Patents

Literature

172results about How to "Guaranteed printing accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

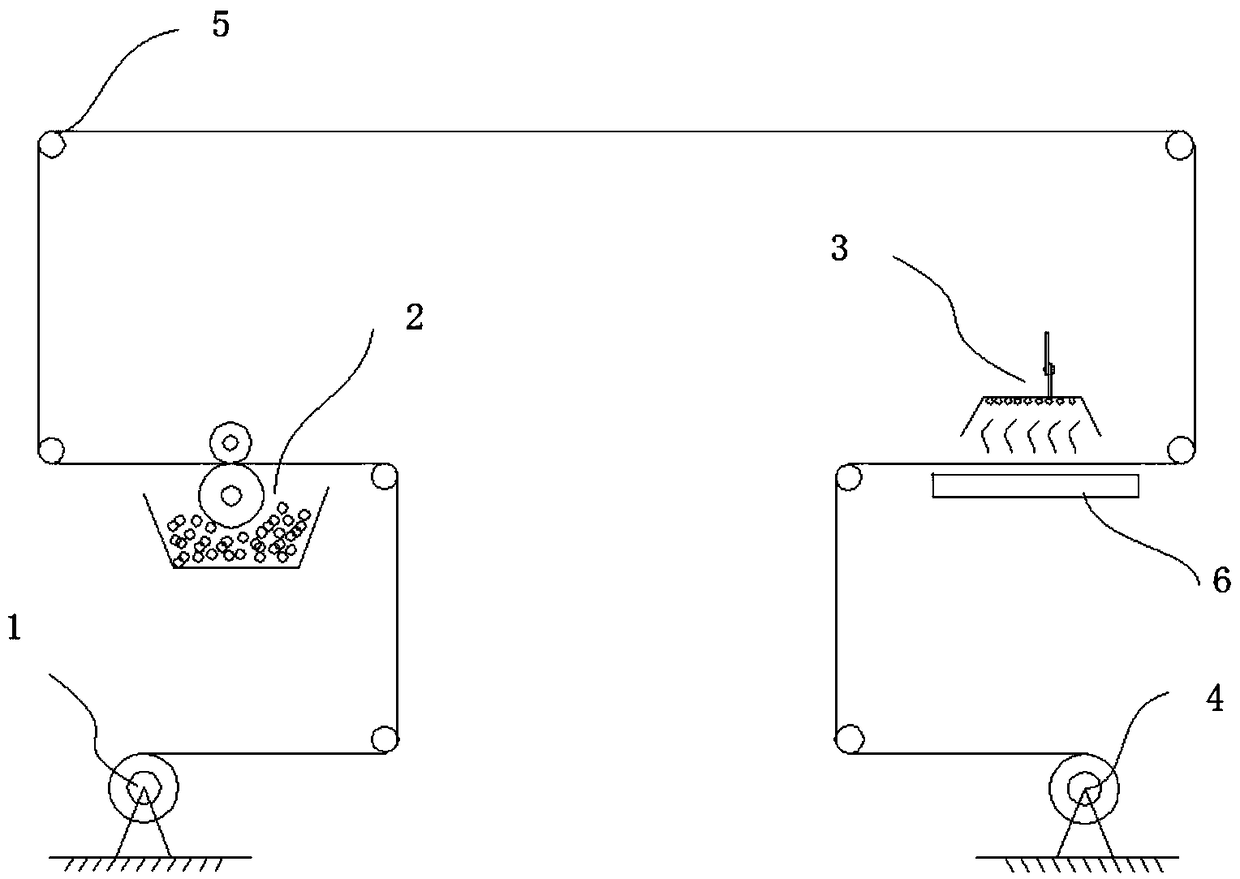

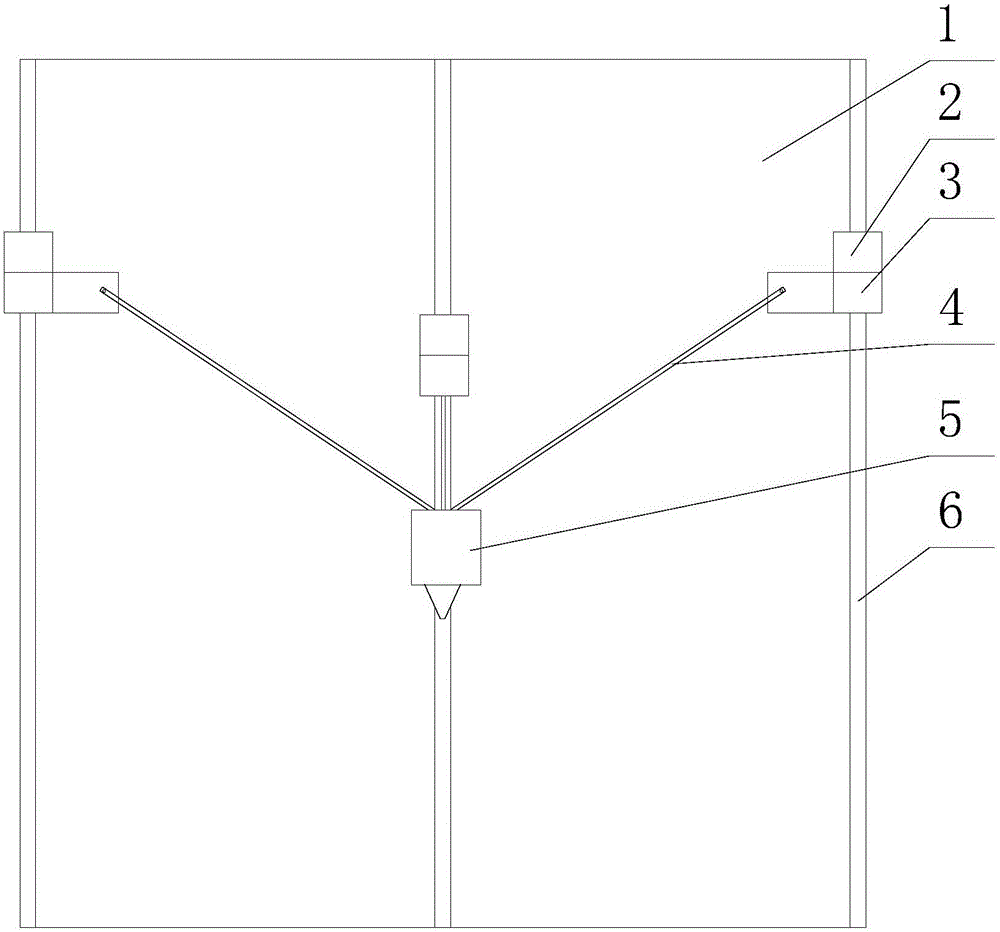

Three-dimensional (3D) rapid forming printing system and method

The invention relates to the field of rapid prototyping and discloses a three-dimensional (3D) rapid forming printing system. The system comprises a personal computer (PC) end with a control unit, an extruder, a printing base plate with a heating function, a servo motor which controls motion of the printing base plate, and a motion control unit, wherein the extruder is positioned above the printing base plate on the top of a body operating area; the servo motor and the printing base plate are positioned below the extruder at the bottom of the body operating area; the motion control unit is an embedded chip group; each chip comprises a task module for executing a control task; the motion control unit is positioned in a chip group slot below the body operating area; the extruder, the servo motor and the printing base plate are respectively and electrically connected with the motion control unit; the motion control unit is electrically connected with the PC end. By virtue of an incremental manufacturing method, namely models are established on the printing base plate layer by layer, rapid manufacturing is realized, processing of any model can be finished, and the system has certain application value and application prospects and can be applied to household and industrial production.

Owner:林岚 +1

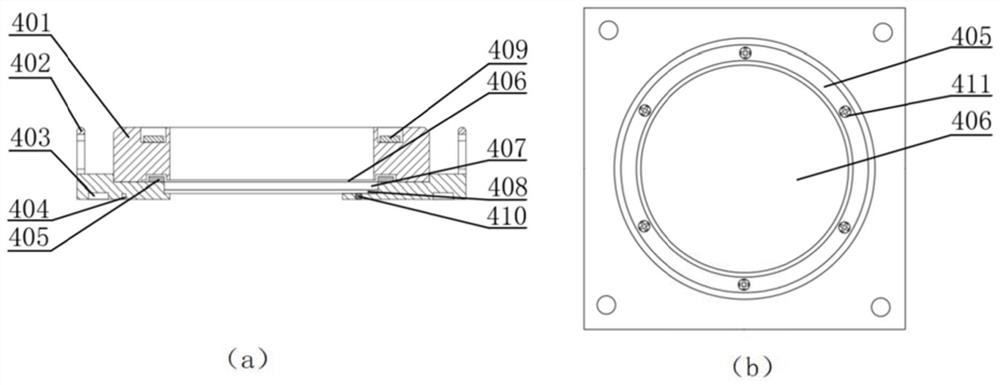

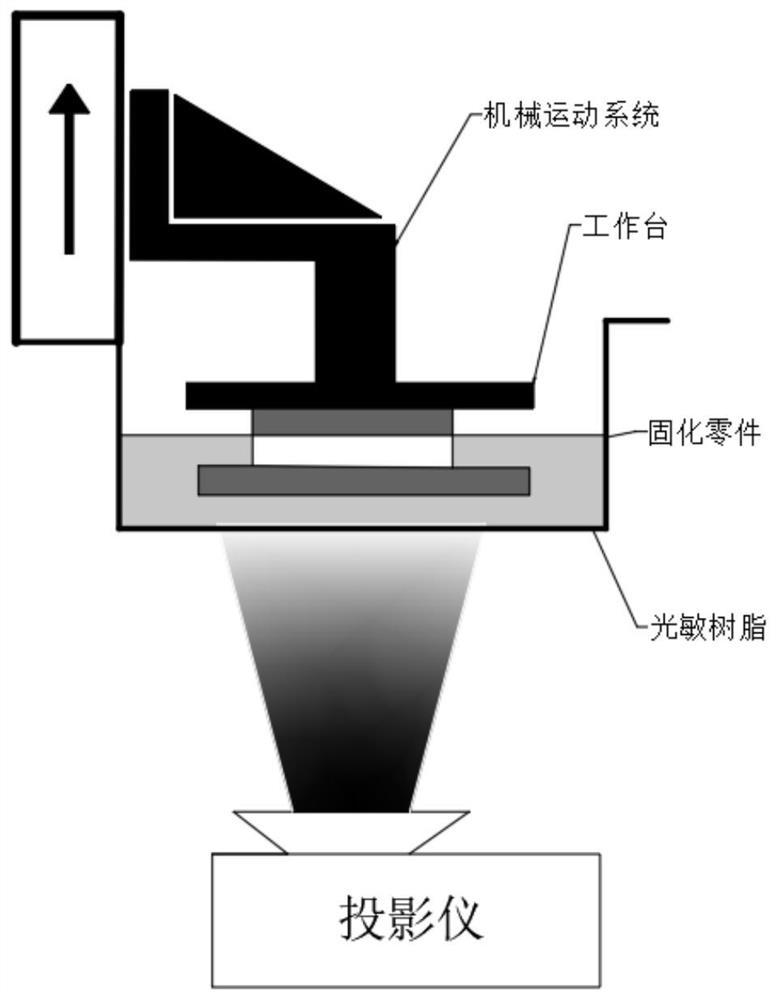

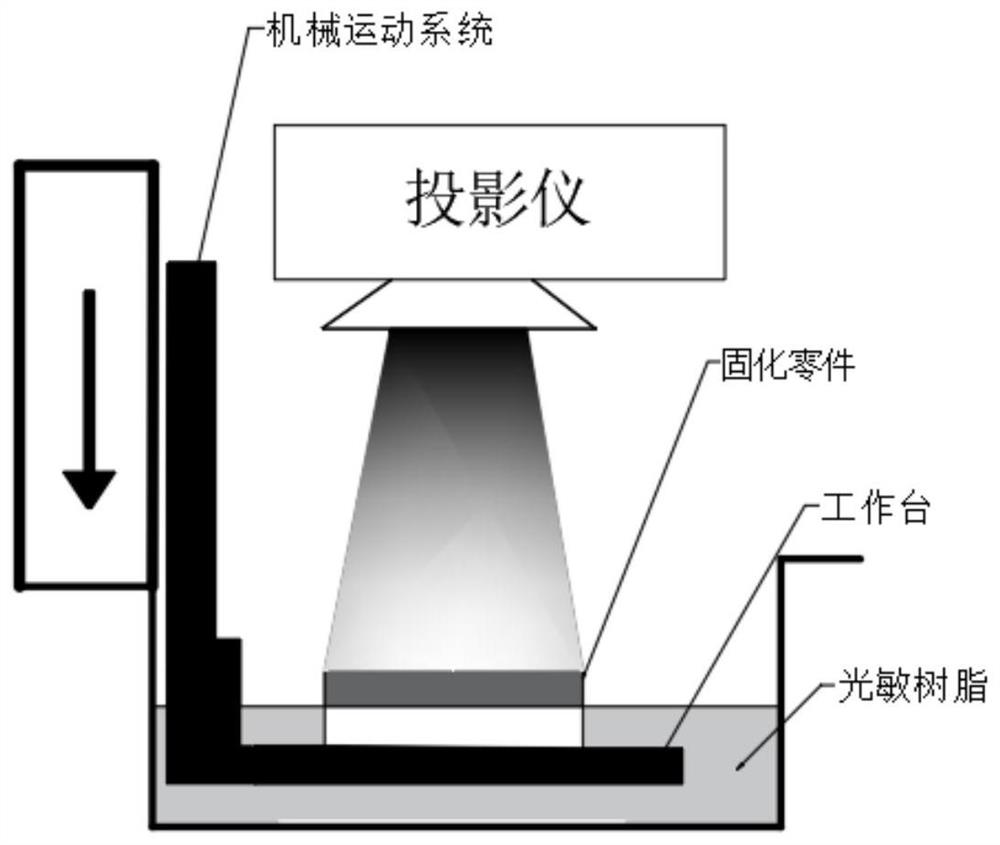

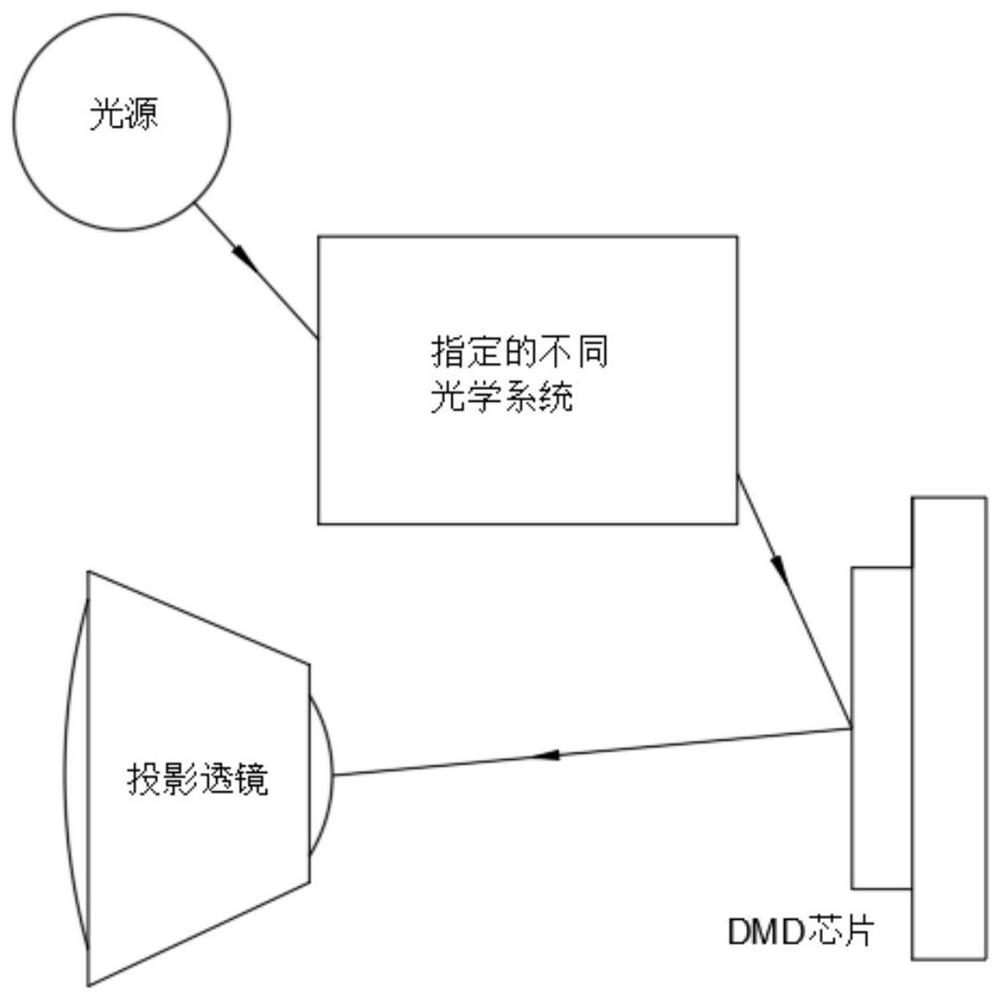

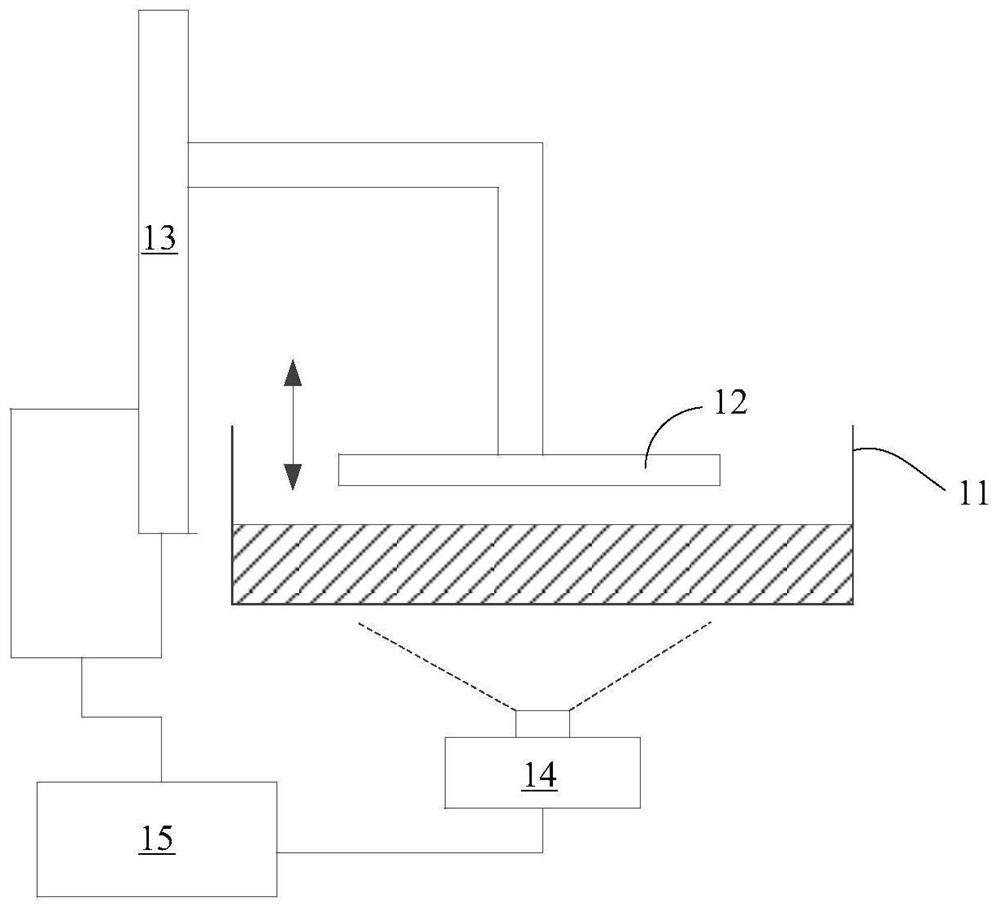

Photo-curing three-dimensional printing method and printing device based on projection

ActiveCN104669625AImprove efficiencyImprove optical power densityAdditive manufacturing apparatusControl systemLocal pattern

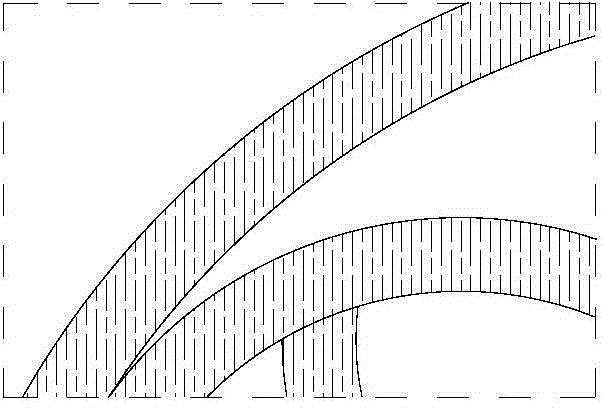

The invention provides a photo-curing three-dimensional printing method and printing device based on projection. The printing method comprises the following steps: a projection system scans, prints and cures layer by layer under the control of a control system; when each layer is printed, the whole pattern needing to be printed on each layer is completed by linearly moving a projection breadth obtained by the projection system in a horizontal plane, and the projection breadth horizontally and linearly moves according to a preset route; during moving, the control system obtains the coordinate position of an area projected by the projection breadth in real time and controls a local pattern, corresponding to the coordinate position, projected by the projection system, and the printing and curing of the local pattern are completed. The projection breadth obtained by the projection system linearly moves in a horizontal plane, namely mobile projection. The large-breadth photo-curing three-dimensional printing can be realized, the printing precision and high efficiency of a projector are ensured, and the printing precision of the whole product is improved.

Owner:SHANGHAI UNION TECH

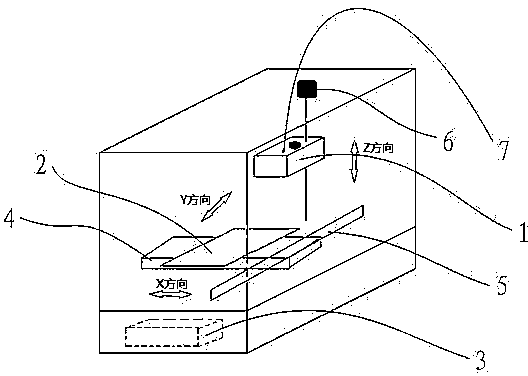

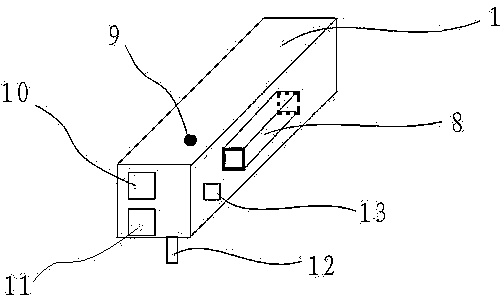

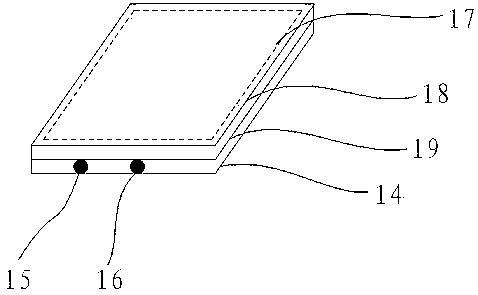

Full-automatic bed leveling device and full-automatic leveling method for 3D printer

InactiveCN104859151AParallel errors cannot be accumulatedGuaranteed printing accuracyAdditive manufacturing apparatusGraphicsComputer printing

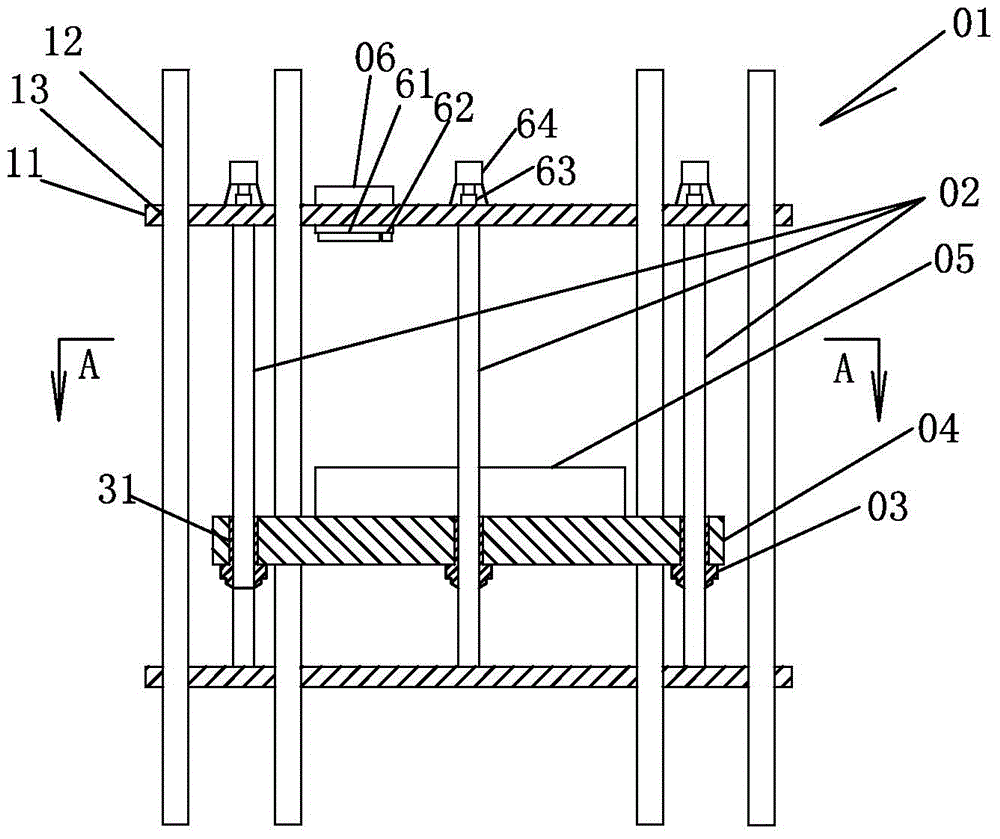

A full-automatic bed leveling device for a 3D printer comprises a bed, a moving mechanism fixed with an infrared distance measurement sensor and a nozzle, a fixed frame, a plurality of parallel lead screw pairs and supporting stepper motors, wherein the moving mechanism drives the nozzle to move horizontally in the fixed frame; the stepper motors drive the lead screw pairs fixed in the fixed frame to move and drive a borne bed to move vertically; the center of gravity of the bed is close to or coincides with the center of a limited plane of the fixed frame and approaches the boundary of a figure defined by the lead screw pairs. According to the full-automatic bed leveling device for the 3D printer, the parallel degree of a bearing surface of the bed stepping along a Z axis is measured in due time by the moving mechanism moving on an X-Y-axis horizontal surface, tiny errors among support mechanisms during stepping along the Z axis are obtained through multi-point measurement, and adjustment is performed timely, so that parallel errors cannot be accumulated. Deviation of the surface height in a consumable curing process is avoided, and the printing accuracy is guaranteed. The invention further provides a full-automatic leveling device.

Owner:SHENZHEN COPREATES TECH CO LTD

High-speed printing head of 3D printer

InactiveCN104552949AImprove liquidityInhibit refluxAdditive manufacturing apparatusHydraulic cylinderSpray nozzle

The invention discloses a high-speed printing head of a 3D (three-dimensional) printer. The printing head comprises a rack, wherein a hydraulic cylinder is fixed above the rack; a piston of the hydraulic cylinder is fixed with a feeding device capable of sliding up and down along the rack; an outlet of the feeding device is communicated with a nozzle structure through a volumetric metering pump; a feeding pipe is longitudinally arranged on the rack; the feeding device comprises a drive device and a screw rod driven by the drive device to rotate; the feeding pipe encircles the screw rod; a feeding hole is formed above the feeding pipe; a feeding hot-melting cavity is formed below the feeding pipe; the end of the screw rod is sleeved with a one-way valve; the nozzle structure comprises a nozzle pipe communicated with the volumetric metering pump; a multi-nozzle head is rotationally arranged at an outlet end of the nozzle pipe and provided with at least two nozzles with different pore diameters; when an opening, rotated to any nozzle, of the multi-nozzle head points to a workpiece, only the nozzle is communicated with the nozzle pipe; the multi-nozzle head is driven by a rotary power device to rotate. The printing head has the advantages that the printing speed can be increased while a high-precision printing effect is guaranteed.

