A preparation method of fuel cell electrode and membrane electrode with fully ordered structure of catalytic layer

A technology of ordered structure and catalytic layer, applied in fuel cells, battery electrodes, structural parts, etc., to achieve the effects of ensuring stability, improving electrochemical reaction efficiency and energy conversion efficiency, and reducing material transport resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

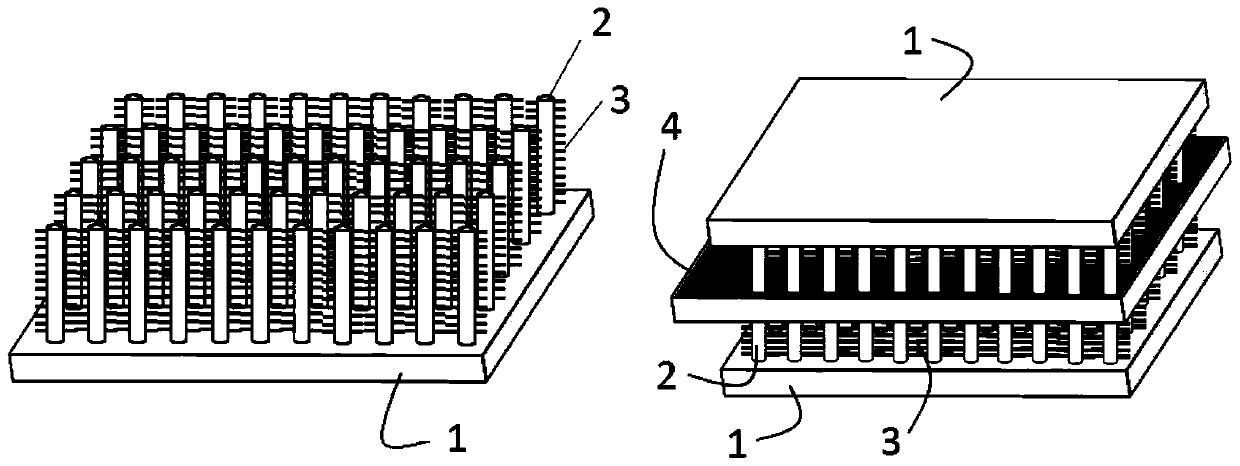

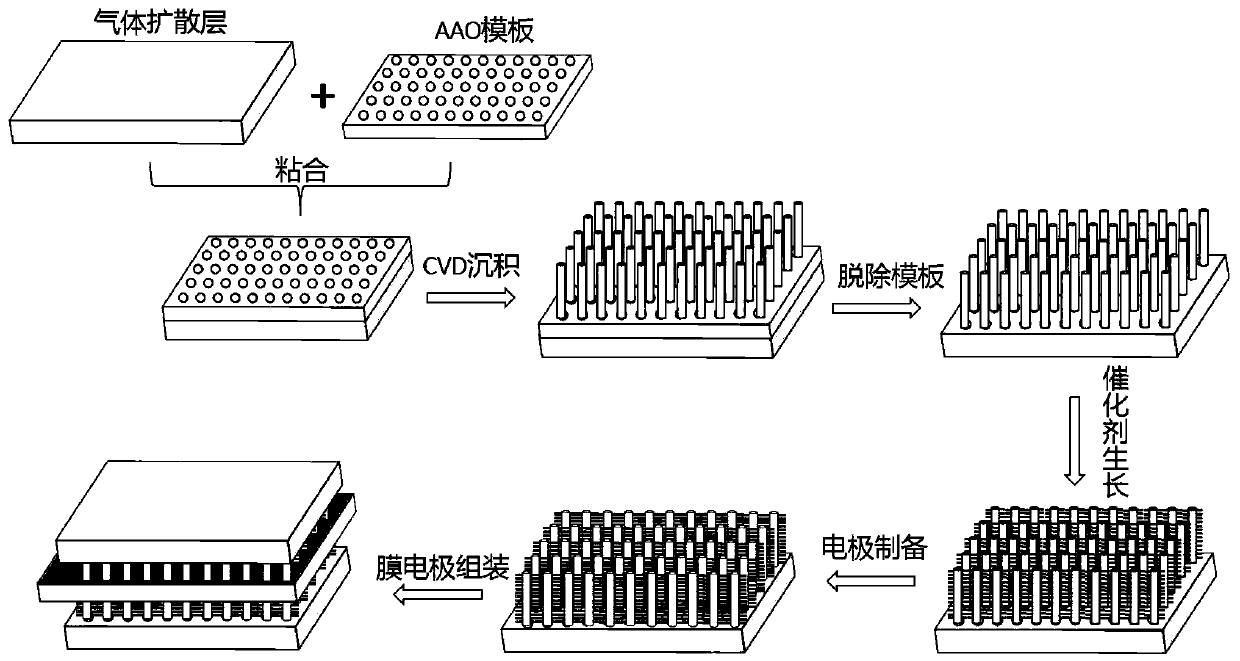

[0034] combined with figure 2 The process and process shown are used to prepare catalyst layer fully ordered polyelectrolyte membrane fuel cell electrodes and membrane electrodes, and conduct discharge tests. The main steps are as follows:

[0035] (1) In situ growth of VACNT arrays on the gas diffusion layer

[0036] After washing and drying a piece of AAO double-pass porous template with a size of 2.3cm×2.3cm (pore size is 30nm, thickness is 100μm), it is bonded with a piece of carbon paper of the same size as the gas diffusion layer 1, and placed in a tube furnace , pass through acetylene at 600°C for 60 minutes, and vapor-deposit it in the pores of the AAO template, and finally use 1mol / L NaOH solution to remove the AAO template to obtain carbon nanotubes 2 vertically grown on the gas diffusion layer 1 Arrays (VACNTs).

[0037] (2) In situ growth of Pt-NW

[0038] The gas diffusion layer loaded with the VACNT array prepared above was impregnated in 50ml with a concentr...

Embodiment 2

[0044] The catalyst layer fully ordered polyelectrolyte membrane fuel cell electrode and membrane electrode with N-doped VACNT array as the carrier were prepared according to the following steps, and the discharge test was carried out.

