Patents

Literature

115results about "Mechanical length measurements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic cord length measuring device

An apparatus that accurately measures rope, wire, tubing and other materials is herein disclosed. A variety of different-sized models would possess different sized openings. One model with a one-inch opening would be used to measure small wire and cable. Another model with approximately a 3-inch opening would be used for larger electrical cables, rope, tubing and the like. An even large model would be available for measuring ductwork, hoses, and other large diameter material. As the material is pulled through the opening, an optical sensor, similar to that used on an optical computer mouse, accurately measures the material to the fraction of an inch. A mechanical sensor, utilizing a guide wheel is also envisioned. The length is displayed on a digital readout on the perimeter of the invention that is provided with a power button, reset button and the like. It is envisioned that various attachments such as a belt loop, a spool attachment and other items to increase the versatility of the invention would also be provided.

Owner:RICHARDSON SHANE D

Special measuring device for building design

InactiveCN108562208AHold tight automaticallyReduce labor intensityMechanical length measurementsMeasurement deviceEconomic benefits

The invention provides a special measuring device for building design. The problems of large error, high labor intensity, low efficiency, economic benefit loss and the like of the existing manual length measurement are effectively solved. The device has the characteristics of raw material consumption reducing, manpower saving, cost saving and the like. The economic efficiency is improved. According to the invention, the length of a steel strand is measured through a mechanical structure; electric energy is not used; the device is conveniently used in the measurement process of the steel strand; the device has the advantages of convenient and accurate measurement and low worker labor intensity, and is suitable for the measurement of batch steel strands; the length of the steel strand is determined on a dial according to needs; and after the steel strand reaches a length, a holding device automatically holds the steel strand tightly to automatically acquire the steel strand of required length.

