Patents

Literature

182 results about "Wind component" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

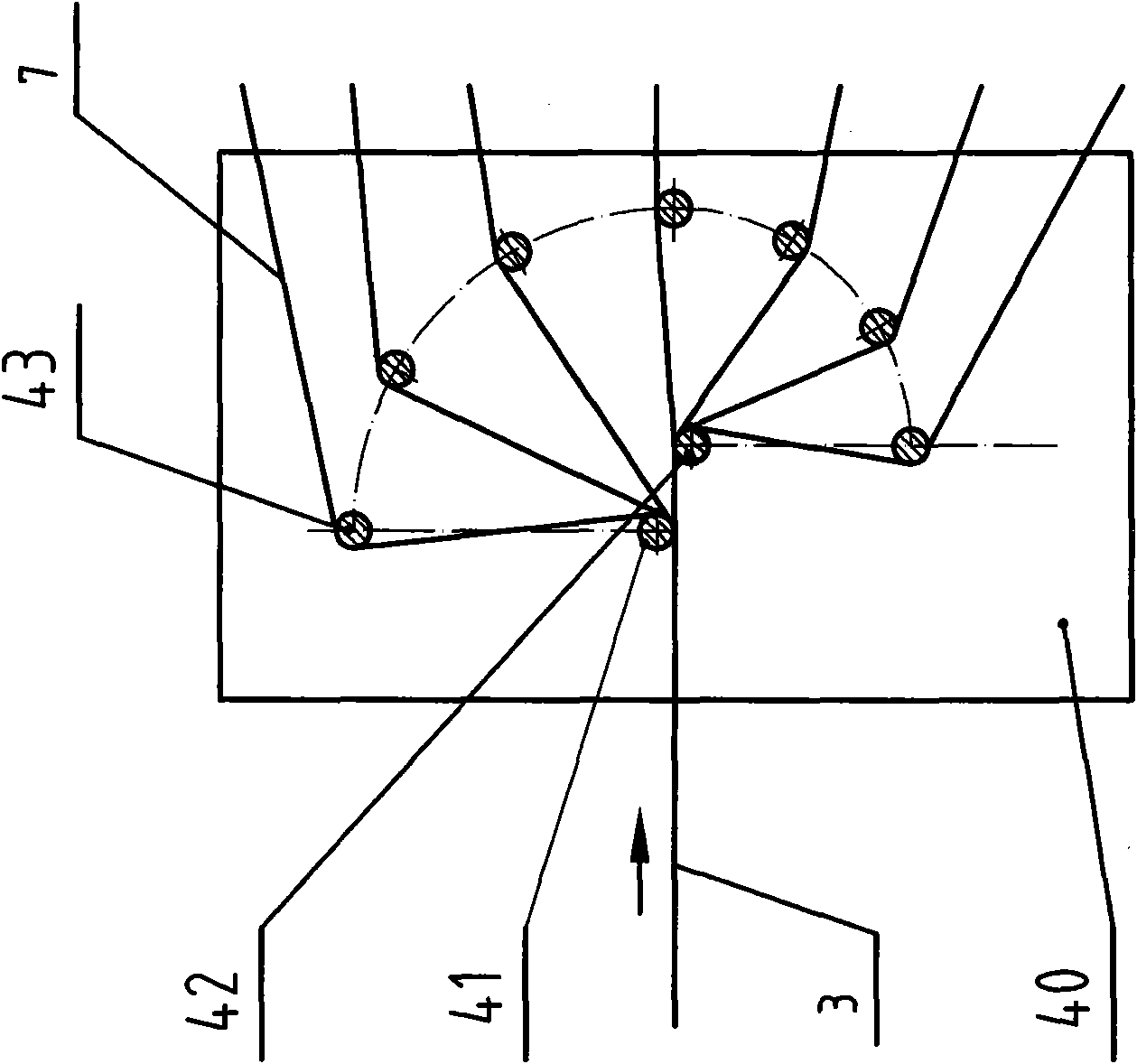

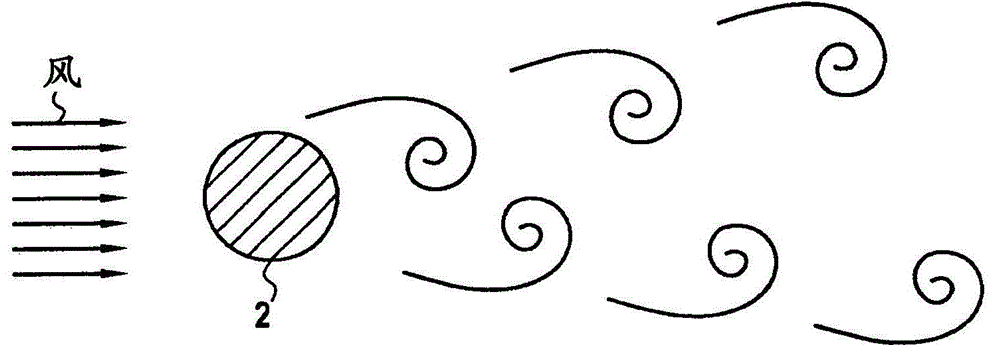

A Wind component chart provides crosswind and head/tail wind components, appropriate to the runway headings, reported wind velocity and direction. Test pilots use crosswind and headwind component charts to calculate the headwind and crosswind component for any given wind direction and wind velocity. This enables them to judge whether a plane can be safely land in given crosswinds.

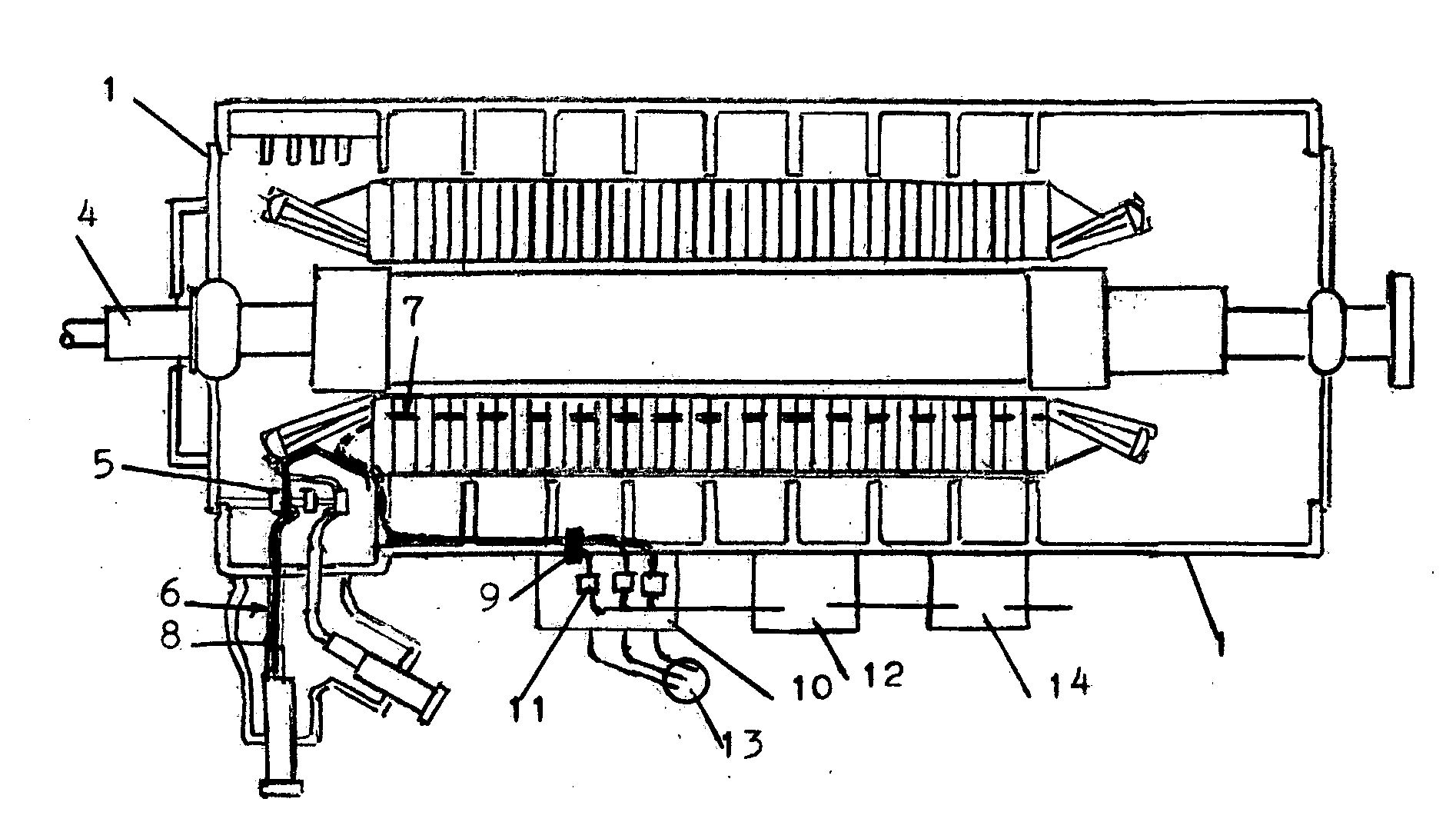

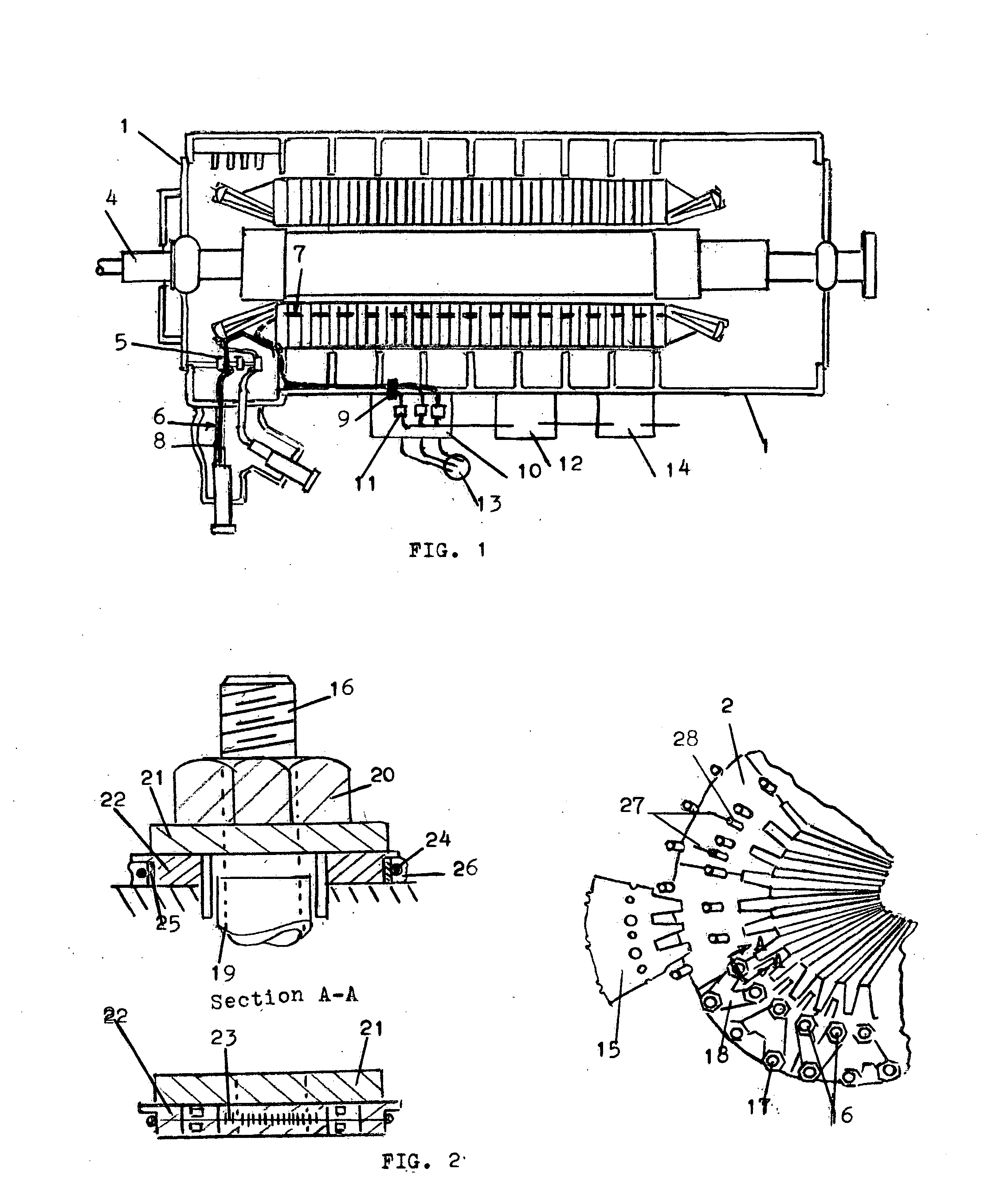

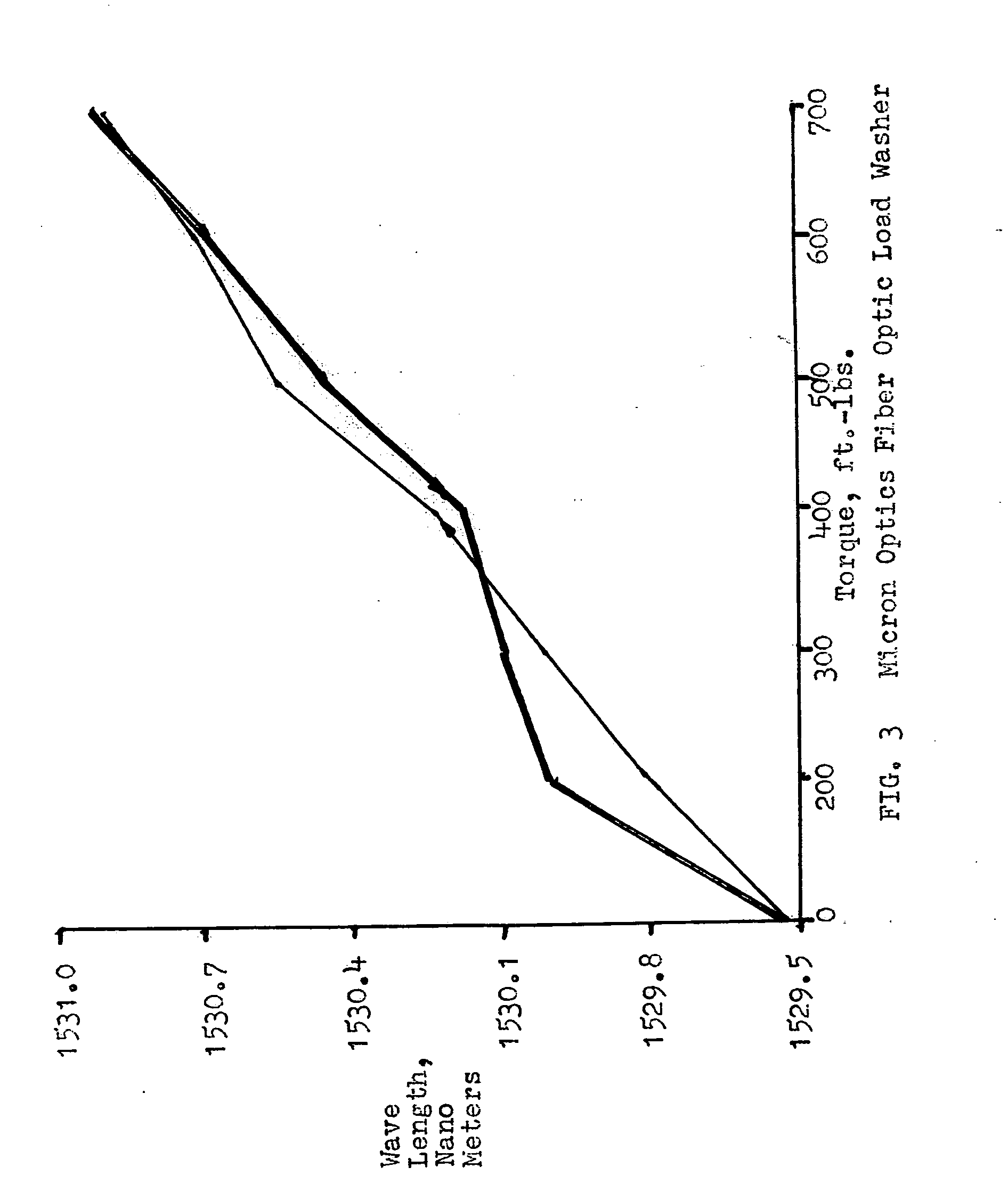

Use of fiber optic sensor techniques for monitoring and diagnostics of large AC generators

ActiveUS20120026482A1Avoid insufficient lengthForce measurementMaterial analysis by optical meansGratingEngineering

A method for monitoring the operating conditions of an electric generator including the entire stator core and all winding components for conditions of mechanical strain and temperature throughout the machine by means of distributive fiber optic sensors based on both Rayleigh back scattering techniques and Brillouin frequency shift fiber optic sensor analysis both of which do not have the gaps and limitations associated with standard fiber Bragg grating fiber optic point sensors, by virtue of the fact that both Rayleigh and Brillouin scans and allow accurate strain and temperature determinations at all points along standard fiber optic cables of considerable length, approximately two kilometers in the case of the Brillouin, which effectively yields many tens of thousands of sensors throughout the entire standard fiber optic cable. Raman distributive temperature sensing also has a limited application. Single mode and polarizing maintaining fibers can both be analyzed and read with any Rayleigh or Brillouin distributive fiber optic sensor laser system allowing great flexibility in sensor spatial resolution, total sensed length, resolution and other factors not possible with conventional fiber Bragg gratings. A sealed fiber collection box located outside the electric generator permits enhanced reliability and reconfiguration into any number of desirable fiber layouts necessary for specific static and dynamic measurements in an optimal manner.

Owner:INNOVATIVE DIAGNOSTIC SYST

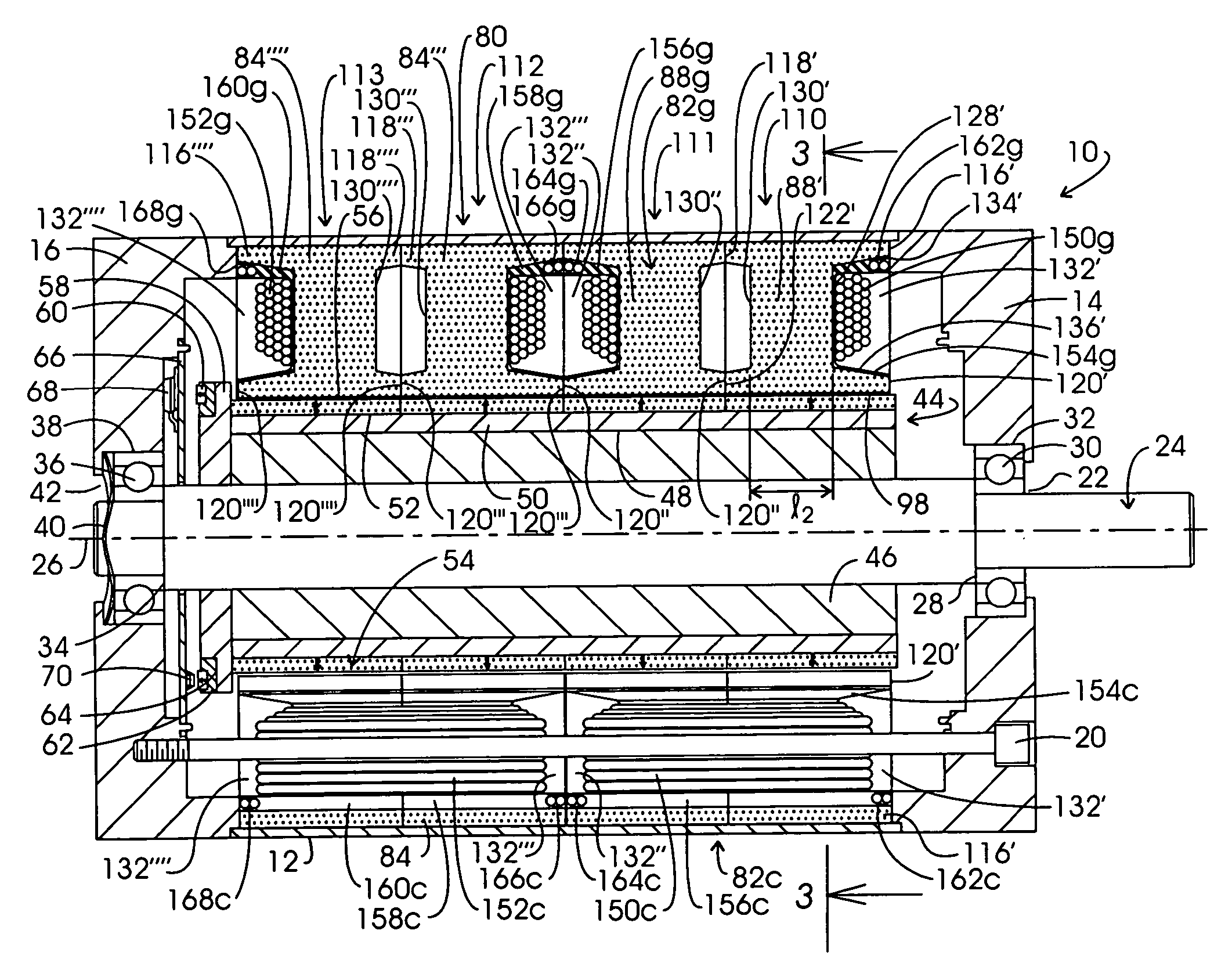

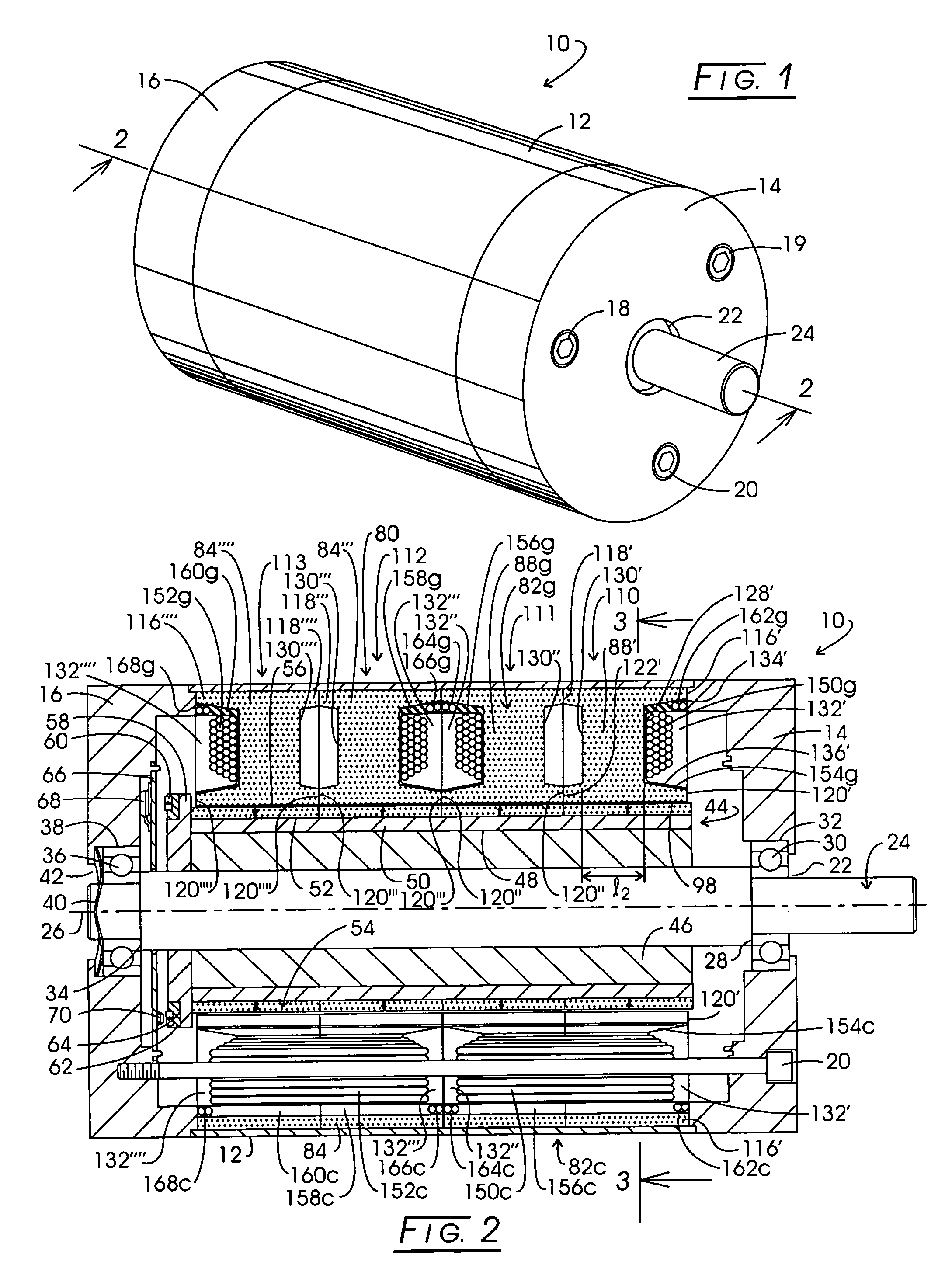

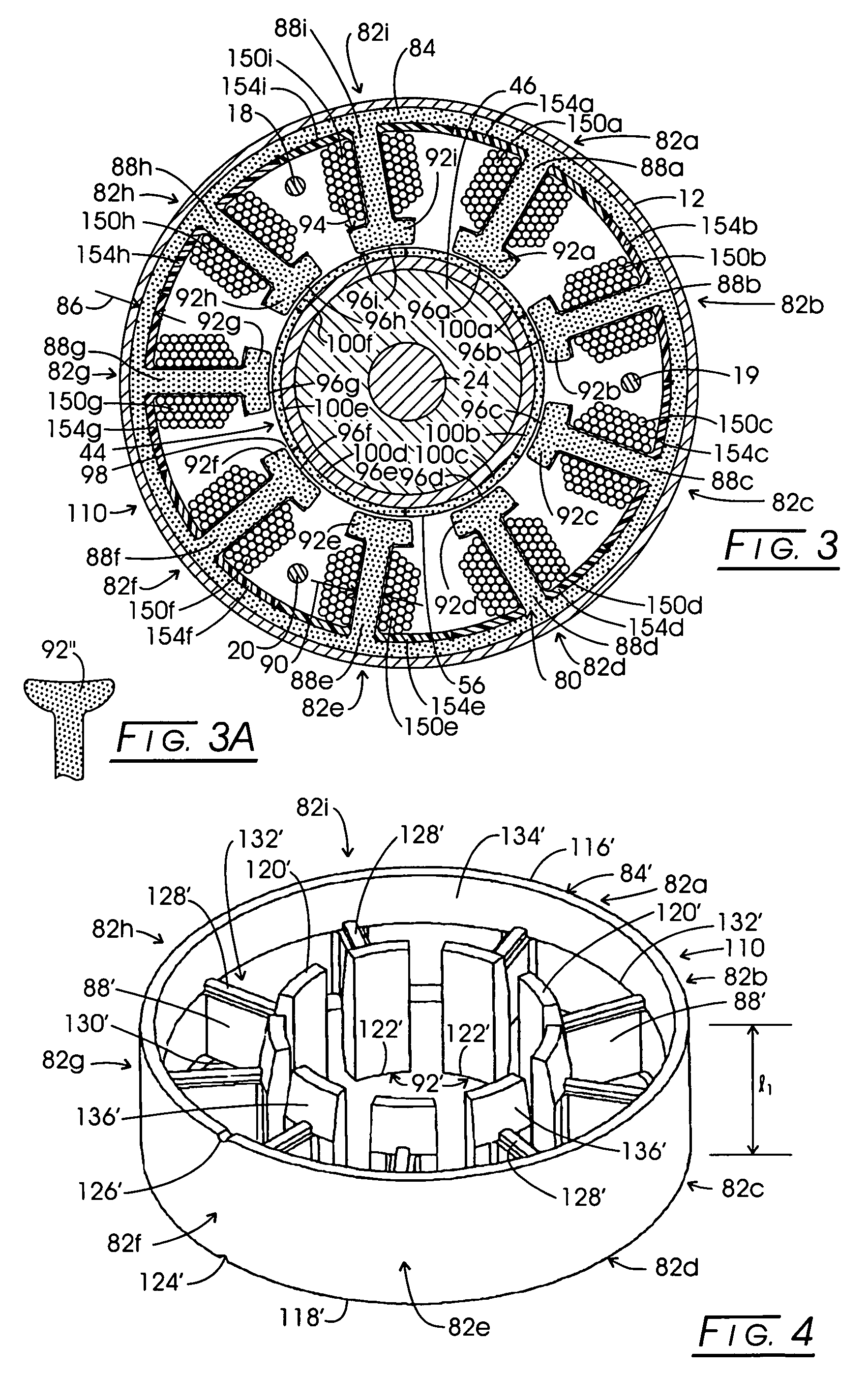

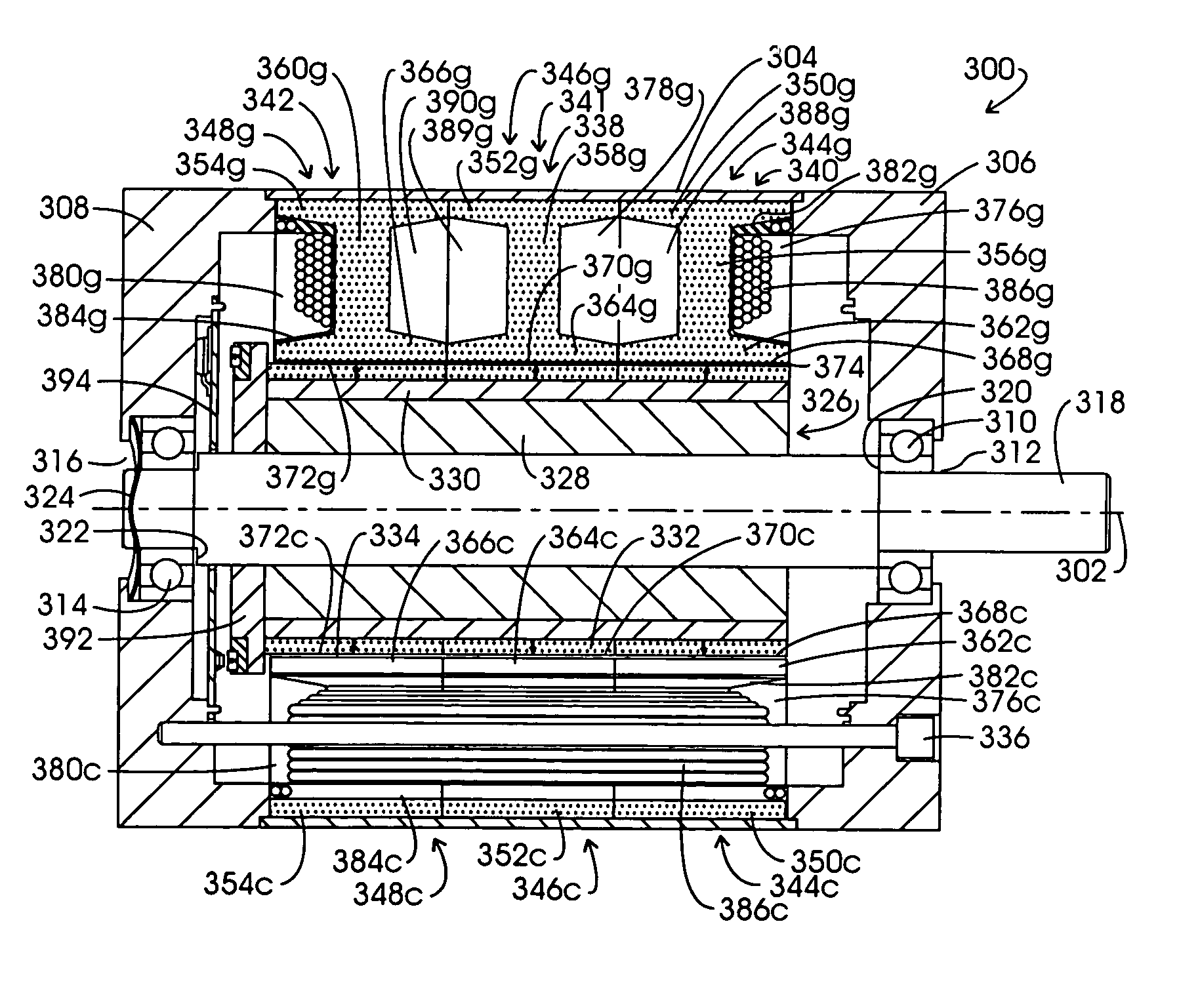

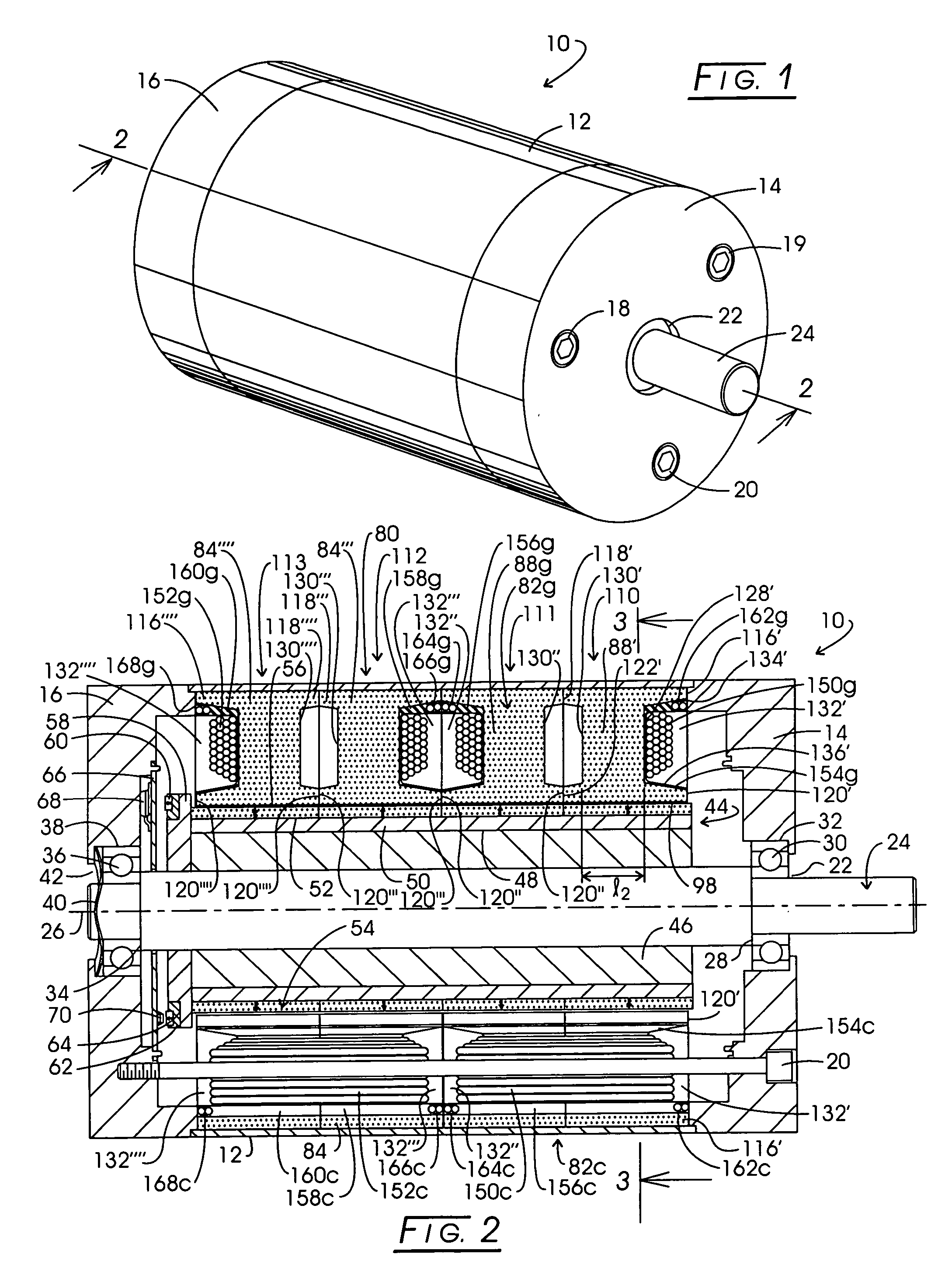

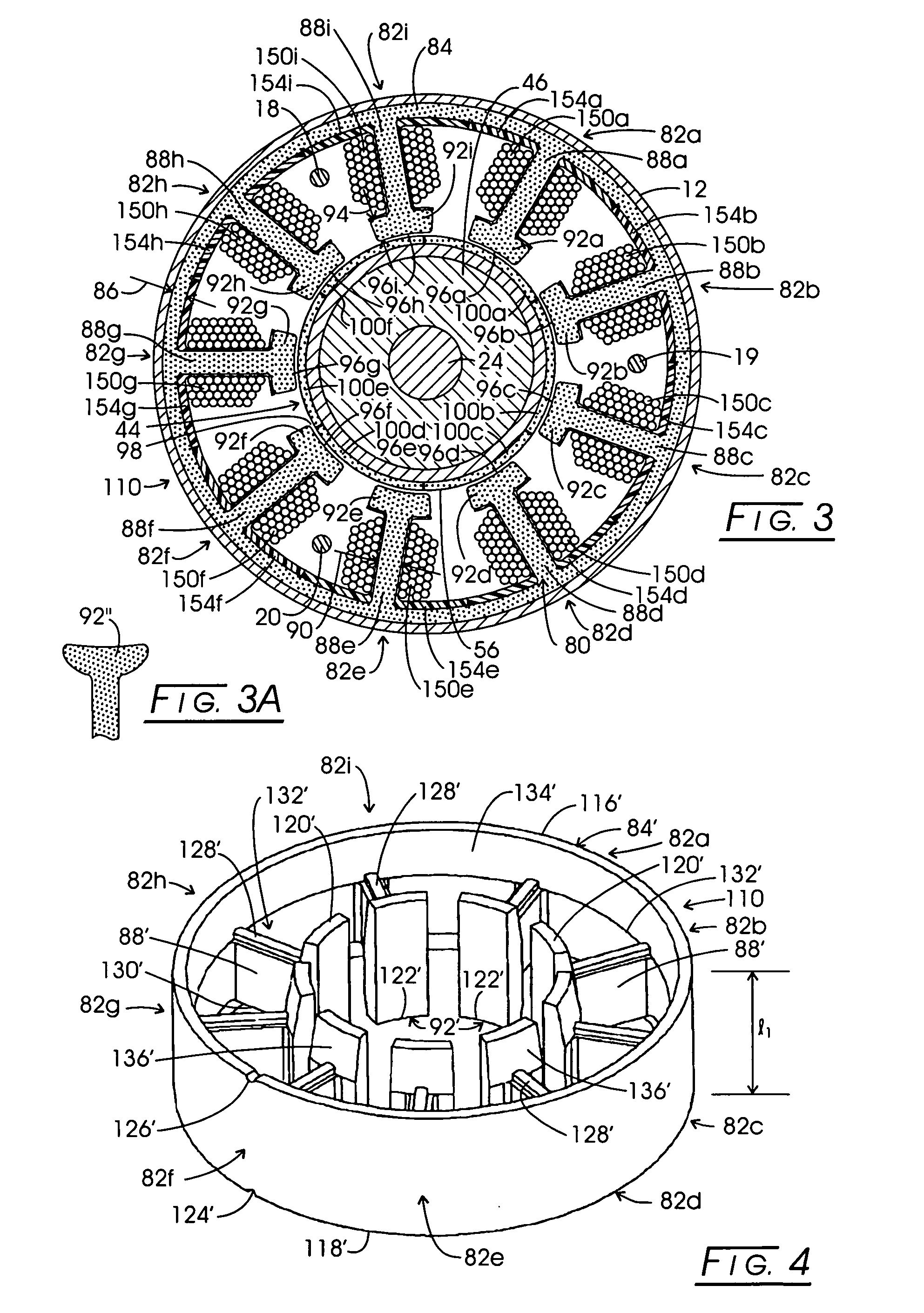

Electrodynamic apparatus and method of manufacture

InactiveUS7005764B2Thickness minimizationTooling costSynchronous generatorsMagnetic circuitWind componentAlternator

Electrodynamic apparatus such as a motor, generator or alternator is configured having a stator core assembly formed of pressure shaped processed ferromagnetic particles which are pressure molded in the form of stator modules. These generally identical stator modules are paired with or without intermediate modules to provide the stator core structure for receiving field winding components. In one embodiment, two sets of the paired stator modules are combined in tandem to enhance operational functions without substantial diametric increases in the overall apparatus.

