Microbial fuel cell air cathode and preparation method thereof

An air cathode and fuel cell technology, applied in battery electrodes, electrical components, circuits, etc., can solve problems affecting oxygen diffusion, catalyst loading error, catalyst performance interference, etc., and achieve the effect of increasing the three-phase interface and reducing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method for the air cathode of the microbial fuel cell, the steps are as follows:

[0028] 1) 1.2g powder (specific surface area is 100m 2 / g) Conductive carbon black is placed in a beaker, and 50ml of ethanol is added to immerse it, and ultrasonically stirred at a temperature of 30°C for 30 minutes to fully disperse and dissolve the conductive carbon black in ethanol;

[0029] 2) Under the condition of ultrasonic and stirring, add 3.6g of PTFE emulsion with a concentration of 60% by weight dropwise, the mass ratio of PTFE emulsion and conductive carbon black is 3: 1, and continue ultrasonic and stirring for 30min;

[0030] 3) Place the above-mentioned container in a water bath at 80°C, and continue stirring until an elastic dough-like substance is formed;

[0031] 4) Take out the dough-like substance and knead it evenly in your hands, then place it on a roller press and roll it into a uniform diffusion layer film with a thickness of 0.3mm;

[0032] 5) Th...

Embodiment 2

[0041] A method for preparing the air cathode of the microbial fuel cell, the preparation steps of this embodiment are basically the same as in Example 1, the difference is that in the preparation of the active layer film step 7), the mass ratio of the PTFE emulsion to the supercapacitor activated carbon is 1 : 6, that is, the consumption of supercapacitor activated carbon is 4.2g.