Owner:SHENZHEN WANWEI IM TECH CO LTD

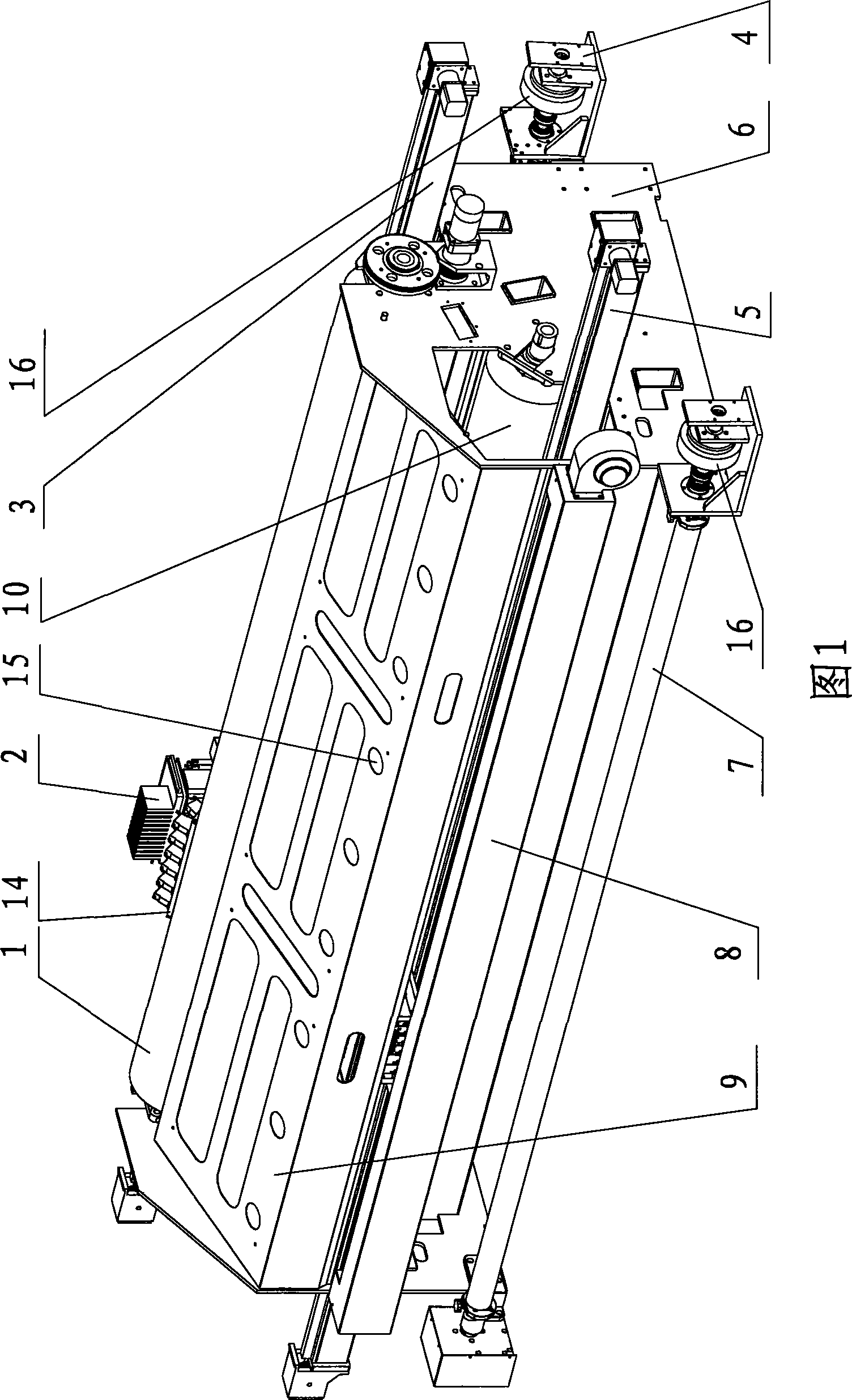

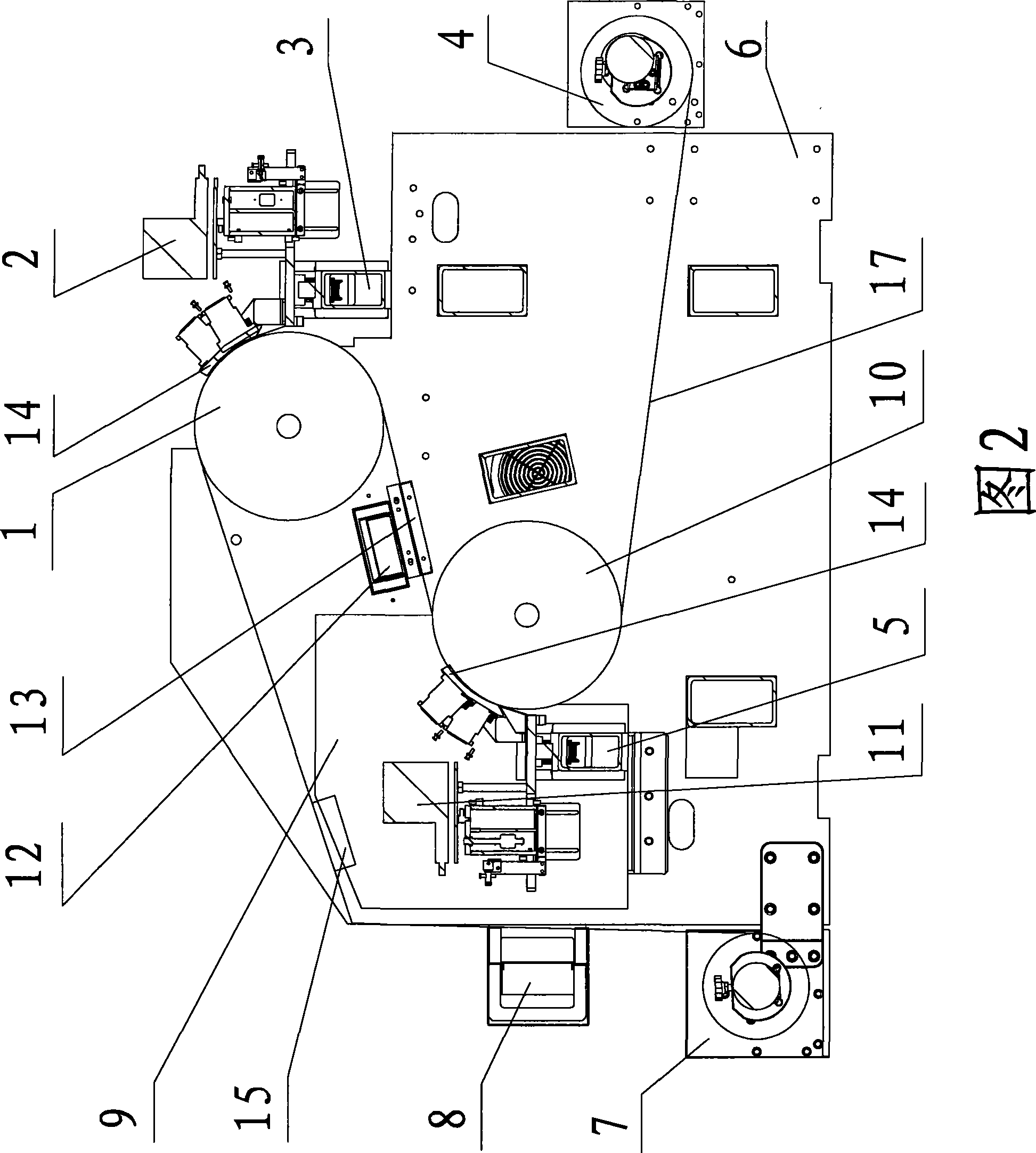

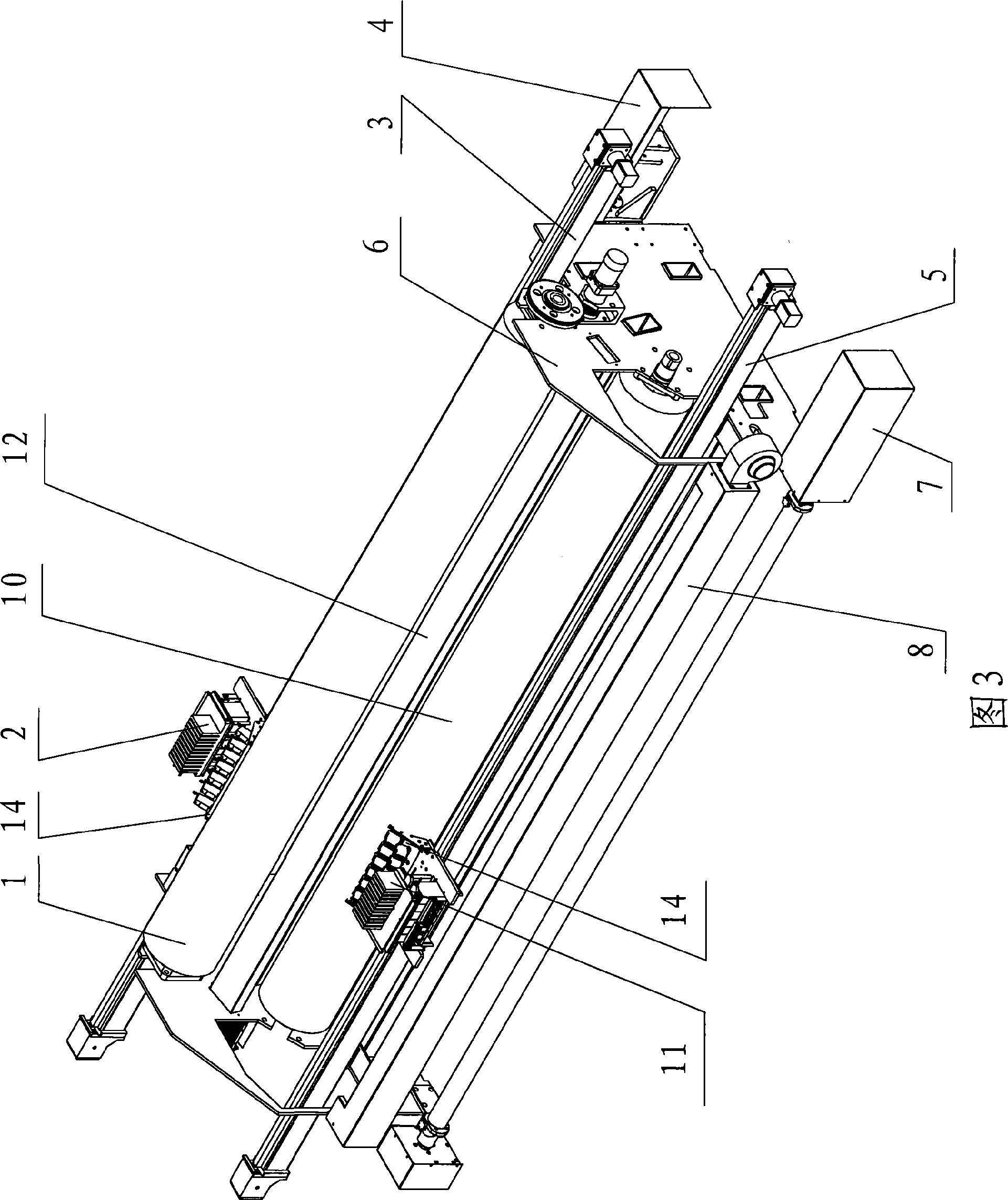

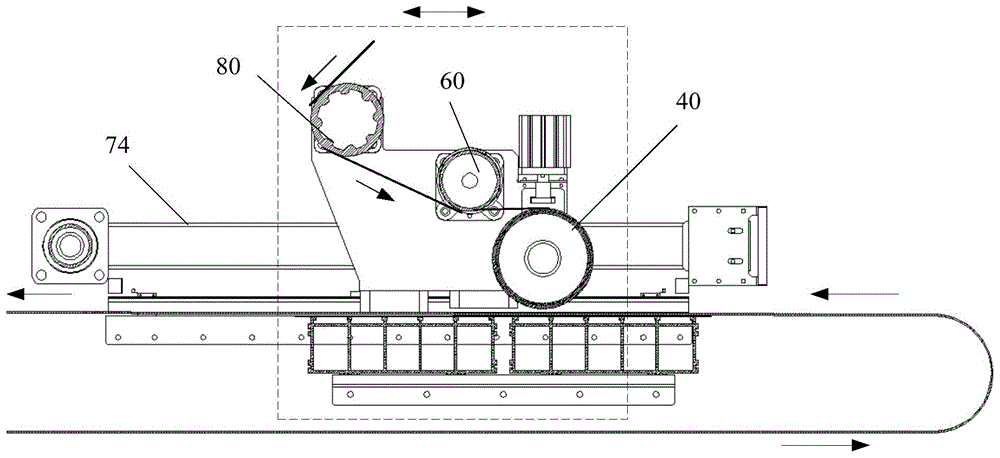

Synchronous two-sided digital ink-jet machine

InactiveCN101439620AWidth limitEnsure printing accuracyTypewritersOther printing apparatusEngineeringMechanical engineering

The invention relates to an inkjet printing device, in particular to a synchronous double-face digital inkjet printing machine which can realize individual inkjet printing without printing width limitation. The device comprises a wall plate, a cloth takeup and placing device which is arranged on the wall plate, an auxiliary inkjet printing roll with the same diameter as a main inkjet printing roll is alternately arranged with the main inkjet printing roll between the wall plates, and the auxiliary inkjet printing roll is driven by the main inkjet printing roll through a material to be printed; the printing material winds the main inkjet printing roll and the auxiliary inkjet printing roll with the front face and the rear face contacting the main inkjet printing roll and the auxiliary inkjet printing roll respectively, and a bearing plate is arranged below the material to be printed between the inkjet printing rolls; one sides of the main inkjet printing roll and the auxiliary inkjet printing roll are equipped with an upper jet head set and a lower jet head set which can reciprocate and an ink supply larry. The jet head sets can horizontally reciprocate for inkjet printing, can print wide printing materials without limitation by the width of the jet head sets; the material to be printed always wind the inkjet printing rolls at the front printing point and the rear printing point without warping and buckling, and the jet heads get close to the material to be printed; the main inkjet printing roll drives the auxiliary inkjet printing roll, which ensures the inkjet printing precision of the two faces.

Owner:沈阳飞图印花科技有限公司

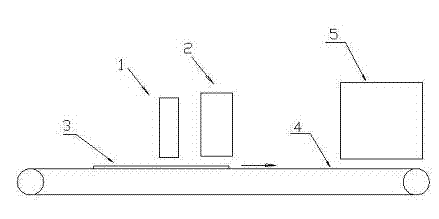

Ink jet-printing curing device and operating method thereof

The invention discloses an ink jet-printing curing device, which comprises a conveyor belt. A print base material is arranged on the conveyor belt; a nozzle, a pre-curing device and a final curing device are arranged above the print base material from left to right in turn; the pre-curing device is an ultraviolet light-emitting diode (LED) curing lamp with the wavelength ranging from 280 to 410 nanometers; a distance between the ultraviolet LED curing lamp and the nozzle is adjustable in a range of 2-30 centimeters; LED chips are arranged in the ultraviolet LED curing lamp; the power of a single LED chip is 2-12 watts; the LED chips are densely arranged to form a line source or a surface source; and the final curing device is a high pressure mercury lamp or a metal halid lamp. By combining the operating method for the curing device, the surface of ink can be effectively cured, the ink is prevented from penetrating the base material and flowing on the base material, positions of ink spots are fixed, the morphology is controlled, the compatibility with ink types is improved, and defects that heat productivity is high, switch-on and switch-off cannot be frequently carried out, and a volume is large are overcome.

Owner:KUSN ZHENGYE ELECTRONICS

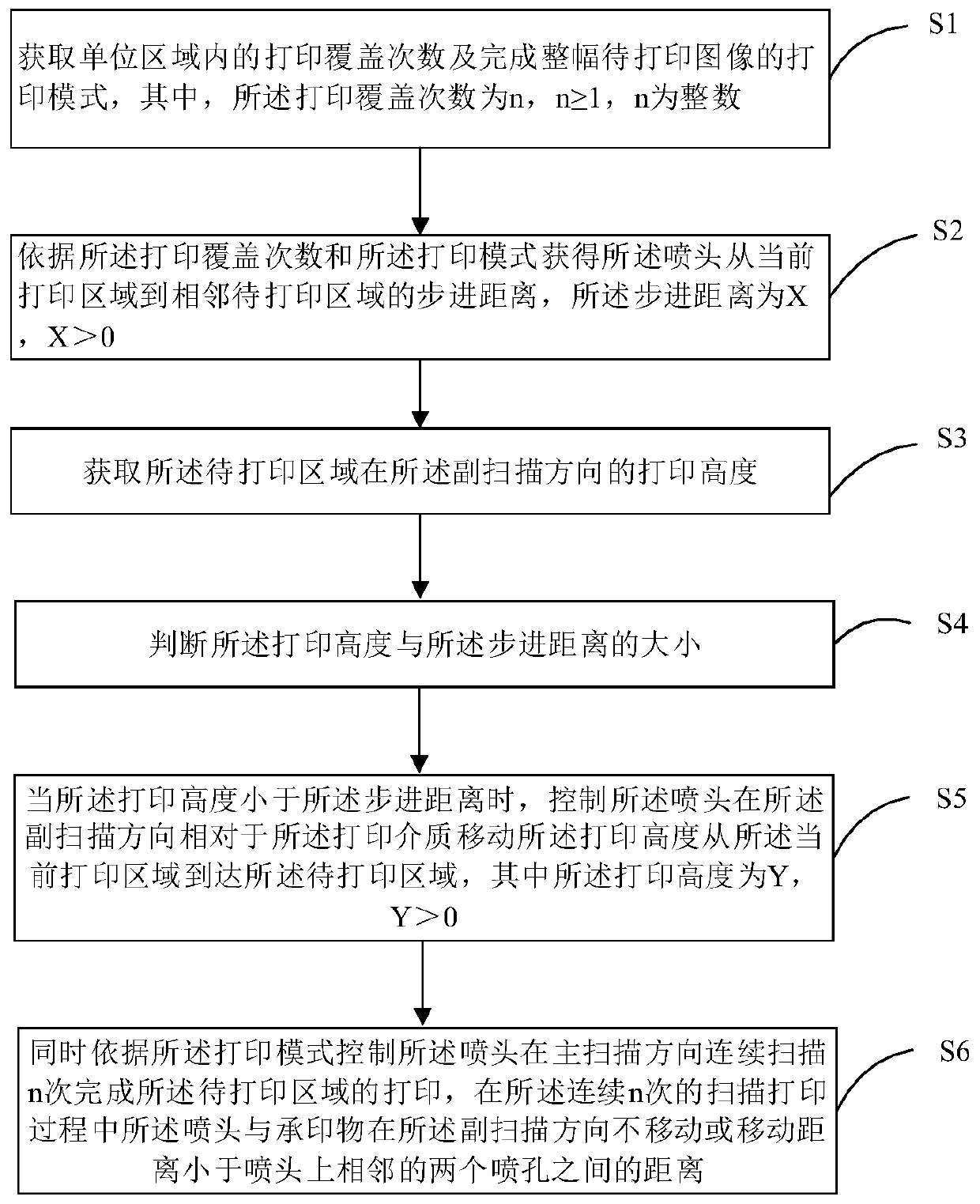

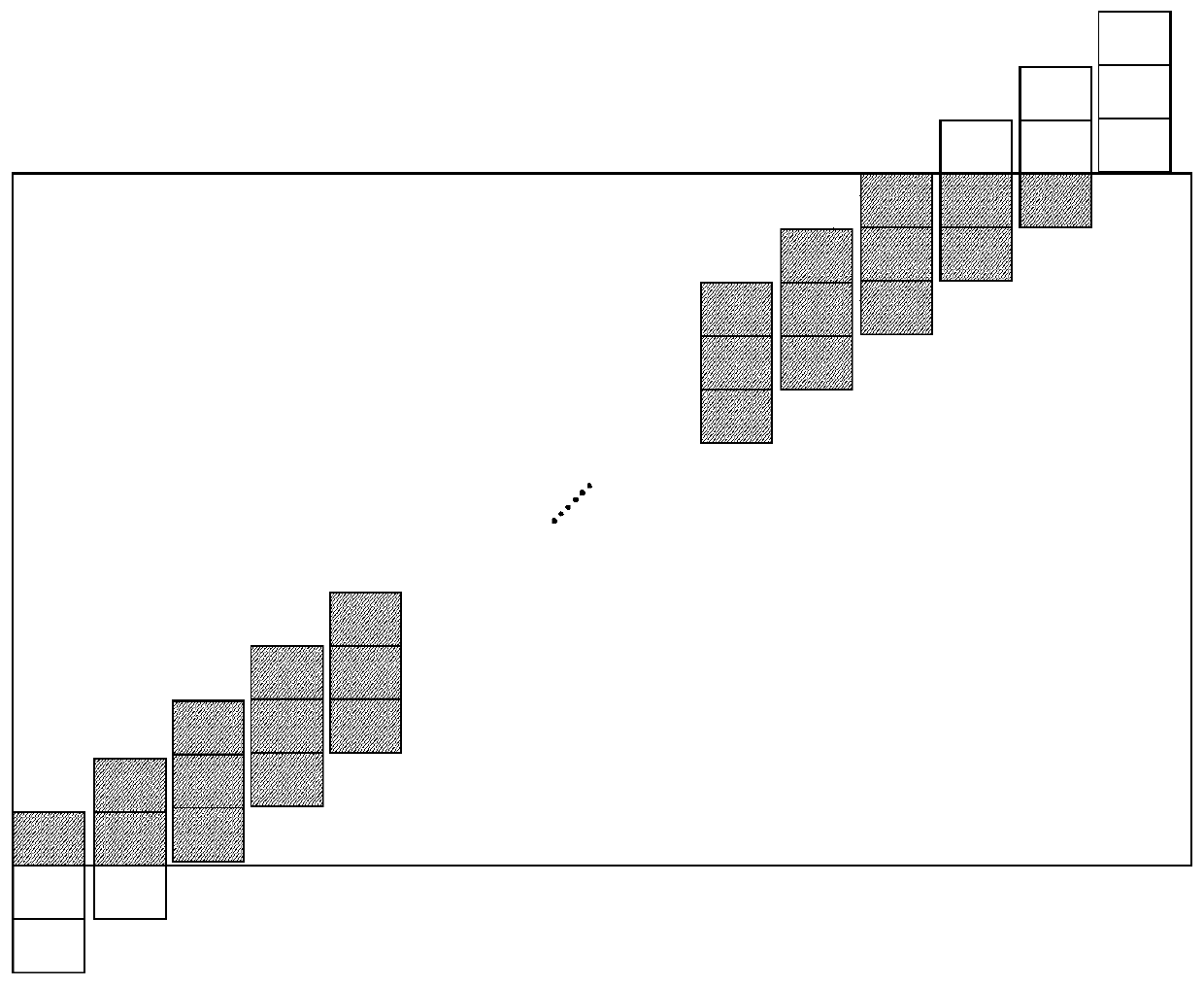

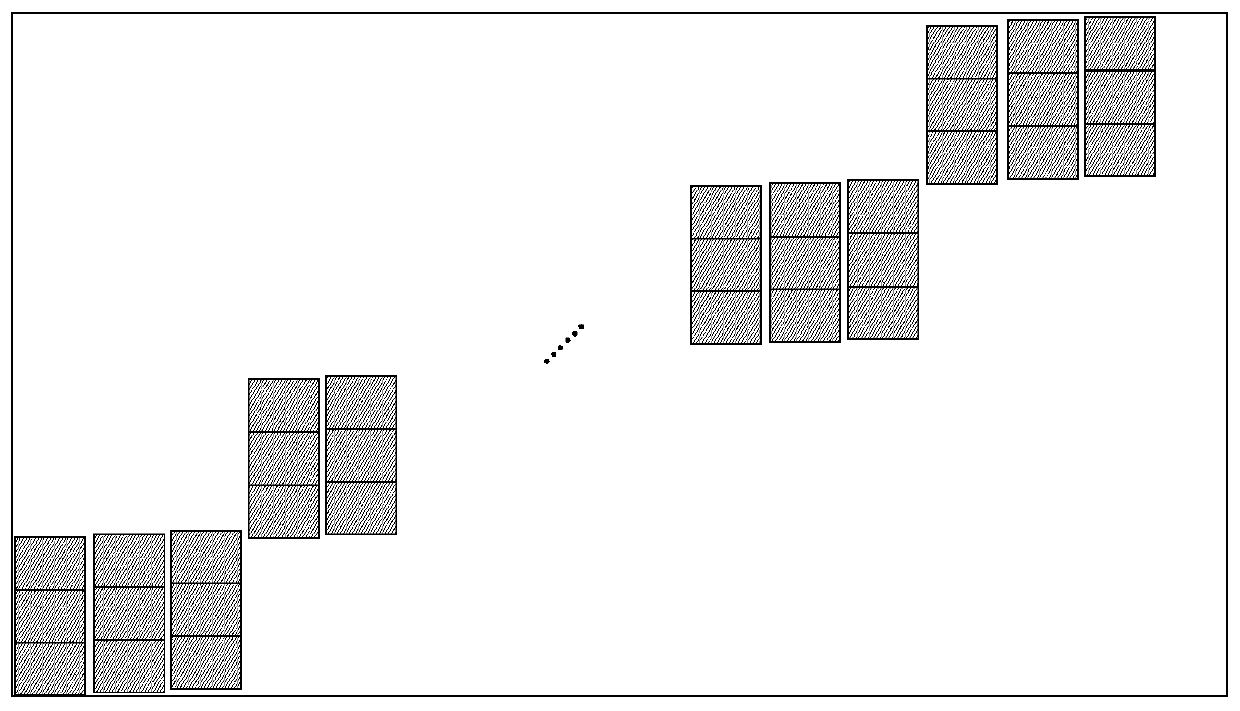

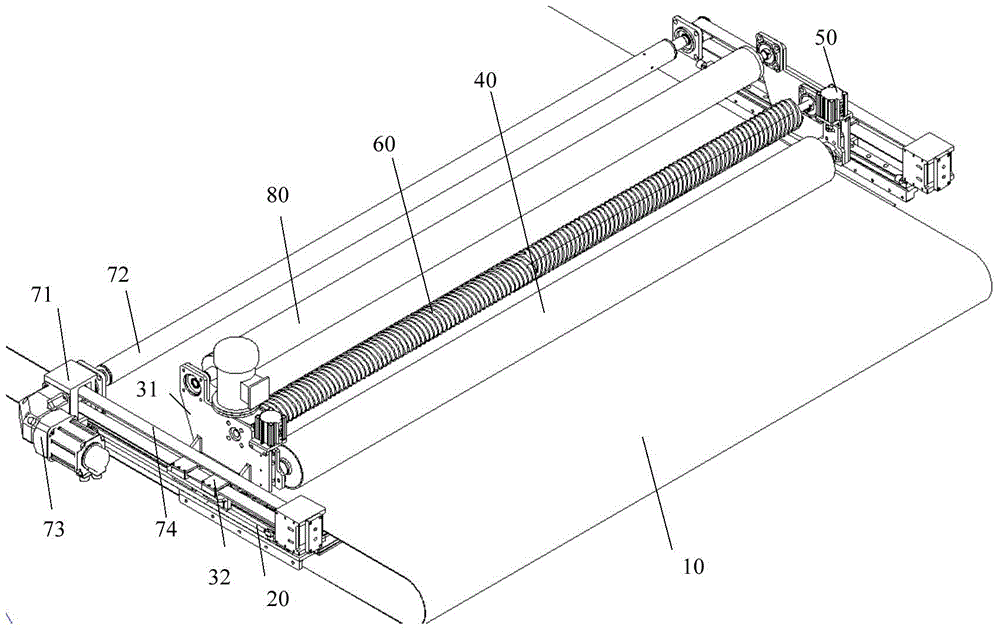

Reciprocating type scanning printing control method and device, equipment and storage medium

ActiveCN110421984AIncrease profitRealize printingOther printing apparatusDigital output to print unitsSpray nozzleEngineering

The invention discloses a reciprocating type scanning printing control method and device, equipment and a storage medium. According to the method, the number of printing coverage times in a unit areaand a printing mode for completing a whole image to be printed are obtained, and according to the number of printing coverage times and the printing mode, the stepping distance of a spraying head fromthe current printing area to the adjacent area to be printed is obtained; the printing height of the area to be printed in the auxiliary scanning direction is obtained; the size of the printing height and the stepping distance is judged; when the printing height is smaller than the stepping distance, the spraying head is controlled to move the printing height to the area to be printed relative tothe printing medium in the auxiliary scanning direction; meanwhile, according to the printing mode, the spraying head is controlled to carry out continuous scanning for n times in the main scanning direction to complete printing of the area to be printed, and in the scanning printing process of n times, the spraying head and a printed material do not move in the auxiliary scanning direction, or the moving distance is smaller than the distance between two adjacent nozzles on the spraying head. The method increases the utilization rate of a printing platform, and printing of any width can be achieved.

