Flower structure nano cerium oxide base composite material and its preparing method and use

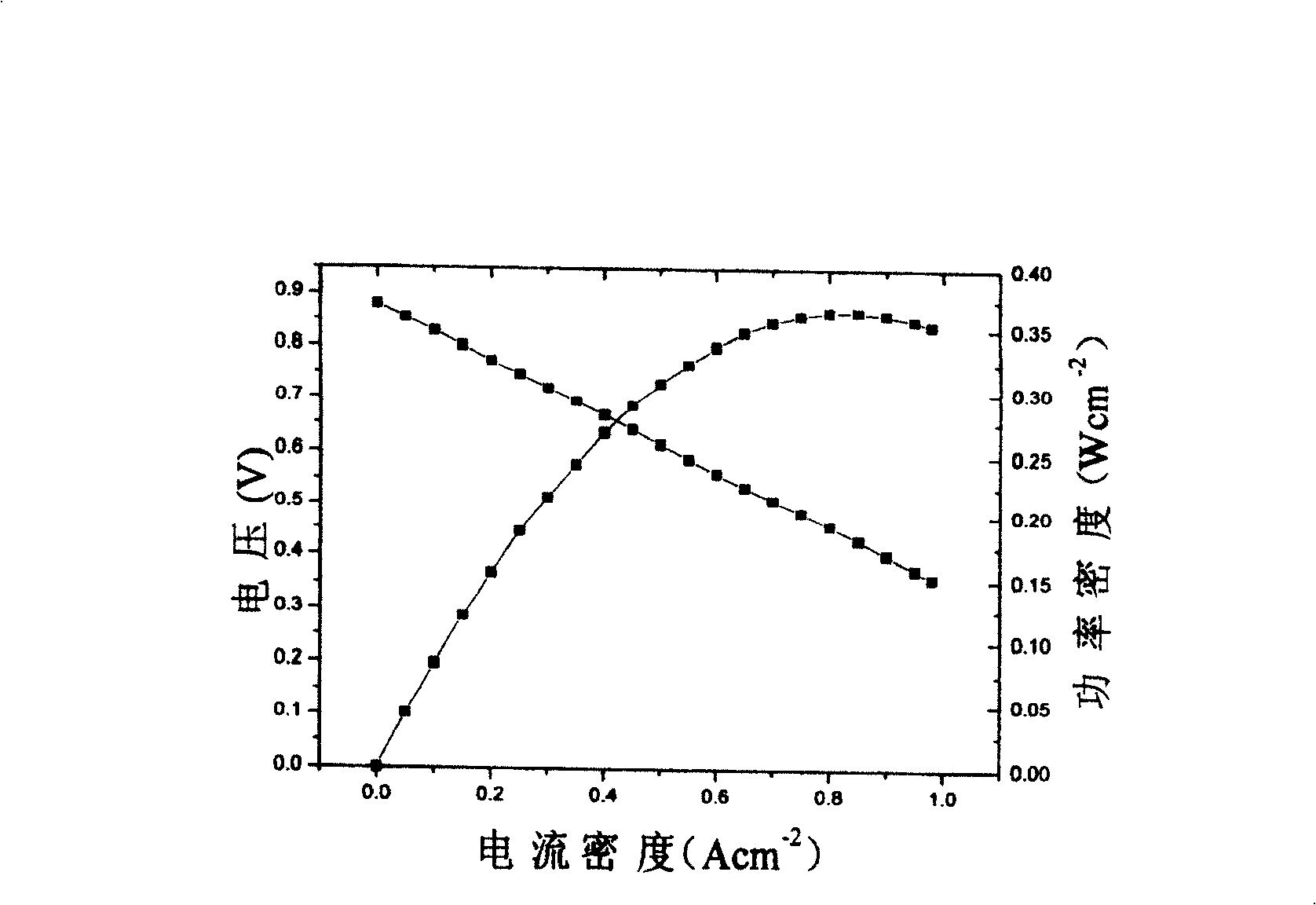

A technology of nano-cerium oxide and flower-like structure, which is applied in nanostructure manufacturing, chemical instruments and methods, nanotechnology, etc., can solve the problems of low battery power density, lower battery efficiency and stability, etc., achieve high yield, avoid Good effect of limitation and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

