Preparation method of a self-humidifying ordered polymer membrane electrode

A polymer membrane and polymer technology, applied in battery electrodes, circuits, fuel cells, etc., can solve problems such as the inability of self-moisturizing three-phase interface, affecting energy conversion efficiency and reaction rate, and destroying proton conductor nanofiber arrays.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

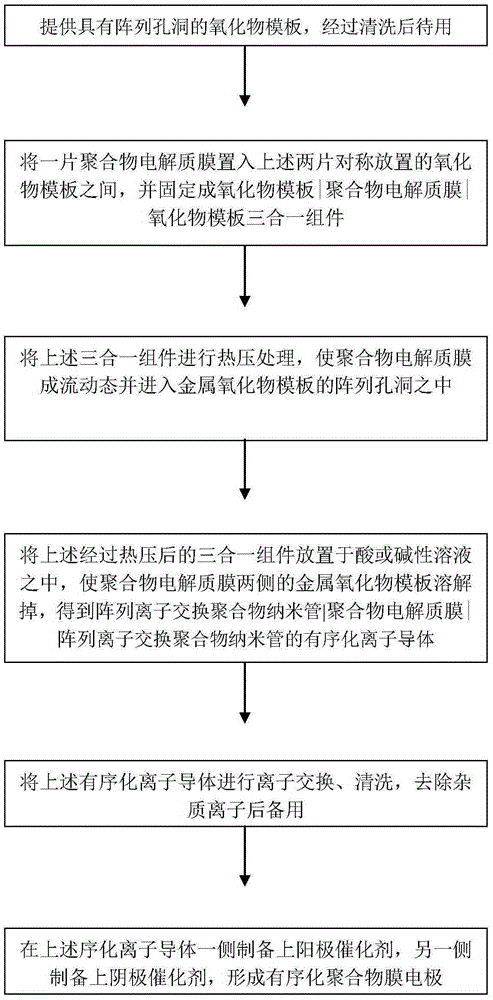

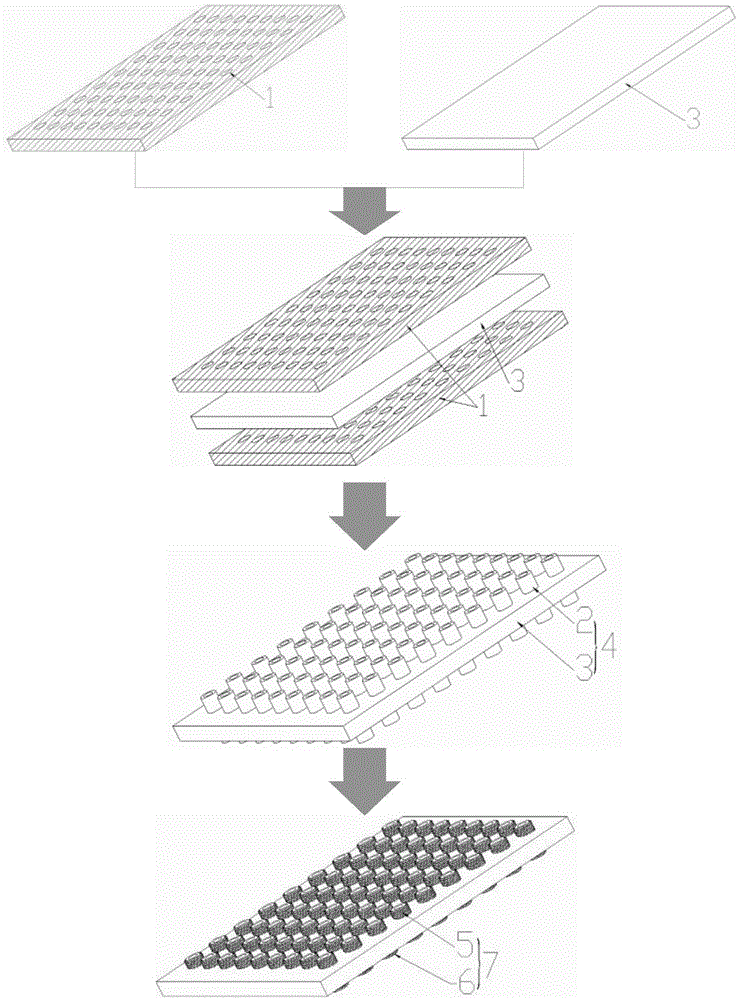

[0039] The preparation method of the ordered polymer membrane electrode of the present invention specifically includes the following steps, and its technological process is shown in the appendix Figure 2-3 .