Owner:SHENZHEN HOSONSOFT CO LTD

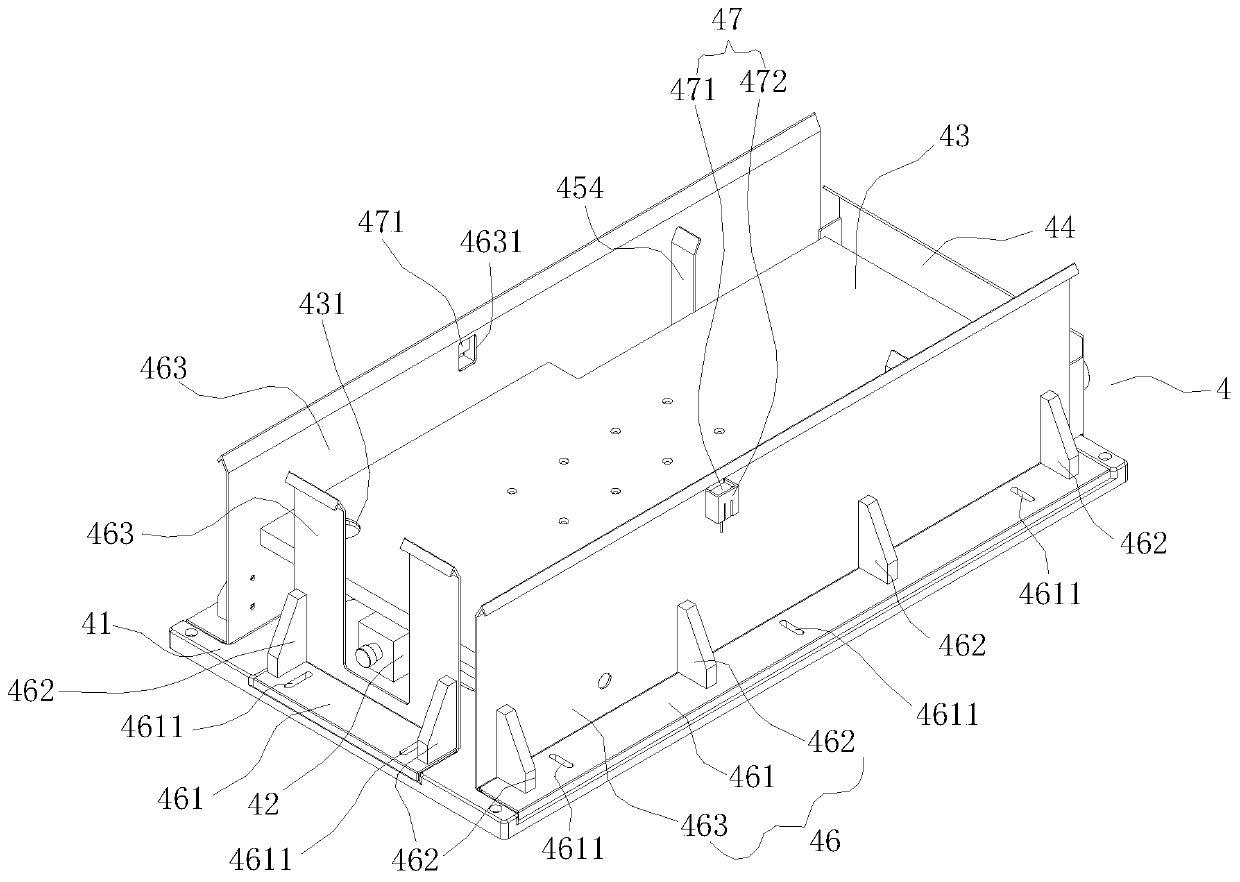

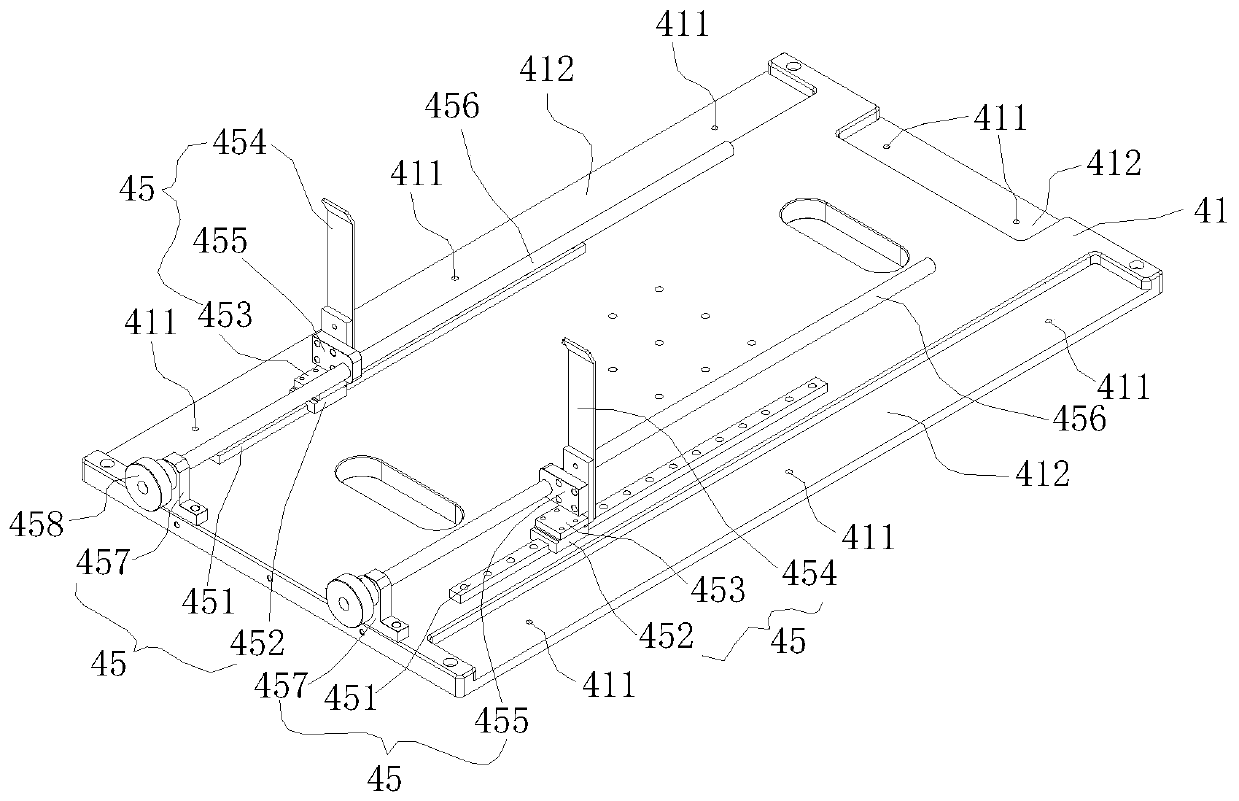

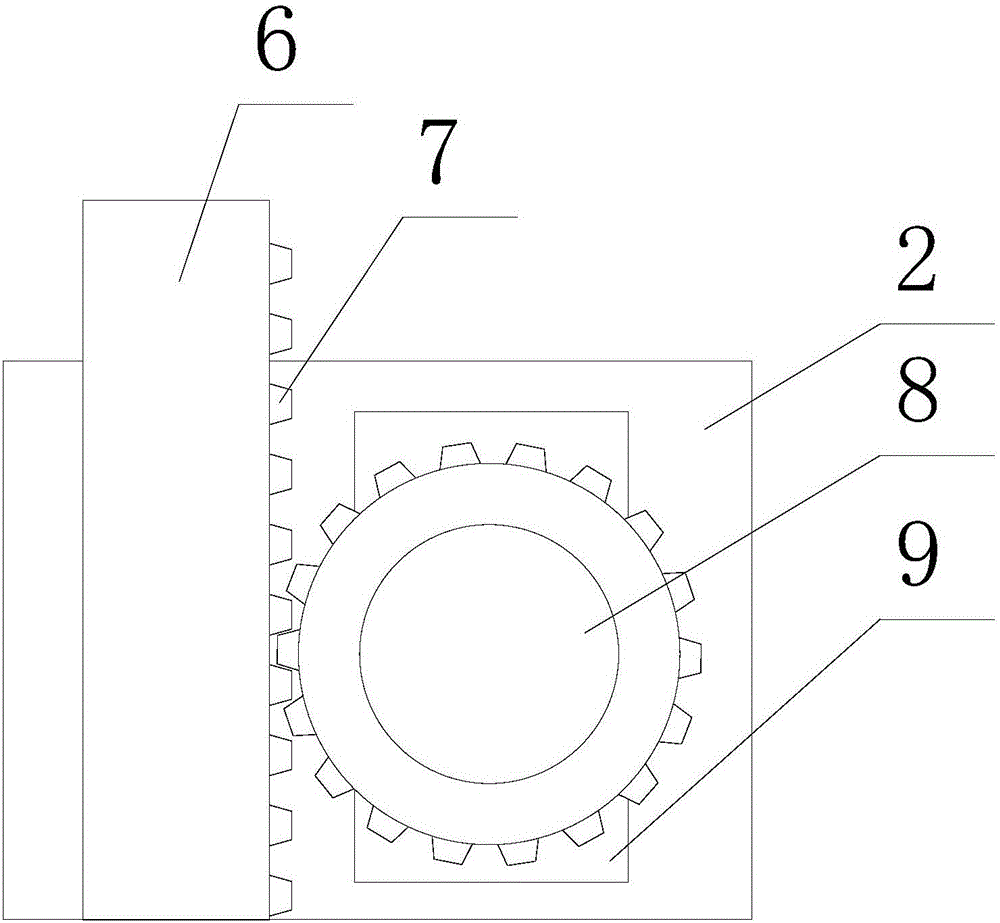

Cloth spreading device of digital printing machine

ActiveCN104476913AGuaranteed printing qualityGuaranteed printing accuracyRotary pressesEngineeringDigital printing

The invention provides a cloth spreading device of a digital printing machine. The two sides of a guide belt of the digital printing machine are each provided with a sliding rail. A sliding mechanism is mounted on each sliding rail. The two ends of a cloth pressing roll and the two ends of a two-way spreading roll are mounted on the sliding mechanisms located on the two sides of the guide belt respectively. Therefore, in the operating process, when a textile arrives at a feed port, the two-way spreading roll makes the textile completely spread out in the transverse direction so as to guarantee that the textile can smoothly arrive at the cloth pressing roll; through control over thrust of air cylinders and under the action of self weight of the cloth pressing roll, the textile is pressed by the cloth pressing roll onto the upper surface of the guide belt and effectively pasted to the surface of the guide belt, and a servo power mechanism controls movement of the cloth pressing roll on the sliding mechanisms so as to make the cloth pressing roll and the guide belt move relatively and synchronously. As a result, the textile on the cloth pressing roll is smoothly pasted to the guide belt in a wrinkleless mode, and subsequent printing quality and accuracy are guaranteed.

Owner:SHENZHEN RUNTIANZHI DIGITAL EQUIP

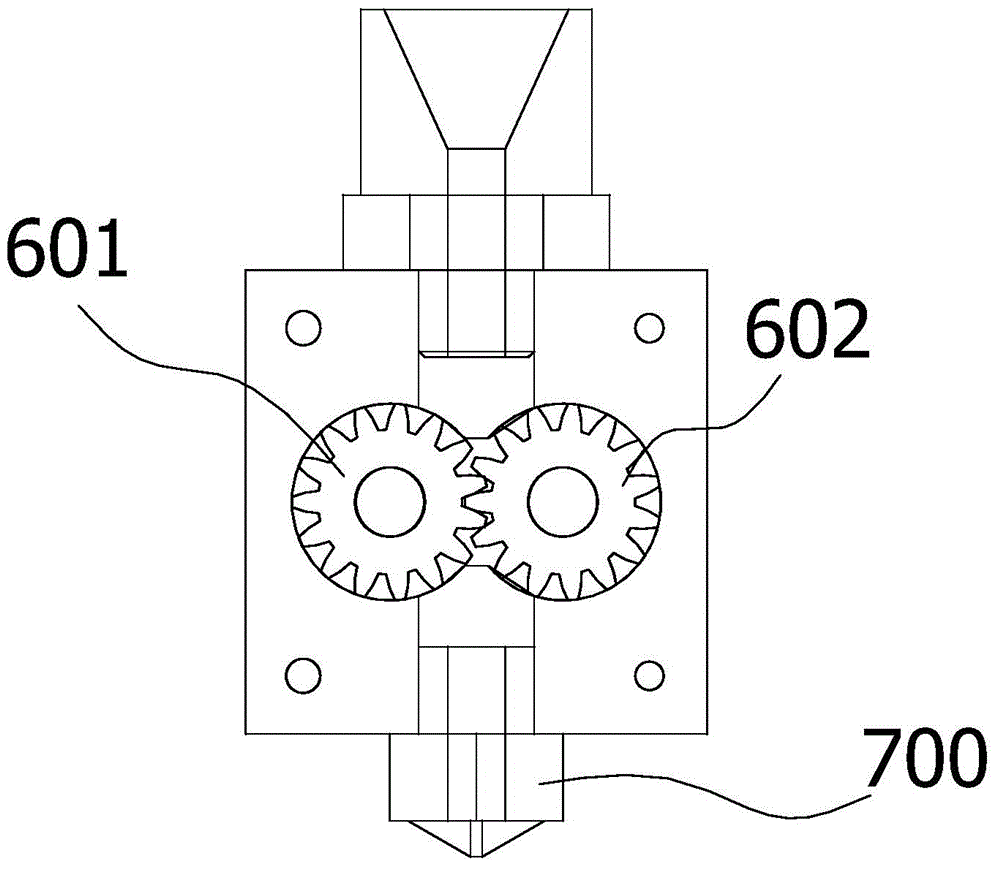

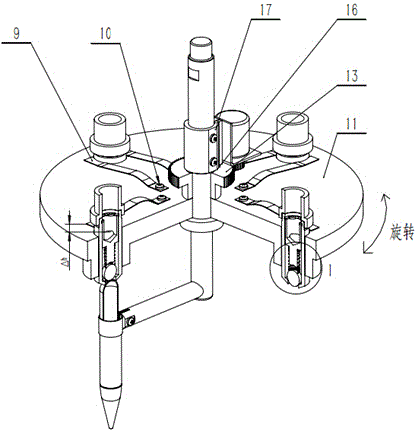

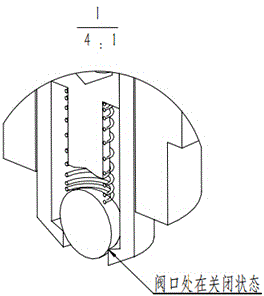

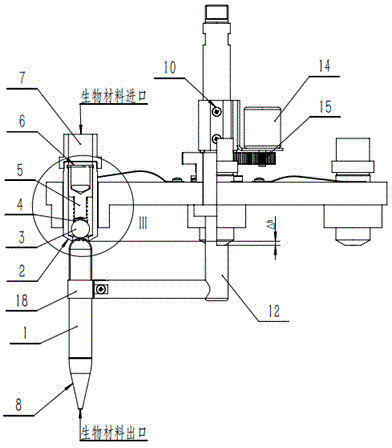

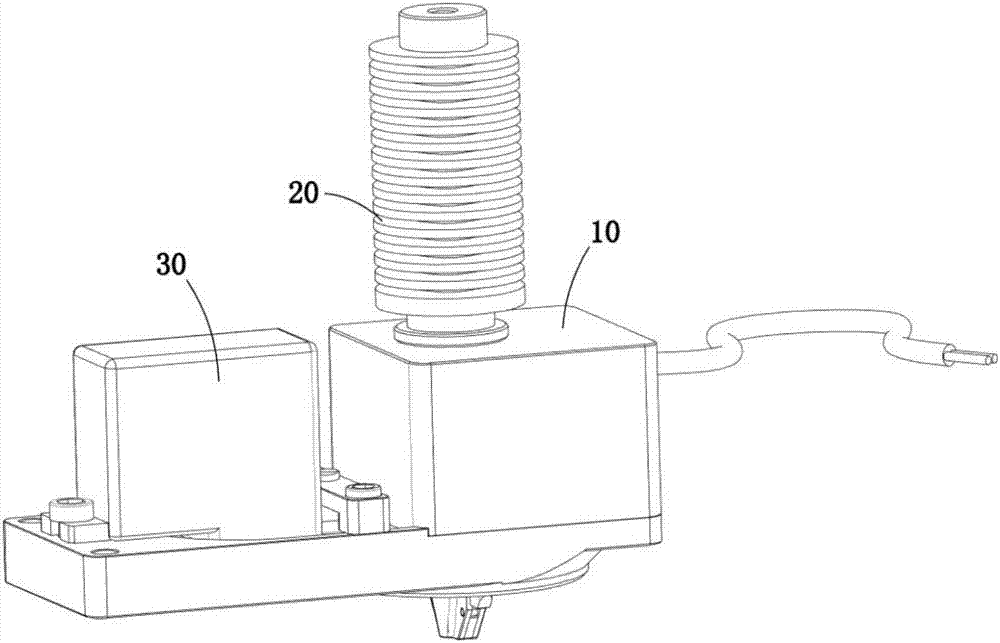

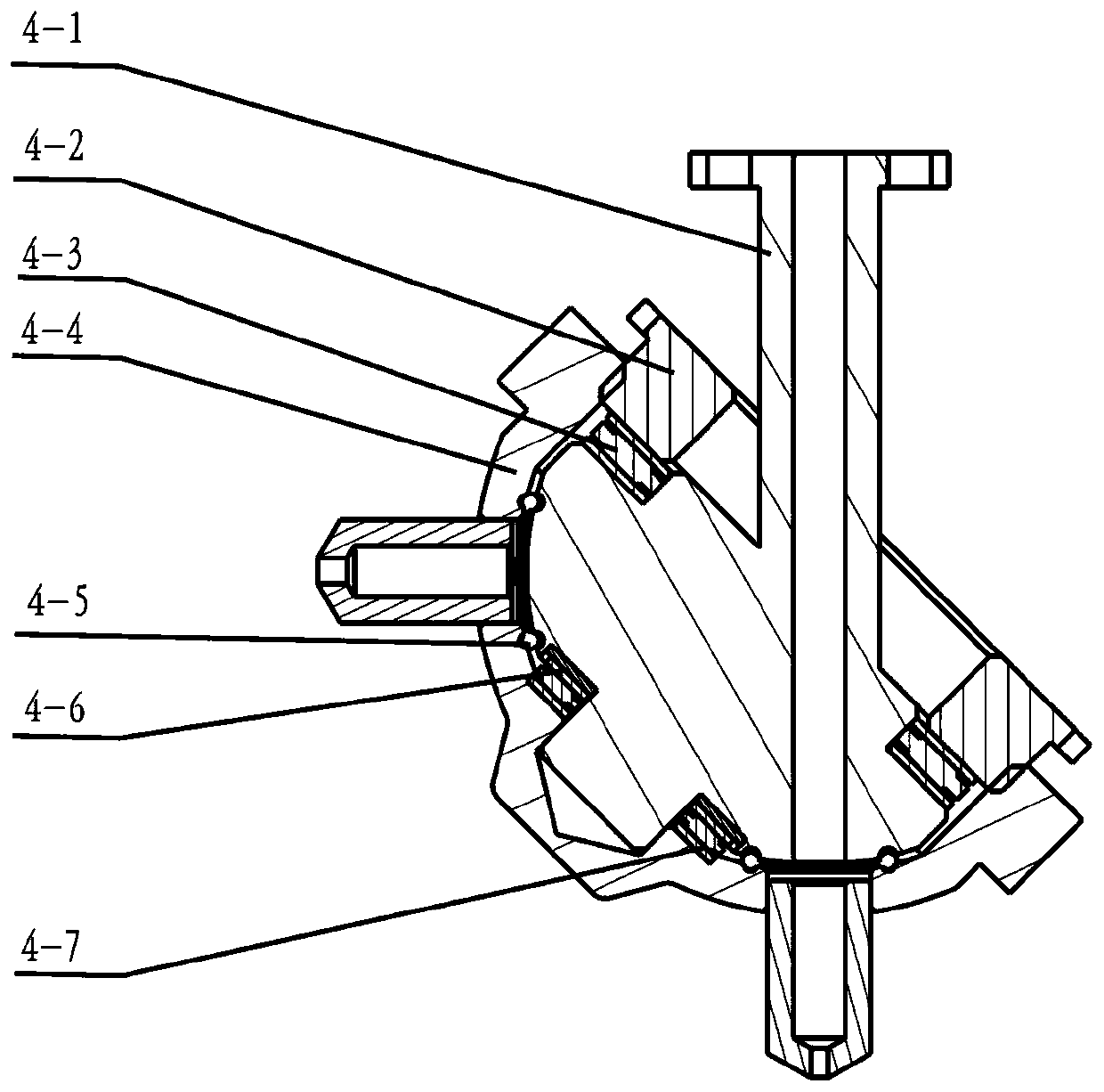

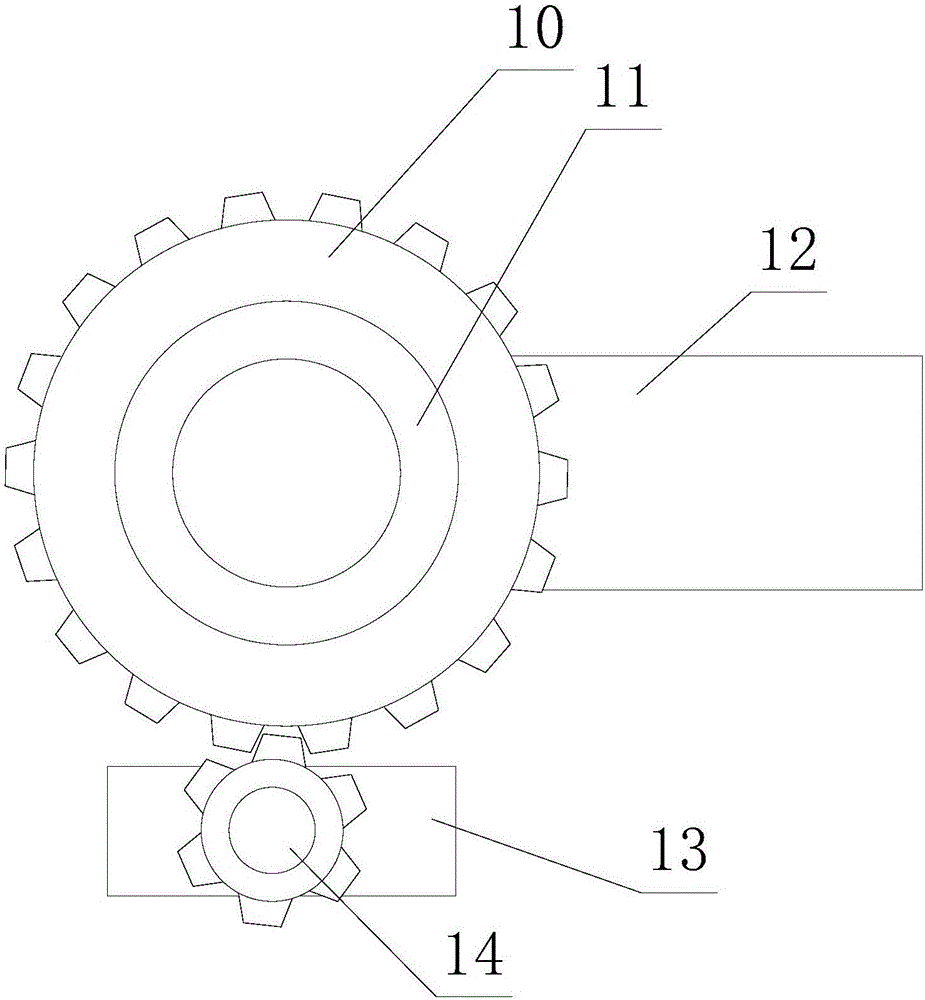

Single-sprayer multi-source biological 3D (three-dimension) printing device and method thereof

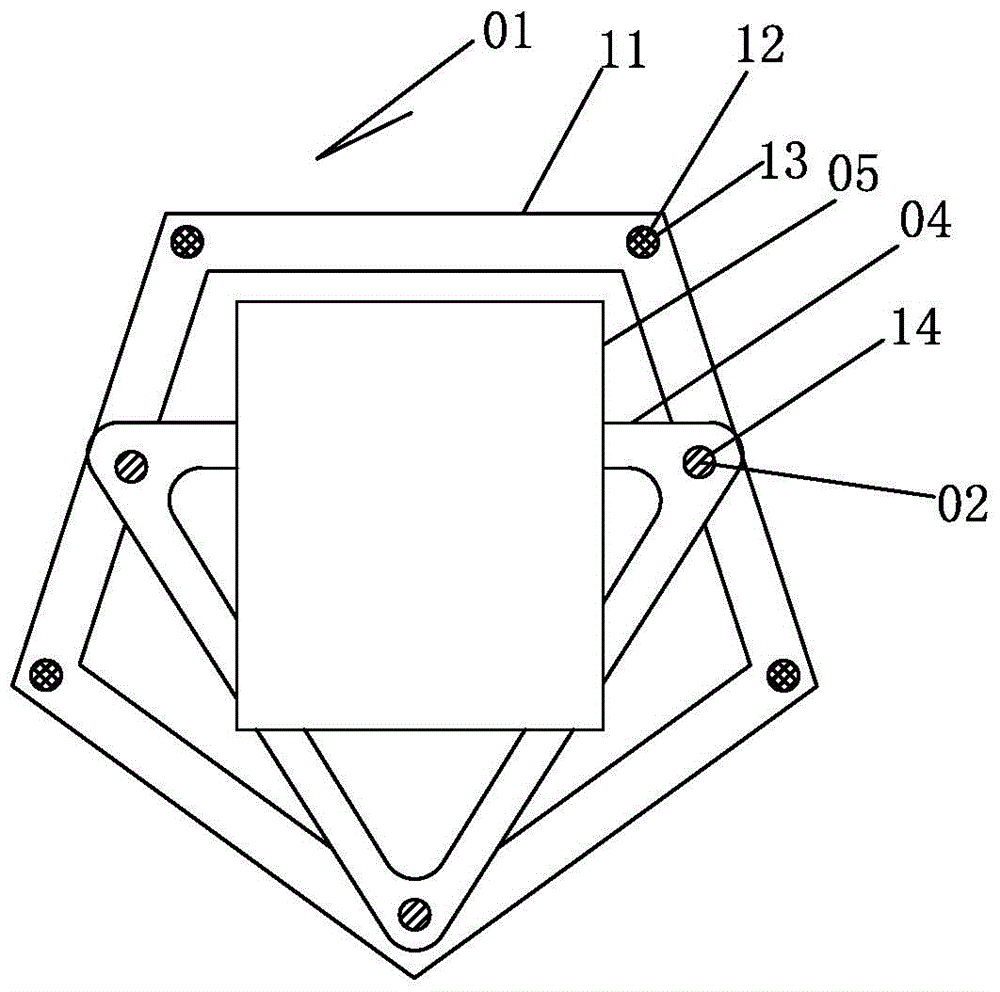

ActiveCN104921840AGuaranteed printing accuracyImprove printing efficiencyAdditive manufacturing apparatusProsthesisSprayerHeight difference

The invention discloses a single-sprayer multi-source biological 3D (three-dimension) printing device and a method thereof, and belongs to the field of tissue engineering and biological 3D printing. The single-sprayer multi-source biological 3D printing device comprises a motor fixing base, an electric motor, an active gear, a fixing rotary shaft, a turntable joining piece, a sprayer body, a unidirectional connecting valve, a spring sheet, a feeding pipe joint and other structures; the fixing rotary shaft is installed and fixed, the electric motor drives a turntable to rotate through a gear transmission belt; the unidirectional connecting valve on the turntable is clamped and pressed through two spring sheets, a height difference delta h forms between the unidirectional connecting valve and the sprayer body; when the unidirectional connecting valve is rotated to the sprayer body, the sprayer body props up the unidirectional connecting valve, and a steel ball is propped up to connect the sprayer body with the unidirectional connecting valve; the spring sheet is popped up to press the unidirectional connecting valve; meanwhile, biological materials enter through the feeding pipe joint so as to realize the printing process. Through rotating the turntable, the printing material can be switched to print multiple biological materials with a single sprayer. The single-sprayer multi-source biological 3D (three-dimension) printing device is simple and ingenious in structure, reduces cost, and is easy to realize the flexible control; besides, the printing efficiency is greatly improved.

