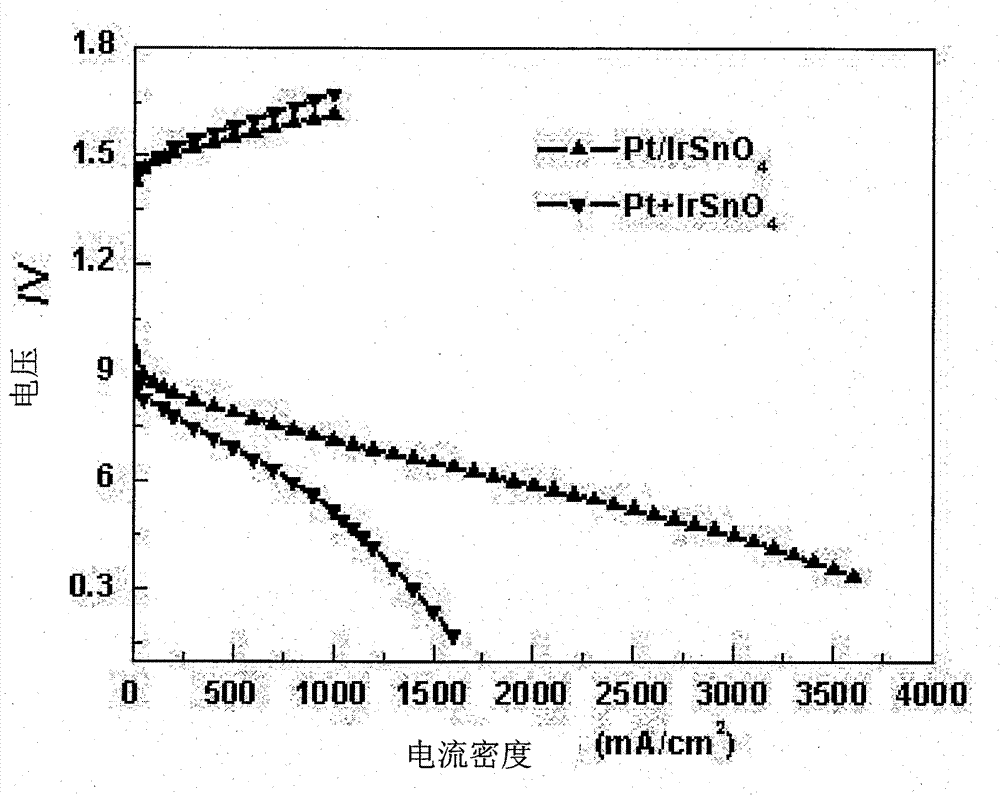

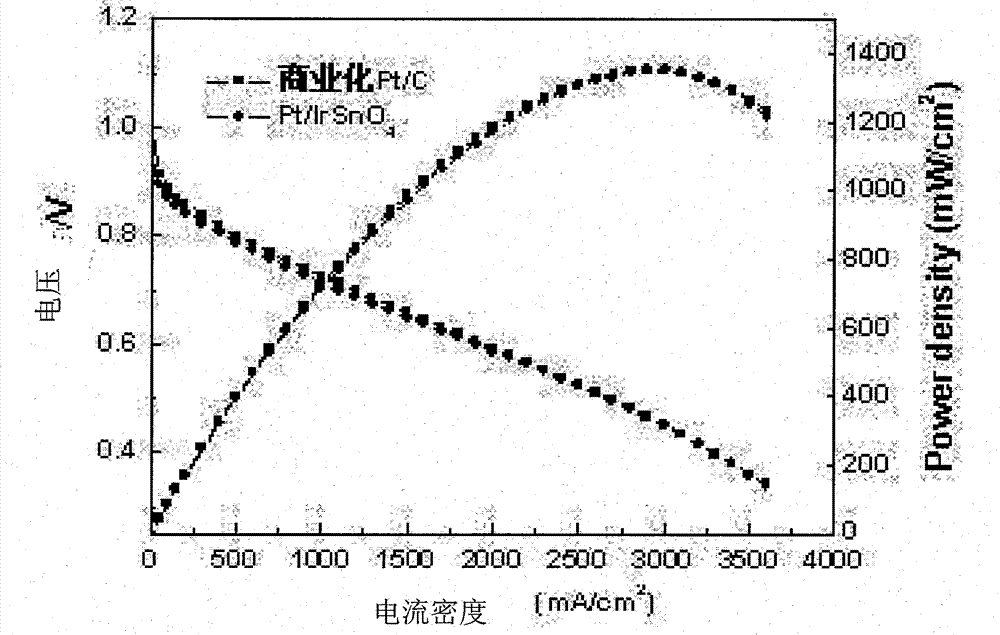

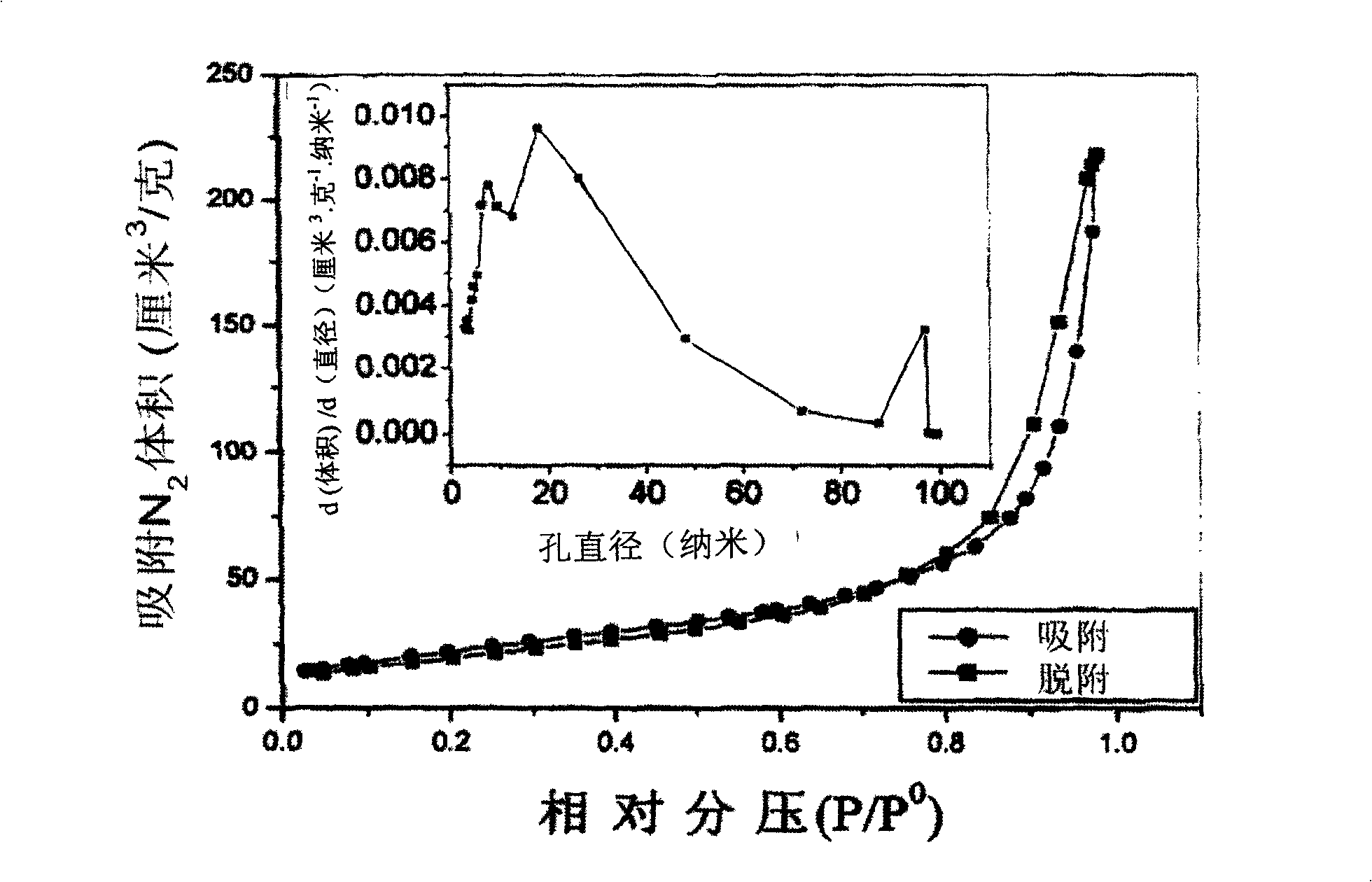

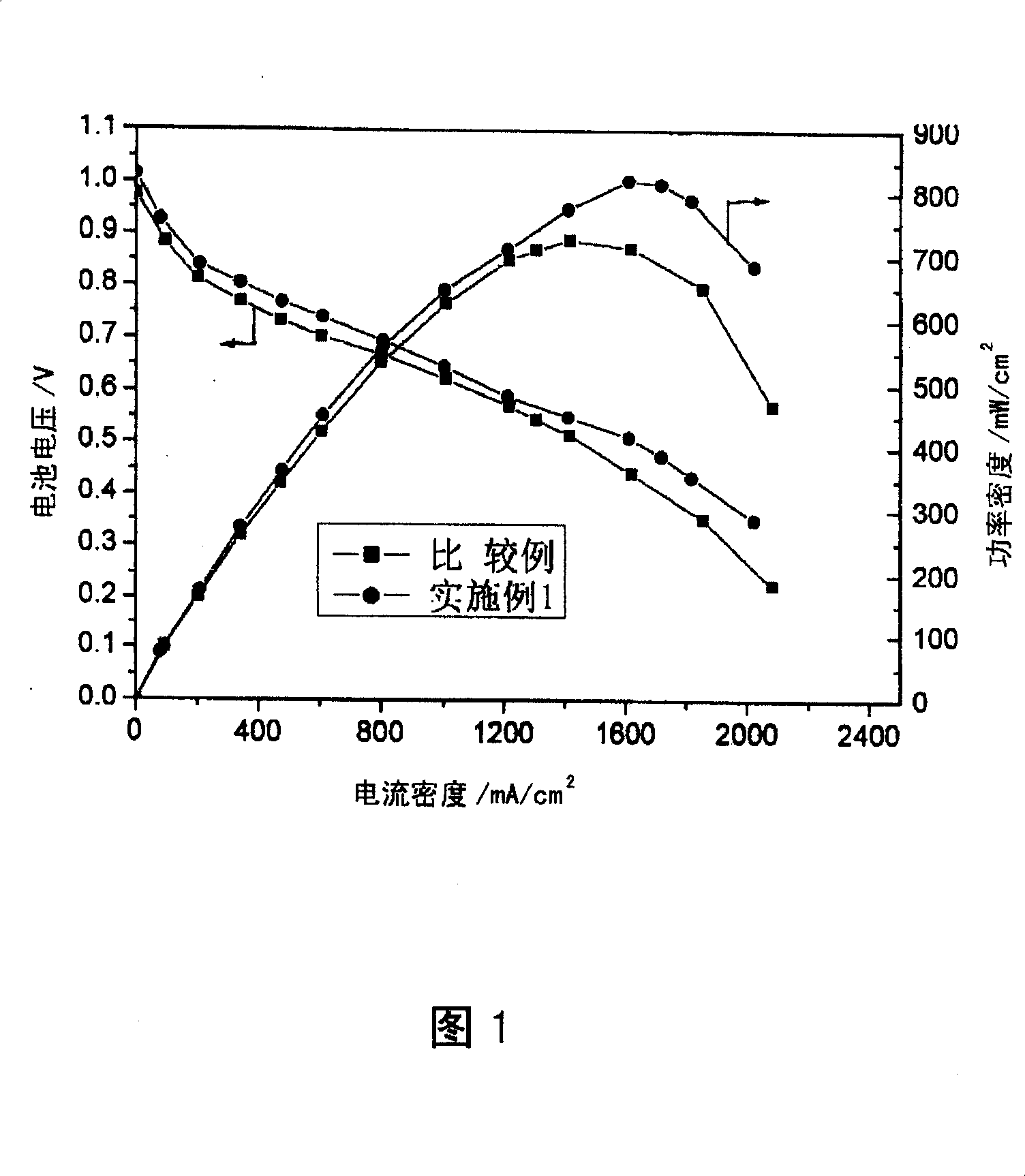

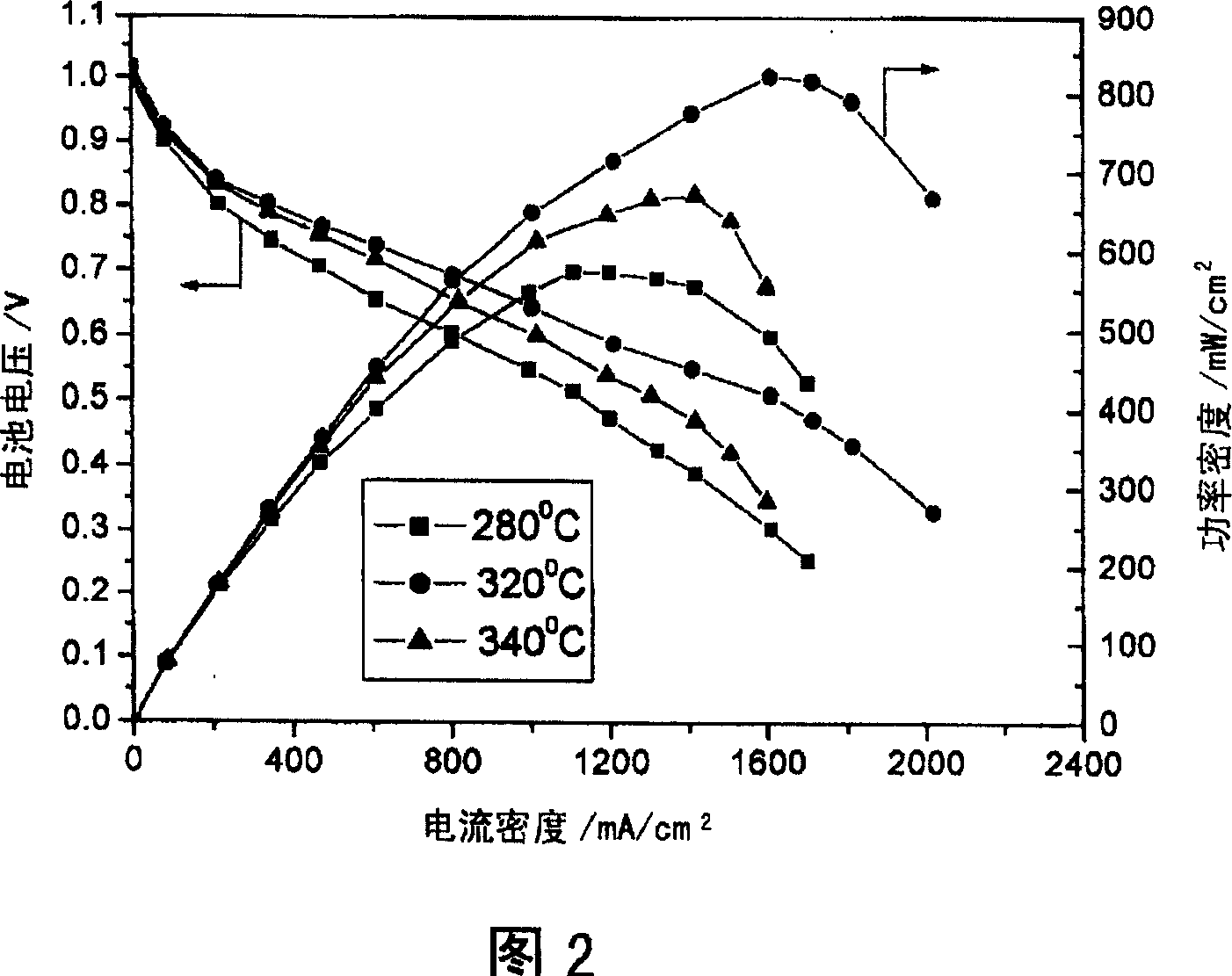

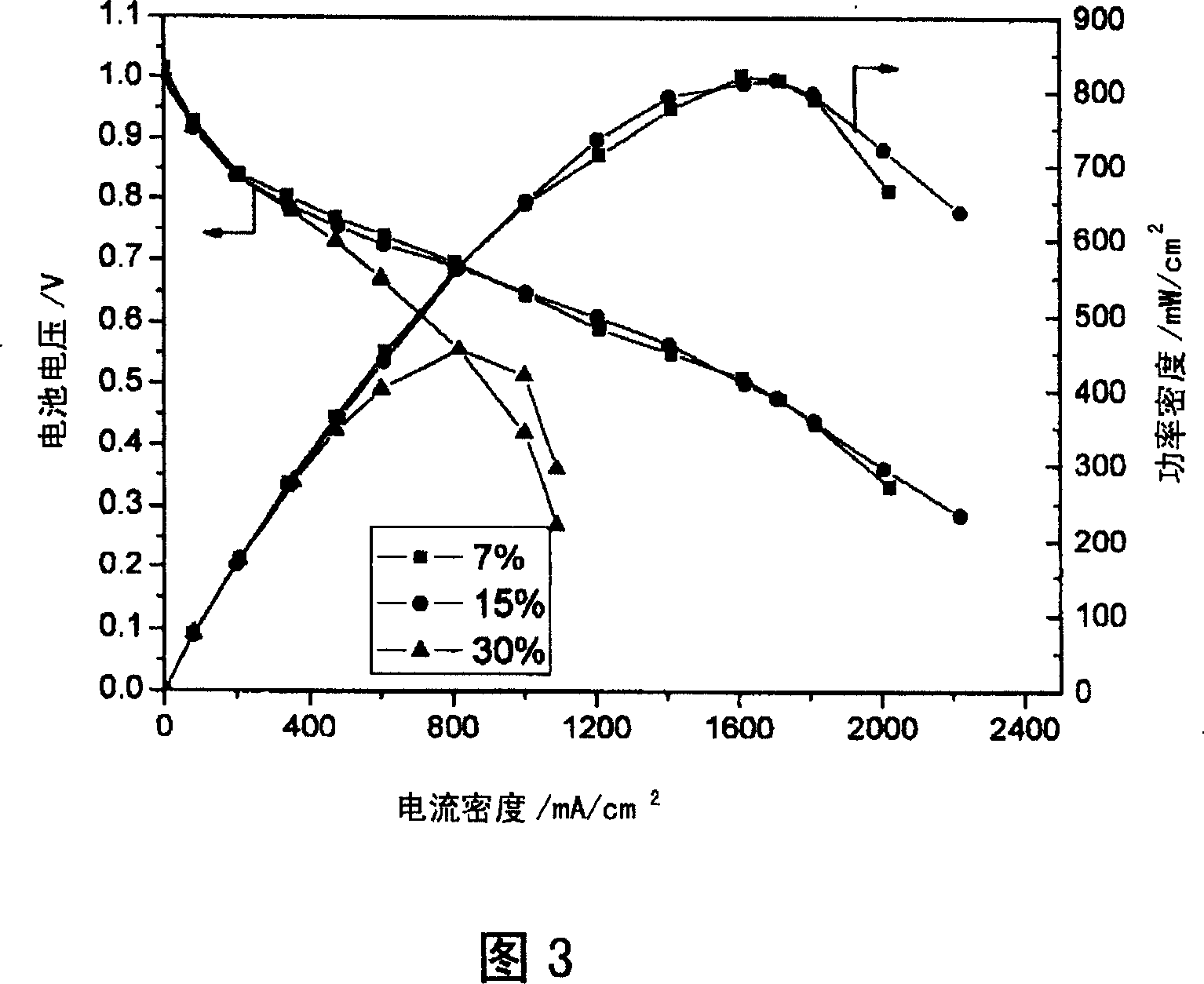

Catalyst using metal oxide as carrier for fuel cells and application thereof

ActiveCN101773826AImprove performanceIncrease profitCell electrodesMetal/metal-oxides/metal-hydroxide catalystsPtru catalystElectrolysis