[0040] (1) Provide a porous template with array holes, such as AAO, to be used after cleaning;

[0041] (2) Place a piece of polymer electrolyte membrane between the above two symmetrically placed porous templates, and fix it into a three-in-one assembly of porous template|polymer electrolyte membrane|porous template;

[0042] (3) The above-mentioned three-in-one assembly is hot-pressed at a certain temperature and pressure for a certain period of time, so that the polymer electrolyte membrane becomes fluid and enters the array holes of the porous template;

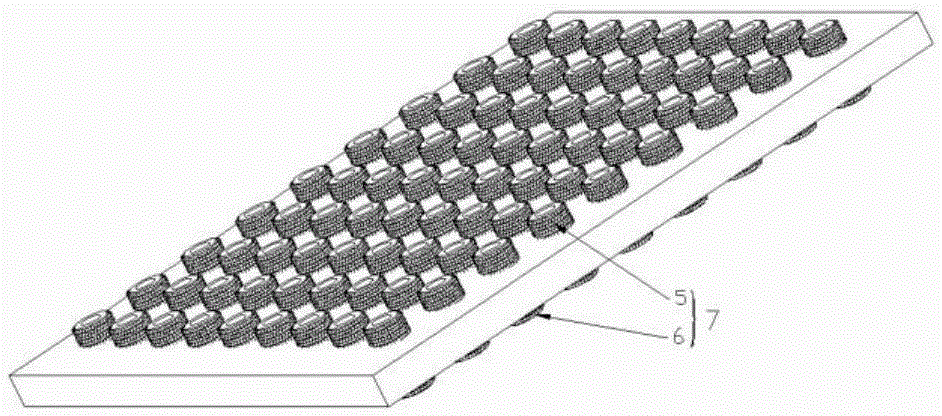

[0043](4) Place the above hot-pressed three-in-one assembly in an acidic or alkaline solution to dissolve the porous templates on both sides of the polymer electrolyte membrane to obtain an ion-exchange polymer na...

Embodiment 1

[0050] Embodiment 1 is used for proton exchange membrane electric fuel cell

[0051] Use 1% (mass fraction) sodium dodecylsulfonate solution to clean the 5cm*5cm AAO porous template (the diameter of the hole can be 400 nanometers and the thickness is 50 microns), put it into a petri dish, and put the petri dish into vacuum oven. The temperature of the oven was set at 50°C, and the vacuum was evacuated to 0.1 atmosphere for 1 hour before use. The aluminum oxide porous template and the 150 micron thick Nafion membrane were fixed on the Cu sheet cleaned with alcohol to form a three-in-one assembly of alumina porous template|Nafion membrane|alumina porous template. Place the above-mentioned three-in-one component in a hot press, set the temperature at 90°C, set the pressure at 10Mpa, and keep the pressure for 1 hour. After hot pressing, take out the three-in-one assembly, put it into a 5mol / L NaOH solution, keep it in a constant temperature box at 60°C, take it out after 1 hour,...

Embodiment 2

[0054] Embodiment 2 is used for alkaline membrane fuel cell

[0055] Use 1% (mass fraction) sodium dodecylsulfonate solution to clean the 5cm*5cm aluminum oxide porous template (pore diameter is 50 nm, thickness 1 micron), put it into a petri dish, put the petri dish into a vacuum oven. The temperature of the oven was set at 50°C, and the vacuum was evacuated to 0.1 atmosphere for 1 hour before use. A stainless steel sheet cleaned with acetone was used to fix the alumina porous template and the quaternized polysulfone membrane with a thickness of 5 microns to form a three-in-one assembly of alumina porous template|quaternized polysulfone membrane|alumina porous template. The above-mentioned three-in-one assembly was placed in a hot press, the temperature was set at 240°C, the pressure was set at 10Mpa, and the pressure was maintained for 1 hour. After hot pressing, take out the three-in-one assembly and put it in a 5mol / L NaOH solution, keep it warm at 60°C in an incubator, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com