Owner:ZHEJIANG UNIV

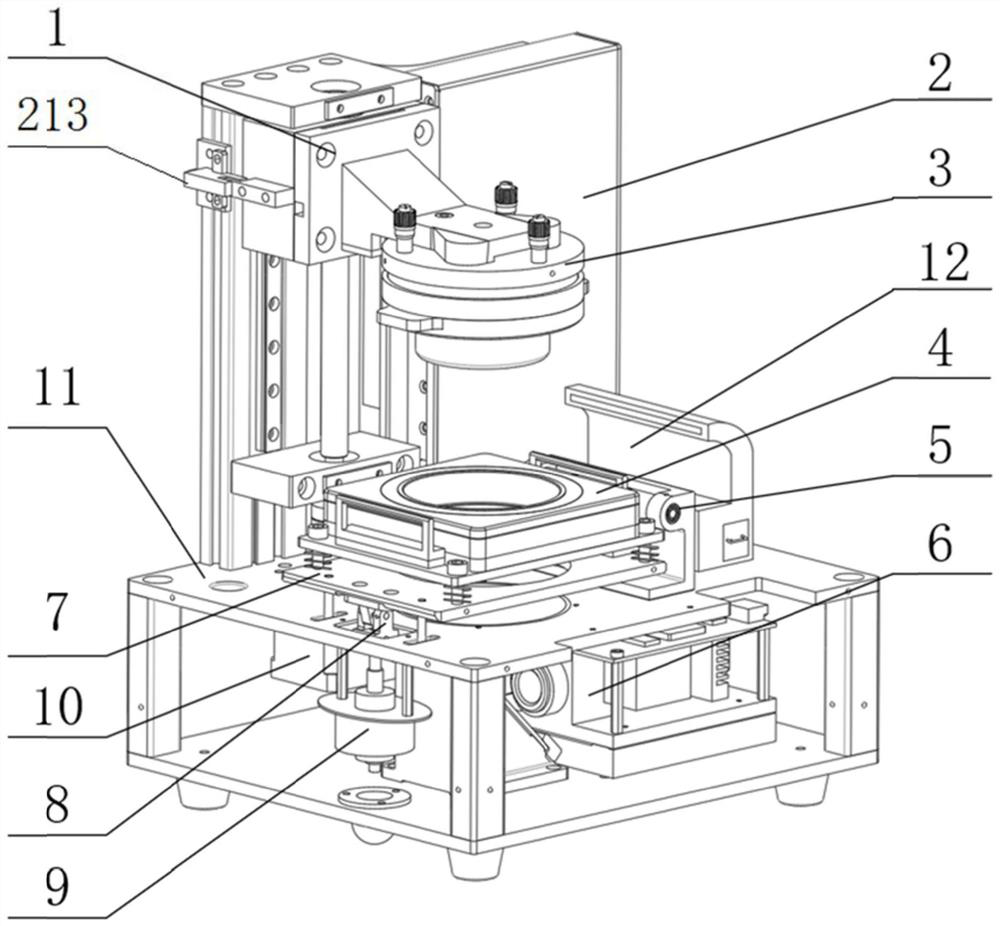

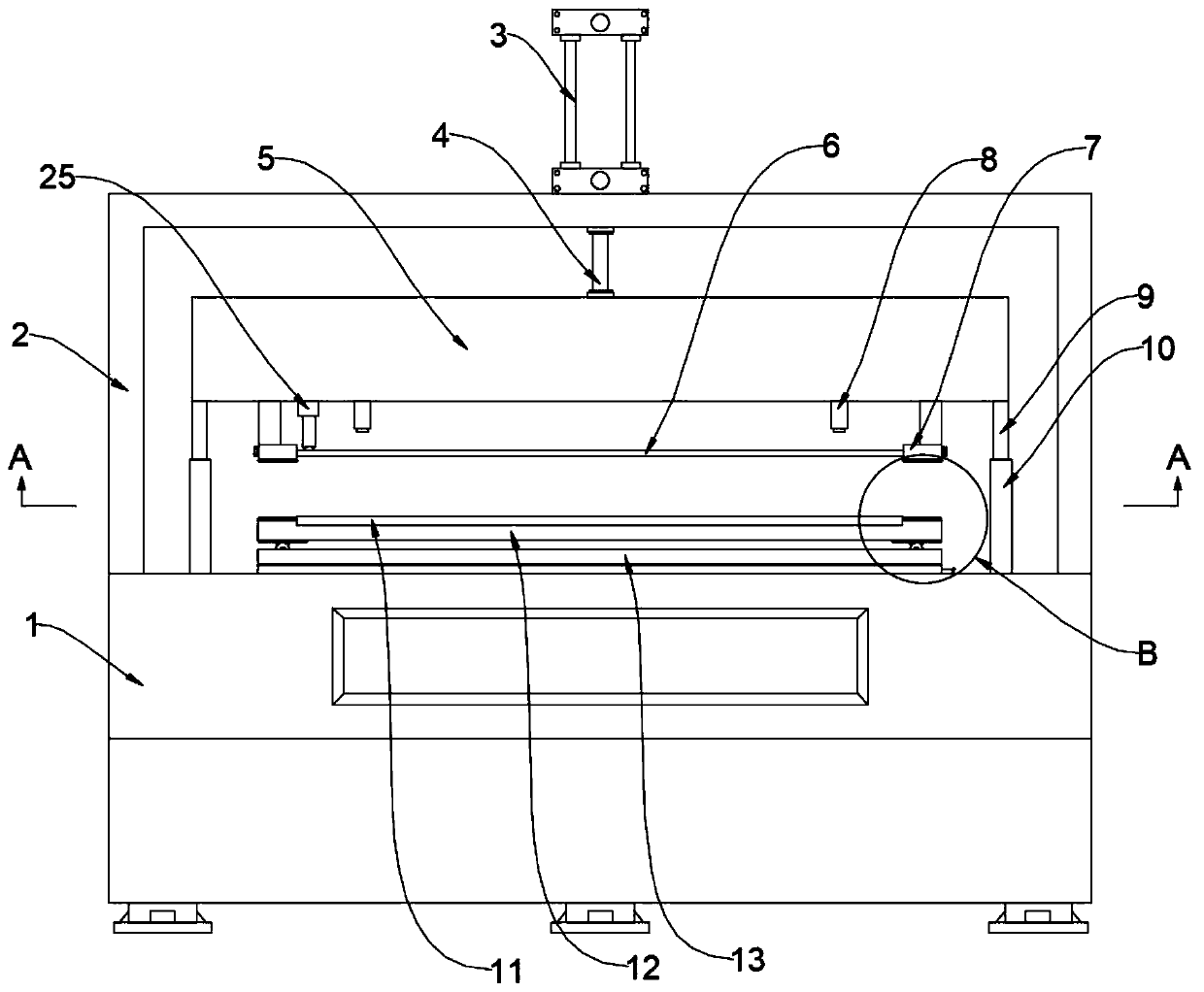

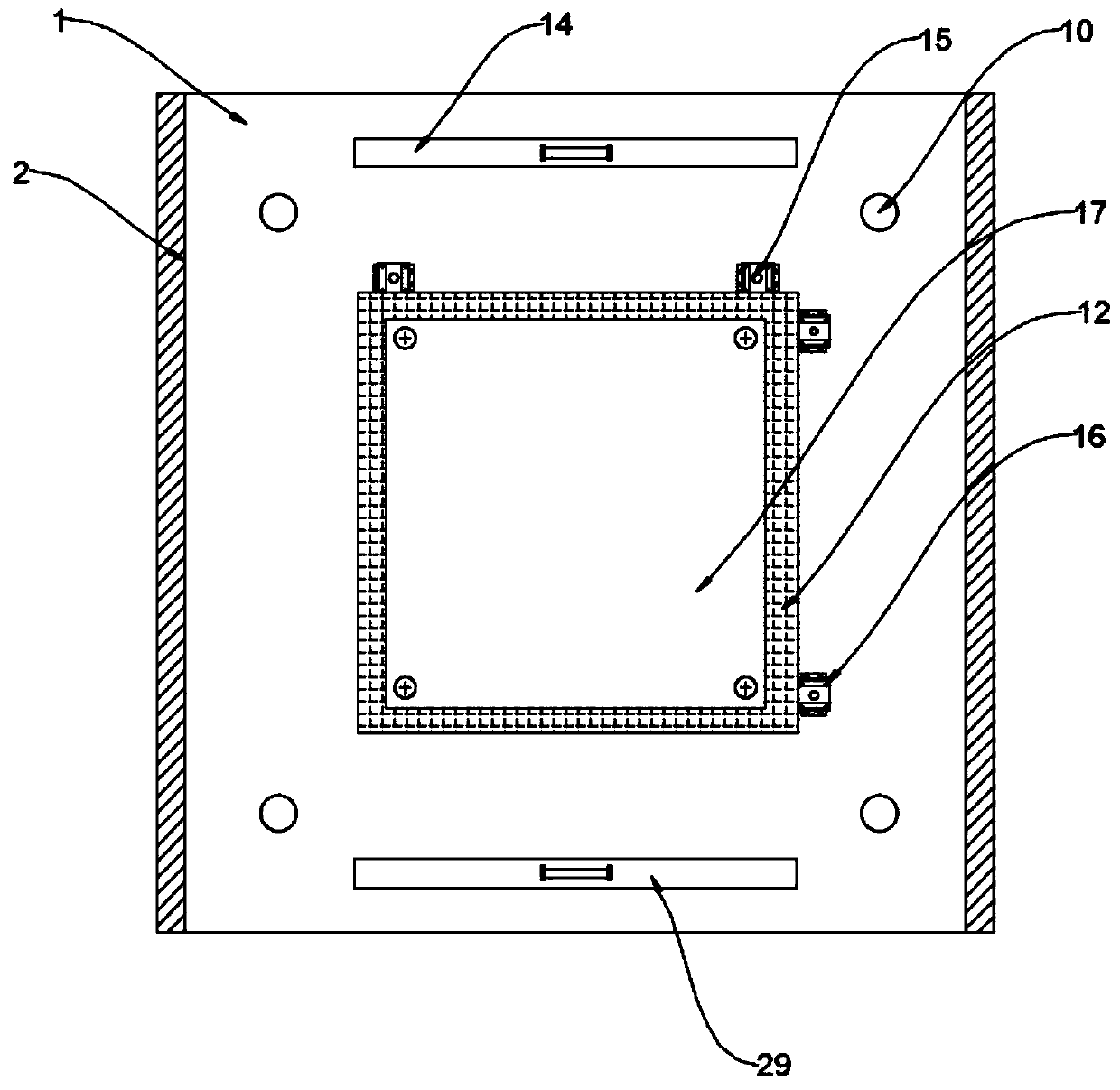

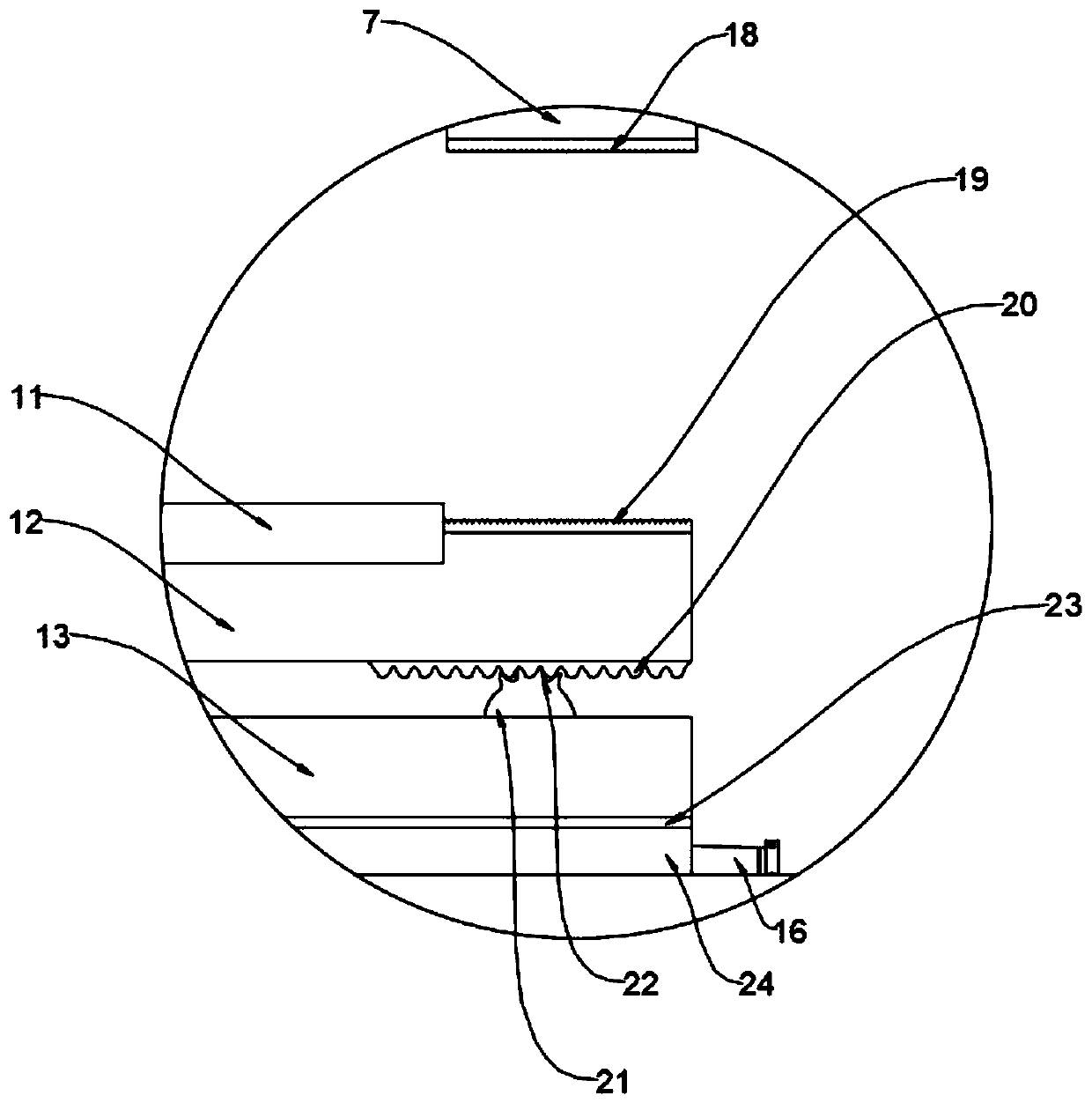

Projection type photocuring 3D printing device

InactiveCN111745958AReduce damageReduce capacityManufacturing platforms/substratesManufacturing driving means3d printMechanical engineering

The invention discloses a projection type photocuring 3D printing device. The projection type photocuring 3D printing device comprises a rack and further comprises a printing forming platform assembly, a trough assembly, a light source generator and a controller which are fixed in the rack. The trough assembly comprises a trough, a trough platform used for fixing and supporting the trough, and a drive mechanism I capable of driving the trough platform to conduct peeling overturning and return overturning. One side of the trough platform is hinged to the rack, and the other side of the trough platform is in shaft connection to the output end of the drive mechanism I. Under driving of the drive mechanism I, the trough platform conducts peeling overturning with the low speed and conducts return overturning with the high speed. The projection type photocuring 3D printing device meets the requirement for wide printing material coverage while the printing precision is ensured, and the forming performance and biology applicability of projection type photocuring 3D printing are improved.

Owner:苏州永沁泉智能设备有限公司

3D printer sprayer with adjustable aperture

ActiveCN107127963AReduce printing timeGuaranteed printing accuracyAdditive manufacturing with liquidsApplying layer meansSprayerEngineering

The invention discloses a 3D printer sprayer with an adjustable aperture. The 3D printer sprayer comprises a supporting body. A melting mechanism, a power supply device and a sprayer assembly are installed on the supporting body. The melting mechanism is used for pouring consumable materials in the melting state into the sprayer assembly. A toggle mechanism is arranged between the power supply device and the sprayer assembly. The power output end of the power supply device is connected with the power input end of the toggle mechanism. The power output end of the toggle mechanism is connected with the sprayer assembly and can adjust the shape or size of the cross section of the material spraying end of the sprayer assembly. According to the 3D printer sprayer with the adjustable aperture, through the power supplied by the power supply device, the shape or size of the cross section of the material spraying end of the sprayer components is automatically adjusted, so that the 3D printer sprayer with the adjustable aperture is adapted to the printing requirements of different target models, the printing efficiency is improved, and the printing time is shortened.