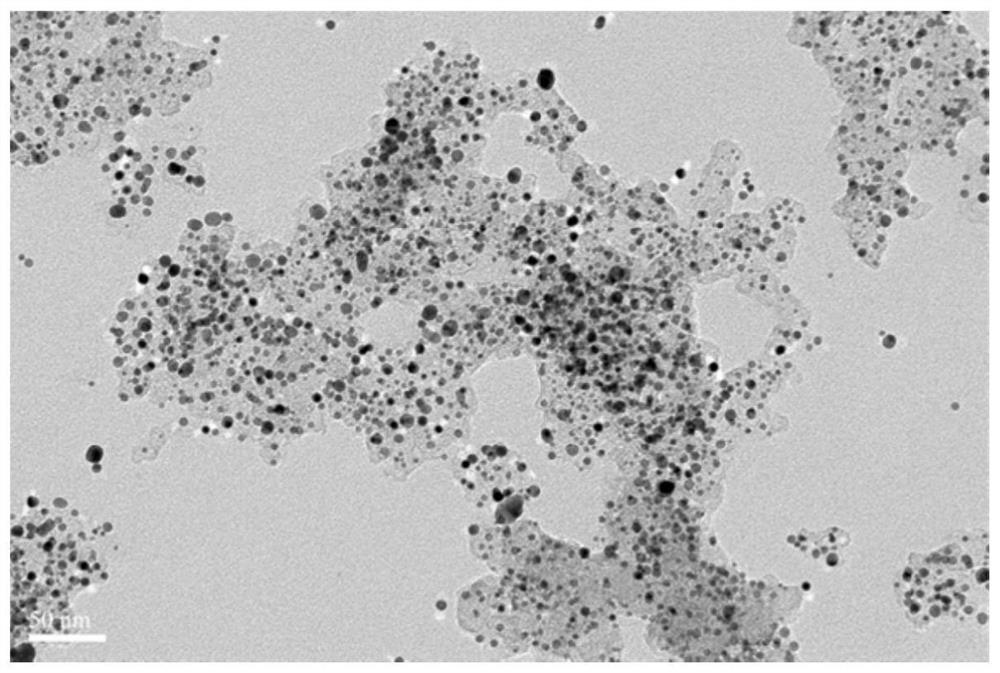

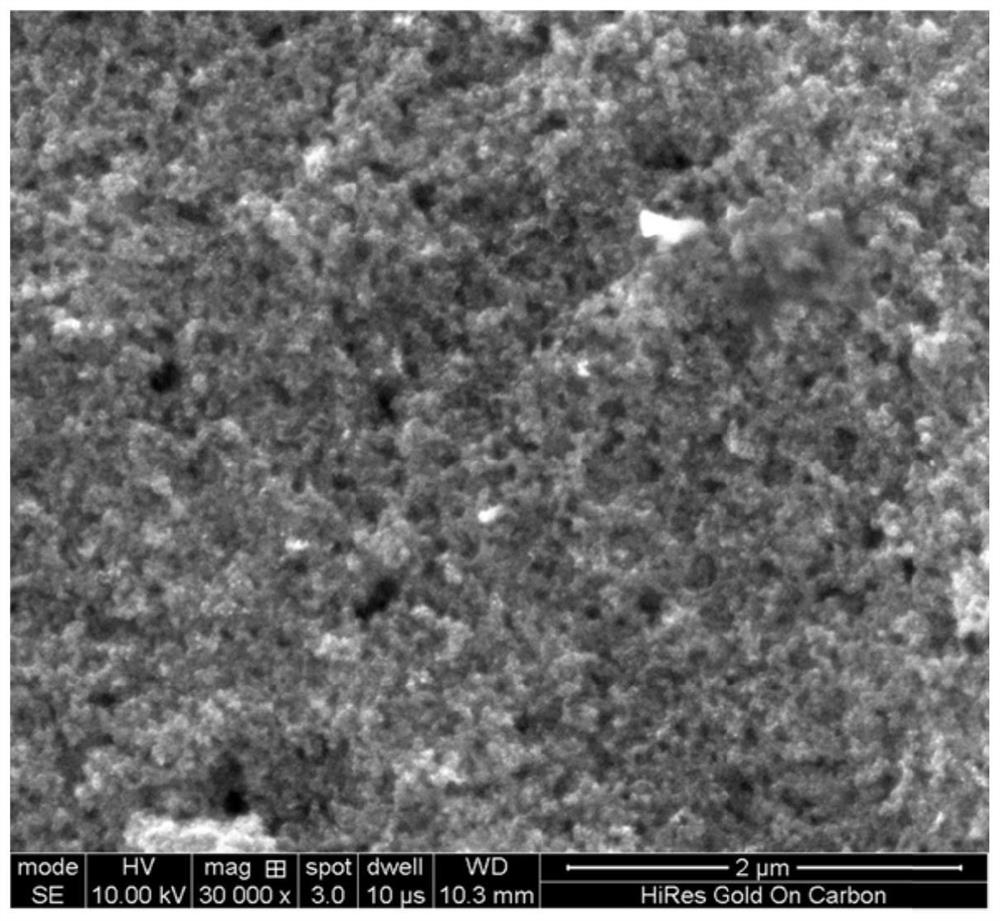

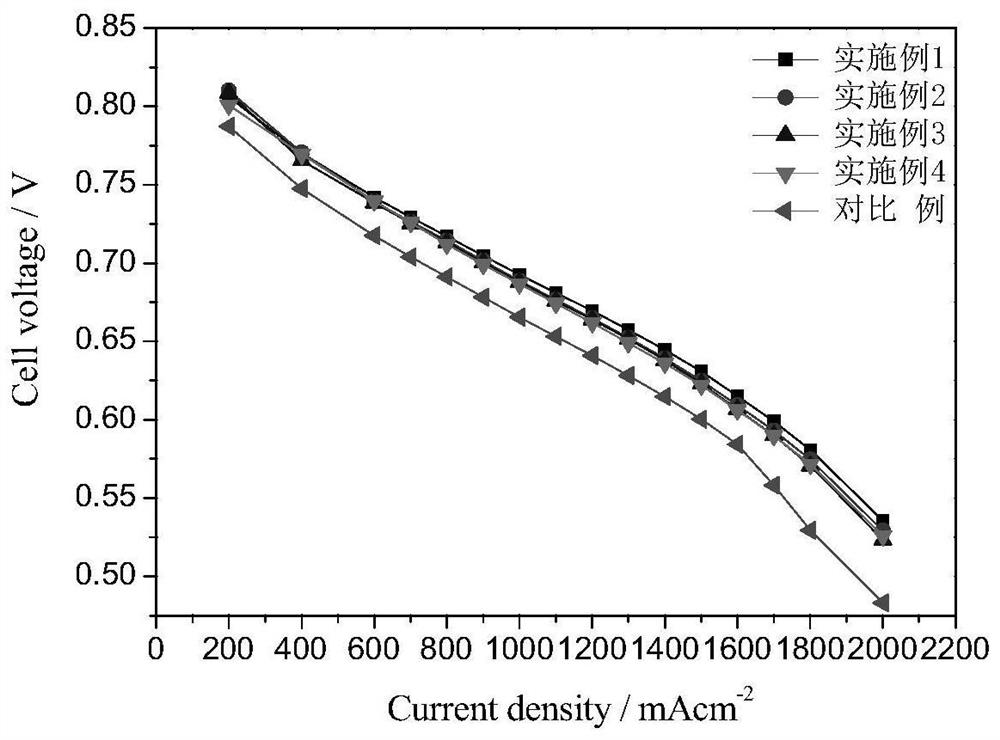

The invention discloses a catalyst using a metal oxide as a carrier for fuel cells and application thereof. The catalyst is characterized in that: the metal oxide as the carrier has catalytic oxygen evolution function simultaneously, and a noble metal with catalytic oxygen reduction function is supported on the metal oxide; the nanoparticles of the noble metal are highly dispersed on the surface of the metal oxide as the carrier, wherein the mass fraction of the noble metal is 2 to 70 percent in the catalyst. The catalyst alone or the catalyst mixed with platinum black in a certain proportionis applied to bifunctional oxygen electrodes for utilized regenerative fuel cells. Compared with the traditional mechanical mixture of platinum black and an oxide from catalytic oxygen evolution reaction, the fuel cell and water electrolysis performances of the cells are greatly improved, and the performance is close to that of a commercial Pt / C catalyst in fuel cells. The catalyst is applied to fuel cell oxygen electrodes to effectively solve the problems that the activity of the catalyst is deceased by the corrosion of the carrier.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

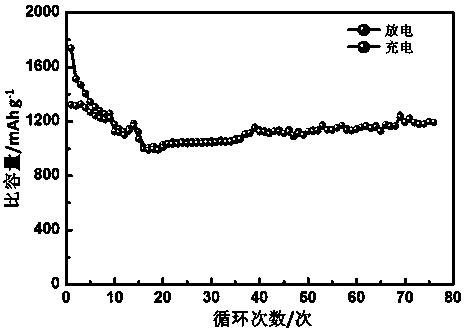

Preparation method of composite sulfur cathode material and application thereof in all-solid-state lithium-sulfur batteries

ActiveCN108539182AAdd three-phase interfaceWell mixedPositive electrodesLi-accumulatorsChemistryAll solid state

A preparation method of composite sulfur cathode material and application thereof in all-solid-state lithium-sulfur batteries belong to the technical field of preparation of battery materials. The preparation method comprises: dispersing sulfur material, solid electrolyte and a conductive agent in a solvent to reach a solid content of 30-70%, performing ball milling, mixing well, and drying to obtain mixture I; dispersing a conductive agent in a solvent to reach a solid content of 30-70%, adding the resultant, accounting for 5-10% of the mixture I by mass, into the mixture I, performing ball milling, mixing well, and drying to obtain mixture II; adding a solvated ionic liquid, accounting for 5-10% of the mixture II by mass, into the mixture II, grinding with a mortar, and mixing well to obtain the composite sulfur cathode material. The composite sulfur cathode material is applicable to all-solid-state lithium-sulfur batteries. It is provided herein that little solvated ionic liquid compatible with the components is added to fill gaps of solid particles; in addition, the solvated ionic liquid has ionic conductivity, which helps further enhance an ionic conductive pathway in the sulfur material in an electrode.

