Stair slab and processing mould for same

A stair and mold technology, applied in the field of stair strips and their processing molds, can solve the problems of single variety of flame retardant boards, cannot be assembled with the floor, and limited use range, and achieves the effect of beautiful appearance, increased aesthetic effect, and prolonged service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] (Embodiment 1, stair strip)

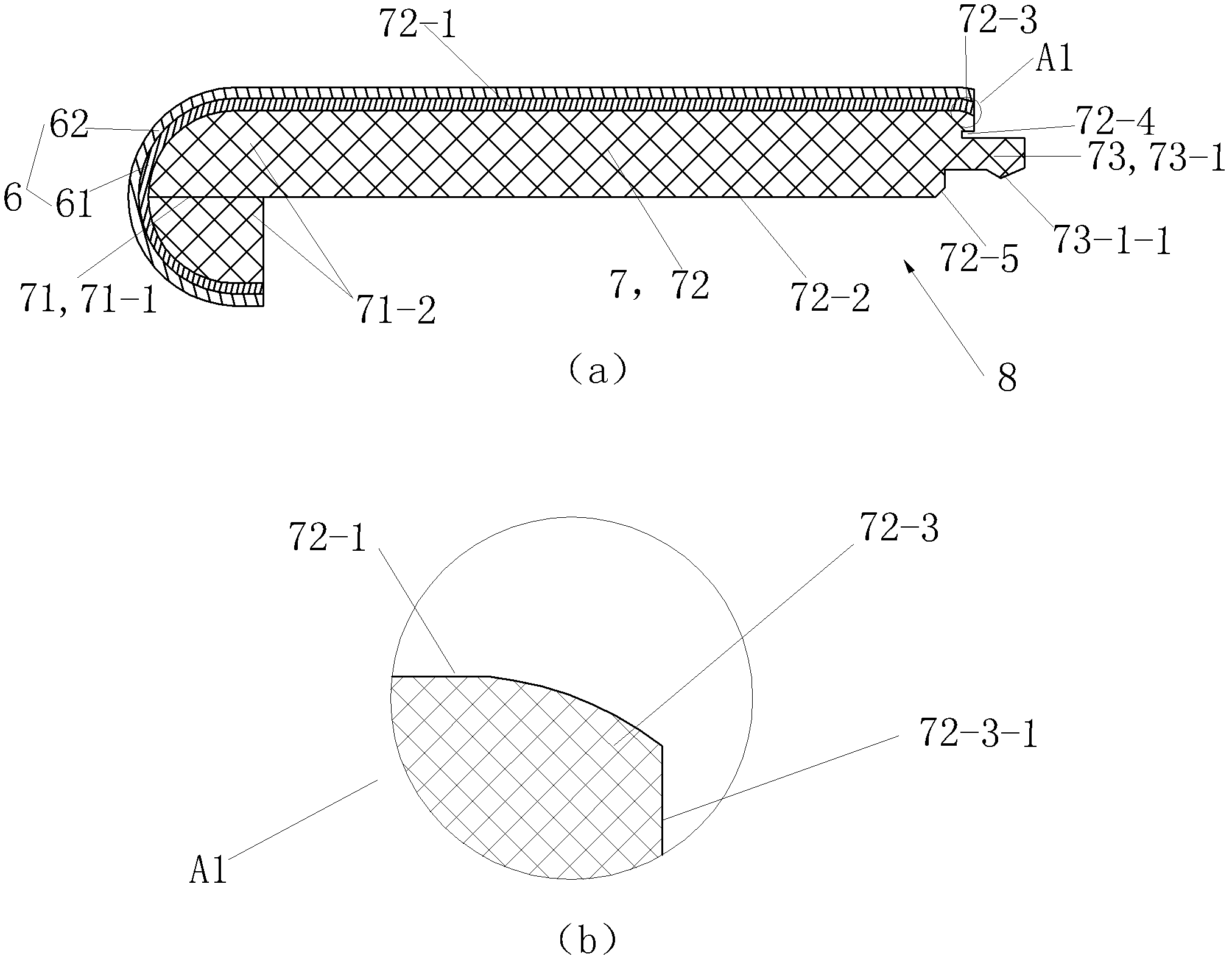

[0071] See figure 1 The stair bar 8 of this embodiment includes a base plate 7 and a veneer paper layer 6 pressed and fixed on the base plate 7 . The base plate 7 is an integral member, and its cross-sections parallel to each other in the front-rear direction and vertically arranged in the left-right direction have the same shape. The overlay paper layer 6 includes an impregnated paper layer 61 and a wear-resistant paper layer 62 .