Owner:李明

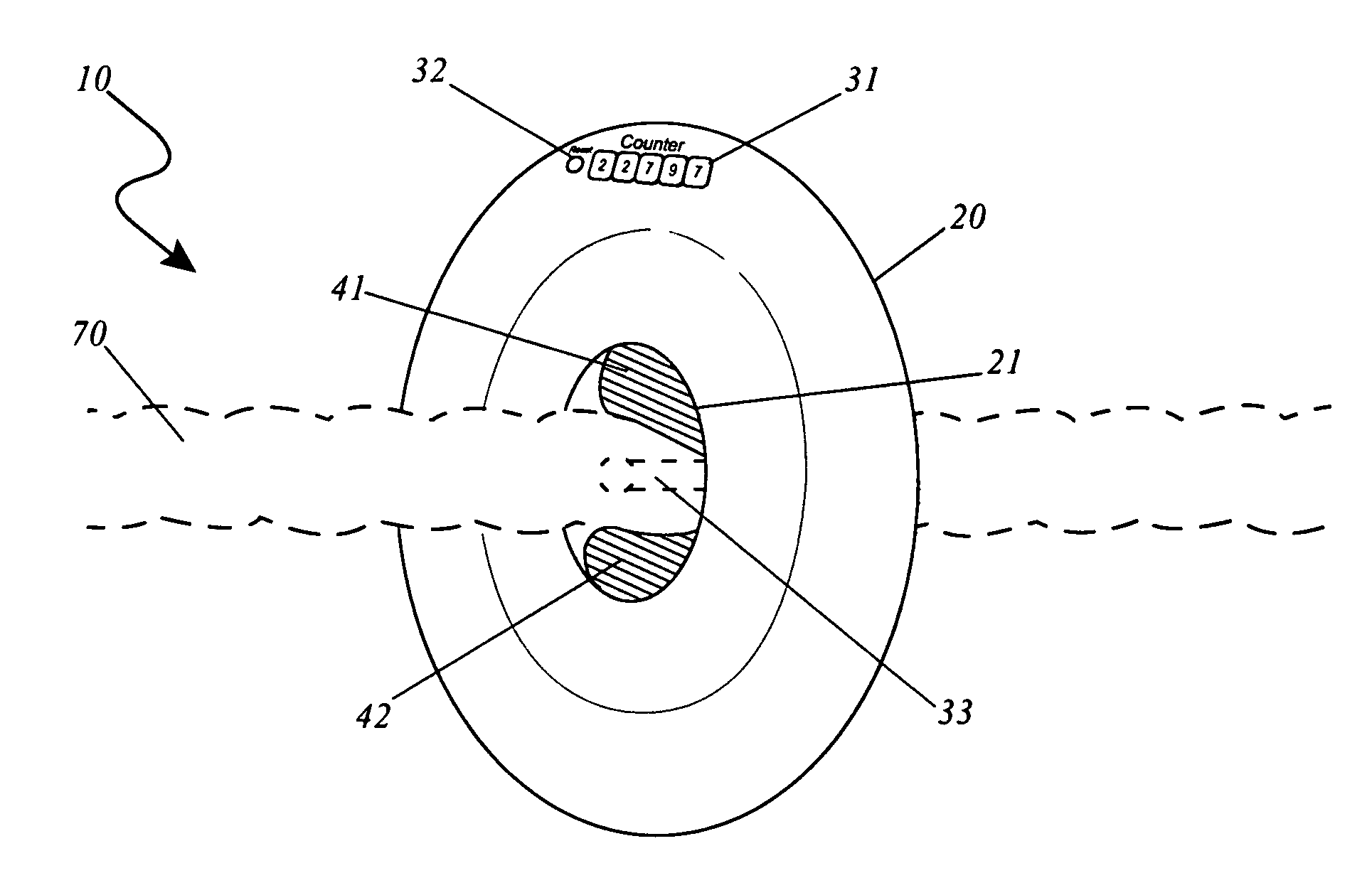