Owner:HARBIN INST OF TECH

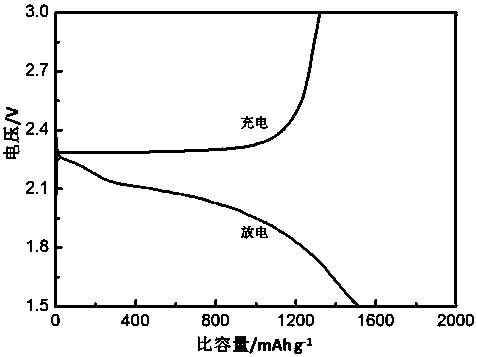

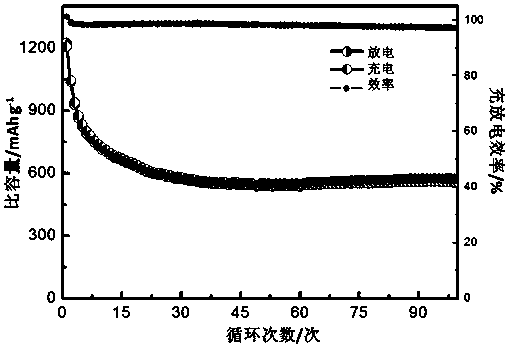

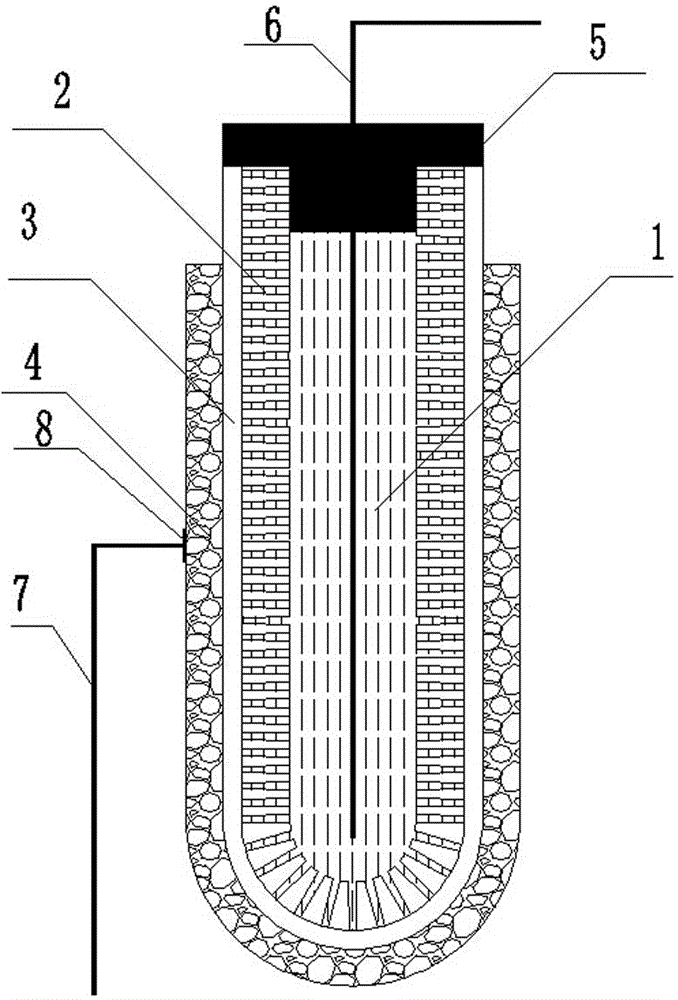

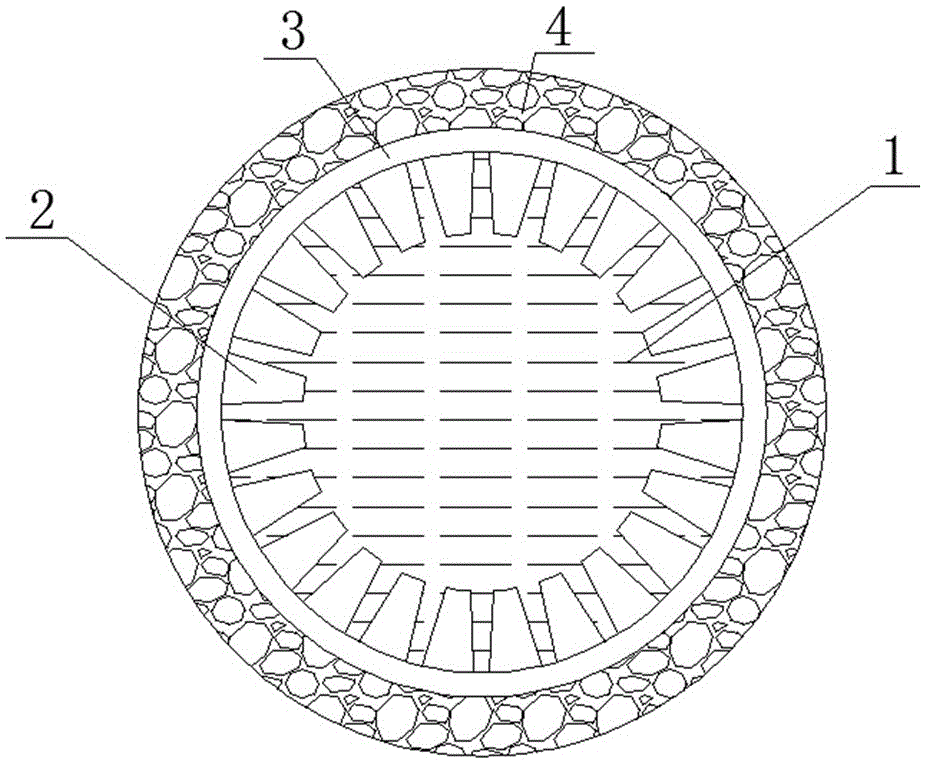

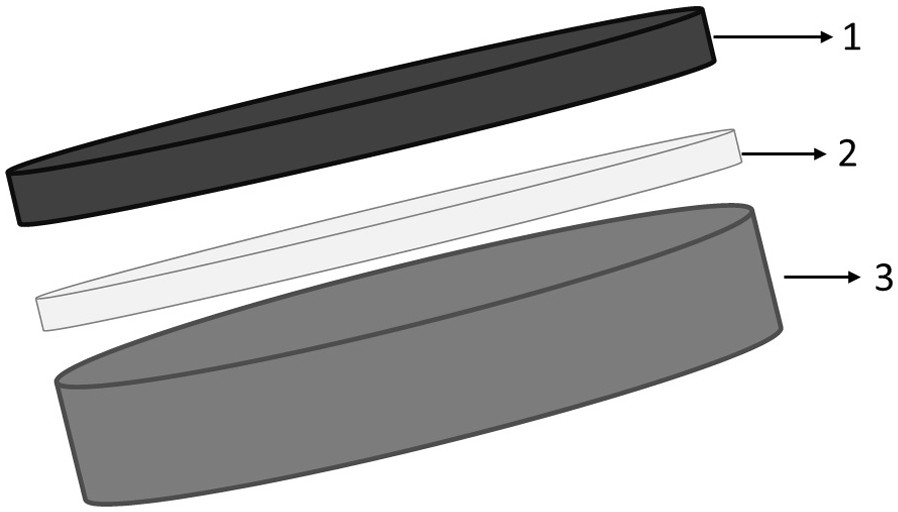

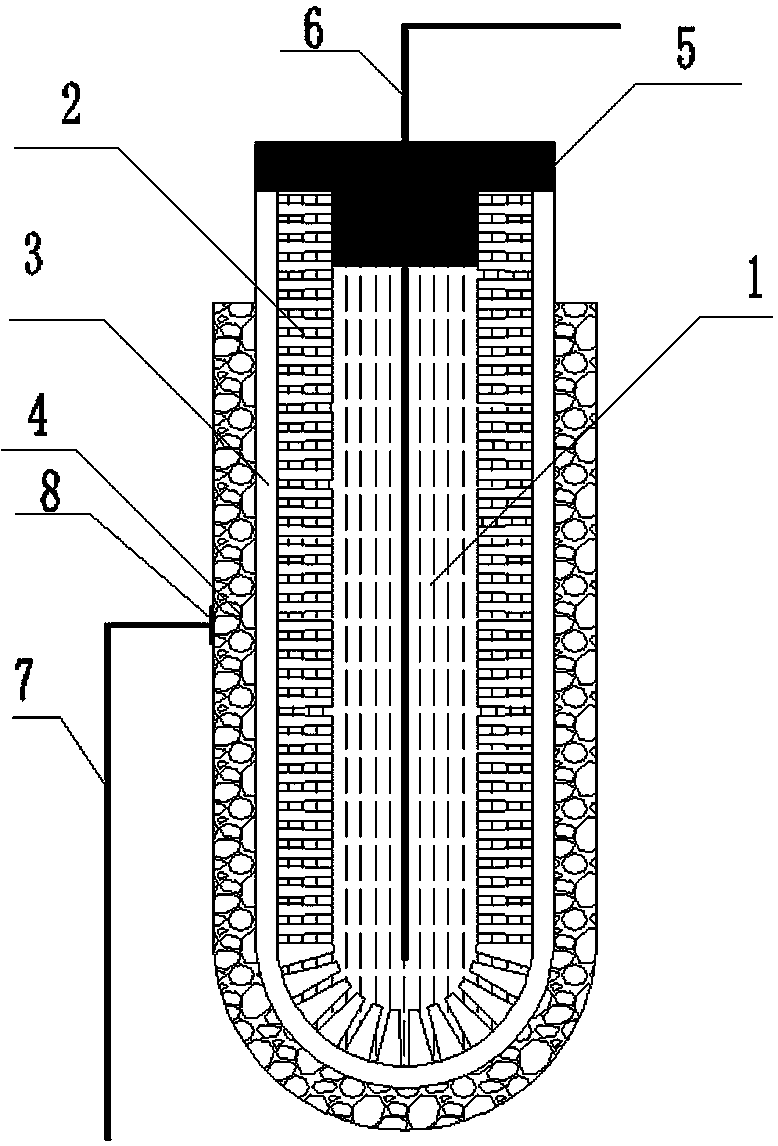

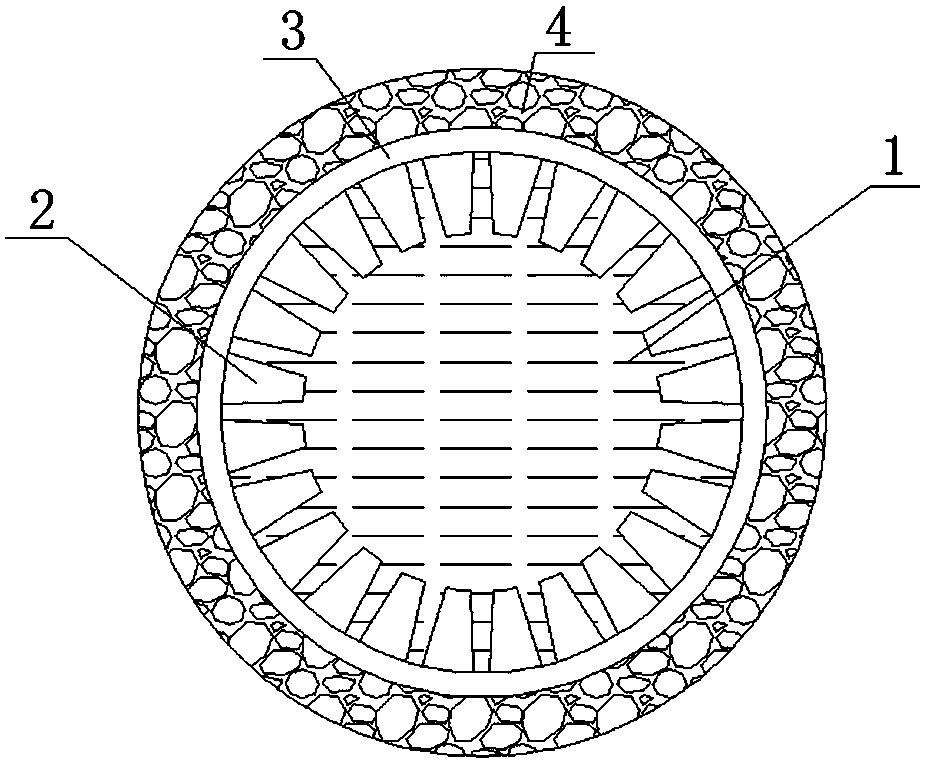

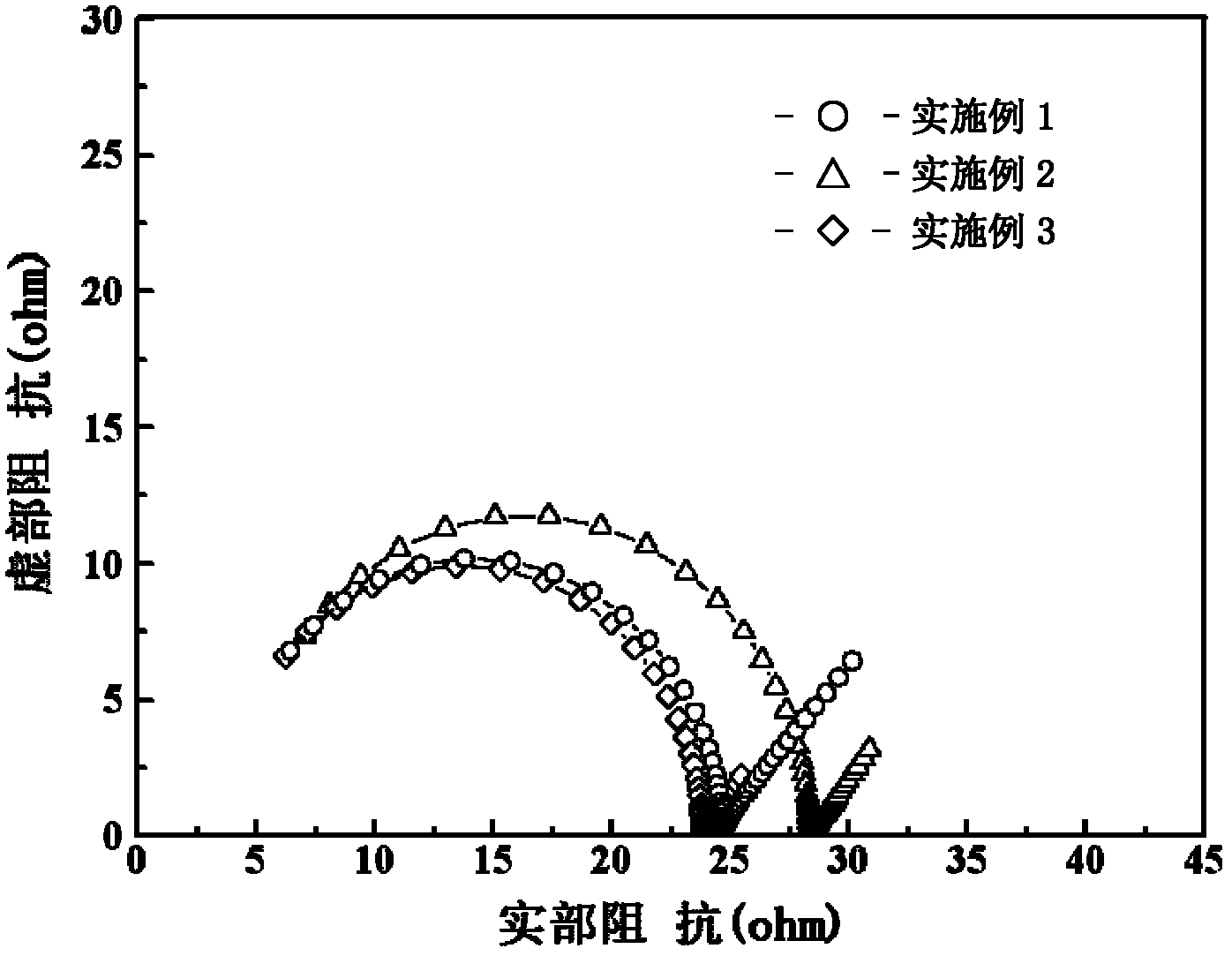

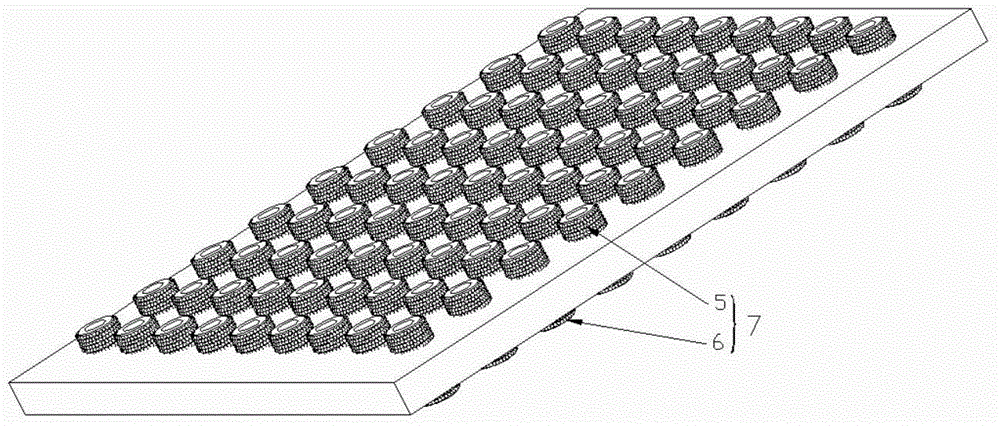

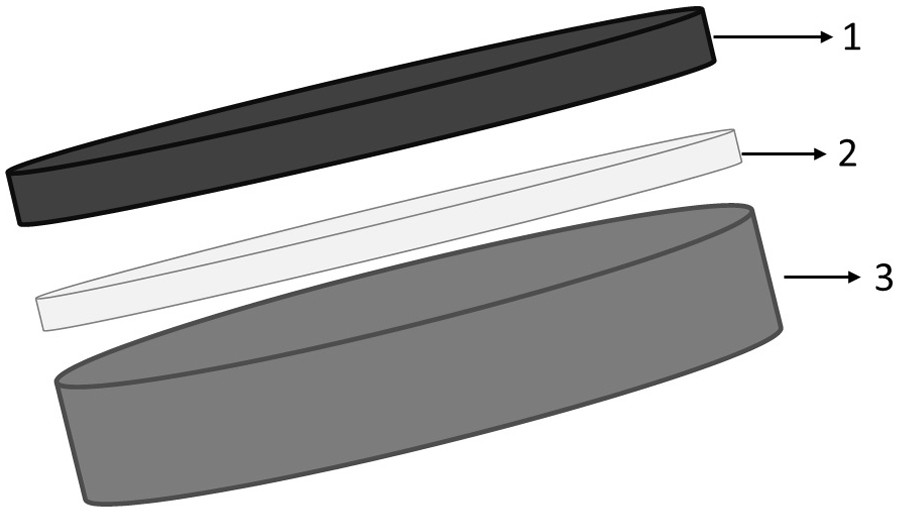

All-solid-state lithium-air battery and preparation method and application thereof

ActiveCN105742761AAll solid state implementationImprove securityFuel and primary cellsPtru catalystElectrical battery

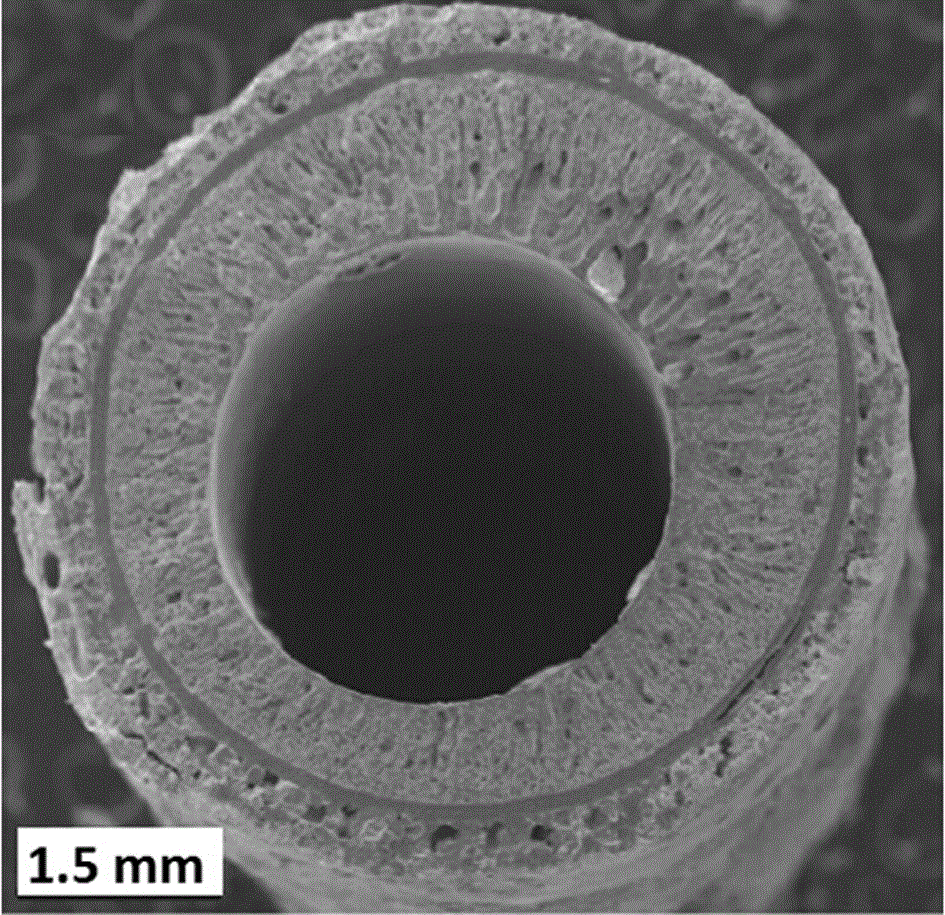

The invention discloses an all-solid-state lithium-air battery and a preparation method and application thereof. The all-solid-state lithium-air battery provided by the invention comprises a lithium metal anode, a porous ceramic support body, a compact electrolyte thin film, a porous cathode thin film, a sealing material, a current collector and a lead, wherein the porous support body is made of garnet type lithium-ion solid electrolyte material; in an air electrode catalyst and permeation holes of the lithium metal anode, a three-phase boundary for battery reaction is expanded, and the battery polarization resistance is reduced; the thickness of the battery electrolyte thin film is smaller than 30 micrometers, a lithium ion transmission path is shortened, and the battery ohmic resistance is reduced; and the battery is a tubular structure with a closed end, the lithium metal anode is poured into a tube, and the battery is easy to seal and is easy to work in different conditions. The all-solid-state lithium-air battery prepared according to the invention has the advantages of high charging-discharging capacity, high rate performance, high cycle stability, wide working temperature range and the like, and is applicable to the field of various mobile electronic devices and power batteries.

Owner:SUZHOU UNIV

Graphene-ceramic composite material and preparation method thereof

The invention discloses a preparation method of a graphene-ceramic composite material. The preparation method comprises the following steps of: (1), penetrating cerate (or zircon salt), auxiliaries and graphene oxide through alcohol dissolving auxiliaries, ultrasonically dispersing the materials uniformly for co-decomposing into metal oxides to obtain a composite material; (2), adding organic adhesive solvent to the graphene-metal oxide composite material for sufficiently mixing and grinding; pressing the mixture into a strip-shaped composite sample by adopting a dry-press process, placing the composite sample in a vacuum tube furnace; and controlling the sintering condition by ventilating a gas mixture of a certain proportion, cooling to the room temperature to obtain the graphene-ceramic composite material. The preparation method of the graphene-ceramic composite material disclosed by the invention can be used for improving the dispersibility and cycling stability of ceramic oxide particles, increasing a three-phase interface among the ceramic oxide particles and improving the electrochemical activity of the composite material, so that the ceramic material has the advantages of being low in density, high in strength, excellent in oxidation resistance, thermal scouring resistance, corrosion resistance and the like.

Owner:SHAANXI COAL & CHEM TECH INST

Nickel-based composite anode material of solid oxide fuel cell and application thereof

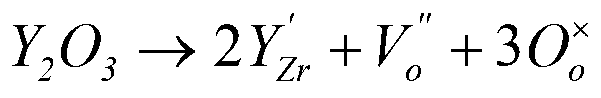

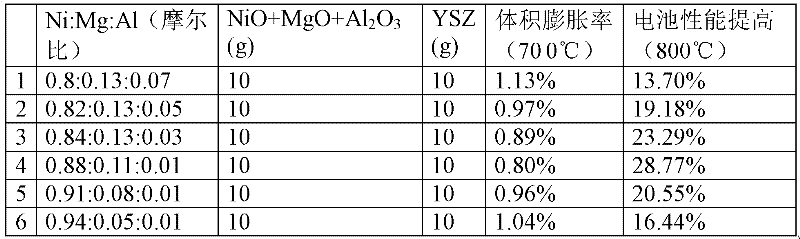

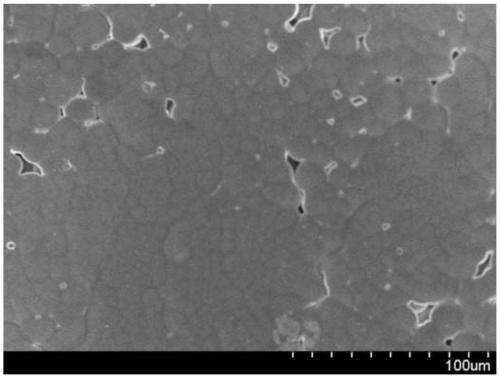

InactiveCN102651477AImprove dispersionHigh particle size and activityCell electrodesComposite oxideNickel oxides

The invention relates to a nickel-based composite anode material of a solid oxide fuel cell and an application thereof. The composition of the composite anode material can be expressed by Ni1-x-yMgxAlyO1 plus 0.5y, wherein x varies from 0.01 to 0.2 and y ranges from 0.001 to 0.2. The composite anode material is compounded with an electrolyte material to prepare an anode, and the weight percentage of magnesium oxide and aluminium oxide modified nickel-based composite oxide material is 30-70 percent. During practical application, the composite anode is put into use after reduction, the reduced anode contains the electrolyte material, metal micron-nickel and nano particles, magnesium oxide, aluminium oxide and a composite oxide formed by magnesium oxide, aluminium oxide and nickel oxide. The novel composite anode can be used for flat-plate-type, tubular, honeycomb-type and oblate-tube-type solid oxide fuel cells.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

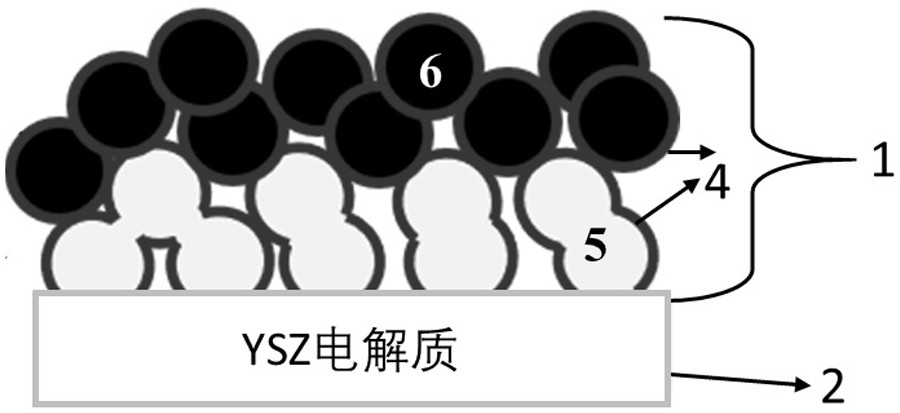

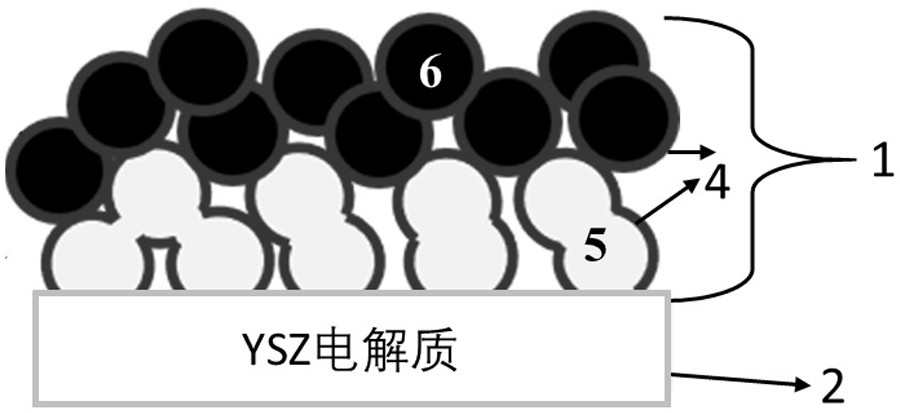

Nano composite cathode as well as preparation and application thereof

ActiveCN111244470AStable structureImprove redox abilityCell electrodesFuel cellsPtru catalystComposite cathode

The invention discloses a nano composite cathode for a high-temperature solid oxide electrolytic tank as well as a preparation method and application thereof. The structure of the nano composite cathode is a YSZ skeleton which is prepared by adopting PMMA as a pore forming agent and has micro-pores, an LSFM-GDC (M = Mn, Fe, Ni) composite nano electrode catalyst is prepared by adopting a co-impregnation method, and the nano composite cathode for the high-temperature solid oxide electrolytic tank is prepared after roasting. The high-temperature solid oxide nano composite cathode prepared by theinvention is suitable for high-temperature CO2 electrolysis and CO2-H2O co-electrolysis; good electrochemical performance is achieved on high-temperature CO2 electrolysis and Co2-H2O co-electrolysis,the performance and the operation stability of the solid oxide electrolytic tank can be remarkably improved, and good development prospects are achieved. The method is suitable for the field of high-temperature carbon dioxide reduction, the field of clean carbon fuel preparation and the technical field of energy and fuel cells.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

