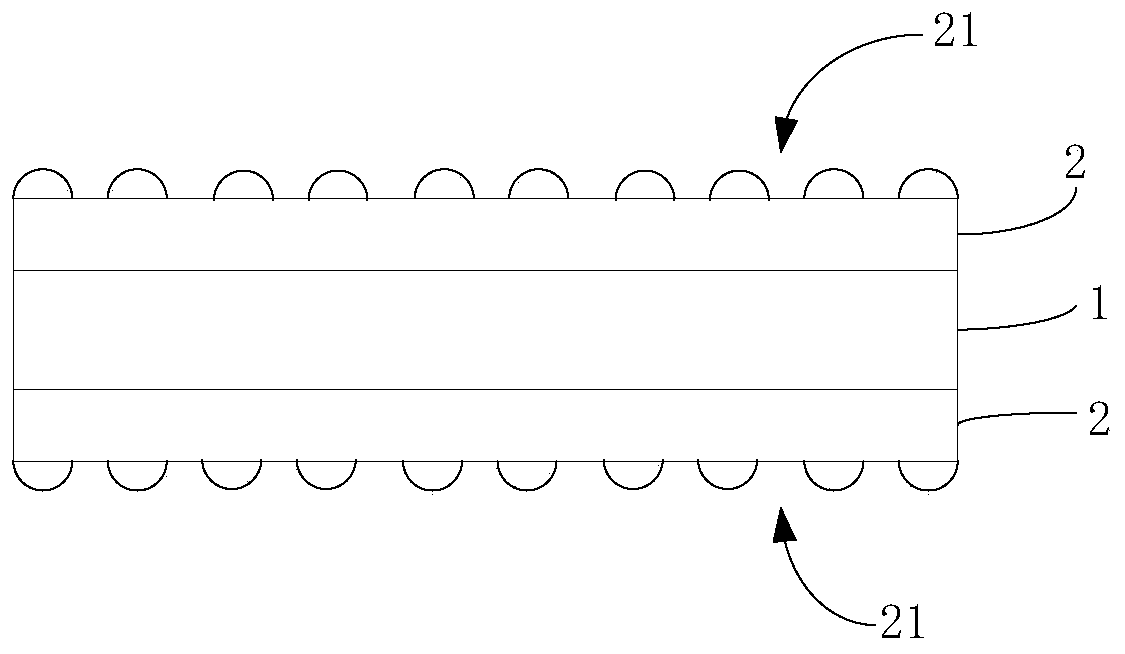

Catalyst coating film, fuel cell and preparation method of catalyst coating film

A catalyst and membrane coating technology, applied in fuel cells, fuel cell components, battery electrodes, etc., can solve the problems of reducing mass transfer impedance, and membrane electrodes cannot take into account water management at the same time, so as to reduce mass transfer impedance and improve Effectiveness of utilization efficiency and increase of active area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] At present, the commonly used preparation methods of membrane electrodes mainly include the following methods. The traditional method is to coat the catalyst on the gas diffusion layer to prepare a gas diffusion layer electrode, and then press the gas diffusion layer electrode and the proton exchange membrane together by high temperature hot pressing to prepare a membrane electrode. In this membrane electrode preparation method, the active material particles in the catalytic layer are easily pressed into the pores of the microporous layer in the gas diffusion layer under high pressure, blocking the pore channels of the gas diffusion layer and greatly increasing the mass transfer. Resistance, and reduce the utilization efficiency of the catalyst. At the same time, since the proton exchange membrane and the gas diffusion layer electrodes are bonded together by high-temperature hot pressing, the contact between the proton exchange membrane and the catalytic layer is not ve...

Embodiment 1

[0082] The first step: the pretreatment of proton exchange membrane and the preparation of catalyst slurry, it comprises the following steps:

[0083] (1) Pretreatment of proton exchange membrane: Soak a 7.1cm*7.1cm proton exchange membrane in 5% hydrogen peroxide solution, place it in an environment of 70°C for 5 hours, and then wash it three times with deionized water , then soak it in 0.5mol / L sulfuric acid, place it in a constant temperature environment of 60°C for 1h, wash it with deionized water three times, and finally place the proton exchange membrane in a vacuum drying oven at 60°C for 24h.

[0084] (2) Preparation of catalyst slurry: fully mix a certain mass of Pt / C catalyst, deionized water, isopropanol, and Nafion solution evenly. Wherein the mass ratio of Pt / C catalyst to nafion is 2:1. The mass ratio of deionized water: isopropanol is 5:3. The solid content of the catalyst slurry is 25%.

[0085] In the above example 1, the mass of Pt / C catalyst is 1.2g, the ...

Embodiment 2

[0090] The first step: the pretreatment of proton exchange membrane and the preparation of catalyst slurry, it comprises the following steps:

[0091] (1) Pretreatment of proton exchange membrane: Soak a 7.1cm*7.1cm proton exchange membrane in 5% hydrogen peroxide solution, place it in an environment of 70°C for 5 hours, and then wash it three times with deionized water , then soak it in 0.5mol / L sulfuric acid, place it in a constant temperature environment of 60°C for 1h, wash it with deionized water three times, and finally place the proton exchange membrane in a vacuum drying oven at 60°C for 24h.

[0092] (2) Preparation of catalyst slurry: fully mix a certain mass of Pt / C catalyst, deionized water, isopropanol, and Nafion solution evenly. Wherein the mass ratio of Pt / C catalyst to nafion is 2:1. The mass ratio of deionized water: isopropanol is 5:3. The solid content of the catalyst slurry is 25%.

[0093] In the above example 2, the mass of the Pt / C catalyst is 1.2 g,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com