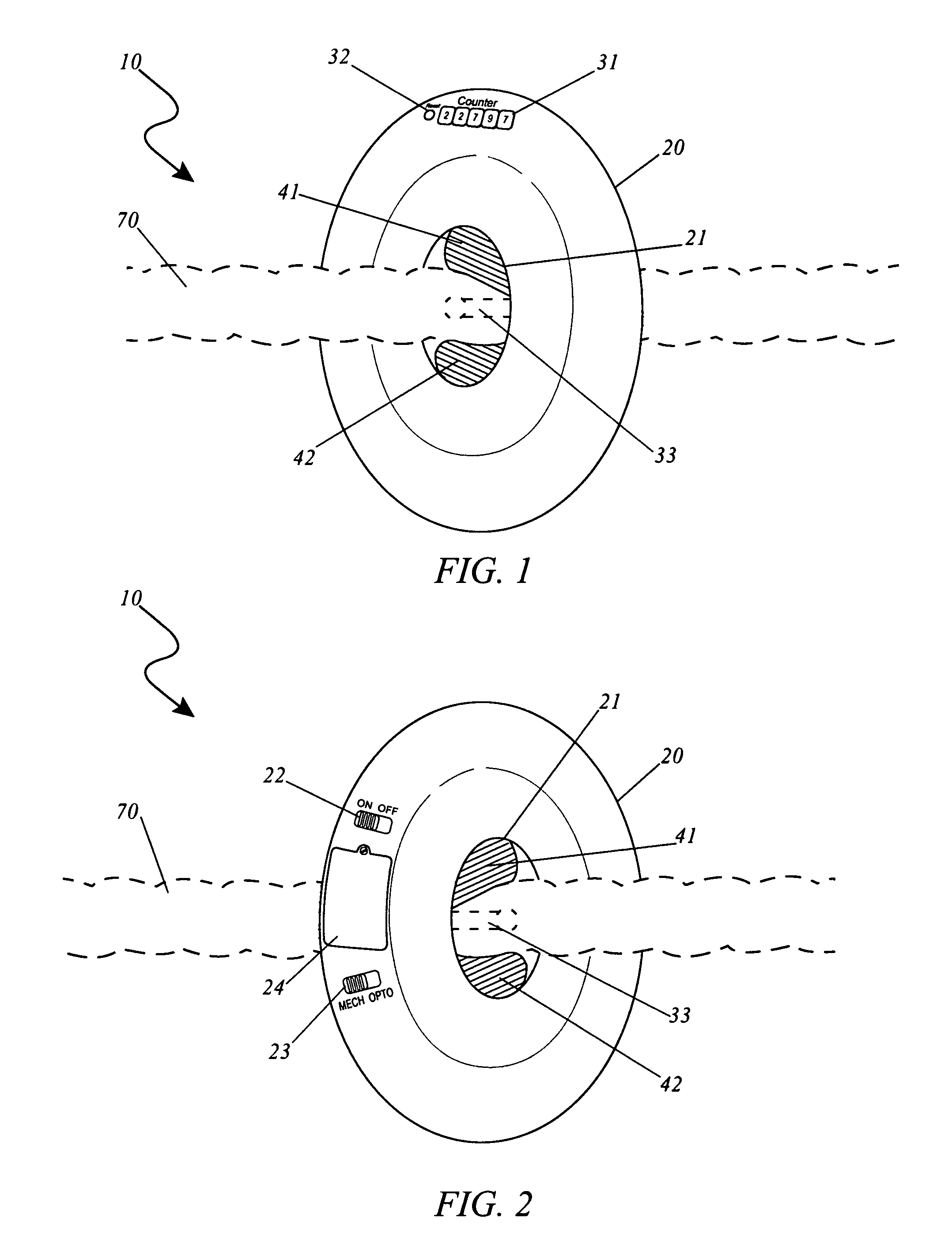