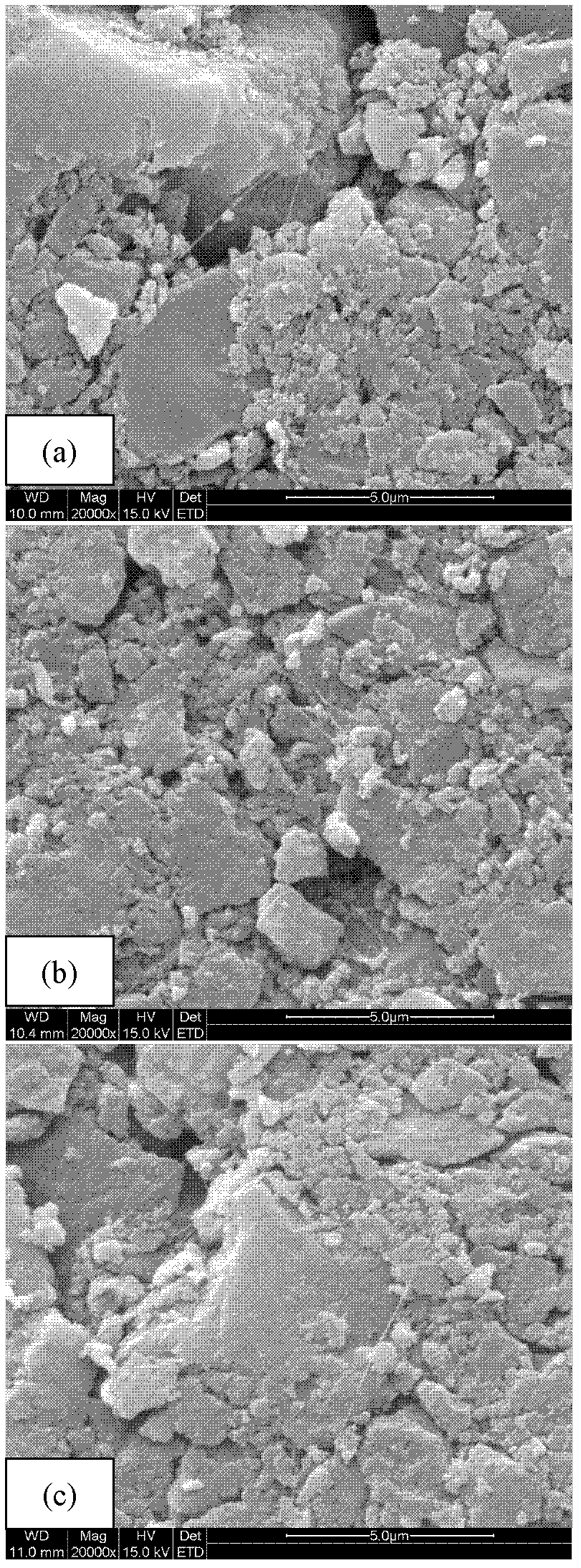

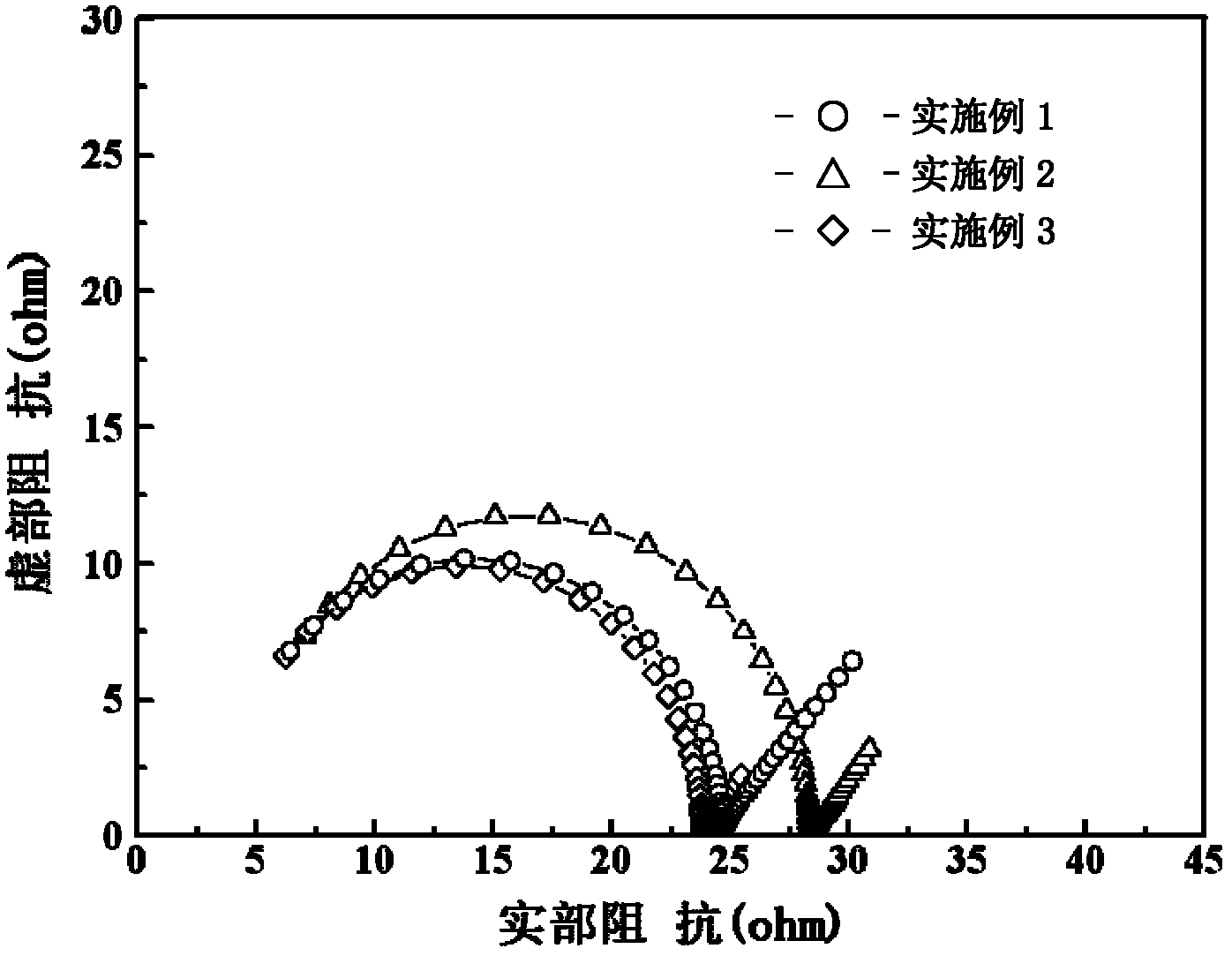

[0042] The SEM image of the air catholyte side active layer that this embodiment obtains is as follows figure 2 (b) shown. Compared figure 2 (a) It can be seen that compared with the air cathode prepared in Example 1, the air cathode prepared in this embodiment has less cross-linked filaments, which confirms that the filaments are formed by PTFE after rolling and curing at high temperature In the non-biological half-cell, the air cathode prepared in this embodiment is used as the working electrode, and the platinum sheet is used as the counter electrode to measure the AC impedance spectrum as ...

Embodiment 3

[0044] A method for preparing the air cathode of the microbial fuel cell, the preparation steps of this embodiment are basically the same as in Example 1, the difference is that in the preparation of the active layer film step 7), the mass ratio of the PTFE emulsion to the supercapacitor activated carbon is 1 : 8, that is, the consumption of supercapacitor activated carbon is 5.6g.

[0045] In the non-biological half-cell, the air cathode prepared in this embodiment is used as the working electrode, and the platinum sheet is used as the counter electrode to measure the AC impedance spectrum as follows: image 3 As shown, the frequency range is 100KHz-0.01Hz. from image 3 It can be seen from the figure that the AC impedance spectrum of the air cathode obtained in this embodiment is in the same form as the AC impedance spectrum of the air cathode obtained in Examples 1 and 2. Due to the reduction of the content ratio of PTFE in the active layer, the The adhesion between the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com