Electrode of fuel battery with proton exchange membrane and its production

A fuel cell electrode and proton exchange membrane technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems affecting the transfer or diffusion of reactants and the performance degradation of fuel cells, so as to achieve uniform distribution, improve electrode performance, increase three The effect of phase interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

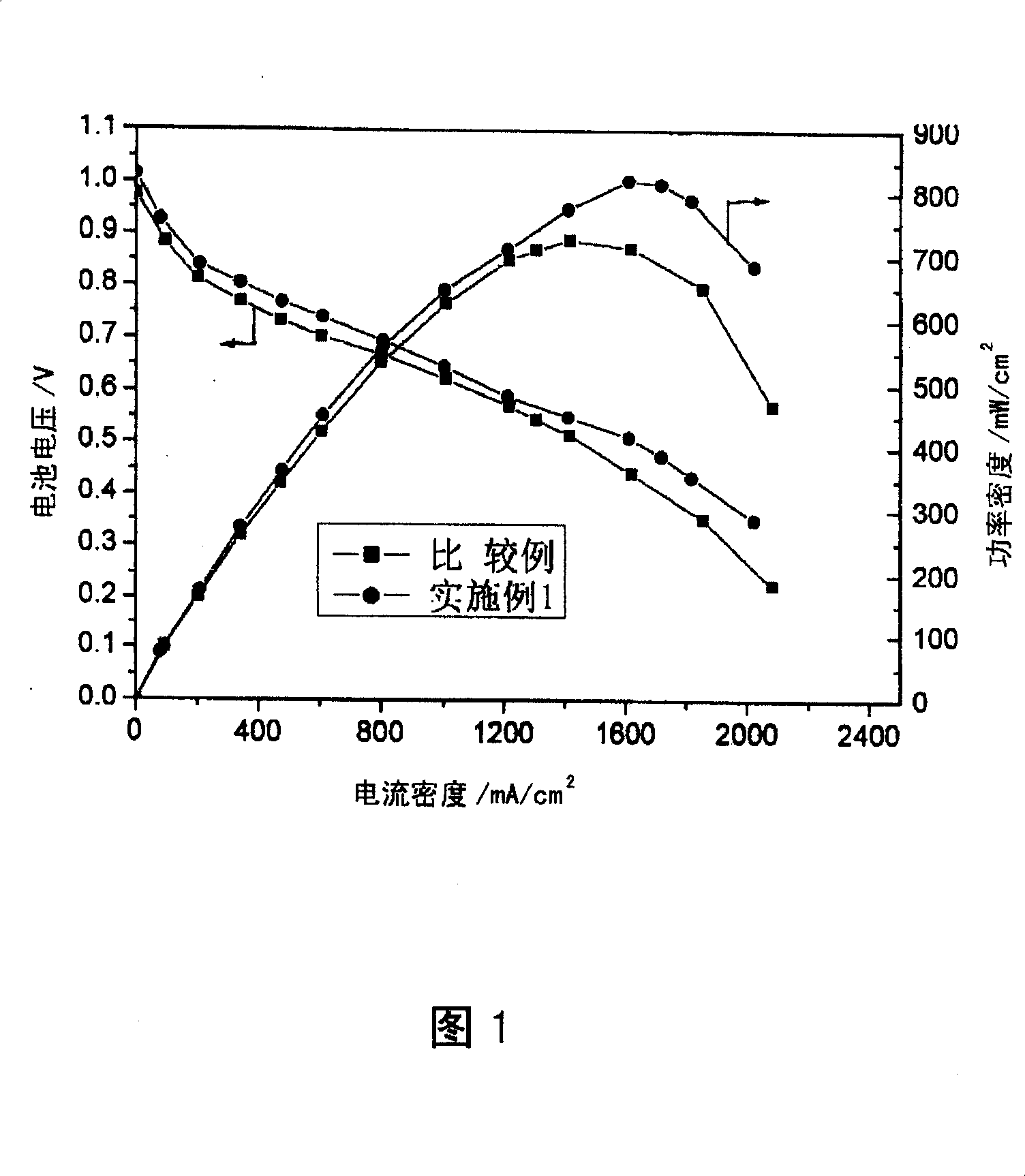

Embodiment 1

[0046] After weighing an appropriate amount of catalyst, Nafion and solvent in a certain proportion, they are mixed by ball milling to form a uniformly mixed slurry, wherein the amount of Nafion resin is 7wt.%. Then, make this slurry on the surface of the gas diffusion layer through the leveling process by scraping to obtain the fuel cell electrode precursor containing the catalyst layer, and the usage amount of platinum (Pt) in the cathode catalyst layer is controlled at 0.2-0.6mg / cm 2 , the amount of platinum (Pt) used in the anode catalytic layer is controlled at 0.1-0.3 mg / cm 2 . After drying at 330°C, nitrogen (N 2 ) under the protection of roasting for 80 minutes, then naturally cool to room temperature, and then spray Nafion on the surface of the electrode catalyst layer with a content of 0.1-0.2 mg / cm 2 solid electrolyte. Using Nafion1135 membrane, the anode and cathode are placed on both sides of the Nafion1135 membrane, and hot-pressed at 180 ° C to obtain a thr...

