Synchronous two-sided digital ink-jet machine

A digital inkjet printing and inkjet technology, which is applied in typewriters, printing devices, printing, etc., can solve the problems of affecting inkjet printing accuracy, inkjet printing accuracy decline, and increasing production costs, so as to ensure inkjet printing accuracy, ensure inkjet printing accuracy, and have a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

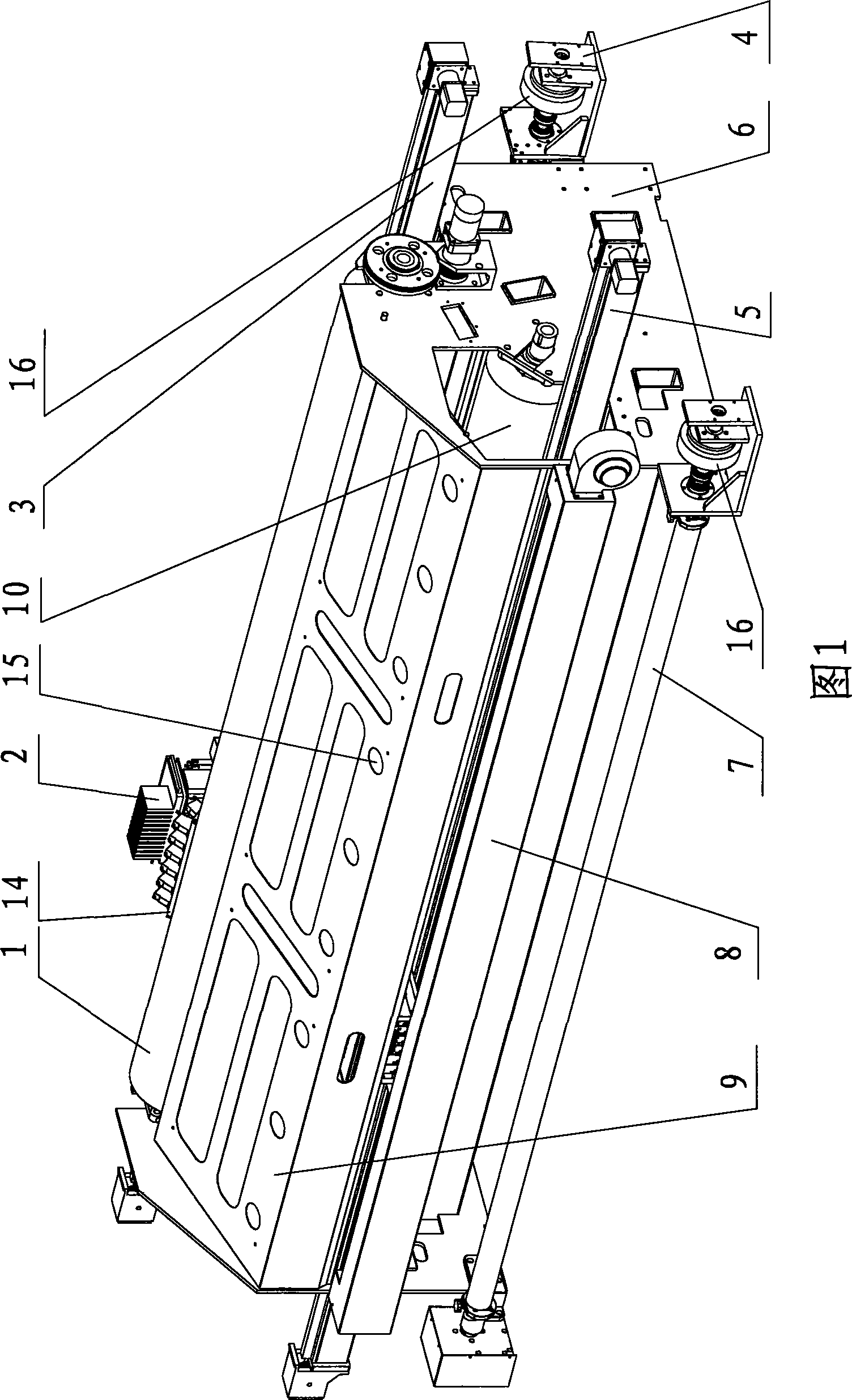

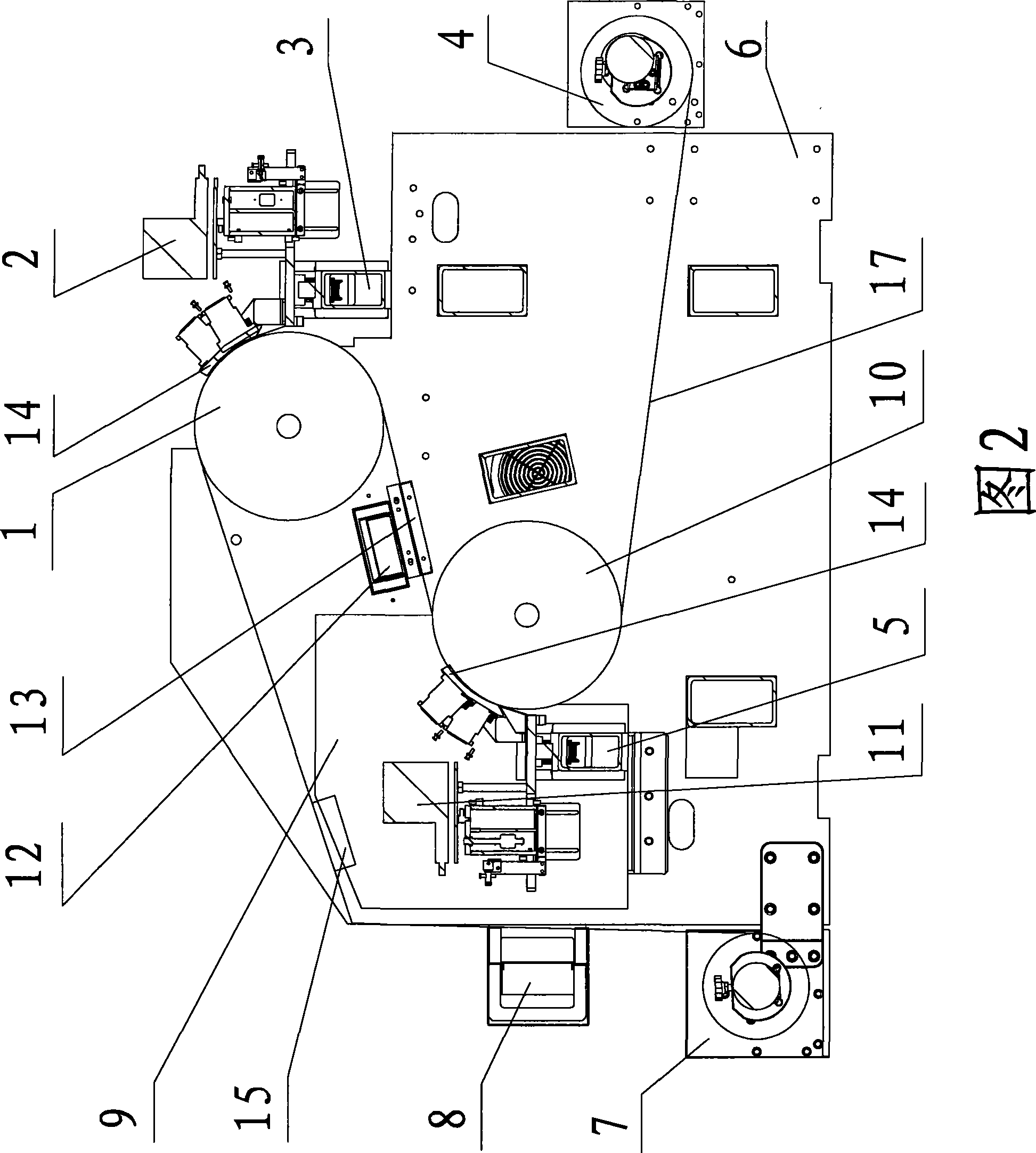