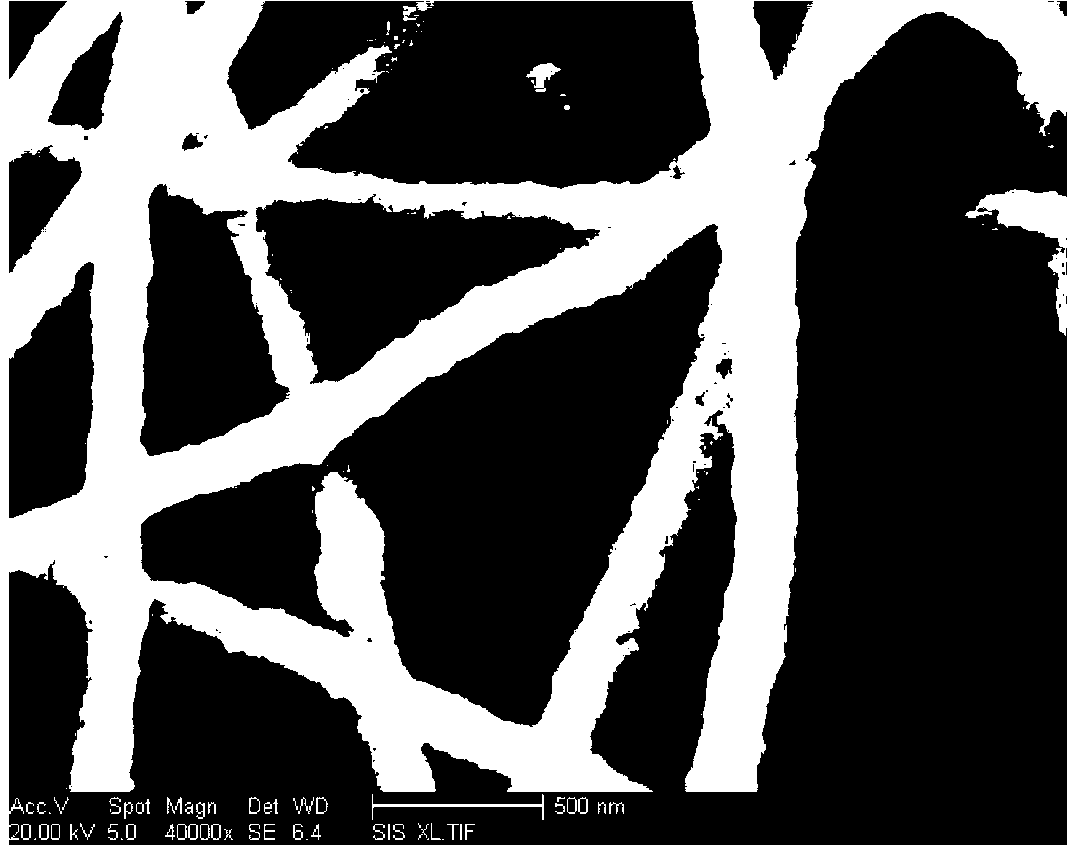

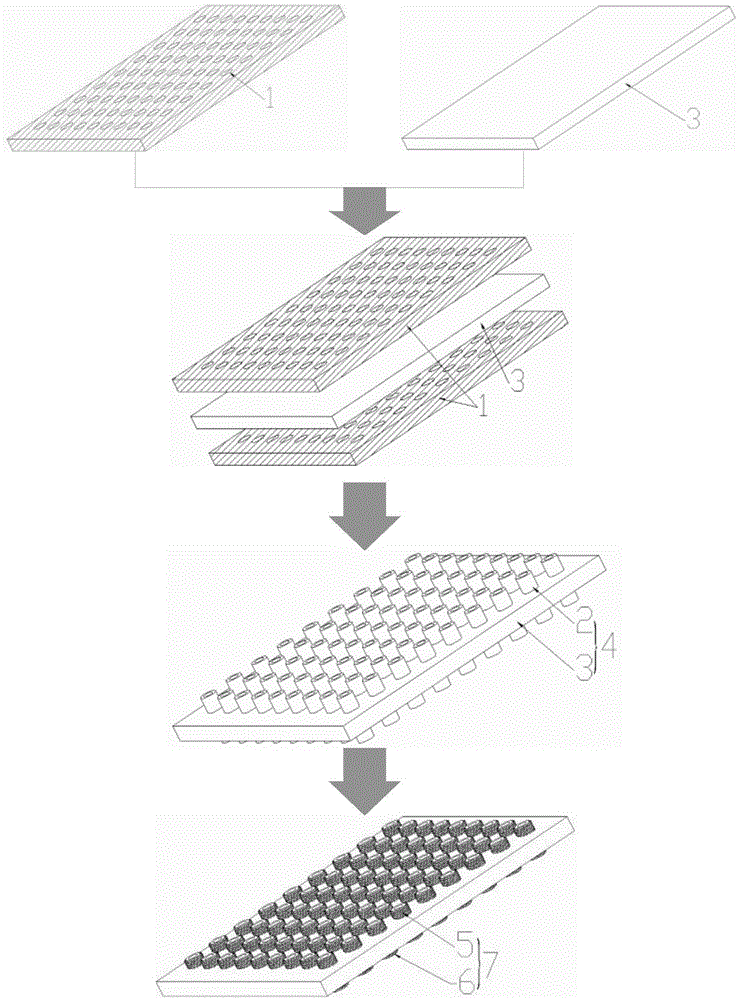

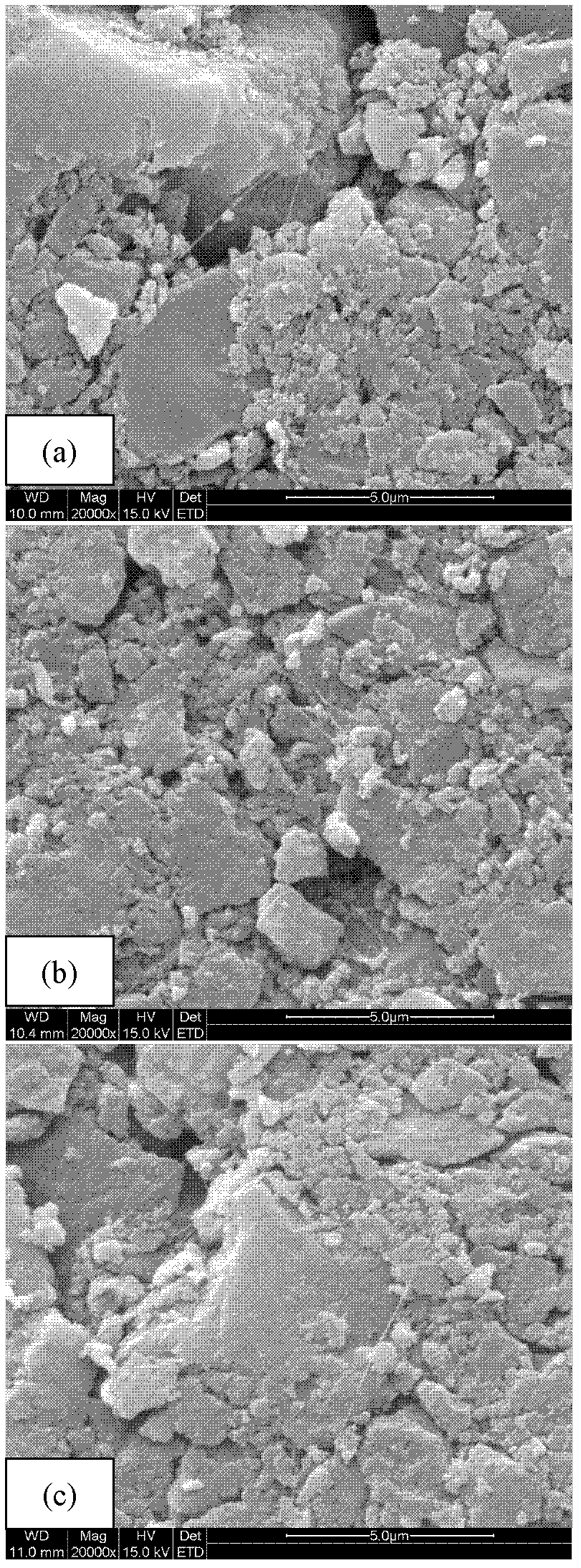

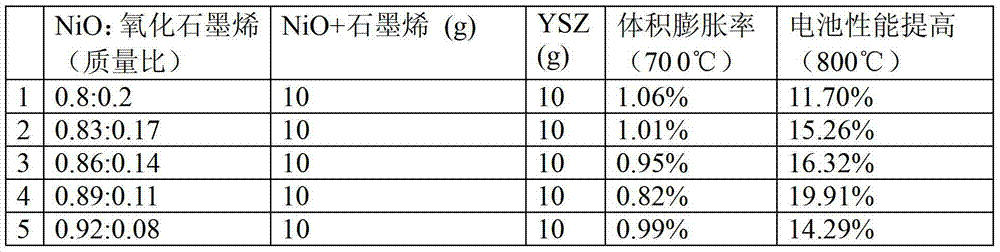

One-dimensional nanofiber SSC (Sm(1-x)SrxCoO(3-delta)) cathode material, preparation method of the cathode material, composite cathode using cathode material and preparation method of composite cathode

