A Zirconium-Based Anode-Supported Solid Oxide Battery Without a Separator

A solid oxide, anode support technology, used in fuel cells, battery electrodes, electrodes, etc., can solve the problem of insufficient cathode modification, high temperature of preparation process, Sr segregation, inability to guarantee compactness and battery life, and cathode materials. Coarse microstructure and other problems, to achieve the effect of reducing oxygen ion migration paths, good performance, and reducing preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] (1) Anode powder pretreatment: select commercial NiO, 8%Y 2 o 3 -ZrO 2 (YSZ), adding ethanol and zirconia balls according to the mass ratio of 1:1 for ball milling pretreatment for 24 h, after ball milling and drying through a 200-mesh sieve to obtain pretreated anode powder.

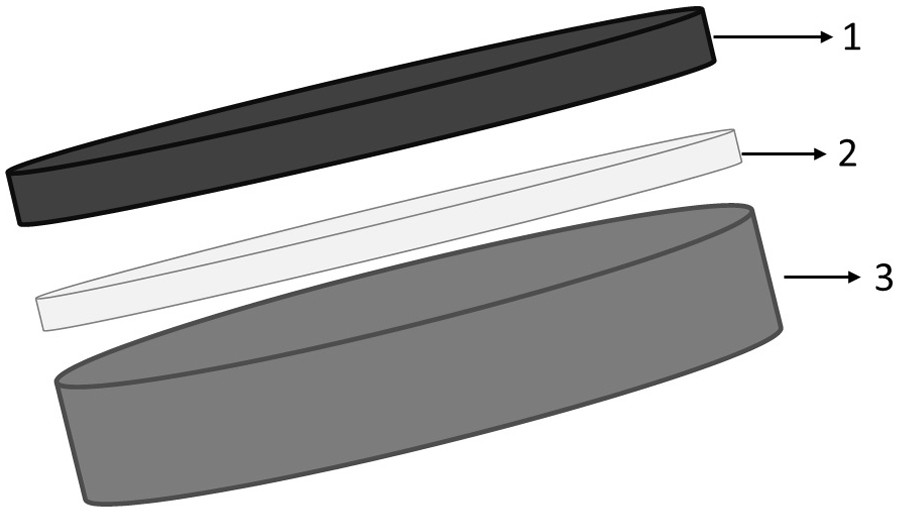

[0080] (2) Preparation of anode support: dry press the pretreated anode powder obtained in step (1), and pre-sinter at 1000 °C to obtain a pre-sintered NiO-YSZ anode support.

