Three-dimensional graphic surface proton exchange membrane for fuel cell as well as preparation method and application of three-dimensional graphic surface proton exchange membrane

A technology of proton exchange membranes and three-dimensional graphics, applied in fuel cells, battery electrodes, circuits, etc., can solve problems such as environmental pollution by-products, time-consuming, cumbersome processes, etc., to reduce the risk of damage to proton exchange membranes, High efficiency, safe and reliable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

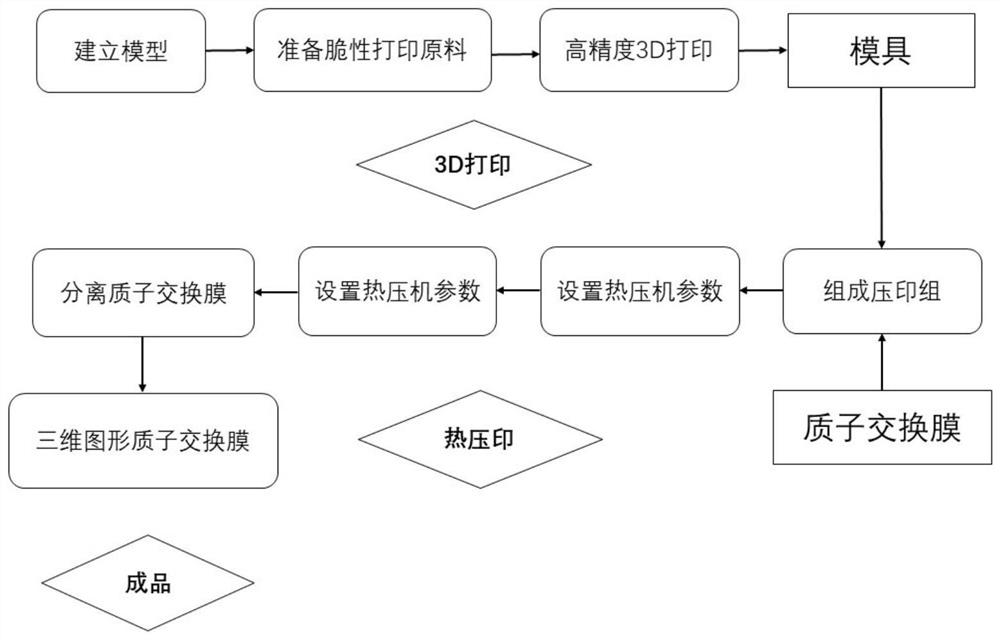

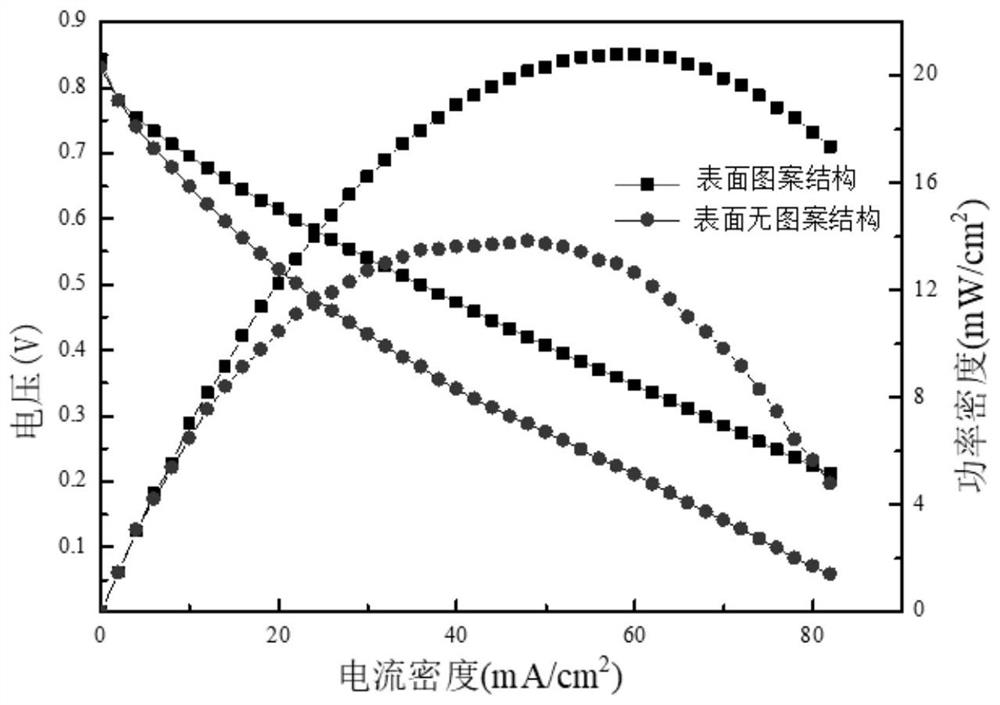

[0030] A method for preparing a proton exchange membrane with a three-dimensional graphic surface for a fuel cell, the preparation process refers to figure 1 , including the following steps:

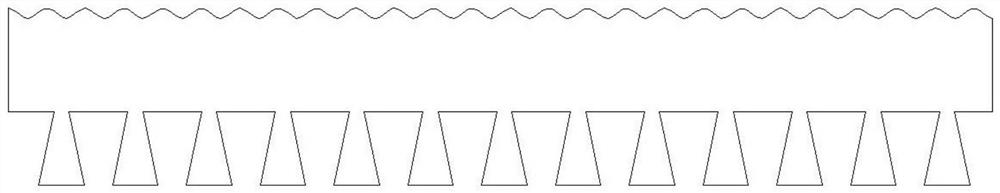

[0031] The first step is to establish a mold model of 2cm*2cm*2mm, the height of 2mm from the side of the graphic is the origin, and the height of the bottom bracket is 1.5mm, which can ensure the flatness of the mold plane during the printing process and ensure the printing accuracy. The total height of the model is 3.5mm, and the surface sine function surface is 0.1mm sin8x (such as figure 2 ). This structure has the effect of reducing the dead zone of the catalyst and reducing the transmission resistance. The raw material of the mold is photosensitive resin, which overcomes the defect that the traditional imprinting process can only use metal mold materials, and has the characteristics of low cost and wide source of materials.

[0032] In the second step, the mold is printed using...

Embodiment 2

[0038] Except that the parameters of the sinusoidal function surface of the mold are changed to 0.1mm sin6x, the rest are the same as in Embodiment 1.

Embodiment 3

[0040] Except that the parameters of the mold sine function surface are changed to 0.1mm sin4x, the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com