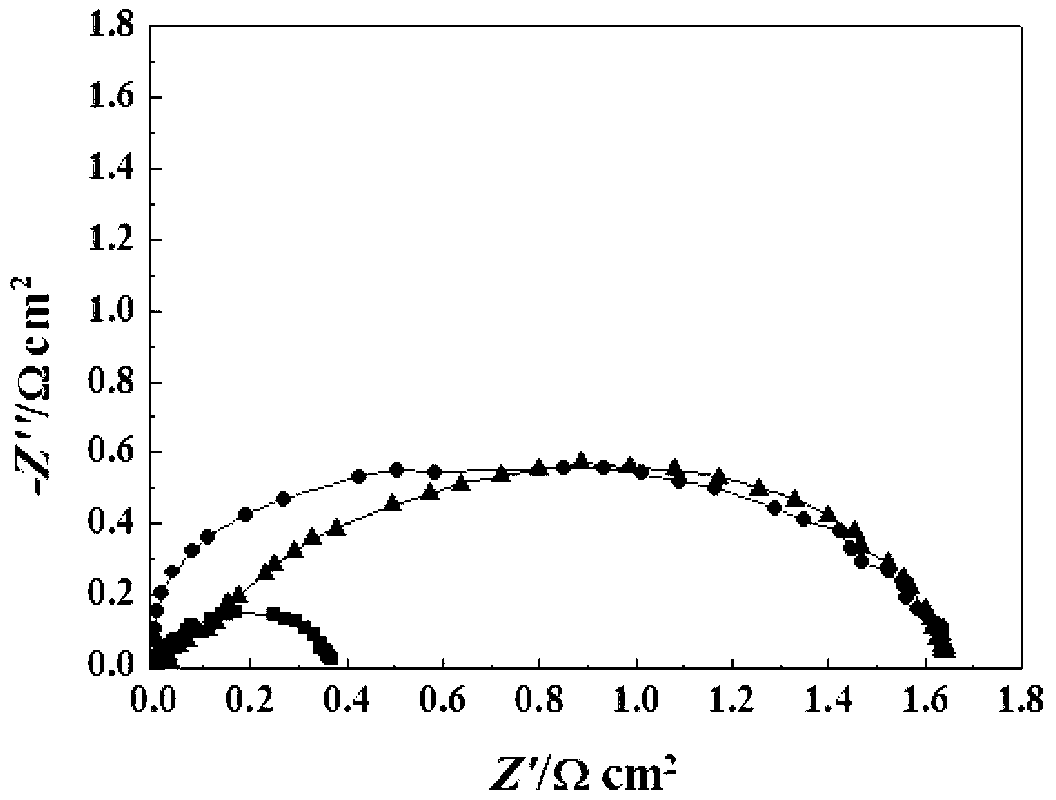

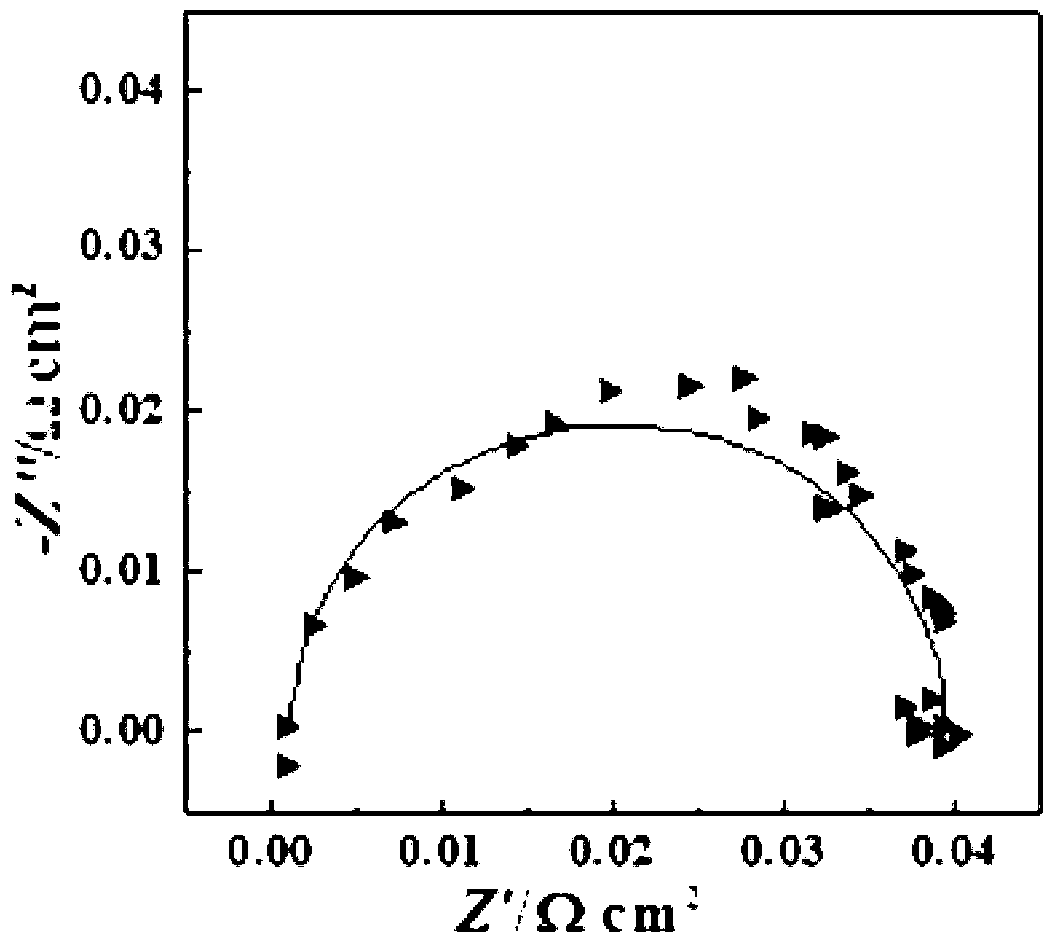

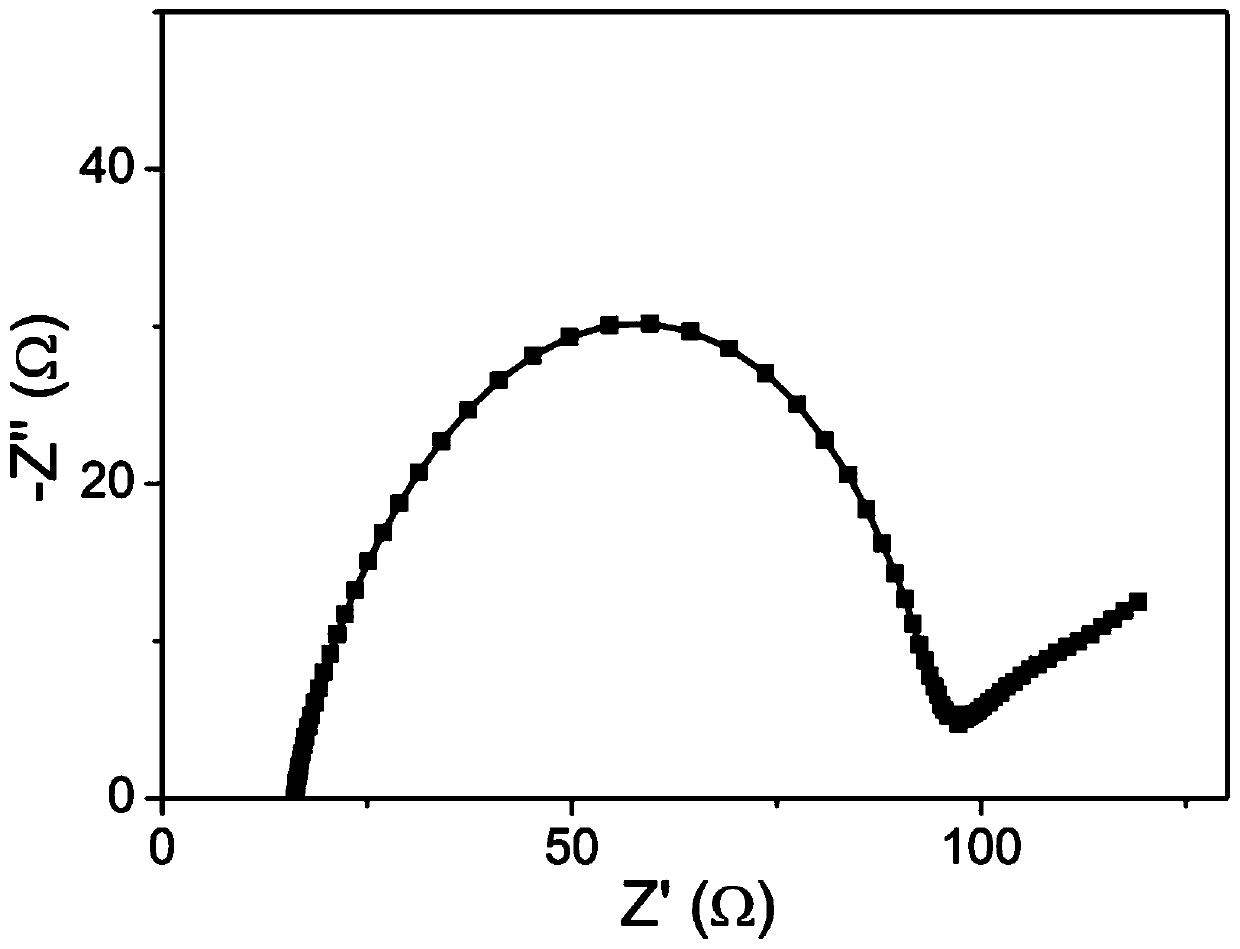

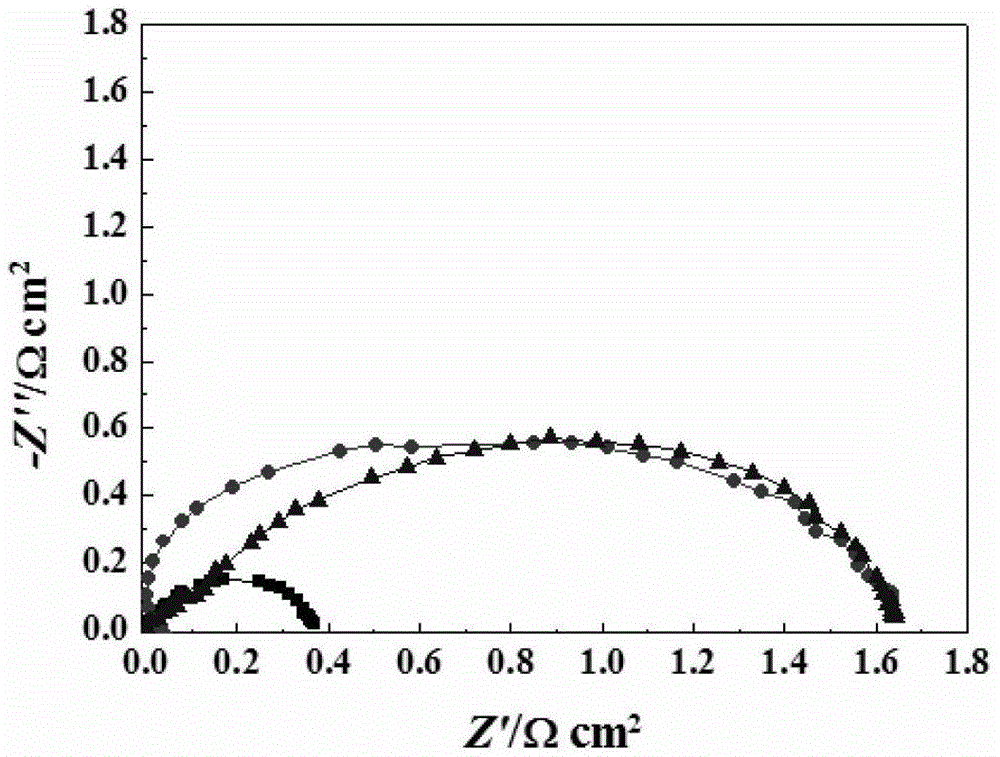

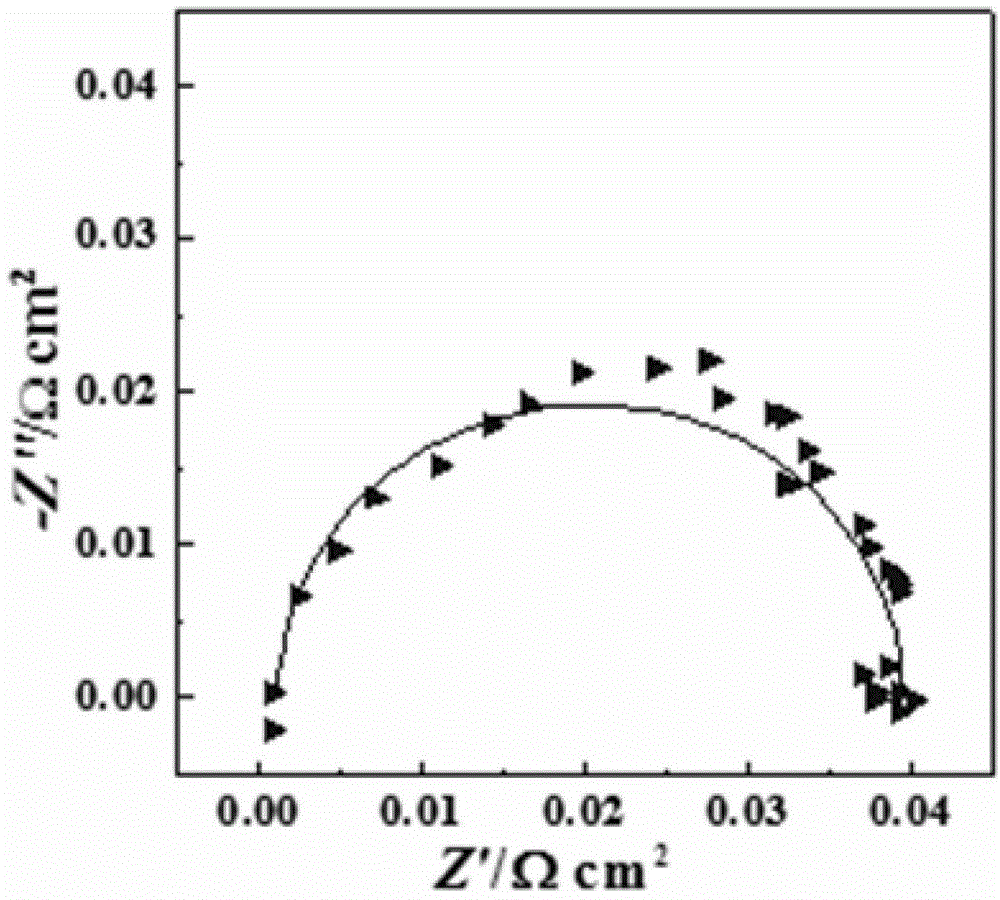

ActiveCN103107342AAdd three-phase interfaceReduced interface polarization resistanceMaterial nanotechnologyCell electrodesElectrospinningComposite cathode

The invention discloses a preparation method of a nanofiber SSC based cathode material, and relates to a preparation method of a cathode, aiming to solve the technical problem of large interfacial polarization impedance of the cathode prepared by the method. The composite cathode comprises an electrolytic strip, an anode or a cathode as support bodies, and the one-dimensional nanofiber SSC cathode material Sm(1-x)SrxCoO(3-delta) adhered on the support bodies, wherein electrolyte nanoparticles are adhered on the SSC fiber. The preparation method of the composite cathode comprises the steps of soaking a one-dimensional nanofiber SSC cathode framework in a small amount of electrolyte precursor liquid by multiple times; and sintering to obtain the composite cathode based on the one-dimensional nanofiber SSC material. The composite cathode provided by the invention can be used in a medium-and-low-temperature solid oxide fuel battery.

Owner:HARBIN INST OF TECH

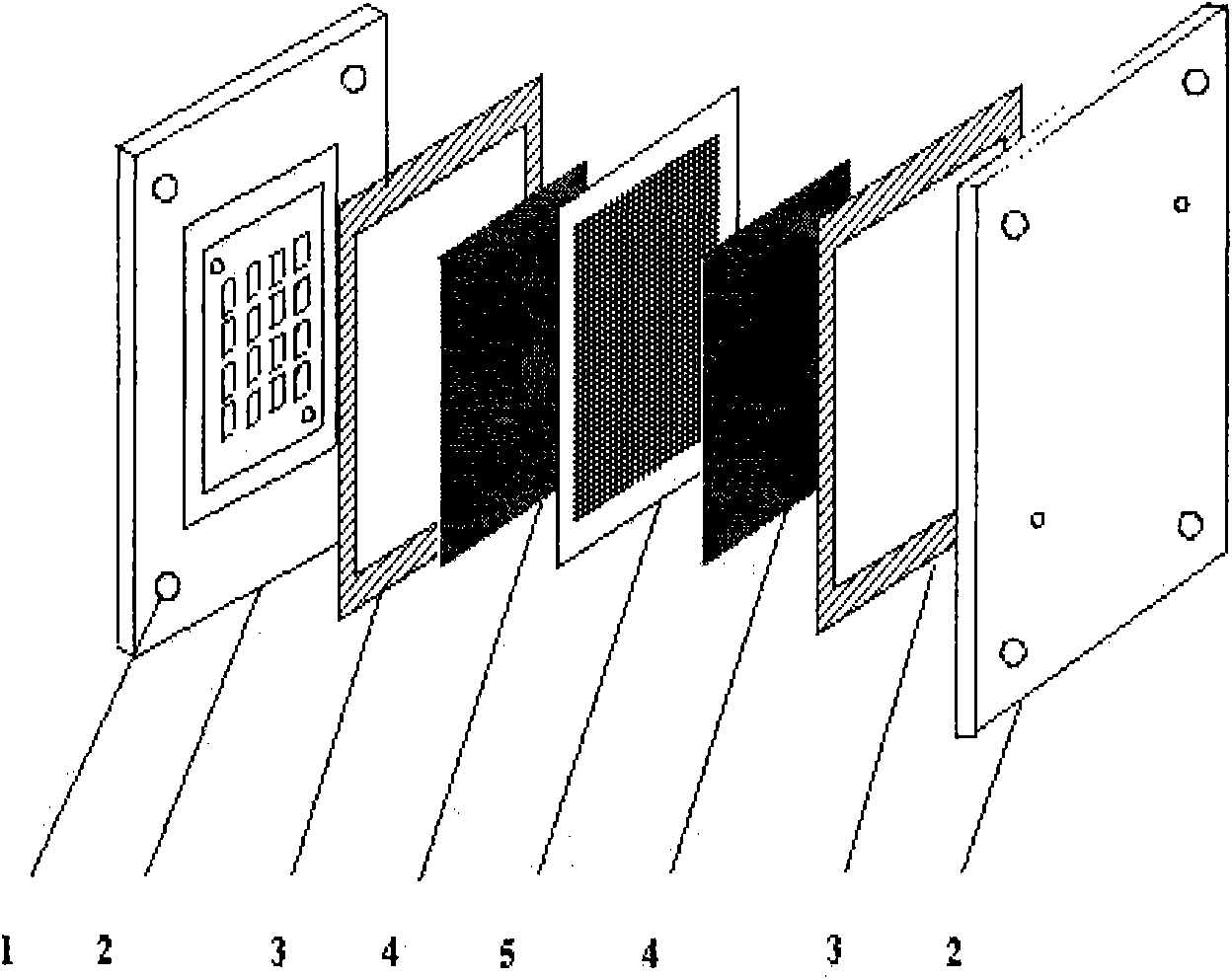

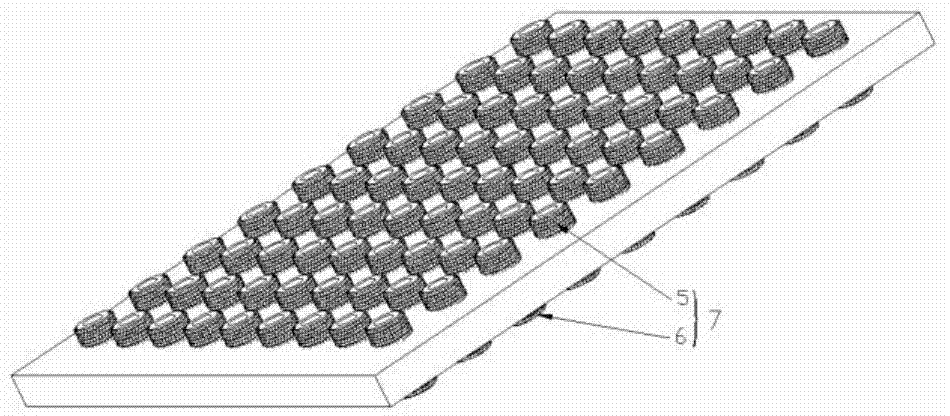

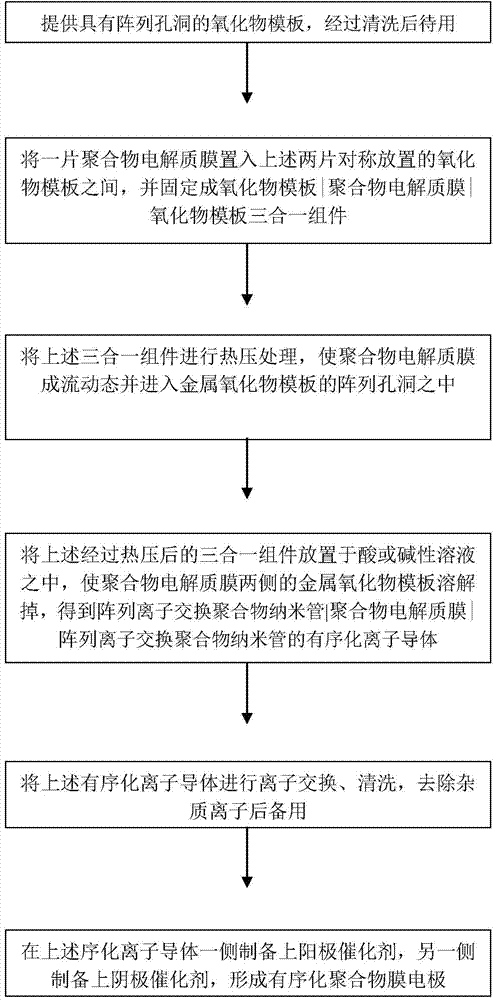

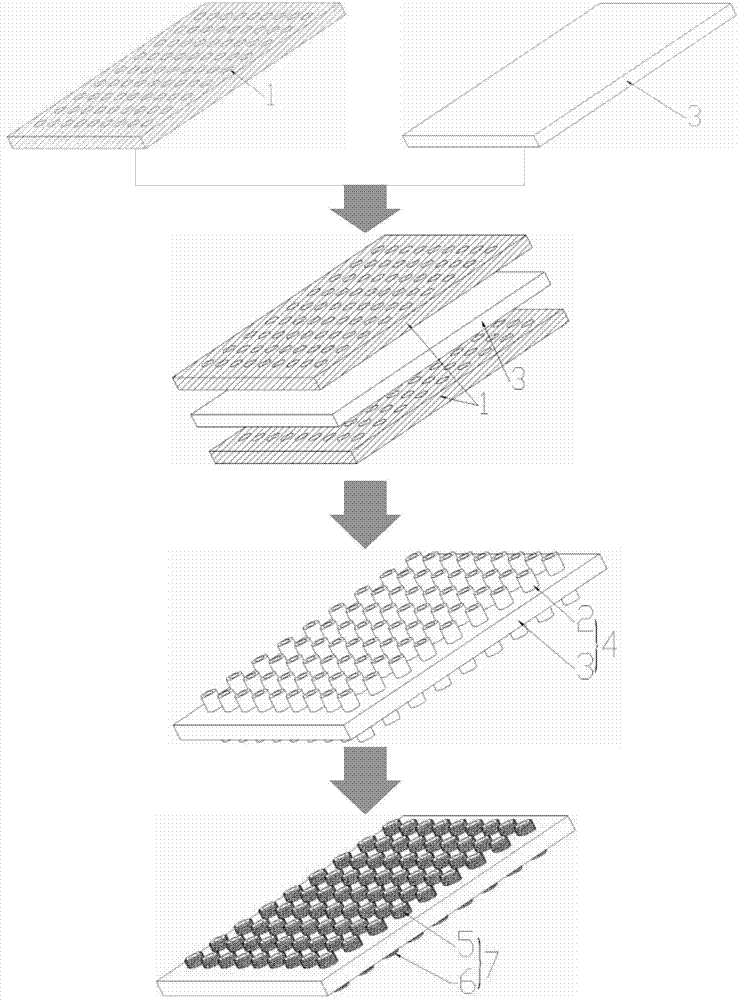

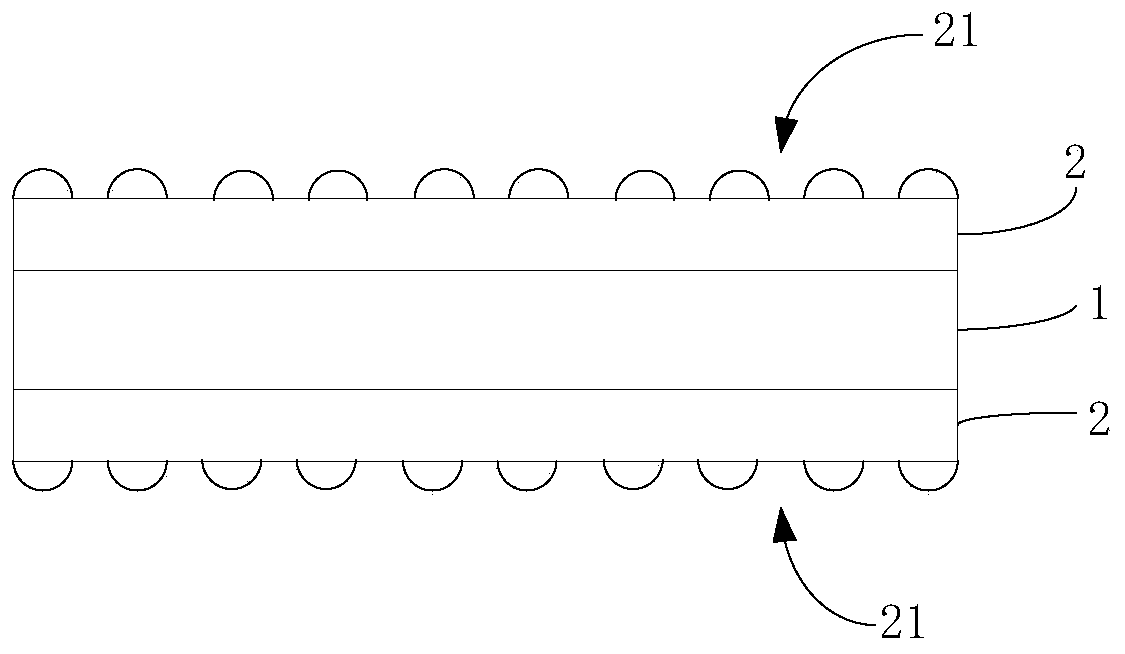

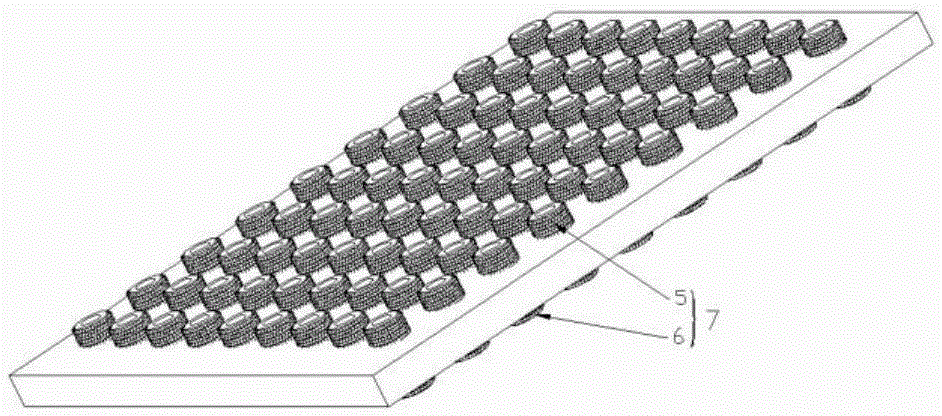

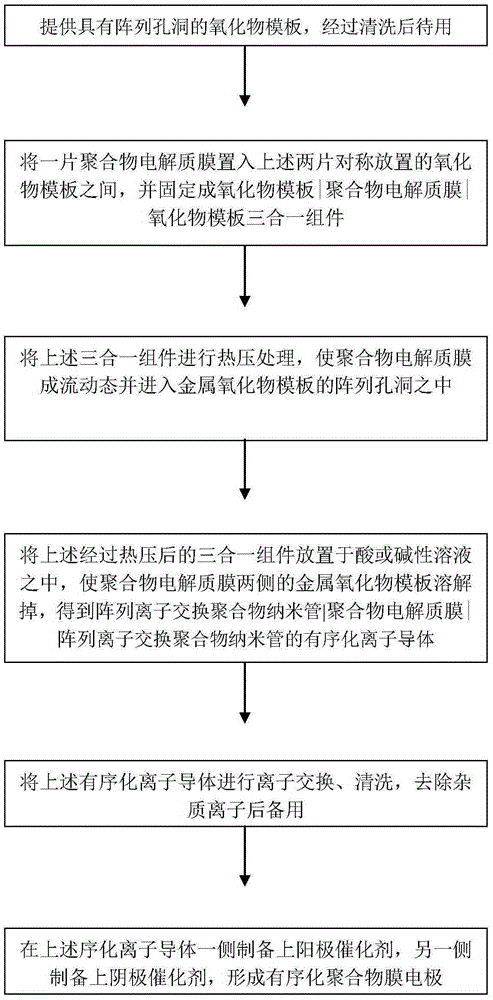

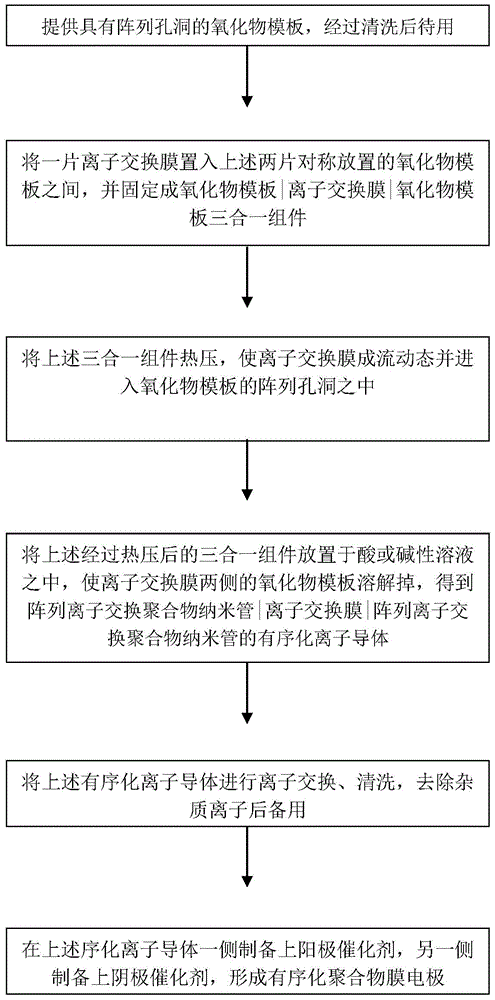

Preparation method of self-humidifying ordered polymer membrane electrode

ActiveCN103887521ARealize self-humidification energy conversionIncrease the three-phase reaction interfaceCell electrodesFuel cellsElectrochemical responseConcentration polarization

The invention discloses a preparation method of a self-humidifying ordered polymer membrane electrode, belonging to the technical field of membrane electrode preparation. An ordered ion exchange polymer nanotube array prepared through the method is fused together with a polymer membrane and is provided with highly ordered ion, electron and gas mass transfer channels, and electrochemical three-phase reaction interfaces are distributed in the outer surfaces of polymer nanotubes with water storage functions, so that a high-efficiency energy conversion process can be carried out in a self-humidifying manner. A catalyst in a nanoparticle or microparticle state is bonded on the surface of the ion exchange polymer nanotube array to form a catalysis layer and is relatively high in specific surface area and catalytic activity, so that the three-phase reaction interfaces of the membrane electrode are greatly added, the electrochemical polarization, the ohmic polarization and the concentration polarization of the electrode are reduced, the energy conversion efficiency is improved, and the reaction speed is increased. According to the preparation method, a membrane electrochemical reactor system is expected to be remarkably simplified, the energy conversion efficiency and the stability are improved, and the operation life is prolonged.