Owner:深圳市金石三维打印科技有限公司

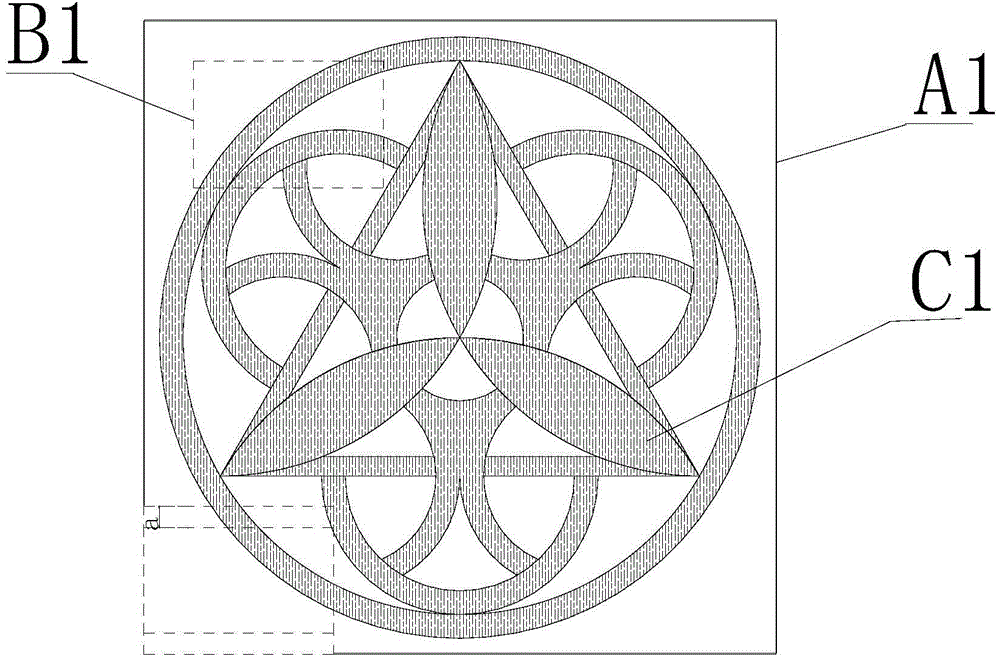

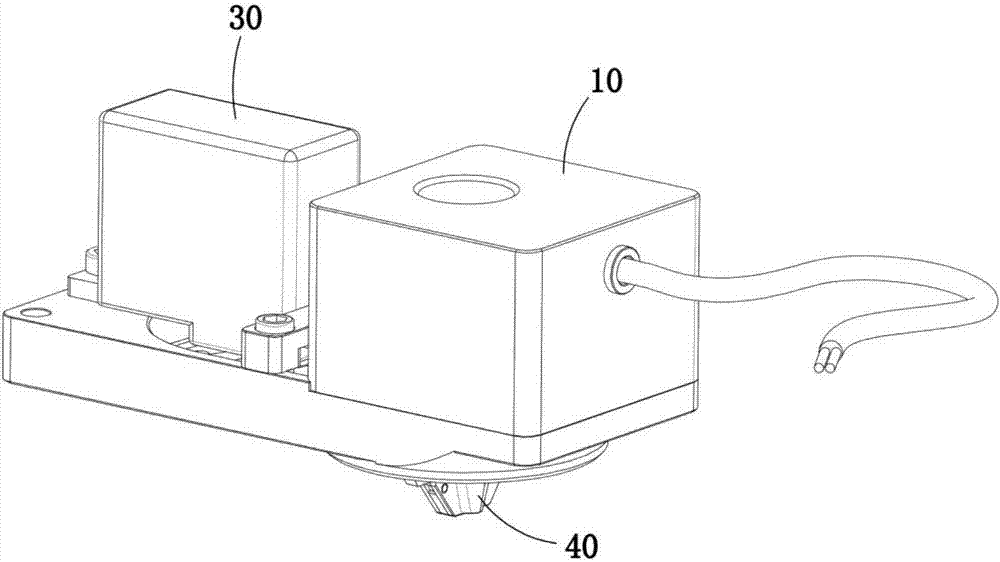

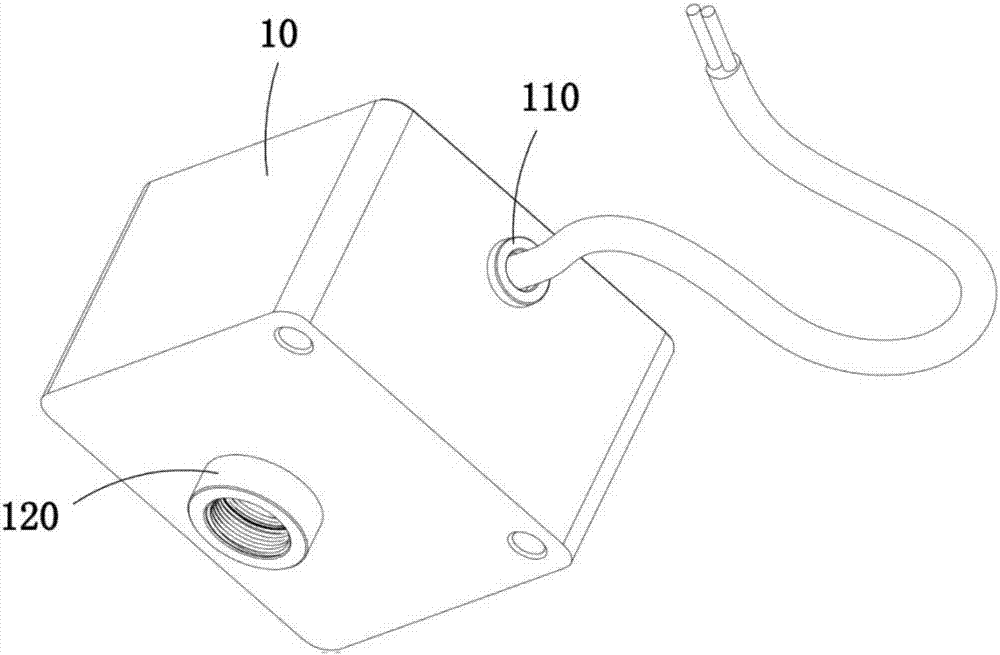

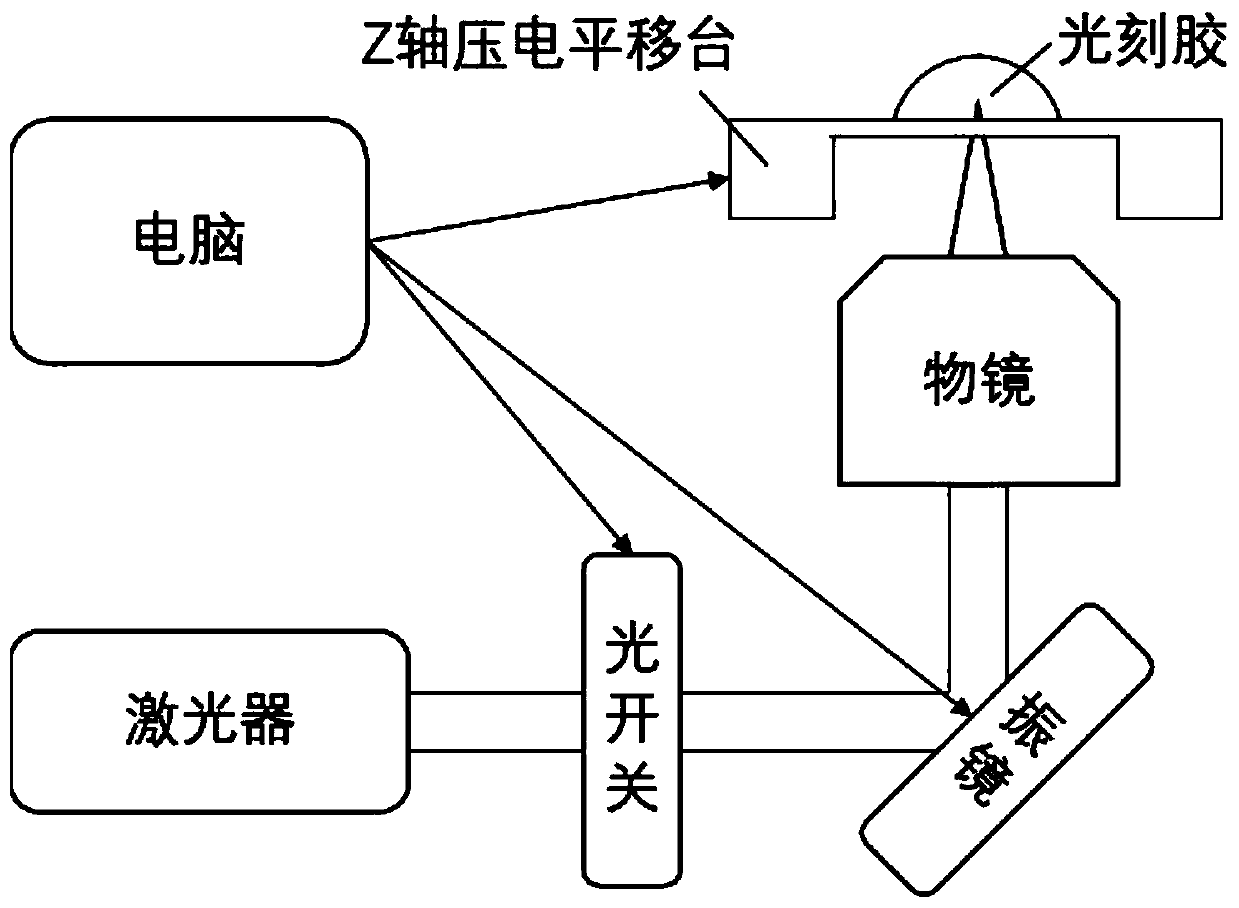

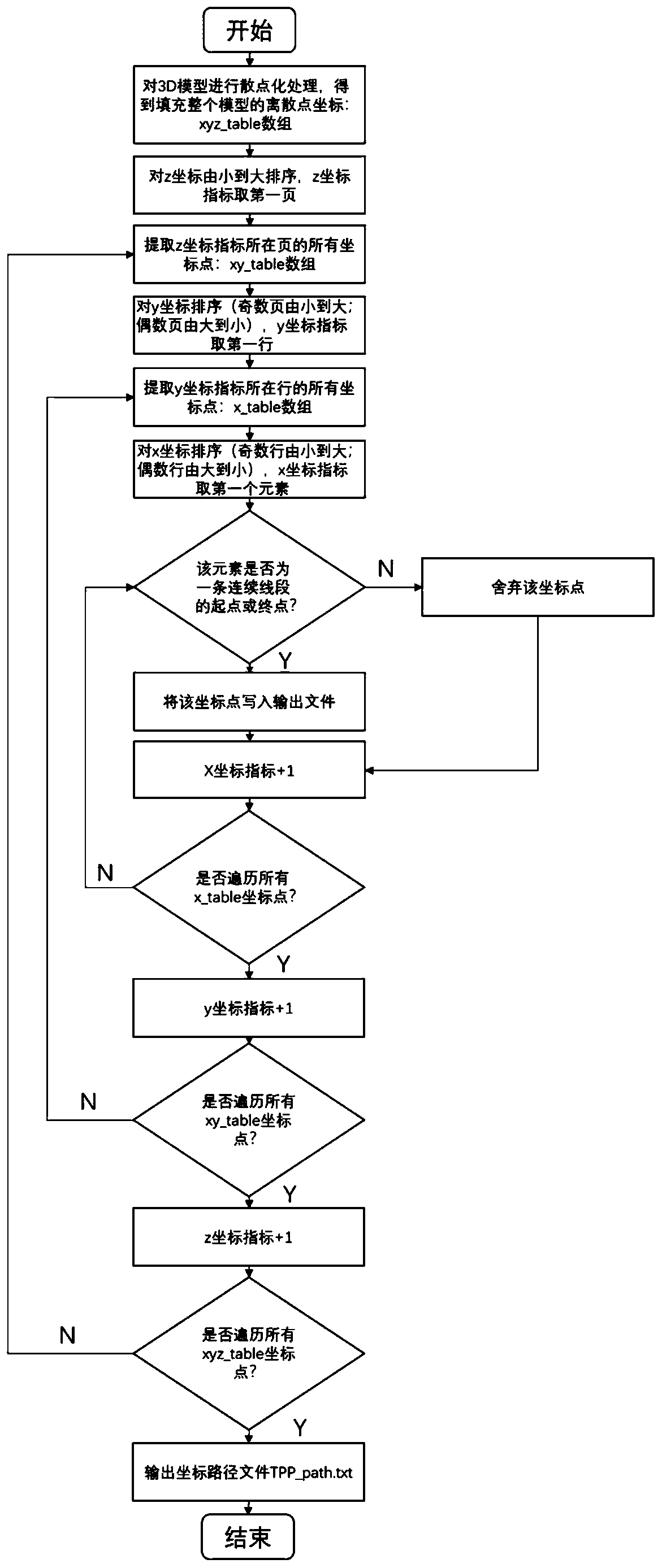

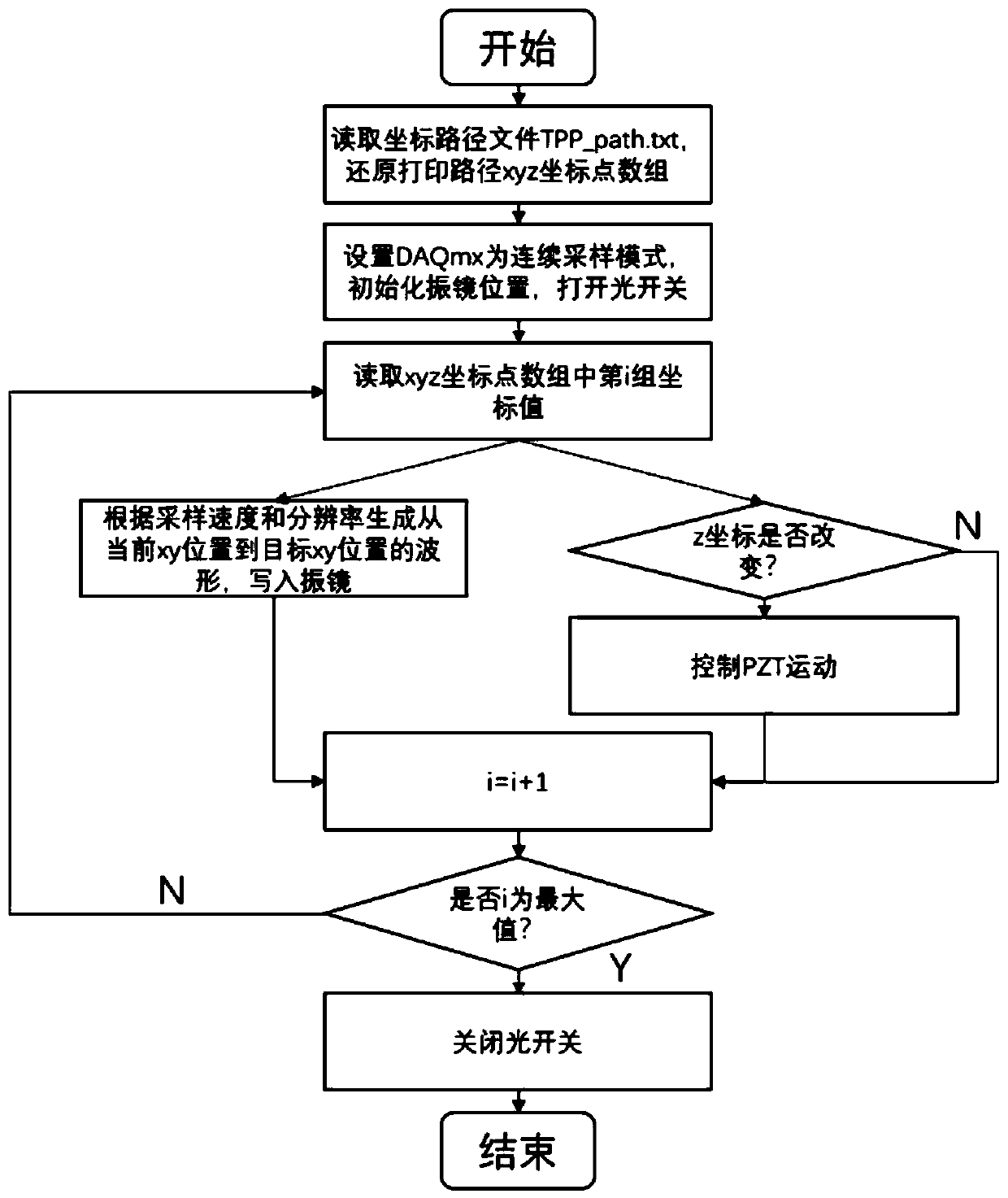

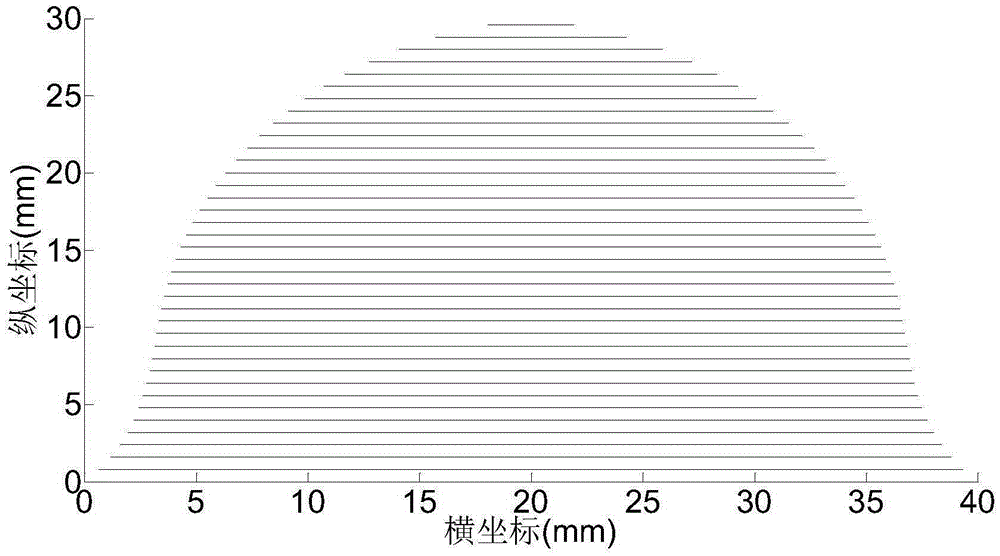

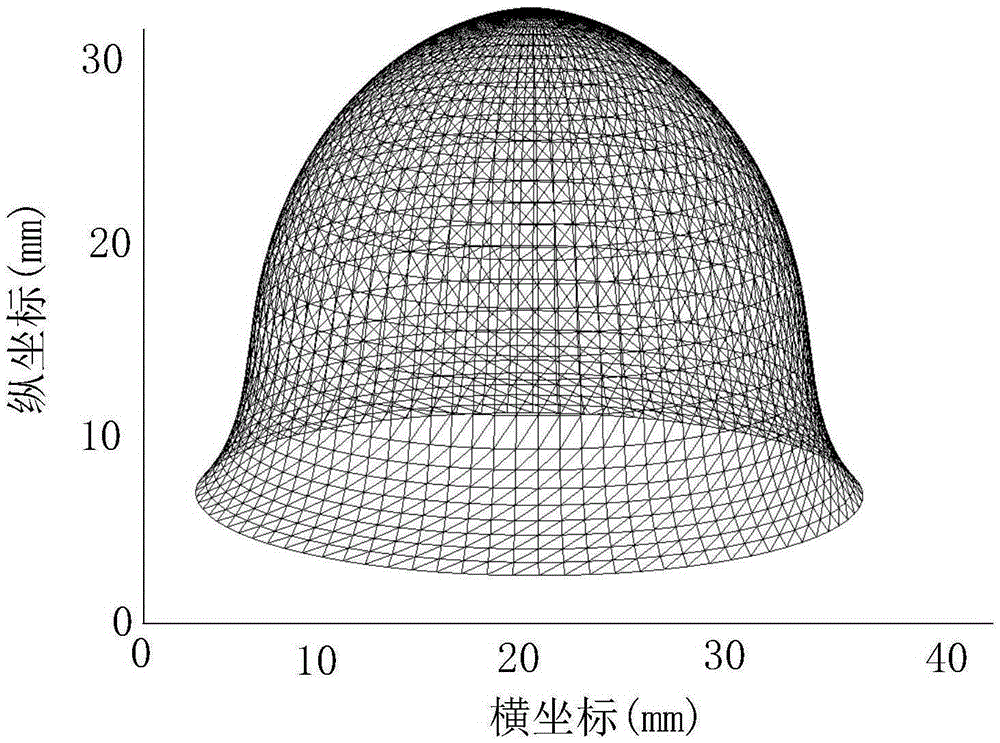

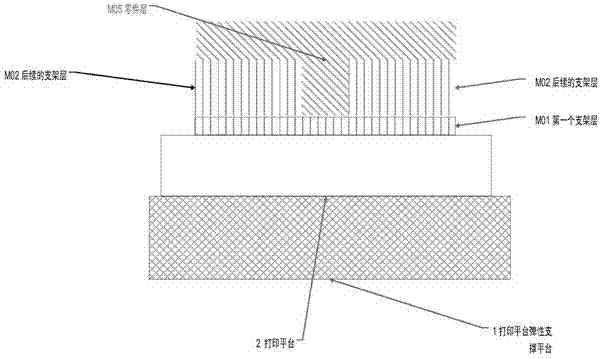

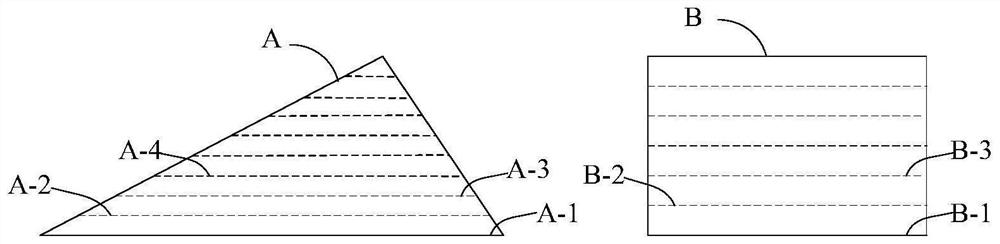

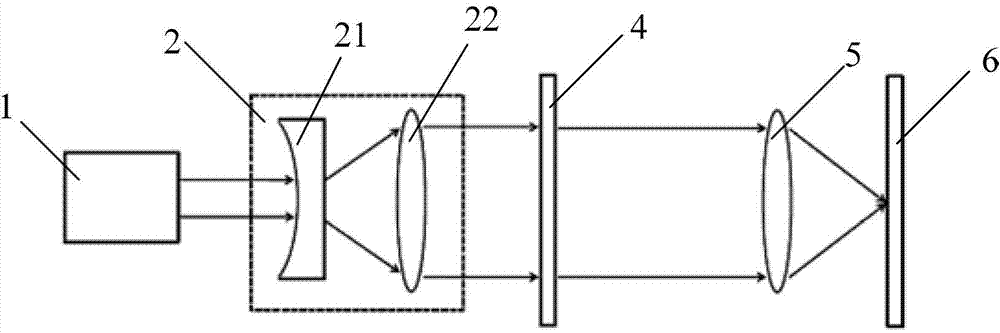

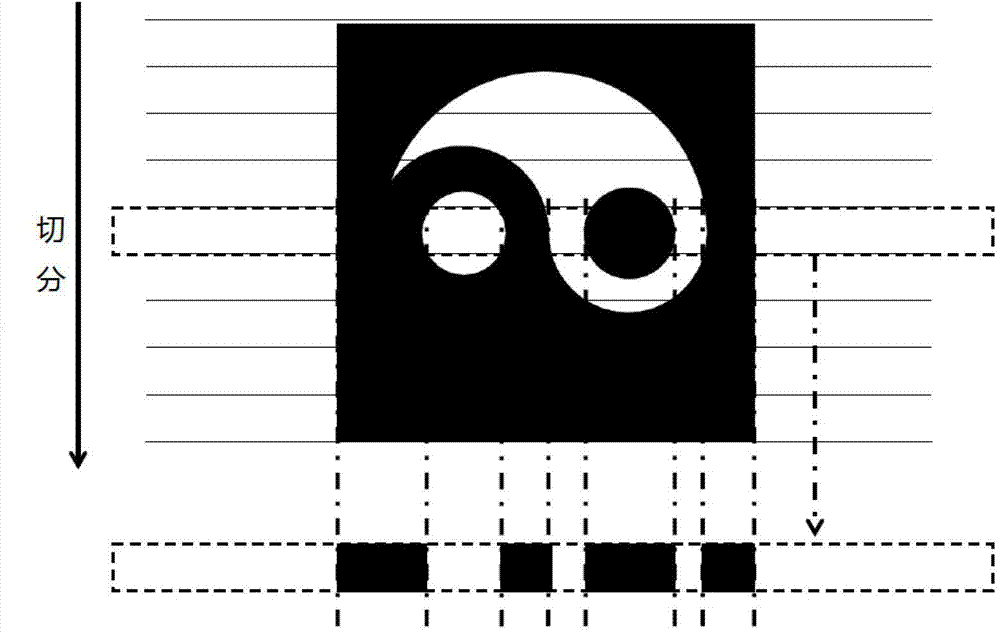

High-speed 3D micro-nanometer printing control method, model slicing method and model slicing device based on femtosecond laser

ActiveCN109774127AReduce data volumeReduce computationAdditive manufacturing apparatus3D object support structuresComputer scienceHigh velocity

The invention relates to the technical field of 3D micro-nanometer printing, in particular to a high-speed 3D micro-nanometer printing control method, model slicing method and model slicing device based on femtosecond laser. The model slicing method comprises the steps that i, coordinate data of dispersing points filling a whole 3D model are obtained; ii, all the dispersing points are layered to obtain the coordinate data of the dispersing points on each layer; iii, the dispersing points of each layer are divided into lines according to y coordinate values of the dispersing points to obtain the coordinate data of the dispersing points on each line; iv, the dispersing points are ranked sequentially according to the sequence of the lines and the layers, and the sequence of the coordinate data of all the dispersing points is obtained; and v, according to the sequence of all the dispersing points in the sequence, whether the dispersing points are starting points or finishing points of continuous line sections or not is judged sequentially, and if no, the dispersing points are removed from the sequence. The high-speed 3D micro-nanometer printing control method and the high-speed 3D micro-nanometer printing model slicing method are used in mutual cooperation, and the 3D micro-nanometer printing speed and precision can be increased and improved greatly.

Owner:杭州志英科技有限公司

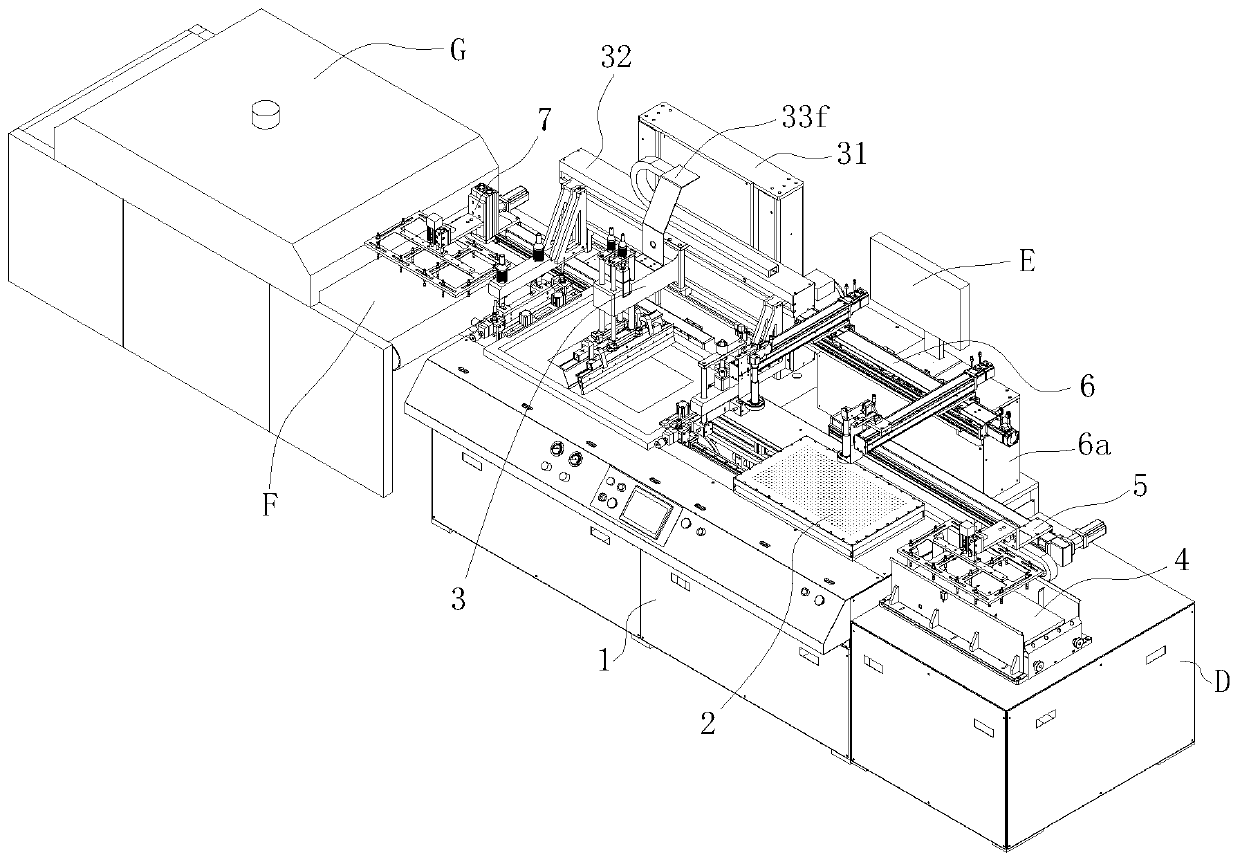

Fully-automatic screen printer for sheets

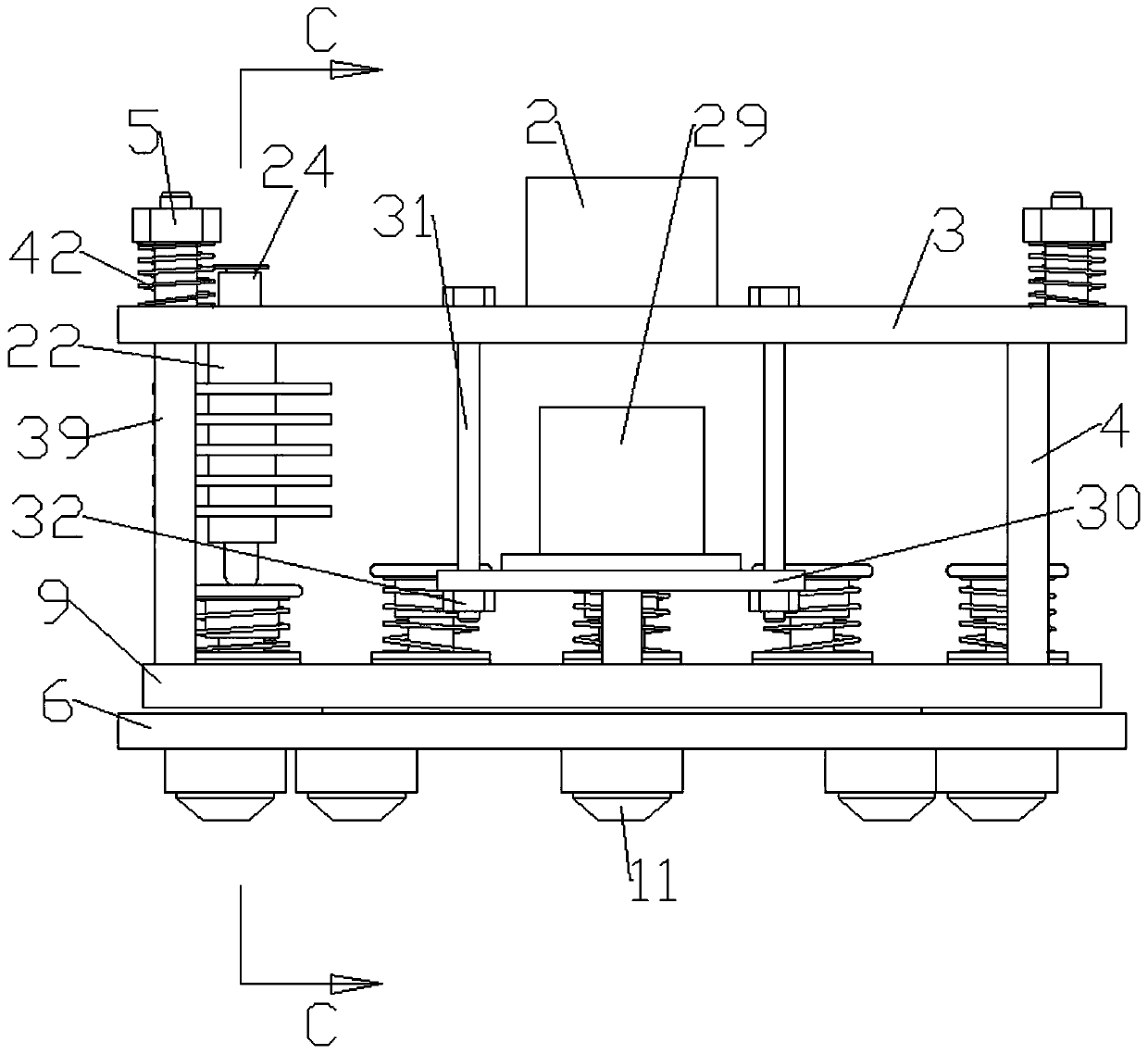

PendingCN110834465AGood depolarization performanceReduce eccentric disturbanceConveyorsScreen printersManufacturing engineeringPrinting press

The invention discloses a fully-automatic screen printer for sheets. The fully-automatic screen printer for the sheets comprises a conveying unit arranged at the inner side of a rack, wherein the conveying unit is used for conveying a material to be processed and correcting a position to be printed, of the material; a printing unit is arranged above one end of the rack, and a discharge lifting unit is arranged at the other end of the rack; the discharge lifting unit is used for supplying the material to be processed and feeding back material lack information in time; a material taking mechanism is arranged at one end connected with the discharge lifting unit, of the rack; a vision unit is arranged above the material taking mechanism, and used for obtaining position image information of thematerial to be processed and on the conveying unit, and carrying out information feedback; and a material receiving mechanism is arranged on a part below the printing unit, of the rack. According tothe fully-automatic screen printer for the sheets, the accuracy of product alignment and printing is effectively increased, so that wider application range and higher universality are achieved, and electricity consumption and ink resource are saved; and moreover, the fully-automatic screen printer for the sheets is convenient to maintain and replace, so that the maintenance cost is greatly reduced.

Owner:深圳市亿宝莱印刷设备有限公司

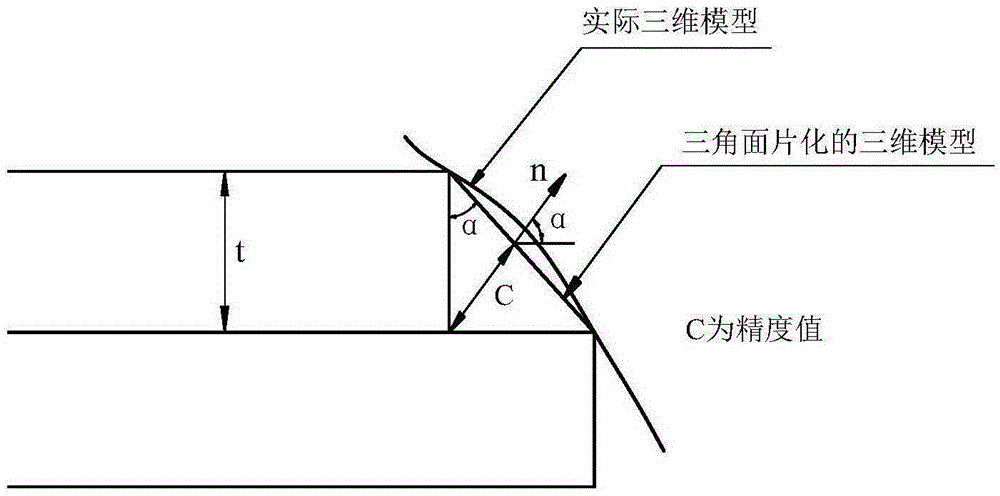

Self-adaptive hierarchical algorithm for 3D (three-dimensional) printing

InactiveCN105398056AGuaranteed accuracyGuaranteed printing accuracyAdditive manufacturing apparatusLayer thicknessSelf adaptive

The invention discloses a self-adaptive hierarchical algorithm for 3D (three-dimensional) printing. The self-adaptive hierarchical algorithm comprises the following steps: (1) according to a triangle normal vector of a 3D model in a STL format, solving an included angle alpha 0 between the normal vector of each triangle and the horizontal plane; (2) solving the corresponding layer thickness t0 of each triangle; (3) taking the maximum value of t0 as a try-cut value, carrying out trial hierarchy on the 3D model in the STL format, and beginning from the bottom the model; (4) after completing the first trial hierarchy, determine a layer thickness value of a first layer; ( 5) after determining the layer thickness value of the first layer, on the basis of the first layer, carrying out secondary trial hierarchy with the try-cut value as a layer thickness; (6) repeating the fourth step to determine a layer thickness value of a second layer; and (7) frequently repeating the fifth and sixth steps until hierarchy of the entire 3D model in the STL format is completed. In the premise of ensuring the accuracy of a shaped product, the algorithm can shorten the shaping time and improve the shaping efficiency, guarantee the printing precision and improve the shaping efficiency.

Owner:TIANJIN UNIV

System used for solar battery cell printing and printing method

PendingCN108656715AOvercome Printing Uniformity IssuesImprove printing qualityTransfer printingRotary intaglio printing pressSolar batteryTransfer mechanism

The invention discloses a system used for solar battery cell printing and a printing method, and belongs to the field of solar photovoltaic manufacturing. Aimed at for solving the problems that in theprior art, printing of a solar battery cell is up and down, printing uniformity is poor, and printing quality and the transfer effect of a solar substrate are poor, the invention provides the systemused for solar battery cell printing and the printing method. The system comprises a transfer medium and further comprises an unwinding mechanism, an intaglio printing mechanism, a transfer mechanismand a winding mechanism which are arranged in sequence, transfer media enter the intaglio printing mechanism sequentially through the unwinding mechanism to print patterns, then, the transfer media enter the transfer mechanism to transfer the patterns to the substrate, and the transfer media enter the winding mechanism finally. Through tension control, laser transfer, slab transfer or round rollertransfer, printing uniformity can be achieved, the printing effect is good, and the transfer effect is excellent.