Owner:PETERSEN TECH

Electrodynamic Apparatus and method of manufacture

InactiveUS20050140241A1Thickness minimizationTooling costSynchronous generatorsMagnetic circuitWind componentAlternator

Electrodynamic apparatus such as a motor, generator or alternator is configured having a stator core assembly formed of pressure shaped processed ferromagnetic particles which are pressure molded in the form of stator modules. These generally identical stator modules are paired with or without intermediate modules to provide the stator core structure for receiving field winding components. In one embodiment, two sets of the paired stator modules are combined in tandem to enhance operational functions without substantial diametric increases in the overall apparatus.

Owner:PETERSEN TECH

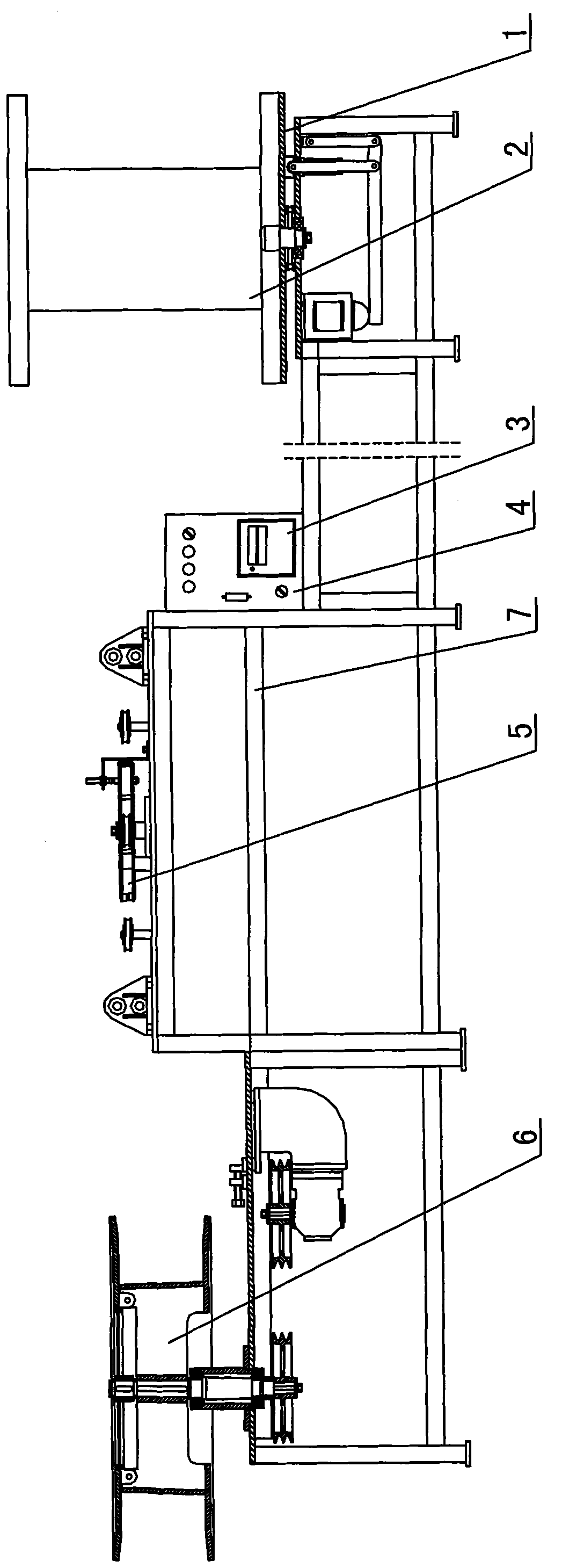

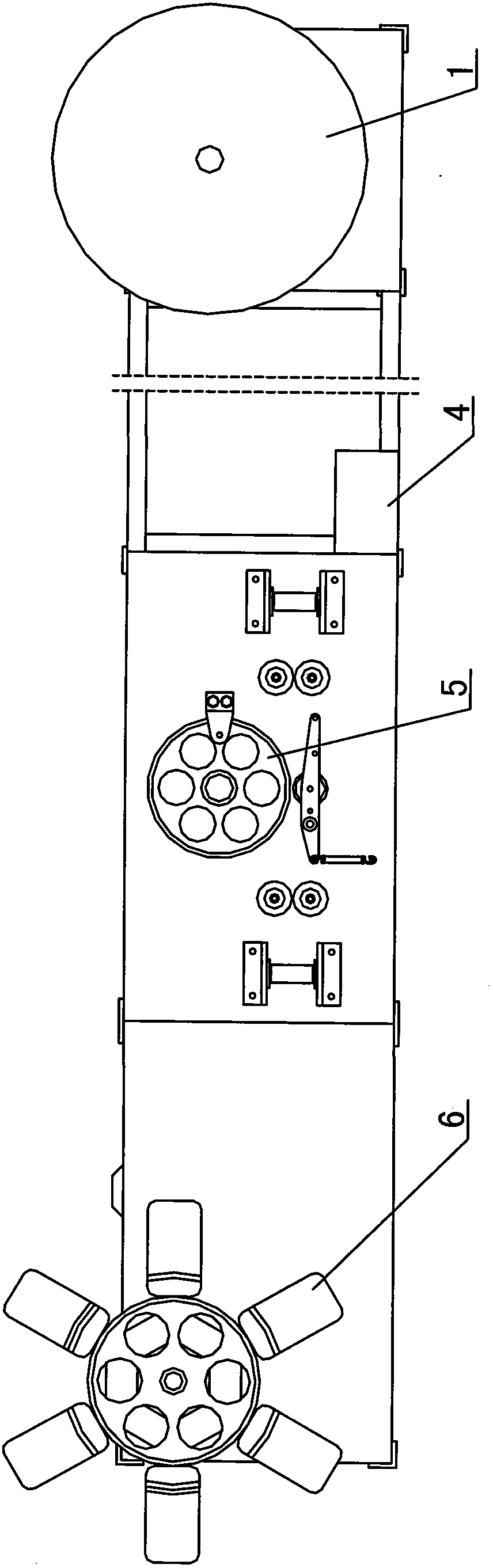

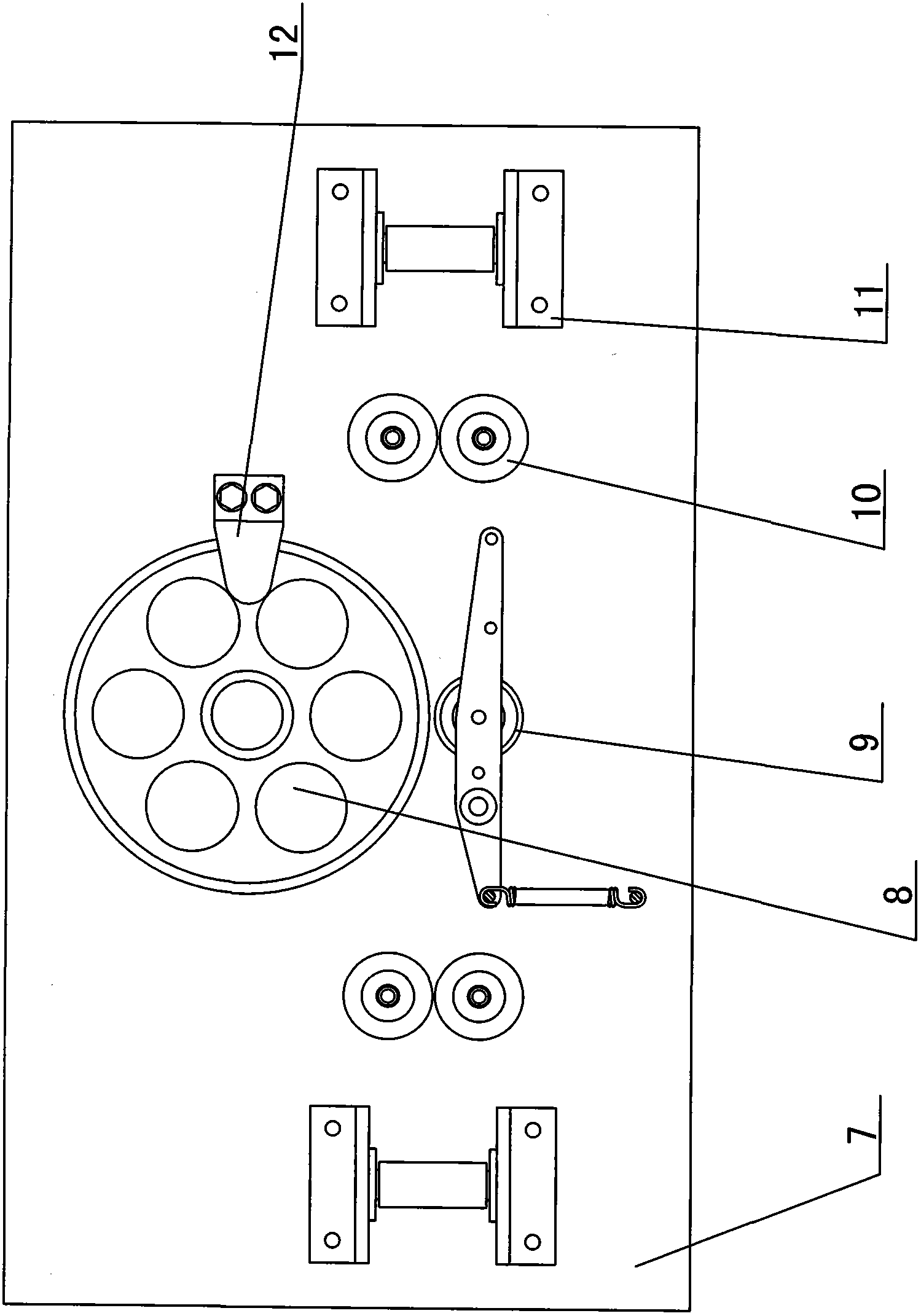

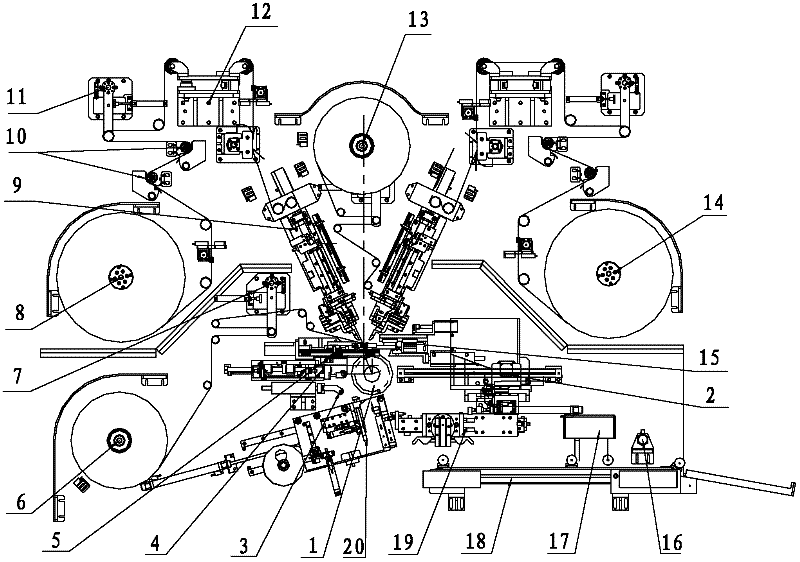

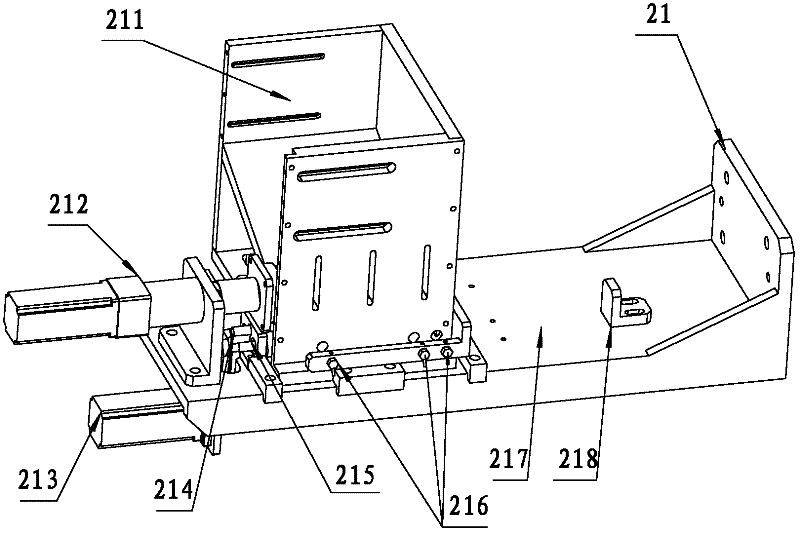

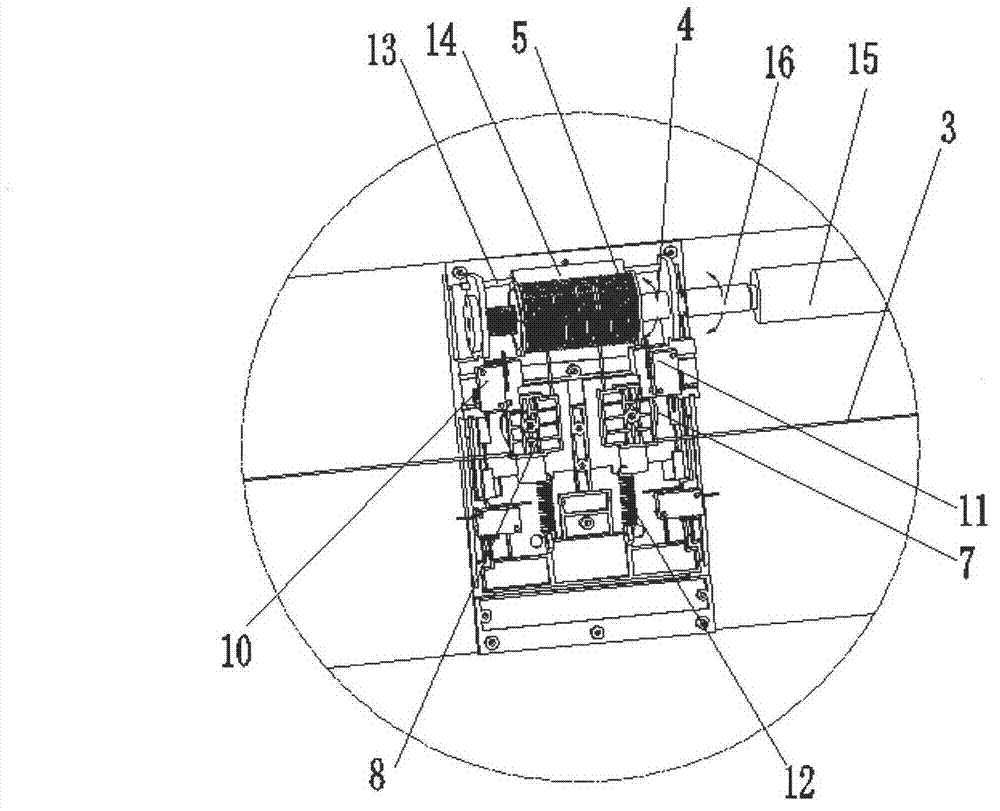

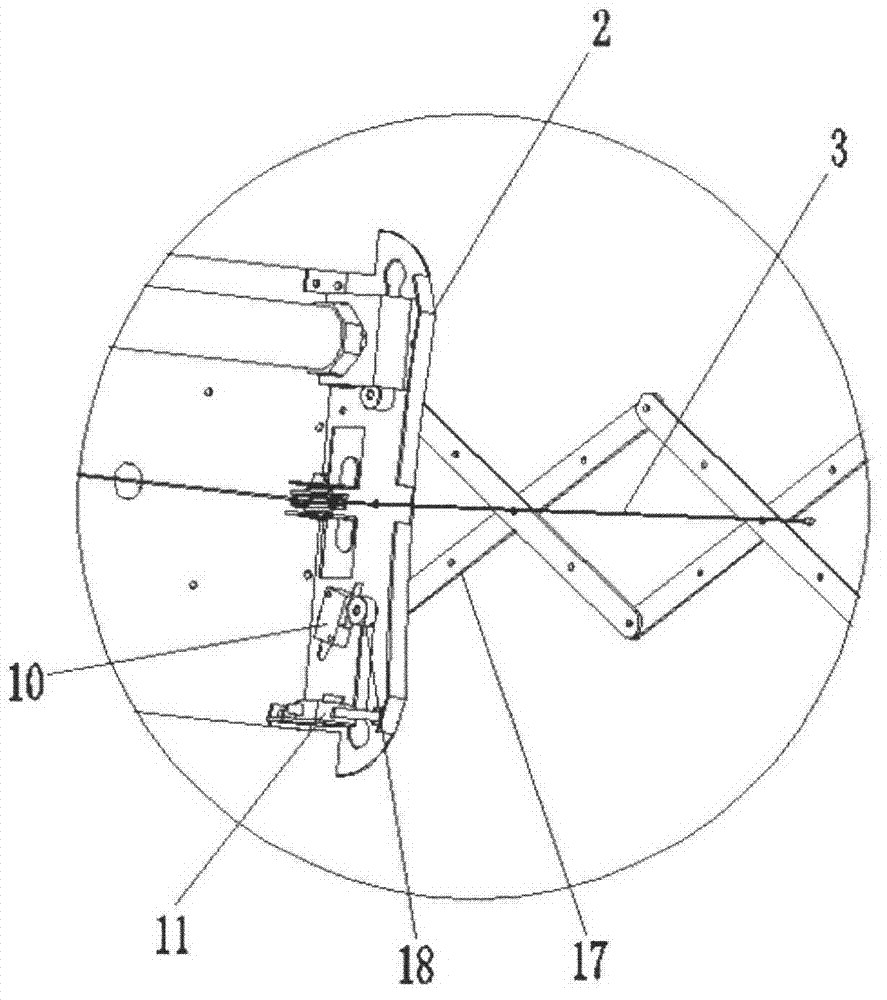

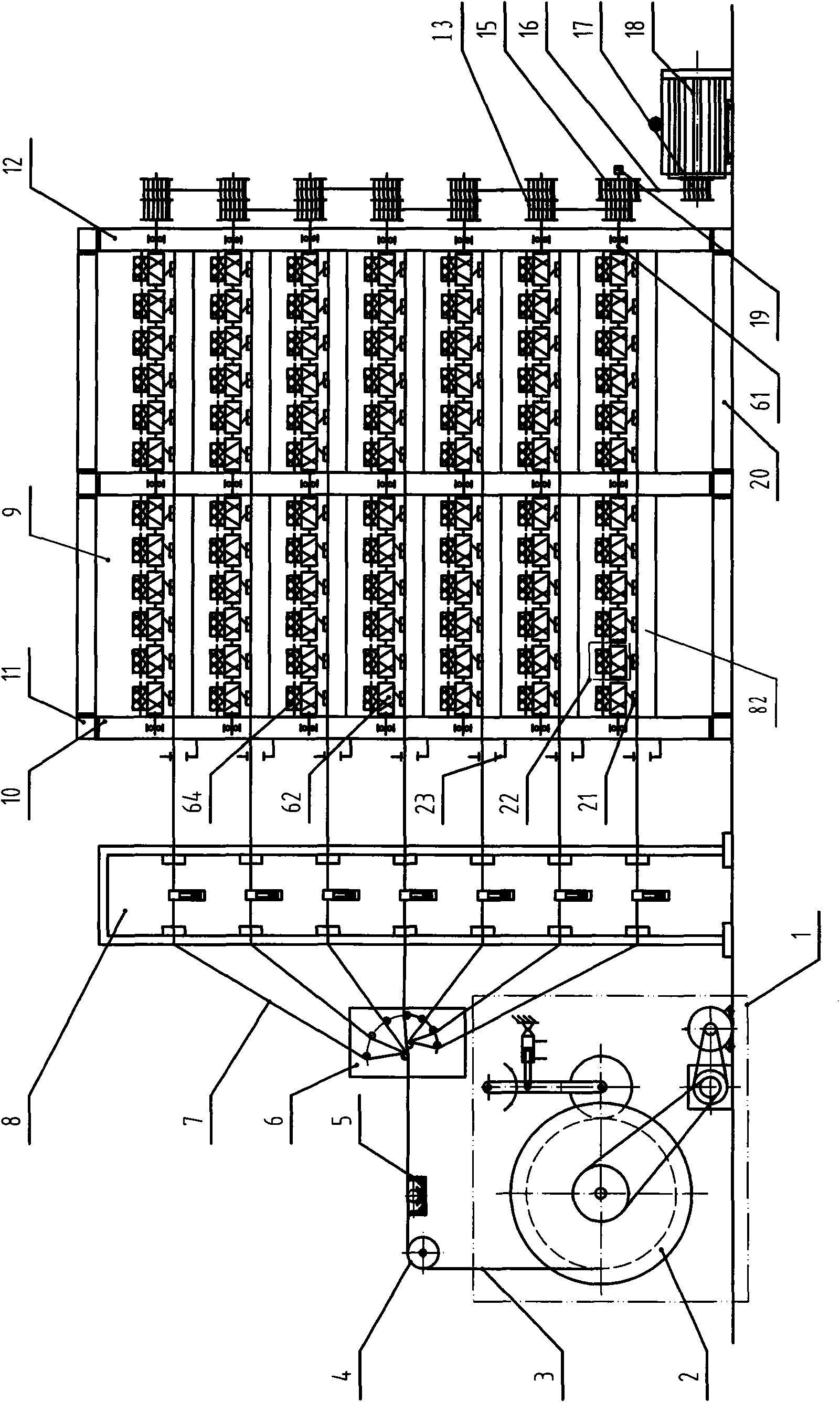

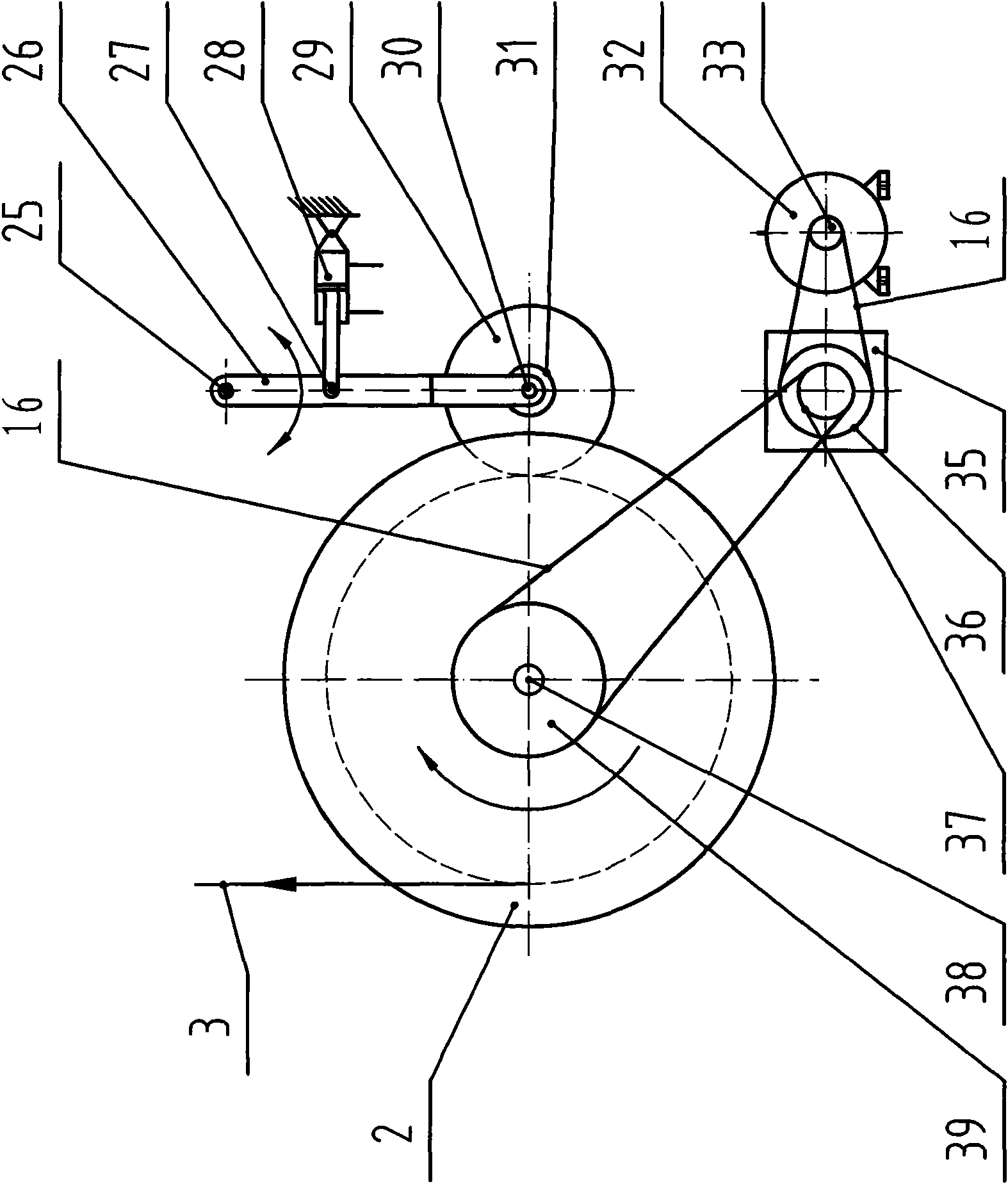

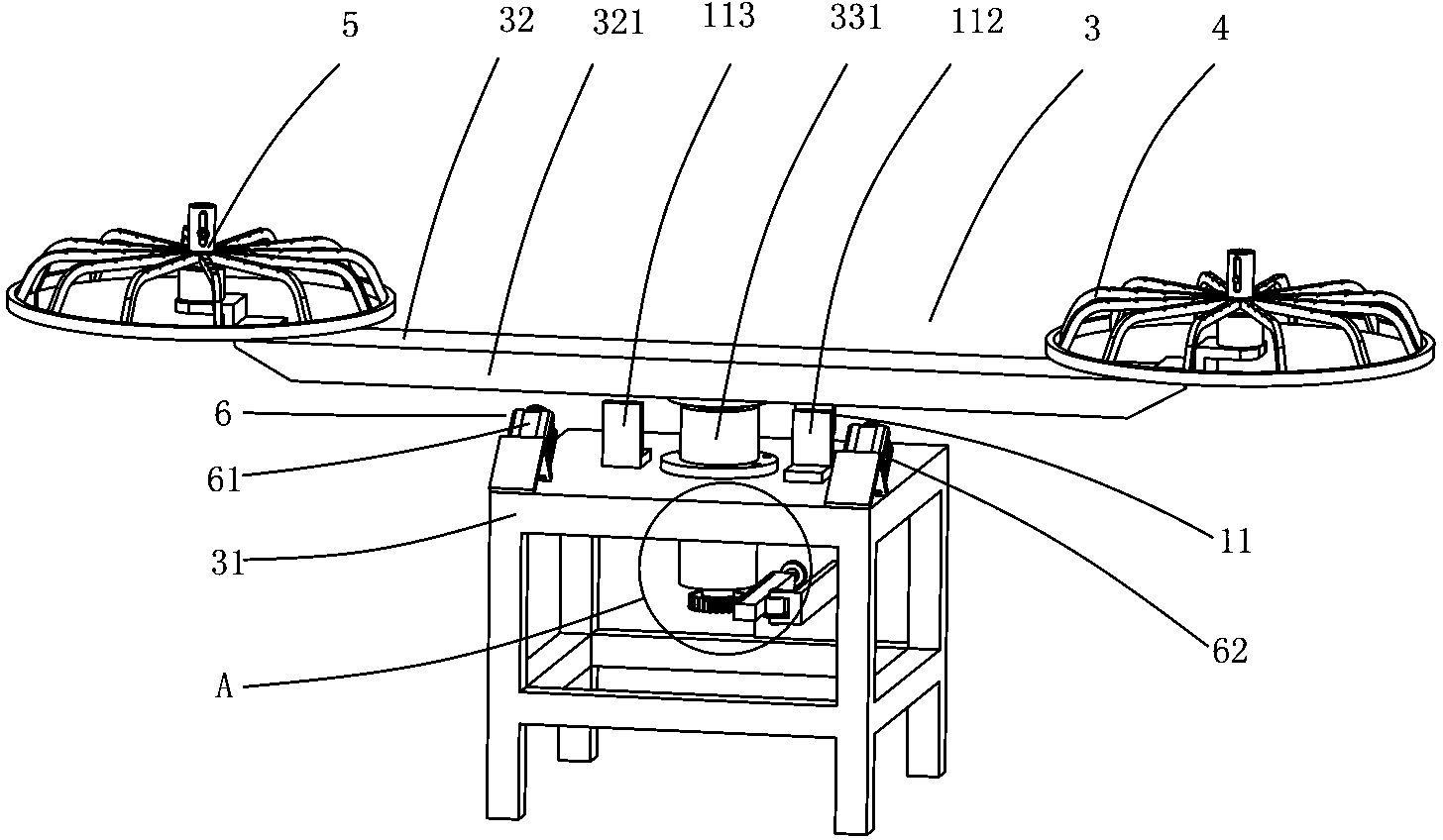

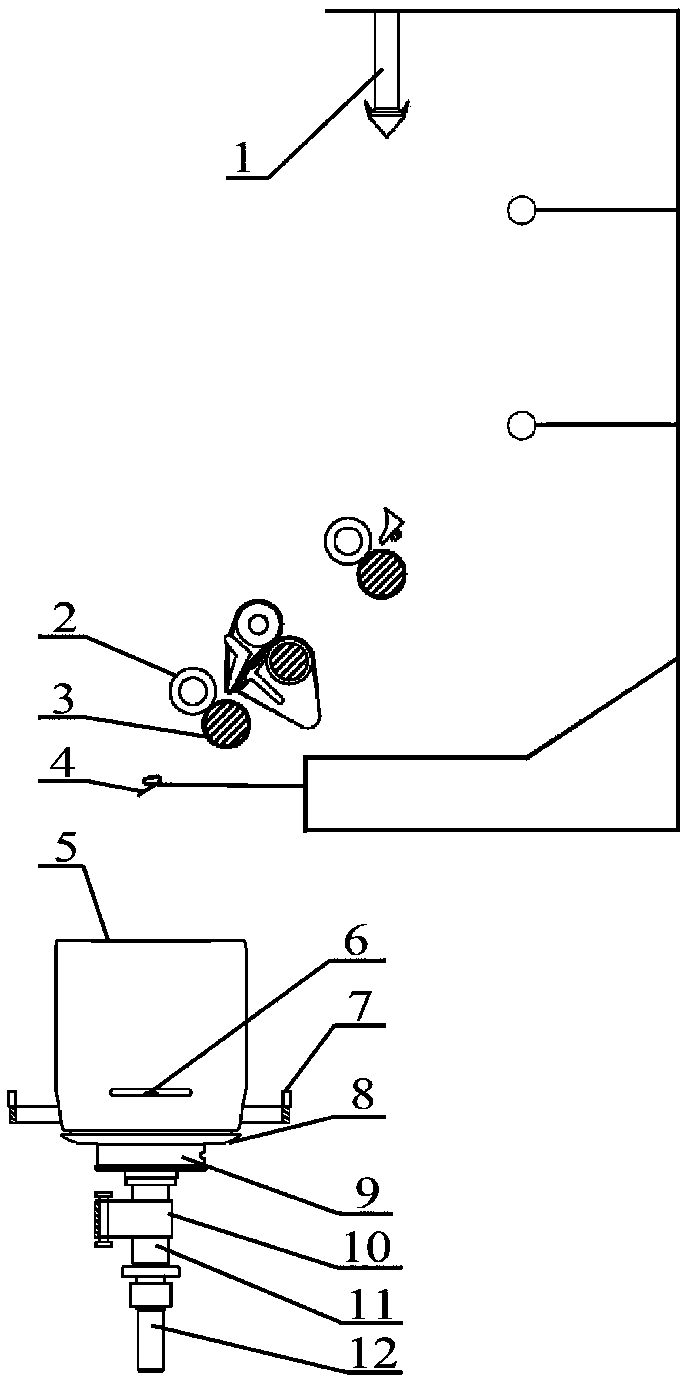

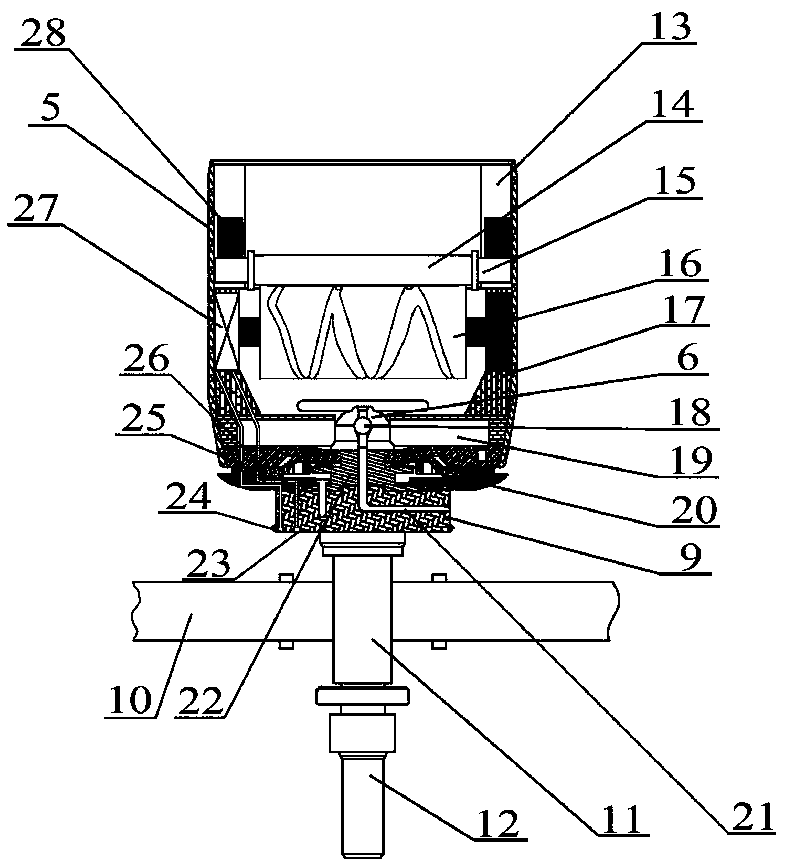

Wire rope automatic length specification winding equipment

InactiveCN102092604ALow operating skill requirementsRealize automatic sizing functionFilament handlingWind componentHigh volume manufacturing

The invention discloses wire rope automatic length specification winding equipment, which comprises a wire releasing tray component, a length specification detection mechanism, a power winding component and an electric control system. A large wire rope reel is supported on the upper part of the wire releasing tray component, and rotates and releases a wire rope on the wire releasing tray component under the winding and traction of the power winding component; the length specification detection mechanism is arranged on a detection rack; and the electric control system and an electronic counter are arranged outside the detection rack. The wire rope automatic length specification winding equipment has the advantages that: the wire rope automatic length specification winding equipment automatically performs length specification winding on the wire rope according to a specified length, electrically winds the wire rope by the power winding component, detects the length of the wound wire rope by the length specification detection mechanism, realizes an automatic length specification function by the fit of metering wheels, a count sensor and the electronic counter; and compared with the prior art, the wire rope automatic length specification winding equipment has the characteristics of compact structure, accurate length specification, high working efficiency and low labor intensity, simultaneously has low requirements on the operating skills of workers and is suitable for large-scale production.