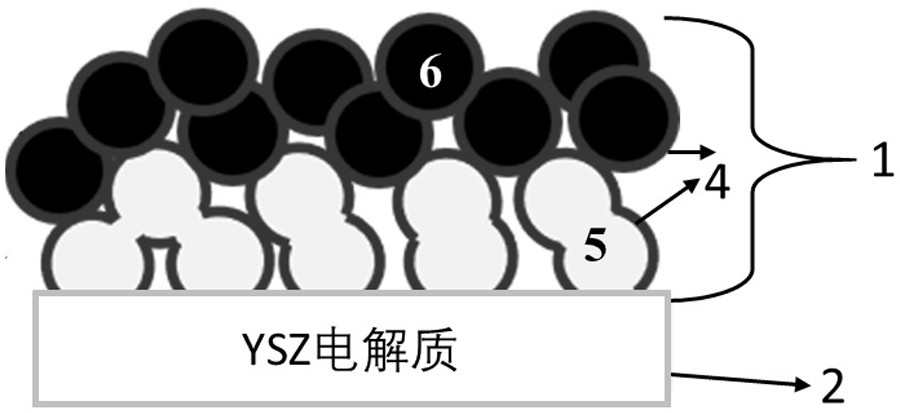

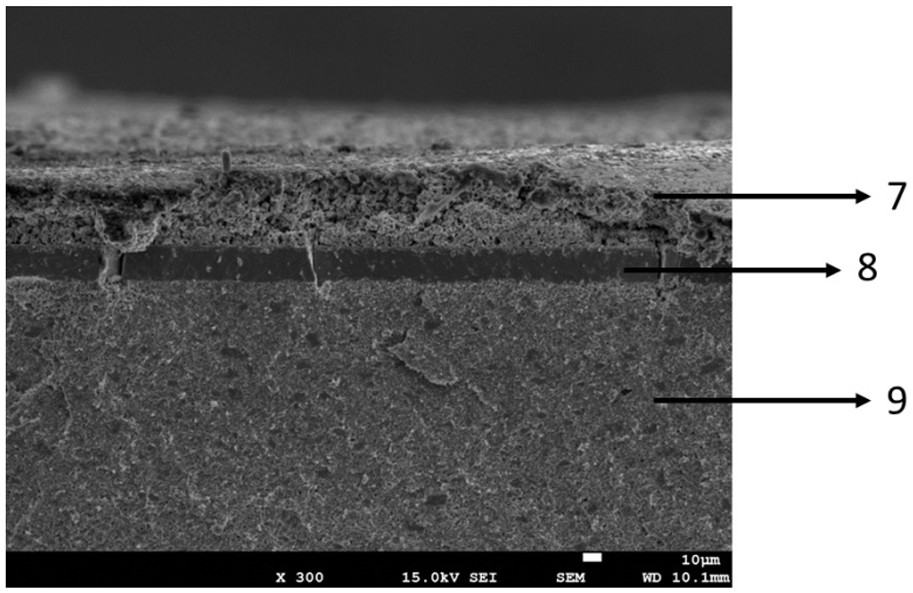

[0081] (3) Preparation of a half-cell with a dense electrolyte layer: mix YSZ powder, isopropanol and castor oil at a ratio of 1:10:0.01 and ultrasonically pass the suspension through a 200-mesh sieve for 2 h; The NiO-YSZ anode support body was immersed in the solution, and after staying for a while, the solution was slowly pulled out, and after drying, it was calcined at 1350 °C for 5 hours to obtain an anode support half-cell with a dense YSZ film.

[0082] (4) Preparation of a separator-free zirconium-based anode-sup...

Embodiment 2

[0085] (1) Anode powder pretreatment: select commercial NiO, 8%Y 2 o 3 -ZrO 2 (YSZ), adding ethanol and zirconia balls according to the mass ratio of 1:1 for ball milling pretreatment for 24 h, after ball milling and drying through a 200-mesh sieve to obtain pretreated anode powder.

[0086] (2) Preparation of anode support body: dry press the pretreated anode powder obtained in step (1), and pre-sinter at 1000 °C to obtain a pre-sintered NiO-YSZ anode support body.

[0087] (3) Preparation of a half-cell with a dense electrolyte layer: mix YSZ powder, isopropanol and castor oil at a mass ratio of 1:10:0.01 and sonicate for 2 h, pass the suspension through a 200-mesh sieve; pre-sinter the obtained product in step (2) The final NiO-YSZ anode support body was immersed in the solution, and after staying for a while, the solution was slowly pulled out, and after drying, it was calcined at 1350 °C for 5 hours to obtain an anode support half-cell with a dense YSZ film.

[0088] (...

Embodiment 3

[0091] (1) Anode powder pretreatment: select commercial NiO, 8% Y 2 o 3 -ZrO 2 (YSZ), adding ethanol and zirconia balls according to the mass ratio of 1:1 for ball milling pretreatment for 24 h, after ball milling and drying through a 200-mesh sieve to obtain pretreated anode powder.

[0092] (2) Preparation of anode support body: dry press the pretreated anode powder obtained in step (1), and pre-sinter at 1000 °C to obtain a pre-sintered NiO-YSZ anode support body.

[0093] (3) Preparation of a half-cell with a dense electrolyte layer: mix YSZ powder, isopropanol and castor oil at a ratio of 1:10:0.01 and ultrasonically pass the suspension through a 200-mesh sieve for 2 h; The NiO-YSZ anode support body was immersed in the solution, and after staying for a while, the solution was slowly pulled out, and after drying, it was calcined at 1350 °C for 5 hours to obtain an anode support half-cell with a dense YSZ film.

[0094] (4) Preparation of a separator-free zirconium-base...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com