[0072] The base plate 7 is composed of a head 71, a main body 72 and a tenon part 73 connected in sequence from left to right, and the head 71 is composed of a round head 71-1 and a connecting part 71-2 connected left and right. The outer peripheral side of the round head 71-1 is an arc-shaped curved surface that protrudes to the left, and the shape of the cross-section vertically arranged along the left and right directions is a circular arc that protrudes to the left with a central angle of 90°-180°....

Embodiment 2

[0081] (Example 2, stair strip)

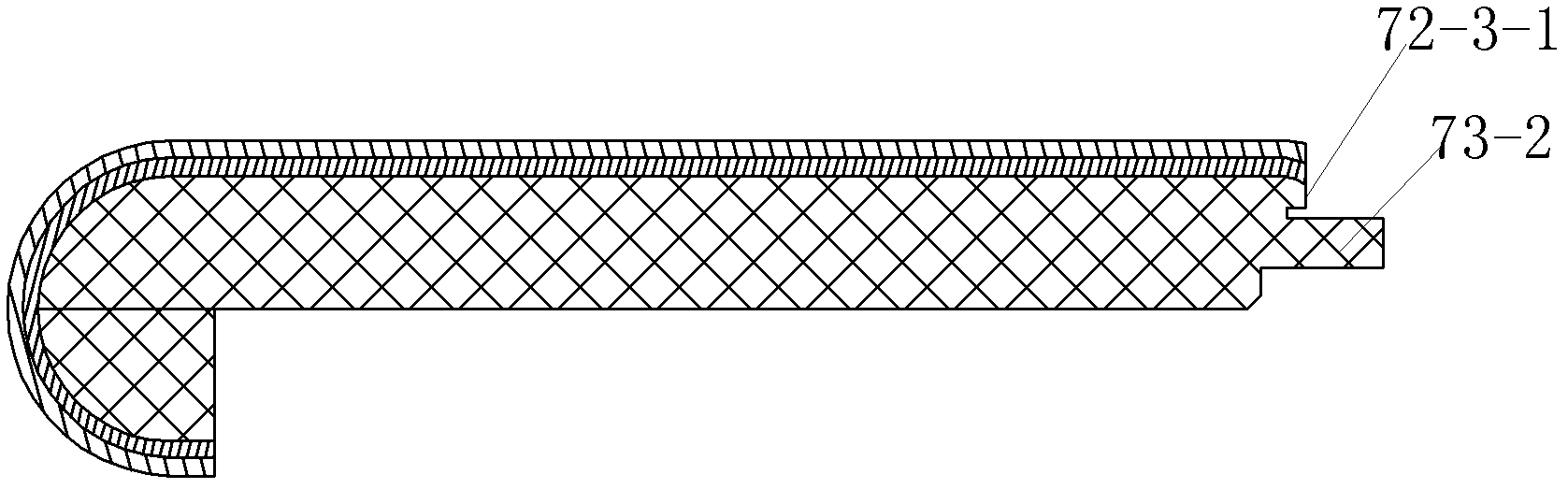

[0082] See figure 2 , the rest of the stair bar 8 of the present embodiment is the same as that of Embodiment 1, the difference is that:

[0083] The tenon portion 73 of the substrate 7 is a flat-button male tenon 73-2, and the upper surface and the lower surface of the flat-button male tenon 73-2 are both plane and parallel to each other.

