A Self-Humidifying Ordered Polymer Membrane Electrode

A polymer film and polymer technology, applied in battery electrodes, circuits, fuel cells, etc., can solve the problem of increasing the energy conversion of membrane electrodes, ohmic polarization, reducing the electrochemical performance of membrane electrodes, three-phase interfaces with less mass transfer microchannels, etc. problems, to achieve the effect of improving energy conversion efficiency and reaction rate, increasing three-phase reaction interface, and reducing concentration polarization loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

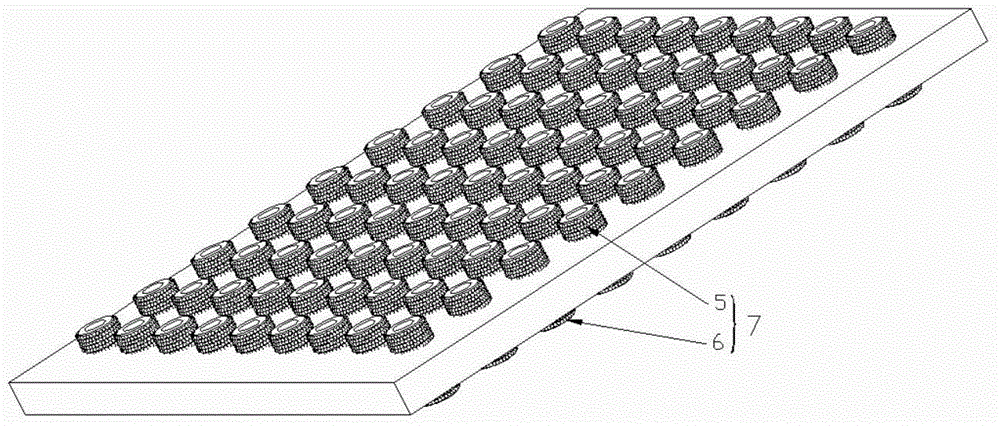

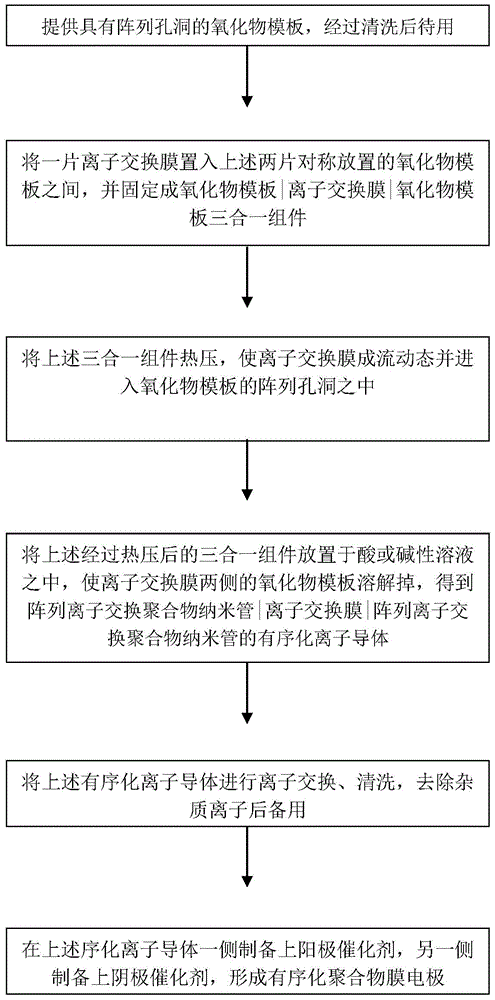

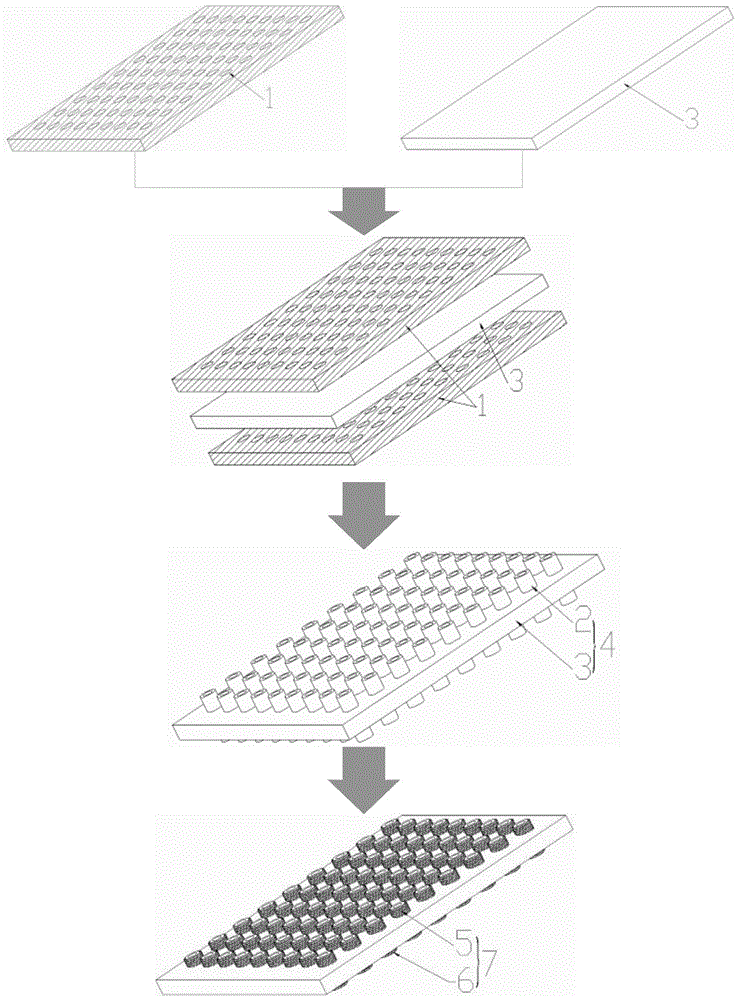

[0035] A method for preparing an ordered polymer membrane electrode of the present invention, the process is shown in Figure 2-3 , including the following steps:

[0036] (1) Provide a porous template with an array of holes, which is ready for use after cleaning;

[0037] (2) Place a piece of ion exchange membrane between the above two symmetrically placed porous templates, and fix it into a three-in-one assembly of porous template|ion exchange membrane|porous template;

[0038] (3) Hot press the above-mentioned three-in-one component, so that the ion-exchange membrane becomes fluid and enters the array holes of the porous template;

[0039] (4) Place the hot-pressed three-in-one assembly in an acidic or alkaline solution to dissolve the porous templates on both sides of the ion-exchange membrane to obtain an ion-exchange polymer nanotube array|ion-exchange membrane|ion Ordered ionic conductors of exchange polymer nanotube arrays;

[0040] (5) Perform ion exchange and clea...

Embodiment 1

[0049] Embodiment 1 is used for proton exchange membrane electric fuel cell