Owner:SUZHOU MAXWELL TECH CO LTD

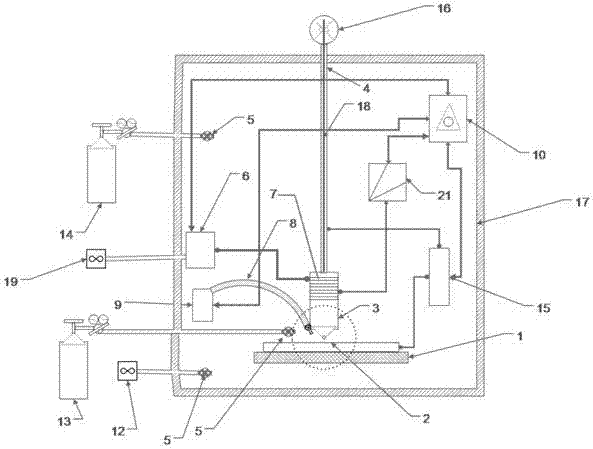

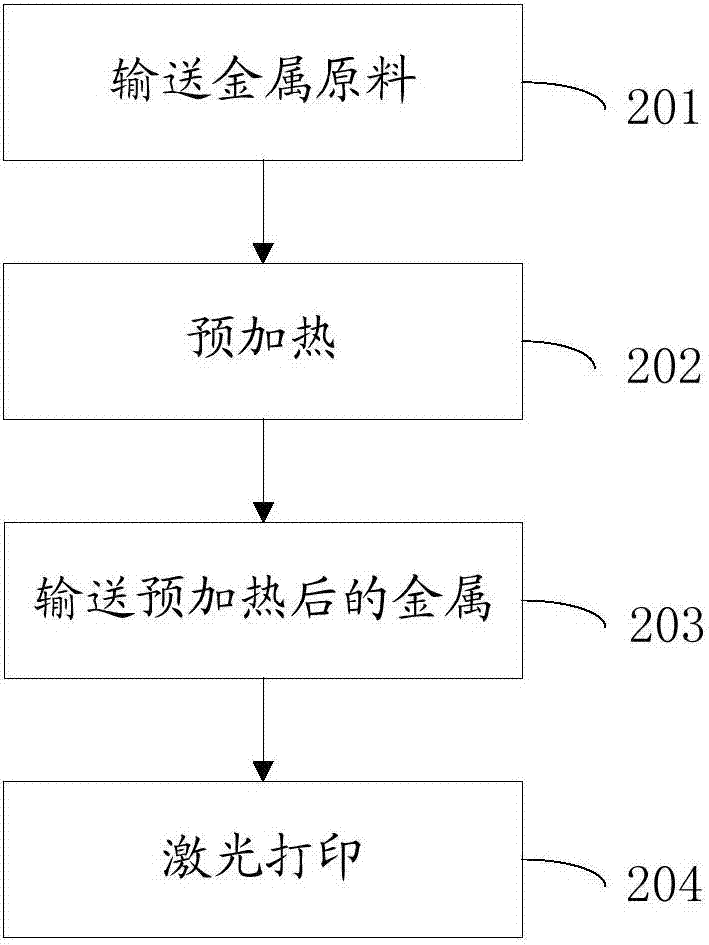

Three-dimensional printing equipment and method

ActiveCN107282925ARealize printingLow costAdditive manufacturing apparatusIncreasing energy efficiencyLaser heating3 dimensional printing

The invention discloses three-dimensional printing equipment and a method. The three-dimensional printing equipment comprises a metal raw material conveying device, a high-frequency magnetic field preheating device, a position driving device, a laser control device, a printing head, a sensor set and a controller; the high-frequency magnetic field preheating device comprises an electromagnetic induction coil; the metal raw material conveying device conveys metal raw materials into a heating cavity formed by the electromagnetic induction coil in the printing head for preheating of the metal raw materials; the position driving device conveys the printing head to a correct pixel position; preheated metal is output to the correct pixel position from a raw material output port of the printing head; the laser printing device performs laser heating on the preheated metal in the correct pixel position to realize three-dimensional laser printing; and the controller controls the printing process in real time according to state and position information detected by the sensor set. The equipment or the method can reduce the production cost when guaranteeing the printing precision.

Owner:河北点赞电子科技有限公司

Printing path planning method and system and 3D printer

ActiveCN112677488AReduce the length of the empty pathImprove printing efficiencyAdditive manufacturing apparatusManufacturing data aquisition/processingAlgorithmComputer printing

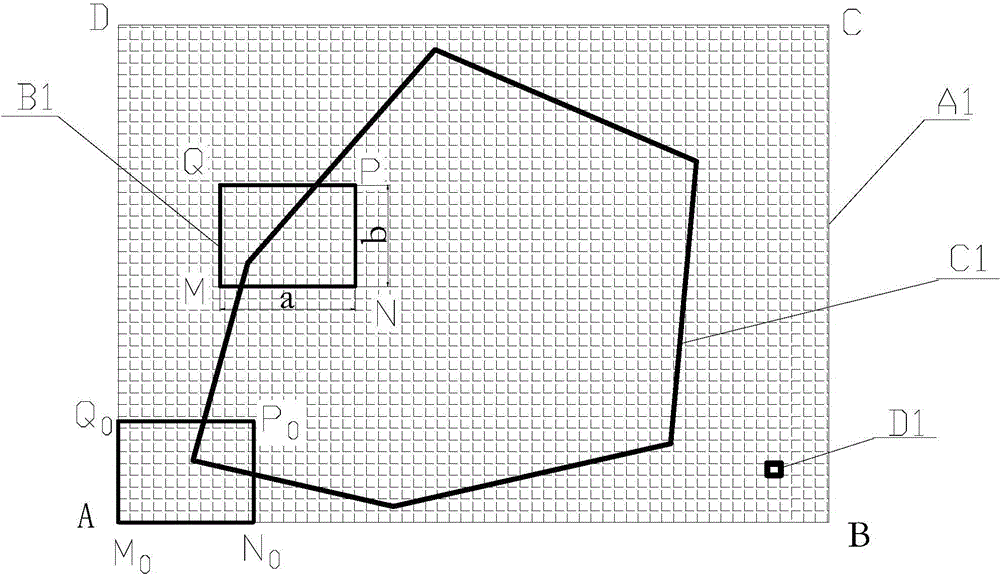

The invention relates to a printing path planning method and system and a 3D printer. The method comprises the steps that firstly, a to-be-printed shape is partitioned through an optimized improved x scanning method, and a plurality of preset rectangles corresponding to each of angles correspondingly are obtained; then the plurality of preset rectangles corresponding to each angle correspondingly are partitioned according to a z-shaped scanning mode and based on an optimal distance principle; and finally, optimizing and traversing are carried out on the path of the preset rectangle of each partition of each of sub-domains corresponding to each angle according to a preset algorithm. The printing precision can be ensured, the idle stroke length of the to-be-printed shape in a two-dimensional layered slice image can be greatly reduced, and the printing path corresponding to the lowest printing time consumption is selected as the optimal printing path, so that the printing time is further shortened, and the printing efficiency is improved.

Owner:TECH & ENG CENT FOR SPACE UTILIZATION CHINESE ACAD OF SCI

Circuit board printing device

PendingCN110789220AImprove drying efficiencyReduce the valueScreen printersConductive pattern formationEngineeringDrying time

The invention discloses a circuit board printing device, and relates to the related field of circuit board printing. The problem that in the prior art, in the drying process, heat is dissipated, heatis not concentrated on the printing portion, and consequently, drying time is long can be solved. The middle of the rear end of the upper end face of a worktable is provided with a first drying device, a second drying device is arranged in the middle of the front end of the upper end face of the worktable, the first drying device and the second drying device are connected with the worktable through sliding strips, the first drying device and the second drying device are embedded in the worktable, and the first drying device and the second drying device each comprise an outer frame, a placing groove, a connecting telescopic rod, a drying plate, a moving groove, a drying area, a drying device supporting plate and a pressure spring.

Owner:SUZHOU HUILIYUAN TECH CO LTD

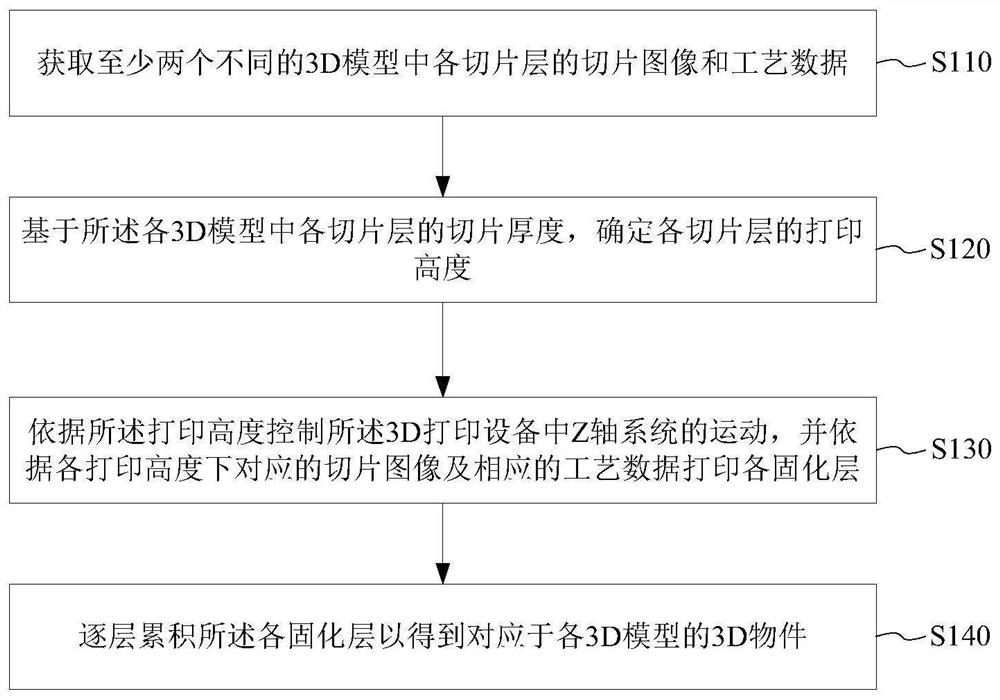

3D printing method and device, data processing method and system and storage medium

ActiveCN113334767AAvoid it happening againImprove printing efficiencyManufacturing platforms/substratesManufacturing driving meansSlice thicknessEngineering

The invention discloses a 3D printing method and device, a data processing method and system and a storage medium. The 3D printing method comprises the steps that the printing height of each slice layer is determined when a plurality of 3D models are printed based on the slice thickness of each slice layer in the multiple 3D models, so that the movement of a Z-axis driving mechanism in the 3D printing device is controlled according to the printing height; and each curing layer is printed according to the corresponding slice image at each printing height and the corresponding process data, and finally each curing layer is accumulated layer by layer to obtain a 3D object corresponding to each 3D model. The multiple 3D models with different process data can be printed in the same printing batch, and the printing efficiency is remarkably improved while the printing precision is guaranteed.

Owner:SHANGHAI UNION TECH

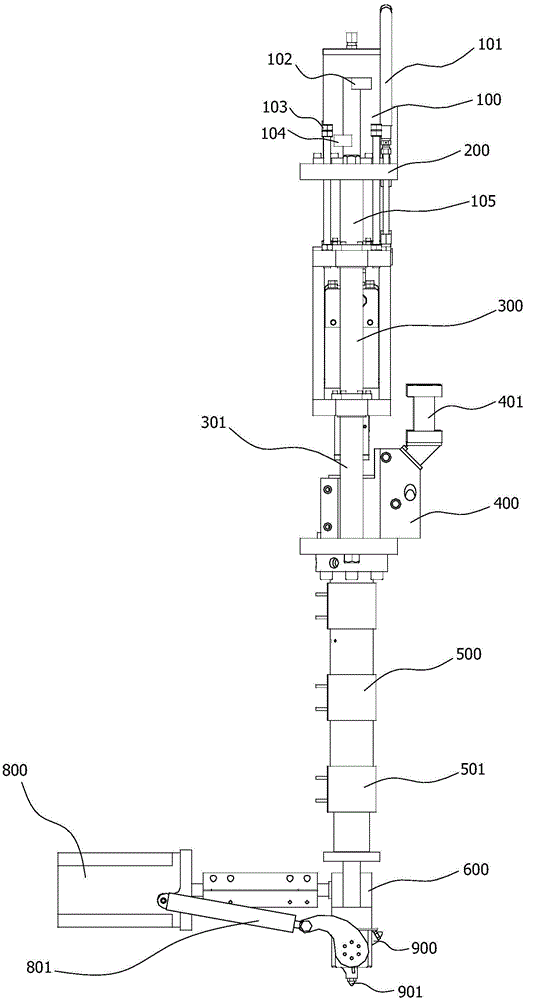

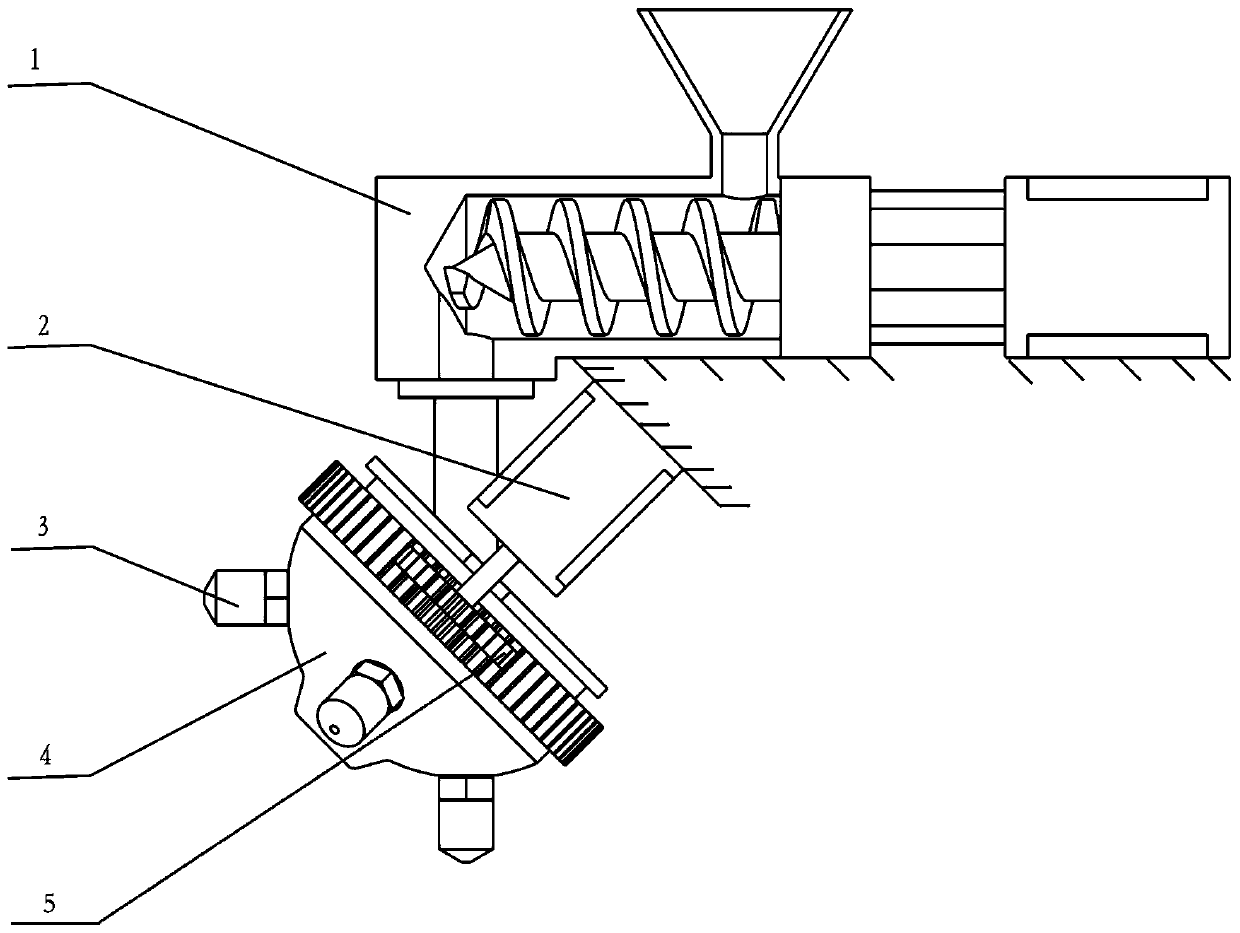

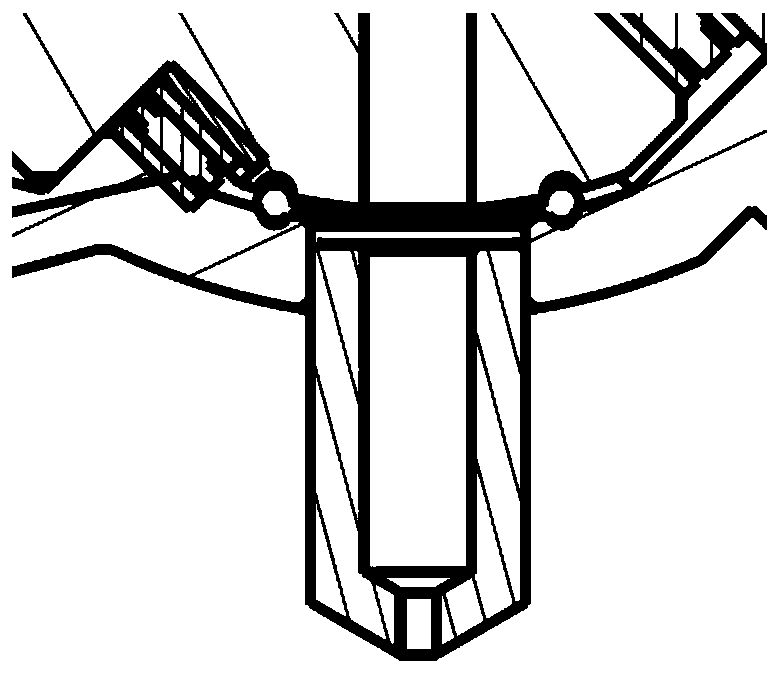

3D printer head with replaceable nozzle for rapidly forming large products

InactiveCN110920065ASimplify the printing processImprove printing efficiency3D object support structuresApplying layer meansRubber ringComputer printing

A 3D printer head with a replaceable nozzle for rapidly forming large products can solve the problem that a conventional FDM 3D printer has a low printing speed and makes it difficult to form large products. The 3D printer head mainly comprises a melt extrusion unit, a nozzle group unit, and a nozzle conversion driving unit. The melt extrusion unit is a single screw extruder. The nozzle group unitis composed of an inner core valve, a compression cover, a thrust needle bearing, a nozzle fixing cover, a nozzle, a sealing ring and a rubber ring. The nozzle conversion driving unit consists of a motor and a gear. When printing a large product, the 3D printer head firstly use the slicing software to perform a multi-stage shelling and slicing process on a model, so that the filling distances between two wires in each layer gradually decrease from the inside to the outside according to the number of shelling stages. The innermost part of the model is filled with a wide path by a large nozzle.The middle part of the model is filled with a narrow path by a smaller nozzle. The outermost part of the model is filled with the narrowest path by the smallest nozzle. The 3D printer head can greatly increase the printing speed of large products and ensure the forming accuracy.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

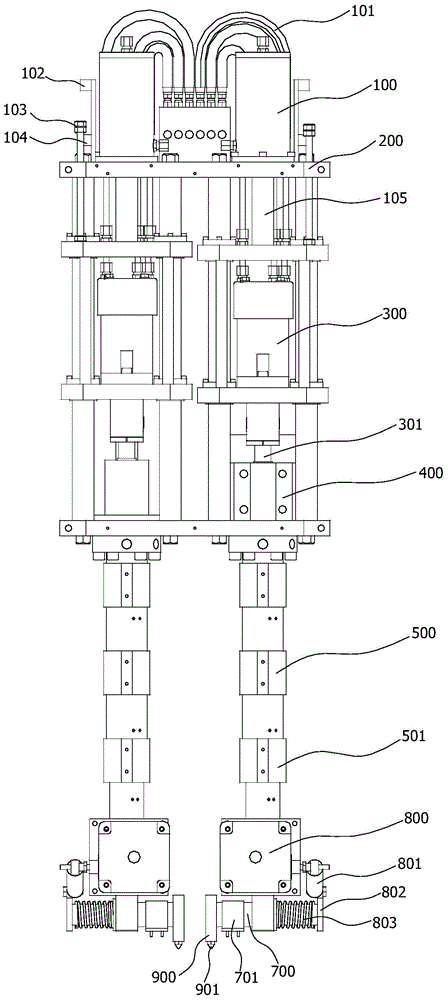

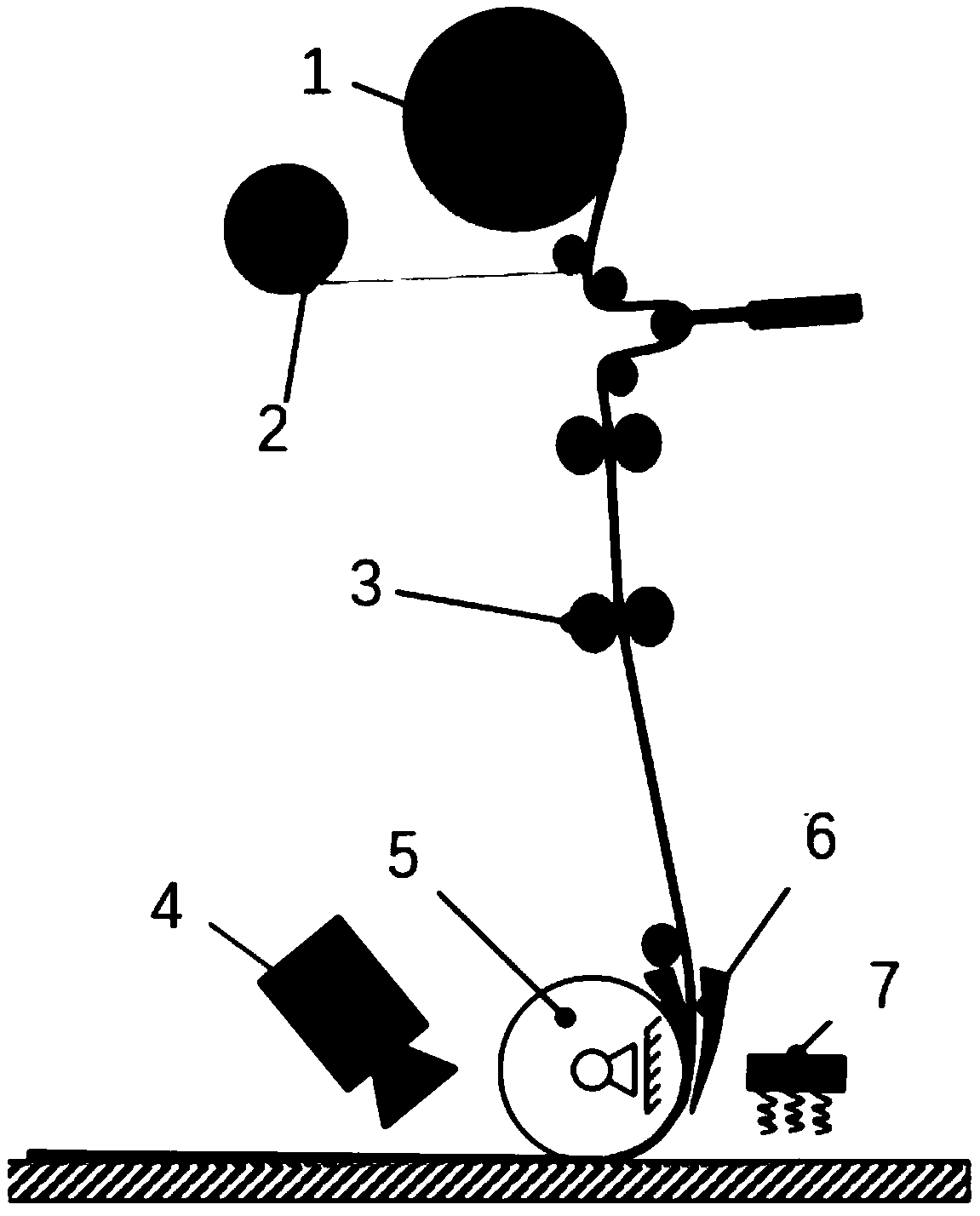

Device for preparing continuous fiber reinforced resin-based composite component

InactiveCN109571932AFast preparationHeating fastManufacturing heating elementsManufacturing material handlingAviationResin-Based Composite

The invention relates to a device for preparing a continuous fiber reinforced resin-based composite component. Adopted parts comprise a raw material storing disc, a tension stabilizing device, a feeding unit, a real-time monitor, a compaction roller, a cutting unit, an infrared heater and the like; and the device adopts far-infrared heating, by combining a fiber laying and in-situ solidifying technology, the high-property composite component is quickly manufactured, and the specific working processes are that raw materials are conveyed to the lower end under control of the feeding unit, the materials are molten through infrared heating, then the upper layer and the lower layer are bonded under the effect of the compaction roller, and the whole component is printed in circulating and reciprocating modes. The device can be applied to the basic fields such as aerospace and military national defense, the technological monopoly of foreign countries on China is broken through, and development in the aspects such as quick manufacturing and quick repairing of the composite component for national aerospace is promoted.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