Owner:国鸿氢能科技(嘉兴)股份有限公司

Preparation method of porous nickle current collector of lithium ion battery

ActiveCN104037423AImprove the problem of insufficient mechanical strengthAchieve tailoringElectrode carriers/collectorsNano structuringSodium-ion battery

The invention relates to a preparation method of a porous nickle current collector of a lithium ion battery and relates to the field of materials of lithium ion batteries. The preparation method comprises the following steps: granulating to obtain mixed powder by adopting nickle oxide and graphite as initial materials; pressing into a green blank body and calcining to obtain a blank body; reducing the blank body to obtain a porous nickle current collector of the lithium ion battery; mixing and grinding a transition-metal-oxide negative material with a nano structure, a bonding agent and a pore forming agent, then uniformly coating the surface of the porous nickle current collector of the lithium ion battery with the mixture I, and sintering to obtain an electrode of the lithium ion battery; uniformly mixing a lithium source, an iron source, phosphate radical solution and an organic complexing agent, coating the surface of the porous nickle current collector of the lithium ion battery with the mixture II; and ageing and calcining to obtain a thin-film electrode made of lithium iron phosphate. The porous nickle current collector of the lithium ion battery has the advantages that due to good communicating characteristics, electrons can be relatively well transferred; due to a relatively high three-phase interface, electrolyte and a negative electrode can be relatively well infiltrated mutually; the thin-film electrode made of the lithium iron phosphate has the communicated three-phase interface, so that the convenience is brought for improving the electro-chemical dynamic characteristics of the material.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

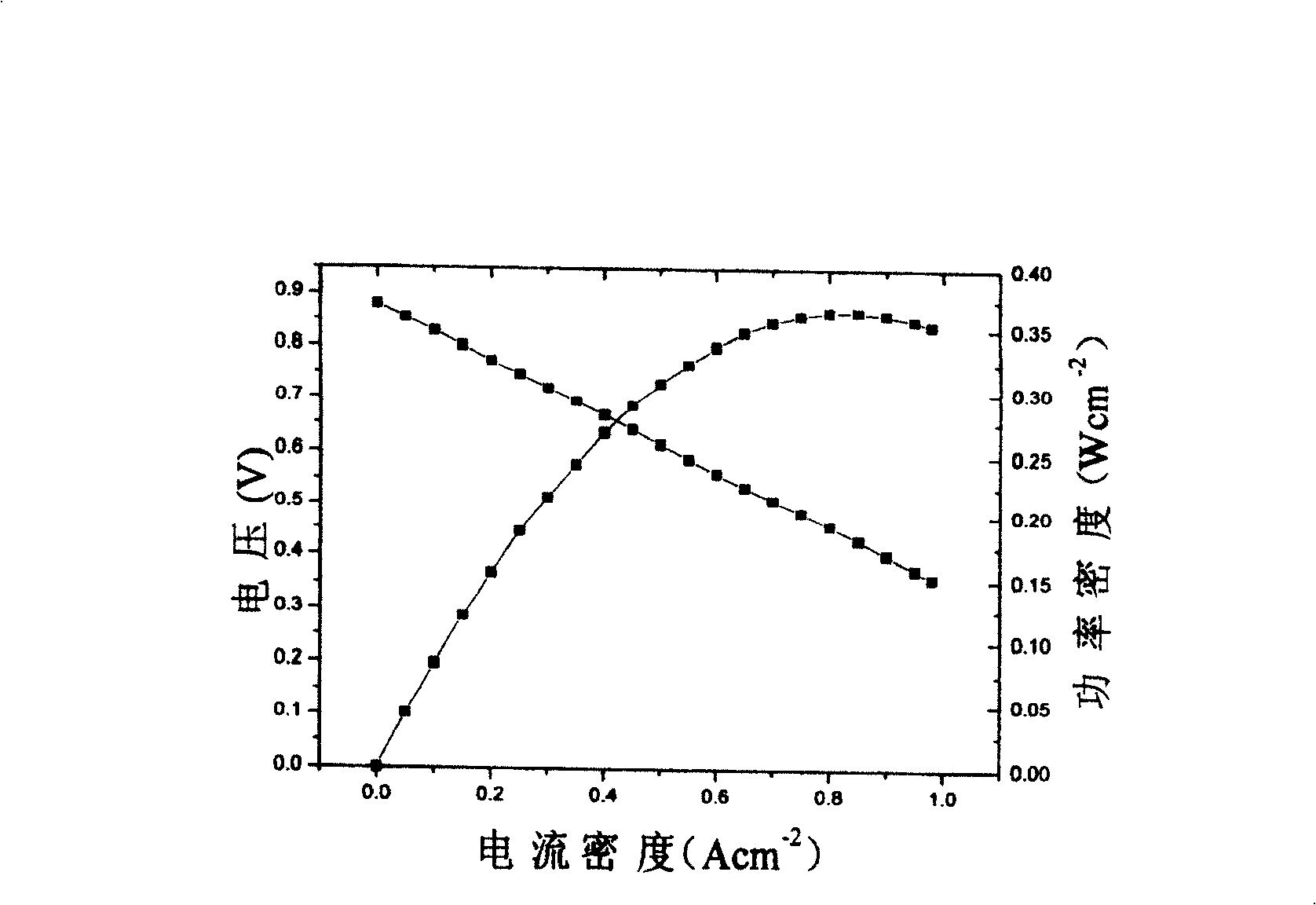

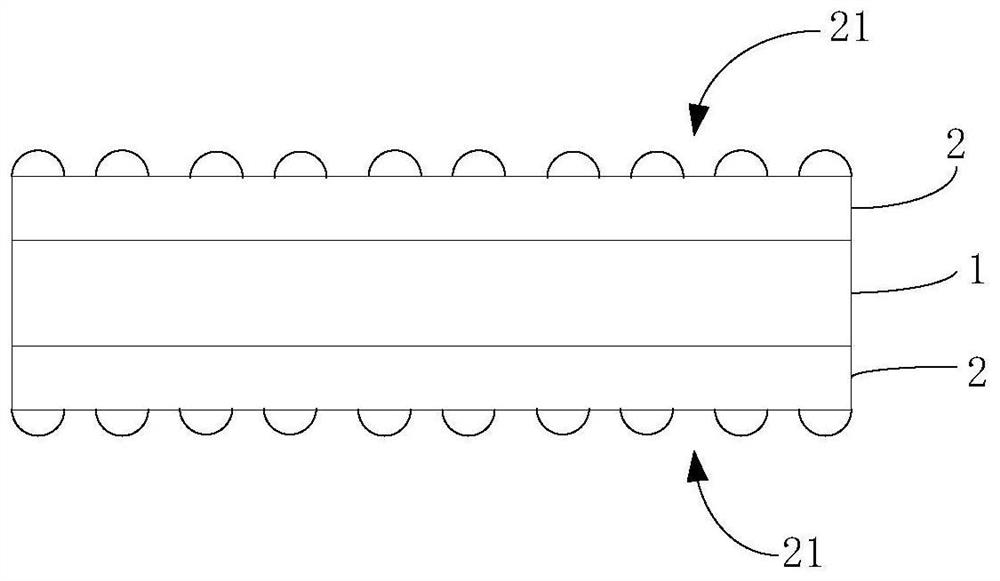

Catalyst coating film, fuel cell and preparation method of catalyst coating film

ActiveCN111063925AImprove utilization efficiencyLarge specific surface areaCell electrodesFinal product manufactureFuel cellsPtru catalyst

The invention discloses a catalyst coating film, a fuel cell and a preparation method of the catalyst coating film. The catalyst coating film comprises: a proton exchange membrane; and catalytic layers formed on the two opposite sides of the proton exchange membrane, wherein the surface of each catalytic layer has a three-dimensional microstructure. Technical support can be provided for obtaininga membrane electrode and the fuel cell which give consideration to water management, mass transfer impedance reduction and catalyst utilization efficiency improvement at the same time.

Owner:SHENZHEN GENERAL HYDROGEN ENERGY TECH CORP LTD

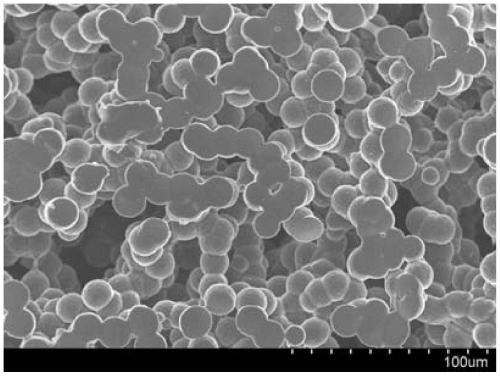

Porous plastic crystal electrolyte for all-solid-state metal-air battery, preparation method of porous plastic crystal electrolyte and all-solid-state metal-air battery

ActiveCN111269509AWith deformationProne to deformationFuel and secondary cellsFinal product manufactureAll solid statePlastic crystal

The invention provides a porous plastic crystal compound. The porous plastic crystal compound has a porous morphology formed by stacking sphere-like particles; wherein the plastic crystal comprises succinonitrile. The invention provides a porous plastic crystal compound, which has the characteristics of good stability, high ionic conductivity, adjustable porosity and the like and is applied to anall-solid-state metal-air battery. The porous plastic crystal compound serves as an electrolyte interlayer and is introduced into a solid-state positive electrode; the interface impedance between theelectrolyte interlayer and the electrode can be effectively reduced; besides, due to the adjustable porosity, gas diffusion is not hindered while tight contact with the active material is realized byintroducing into the solid-state positive electrode; according to the invention, the three-phase interface is effectively increased, reaction sites are increased, the problems of high interface impedance and few positive electrode three-phase interfaces of an existing metal-air battery are solved, and the electrochemical properties such as the discharge capacity of the all-solid-state lithium-oxygen battery are improved.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

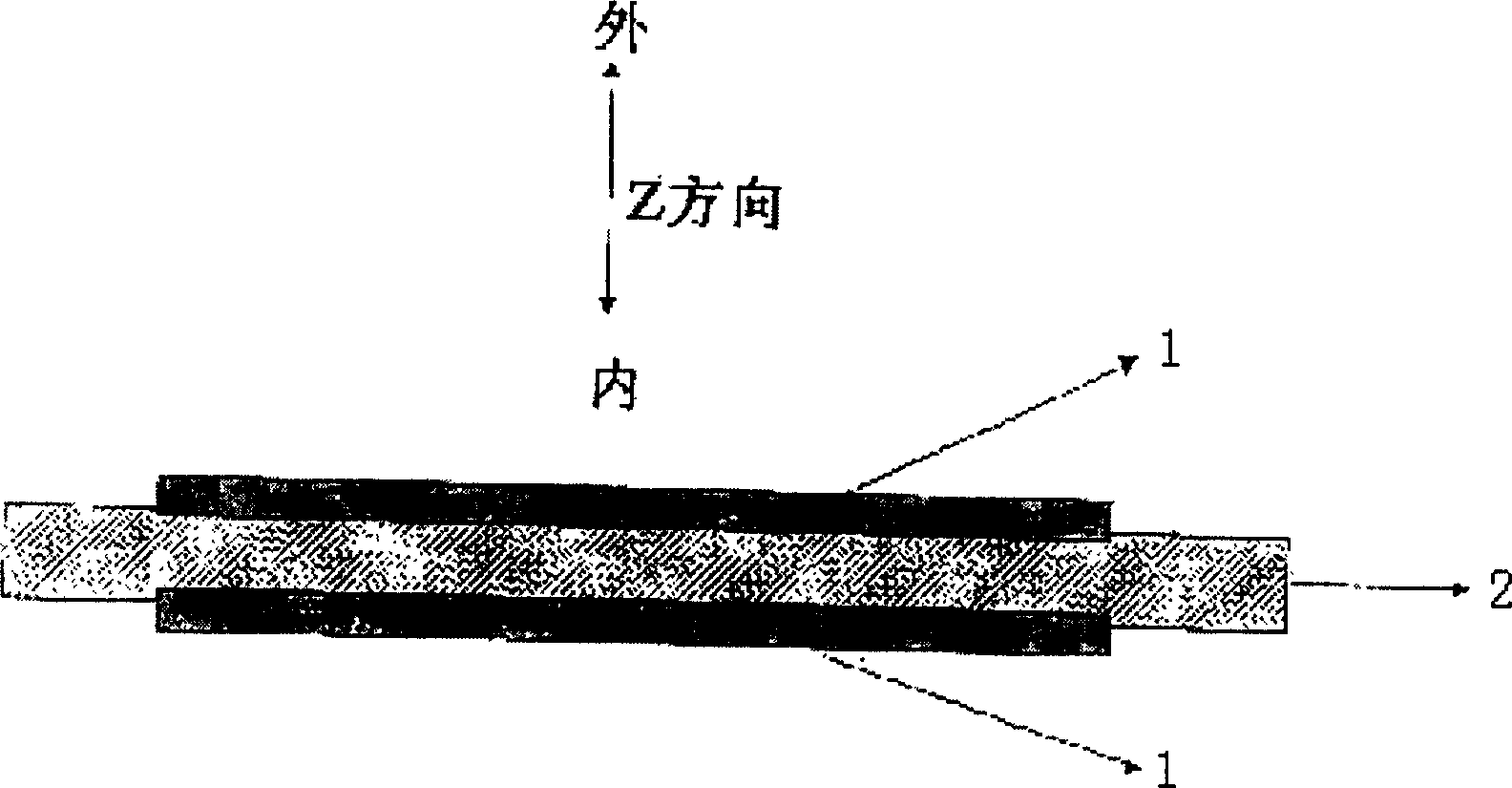

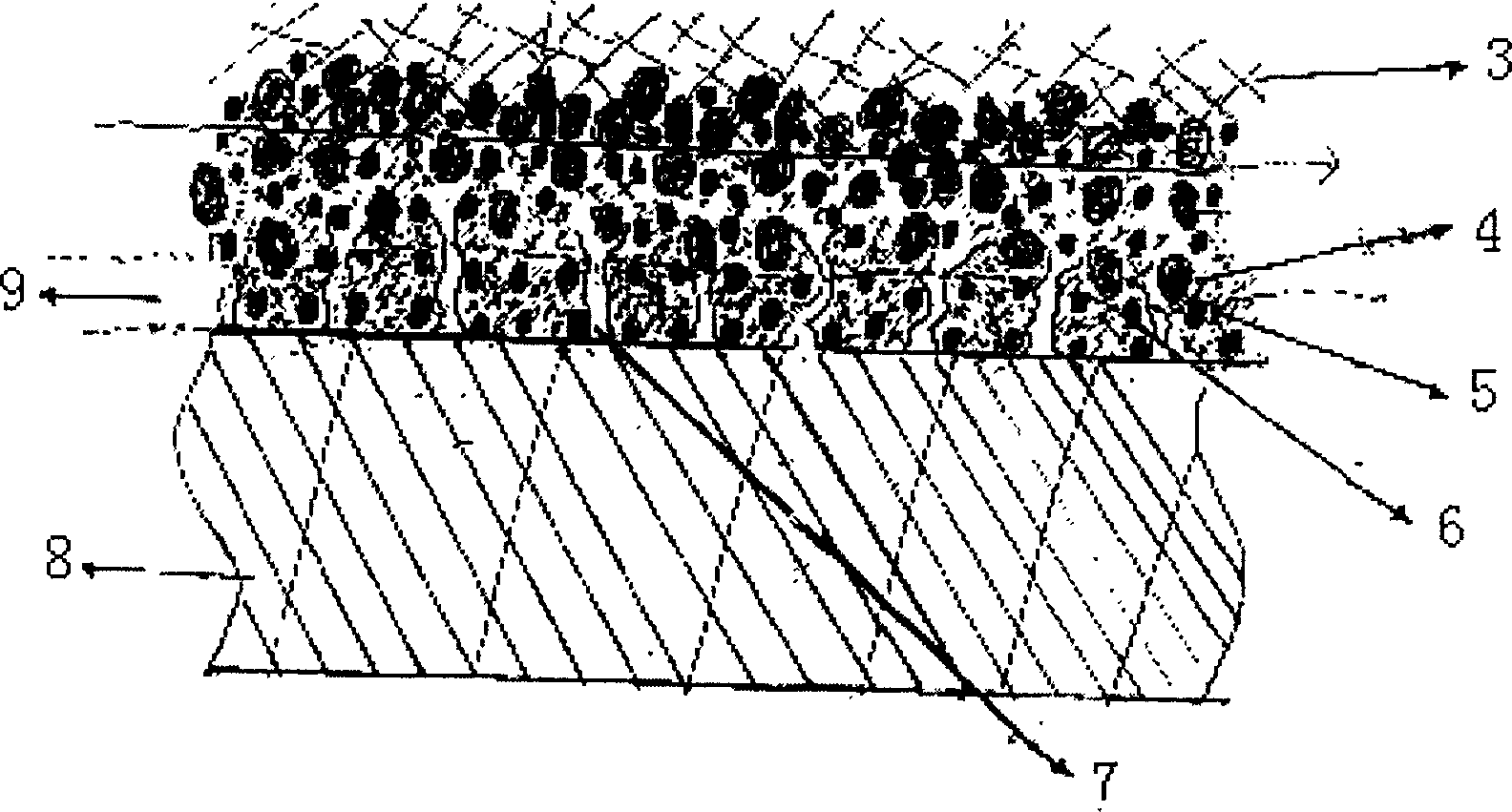

Porous gas diffusion electrode for fuel battery and preparing method thereof

InactiveCN1274044CIncrease profitImprove conduction efficiencyCell electrodesElectronGas diffusion electrode

Each component constituting electrode catalysis layer is in gradient distribution in Z direction of electrode (perpendicular to direction of catalysis layer). In macroscopy, electrode catalysis layer is in structure of multiple layers for example at least divided into two layers structure. First layer structure as partial hydrophobic catalysis layer composed of first catalytic activity metal, water repellent and conducting ionic polymer. Second layer structure as hydrophilic catalysis layer composed of second catalytic activity metal and conducting ionic polymer. Composite two layers constitute partial hydrophobic and partial hydrophilic composite electrode. Advantages of the structure of electrode are: enhancing capability of mass transfer of gas, especially when air as oxidant, meanwhile keeping enough capability of electron conduction and proton transfer; extending effective triphase interface of catalytic reaction; raising output power density.