[0050] Use 1% (mass fraction) sodium dodecylsulfonate solution to clean the 5cm*5cm AAO porous template (hole diameter is 400nm, thickness 50μm), put it into a petri dish, put the petri dish into vacuum oven. The temperature of the oven was set at 50°C, and the vacuum was evacuated to 0.1 atmosphere for 1 hour before use. The aluminum oxide porous template and the 150 micron thick Nafion membrane were fixed on the Cu sheet cleaned with alcohol to form a three-in-one assembly of alumina porous template|Nafion membrane|alumina porous template. Place the above-mentioned three-in-one component in a hot press, set the temperature at 90°C, set the pressure at 10Mpa, and keep the pressure for 1 hour. After hot pressing, take out the three-in-one assembly, put it into a 5mol / L NaOH solution, keep it in a constant temperature box at 60°C, take it out after 1 hour, clean it with deionized water, and get an o...

Embodiment 2

[0053] Embodiment 2 is used for alkaline membrane fuel cell

[0054] Use 1% (mass fraction) sodium dodecylsulfonate solution to clean the 5cm*5cm aluminum oxide porous template (pore diameter is 50 nm, thickness 1 micron), put it into a petri dish, put the petri dish into a vacuum oven. The temperature of the oven was set at 50°C, and the vacuum was evacuated to 0.1 atmosphere for 1 hour before use. A stainless steel sheet cleaned with acetone was used to fix the alumina porous template and the quaternized polysulfone membrane with a thickness of 5 microns to form a three-in-one assembly of alumina porous template|quaternized polysulfone membrane|alumina porous template. The above-mentioned three-in-one assembly was placed in a hot press, the temperature was set at 240°C, the pressure was set at 10Mpa, and the pressure was maintained for 1 hour. After hot pressing, take out the three-in-one assembly and put it in a 5mol / L NaOH solution, keep it warm at 60°C in an incubator, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com