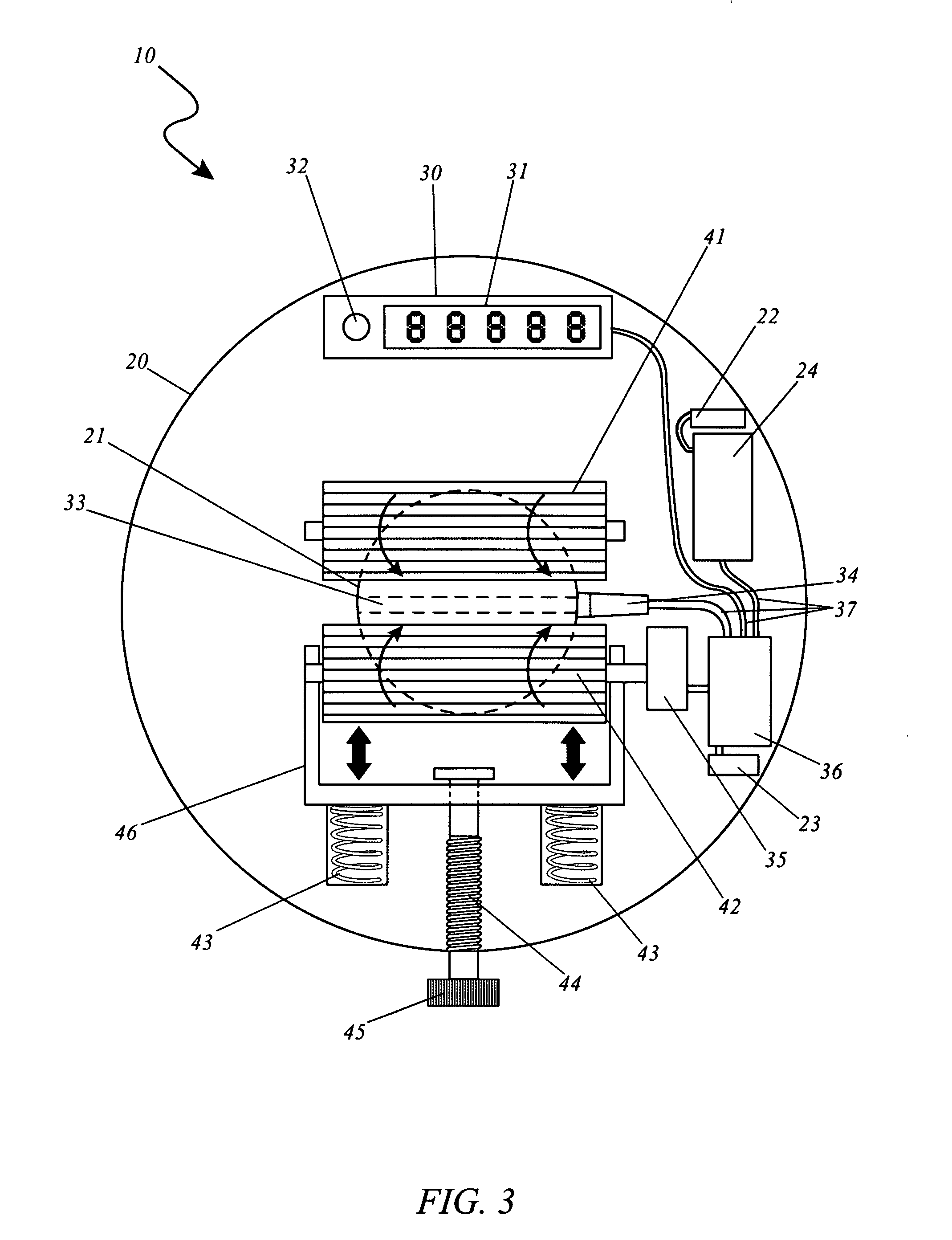