Embodiment 2

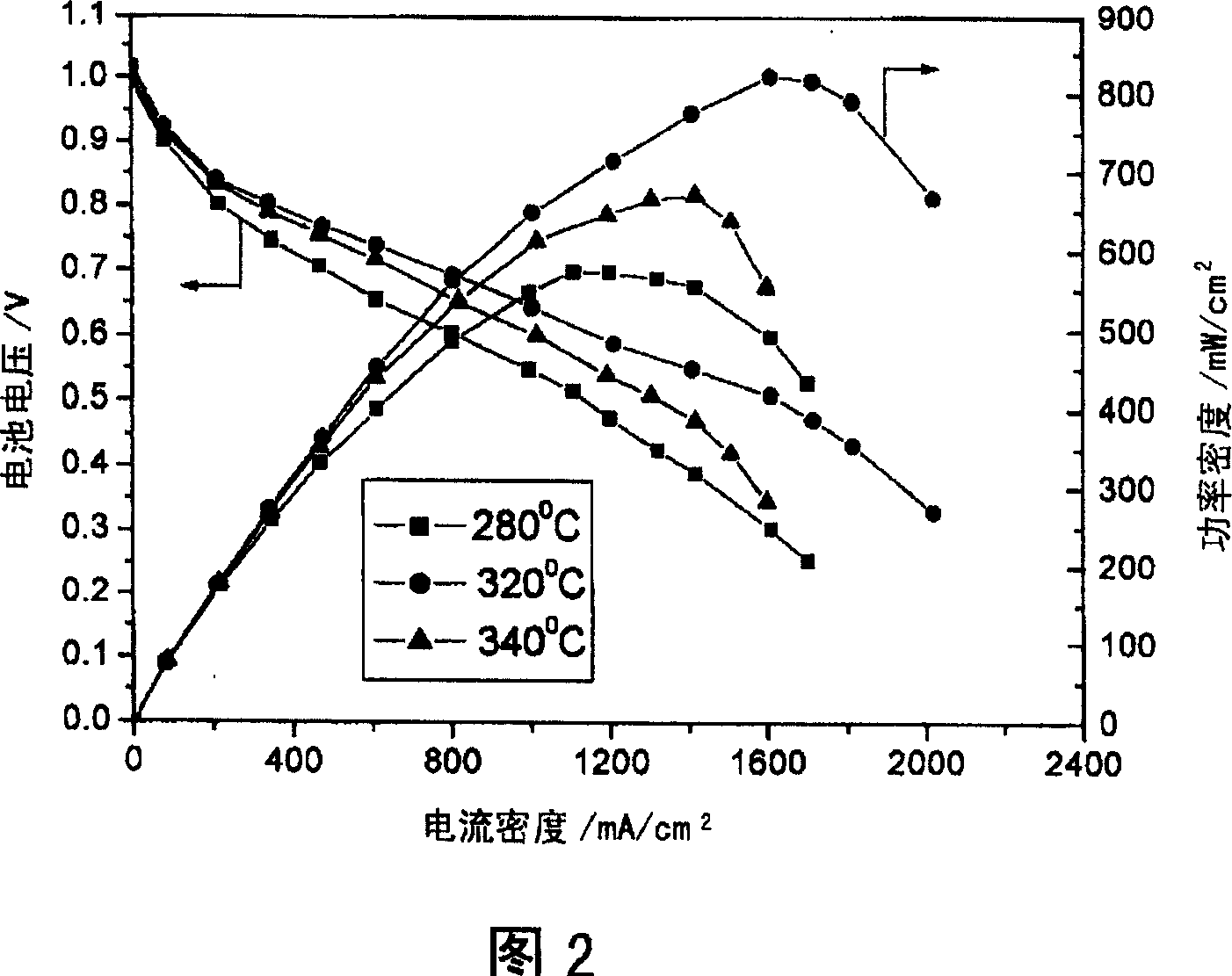

[0050] According to the method of Example 1, after preparing the precursor containing the catalytic layer, the calcination temperatures were 280°C, 320°C, and 340°C respectively, and the membrane-electrode three-in-one and the single cell were prepared according to the method of Example 1.