Owner:SUNRISE POWER CO LTD

Catalyst using metal oxide as carrier for fuel cells and application thereof

ActiveCN101773826BGood dispersionHigh active specific surface areaCell electrodesMetal/metal-oxides/metal-hydroxide catalystsOxygenOxygen evolution

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

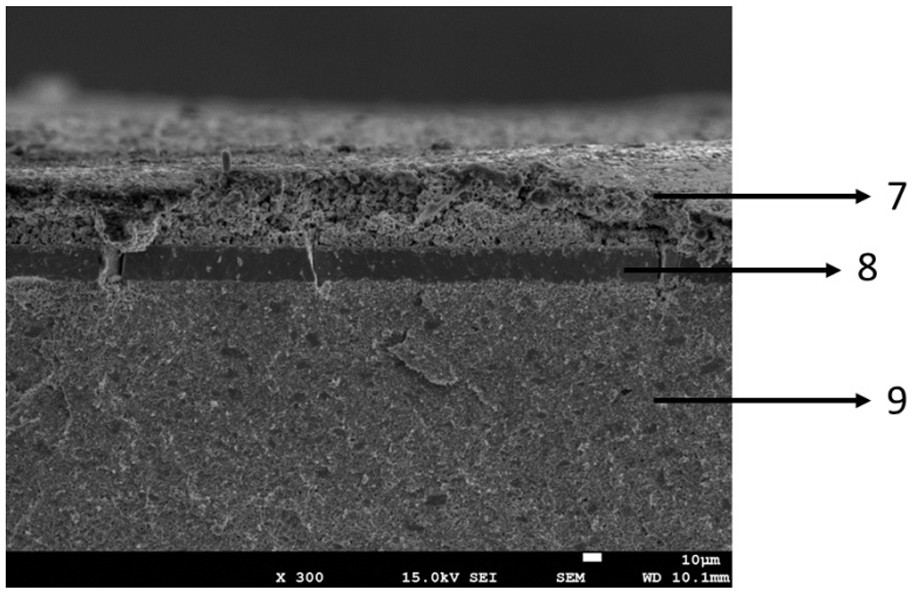

Zirconium-based anode-supported solid oxide battery without isolating layer

ActiveCN113258111AGuaranteed stabilityGuaranteed service lifeCellsCell electrodesElectrical batteryPerovskite (structure)

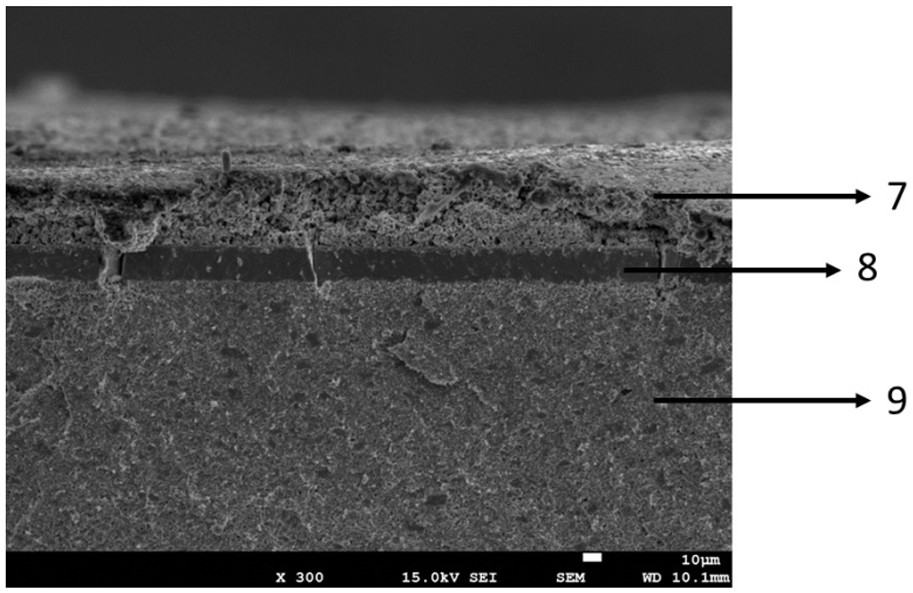

The invention relates to a zirconium-based anode-supported solid oxide battery without an isolating layer. The battery is characterized by sequentially comprising an anode layer, an electrolyte layer and a membrane-coated cathode layer, wherein the anode layer is made of a NiO and zirconium-based electrolyte mixed material, and the electrolyte layer is made of a zirconium-based electrolyte material; and the membrane-coated cathode layer is composed of a membrane-coated functional layer and a membrane-coated collector layer, the membrane is a full nano membrane with the thickness of 5-30 nm, the membrane is a Sr-based perovskite material or metal oxide, and a nano membrane coating structure is formed on the surface of the cathode layer by dipping the cathode layer in a precursor mixed solution of a coating material and calcining. According to the zirconium-based anode-supported solid oxide battery, the cerium oxide isolation layer between the electrolyte layer and the cathode layer is removed, so that a high-temperature sintering process is reduced; and the microstructure of the cathode material is optimized, the reaction between the cathode and the electrolyte is avoided, and the stability of the battery is improved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Proton exchange membrane fuel cell slurry capable of improving dispersity of ionomers in catalyst slurry and preparation method thereof

ActiveCN113488668AScattered and orderlyIncrease contact areaCell electrodesFuel cellsIonomerPtru catalyst

The invention relates to proton exchange membrane fuel cell slurry capable of improving dispersity of ionomers in catalyst slurry and a preparation method thereof. The method comprises the steps that a fractional step method is adopted, firstly, a catalyst and water are added and dispersed to prepare catalyst turbid liquid, then alcohol and a perfluorosulfonic acid resin solution are dispersed to prepare an ionomer solution, and finally, the ionomer solution is divided into three parts, sequentially the three parts are added into the catalyst turbid liquid, and sequentially dispersed to prepare the proton exchange membrane fuel cell catalyst slurry. Compared with the prior art, the method has the advantages that non-adsorbed ionomers in the catalyst slurry can be reduced, so that the ionomers are more uniformly adsorbed on the catalyst, meanwhile, the microstructure of an interface of a cluster catalyst / ionomer on a catalyst layer can be improved, a three-phase interface is increased, and the performance of the fuel cell is improved; in addition, the method is simple to operate, the preparation process is easy to control, and the prepared slurry is suitable for preparing roll-to-roll high-flux membrane electrodes for slit coating, brush coating and the like.

Owner:TONGJI UNIV

A kind of graphene-ceo2 base ceramic composite material and preparation method thereof

The invention discloses a preparation method of a graphene-CeO2 based ceramic composite material. The preparation method comprises the following steps: 1) sufficiently grinding cerium salts, additives and graphene oxide uniformly in a ball mill to obtain a graphene-metal oxide composite material; and 2) adding an organic adhesive solvent into the graphene-metal oxide composite material, and sufficiently mixing and grinding, dryly pressing into strip composite samples through use of a dry-press method, putting the strip composite samples into a vacuum tubular furnace, letting in a mixed gas of a certain ratio, controlling sintering conditions, and then cooling to the room temperature to obtain the graphene-CeO2 based ceramic composite material. Through improvement of dispersibility of CeO2-ceramic oxide particles, cycle stability of the composite material is increased. Through increase of the three-phase interface among the ceramic oxide particles, the electrochemical activity of the composite material is improved. The preparation processes has the advantages of simple operation, no pollution, good repeatability and easy large-scale magnification.

Owner:SHAANXI COAL & CHEM TECH INST

Flower structure nano cerium oxide base composite material and its preparing method and use

ActiveCN100445207CImprove power densityIncrease varietyIndividual molecule manipulationRare earth metal compoundsCobalt oxideComposite oxide

The invention relates to a nano-cerium oxide-based composite material with a flower-like structure, which is a powder material with an average particle diameter of 100nm-100μm, and flakes with a thickness of 2-500nm grow on each particle, showing a flower-like structure. The cerium oxide-based composite material is cerium oxide and selected from lanthanum oxide, copper oxide, zirconia, titanium oxide, aluminum oxide, magnesium oxide, manganese oxide, iron oxide, cobalt oxide, nickel oxide, vanadium oxide, tungsten oxide, Binary or ternary composite oxide formed by one or two oxides of molybdenum oxide, silicon oxide, zinc oxide, gadolinium oxide, yttrium oxide, spectrum oxide, samarium oxide, scandium oxide, europium oxide, erbium oxide, and ytterbium oxide The molar ratio of oxides other than cerium oxide to cerium oxide is 0.001-0.5:1. The composite material has a very large specific surface area and can be used as an anode material of a solid oxide fuel cell or a support body of a noble metal catalyst.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

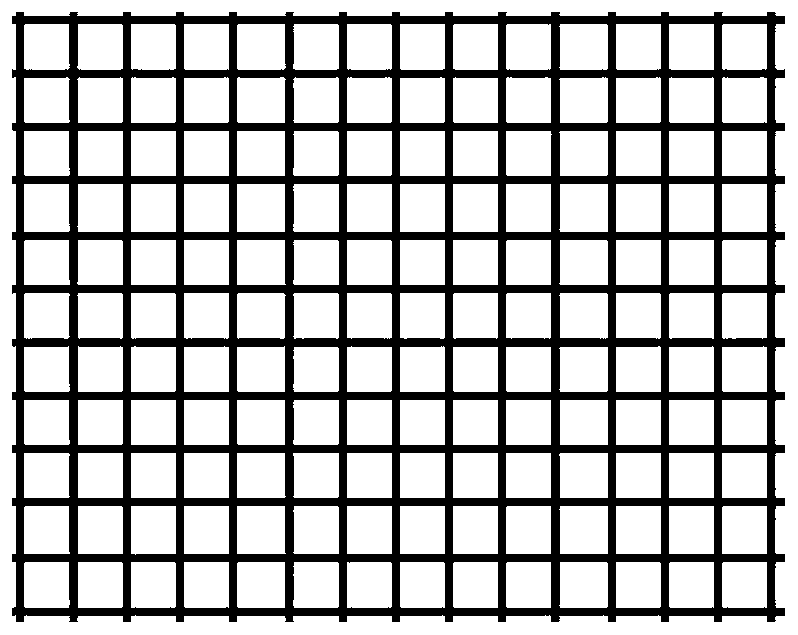

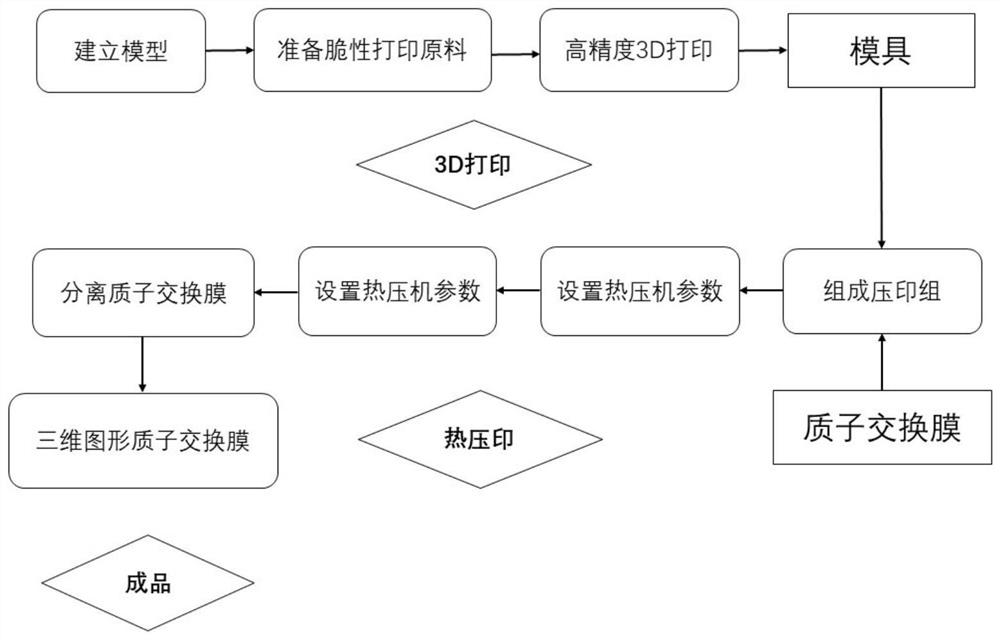

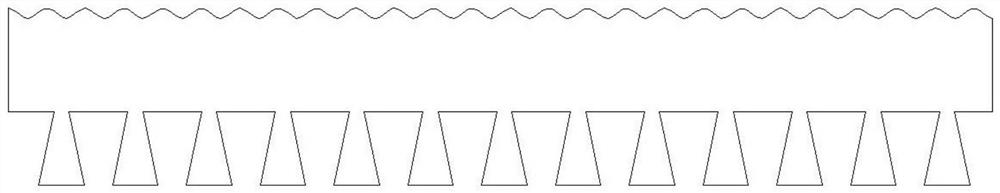

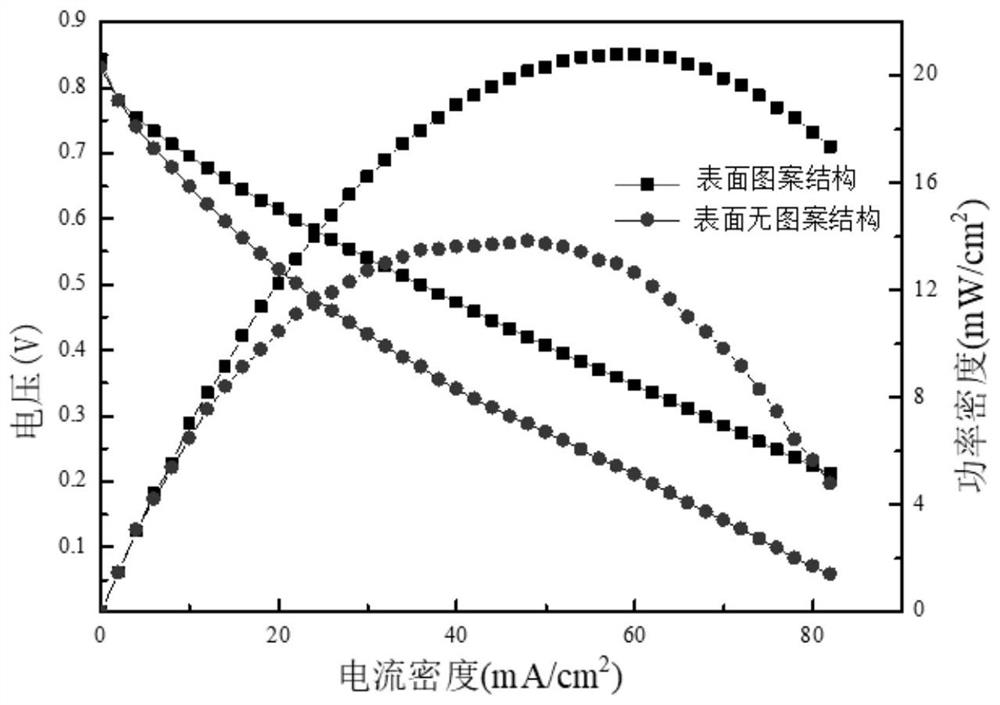

Three-dimensional graphic surface proton exchange membrane for fuel cell as well as preparation method and application of three-dimensional graphic surface proton exchange membrane

ActiveCN113681782AWide variety of sourcesAvoid defectsAdditive manufacturing apparatusCell electrodesHot stampingHydrogen fuel cell

The invention discloses a three-dimensional graphic surface proton exchange membrane for a fuel cell as well as a preparation method and application of the three-dimensional graphic surface proton exchange membrane. The preparation method of the proton exchange membrane comprises the steps of a 3D printing process and a hot stamping process. The 3D printing process is used for printing a precise pattern hot stamping mold, and the hot stamping process is used for preparing a high-specific-surface-area proton exchange membrane with a three-dimensional pattern. A high-hardness polymer material is adopted as a raw material of the hot stamping mold, and the defects of a traditional preparation process based on a metal mold are overcome; and the hot stamping process adopts an upper buffer layer structure and a lower buffer layer structure, and has the characteristic of one-step stamping forming. The prepared and formed proton exchange membrane with the surface pattern structure has a high specific surface area, a rapid proton transmission channel can be provided, the three-phase boundary of a fuel cell membrane electrode can be expanded, so that the output performance of the fuel cell is improved; and the proton exchange membrane with the surface pattern structure can effectively improve water management of a hydrogen fuel cell, and construction of the proton exchange membrane fuel cell with high performance and long service life is realized.