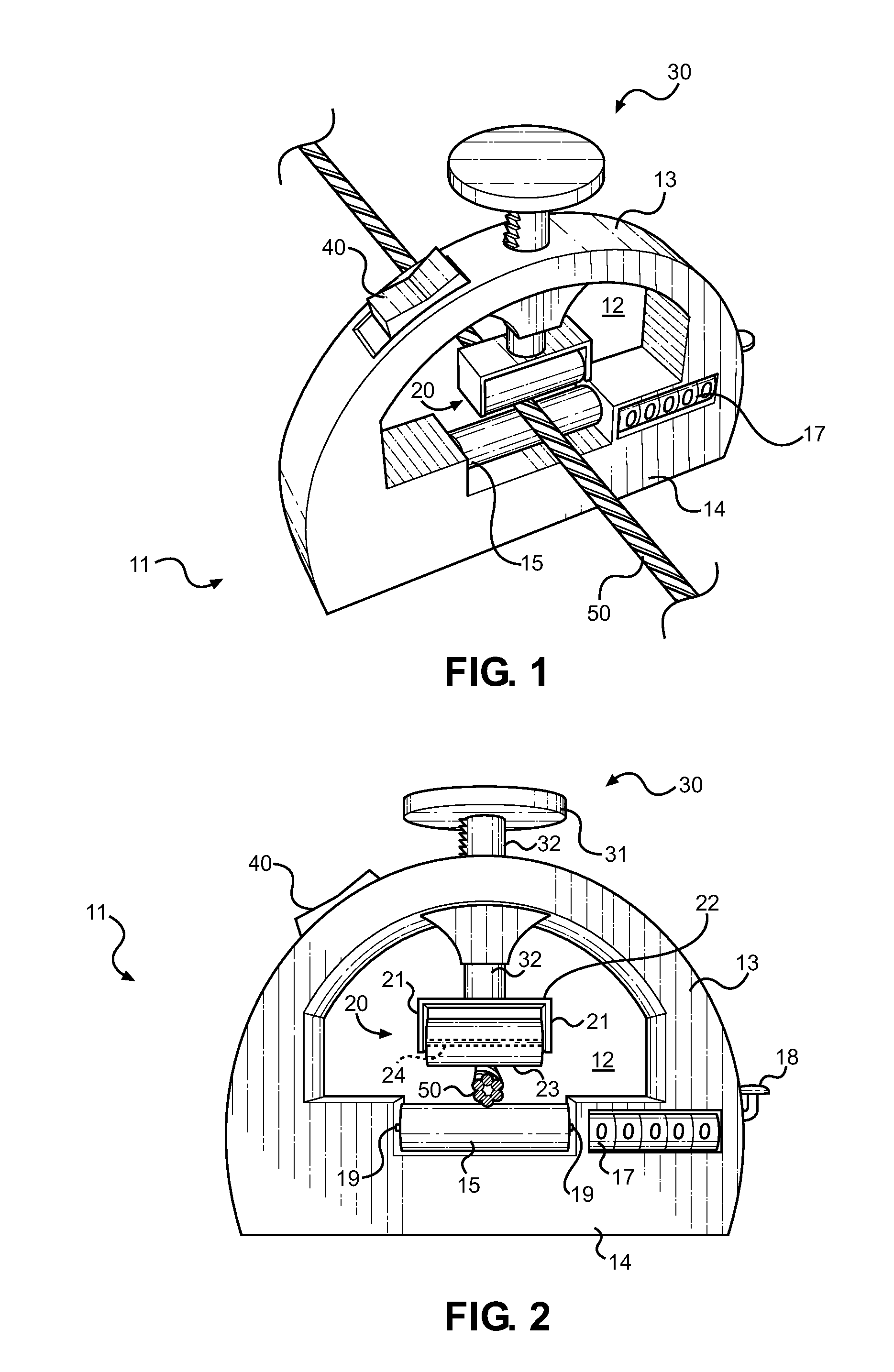

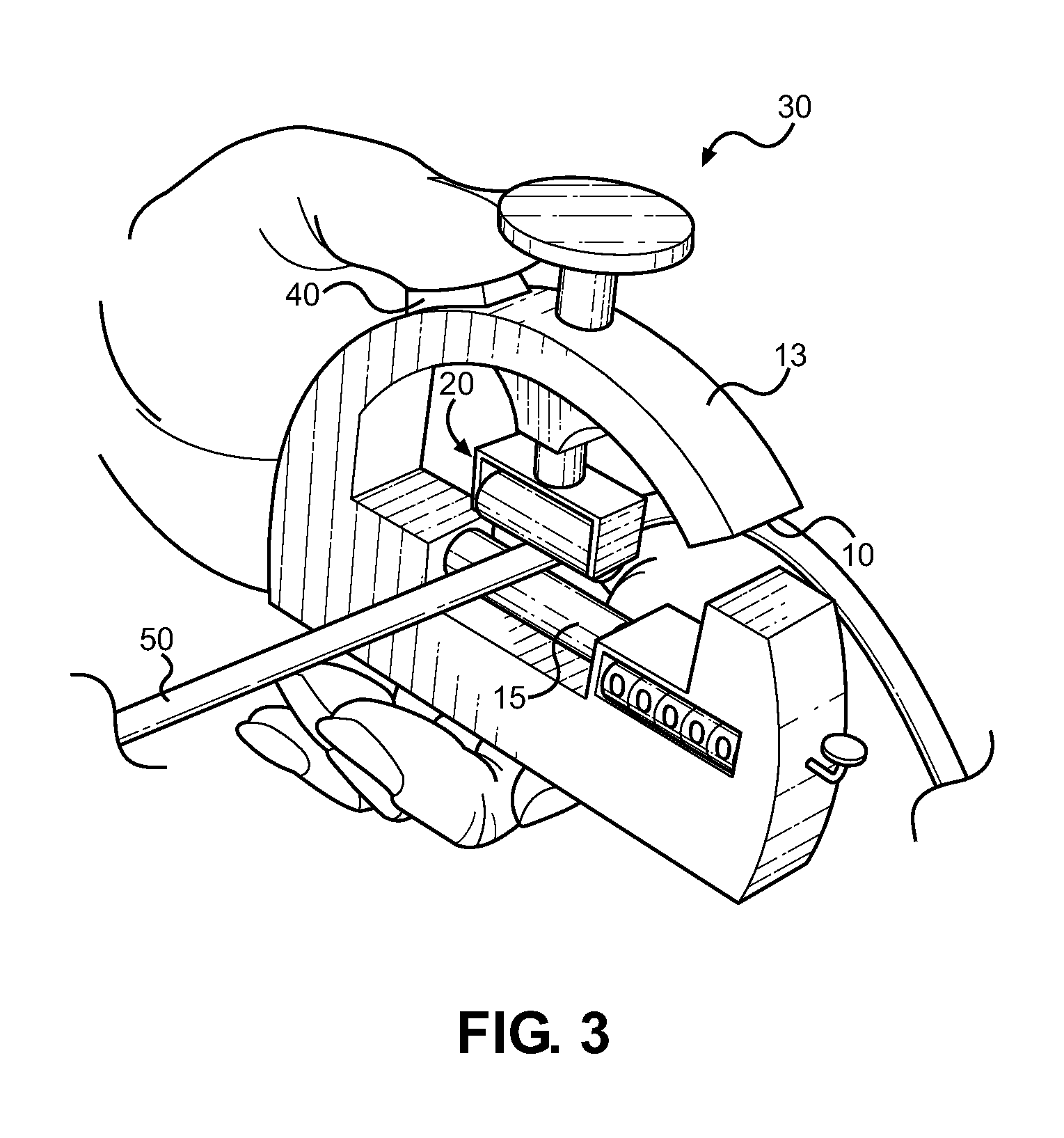

