Projection combining type 3D printing method and 3D printing device

A 3D printing and split technology, applied in the field of 3D printing, can solve the problem of insufficient size of printed products, achieve good practicability and ensure printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

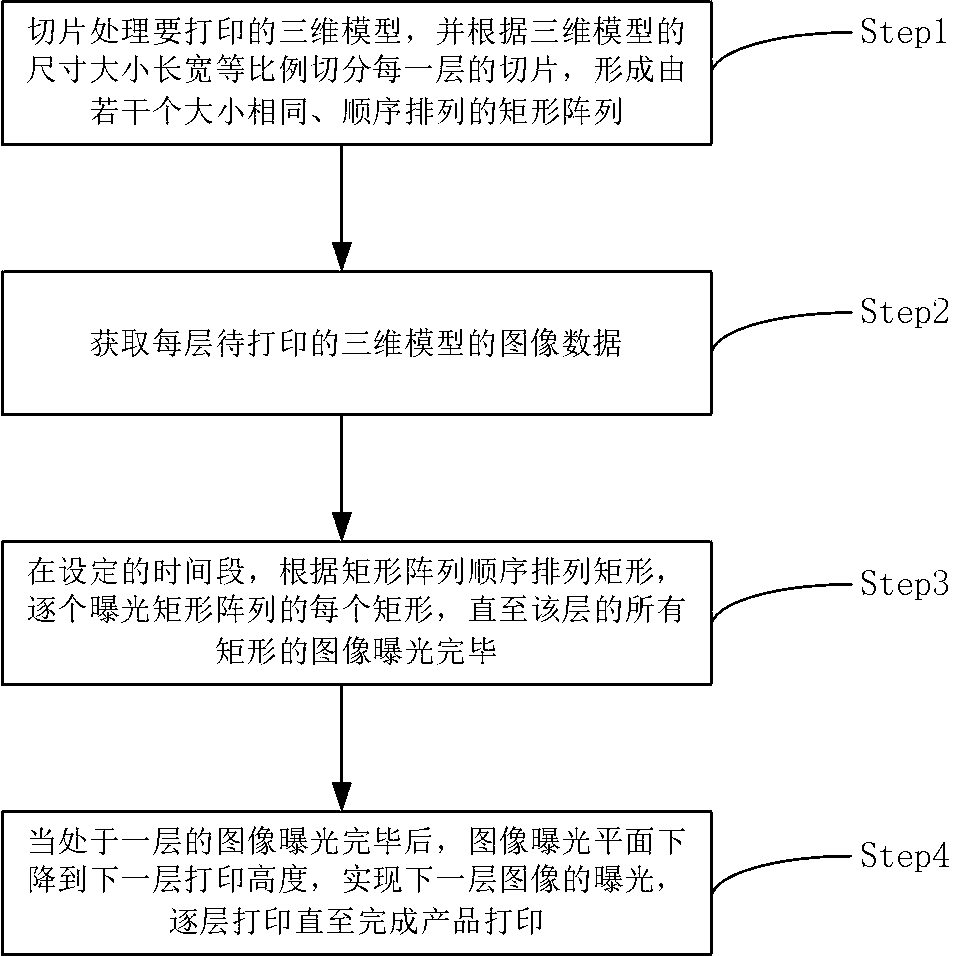

[0033] see figure 1 , a kind of projective mosaic type 3D printing method, comprises the following steps:

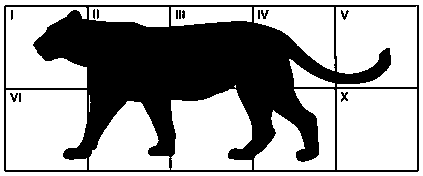

[0034] Step1: Slice the 3D model to be printed, and slice the slices of each layer according to the size, length and width of the 3D model, forming several rectangular arrays of the same size and arranged in order;

[0035] Step2: Obtain the image data of the 3D model to be printed on each layer;

[0036] Step3: Arrange the rectangles according to the order of the rectangle array in the set time period, and expose each rectangle in the rectangle array one by one until all the images of the rectangles in the layer are exposed.

[0037] In an embodiment, the above method further includes Step4: after the exposure of the image on one layer is completed, the image exposure plane drops to the printing height of the next layer to realize the exposure of the image on the next layer, and print layer by layer until the product is printed.

[0038] In the embodiment, the specifi...

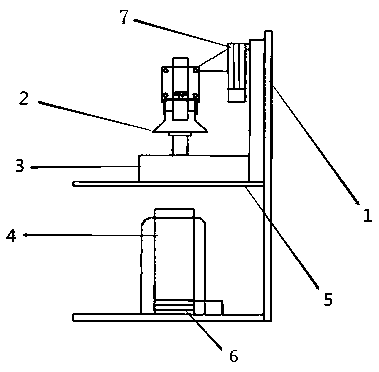

Embodiment 2

[0051] The difference from Embodiment 1 is that the projection device 4 can also be placed above the resin tank 3 to form a top projection type.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com