Owner:SHENXI MACHINERY

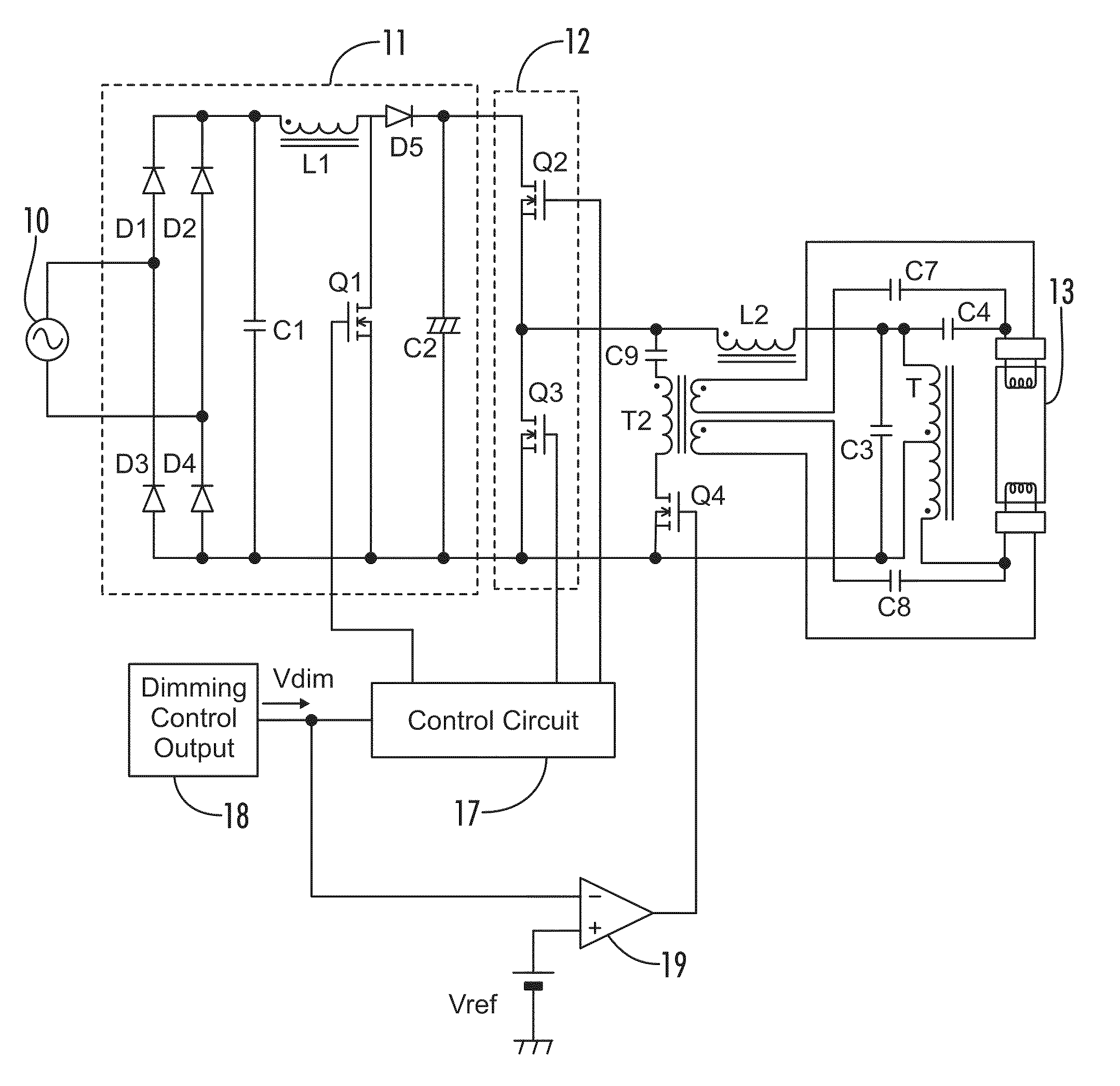

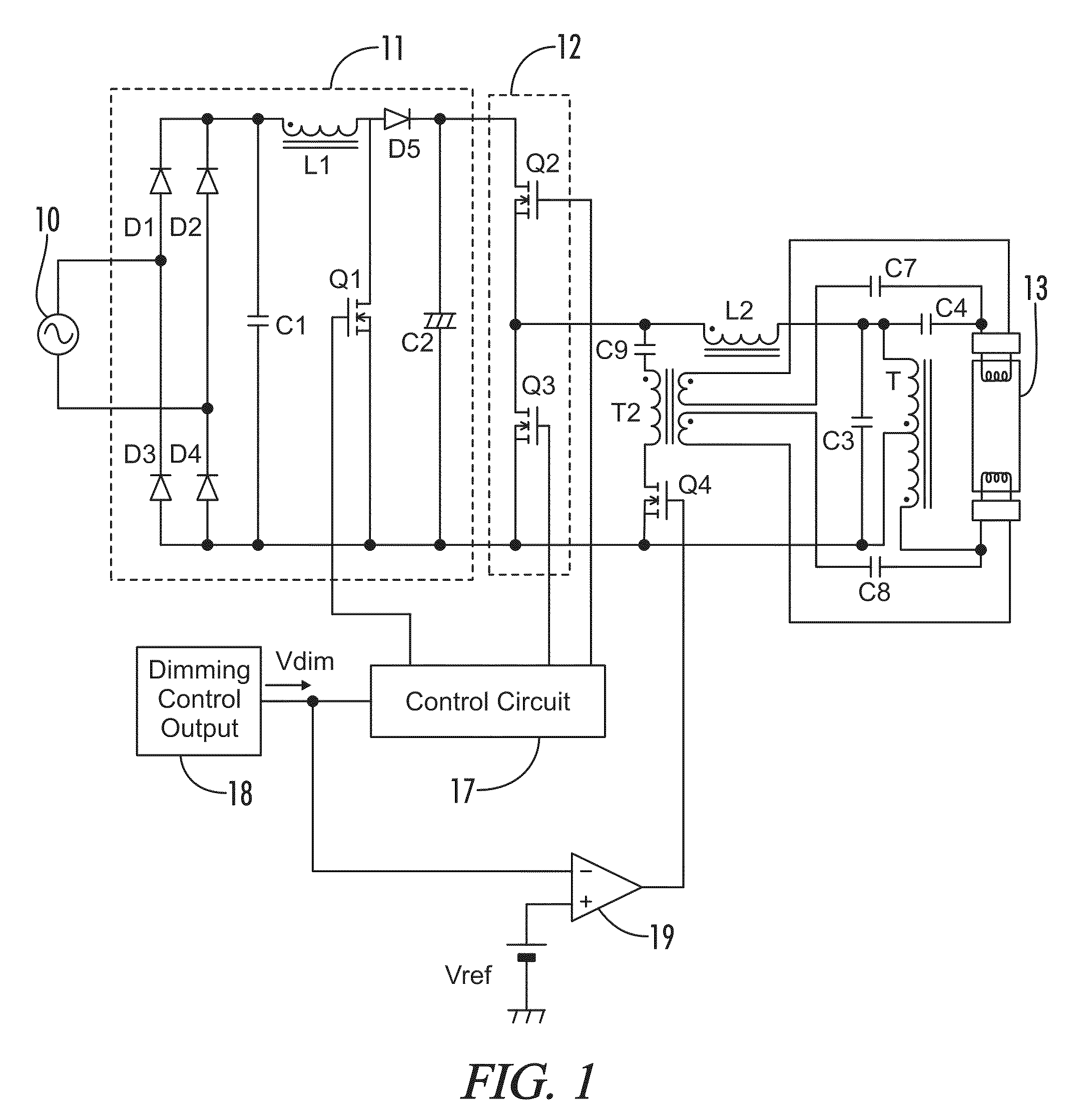

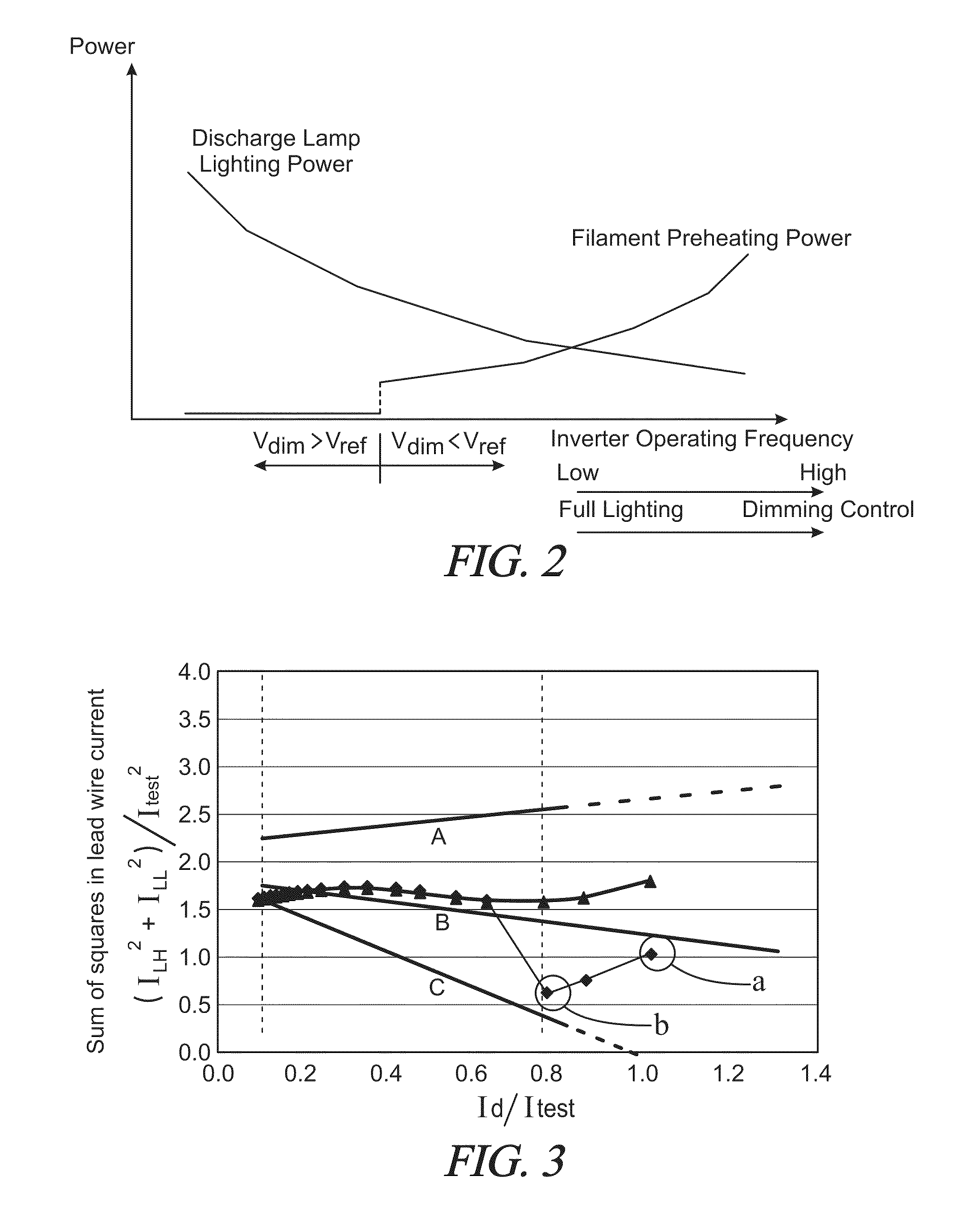

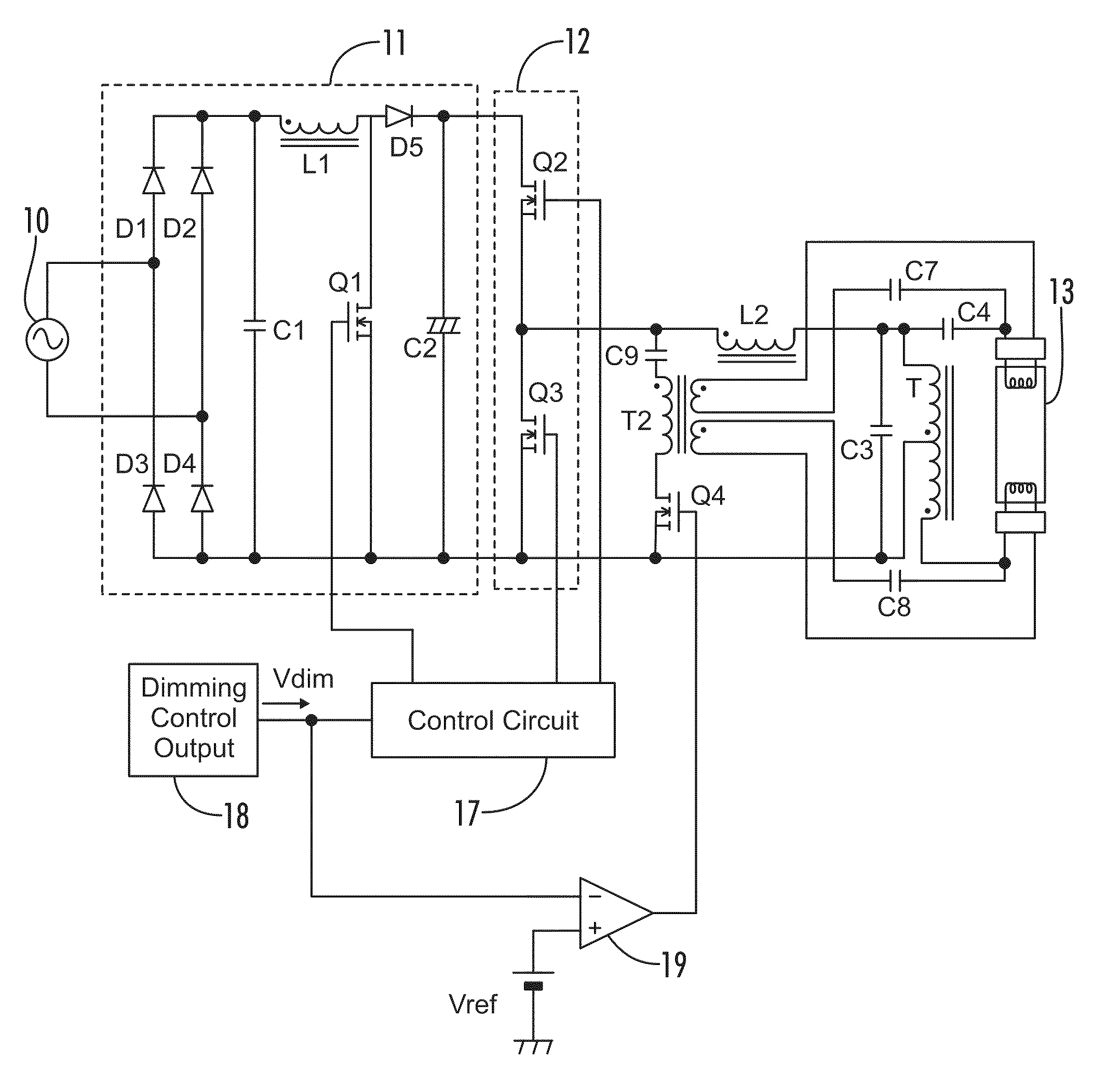

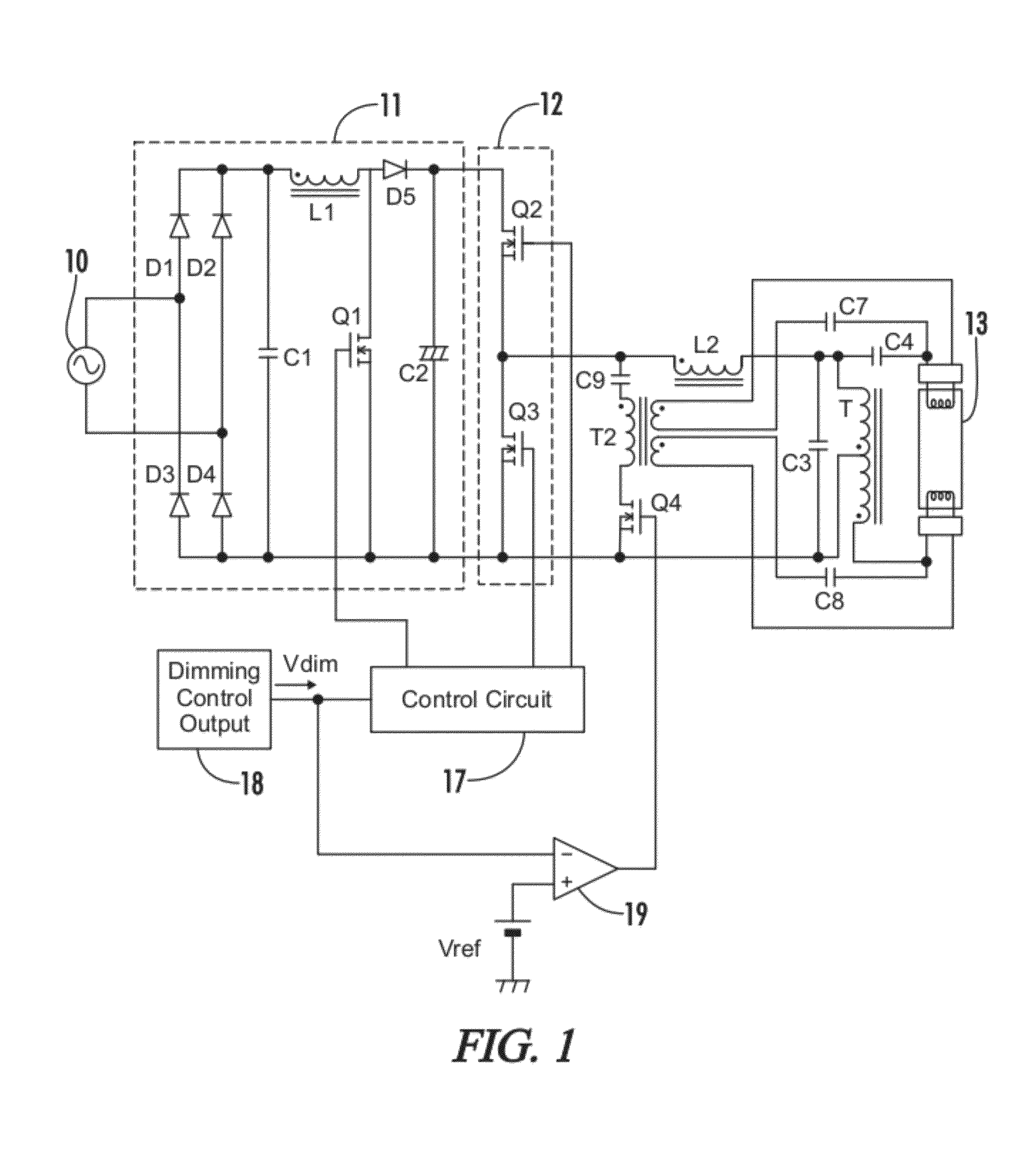

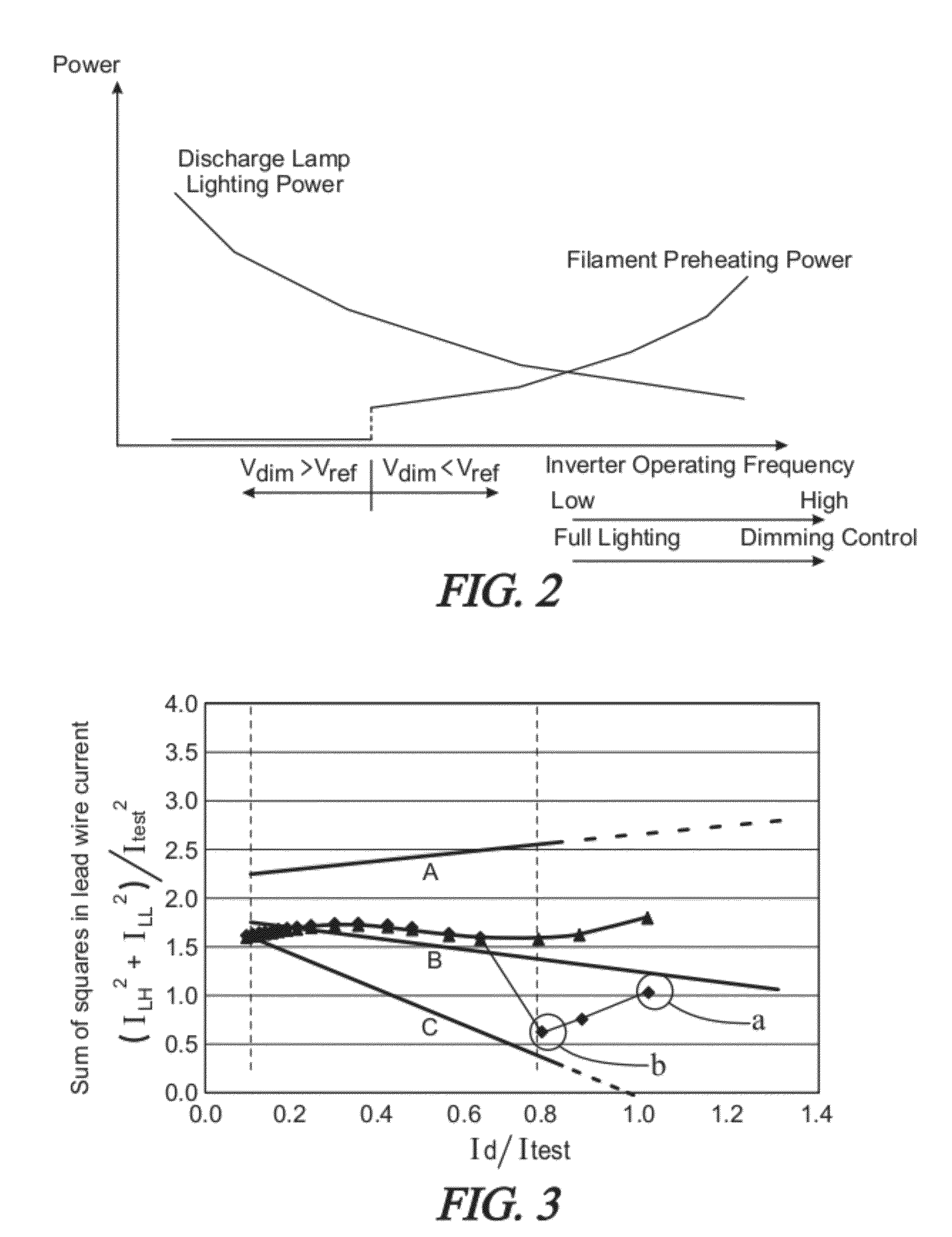

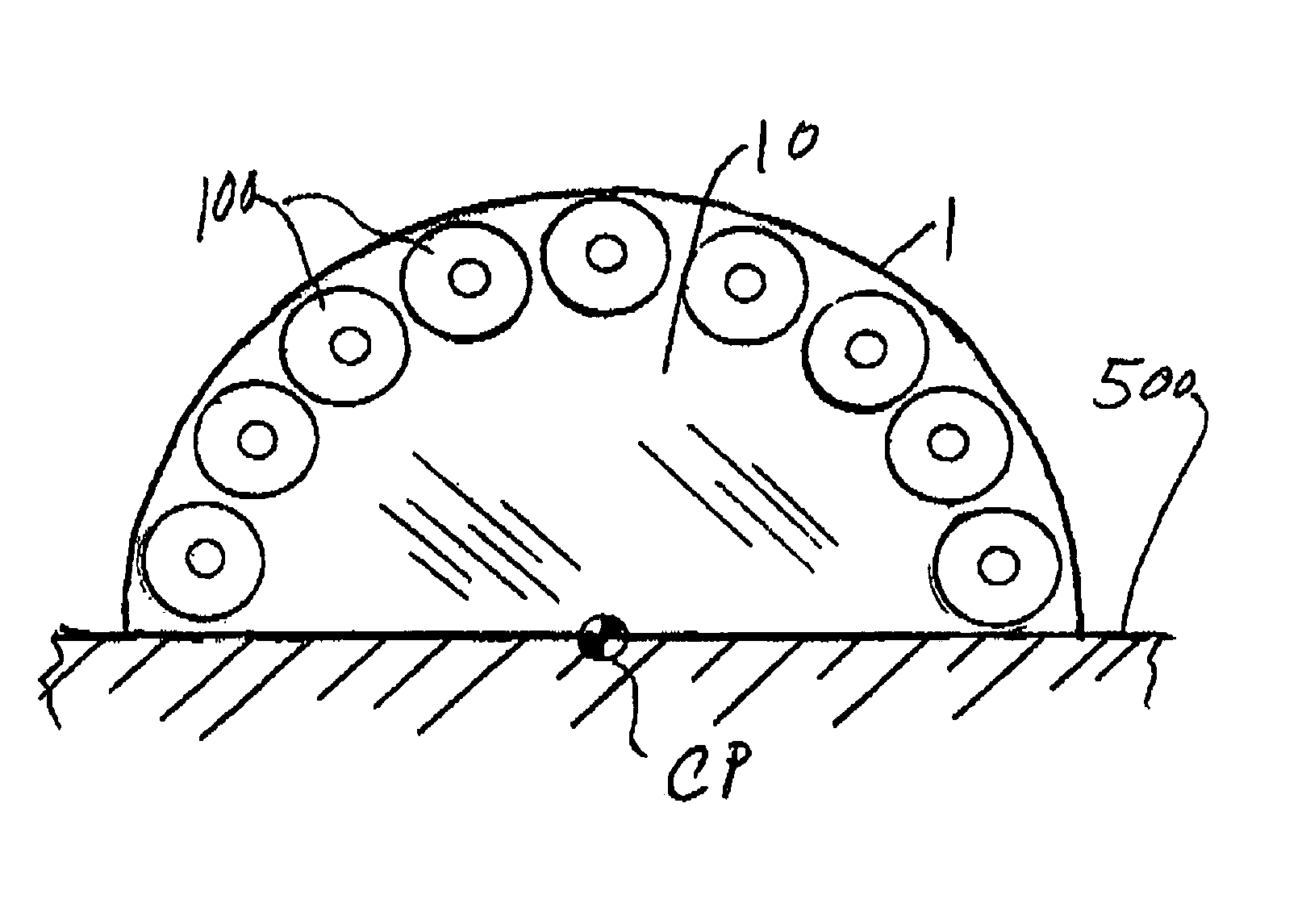

Dimming electronic ballast with preheat current control

InactiveUS20100109548A1Prolong lifeReduce power lossElectrical apparatusElectric light circuit arrangementWind componentEffect light

An electronic ballast is capable of realizing high frequency lighting of a discharge lamp and switching between at least two lighting modes with different light outputs. The ballast includes a preheating circuit having a winding component connected in parallel with a main resonant circuit with a lamp current flowing therein for the discharge lamp. A constant preheating current for the lamp filaments is supplied from a secondary winding of the winding component during lighting of the discharge lamp and a path of a current flowing on a primary winding side of the winding component is switched by a switch according to the lighting mode.

Owner:PANASONIC CORP

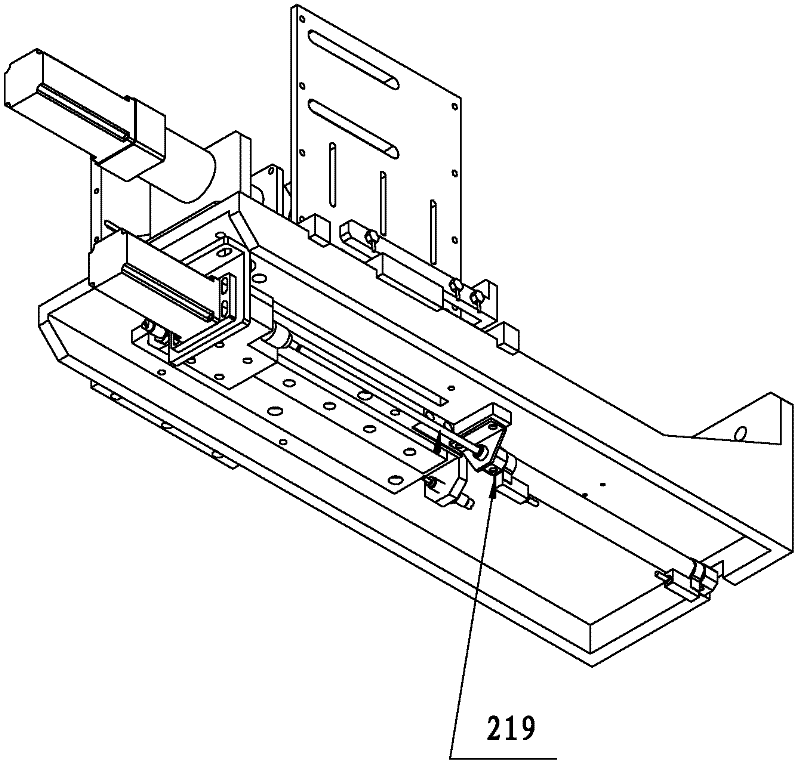

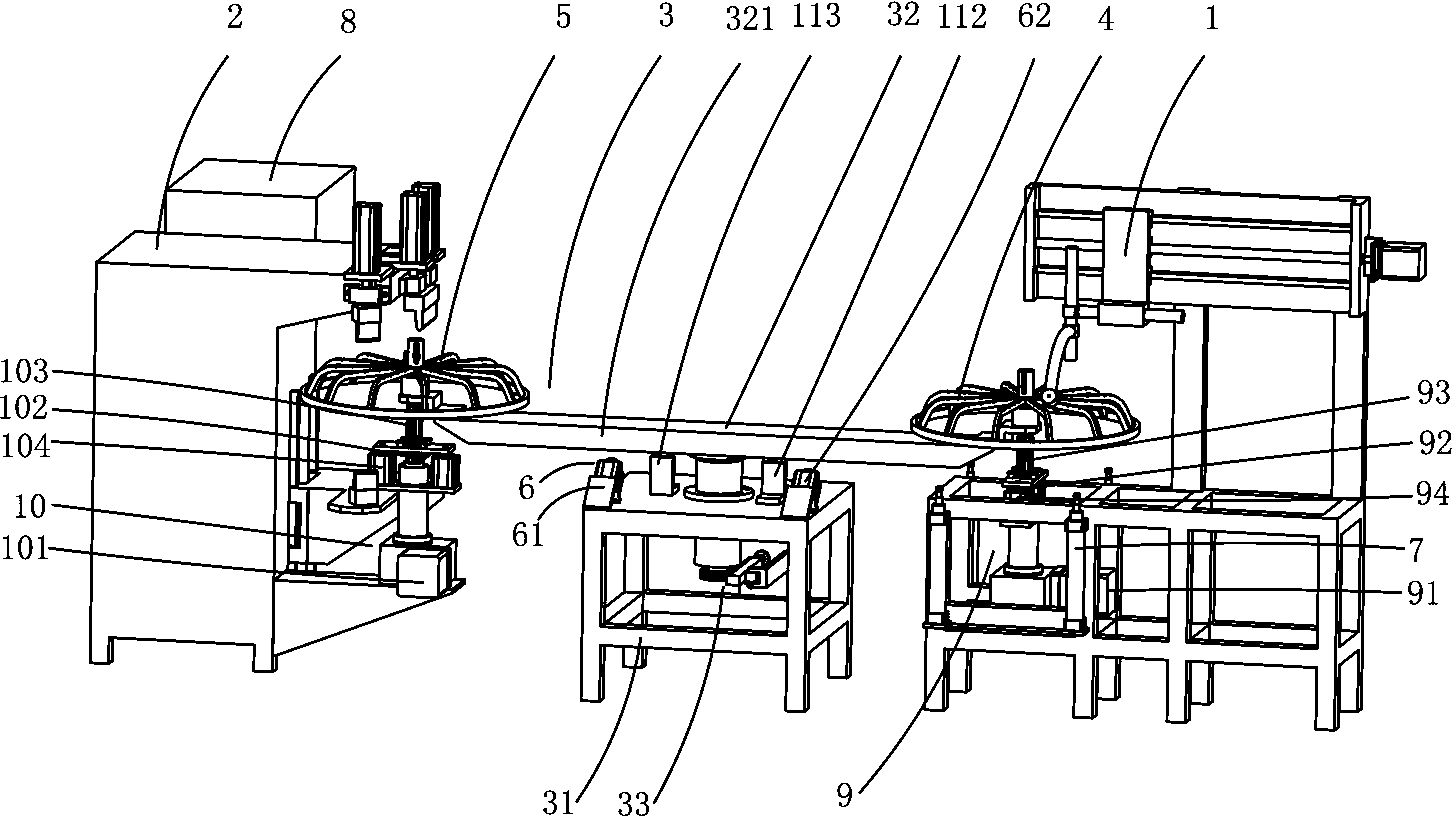

A battery automatic winding equipment

ActiveCN102263294ARealize automatic core changing functionReduce labor intensityAssembling battery machinesFinal product manufactureWind componentEngineering

The invention discloses an automatic winding device for a battery cell. The automatic winding device comprises a frame, a winding component mounted on the frame, an automatic cell changing component and a controller, wherein the winding component has a winding position and a charging position; the automatic cell changing component comprises a material dividing component and a material conveying component; the material dividing component comprises a storage bin, a material-dividing idler wheel and a material-dividing driving component; the material-dividing idler wheel is arranged at the bottom opening of the storage bin; the material dividing component further comprises a discharging position; the material conveying component comprises a spindle clamping mechanism, a feeding rail and a conveying driving component; the conveying driving component is used for driving the spindle clamping mechanism to move along the feeding rail and conveying a spindle from the discharging position to the charging position; and the material-dividing driving component and the conveying driving component are both connected with the controller. The automatic winding device for the battery cell provided by the invention achieves a full-automatic cell changing function and is very simple and convenient to operate; and in addition, the process efficiency is obviously improved, the labor intensity of workers is reduced, and the stable material dividing, accurate positioning, reliable clamping and stable conveying of the spindle are realized.