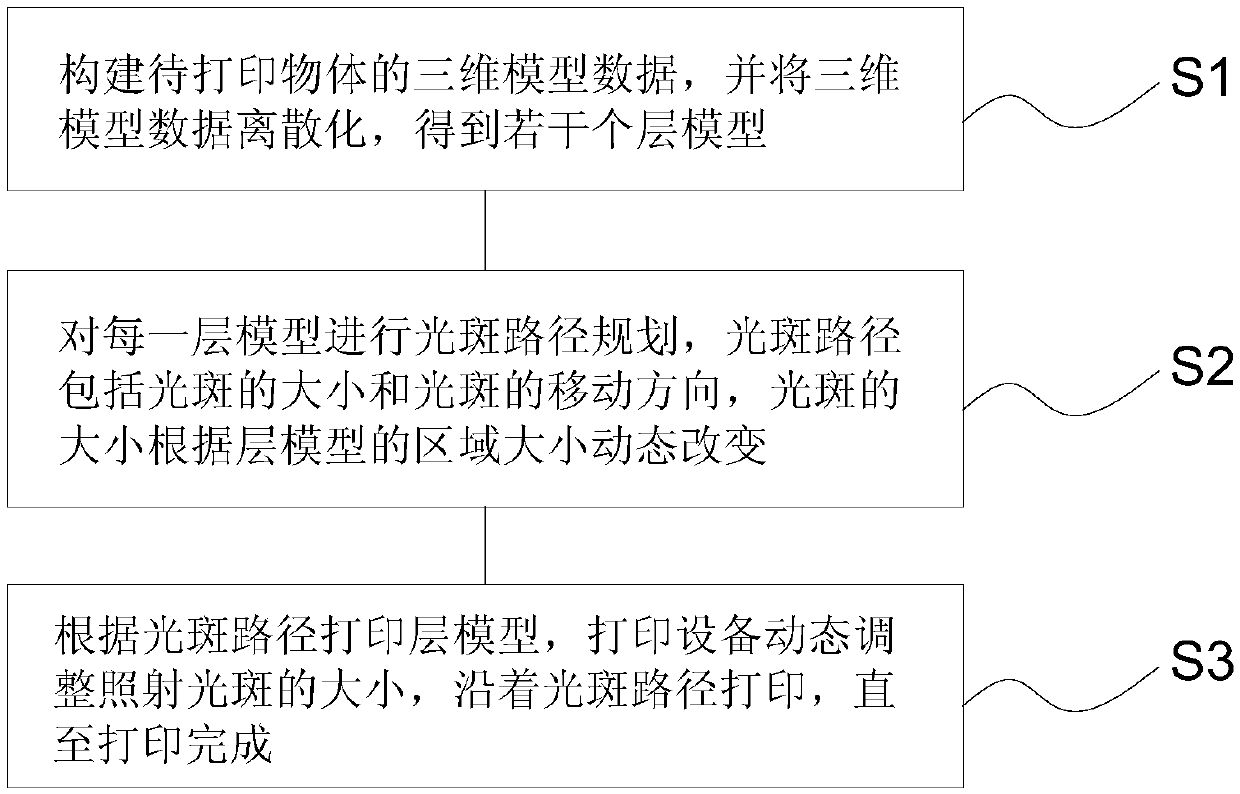

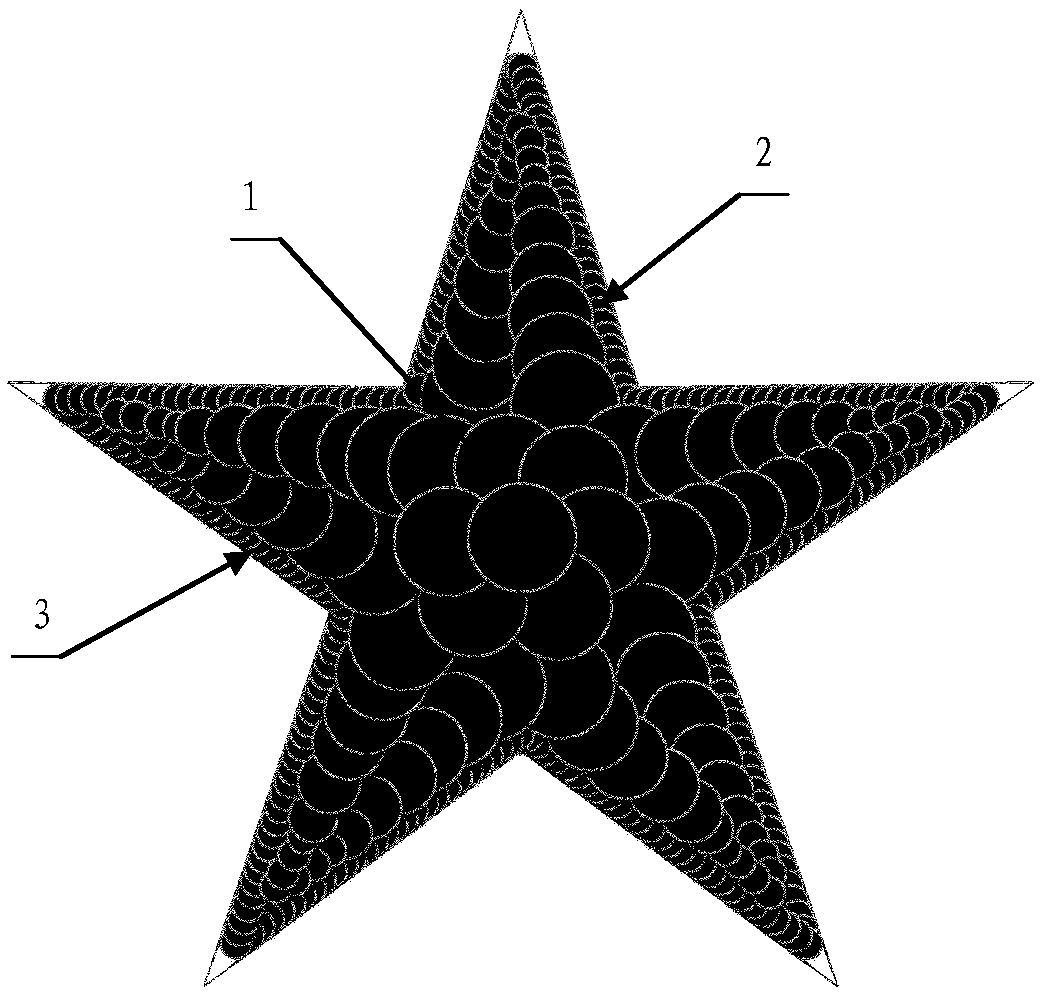

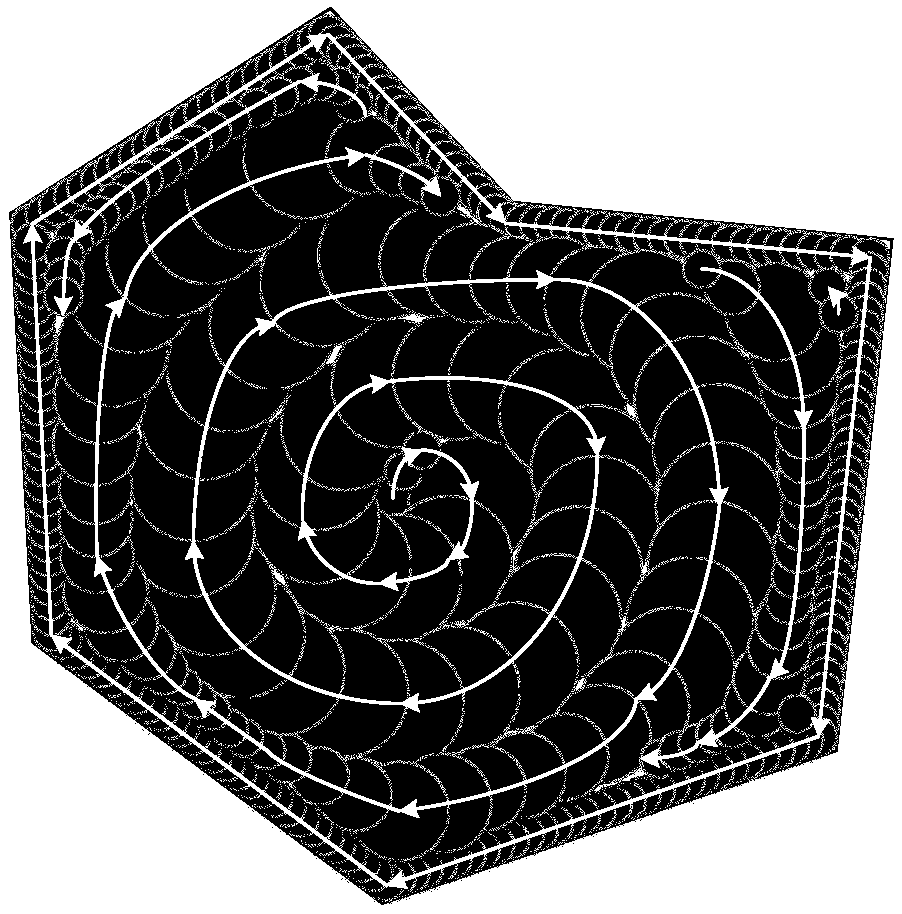

3D photocuring dynamic focusing self-adaption light spot printing method

ActiveCN109532005AGuaranteed performanceRealize dynamic spot printingAdditive manufacturing apparatus3D object support structuresLight spotSelf adaptive

The invention provides a 3D photocuring dynamic focusing self-adaption light spot printing method and equipment. The method comprises the steps that 1, three-dimensional model data of a to-be-printedarticle are built anddiscretized,so that multiple layer models are obtained; 2, light spot route planning is conducted on each model, wherein a light spot route comprises the sizes and the moving direction of light spots, and the sizes of the light spots are dynamically changed according to the area size of the layer models; and 3, according to the light spot route obtained through planning of step 2, the layer models are printed, the sizes of the light spots are dynamically adjusted through the printingequipment, and printing is conducted along the light spot route until printing is completed. Light spot route planning is conducted on each layer model, The proper light spot sizes are set for printing in all different areas in the layer models according to the shape and performance requirements; and the light spots are gradually decreased at positions with sharp corners; and on the premise that the printing precision and printing article performance are guaranteed, dynamic light spotprinting can be achieved in all directions, and the printing speed can be increased.

Owner:J H TECH ELECTRONICS GZ LTD

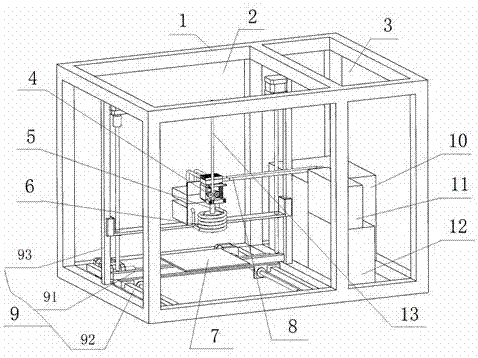

3D printer with high accuracy

InactiveCN106827538AHigh feasibilityIngenious designManufacturing driving meansEngineering3d printer

The invention relates to a 3D printer with high accuracy. The 3D printer comprises a shell body, supporting columns, sliding blocks, rotating assemblies, connecting rods, a PLC and a balancing assembly. Each sliding block is further provided with a first motor and a first round gear. Each rotating assembly comprises a second round gear, a bearing, a supporting rod, a second motor and a third round gear. The balance assembly comprises third motors, a fixed block, lead screws, an adjusting block, a spraying head and a balance unit. The balance unit comprises a pulling rope, a sphere, limiting blocks, springs, a touch block and touch pieces. The 3D printer with the high accuracy is ingenious in design and high in feasibility, the height of the spraying head can be adjusted through sliding of the sliding blocks, the printing range of the spraying head can be enlarged through the rotating assemblies and the accuracy is high, and the spraying head can keep the vertical state all the time through the balance assembly, so that the printing accuracy is guaranteed, and the printing quality is improved.

Owner:JIAXING MINHUI AUTOMOTIVE PARTS CO LTD

3D (three-dimension) printer for printing vitreous body and printing method

InactiveCN107285609ABroaden your optionsControl feedAdditive manufacturing apparatusGlass shaping apparatusHigh energyControl system

The invention relates to a 3D (three-dimension) printer for printing a vitreous body and a printing method. The 3D printer is composed of a frame, a printing silo and a control cooling silo; the printing silo is connected with the control cooling silo and arranged in the frame; the inner part of the printing silo is provided with a delivering mechanism, a nozzle printing mechanism, a sensing heating device, a printing bottom plate, a cooling medium guide flow pipe and a three-dimensional movement mechanism; the inner part of the control cooling silo is provided with a cooling device, a control system and a power supply. By applying the 3D printer for printing the vitreous body and the printing method, the selection scale of the printing raw material is enlarged; the sensing heating method has the significant advantages of high working efficiency, high energy utilization rate, quick temperature rise, control easiness, small equipment volume, pollution free and others; besides, the printer and the printing device have the advantages of simple and reliable structure, high automatic degree, control easiness, strong practicability and others.

Owner:贵州云上左岸科技有限公司

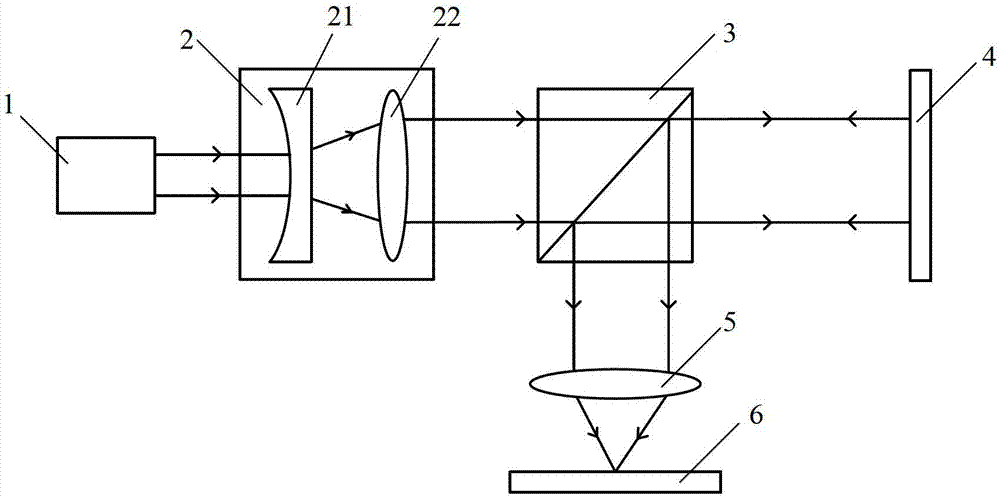

An optical system for 3D printing and a control method thereof

InactiveCN104118120AQuality improvementImprove printing efficiencyAdditive manufacturing apparatusIncreasing energy efficiencySpatial light modulatorBeam splitter

An optical system for 3D printing and a control method thereof are disclosed. The optical system comprises a laser, a beam expanding system, a beam splitter, a spatial light modulator and a focusing system. The spatial light modulator is connected to a computer used for generating a target modulation pattern. The spatial light modulator receives the target modulation pattern generated by the computer and then generates the modulation pattern. A light beam emitted by the laser is subjected to beam expansion into a parallel beam by the beam expanding system and the parallel beam irradiates the beam splitter. The light beam after partial beam expansion reaches the spatial light modulator to be modulated after passing through the beam splitter. After the modulated light beam is reflected to the beam splitter, the light beam after partial beam expansion irradiates a target plane of 3D printing after being focused by the focusing system. According to the optical system and the control method, optical modulation and focusing demodulation are performed by adopting the modulation pattern as a unit, and printing line by line, printing paragraph by paragraph and even printing of the whole plane can be achieved, thus increasing the printing efficiency, accelerating the printing speed, and guaranteeing the 3D printing quality. The optical system and the control method can be widely used in the field of 3D printing.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

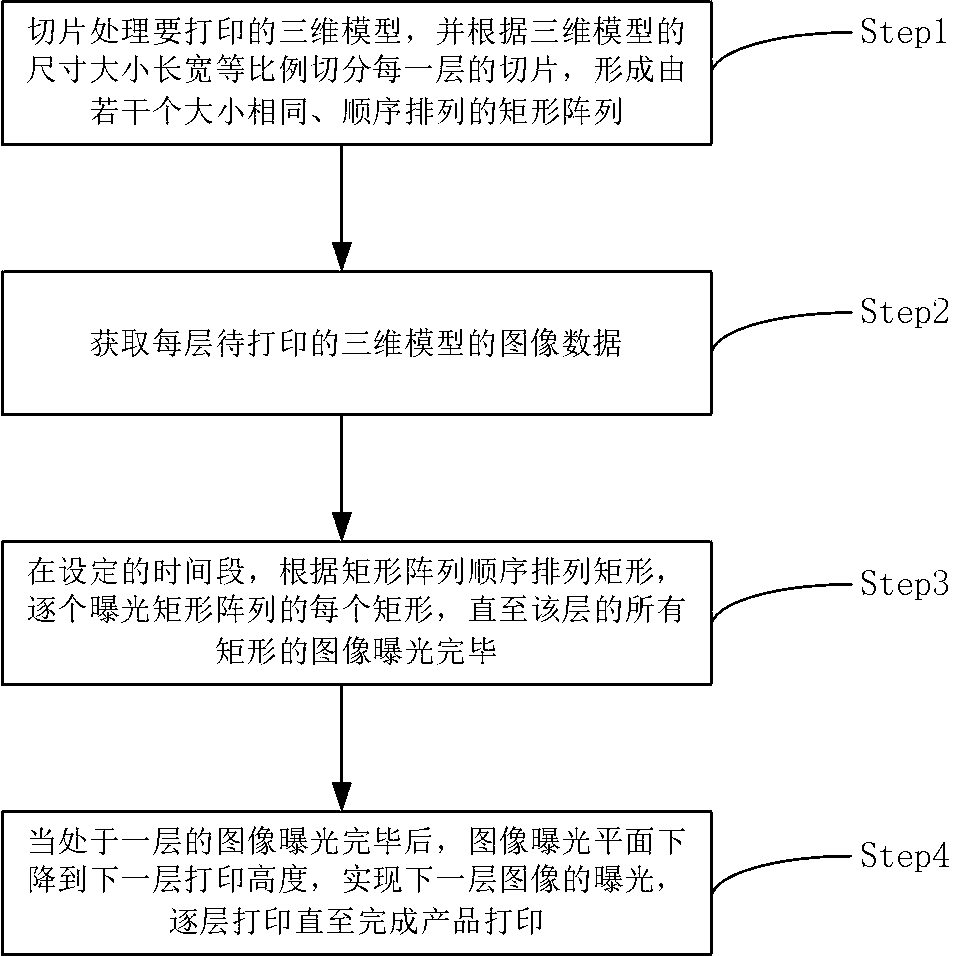

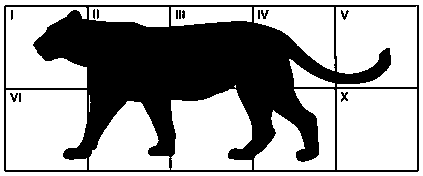

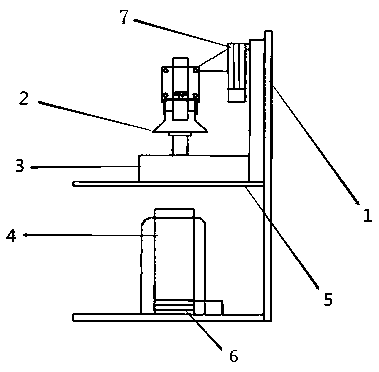

Projection combining type 3D printing method and 3D printing device

InactiveCN109968663AGuaranteed printing accuracyGood practicalityAdditive manufacturing apparatus3D object support structuresSetting time3D printing

The invention discloses a projection combining type 3D printing method and a 3D printing device. The 3D printing method comprises the following steps that a to-be-printed 3D model is subjected to slicing treatment firstly, then each layer is sliced according to equal proportions based on the size, the length and the width of the 3D model, and a plurality of rectangular arrays with the same size and arranged in sequence are formed; image data of all layers of the to-be-printed 3D model are obtained; rectangles are arranged according to the sequence of the rectangular arrays in a set time period, and the rectangles of the rectangular arrays are gradually exposed until images of all the rectangles of the layer are exposed; and after the images located on the layer are exposed, an image exposing plane declines to the printing height of a next layer, images of the next layer are exposed, and layer-by-layer printing is performed until product printing is completed. By means of the projectioncombining type 3D printing method and the 3D printing device, the problem that the size of a product printed by 3D printing equipment adopting a digital light processing technology is not big enoughis solved.

Owner:上海幻嘉信息科技有限公司

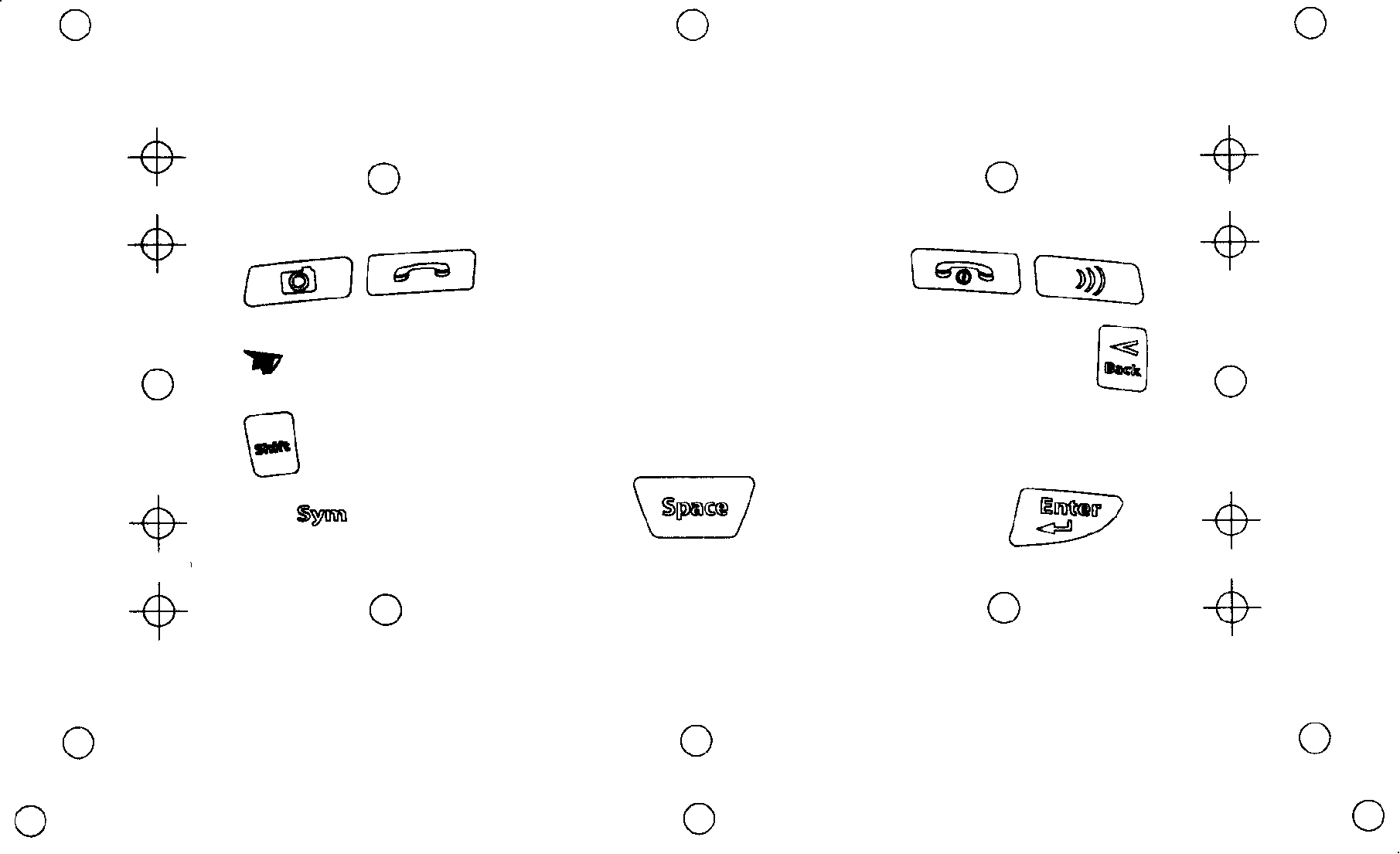

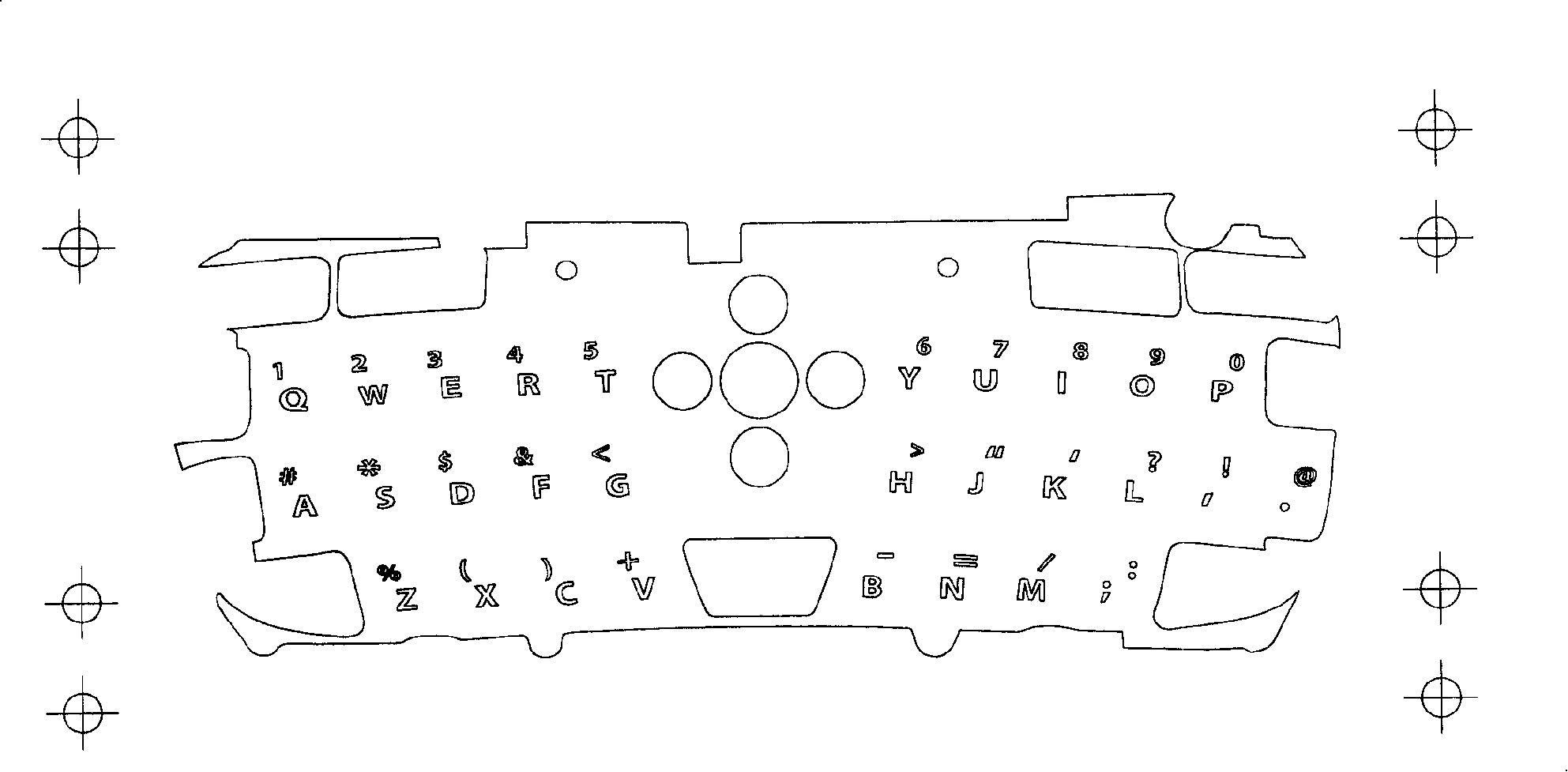

Chromaticity printing technique of in-mold label injection molding sheet material

ActiveCN101190615AReduce printing timesGuaranteed printing accuracyPattern printingOther printing apparatusPunchingAdhesive

The invention discloses an injection chromatic printing technique of a label in a mould, and the process is mainly to print a background color and a location hole simultaneously on a moldable sheet; the location hole is punched through by a digital controlling punching machine, then other colors are printed; after all ink is used out for printing, colorless adhesive or glossy oil is printed on a whole edition so as to prevent the ink from colliding when the injection is done; meanwhile, a level printing surface is formed, therefore any pressing trace can not appear on the surface of a keypad after the molding.