Embodiment 3

[0084] (Embodiment 3, stair strip)

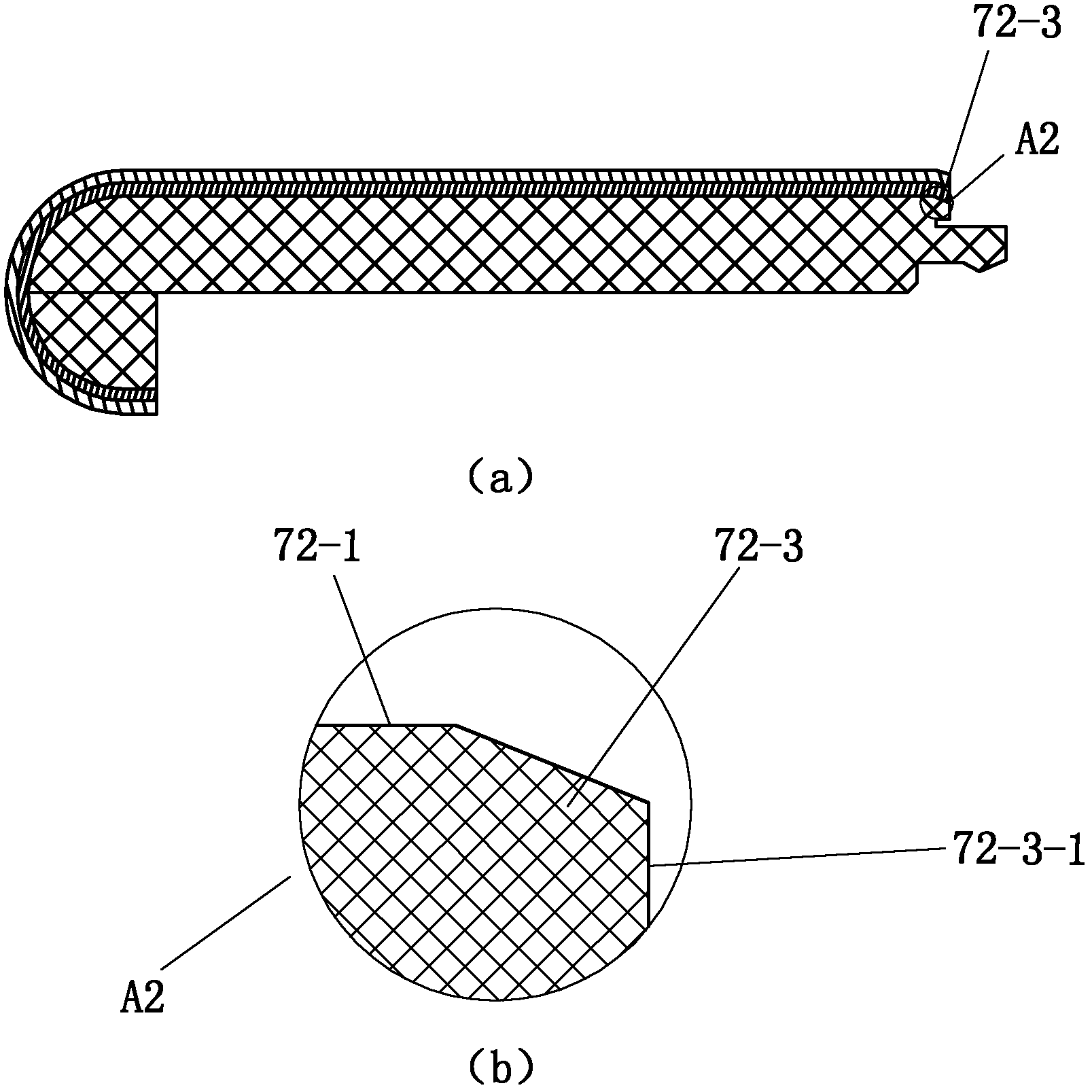

[0085] See image 3 The rest of the stair bar 8 of this embodiment is the same as that of Embodiment 1, except that the upper right corner of the main body portion 72 of the base plate 7 as the corner sinking portion 72-3 is a portion provided with a slope, and its outer peripheral surface It is composed of an inclined surface inclined from upper left to lower right on the upper part and a front-to-back vertical surface 72-3-1 located on the lower part. The acute angle between the inclined surface and the horizontal plane is 20°.

[0086] On the inclined surface of the corner sinking part 72-3 of the main body part 72 of the substrate 7, on the upper plane 72-1 and the outer peripheral side of the head part 71, the whole sheet of continuous overlay paper 6a is pressed and pasted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com