Owner:GEESUN AUTOMATION TECH

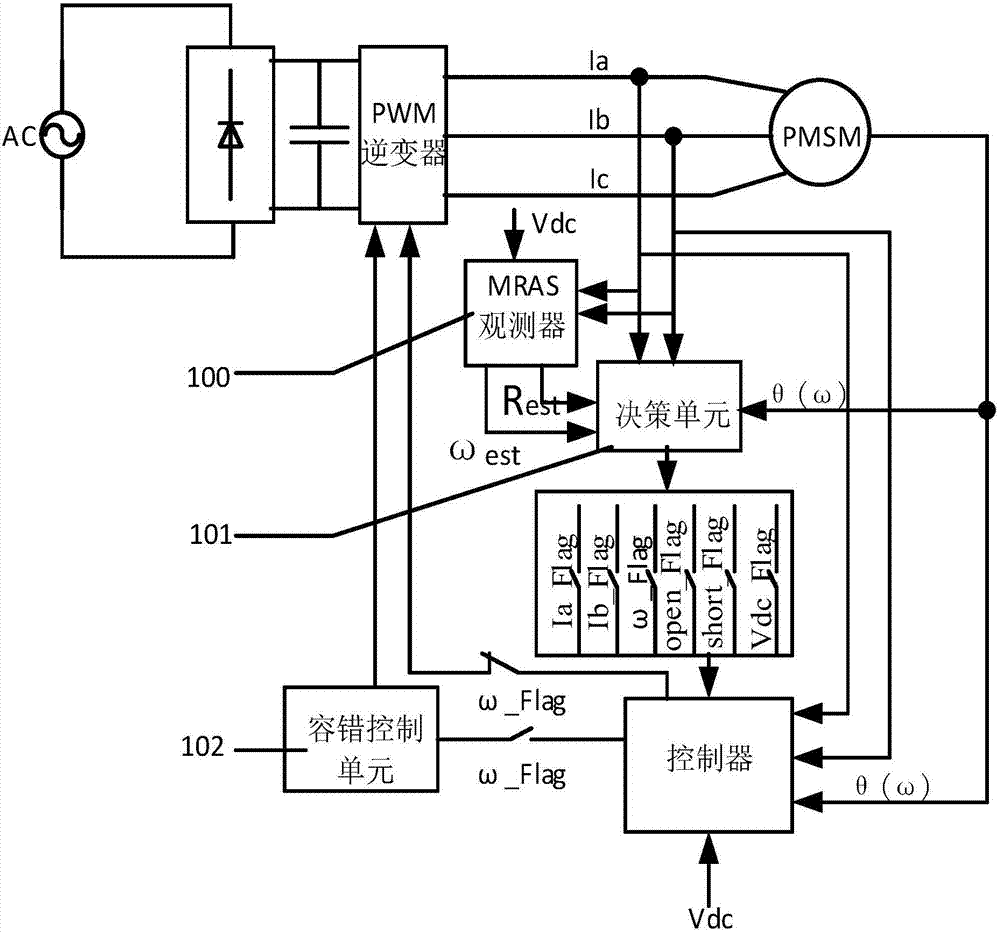

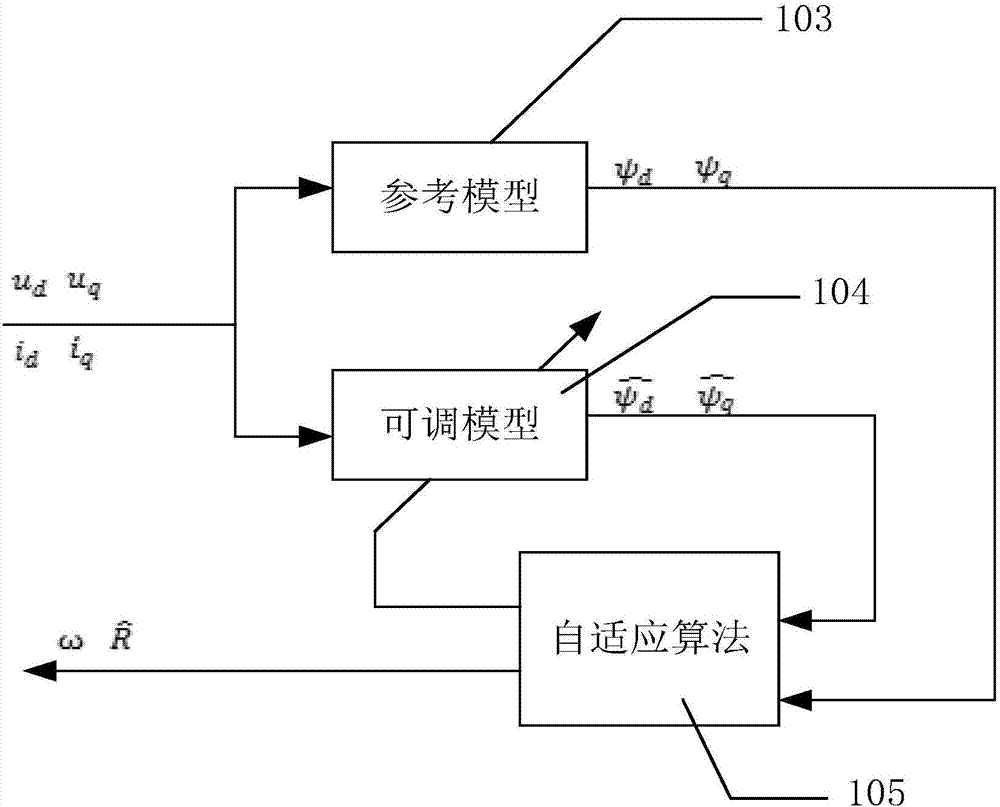

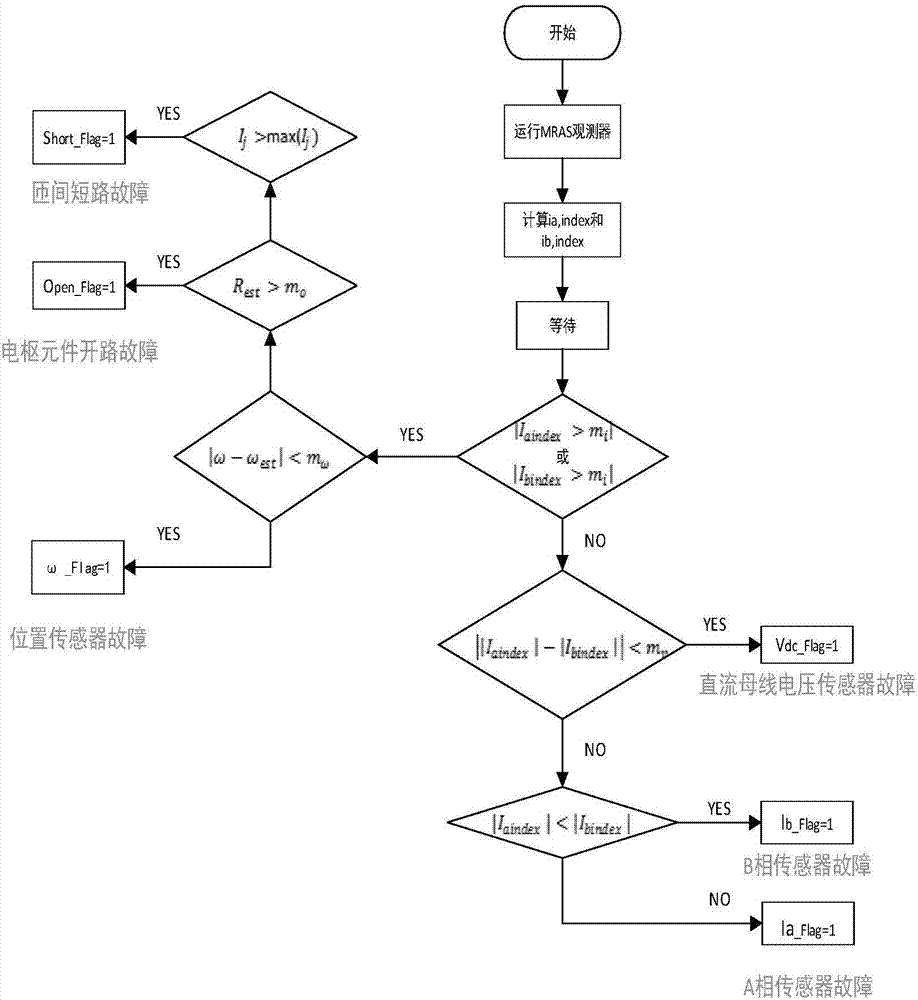

Permanent magnet synchronous motor (PMSM) fault diagnosis and fault-tolerant control system and method

ActiveCN106998164AGuaranteed uptimeAccurately judge the failure situationElectronic commutation motor controlElectric motor controlPhase currentsMotor speed

The present invention discloses a permanent magnet synchronous motor (PMSM) fault diagnosis and fault-tolerant control system and method. The method can be used in motor medium-high speed running period. In PMSM field oriented control (FOC), position and speed information of a rotor, DC bus voltage and two or three current sensors are required. According to the PMSM fault diagnosis and fault-tolerant control system and method, an estimated rotor speed and an estimated resistance value are inputted into a decision making unit based on a model reference adaptive system (MRAS) observer capable of motor speed and resistance value identification, so that the fact that whether a motor position sensor goes wrong, an armature winding component open circuit fault and an inter-turn short circuit fault are identified. According to the PMSM fault diagnosis and fault-tolerant control system and method, the fact that whether a motor phase current sensor goes wrong, a fault location and fault status of the position sensor can be judged, when the position sensor goes wrong, the control system can switch to speed sensorless vector control automatically, so that the system has a certain fault-tolerant capability, and thus the system can ensure normal operation of the motor in some specific applications.

Owner:WUHAN UNIV OF TECH

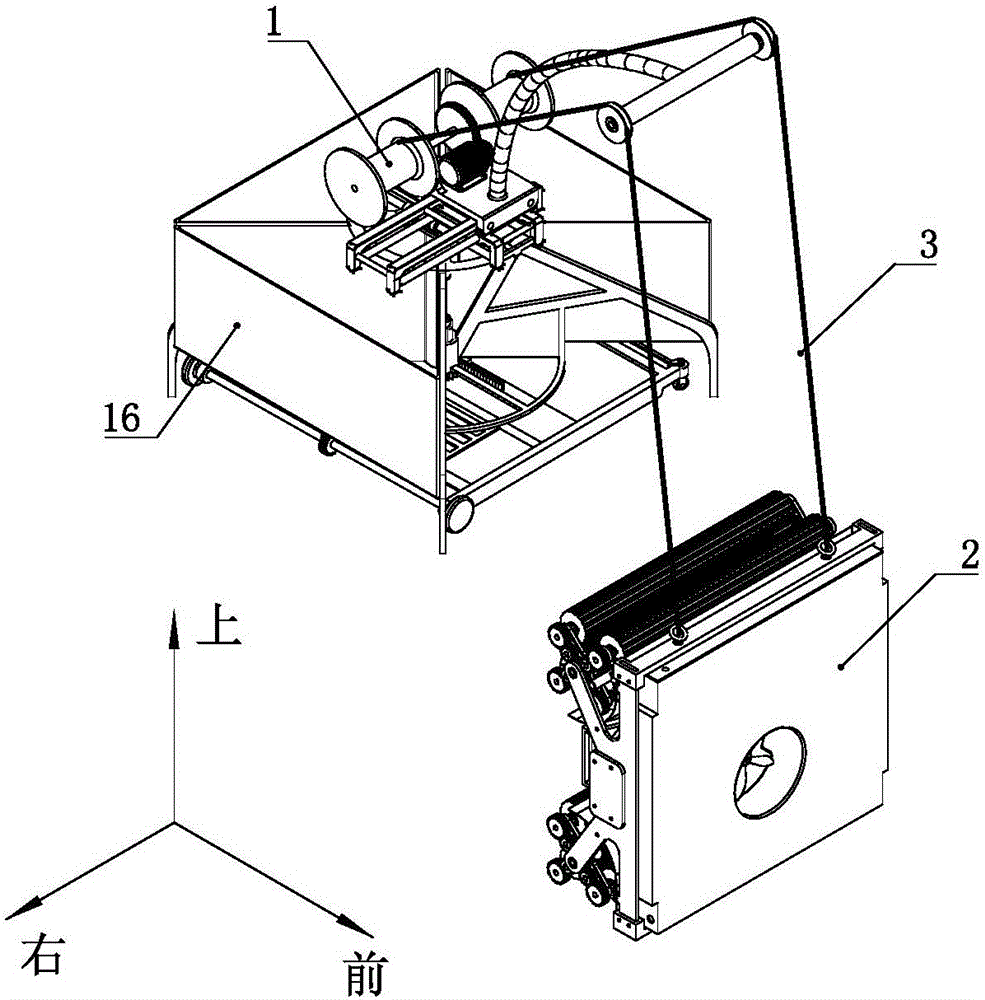

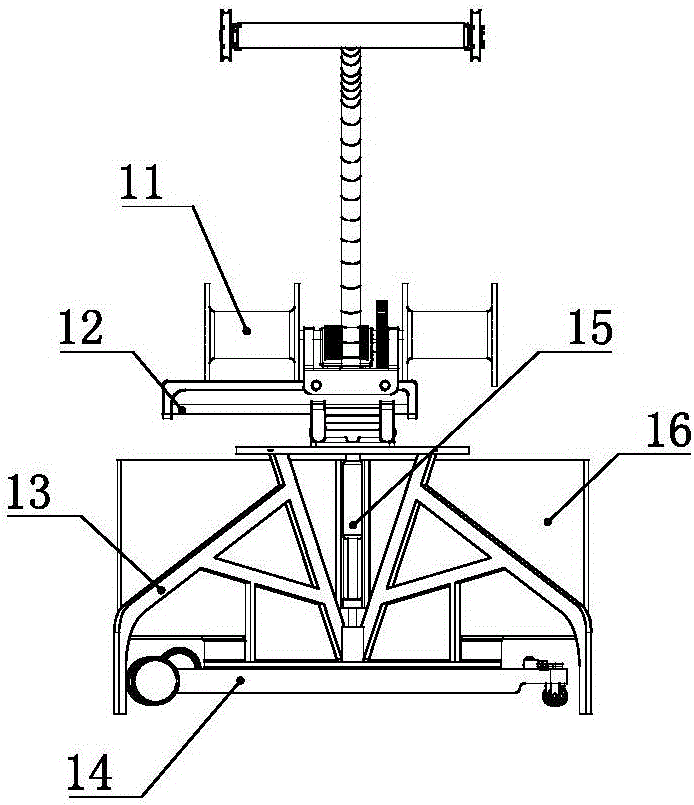

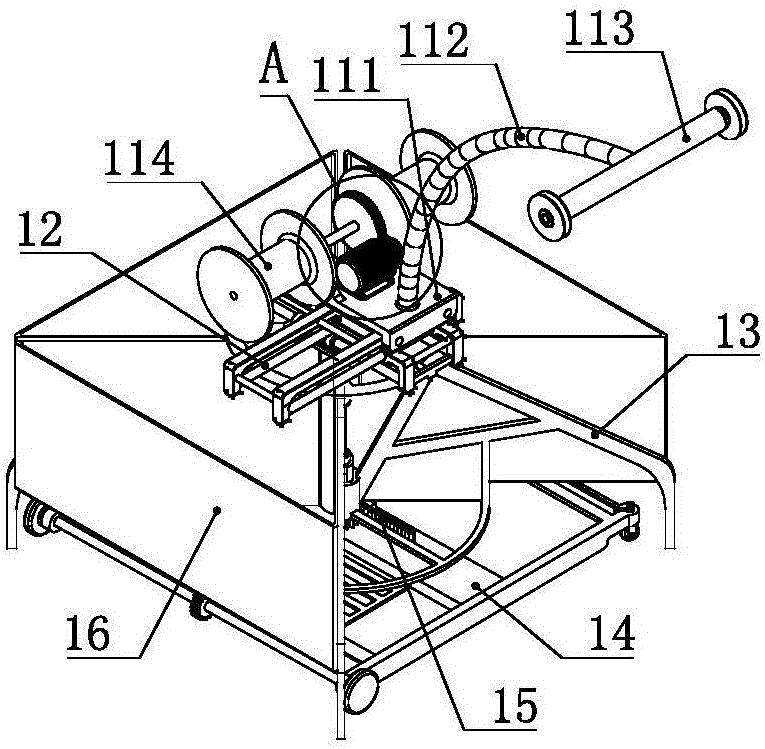

Automatic cleaning machine for high-rise curtain wall

InactiveCN106073654AImprove adaptabilityHigh degree of automationCarpet cleanersFloor cleanersWind componentElectric machinery

The invention discloses an automatic cleaning machine for a high-rise curtain wall. The automatic cleaning machine comprises a hanging unit, a cleaning unit and a rope used for connecting the hanging unit with the cleaning unit, wherein the hanging unit successively comprises a winding component, a rotating frame and a moveable chassis from top to bottom; a rotating lifting component is arranged between the rotating frame and the moveable chassis; the cleaning unit comprises a cleaning frame, brush components, a driving mechanism, a water-spraying component and a storage battery; inward extending mounting plates are respectively arranged on the two sides of the cleaning frame; two sets of brush components are arranged between the two mounting plates; the driving mechanism comprises a third motor arranged on a cross beam; the third motor is connected with the brush components through the driving component. The automatic cleaning machine for the high-rise curtain wall, provided by the invention, can realize automatic cleaning for the high-rise curtain wall, can increase the cleaning efficiency, and can avoid the cleaning danger of worker.

Owner:SHANDONG YINGCAI UNIV

Impedance transformer and applications thereof

InactiveUS20070296537A1Multiple-port networksHigh frequency amplifiersWind componentImpedance transformer

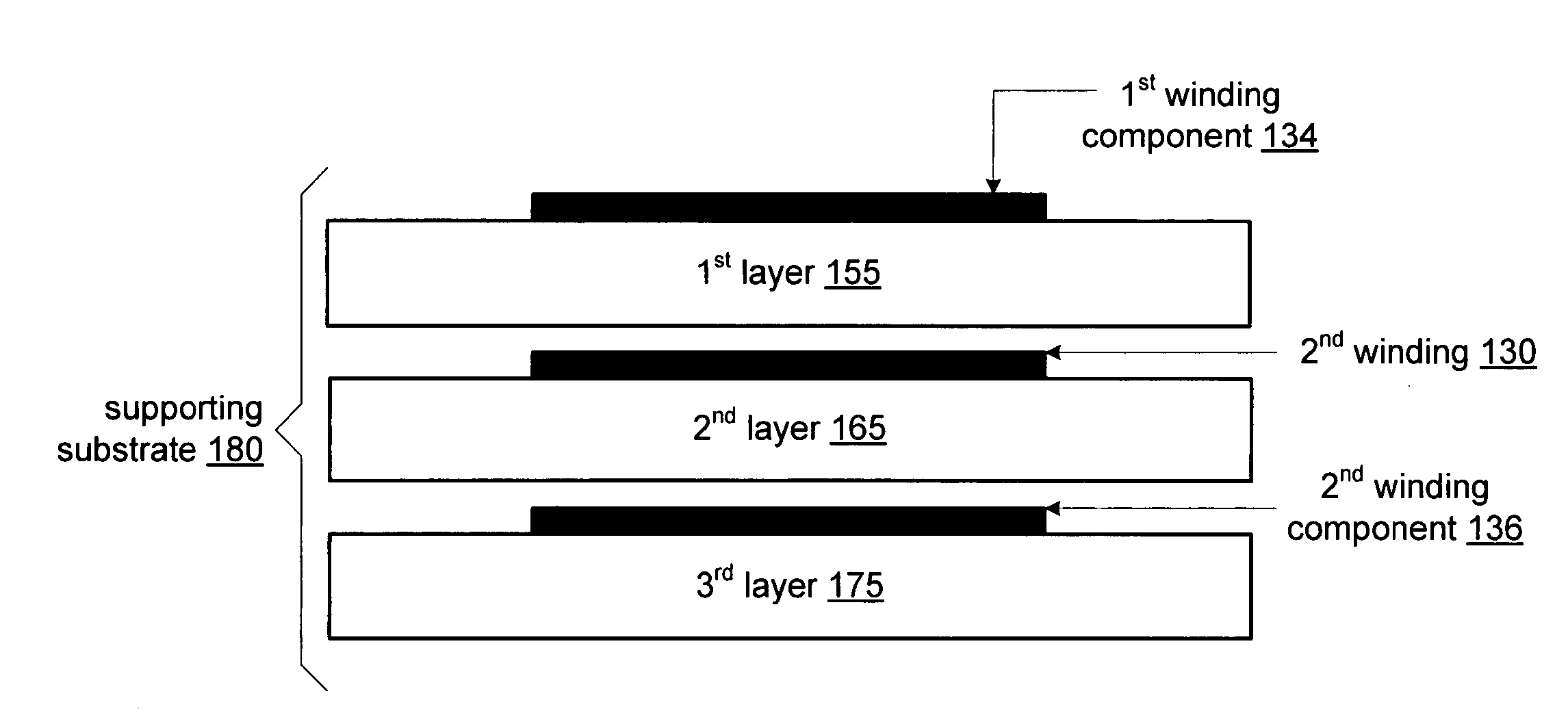

An impedance transformer includes a first winding and a second winding. The first winding includes a first plurality of winding components, wherein each of the first plurality of winding components is on a corresponding layer of a first set of layers of a supporting substrate. The second winding includes a second plurality of winding components, wherein each of the second plurality of winding components is on a corresponding layer of a second set of layers of the supporting substrate and the first and second sets of layers are interleaved. The first winding has a first impedance within a desired frequency range and the second winding has a second impedance within the desired frequency range, where the first and second impedances are based on at least one of spacing, trace width, and trace length of the first and second plurality of winding components.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

Electric laundry rack

ActiveCN102864617AControl scalingStable jobOther drying apparatusTextiles and paperWind componentEngineering

The invention discloses an electric laundry rack which comprises a bracket, a driving component, a winding component, hanging bridge connecting rod components and a steel wire. The driving component and the winding component are arranged on the support and connected in a driving mode; the hanging bridge connecting rod components are arranged at two ends of the support; the winding component comprises a spindle, a reel, a screw, a slider pulley, a slider and a cincture, wherein the spindle is connected with the driving component, one end of the reel is connected with the spindle, the other end of the reel is connected with the screw, the slider is arranged on one side of the reel, the slider pulley is arranged in the slider, and the cincture is arranged on one side of one hanging bridge connecting rod component; and one end of the steel wire is connected with the reel, the other end is connected with the other hanging bridge connecting rod component, and the steel wire is wound on the slider pulley and the cincture. Through the mode, a motor is used for supplying power for the rack, the rack is controlled to stretch and contract, the operation is stable, automatic limit is performed when the rack is in place, mechanical failures due to resistance meeting can be prevented effectively, and the rack is convenient to use.

Owner:苏州市沃旗电器有限公司

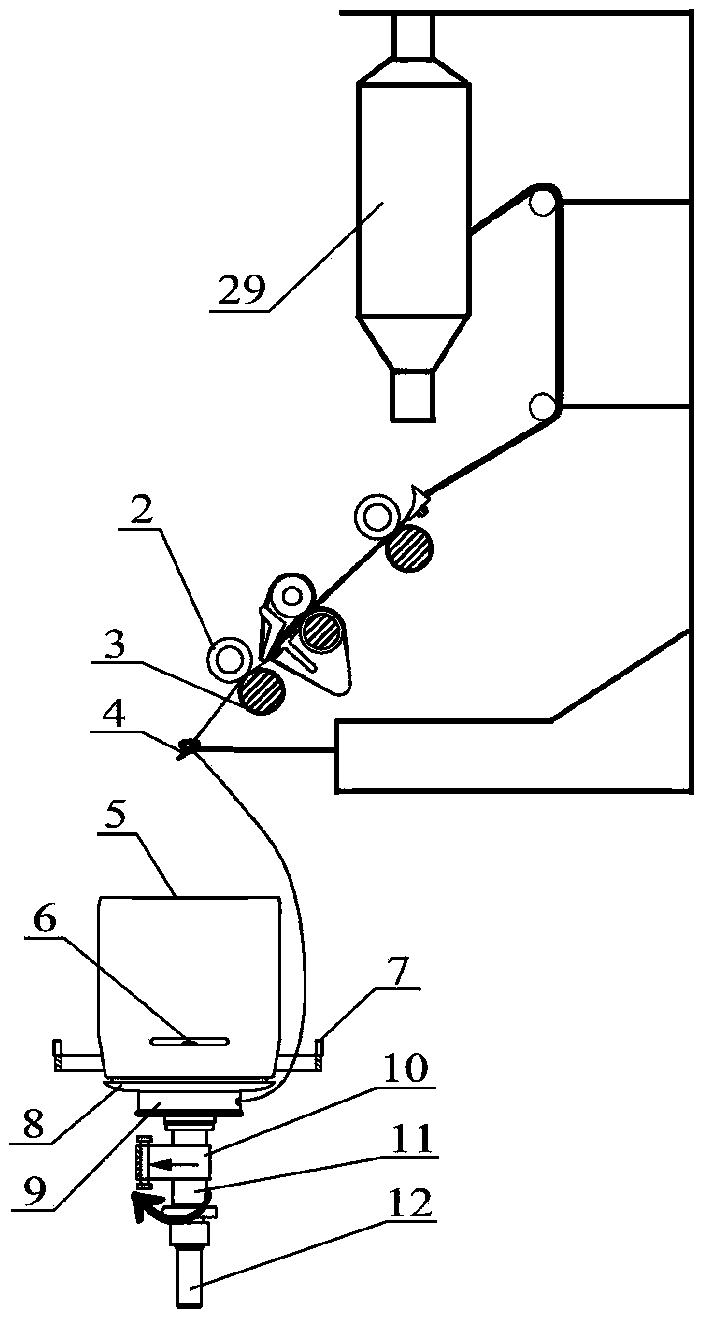

Coating sheet yarn winder

The invention relates to a coating sheet yarn winder, which is characterized in that: the winder is provided with a disc-head active unwinding mechanism (1), a device for controlling the synchronous operation of an unwinding motor (32) and a winding motor (18), and a yarn dividing device (6). The yarn dividing device (6) separates coating sheet yarns (3) into a plurality of layers of coating single yarns (7) which do not adhere to each other and remain a certain distance; and the coating single yarns (7) are led into yarn guiding porcelain plates (23) of the corresponding layers on a winding component (9) after passing through a tension adjusting gear (8), and enter a single yarn winding mechanism (22) after being guided to a tensioner (21) in one-to-one correspondence. The coating sheet yarn winding machine adopts a multi-layer multi-gear structure and a same-direction same-side yarn-guiding arrangement manner to achieve around 400 spindles in each winding, has the characteristics oflarge bobbin amount, small occupied space, convenient yarn guiding and bobbin replacement operations, high yield, low cost, capacity of satisfying the needs of coating cheese industrialization for high-count high-speed knitting, and the like, and opens up new ways for weaving novel fabrics which are energy-saving, emission-reducing, environmentally-friendly and good for health.

Owner:射阳县杰力纺织机械有限公司

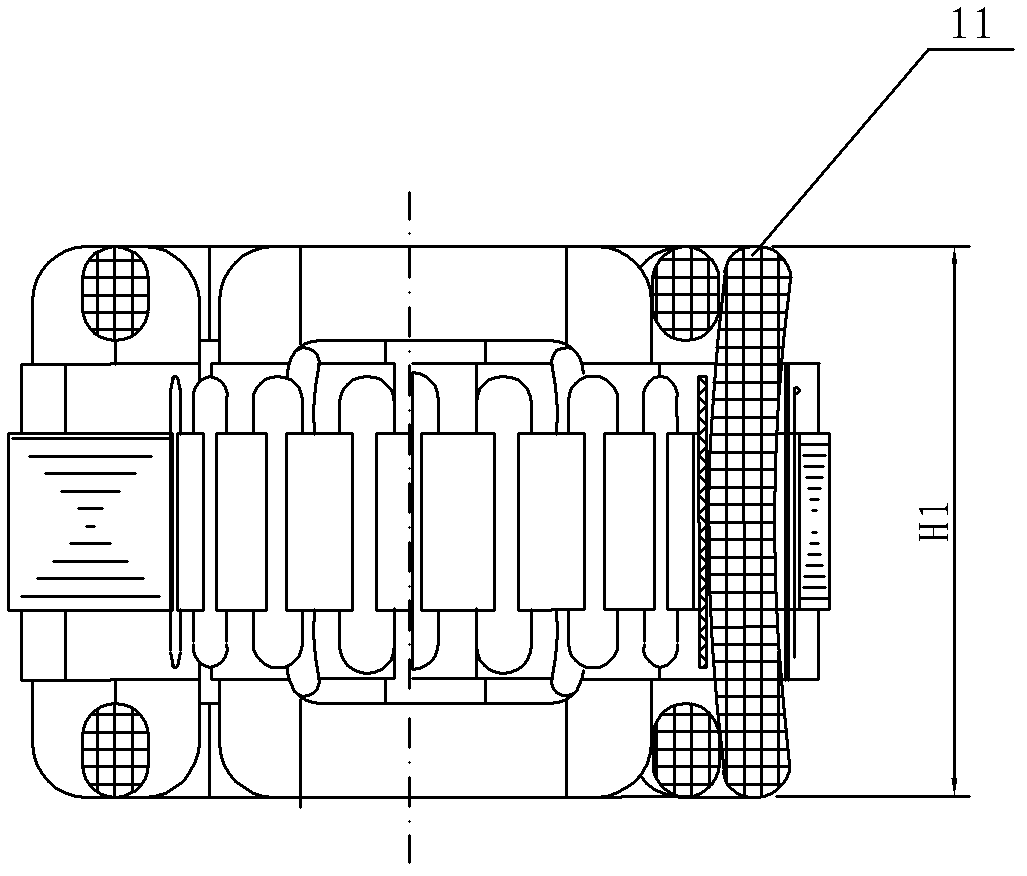

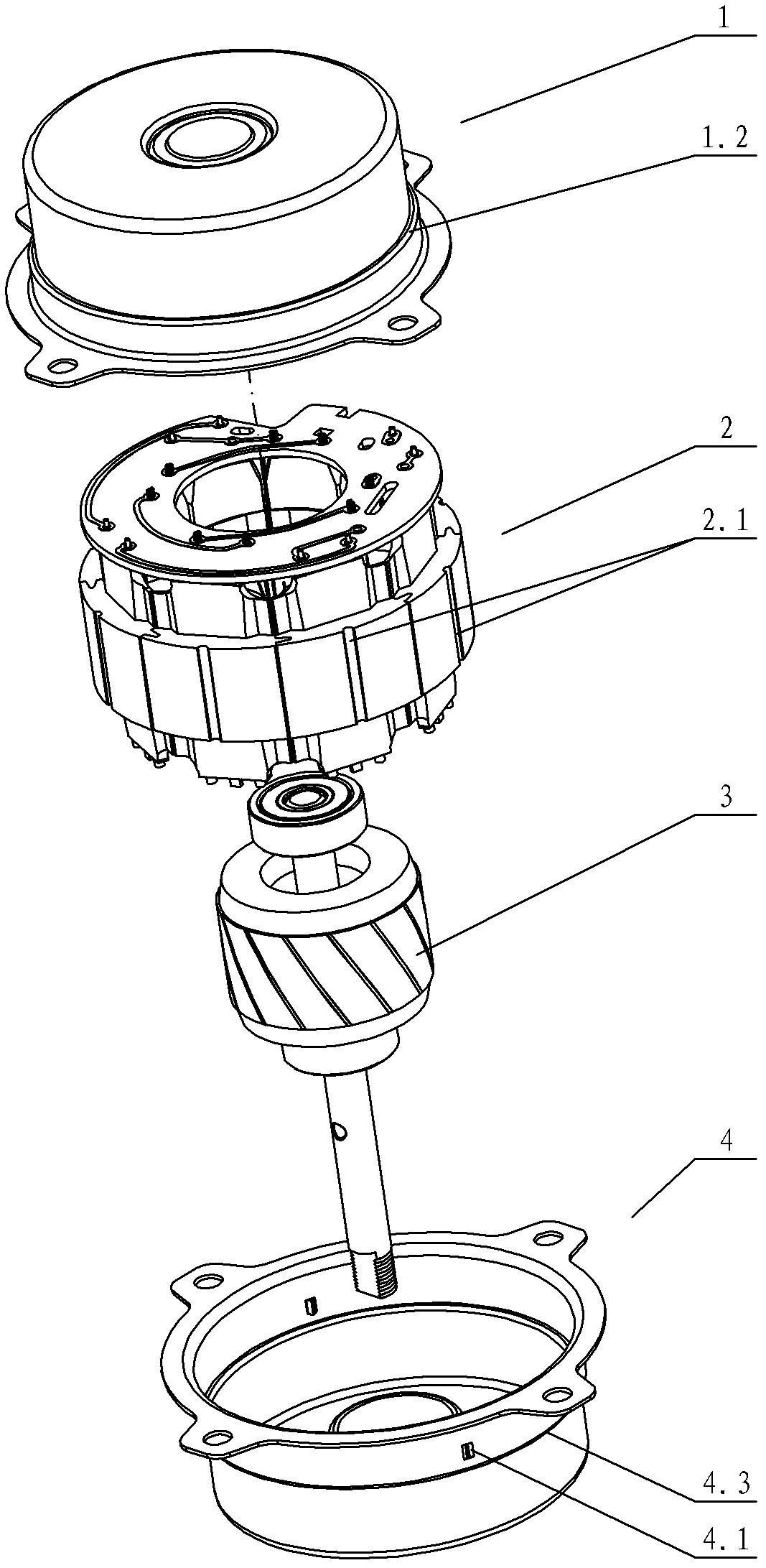

Single phase capacitor motor and manufacturing method thereof

InactiveCN102522867AReduce usageRealize automatic winding operationMagnetic circuit stationary partsAsynchronous induction motorsCapacitanceWind component

The invention discloses a single phase capacitor motor and a manufacturing method thereof. The single phase capacitor motor comprises a stator and a rotor arranged in a casing; the casing is formed by a rear cover and a front cover; the stator comprises N main coil winding components and N auxiliary coil winding components; the main coil winding components and the auxiliary coil winding components are arranged in a staggered manner to form the ring-shaped stator; each main coil winding component, as well as each auxiliary coil winding component respectively, comprises windings wound on the an stator iron core; the N is the number of the stator poles; the stator iron is provided with an insertion head and an insertion groove on the left and the right sides of the stator poles; each two adjacent stator iron cores are connected via the insertion head and the insertion groove; an upper coil holder and a lower coil holder are respectively arranged at the upper part and the lower part of the stator iron core; and the upper coil holder is provided with an upper winding groove, and the lower coil holder is provided with a lower winding groove. The single phase capacitor motor has the advantages of simple and reasonable structure, flexible operation, simple process, low consumption of winding, high degree of automation and low manufacturing cost.