Owner:BYD PRECISION MFG

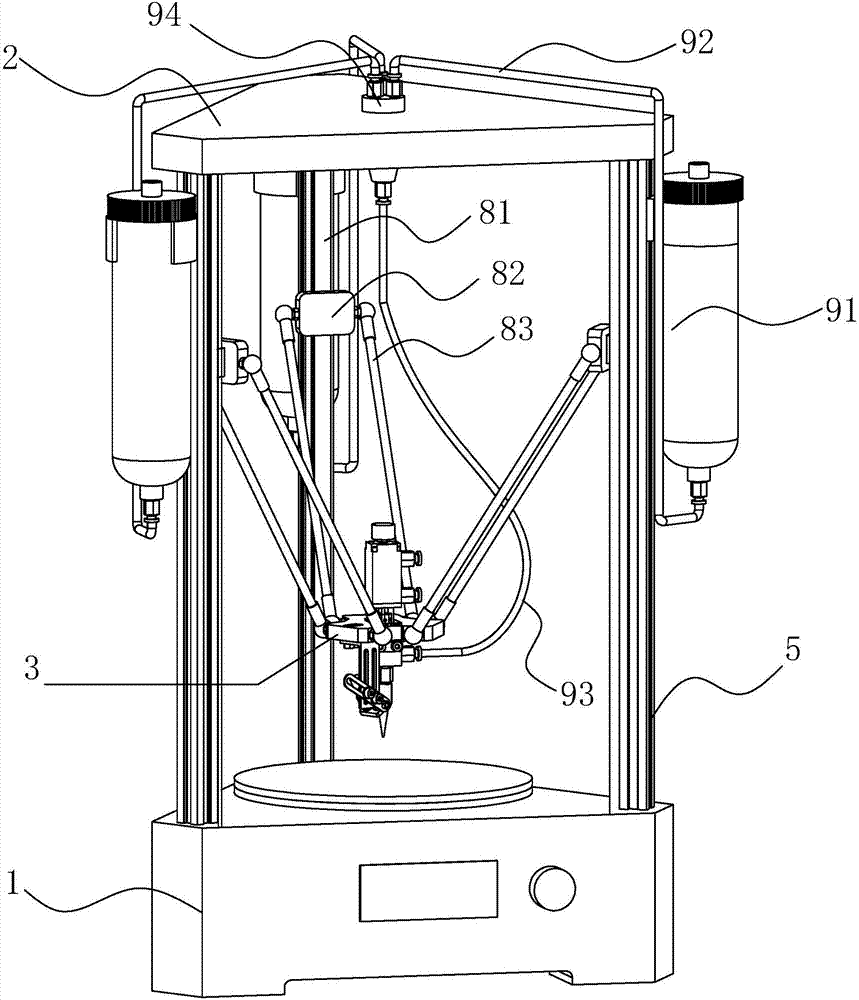

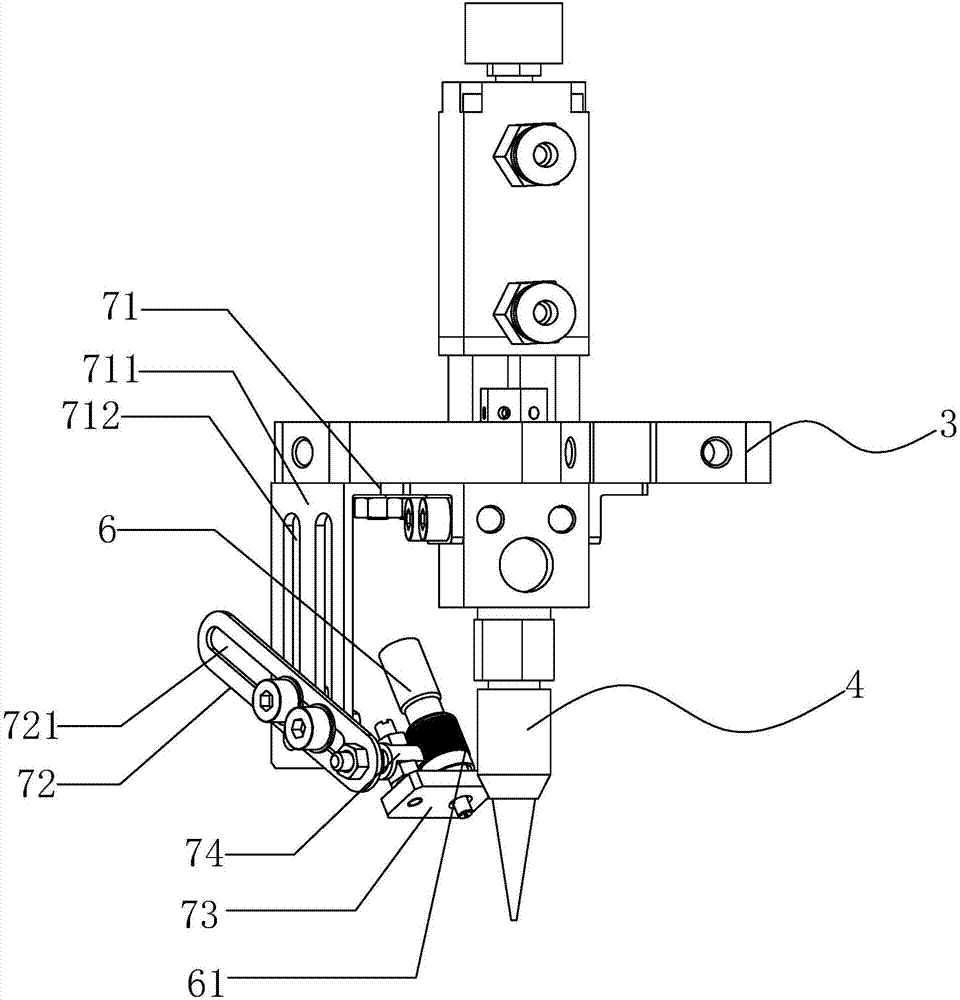

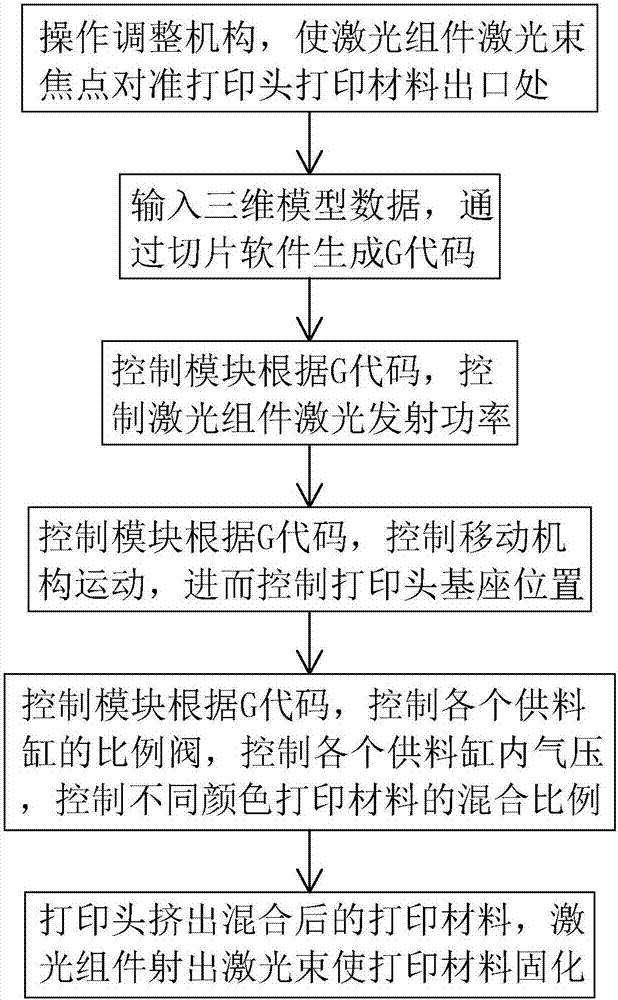

Novel 3D printer and using method thereof

PendingCN107364114AGuaranteed printing accuracyGuaranteed priceAdditive manufacturing apparatusAdditive manufacturing with liquidsComputer printing3d printer

The invention discloses a novel 3D printer. The novel 3D printer comprises a pedestal, a top cover, a printing head base, a printing head and a laser assembly, wherein the printing head is installed on the printing head base. The pedestal is connected with the top cover through a stand column in an assembled mode, the printing head base is connected with the stand column through a moving mechanism, the laser assembly is installed on the printing head base, and the focal point of a laser beam emitted by the laser assembly is located at a print material outlet in the printing head. According to the novel 3D printer, the novel 3D printer is used for achieving a FDM printer, the printing head and the laser assembly are installed together, so that the printing head and the laser assembly move together, and meanwhile the focal point of laser emitted by the laser assembly further needs to be aligned with a print material extruding end of the printing head; and an SLA printing technology can be achieved on the structure of an existing FDM printer, a complex optical system is not needed, meanwhile the printing precision and the price are guaranteed, and high cost performance is achieved.

Owner:SHENZHEN CAS DERUI INTELLIGENT TECH CO LTD

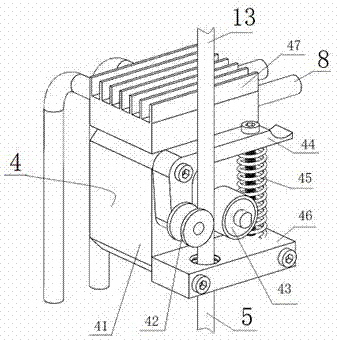

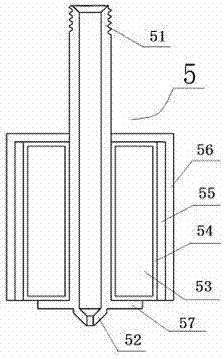

Printing head of 3D printer

A printer head of a 3D printer comprises a screw rod nut which is in transmission connection to a screw rod, wherein a first connecting plate is disposed on the lower end of the screw rod nut; a second connecting plate is connected to the lower end of the first connecting plate by a fixation bolt; a rotary hole is formed in the center of the inner side of the second connecting plate; a rotation plate is disposed on the upper end of the second connecting plate; a spray nozzle is in threaded connection to the lower end of the rotation plate; a heating block is disposed on the outer side of the lower end of the spray nozzle; a connecting base is disposed on upper ends of threaded holes; a connecting part is disposed on the inner side in the middle end of the connecting base; a limiting boss is disposed on the outer side of the upper end of the connecting part; a telescopic cylinder is disposed on the outer side of the boss; a seal plate is disposed on the upper end of the telescopic cylinder; a first installation groove is formed in the lower end of the seal plate; a second installation groove is formed in the upper end of the connecting base; a compression spring is disposed on innersides of the first installation groove and the second installation groove; a chock pipe is disposed on the upper end of the left threaded hole; a feeding hole is formed in the inner side of the chockpipe; an installation hole is formed in the upper end of the feeding hole; a pneumatic joint is disposed on the inner side of the upper end of the installation hole; and a feeding hole is disposed onthe lower end of the chock pipe.

Owner:HANGZHOU HIMALAYA INFORMATION TECH

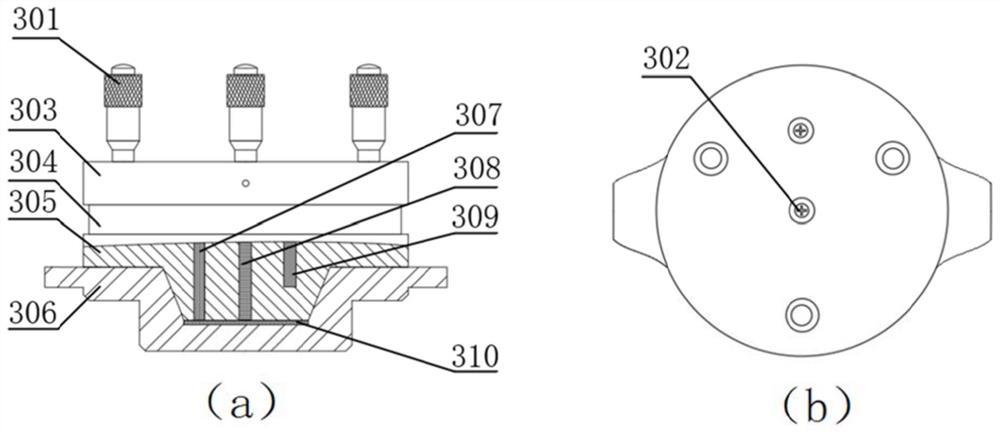

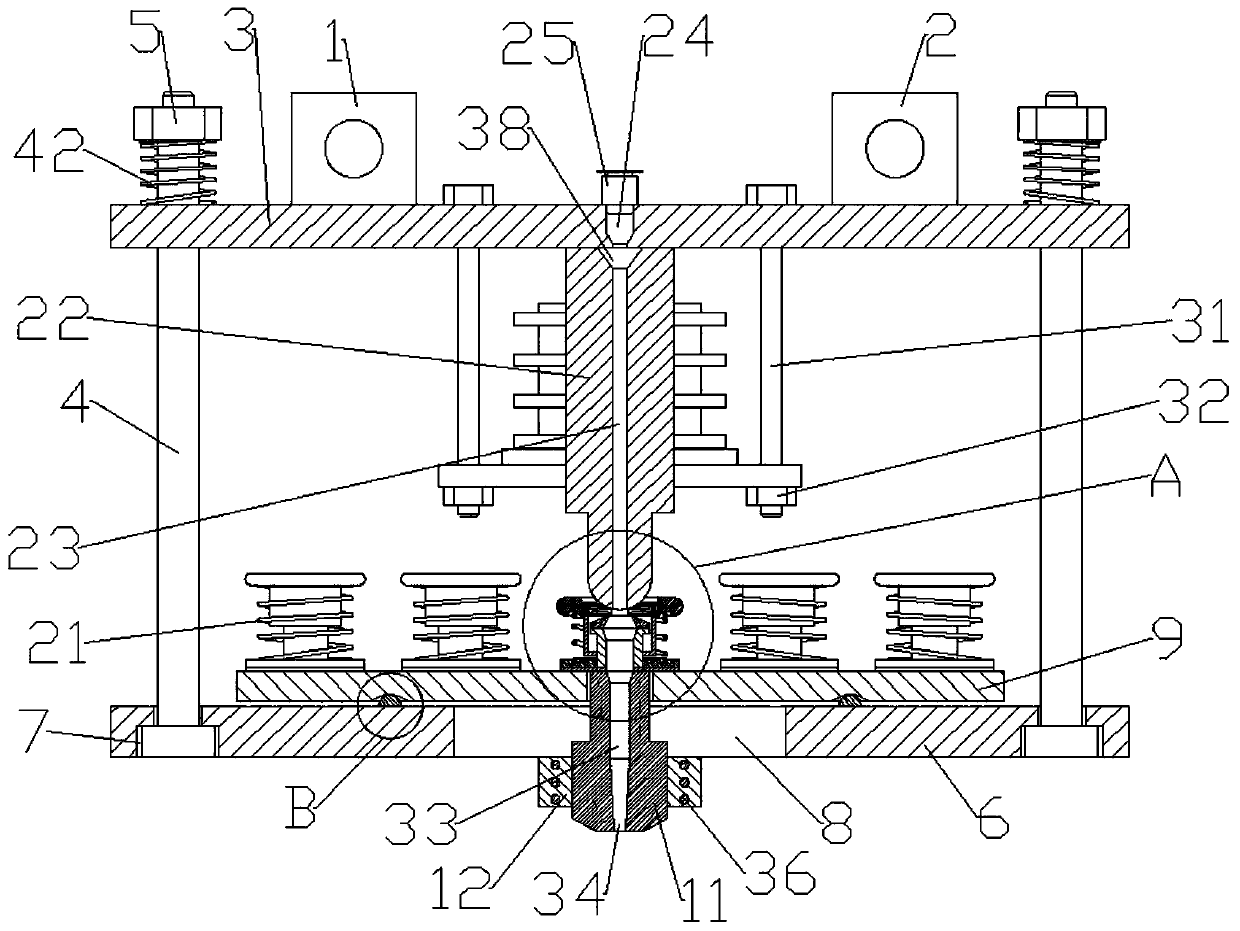

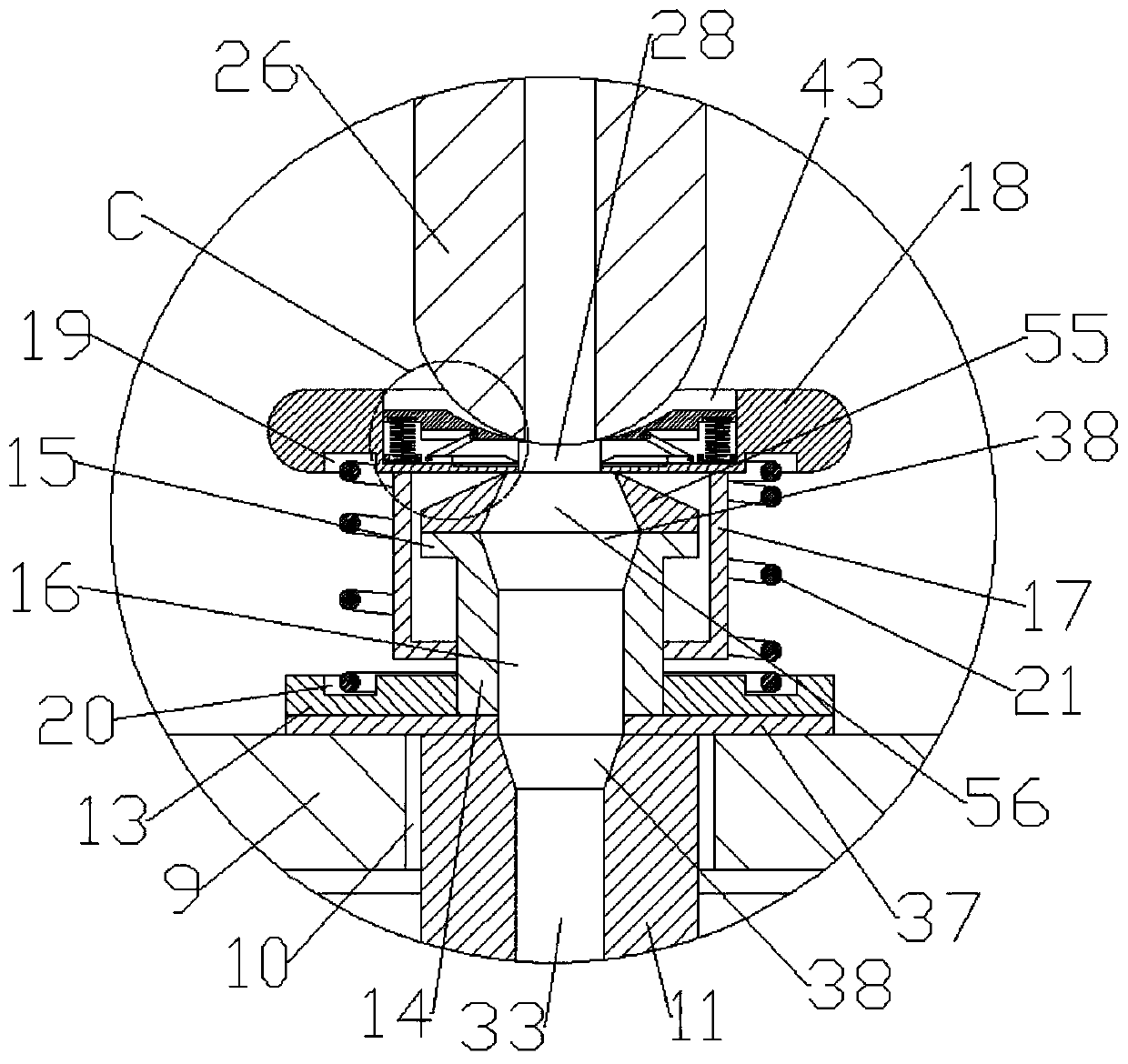

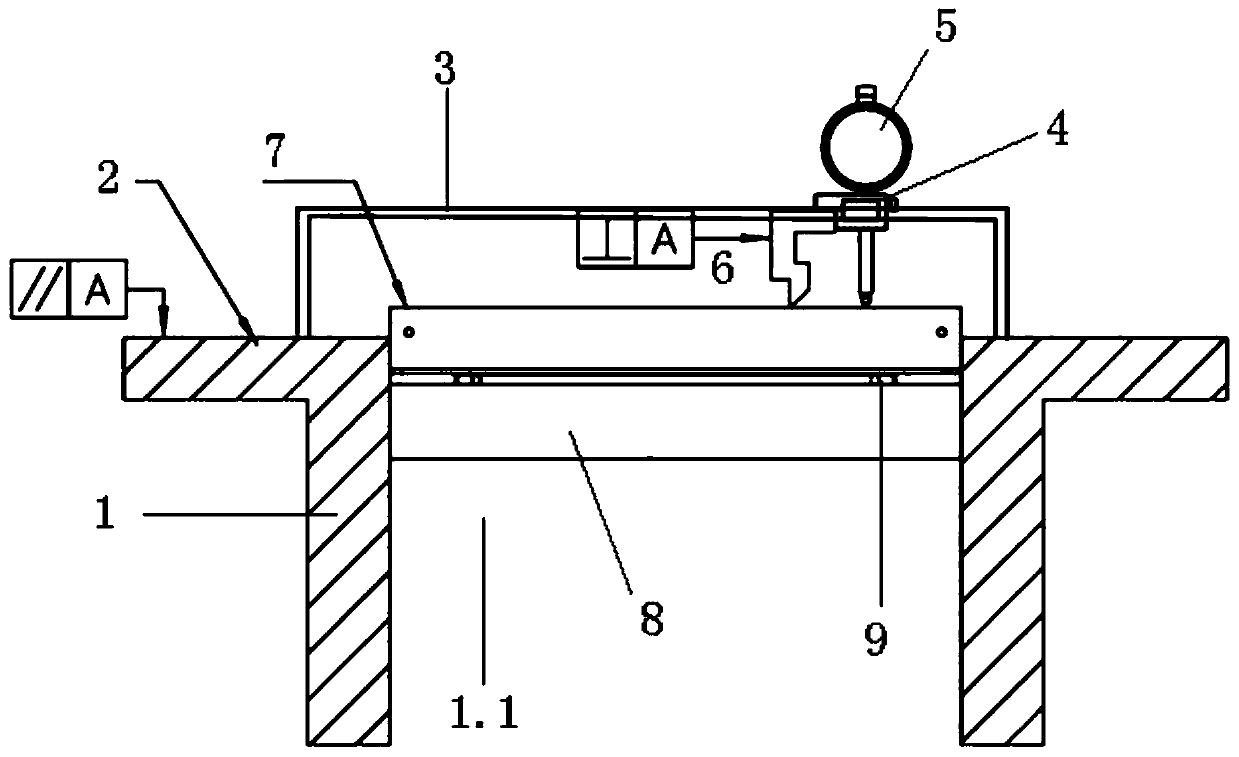

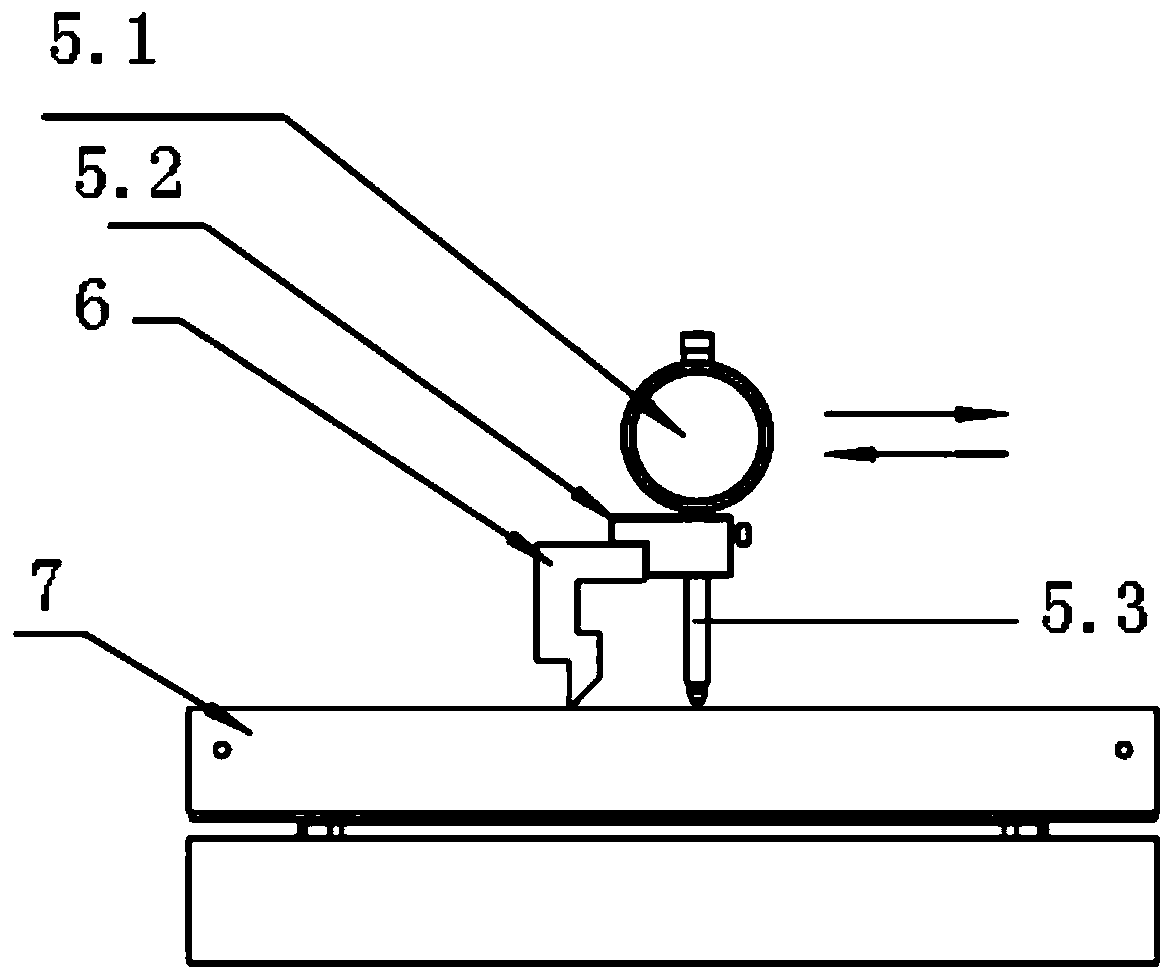

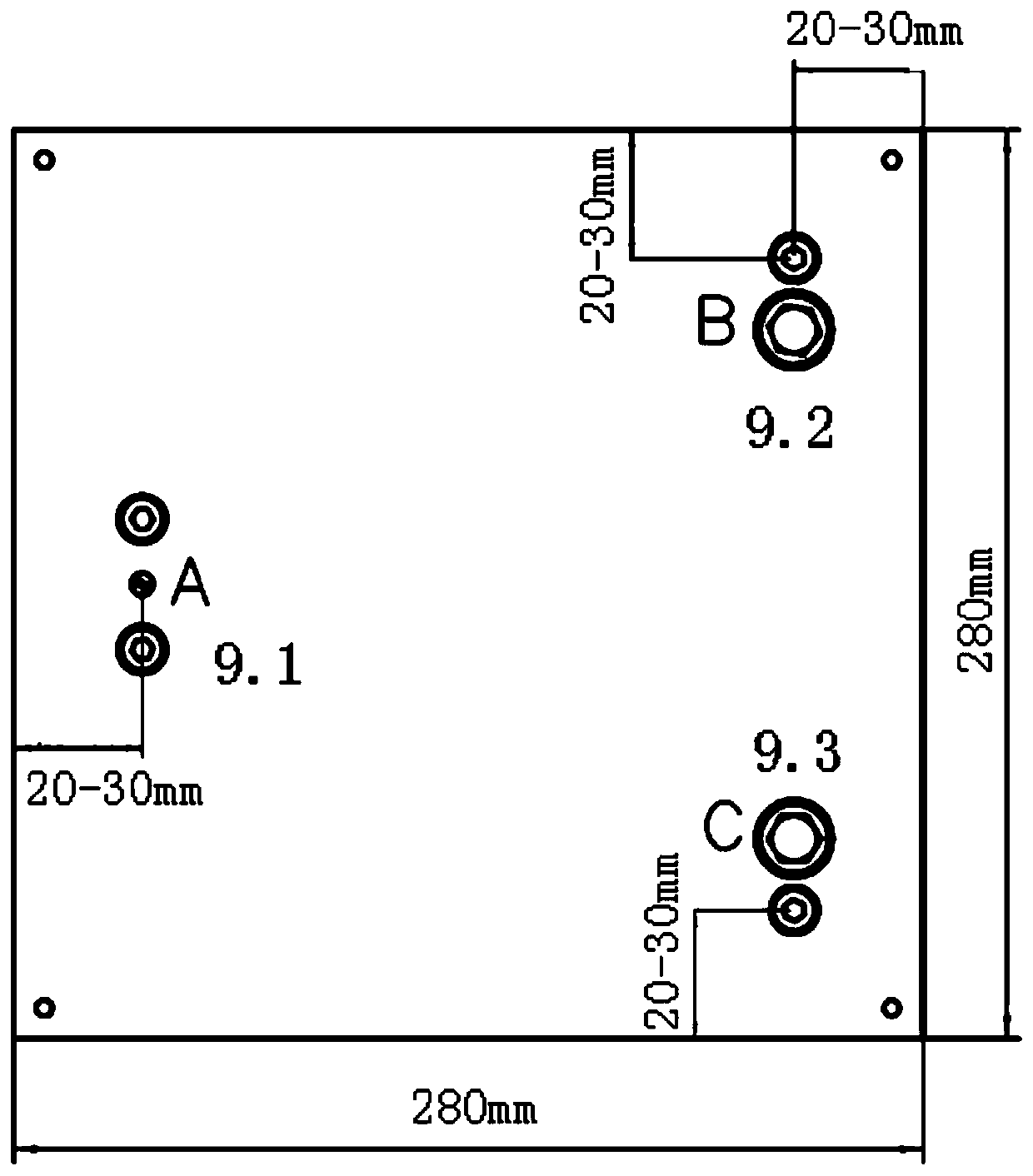

Three-point fixed printing substrate levelness adjusting structure and method

PendingCN110039055AEasy, quick and accurate adjustmentGuaranteed printing accuracyAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringMetal

The invention provides a three-point fixed printing substrate levelness adjusting structure and a method. The three-point fixed printing substrate levelness adjusting structure comprises a printing powder cylinder, a printing powder metal flat panel, a sliding rail, a sliding block, a dial indicator assembly, a powder paving scraper, a printing substrate, a printing moving plate and a three-pointfixed levelling assembly. The levelness of the printing substrate is adjusted through the three-point fixed levelling assembly; and the dial indicator assembly is slid along the sliding rail, the powder paving scraper is driven synchronously to slide, and accordingly, the levelness of the printing substrate is detected. The three-point fixed printing substrate levelness adjusting structure and themethod have the following advantages that (1) under the condition that the scraper is replaced or the printing substrate moves to a certain extent, the levelness of the printing substrate can be adjusted conveniently, fast and accurately at regular intervals, the printing precision of a part in the vertical direction can be guaranteed, and the purpose that the part quality is guaranteed is achieved; and (2) the three-point fixed printing substrate levelness adjusting structure has the characteristics of simple adjusting structure, convenient adjusting and easy maintaining of levelness in theaspect of printing substrate levelness adjusting of the laser selective melting 3D printing field.

Owner:HARBIN FORWEDO MULTI DIMENSIONAL INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com