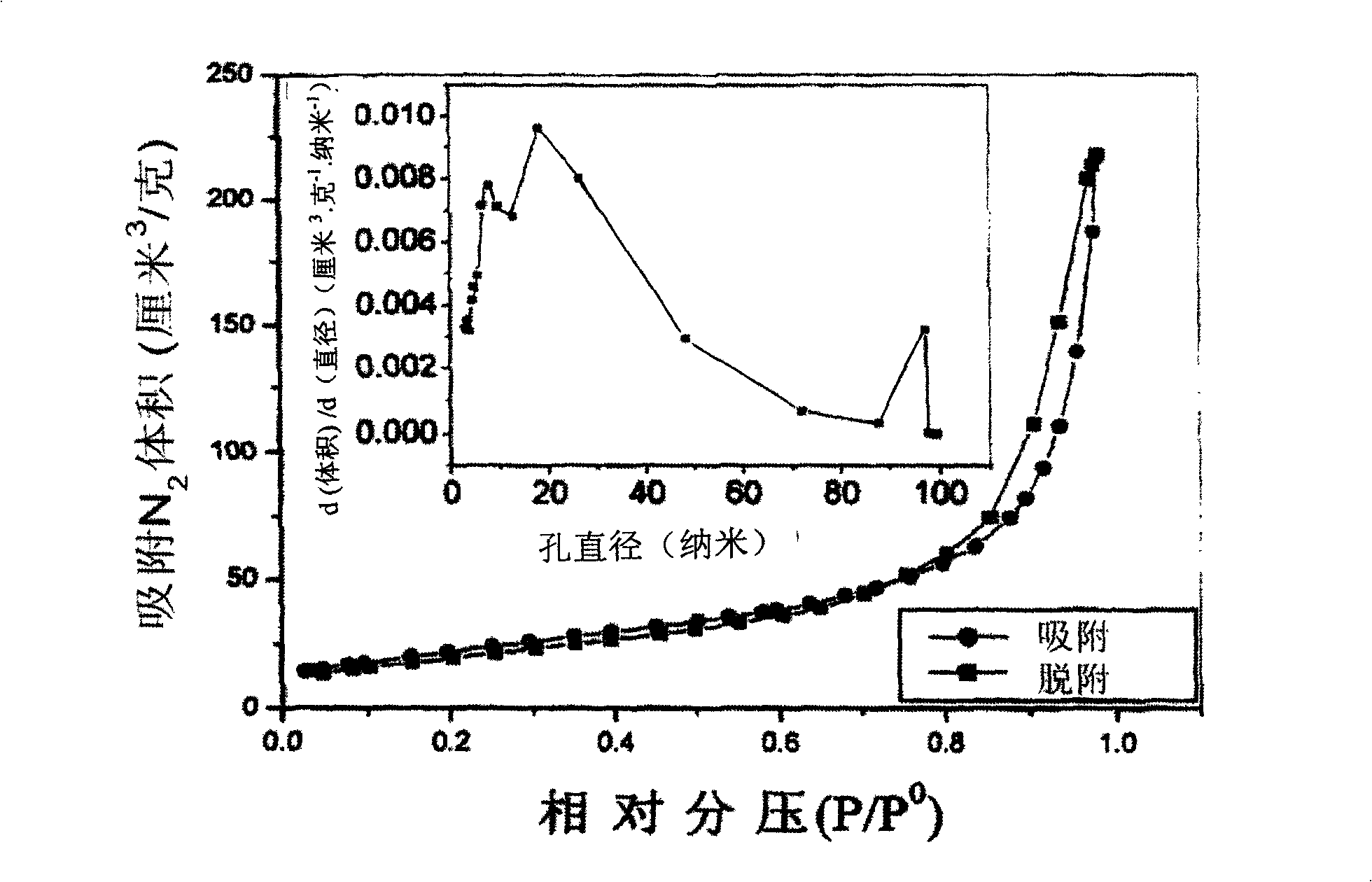

[0036] Example 1, preparation of cerium oxide-copper oxide composite material with flower-like structure

[0037] Weigh 0.2 mol of glucose, add it into a container containing 80 ml of deionized water under strong stirring, and prepare it into a 2.5M glucose aqueous solution, then add 0.8 mol of acrylamide, and after it is completely dissolved, add 0.5 mol of hydrated Cerium nitrate, stir to make the cerium nitrate completely dissolved, then add dropwise 0.5M NaOH solution to adjust the pH value of the mixture to 11, with the addition of lye, the mixture changes from a colorless solution to a light yellow-green gel , the pH value of the gel was about 11; after fully stirring for 1 hour, the obtained gel was transferred to 100 ml of Teflon-lined autoclave, and the filling degree was 80v%, and then The autoclave is sealed. And keep it in a constant temperature oven at 180°C for 72 hours. After the hydrothermal reaction, cool naturally to room temperature, centrifuge the obtaine...

Embodiment 2

[0043] Example 2, preparation of cerium oxide-nickel oxide composite material with flower-like structure

[0044] Weigh 0.0007 mol of glucose, add it into a container containing 70 ml of deionized water under strong stirring, and make it into a 0.01M glucose aqueous solution, then add 0.000175 mol of acrylamide, and after it is completely dissolved, add 0.00007 mol of hydrated Cerium nitrate and 0.000021mol hydrated nickel nitrate, after stirring to completely dissolve the cerium nitrate and nickel acetate, add 25wt% NH 3 .H 2 O solution adjusts the pH value of the mixed solution to 10, and along with the dripping of ammoniacal liquor, the mixed solution turns into a gel, and the pH of the gel is about 10; after fully stirring for 5 hours, the mixture will be obtained The gel was transferred to a 100 ml polytetrafluoro-lined autoclave with a filling degree of 70v%, and then the autoclave was sealed. And keep it in a constant temperature oven at 180°C for 72 hours. After the...

Embodiment 3

[0047] Example 3, preparation of cerium oxide-manganese oxide-copper oxide composite material with flower-like structure

[0048] Weigh 0.45 mol of glucose, add it into a container containing 90 ml of deionized water under strong stirring, and make it into a 5M glucose aqueous solution, then add 1.8 mol of acrylamide, and after it is completely dissolved, add 2.25 mol of hydrated acetic acid Cerium and 0.5625mol hydrated manganese nitrate, stir to completely dissolve cerium acetate and manganese nitrate, then add dropwise 0.5M NaOH solution to adjust the pH value of the mixed solution to 11, with the addition of lye, the mixed solution becomes shallow Gel, the pH value of this gel is about 11; After fully stirring for 1 hour, the gel obtained is transferred to a 100 ml autoclave lined with polytetrafluoroethylene, and the filling degree is 90v %, and then seal the autoclave. And keep it in a constant temperature oven at 220°C for 10 hours. After the hydrothermal reaction, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com