Owner:LONON IND CO LTD

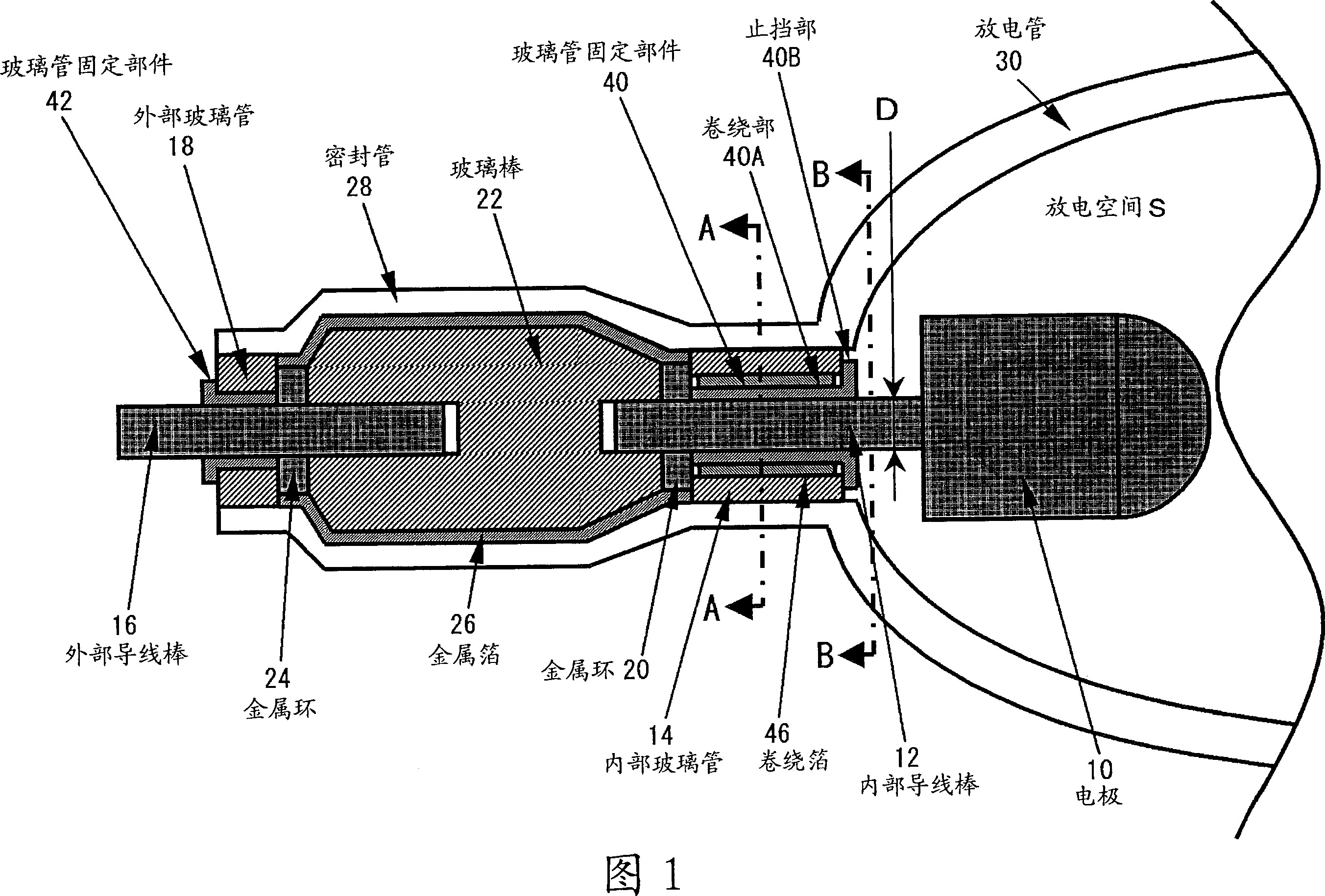

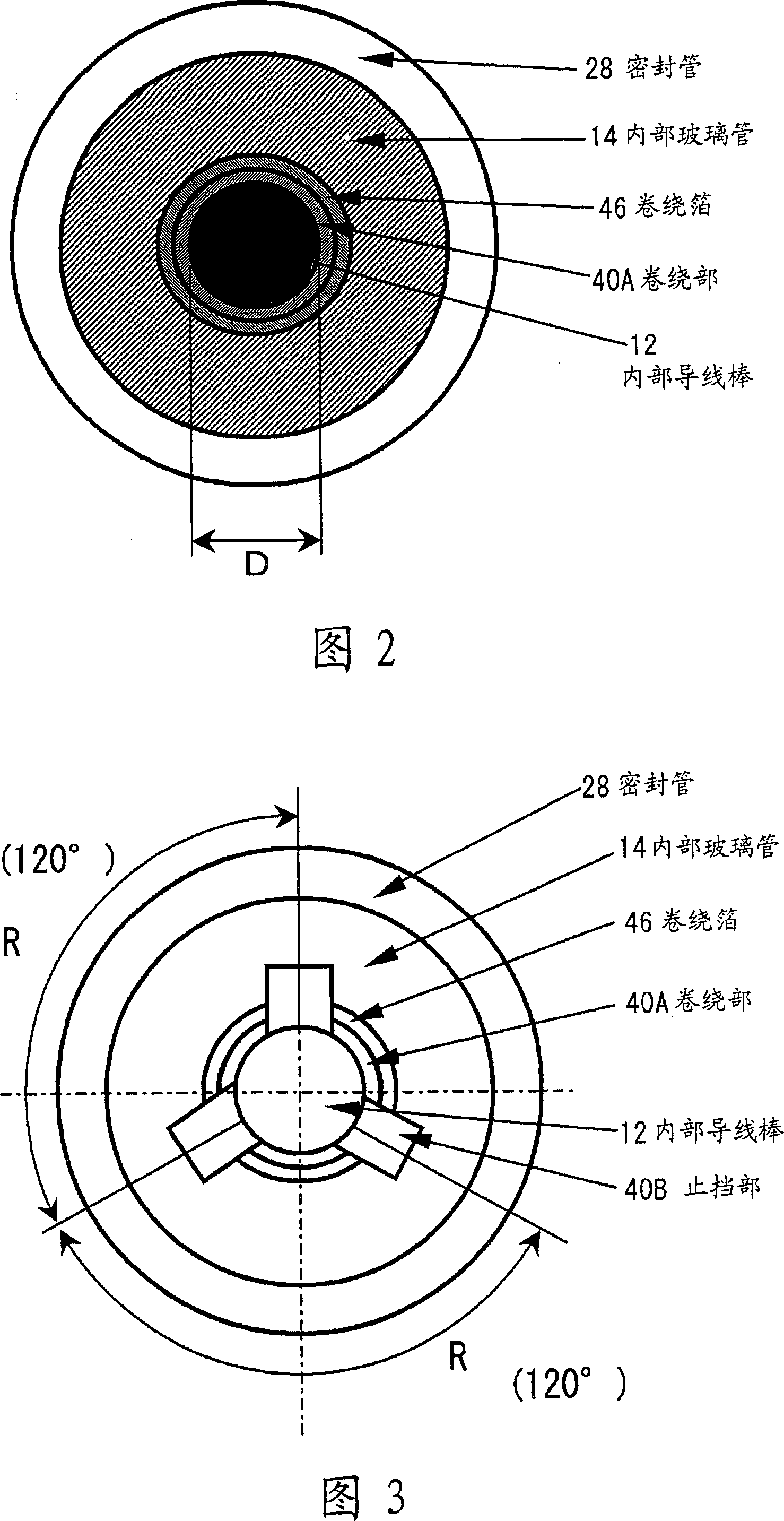

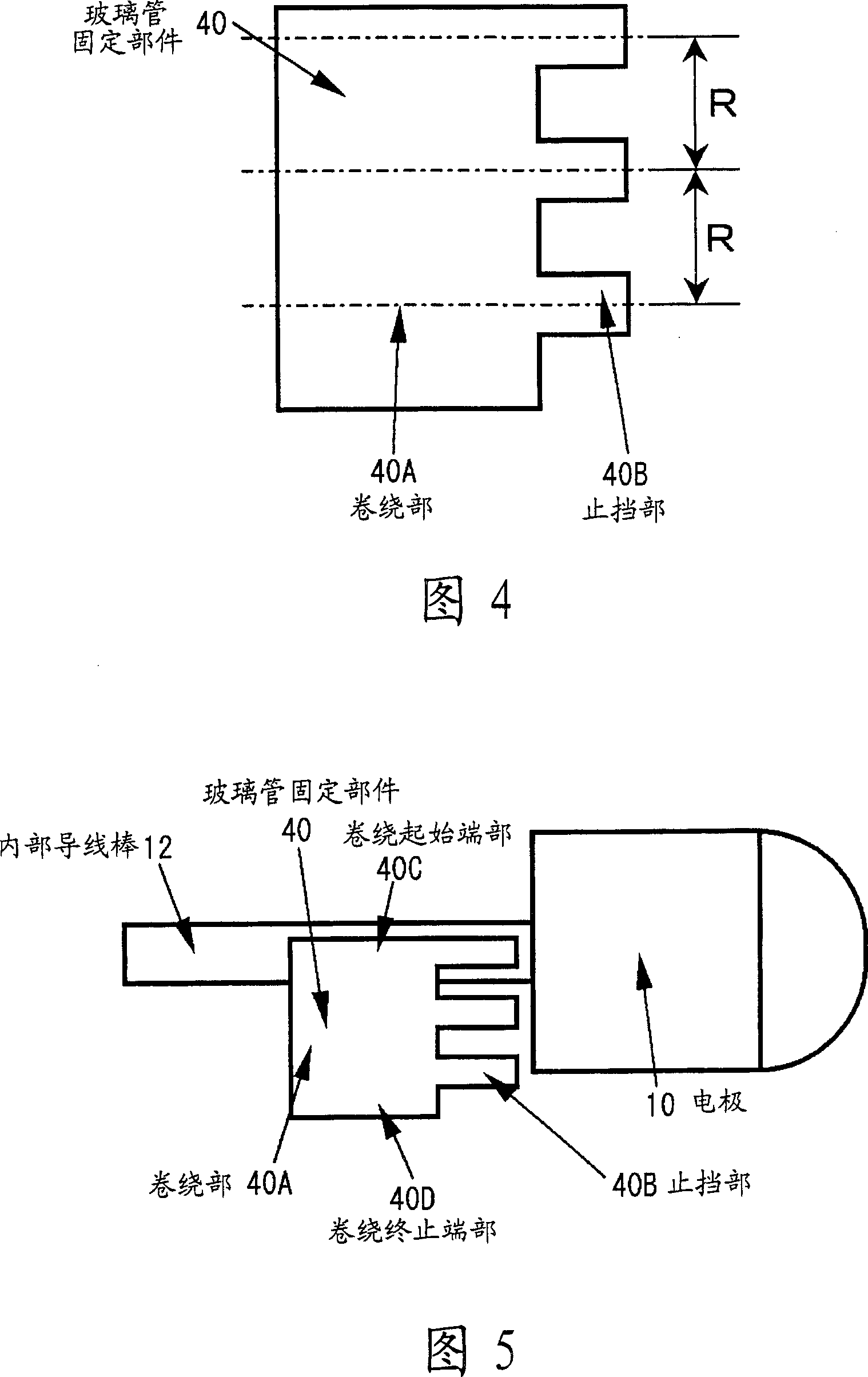

Sealing structure of discharge lamp

ActiveCN1953137APrevent movementEasy to assembleTube vessels vacuum closureGas discharge lamp detailsGas-discharge lampWind component

The present invention provides a sealing structure of discharge lamp which accurately mounts the installing component on the discharge tube with high efficiency in the assembly procedure of the sealing discharge lamp. The circle surface of the interior conductor rod (12) in the electrode (10) is winded with a glass tube fixing component (40). The interior conductor rod (12) is inserted into the cylindraceous interior glass tube (14). A linguiform stopping component (40B) is extended from the winding component (40A) of the glass tube fixing component (40). Curving the stopping component (40B) which is projecting in the end of the interior glass tube (14) prevents the movement of the interior glass tube (14) along the tube axial direction. A winding foil which has same axis with the interior conductor rod (12) is arranged between the winding component (40A) and the interior glass tube (14). The glass tube fixing component (40) comprises an arbitrary components selected from the group of Ta, Nb, W, and Mo. The winding component (40A) contains Ta or Nb, and the winding foil contains an arbitrary component of Ta, Nb, W, and Mo.

Owner:ORC MFG

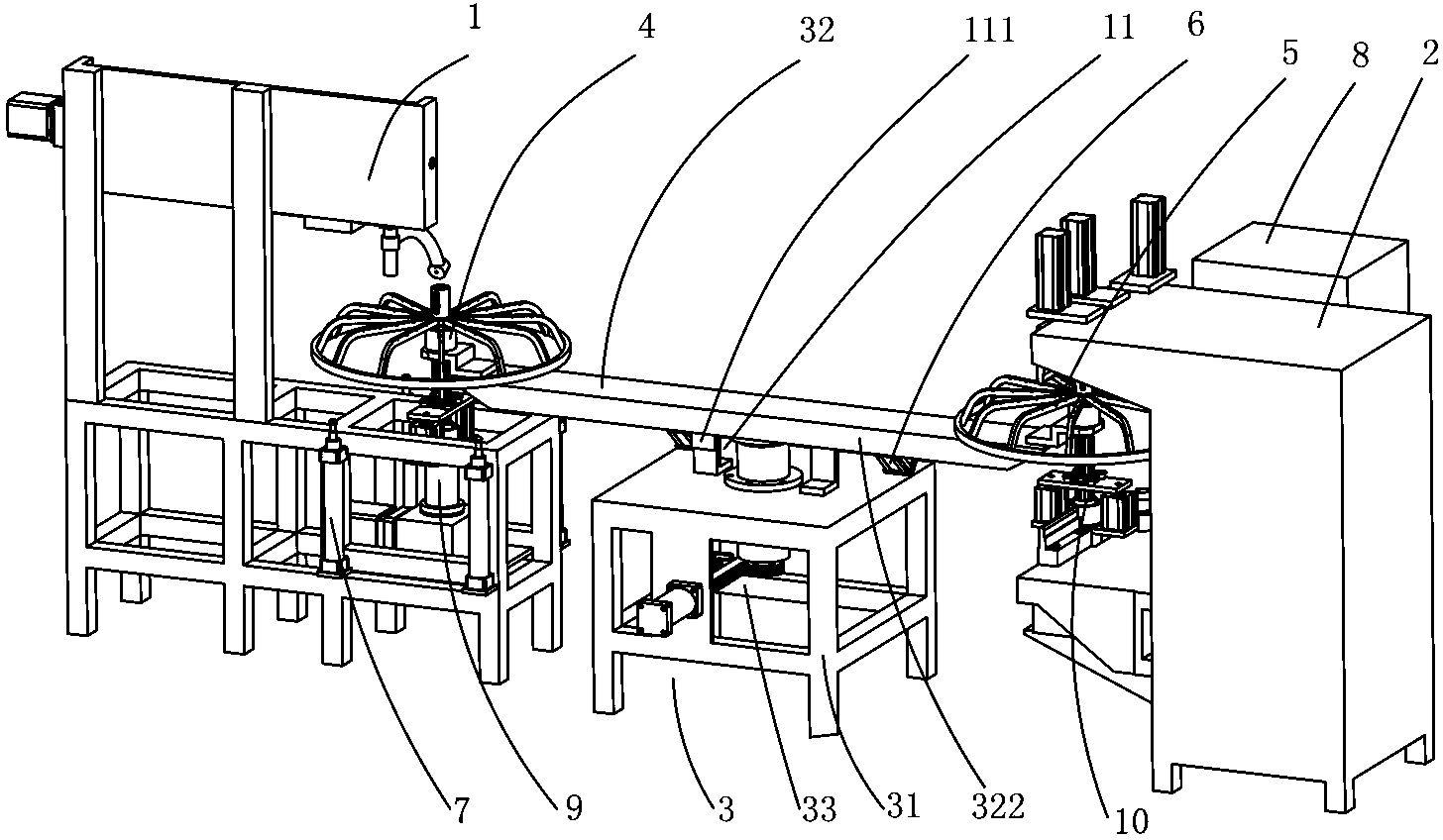

Automatic production device for fan housings

The invention discloses an automatic production device for fan housings. According to the automatic production device for the fan housings, a first machining mould and a second machining mould accurately rotate on a winding component or a welding component respectively through structural matching among the winding component, the welding component, a rotary component, a positioning device and a demoulding component, wherein the first machining module and the second machining module are arranged at the left end and the right end of the rotary component respectively, and working procedures of winding, welding and demoulding are accurately conducted on workpieces installed on the first machining mould and the second machining module orderly and automatically. The automatic production device for the fan housings is high in automation, high in efficiency, low in cost and accurate in positioning, time and labor are saved, manual errors are reduced, and the yield and quality of the fan housings are improved.

Owner:佛山市顺德区焯鑫金属制品有限公司

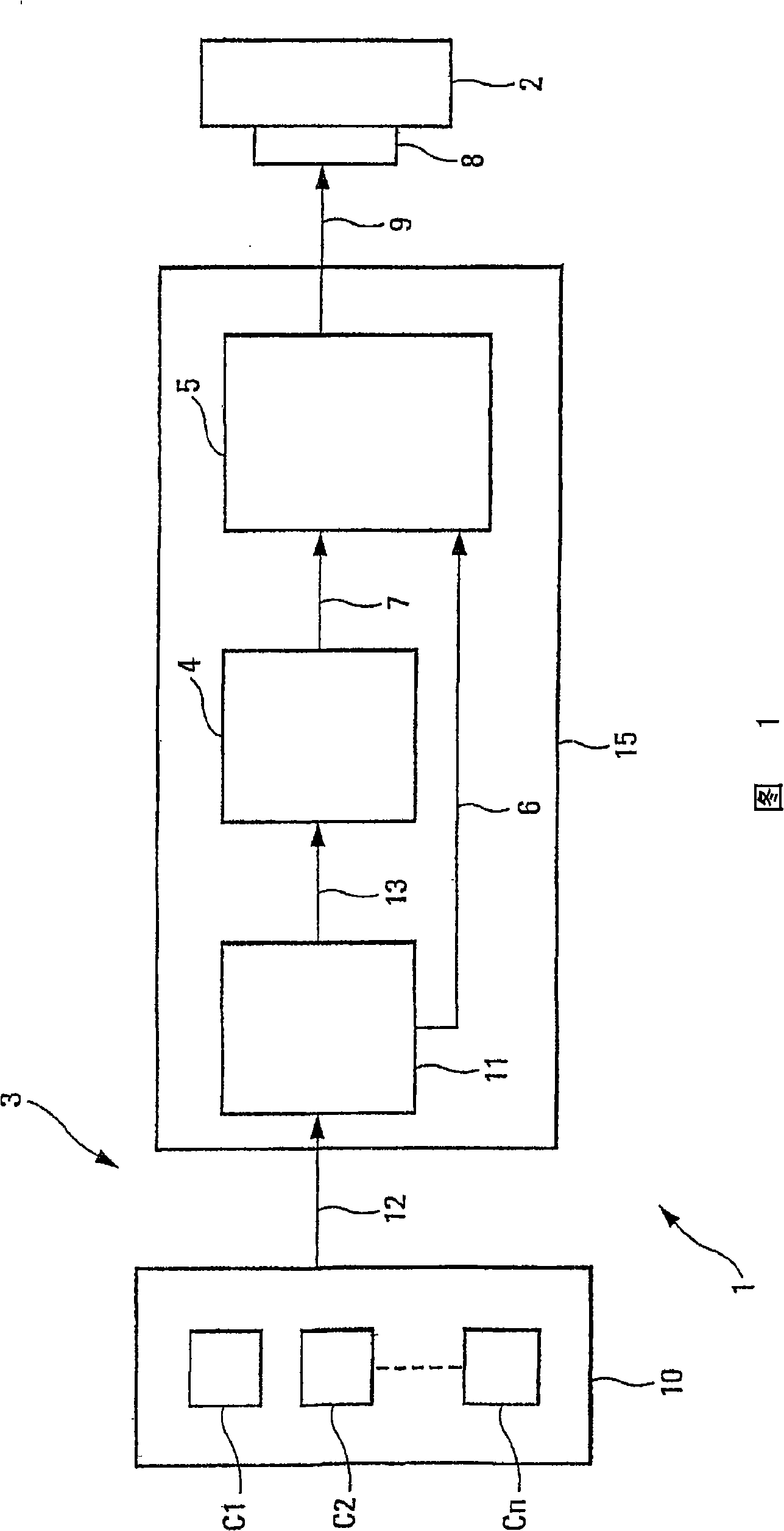

Method and device for attenuating on an aircraft the effects of a vertical turbulence

ActiveCN101283319AMagnitude of reduced vertical load factorSmall height changeActuated automaticallyAltitude or depth controlWind componentAerospace engineering

The invention concerns a device (1) comprising means (4) for determining automatically, using a vertical wind component, a level of severity concerning a vertical turbulence, and means (5) for computing automatically, using said vertical wind component, a control instruction for a controllable member (2), which enables the amplitude of load factors generated on the aircraft by the vertical turbulence to be minimized.

Owner:AIRBUS OPERATIONS (SAS)

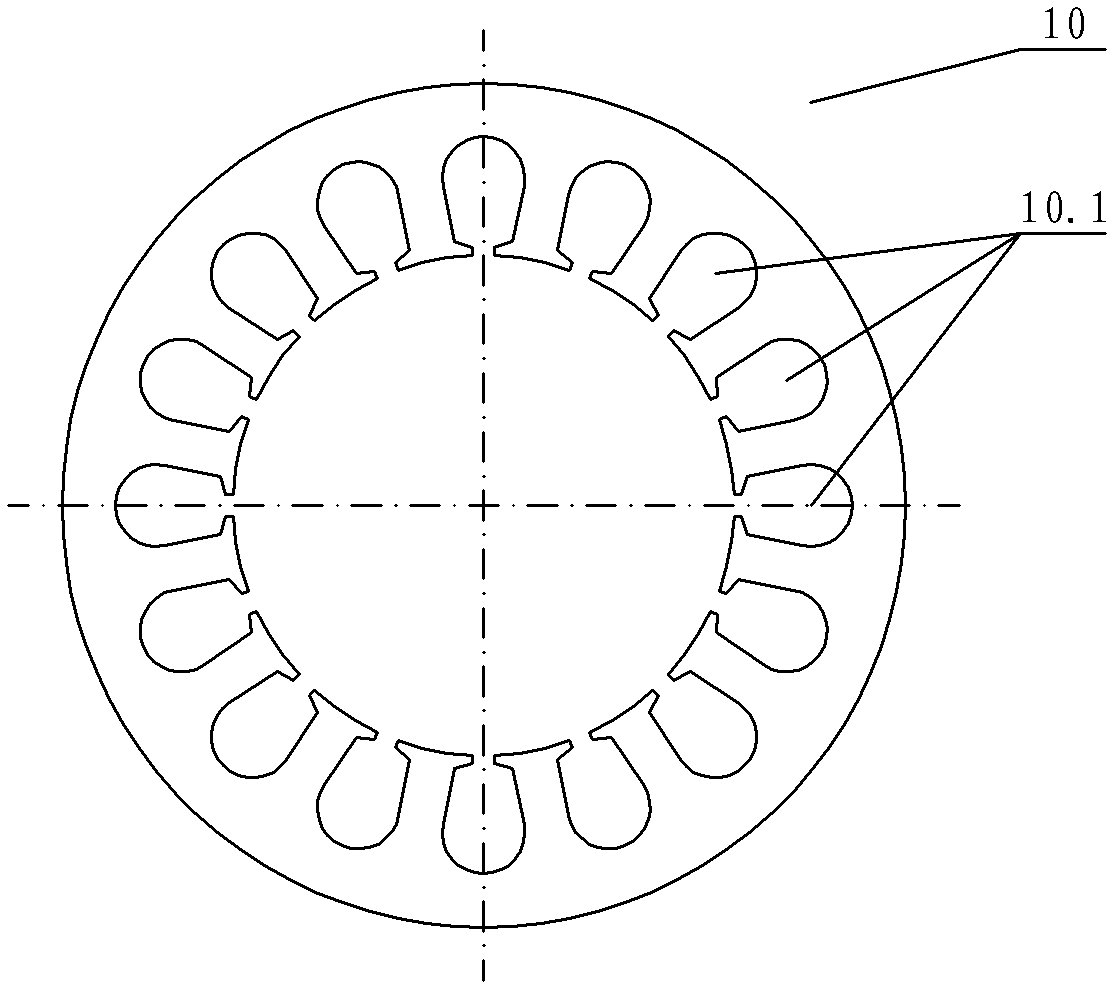

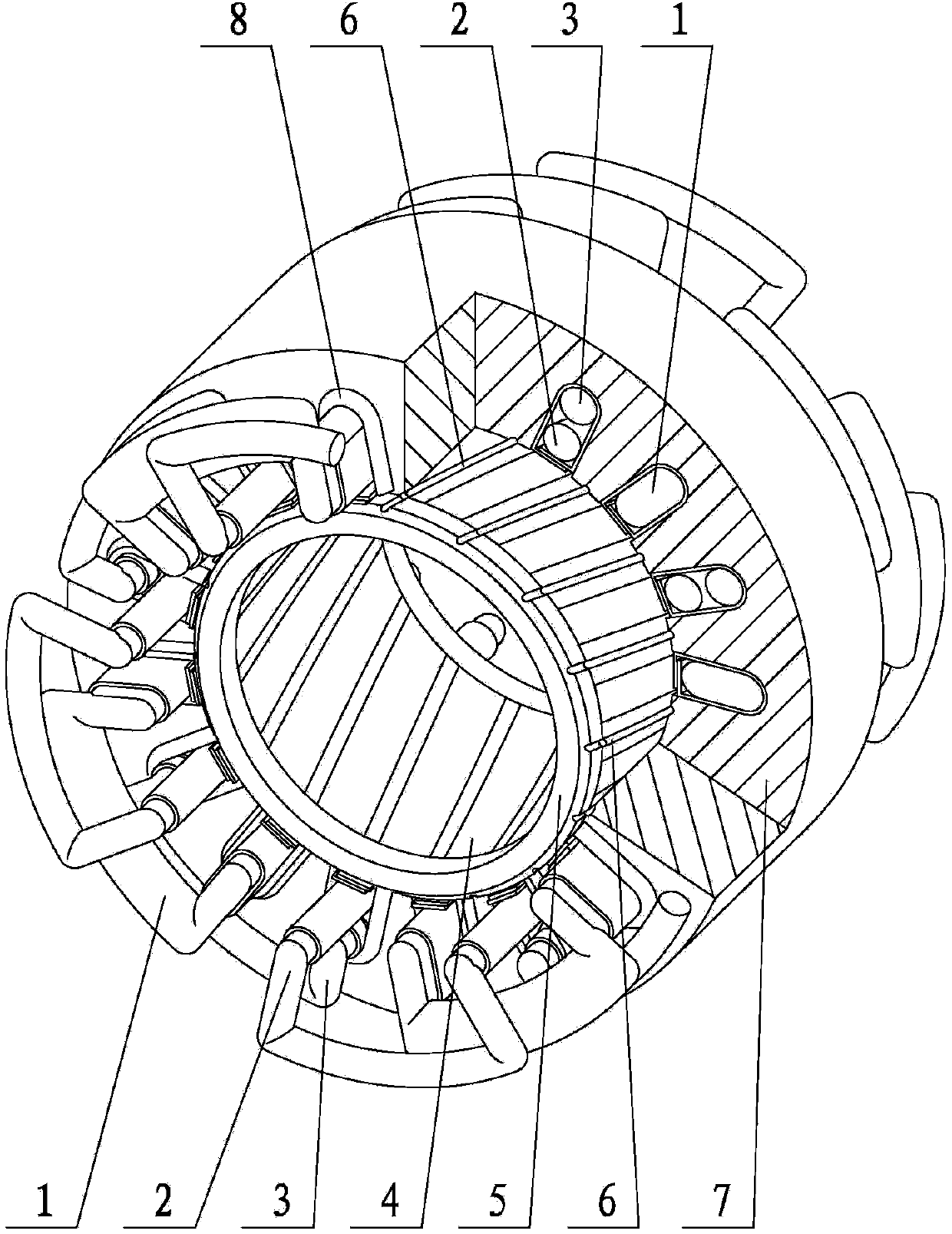

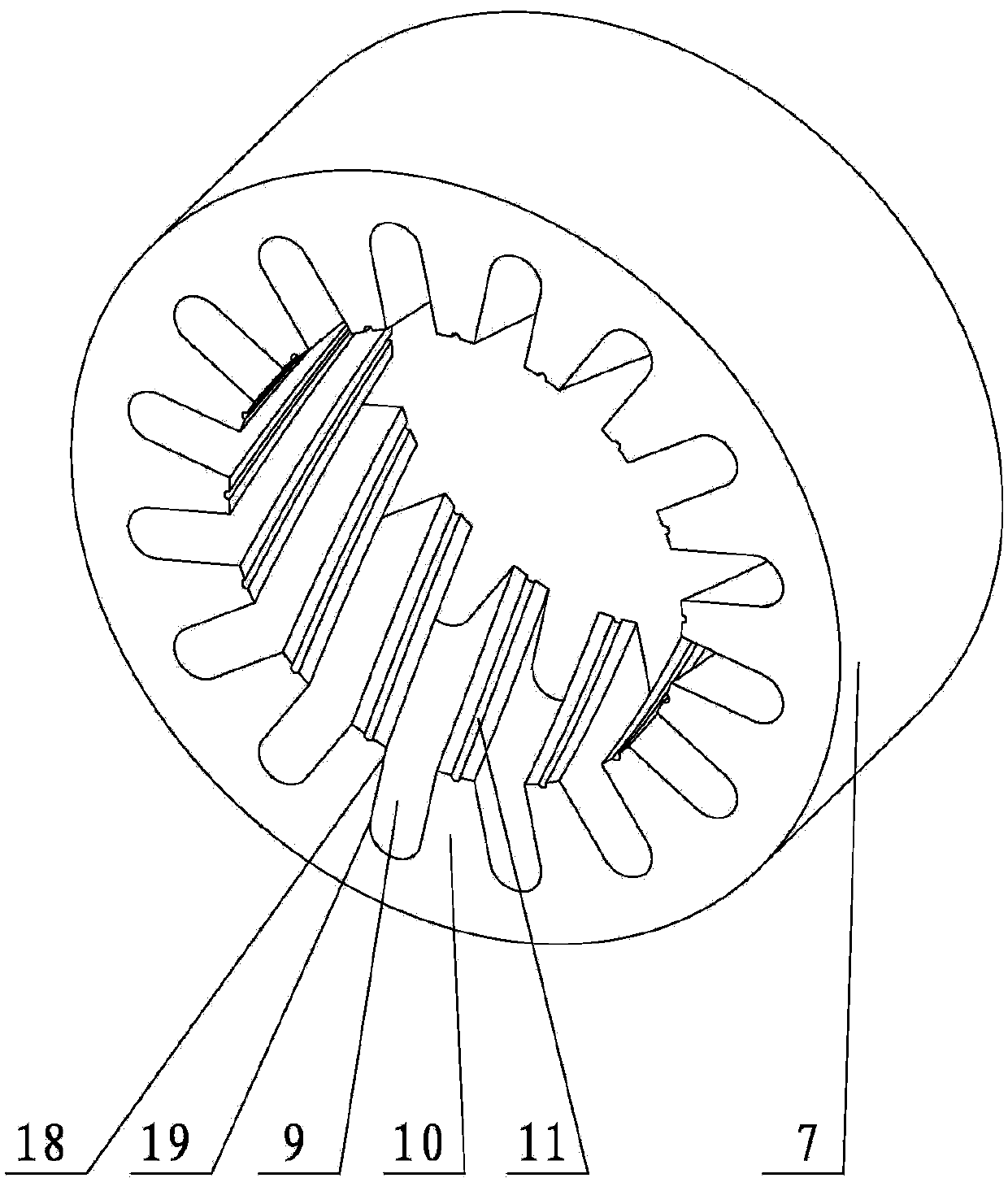

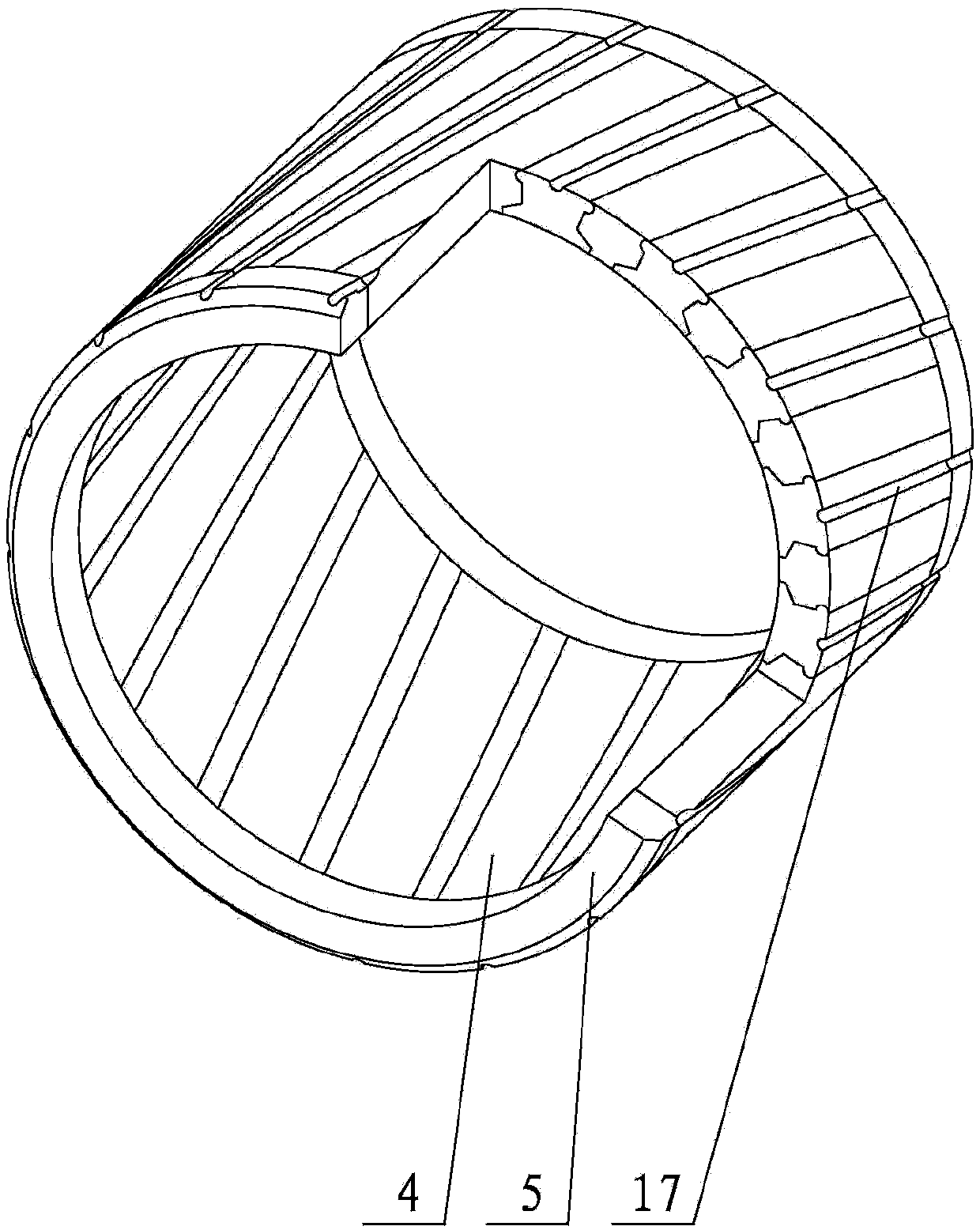

Concentrically-split-type stator and stator winding centralized assembling method

ActiveCN104184227AEmbedding work efficiency is highIncrease productivityMagnetic circuit stationary partsManufacturing stator/rotor bodiesWind componentInduction motor

The invention provides a concentrically-split-type stator and stator winding centralized assembling method and relates to a method applied to a small-size permanent-magnet synchronous motor or an AC asynchronous motor. According to the concentrically-split-type stator and stator winding centralized assembling method, a nonsalient-pole-type stator iron core is segmented into a concentric main stator iron core and a notch iron core component along the radial direction. During the assembling of the concentrically-split-type stator, the stator winding centralized assembling method is used to install a stator winding component first, then, the notch iron core component is installed, and the stator winding component is fixed by the notch iron core component. In the craft process of the stator winding centralized assembling method, stator windings are prepared first and then, the stator windings are assembled in a centralized manner. According to the concentrically-split-type stator and the stator winding centralized assembling method, the method of manual line marking and line pressing which are used to embed wires into a stator wire groove in the scattered embedding process of the stator windings is no longer needed, so that wire embedding efficiency in the stator winding centralized assembling method is high; and the continuous winding forming processing process of closed-slot-type notch iron core punched plates of the concentrically-split-type stator is a continuous processing process, so that mechanical equipment can be used favorably to improve production efficiency.