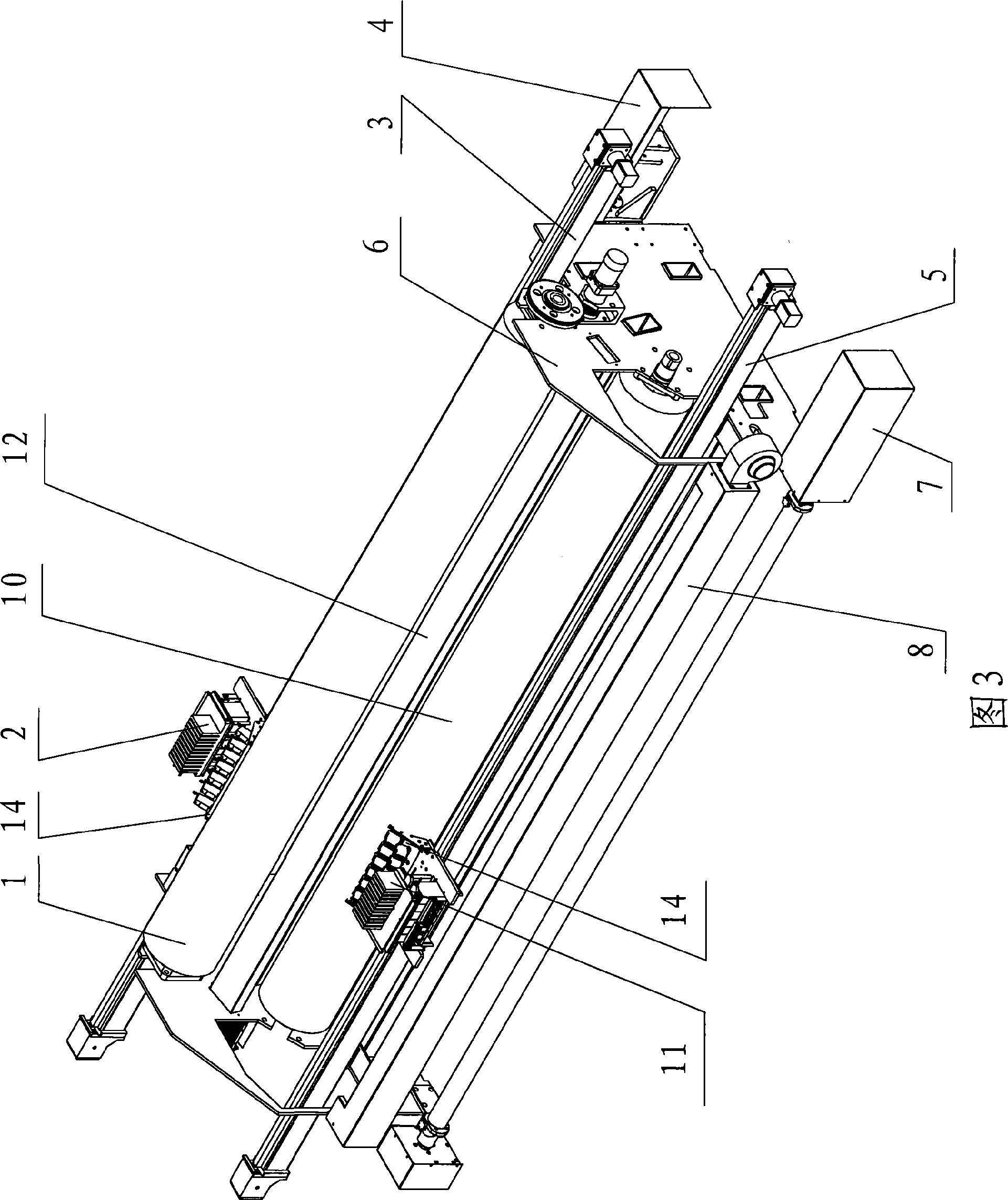

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0028] As shown in Figures 1-5, the present invention includes a wallboard 6 and a cloth releasing device 4 and a cloth receiving device 7 installed thereon, and the wallboards 6 are supported by a plurality of support beams. One end of the cloth releasing device 4 and the cloth receiving device 7 may also be provided with a tension clutch 16 respectively. The tension clutch 16 on the cloth releasing device 4 will force the sprayed material 17 to the reverse direction of material running; the tension clutch 16 on the cloth receiving device 7 will make the sprayed material 17 to bear force on the forward direction of material running. The tension clutch 16 ensures the frictional force of the sprayed material 17 on the main inkjet roller 1, and can keep the sprayed material 17 in a taut state all the time. Between the wall boards 6 are provided with main and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com