Owner:SOUTH CHINA UNIV OF TECH

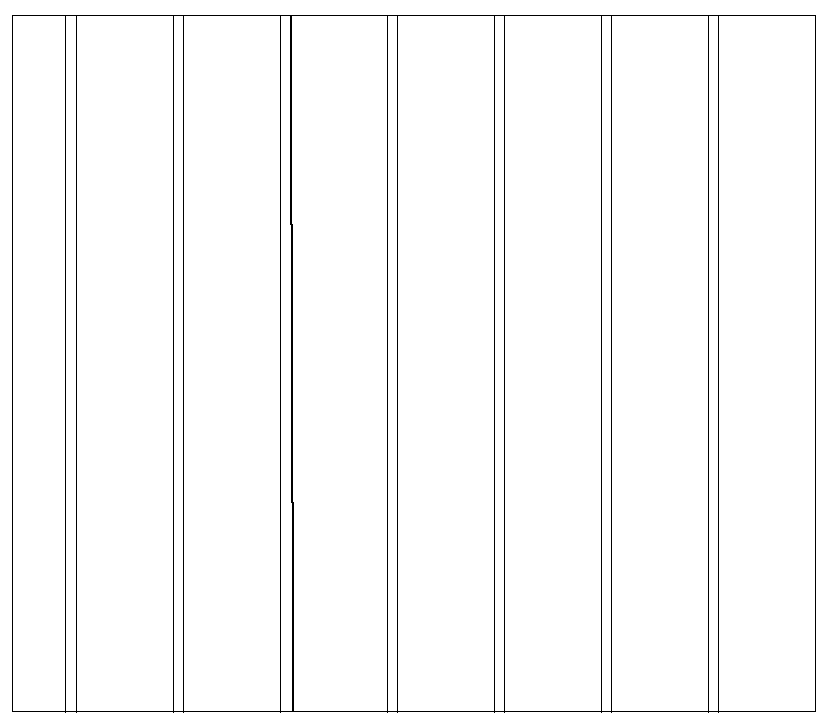

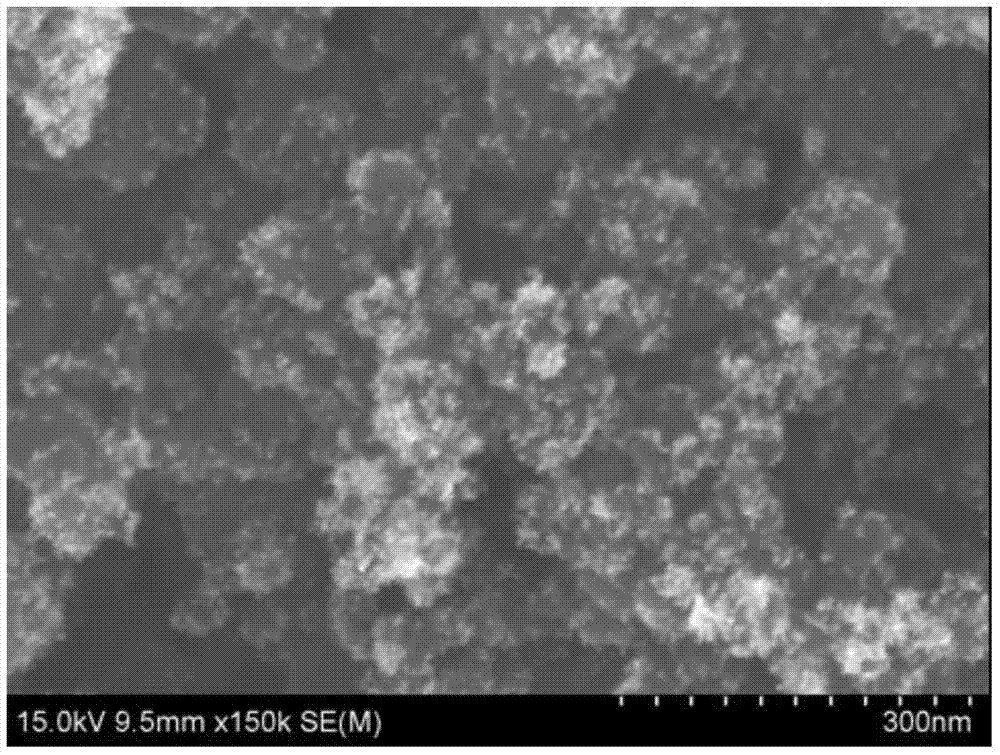

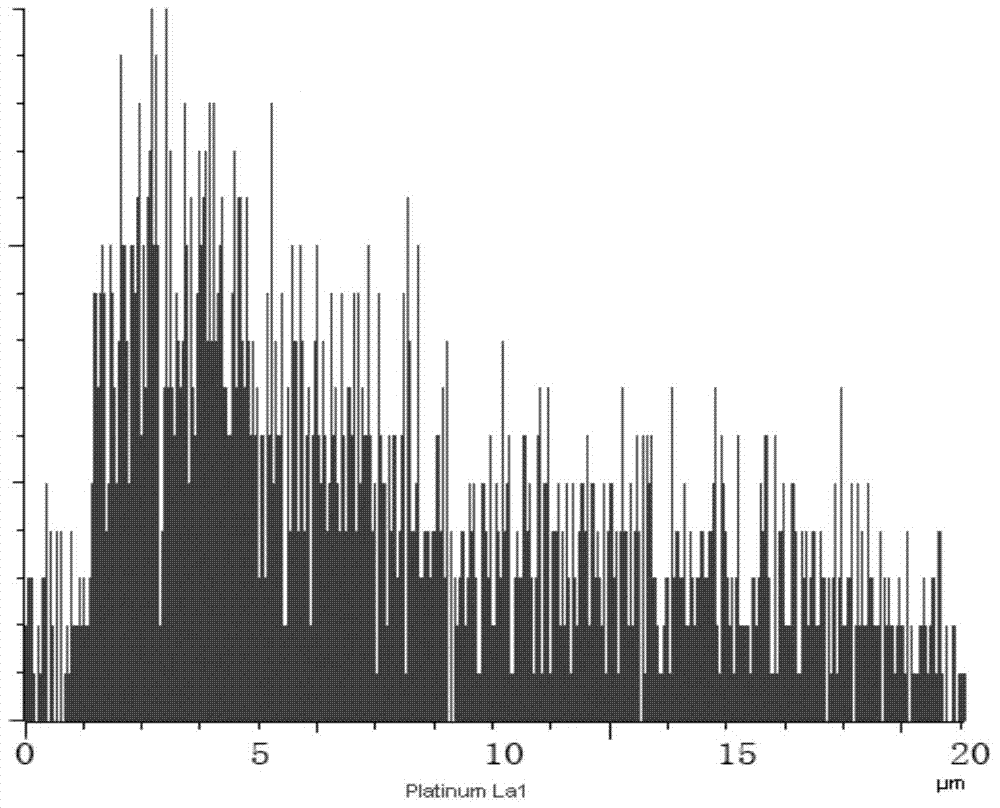

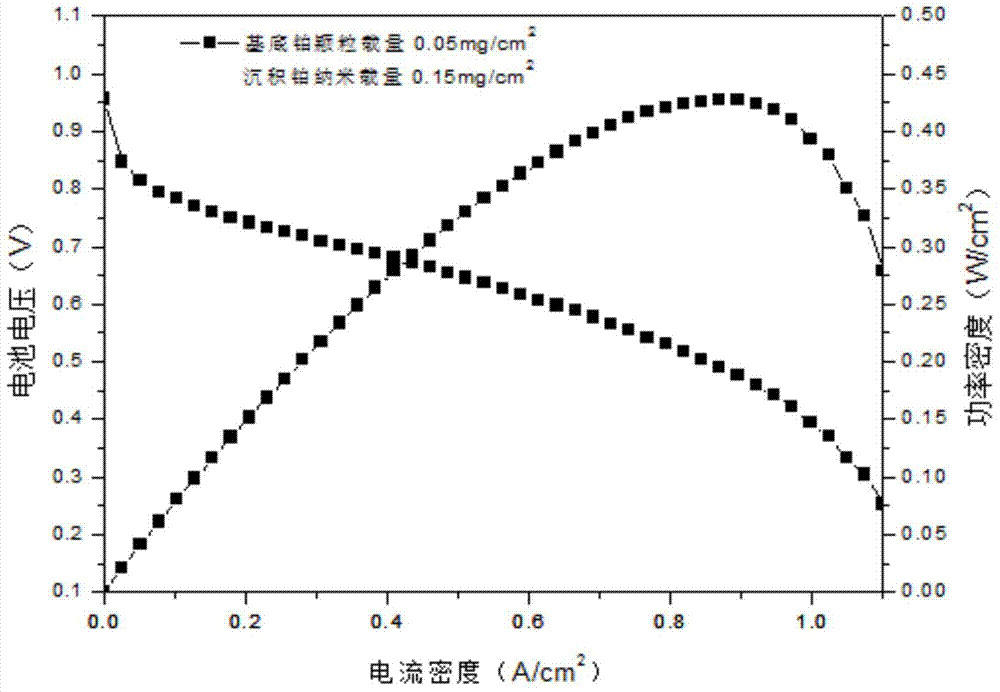

Method for preparing platinum gradient-distribution catalyst layer structure of proton exchange membrane fuel cell

ActiveCN103326032BIncrease profitImprove performanceCell electrodesPolymer electrolytesSpray coating

The invention discloses a method for preparing a platinum gradient-distribution catalyst layer structure of a proton exchange membrane fuel cell. The method comprises the following steps of 1, uniformly spraying a layer of a low-platinum load capacity carbon-supported platinum catalyst as a matrix on a polymer electrolyte membrane, 2, dipping the polymer electrolyte membrane with the matrix layer into a platinum precursor-containing solution so that platinum is reduced by a weak reductant and platinum nano-wires form on the matrix layer, 3, uniformly spray-coating a layer of an electrolyte resin solution on the platinum nano-wires to obtain a three-phase interface, and 4, carrying out hot-pressing with a diffusion layer to obtain a membrane electrode.

Owner:SHANGHAI JIAOTONG UNIV

Catalyst coated membrane, fuel cell and preparation method

ActiveCN111063925BImprove utilization efficiencyLarge specific surface areaCell electrodesFinal product manufactureCoated membraneFuel cells

The invention discloses a catalyst coating film, a fuel cell and a preparation method of the catalyst coating film. The catalyst coating film comprises: a proton exchange membrane; and catalytic layers formed on the two opposite sides of the proton exchange membrane, wherein the surface of each catalytic layer has a three-dimensional microstructure. Technical support can be provided for obtaininga membrane electrode and the fuel cell which give consideration to water management, mass transfer impedance reduction and catalyst utilization efficiency improvement at the same time.

Owner:SHENZHEN GENERAL HYDROGEN ENERGY TECH CORP LTD

Electrode of fuel battery with proton exchange membrane and its production

The precursor of electrode with catalysis layer is calcined under protection of inert gas at 250-450 DEG C to make the solid polyelectrode in catalysis layer lose sulfonic acid radical. The other organic groups have hydrophobic behavior, and the undecomposed solid polyelectrolyte has hydrophilicity so that the electrode catalysis layer of proton exchange film fuel cell with evenly distributed hydrophile structure and hydrophobic structure is formed. With conventional method, makes the electrode.

Owner:SUNRISE POWER CO LTD

Preparation method of a self-humidifying ordered polymer membrane electrode

ActiveCN103887521BRealize self-humidification energy conversionIncrease the three-phase reaction interfaceCell electrodesFuel cellsElectrochemical responseConcentration polarization

The invention discloses a preparation method of a self-humidifying ordered polymer membrane electrode, belonging to the technical field of membrane electrode preparation. An ordered ion exchange polymer nanotube array prepared through the method is fused together with a polymer membrane and is provided with highly ordered ion, electron and gas mass transfer channels, and electrochemical three-phase reaction interfaces are distributed in the outer surfaces of polymer nanotubes with water storage functions, so that a high-efficiency energy conversion process can be carried out in a self-humidifying manner. A catalyst in a nanoparticle or microparticle state is bonded on the surface of the ion exchange polymer nanotube array to form a catalysis layer and is relatively high in specific surface area and catalytic activity, so that the three-phase reaction interfaces of the membrane electrode are greatly added, the electrochemical polarization, the ohmic polarization and the concentration polarization of the electrode are reduced, the energy conversion efficiency is improved, and the reaction speed is increased. According to the preparation method, a membrane electrochemical reactor system is expected to be remarkably simplified, the energy conversion efficiency and the stability are improved, and the operation life is prolonged.

Owner:国鸿氢能科技(嘉兴)股份有限公司

An all-solid-state lithium-air battery and its preparation method and application

ActiveCN105742761BAll solid state implementationImprove securityFuel and primary cellsHigh rateLithium metal

The invention discloses an all-solid-state lithium-air battery and its preparation method and application. The all-solid-state lithium-air battery provided by the invention includes a lithium metal anode, a porous ceramic support, a dense electrolyte film, a porous cathode film, a sealing material, a current collector and a lead; a garnet-type lithium-ion solid electrolyte material is used to make the porous support The air electrode catalyst and lithium metal anode penetrate into the pores to expand the three-phase interface of the battery reaction and reduce the battery polarization resistance; the thickness of the battery electrolyte film is less than 30 μm, shortening the lithium ion transmission path and reducing the battery ohmic resistance; the battery is closed at one end The tubular structure has a lithium metal anode perfused in the tube. The battery is easy to seal and easy to work under different conditions. The all-solid-state lithium-air battery prepared by the invention has the advantages of high charge and discharge capacity, good rate performance, high cycle stability, wide operating temperature range, etc., and is suitable for various mobile electronic equipment and power battery fields.

Owner:SUZHOU UNIV

Microbial fuel cell air cathode and preparation method thereof

The invention discloses a microbial fuel cell air cathode which is composed of a diffusion layer thin film, a stainless steel net and an active layer thin film in an overlapped mode from an air side to an electrolyte side. The preparation method comprises the following steps of: mixing a carbon powder material which has good electrical conductivity and is hydrophilic and PTFE (Poly tetra fluoro ethylene) emulsion which is hydrophobic and is air conductive in ethanol; clustering through ultrasound and water bath; and finally rolling into a thin-film-shaped diffusion layer and an active layer; with the stainless steel net as an electrical conductive framework, overlapping and rolling so as to form the air cathode. The microbial fuel cell air cathode and the preparation method thereof have the following advantages: according to the preparation method, since electrical conductive carbon black is added into the air diffusion layer, the resistance of an air diffusion electrode is reduced; since the ultrasound stirring is carried out after the PTFE emulsion is dropped in, uniform and fine air holes can be formed in the electrode and the three-phase interface reduction site in the active layer is increased; and heating and curing are carried out twice in a muffle furnace, thus PTFE forms an air conveying pore canal of a three-dimensional network structure, the three-phase interface in the active layer is increased, and the microbial fuel cell air cathode is applicable to normalized mass production.

Owner:NANKAI UNIV

Preparation method of porous nickel current collector for lithium ion battery

ActiveCN104037423BImprove the problem of insufficient mechanical strengthAchieve tailoringElectrode carriers/collectorsNano structuringLithium-ion battery

The invention relates to a preparation method of a porous nickle current collector of a lithium ion battery and relates to the field of materials of lithium ion batteries. The preparation method comprises the following steps: granulating to obtain mixed powder by adopting nickle oxide and graphite as initial materials; pressing into a green blank body and calcining to obtain a blank body; reducing the blank body to obtain a porous nickle current collector of the lithium ion battery; mixing and grinding a transition-metal-oxide negative material with a nano structure, a bonding agent and a pore forming agent, then uniformly coating the surface of the porous nickle current collector of the lithium ion battery with the mixture I, and sintering to obtain an electrode of the lithium ion battery; uniformly mixing a lithium source, an iron source, phosphate radical solution and an organic complexing agent, coating the surface of the porous nickle current collector of the lithium ion battery with the mixture II; and ageing and calcining to obtain a thin-film electrode made of lithium iron phosphate. The porous nickle current collector of the lithium ion battery has the advantages that due to good communicating characteristics, electrons can be relatively well transferred; due to a relatively high three-phase interface, electrolyte and a negative electrode can be relatively well infiltrated mutually; the thin-film electrode made of the lithium iron phosphate has the communicated three-phase interface, so that the convenience is brought for improving the electro-chemical dynamic characteristics of the material.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

A Self-Humidifying Ordered Polymer Membrane Electrode

ActiveCN103887518BRealize self-humidification energy conversionIncrease the three-phase reaction interfaceCell electrodesFuel cellsPorosityElectrical conductor

The invention discloses a self-humidifying ordered polymer membrane electrode in the technical field of membrane electrodes. The membrane electrode mainly comprises an ion conductor, an anode and a cathode, wherein the ion conductor comprises an ion exchange membrane and ion exchange polymer nanotube arrays which orderly and directionally grow on two surfaces of the ion exchange membrane. A support body of a catalyst in the membrane electrode is an ion exchange polymer nanotube array with one end fused together with the ion exchange membrane. The highly ordered ion exchange polymer nanotube arrays define the electrode porosity and the catalyst surface size in the ordered membrane electrode and can greatly optimize ion, electron and gas three-phase channels of a catalyst layer. The ion exchange polymer nanotube structures have water storage functions, self-humidifying electrochemical energy conversion of the membrane electrode can be achieved, the device system structure is simplified and the energy conversion efficiency is improved.

Owner:国鸿氢能科技(嘉兴)股份有限公司

Preparation method of lithium-air battery based on lithium-ion solid electrolyte

ActiveCN105762441BShorten the transmission pathSolid state implementationFuel and primary cellsElectrical batteryLithium metal

The invention discloses a preparation method of a lithium air battery based on lithium ion solid electrolyte. The preparation method comprises the following steps of: preparing an electrolyte skeleton, preparing an air electrode, preparing a metal electrode and preparing a battery lead. An obtained all-solid-state lithium air battery adopts a garnet or perovskite lithium ion solid electrolyte material to prepare a porous supporting body, and a battery reaction three-phase interface is enlarged in permeation pores of an air electrode catalyst and a lithium metal anode, so that the battery polarization resistance is decreased, a lithium ion transmission route is shortened, and the battery ohmic resistance is reduced; the battery is of a tubular structure with a closed end, the lithium metal anode is poured into a tube, and the battery is simple to seal and easy to operate under different conditions; and the preparation method has the advantages of high charge and discharge capacity, good multiplying power performance, high cycling stability and wide operation temperature range and is suitable for the fields of various mobile electronic devices and power batteries.

Owner:ZHANGJIAGANG INST OF IND TECH SOOCHOW UNIV +1

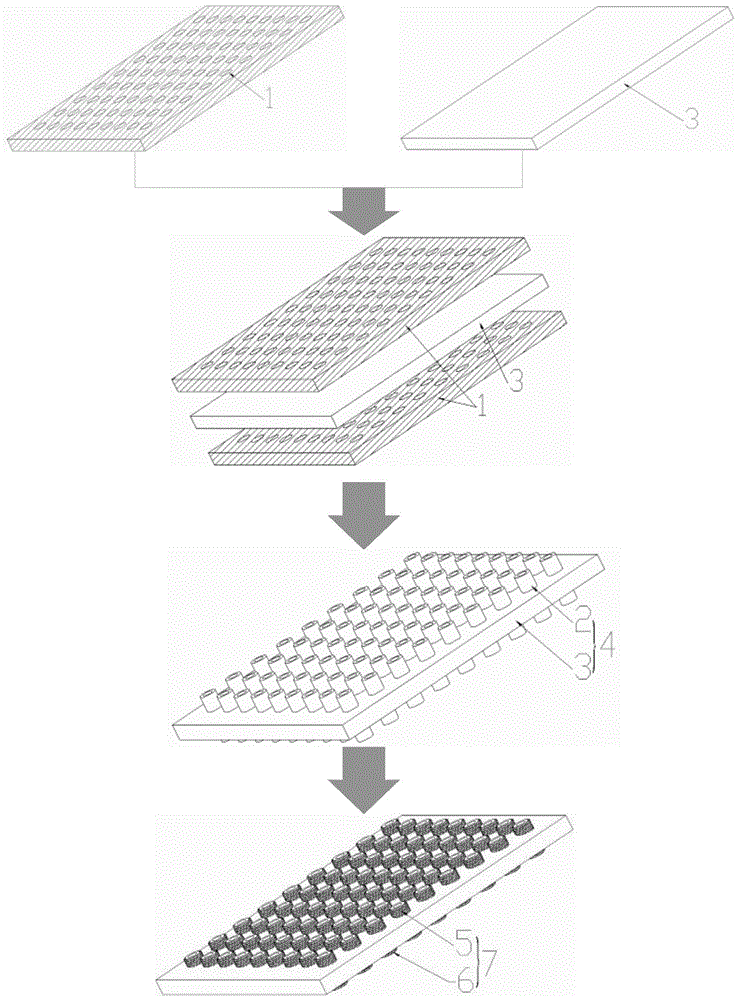

Graphene-modified nickel-base composite anode material of solid oxide fuel cell and preparation method thereof

ActiveCN103236550BImprove anti-cyclic redox performanceGood dispersionCell electrodesFuel cellsCvd graphene

The invention discloses a graphene-modified nickel-base composite anode material of a solid oxide fuel cell and a preparation method thereof. The modified nickel-base composite anode material is prepared by compounding metal salt, an oxide or hydroxide of metal, YSZ ((Yttria Stabilized Zirconia) and graphene oxide, and then a battery assembly is prepared by compounding the nickel-base composite anode material and an electrolyte material. Through testing the performance of the battery assembly, the performance of the battery assembly is greatly improved in comparison with a battery with an un-modified anode. The graphene oxide is added in a conventional nickel-base anode material for modifying the anode material, the reduced graphene is capable of stopping nickel particles from sintering and growing, and the surface appearance of the material is improved. The graphene-modified nickel-base composite anode material has the characteristics of uniformity in particle distribution, difficulty in sintering, high strength, small volume expansion ratio, stable structure and the like; and the cyclic oxidation-reduction resisting capability of the nickel-base anode material is improved. The application of the anode material has important significance to the promotion of the application of a nickel-base anode solid oxide fuel cell technology.

Owner:SHAANXI COAL & CHEM TECH INST

Preparation method of one-dimensional nanofiber SSC based composite cathode

ActiveCN103107342BGood electrochemical propertiesImprove stabilityMaterial nanotechnologyCell electrodesFiberMicroparticle

The invention discloses a nanofiber SSC (Sm(1-x)SrxCoO(3-delta)) cathode material as well as a preparation method thereof, a composite cathode by utilizing the cathode material as well as a preparation method thereof, and relates to a cathode material, a cathode as well as preparation methods thereof, aiming to solve the technical problem of large interfacial polarization impedance of the cathode prepared by the method. The one-dimensional nanofiber SSC cathode material is a Sm(1-x)SrxCoO(3-delta) material, which is a one-dimensional nanofiber prepared by electrostatic spinning and sintering. The composite cathode comprises an electrolytic strip, an anode or a cathode as support bodies, and the one-dimensional nanofiber SSC cathode adhered on the support bodies, wherein electrolyte nanoparticles are adhered on the SSC fiber. The preparation method of the composite cathode comprises the steps of soaking a one-dimensional nanofiber SSC cathode framework in a small amount of electrolyte precursor liquid by multiple times; and sintering to obtain the composite cathode based on the one-dimensional nanofiber SSC material. The composite cathode provided by the invention can be used in a medium-and-low-temperature solid oxide fuel battery.

Owner:HARBIN INST OF TECH

A Zirconium-Based Anode-Supported Solid Oxide Battery Without a Separator

ActiveCN113258111BGuaranteed stabilityGuaranteed service lifeCellsCell electrodesPhysical chemistryBattery cell

The invention relates to a solid oxide battery supported by a zirconium-based anode without a separator, which is characterized in that it includes an anode layer, an electrolyte layer and a membrane-coated cathode layer in sequence; wherein, the anode layer is a mixed material of NiO and zirconium-based electrolyte, and the electrolyte The layer is a zirconium-based electrolyte material; the membrane-wrapped cathode layer is composed of a membrane-wrapped functional layer and a membrane-wrapped current collector layer, the membrane is a full nanometer membrane with a thickness of 5-30 nm, and the membrane contains Sr Based on the perovskite material or metal oxide, the cathode layer is impregnated with the mixed solution of the precursor of the coating material and calcined to form a nano-film coating structure on the surface of the cathode layer. The zirconium-based anode-supported solid oxide battery of the present invention removes the cerium oxide separation layer between the electrolyte layer and the cathode layer, reducing the one-step high-temperature sintering process; optimizes the microstructure of the cathode material, avoids the reaction between the cathode and the electrolyte, Improve battery stability.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com