Owner:湖北久特机电科技有限公司

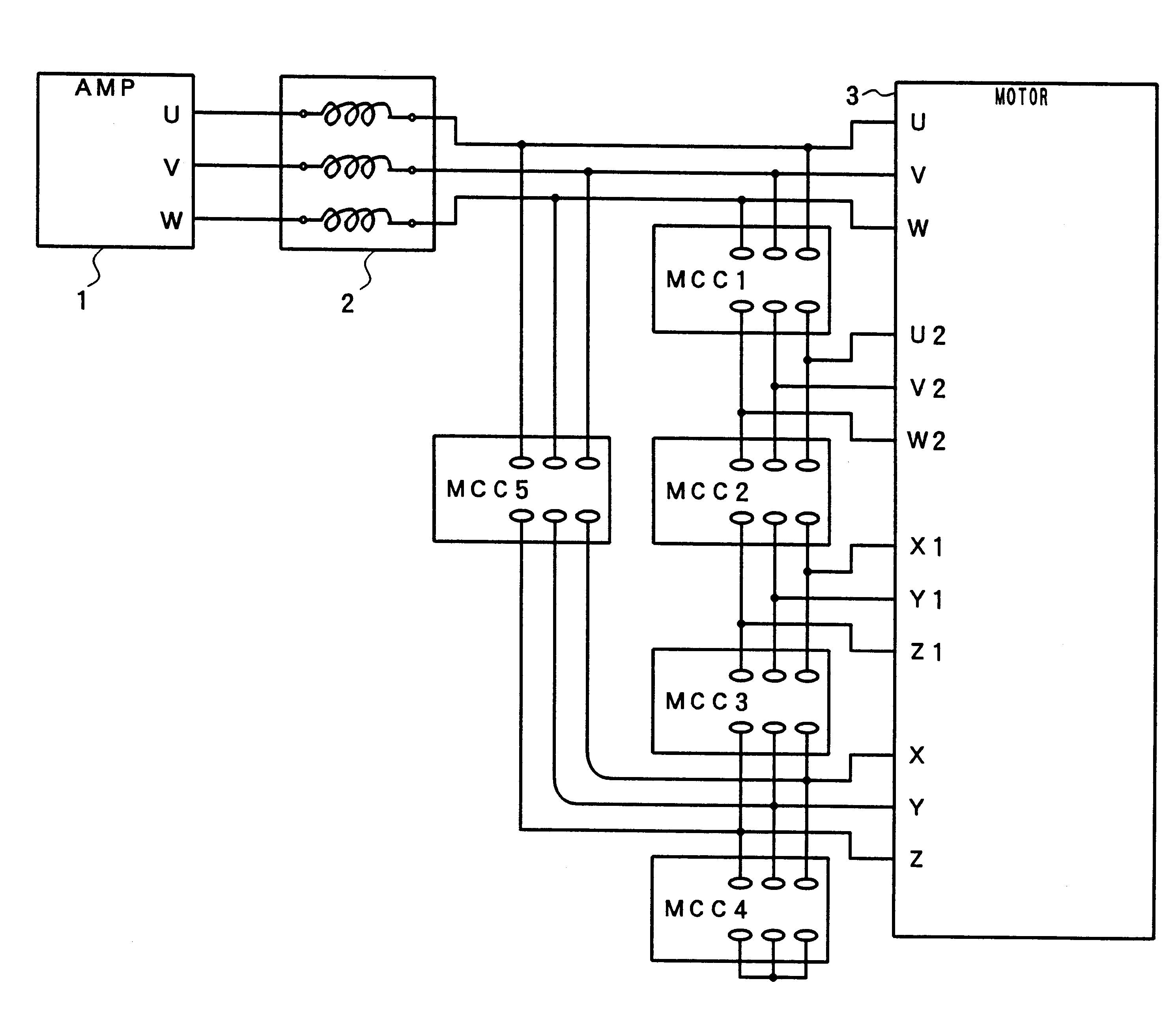

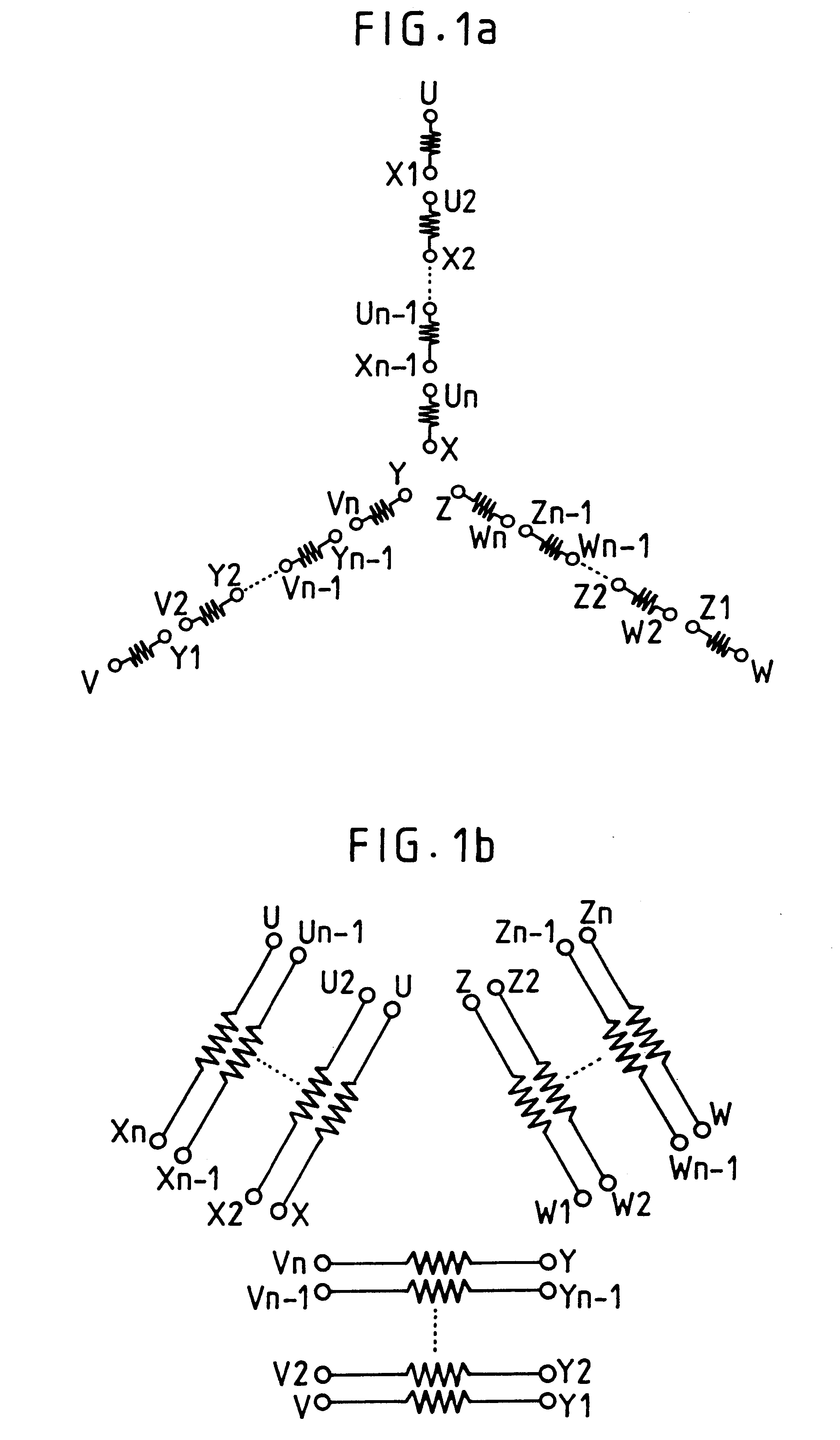

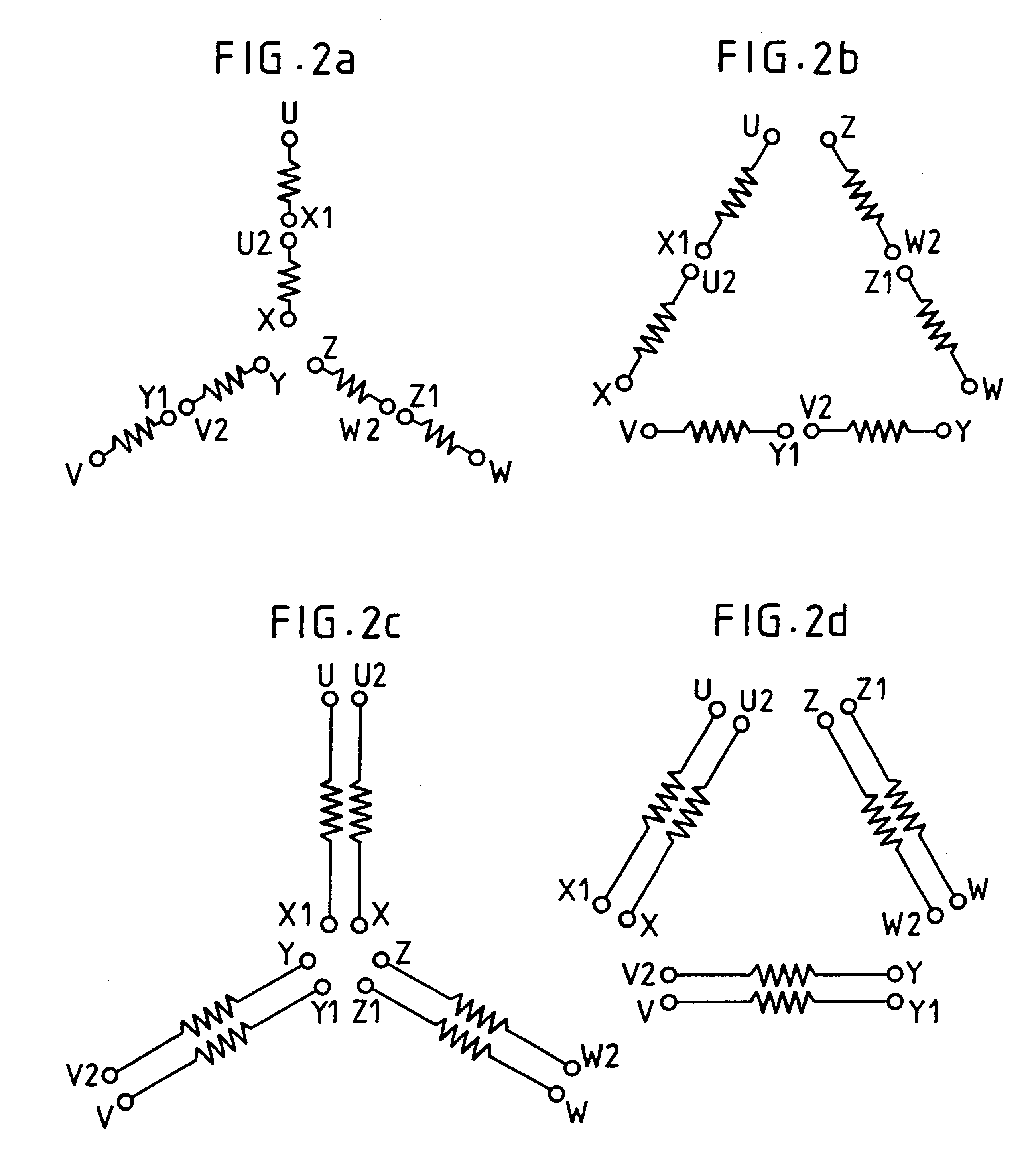

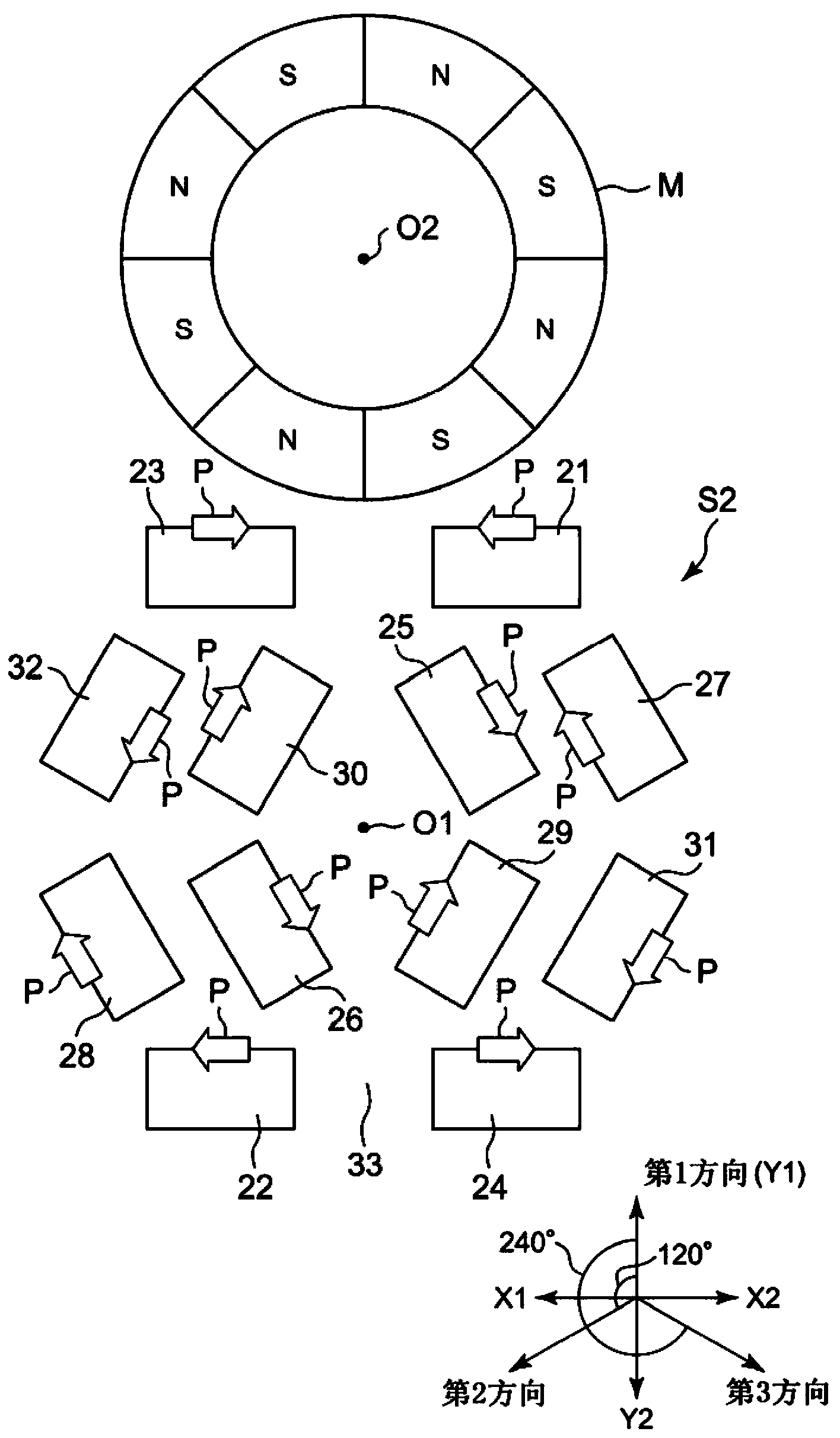

Induction motor

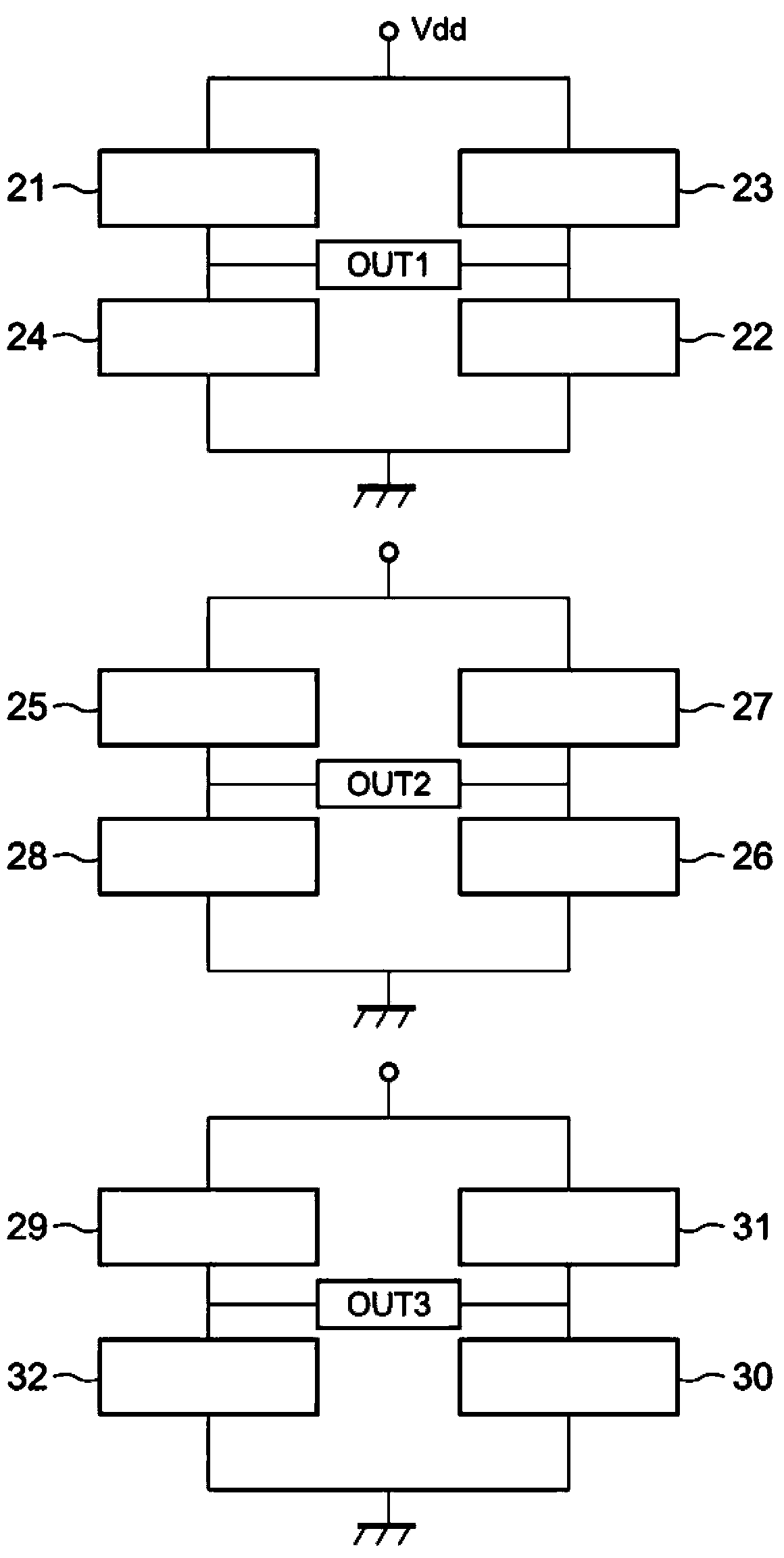

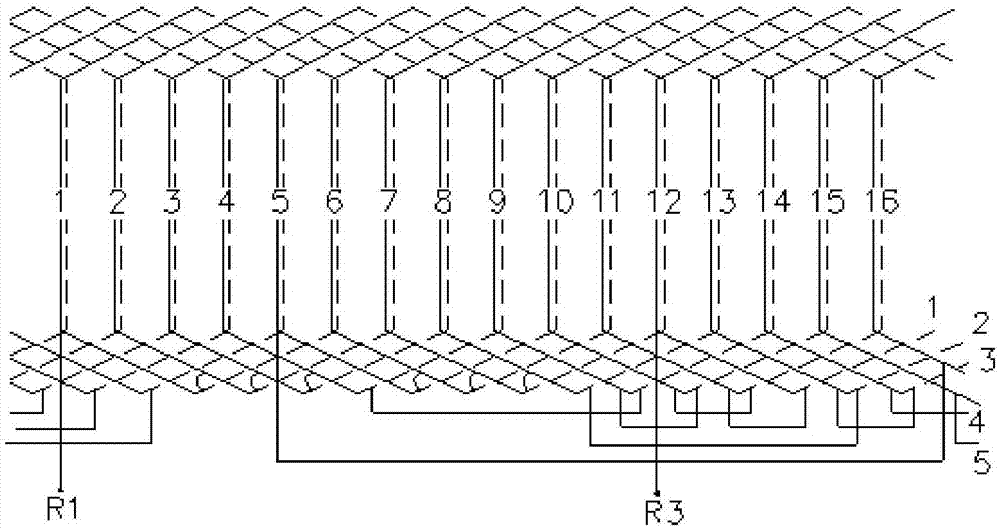

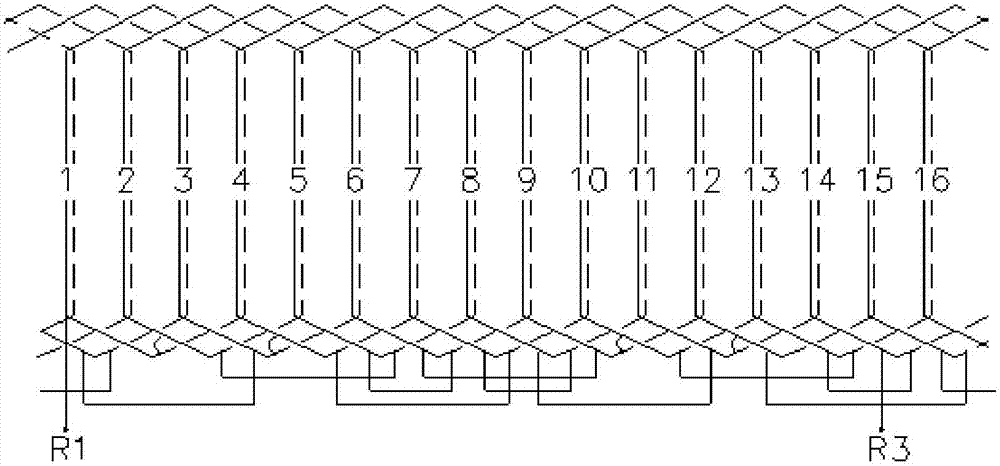

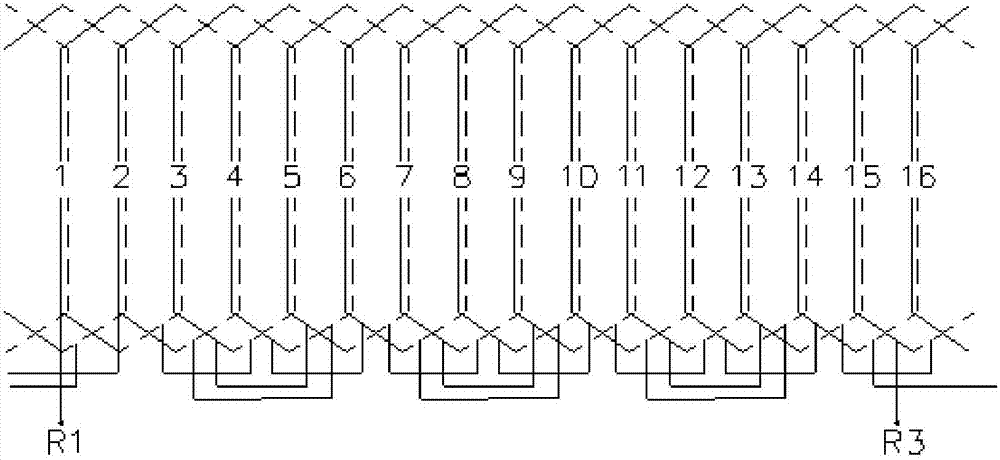

InactiveUS6333578B1Improve power characteristicsHigh torqueAsynchronous induction motorsMotor control in four quadrantsWind componentLow speed

An induction motor capable of obtaining a high power characteristic in a wide range without producing induced voltage. A winding for each phase is composed of a plurality of winding components having the same number of turns. When high torque is needed with low speed rotation, a Y-connection in which winding components for each phase are connected in series is formed as shown in FIG. 2a. For medium low speed rotation, a DELTA-connection in which winding components for each phase are connected in series is formed as shown in FIG. 2b. For medium high speed rotation, a Y-connection in which winding components for each phase are connected in parallel is formed as shown in FIG. 2c. For high speed rotation, a alpha-connection in which winding components for each phase are connected in parallel is formed as shown in FIG. 2d. Using the entire winding for each phase, the number of turns is decreased stage by stage to switch from low speed rotation to high speed rotation. Since there is no unused part of windings, there is no problem of induced voltage. A fall in power at the time of switching the winding formation can be restrained, so that a high power characteristic can be obtained in a wide range.

Owner:FANUC LTD

Two-for-one twisting type spinning frame

ActiveCN109554784AImprove twisting efficiencyDestroy qualityDrafting machinesContinuous wound-up machinesYarnWind component

The invention relates to a two-for-one twisting type spinning frame, and belongs to the technical field of textile. The two-for-one twisting type spinning frame has the advantages that a twisting andspinning mechanism of an ordinary ring spinning frame is changed into a two-for-one twisting winding mechanism, the two-for-one twisting winding mechanism comprises a two-for-one twisting mechanism and a winding mechanism, a twisting disc can rotate by a circle for silver operated in zones from jaws of a front roller to a tension device, accordingly, two-twist two-for-one twisting effects can be realized for the silver, and the twisting efficiency can be improved; the winding mechanism is positioned in a yarn storage tank of the two-for-one twisting mechanism, twisting components and winding components are substantially separated from one another, twisting and winding can be separately individually controlled, the twisting and winding mechanism, by which twisting and winding can be simultaneously carried out and are constrained by each other, of the ordinary ring spinning frame is thoroughly changed, large-package spun yarns of cheese can be formed, the shortcomings of great winding balloon and tension difference of the traditional spinning frame mechanisms and high fluctuation of the quality of existing resultant yarns can be overcome, and accordingly the quality and the uniformity of resultant yarns can be improved; the two-for-one twisting type spinning frame is reasonable in structure and convenient to operate, and popularization can be facilitated.

Owner:WUHAN TEXTILE UNIV

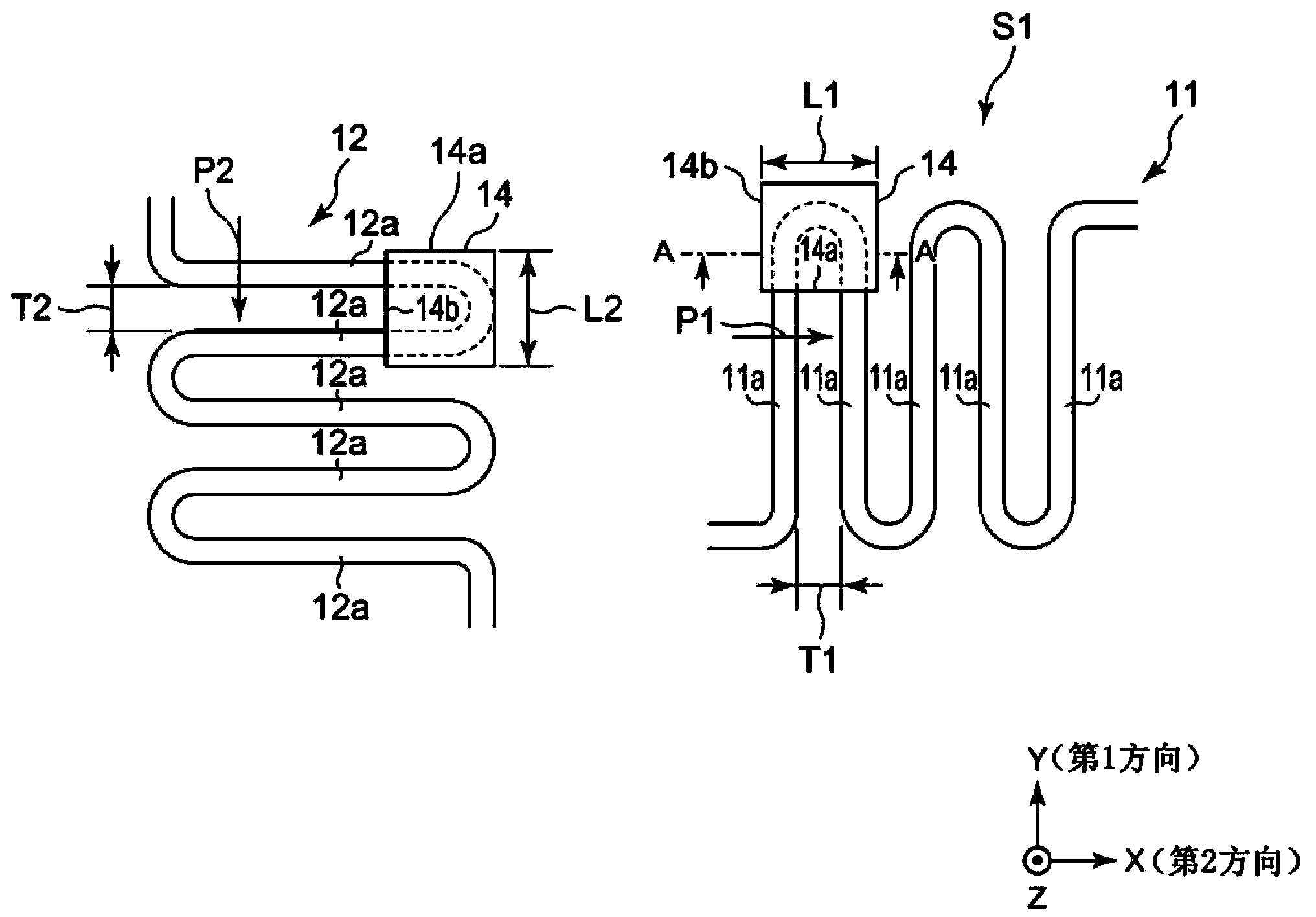

Magnetic sensor

ActiveCN103389118AHigh precisionReduce manufacturing costMagnetic measurementsConverting sensor output electrically/magneticallyWind componentElectrical conductor

