Solid Electrolytic Capacitor

A solid electrolysis, solid electrolyte technology, applied in solid electrolytic capacitors, electrolytic capacitors, capacitors and other directions, can solve the problems of labor-hours, large thickness space, long time, etc., to shorten the lead-out path, eliminate the bending step difference, electrostatic capacitance value added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

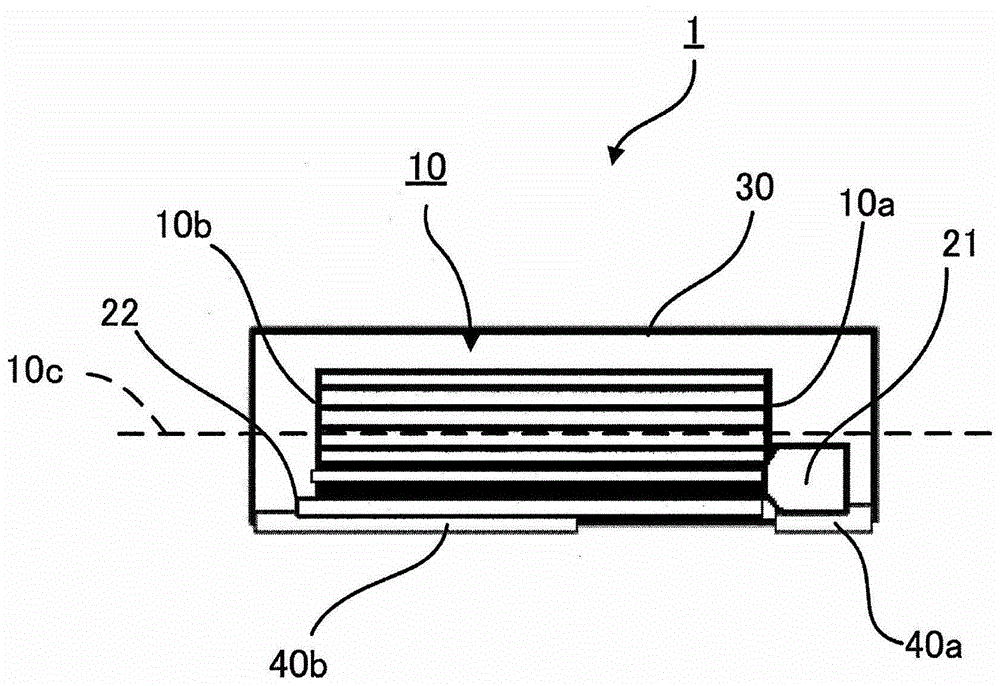

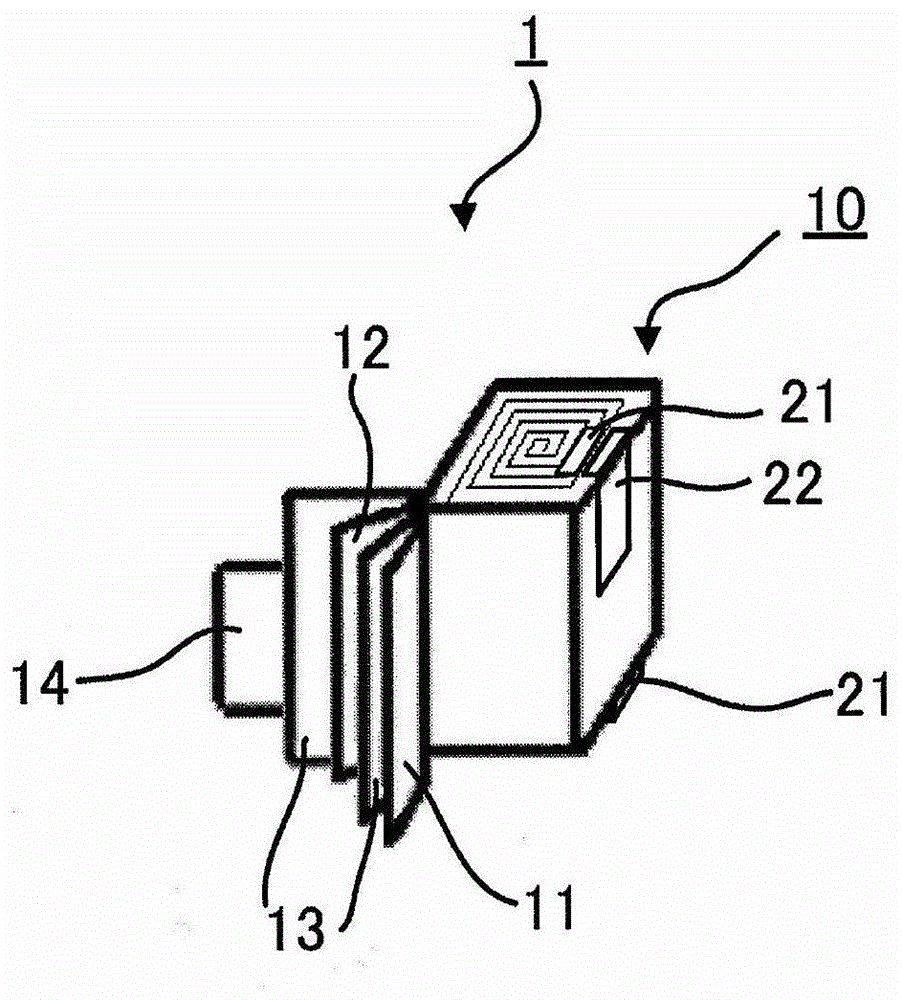

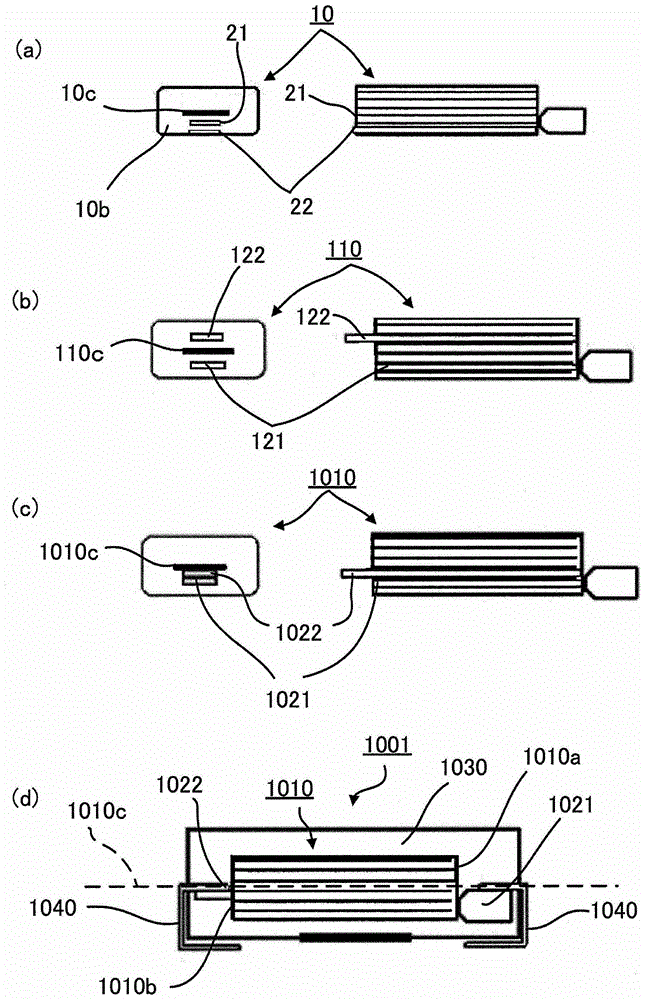

[0056] figure 1 It is a schematic longitudinal sectional view schematically showing the solid electrolytic capacitor according to the first embodiment of the present invention. figure 2 It is a schematic perspective view schematically showing the disassembled structure of the solid electrolytic capacitor of the first embodiment before the solid electrolyte is formed.

[0057] Such as figure 2 As shown, the solid electrolytic capacitor 1 includes: a rectangular parallelepiped element 10, the coiled element formed by winding the anode foil 11, the cathode foil 12, and the separator 13 arranged between the anode foil 11 and the cathode foil 12 is in the shape of a flat cuboid , form a solid electrolyte; anode lead-out terminal 21 is connected to anode foil 11; cathode lead-out terminal 22 is connected to cathode foil 12; figure 1 ).

[0058] exist figure 2 In , the end of the anti-roll tape 14 is free, but in fact, the end of the anti-roll tape 14 is pasted on the side o...

no. 2 approach

[0115] Hereinafter, the same components as those of the solid electrolytic capacitor 1 according to the first embodiment will be described with the same reference numerals. In addition, the description in the first embodiment is also applicable to the part in the second embodiment, and the description thereof will be omitted.