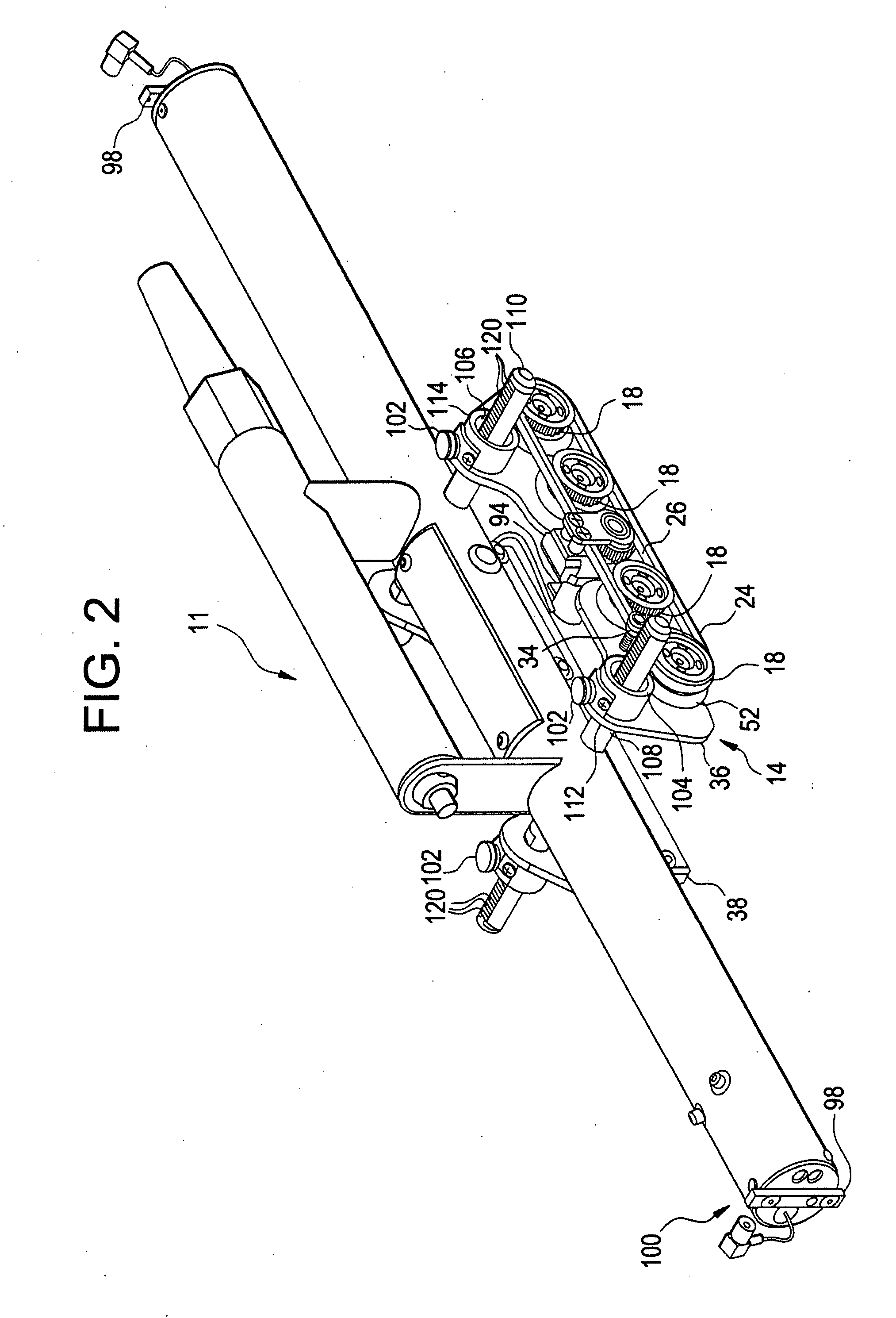