Owner:ALPS ALPINE CO LTD

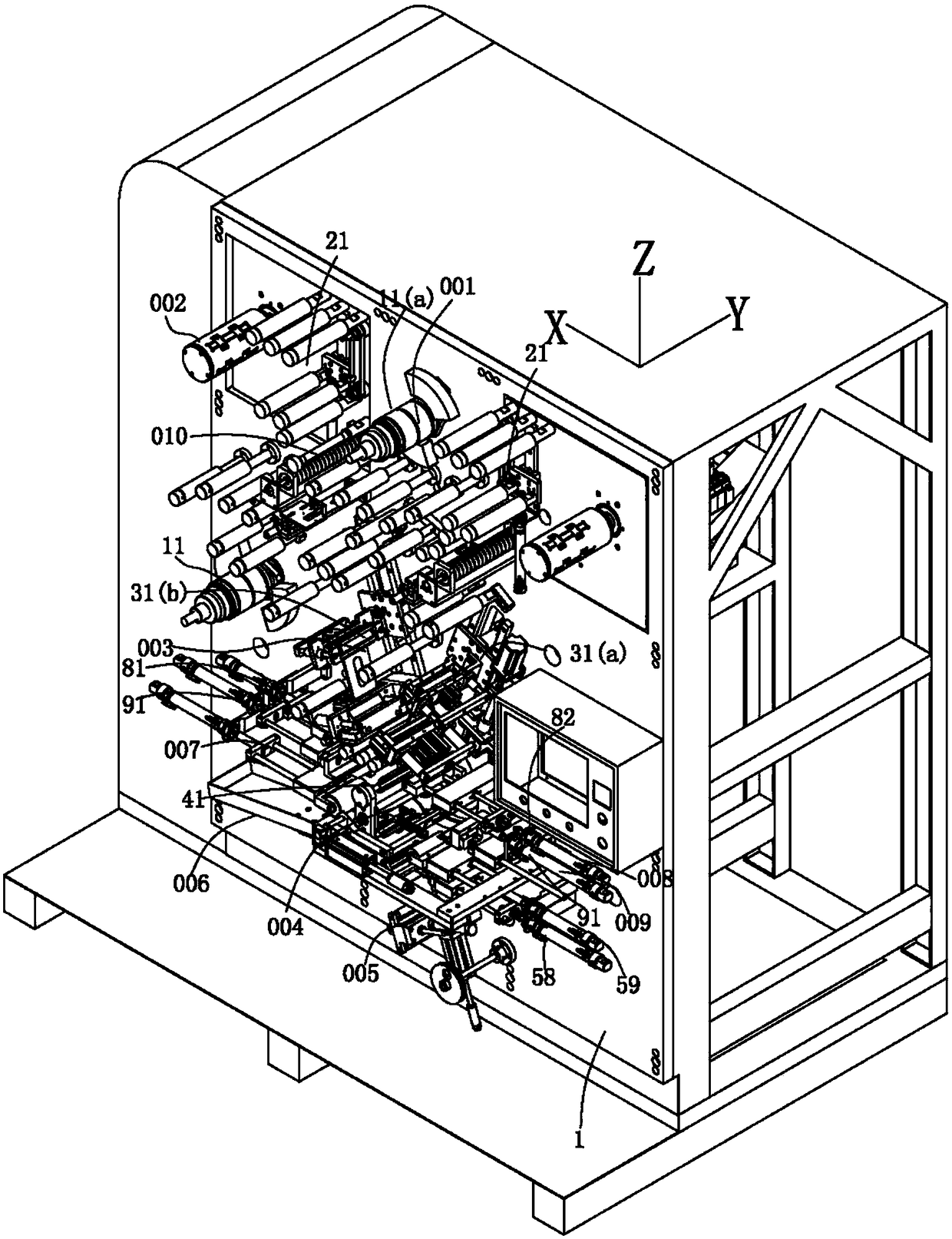

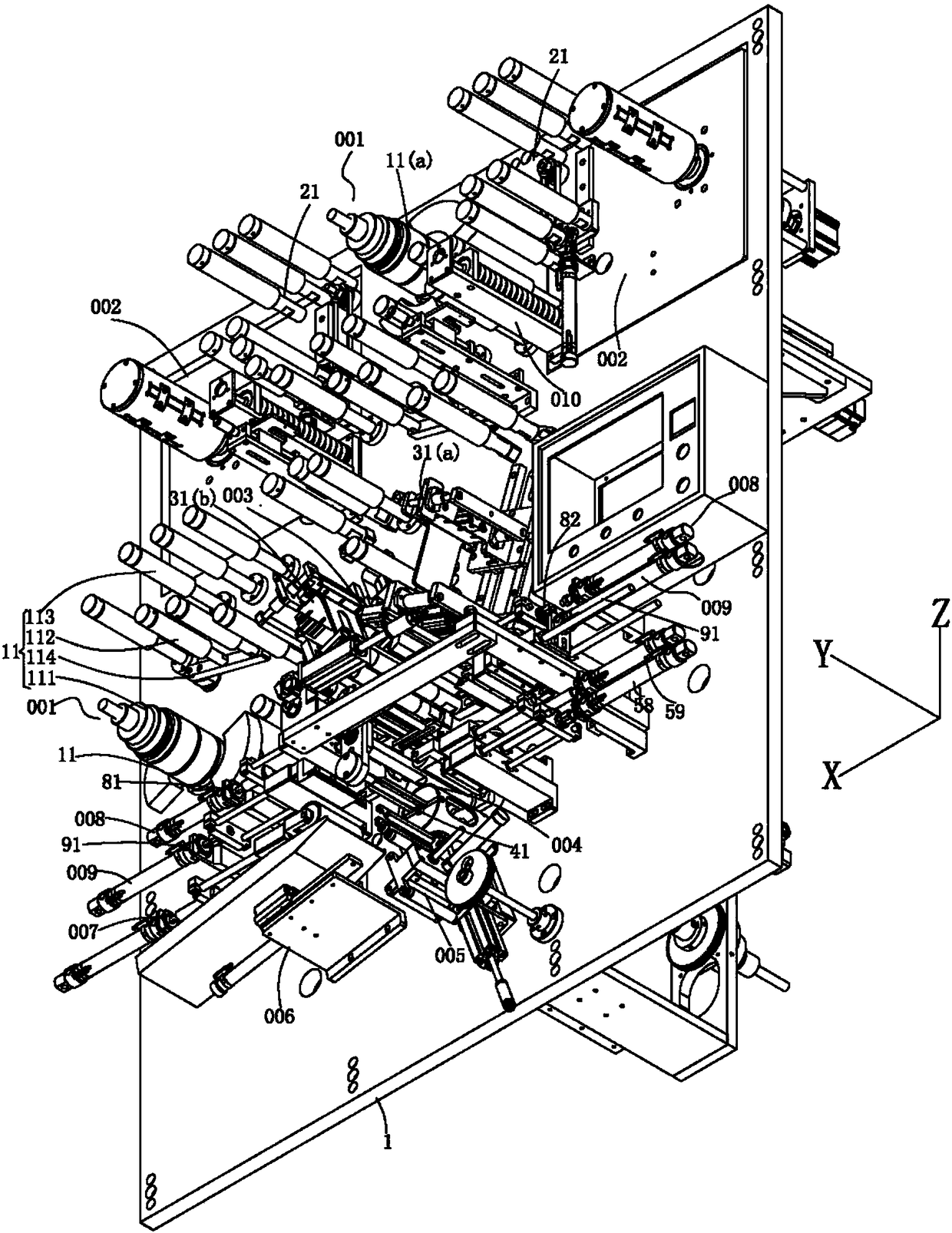

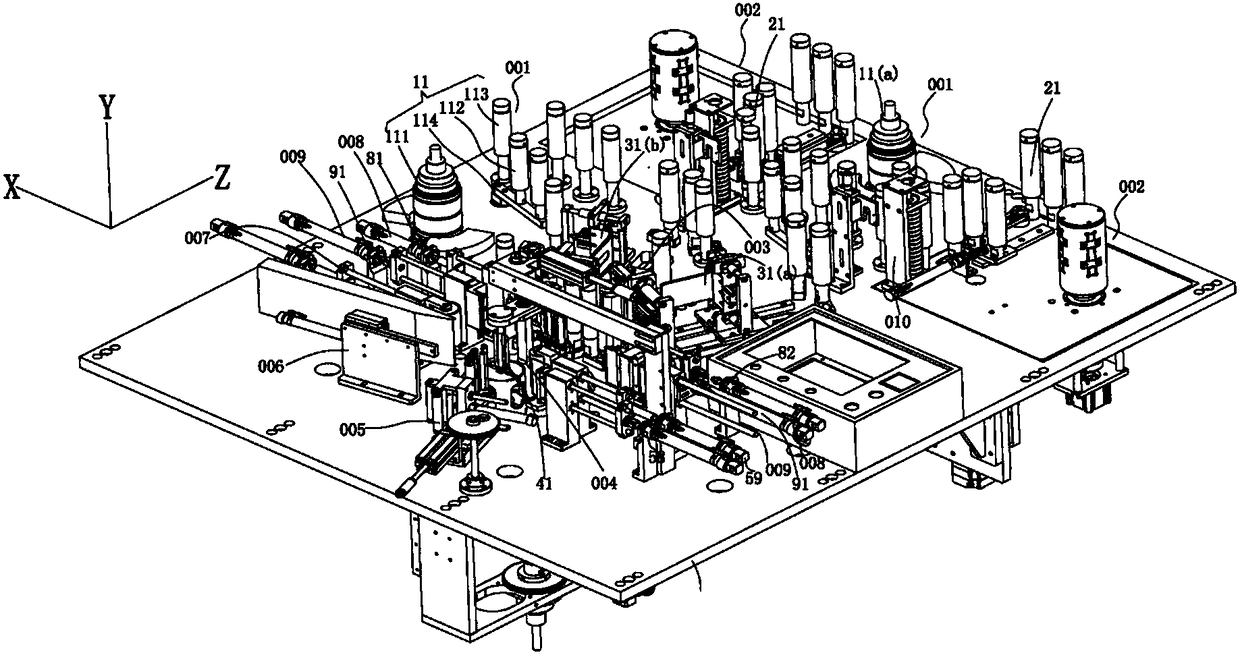

Full-automatic battery electric core winding machine

ActiveCN108400371AQuality improvementReduce manufacturing costAssembling battery machinesFinal product manufactureWinding machineWind component

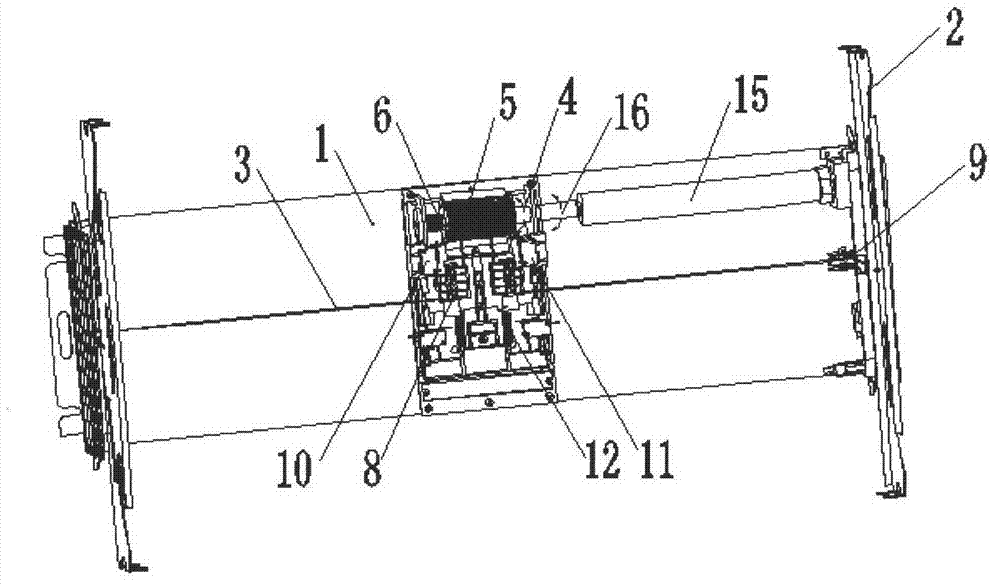

The invention discloses a full-automatic battery electric core winding machine. The full-automatic battery electric core winding machine comprises a rack panel used for sending a diaphragm of an electric core to a diaphragm unwinding mechanism of a winding mechanism; a polar sheet unwinding mechanism which comprises two polar sheet deviation-correction and unwinding components and is used for performing unwinding length measurement, deviation correction and unwinding on positive and negative polar sheets of the electric core and sending the processed material to a polar sheet transmission andcutting mechanism; the polar sheet transmission and cutting mechanism which comprises two sheet transmission and cutting components and is used for transmitting the positive polar sheet / the negative polar sheet unwound by the matched polar sheet deviation-correction and unwinding component to a winding machine and cutting off the polar sheet after the winding mechanism winds the positive polar sheet / the negative polar sheet for a set length; the winding mechanism which comprises at least two rolls of winding components and cooperates with a diaphragm top-pressing component, a diaphragm weldingand cutting component and an ending component which are arranged aside the winding components to finish the electric core winding; a gluing mechanism used for gluing an adhesive tape at the wound electric core; and a laying-off mechanism used for laying-off the electric core which finishes the adhesive tape gluing and is released from the winding mechanism. The winding machine is low in manufacturing cost, easy to produce and operate, and simple to maintain.

Owner:东莞市安洋智能科技有限公司

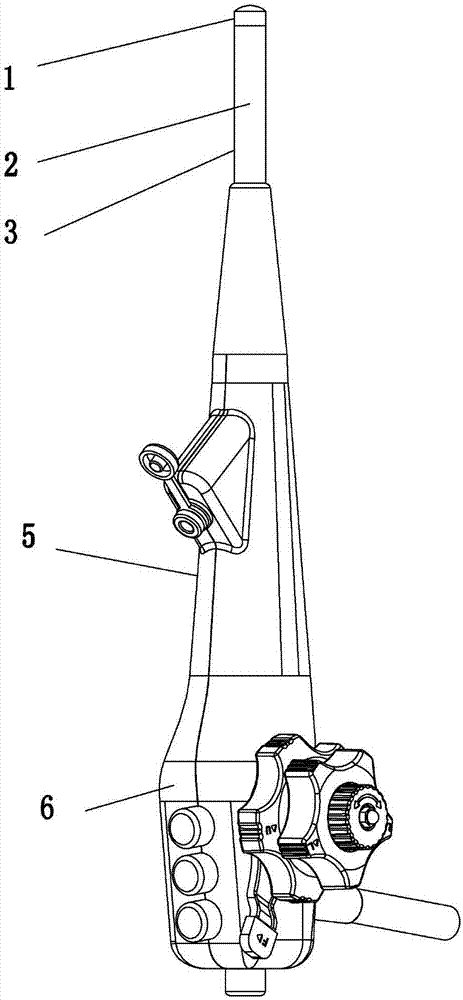

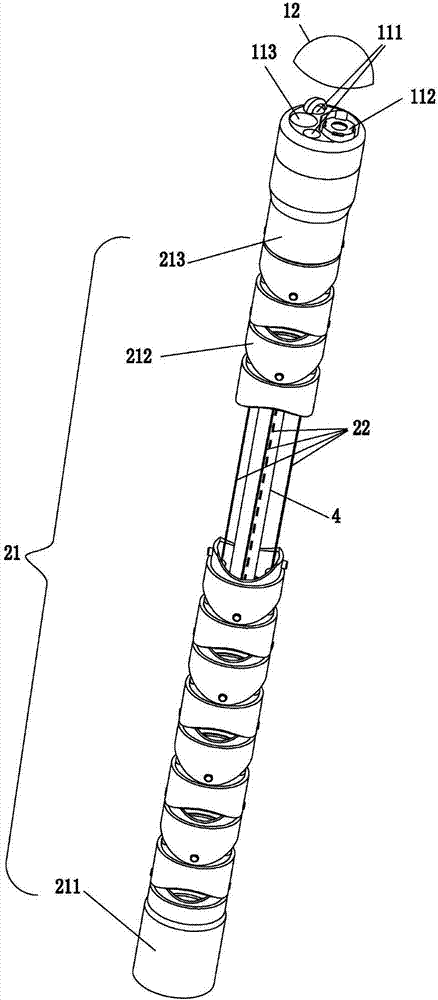

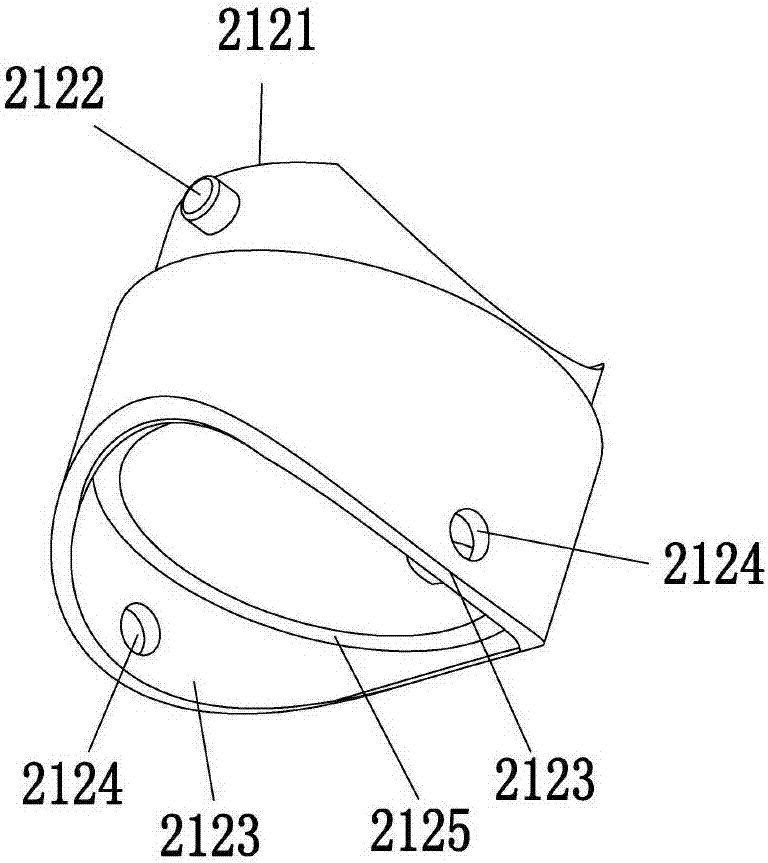

Disposable medical endoscope

The invention provides a disposable medical endoscope. The disposable medical endoscope comprises a bending part, a connecting part and a hand wheel control part, the bending part comprises a near end connector, a hinging ring set and a far end connector, the hand wheel control part comprises a first hand wheel component, a second hand wheel component and a winding component which is used for driving a bending component, one end of a first control cable is arranged on the first control wheel in a winding mode, the other end of a first control cable is connected with the bending part, one end of a second control cable is arranged on a second control wheel in a winding mode, the other end of the second control cable is connected with the bending part, the first hand wheel component controls the first control wheel to move, and the second hand wheel component controls the second control wheel to move. Multiple hinging rings prepared through injection are mutually hinged, and through plastic change, the hinging rings are successfully installed in the mounting groove which is in an open type, so that every two hinging rings are hinged, two control cables are distributed and arranged on two control wheels in a winding mode, four directions can be controlled, through the control of the hand wheel control part, the bending angle is controllable, and the reliability is high.

Owner:SHENZHEN XZING TECH CO LTD

Dimming electronic ballast with preheat current control

InactiveUS8294384B2Improve electronic efficiencyReduce power lossElectrical apparatusElectric light circuit arrangementWind componentEffect light

An electronic ballast is capable of realizing high frequency lighting of a discharge lamp and switching between at least two lighting modes with different light outputs. The ballast includes a preheating circuit having a winding component connected in parallel with a main resonant circuit with a lamp current flowing therein for the discharge lamp. A constant preheating current for the lamp filaments is supplied from a secondary winding of the winding component during lighting of the discharge lamp and a path of a current flowing on a primary winding side of the winding component is switched by a switch according to the lighting mode.

Owner:PANASONIC CORP

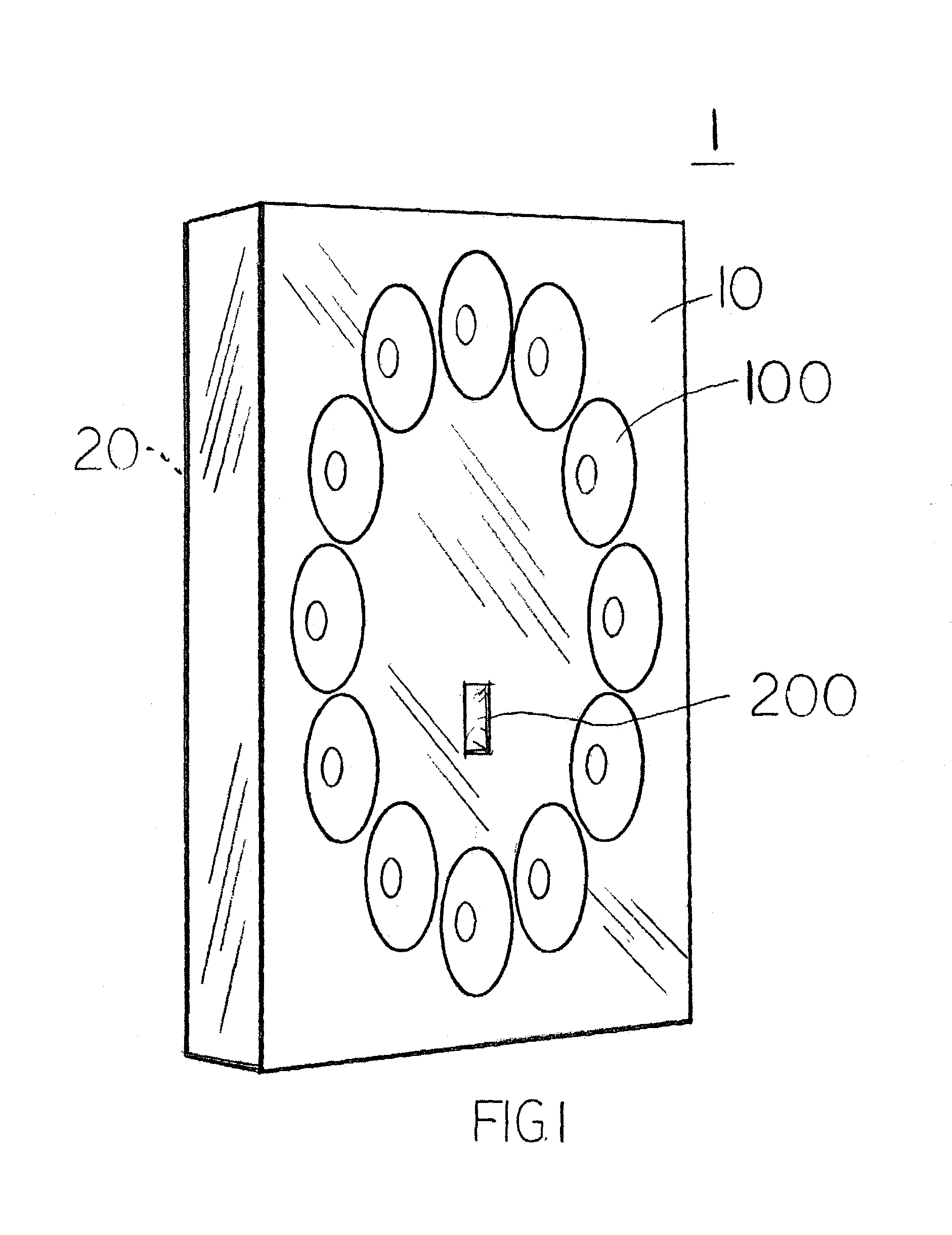

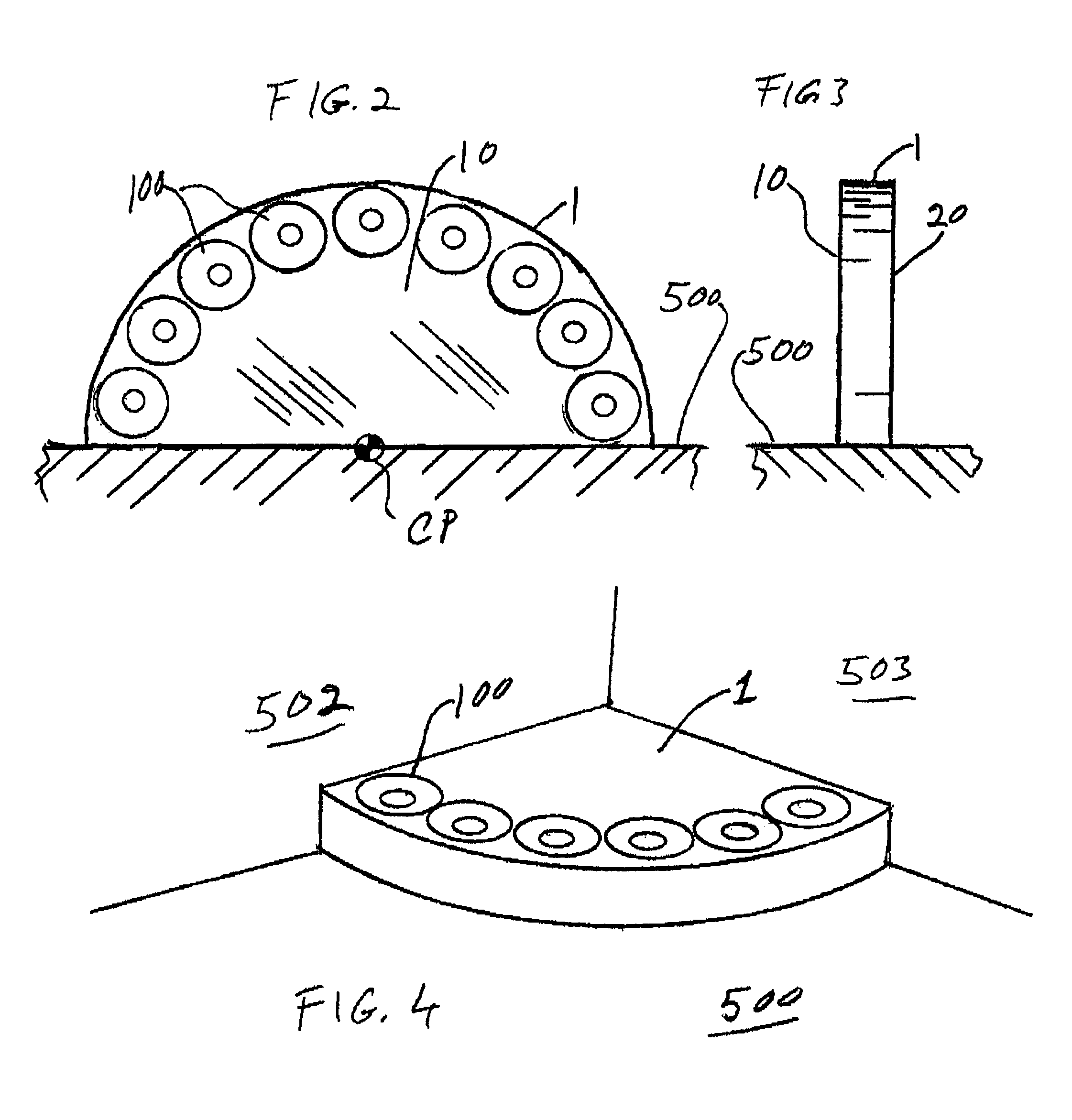

Large-diameter arcuate speaker

InactiveUS7409071B1Improve fidelityReduce in quantityFrequency/directions obtaining arrangementsTransducer casings/cabinets/supportsWind componentEngineering

In an arcuate array of speakers (100) the wind component of air motion near each speaker is converted into sound because the wind is trapped within the arc, and therefore the bass response is improved. The array acts like a single large speaker, of diameter equal to the array diameter, when radiating bass sounds. A central baffle (10) also directs the wind and contributes to converting wind into sound. A semi-circular arc can be used along with a symmetry baffle (500) that further directs the wind, so that the number of speakers required is reduced. The symmetry baffle can be the floor, on which rests a cabinet (1) embodying the arcuate array.

Owner:BROMER NICK

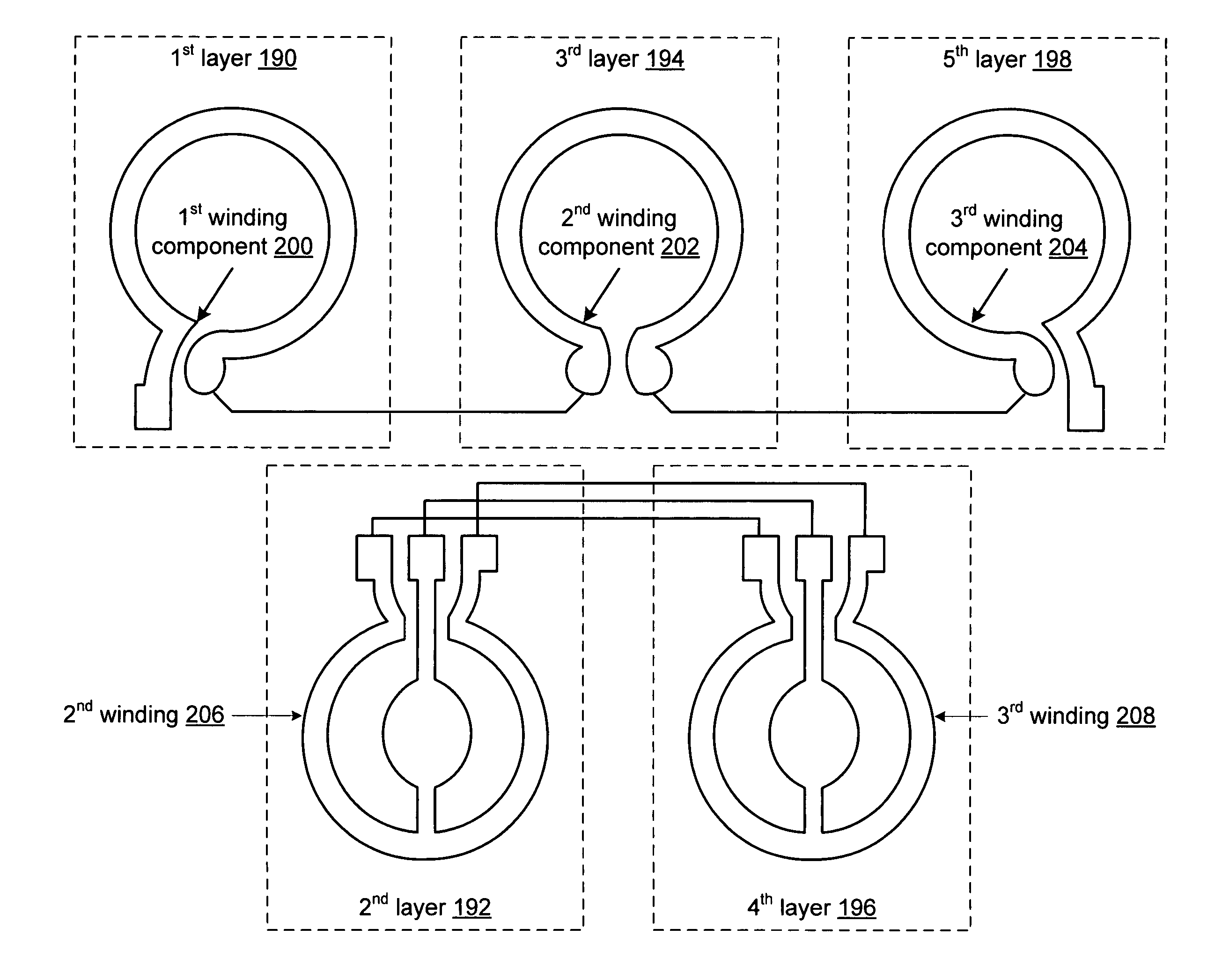

Impedance transformer and applications thereof

InactiveUS7750787B2Multiple-port networksHigh frequency amplifiersWind componentImpedance transformer

An impedance transformer includes a first winding and a second winding. The first winding includes a first plurality of winding components, wherein each of the first plurality of winding components is on a corresponding layer of a first set of layers of a supporting substrate. The second winding includes a second plurality of winding components, wherein each of the second plurality of winding components is on a corresponding layer of a second set of layers of the supporting substrate and the first and second sets of layers are interleaved. The first winding has a first impedance within a desired frequency range and the second winding has a second impedance within the desired frequency range, where the first and second impedances are based on at least one of spacing, trace width, and trace length of the first and second plurality of winding components.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

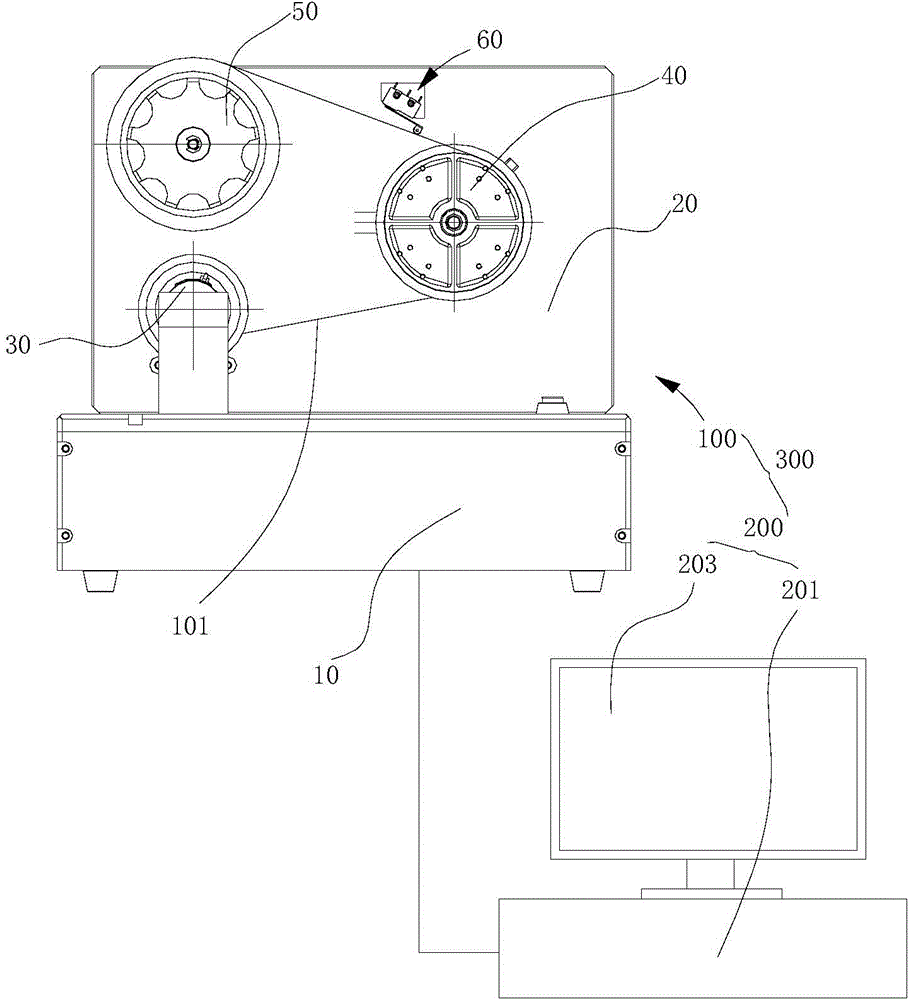

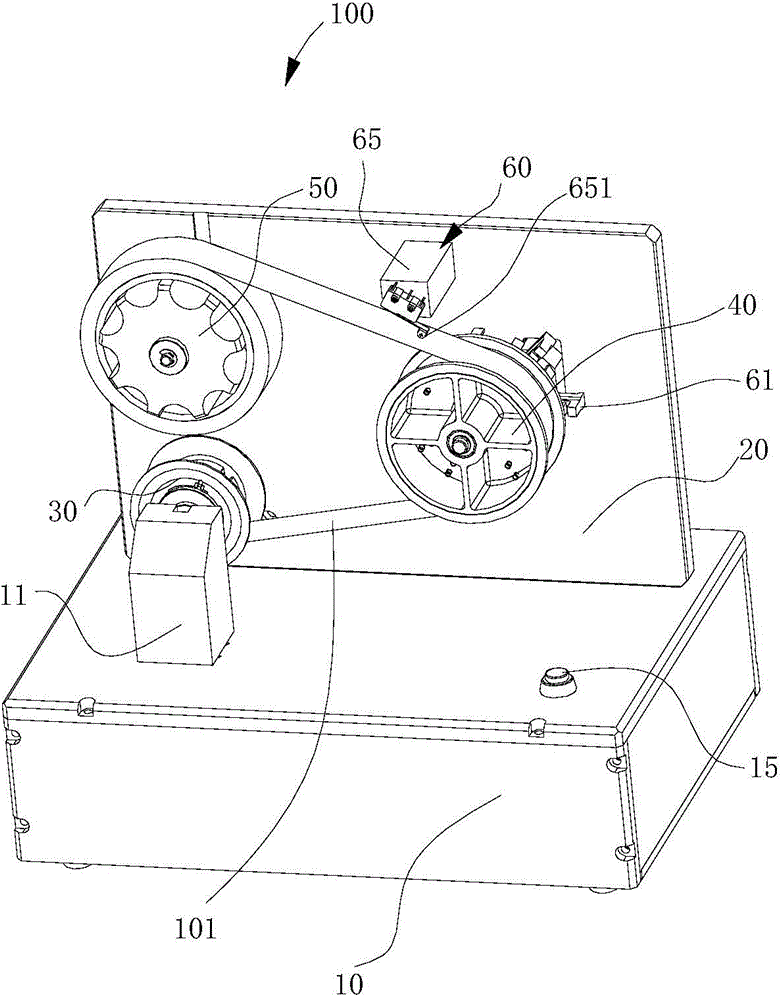

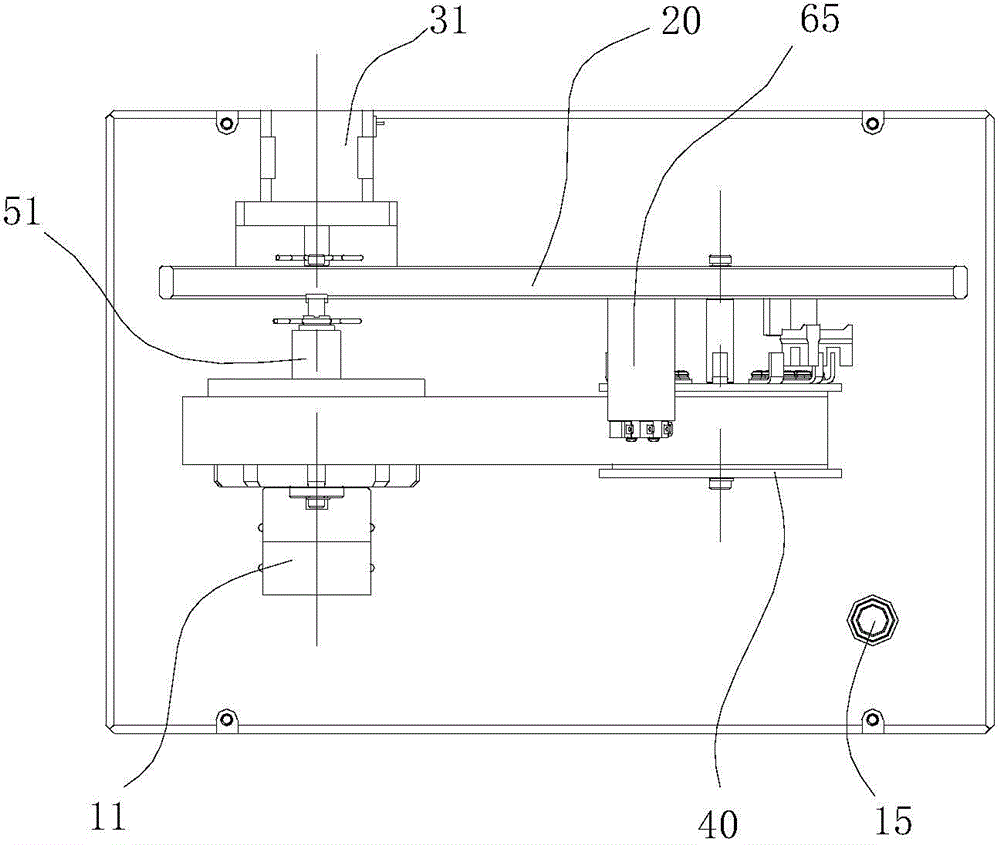

Bank note coiling band measurement equipment and method

PendingCN104567775AImprove measurement efficiencyMechanical length measurementsArticle deliveryWind componentEngineering

The invention relates to bank note coiling band measurement equipment and a bank note coiling band measurement method. The equipment comprises a measuring mechanism and a data processing terminal, wherein the measuring mechanism comprises a supporting frame, a winding component, a measuring wheel, a rotating wheel and a sensing component; the winding component comprises a rotating driving piece arranged on the supporting frame, and a winding wheel connected with the rotating driving piece; the measuring wheel and the winding wheel as well as the rotating wheel and the winding wheel are arranged at an interval; the measuring wheel and the rotating wheel are arranged on the supporting frame; the winding wheel, the measuring wheel and the rotating wheel form a triangular profile; the sensing component comprises a micro switch and a photoelectric disconnection sensor which are arranged on the supporting frame, and a sensor induction piece; the data processing terminal comprises a data processor electrically connected with the micro switch and a photoelectric disconnection sensor, and an output part electrically connected with the data processor. The bank note coiling band measurement equipment is high in efficiency.