[0045] (1) In situ growth of N-doped VACNT arrays on the gas diffusion layer

[0046] After washing and drying a piece of AAO double-pass porous template with a size of 2.3cm×2.3cm (pore size is 30nm, thickness is 100μm), it is bonded with a piece of carbon paper of the same size as the gas diffusion layer 1, and placed in a tube furnace , pass through acetylene at 600°C for 60 min, make it vapor-deposit in the channels of the AAO template, and finally use 1mol / L NaOH solution to remove the AAO template, and obtain the carbon nanotube 2 array vertically grown on the gas diffusion layer 1 (VACNTs). Then, the gas diffusion electrode 1 grown with VACNT was placed in the tube furnace again, and NH was fed at a temperature of 500 °C 3 gas, the fl...

Embodiment 3

[0049] A fully ordered polyelectrolyte membrane fuel cell electrode and a membrane electrode with catalytic layer using S-doped VACNT array as a carrier were prepared according to the following steps, and the discharge test was carried out.

[0050] (1) In situ growth of S-doped VACNT arrays on the gas diffusion layer

[0051] Using the same method as in Example 1, VACNTs grown in situ on the gas diffusion layer 1 were firstly prepared. Then, the gas diffusion electrode grown with VACNT was placed in the tube furnace again, and H was introduced at 500 °C. 2 S gas, the flow rate is 0.1slpm, and the surface S-doped VACNT array is obtained

[0052] Step (2) in-situ growth of Pt-NW and step (3) membrane electrode assembly method are the same as in Example 1. Under the same conditions as in Example 1, the discharge test was carried out, and at a working voltage of 0.6V, the current density can reach 0.48A / cm 2 , the maximum power density reaches 0.82W / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com