[0116] use Figure 13 to Figure 16 A second embodiment will be described.

[0117] Figure 13 is a schematic longitudinal sectional view schematically showing a solid electrolytic capacitor according to the second embodiment.

[0118] Such as Figure 13 As shown, also in the second embodiment, the cathode lead-out terminal 22 is arranged at the outermost shell of the rectangular parallelepiped element 10 similarly to the first embodiment. That is, the cathode lead-out terminal 22 is on the side of the cuboid element 10 (the bottom surface of the cuboid element 10, Figure 13 bottom face) exposed. And, the exposed cathode lead-out terminal 22 is co...

Embodiment 1

[0135] As Example 1, the solid electrolytic capacitor 1 (6.3 V, 100 μF) shown in the first embodiment was produced ( figure 1 ). The size of the packaging box of the solid electrolytic capacitor 1 is 7.3mm×4.3mm×2.8mm. As the lead frames 40 ( 40 a and 40 b ), a copper frame material whose surface was nickel-plated and whose thickness was 100 μm was used. In addition, at the time of manufacture, before the lead frame 40a is connected to the anode lead-out terminal 21 (aluminum anode tab), a needle is inserted through the connection position of the lead frame 40a to the anode lead-out terminal 21, thereby, at the connection position The protruding portion 41 is formed. Use a quadrangular pyramid-shaped front end of needles as needles. The lead frame 40a and the anode lead-out terminal 21 are connected by an inverter resistance welding machine. Then, before the lead frame 40b is connected to the cathode lead-out terminal 22 (nickel-plated copper base material cathode tab),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com