Owner:SHENZHEN YIHUA COMP +2

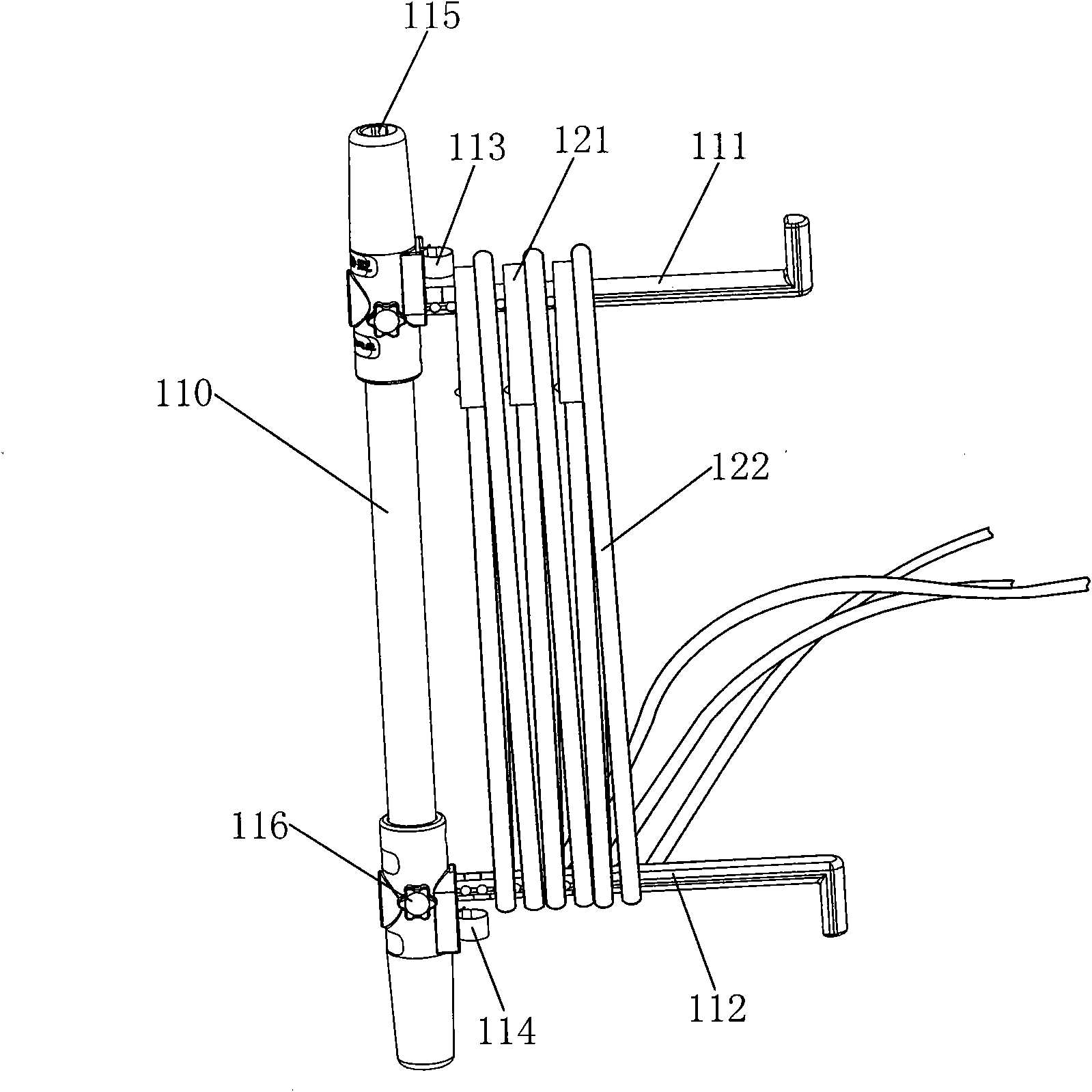

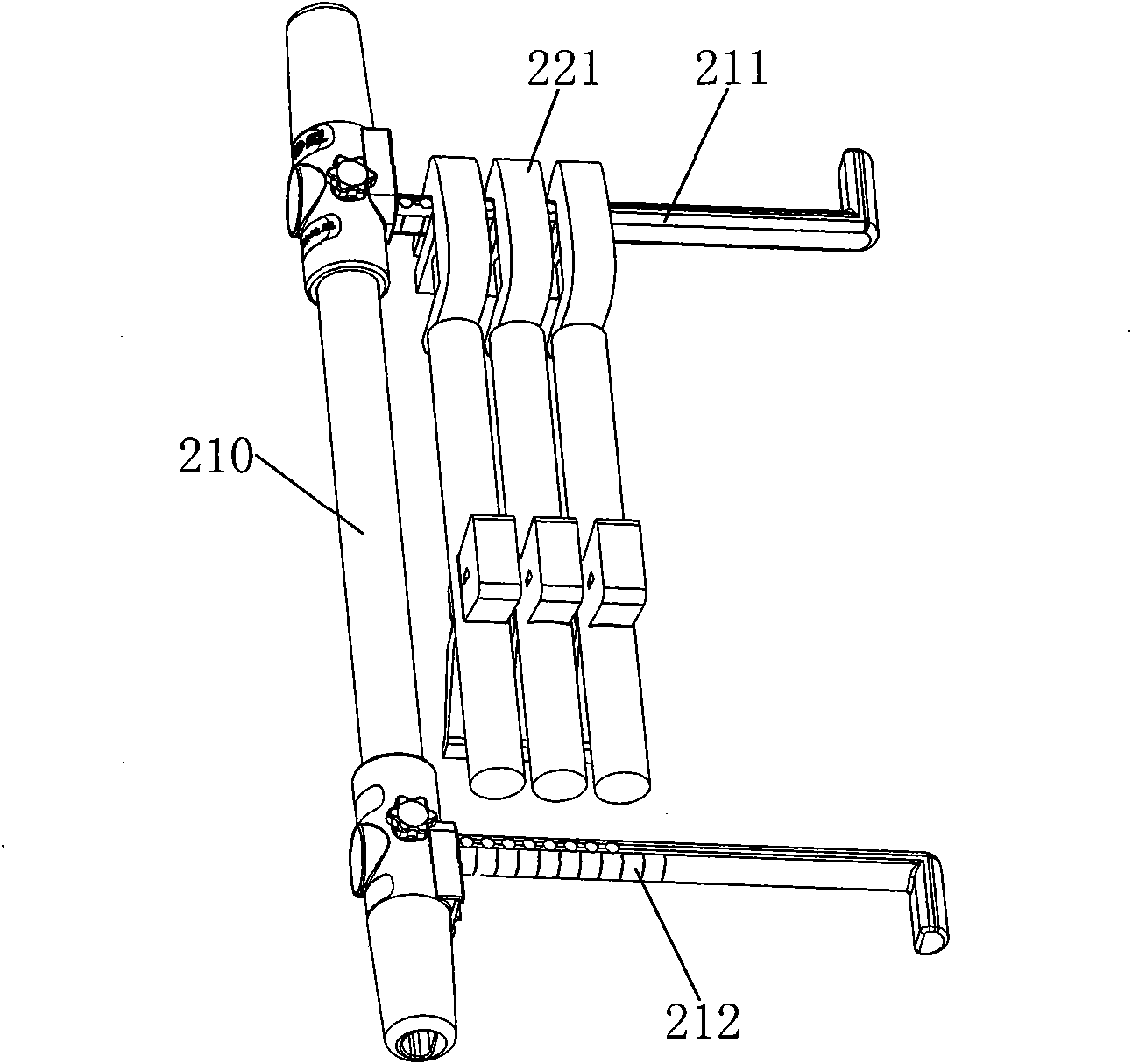

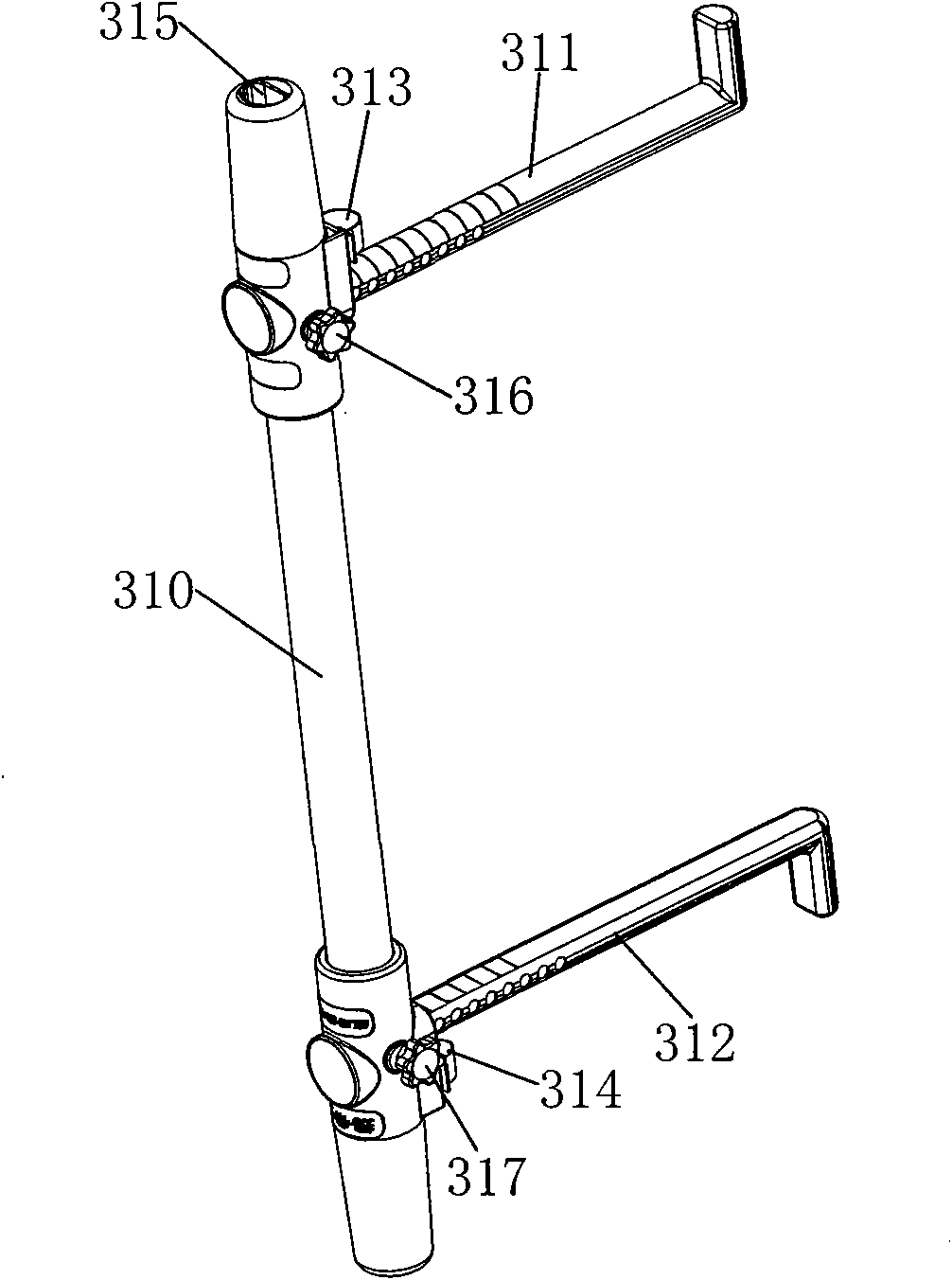

Detachable or short-rod carrying type short-circuit earthing wire winding method and winding mechanism

The invention discloses a detachable or short-rod carrying type short-circuit earthing wire winding method and winding mechanism. The winding method comprises the following steps: adopting a bearing body provided with a winding mechanism, firstly arranging a lead chuck of a detachable or short-rod carrying type short circuit earthing wire on a winding component of the winding mechanism, and then winding the earthing wire on the winding mechanism by taking the wire clamp end as an initial end. The detachable or short-rod carrying type short circuit earthing wire winding method and winding mechanism can effectively realize the orderly winding and storage of the earthing wire, can orderly wind the detachable or short-rod carrying type short circuit earthing wire with small volume, and has high firmness of the winding during the storage and carrying processes; the winding device has small volume, light weight and firm winding effect, also can realize the random use of the bearing body, and the winding mechanism cannot be lost.

Owner:南通市升昊暖通设备有限公司

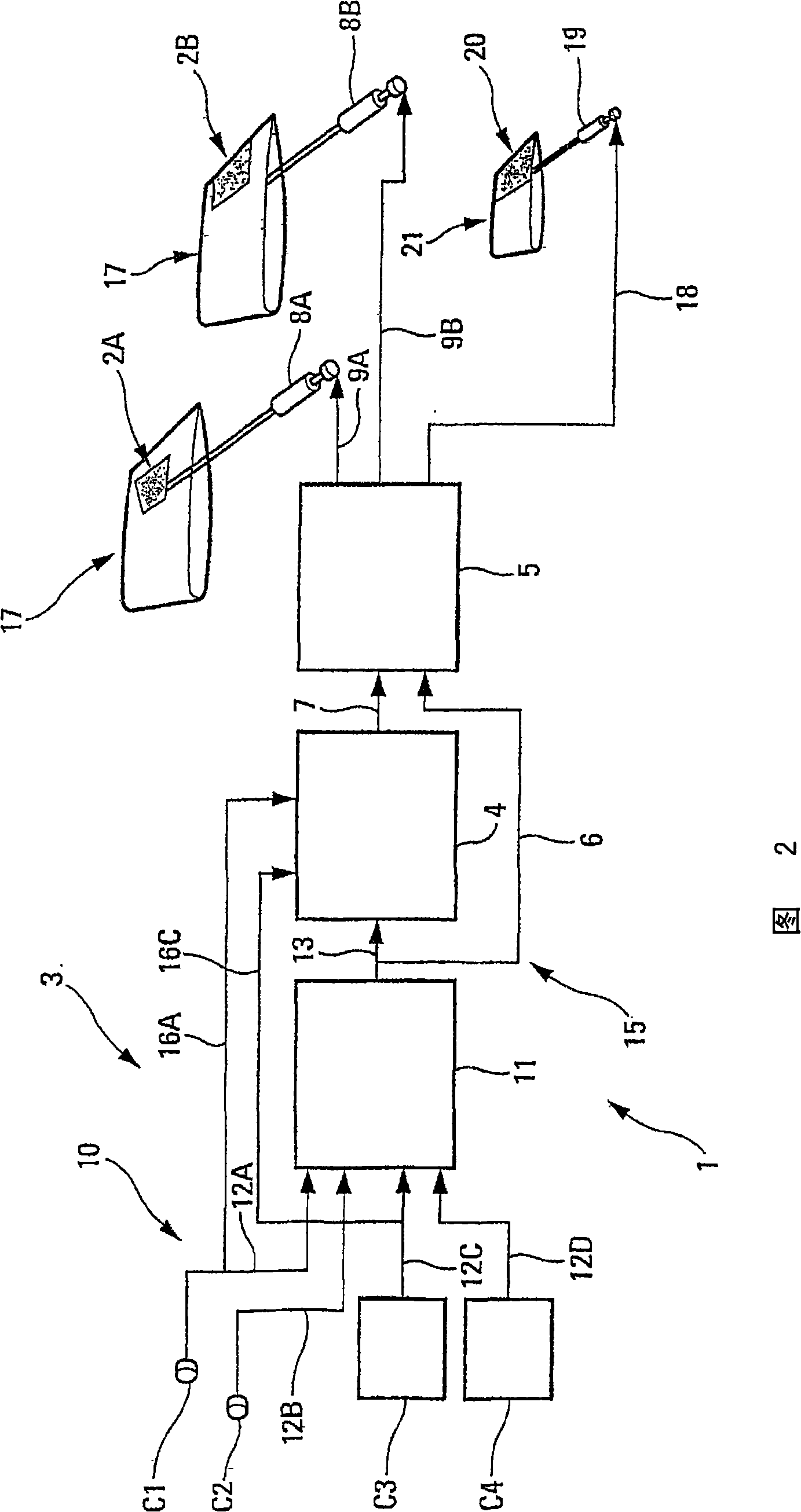

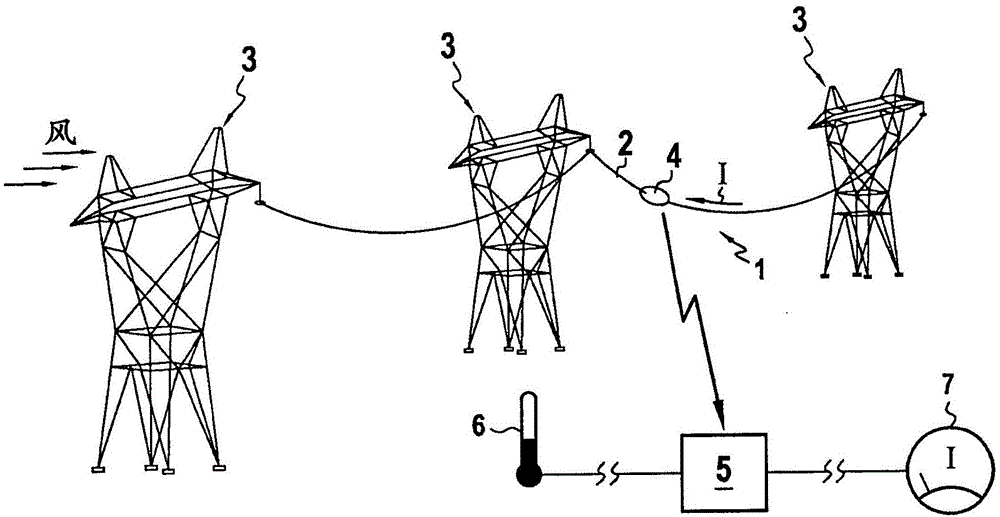

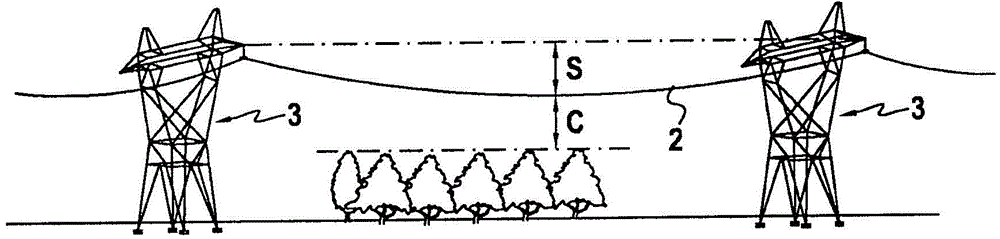

Method and system for measuring a perpendicular wind component

ActiveCN104981699AOverhead installationFluid speed measurement using thermal variablesWind componentEngineering

The present invention relates to a method and system for the determination of parameters related to the speed of wind that blows near an overhead electrical power line (single or bundle conductors). The parameters include an “effective wind speed” as well as an “effective incident radiation” acting on a power line span. The measurement is made by using the combination of mechanical vibrations and movements / positions in two or three dimensions through sensors in direct link with the power line conductor.

Owner:AMPACIMON

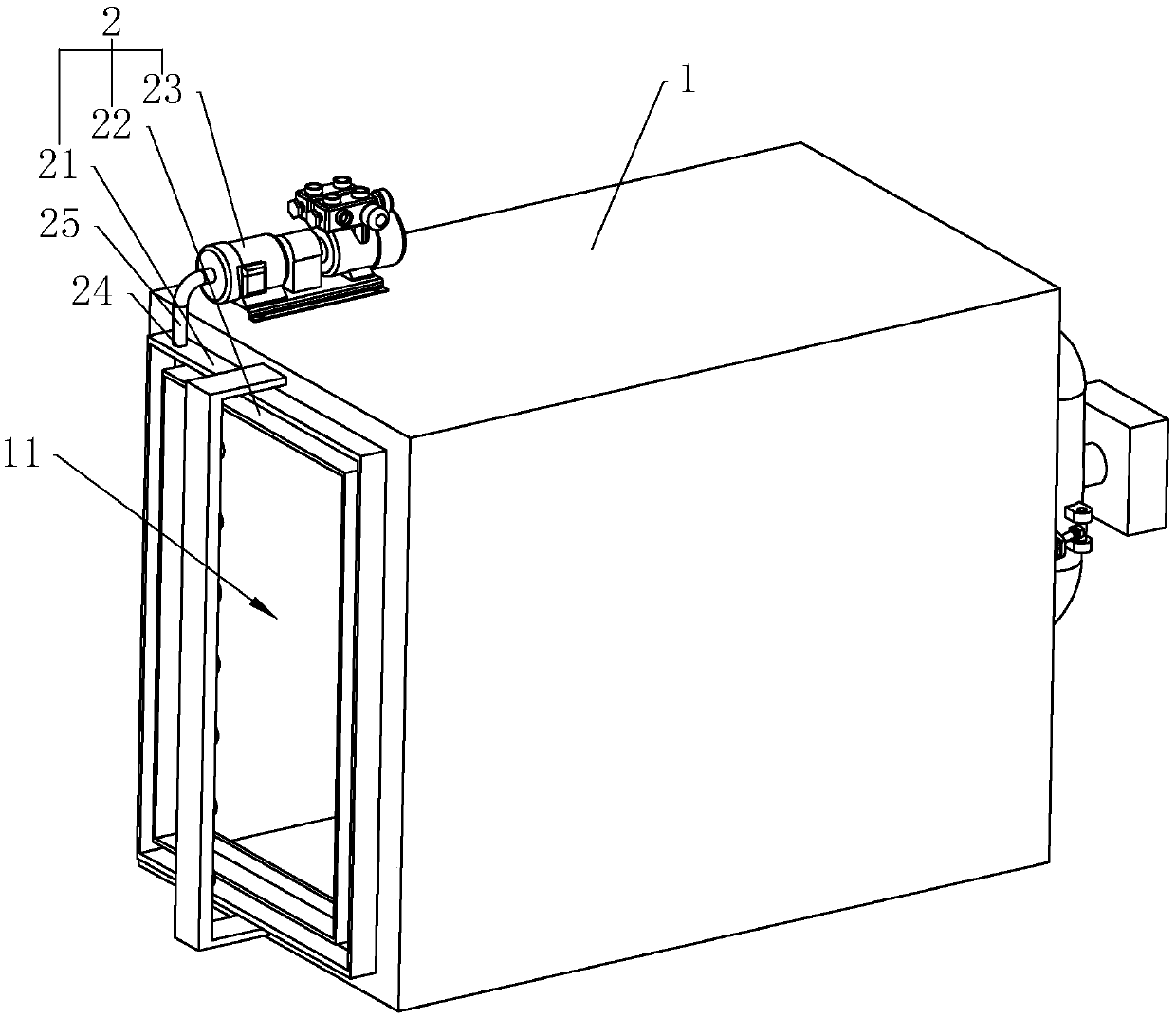

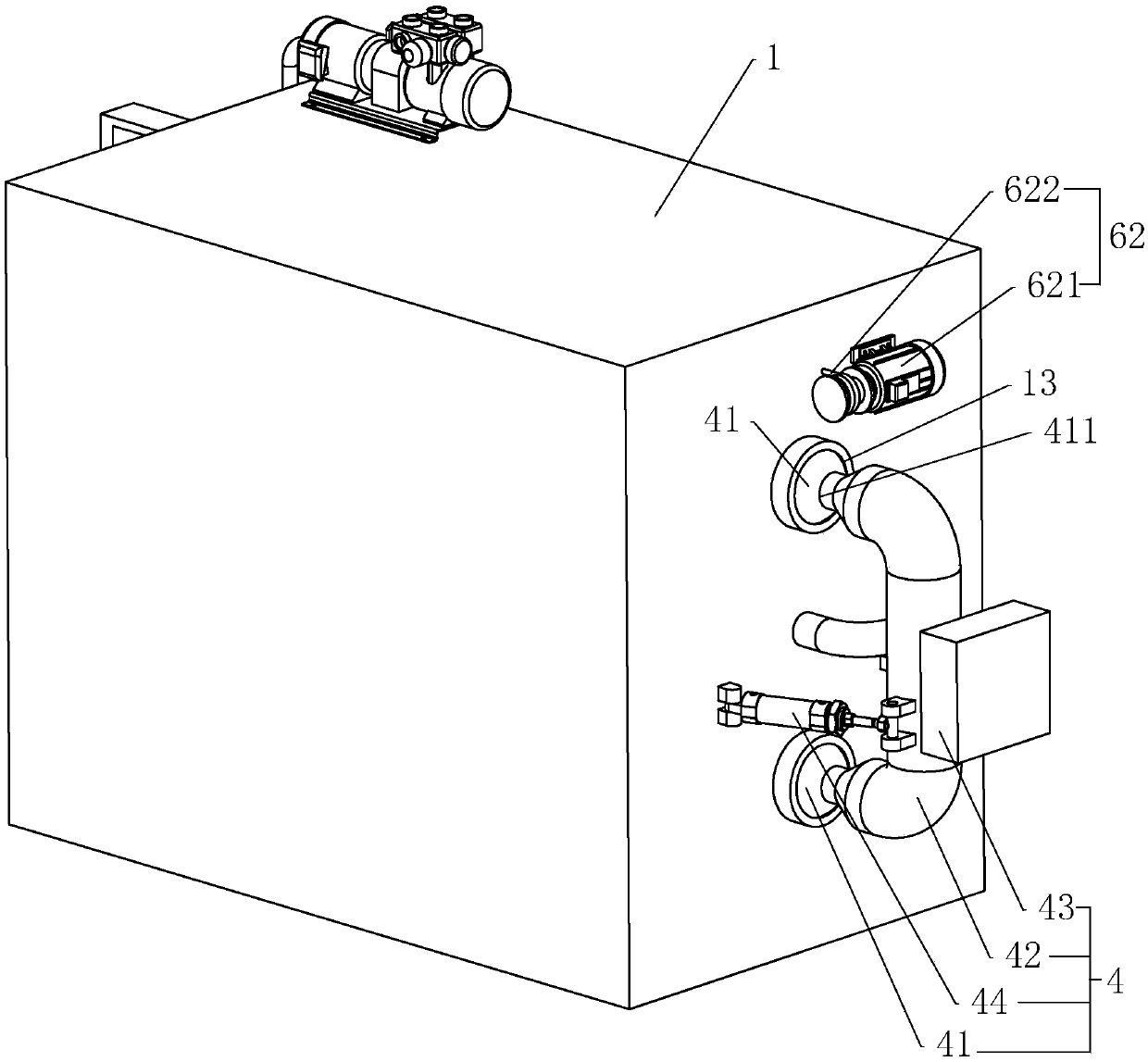

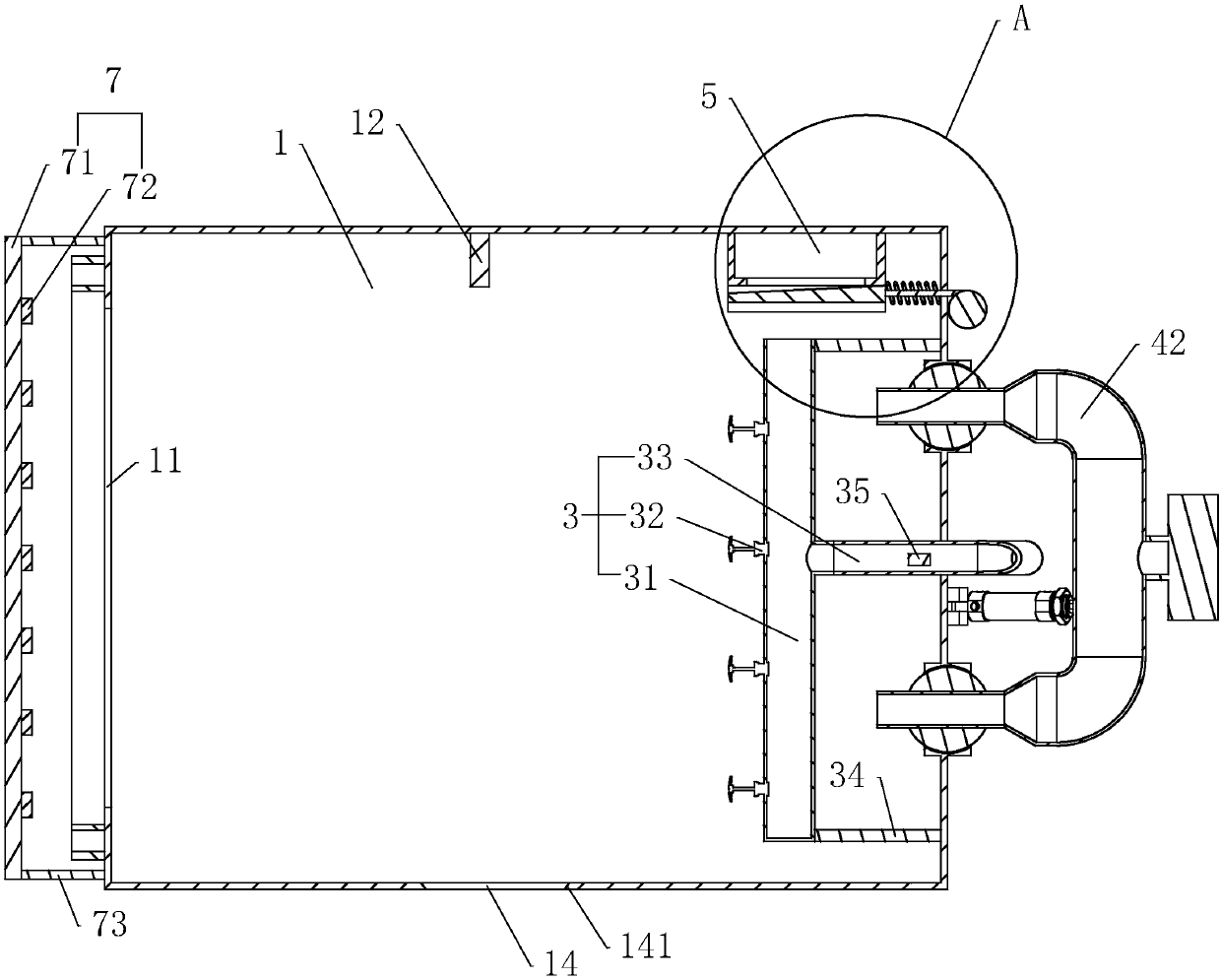

Special detection equipment and method for building door and window

ActiveCN109540413AImprove accuracyMeasurement of fluid loss/gain rateMaterial strength using tensile/compressive forcesWind componentWindow detection

The invention relates to the field of door and window detection, and discloses a special detection device and method for a building door and window. The device comprises a detection box. The detectionbox is provided with an installation component, a spray component, and a strong wind component. The strong wind component comprises a universal ball rotatably connected to the detection box, an air outlet pipe fixedly connected to the universal ball, a fan installed on the air outlet pipe, and a driving cylinder hinged on the detection box. The push rod that drives the cylinder is hinged to the outlet pipe. A wind speed detecting device is installed in the detection box. The method comprises the following steps of: fixing the building door and window to the detection box by the installation component; adjusting fixing strength of the installation component according to the wind; detecting the building door and window according to the spray component and the strong wind component; openingan outlet and pouring the leaves; acquiring data through a wind speed detecting device, an infrared distance measuring device, and a flow meter; and acquiring capacity data of water leaking from the building door and window. The special detection device and method for the building door and window has the effect of improving the accuracy of a detection result.

Owner:深圳市华科达检测有限公司

Tooth groove matching and winding selection method of small-size rotation transformer

InactiveCN106920666AEasy to machine windingEasy to windTransformersTransformers/inductances detailsWind componentMiniaturization

The invention provides a tooth groove matching and winding selection method of a small-size rotation transformer. The method comprises the following steps of firstly, determining a stator tooth number and a rotor tooth number, wherein the stator tooth number is 13, and the rotor tooth number is 16; secondly, allowing a stator winding to employ a winding mode with a pitch being 1 under all pole pair numbers, allowing all winding components to be wound around a certain fixed tooth, wherein the components are not crossed and are not intersected, the component number of each phase winding is equal to the groove number, namely, each phase is provided with 13 components, and the turns of each component are distributed according to a set rule; and finally, allowing a rotor winding to employ a folded equal-pitch distributed winding, and determining the corresponding pitch according to the set rule on the condition of different pole pair numbers. By the method, a product with various pole pair numbers, machine winding and automatic manufacturing can be conveniently achieved on the basis of achieving miniaturization.

Owner:SHANGHAI WIN DOUBLE ELECTRIC

Method for handling stacked steel due to strip breakage on rolling mill

ActiveCN103191933AEnsure safetyReduce downtimeMetal rolling stand detailsTensioning/braking arrangementsWind componentWork roll

The invention provides a method for handling stacked steel due to strip breakage on a rolling mill and is applied to the technical field of production and processing of rolling mills. Strip steel of the rolling mill is wound through a winding component after being rolled out of gaps between working rolls. The handling steps for stacked steel due to strip breakage include that: when steel stacking due to strip breakage occurs to the rolling mill, the gap of each working roll assembly is controlled to clamp stacked steel; the working rolls of the rolling mill are controlled to rotate reversely, and the working rolls which clamp the stacked steel pour back the strip steel in the direction opposite to the rolling direction; and the working roll assemblies drive the stacked steel to quit a steel rolling port to finish handling of the stacked steel due to strip breakage. By means of the method, time for handling strip breakage can be saved, the production efficiency can be improved, the safety of operators and devices in an accident handling process can be guaranteed, and the labor intensity and operating time of the operators can be reduced.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com