Embodiment 3

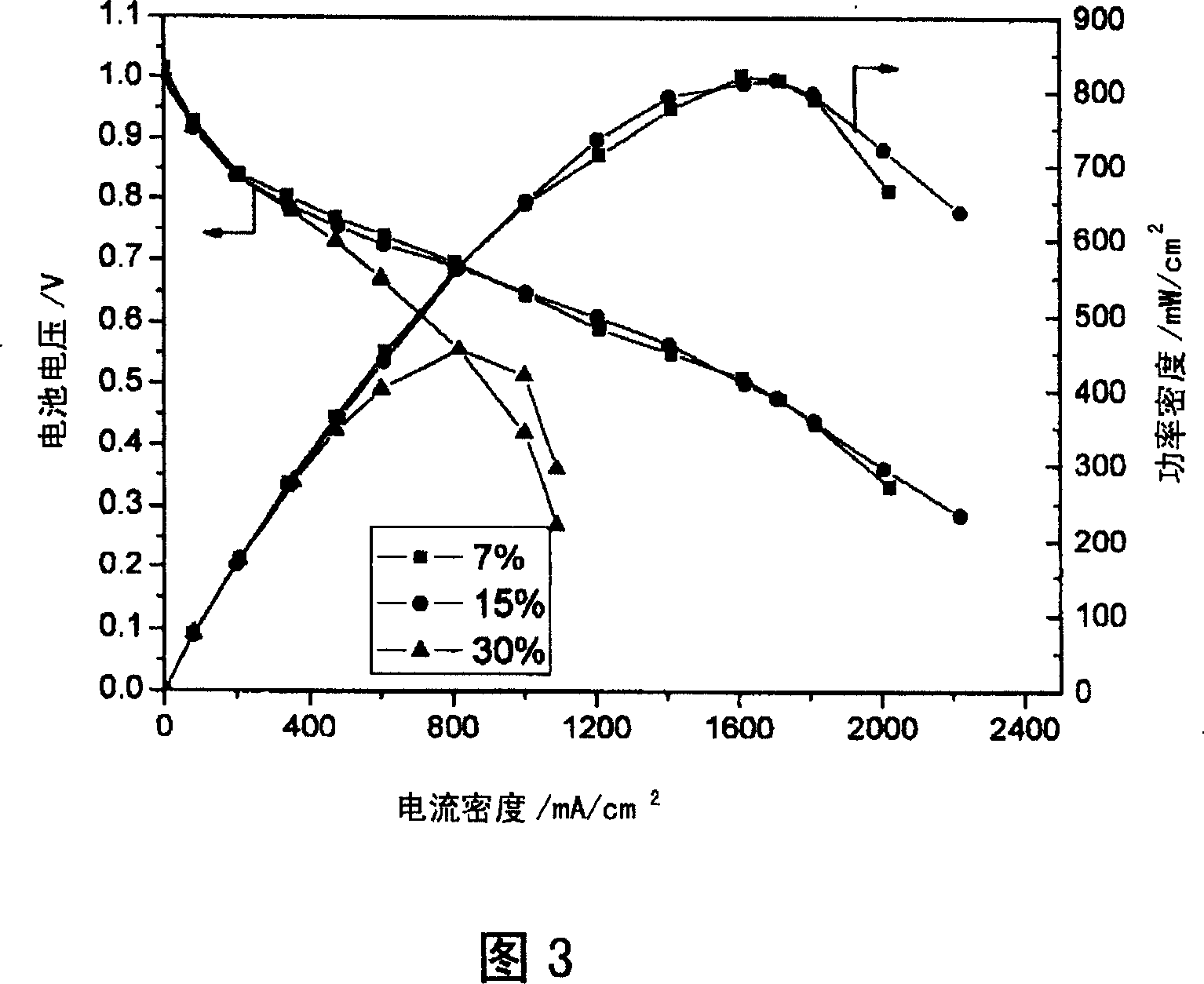

[0052] According to the method of embodiment 1, the amount of Nafion resin in the catalytic layer is adjusted to 15wt.% and 30wt.% by the 7wt.% of embodiment 1 to prepare electrodes, and the method of embodiment 1 is used to prepare membrane-electrode three-in-one and single cell . Add the anode and cathode flow field plates on both sides of the three-in-one membrane electrode, the current collector plate and the end plate to form a single cell.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com