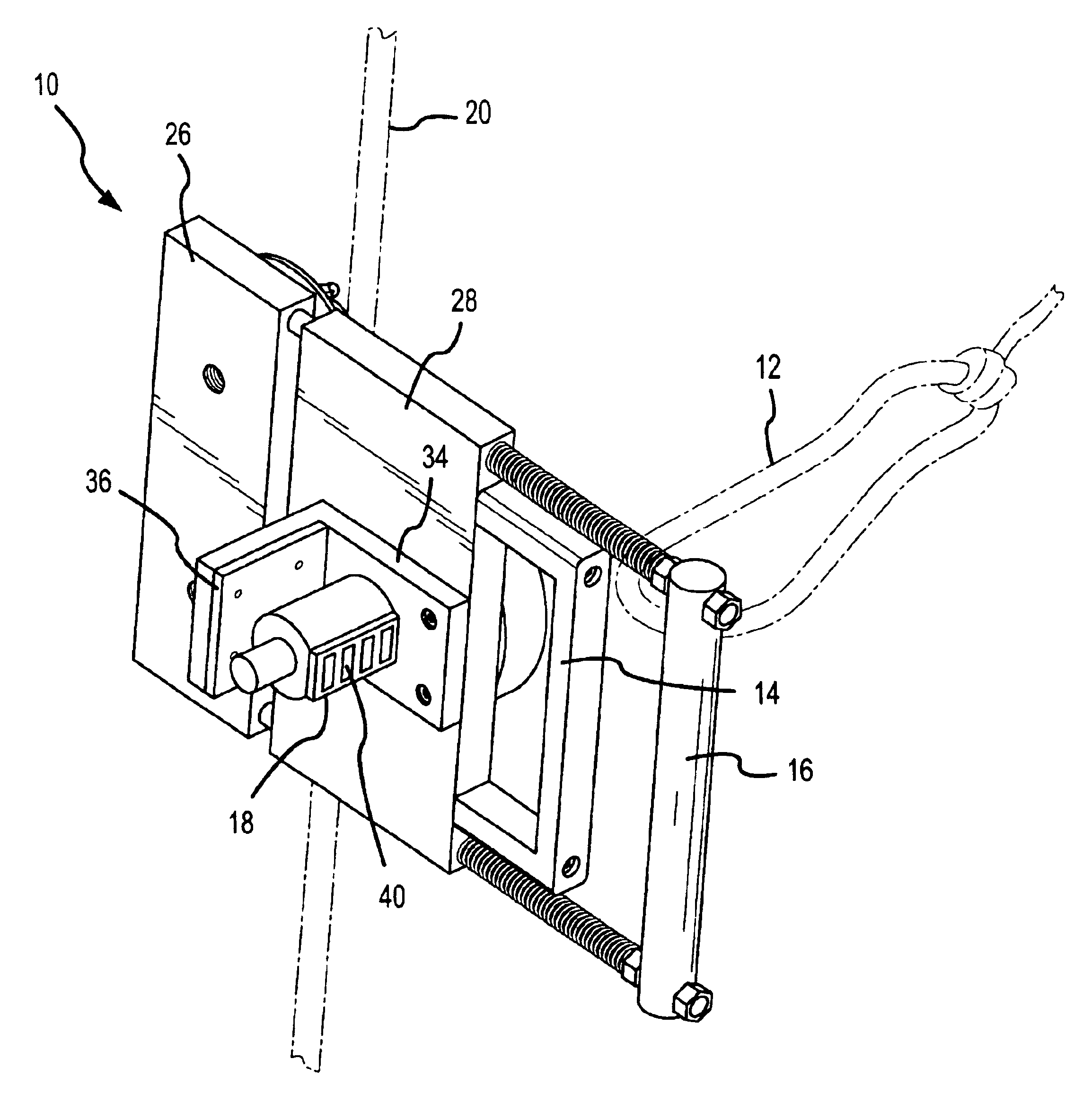

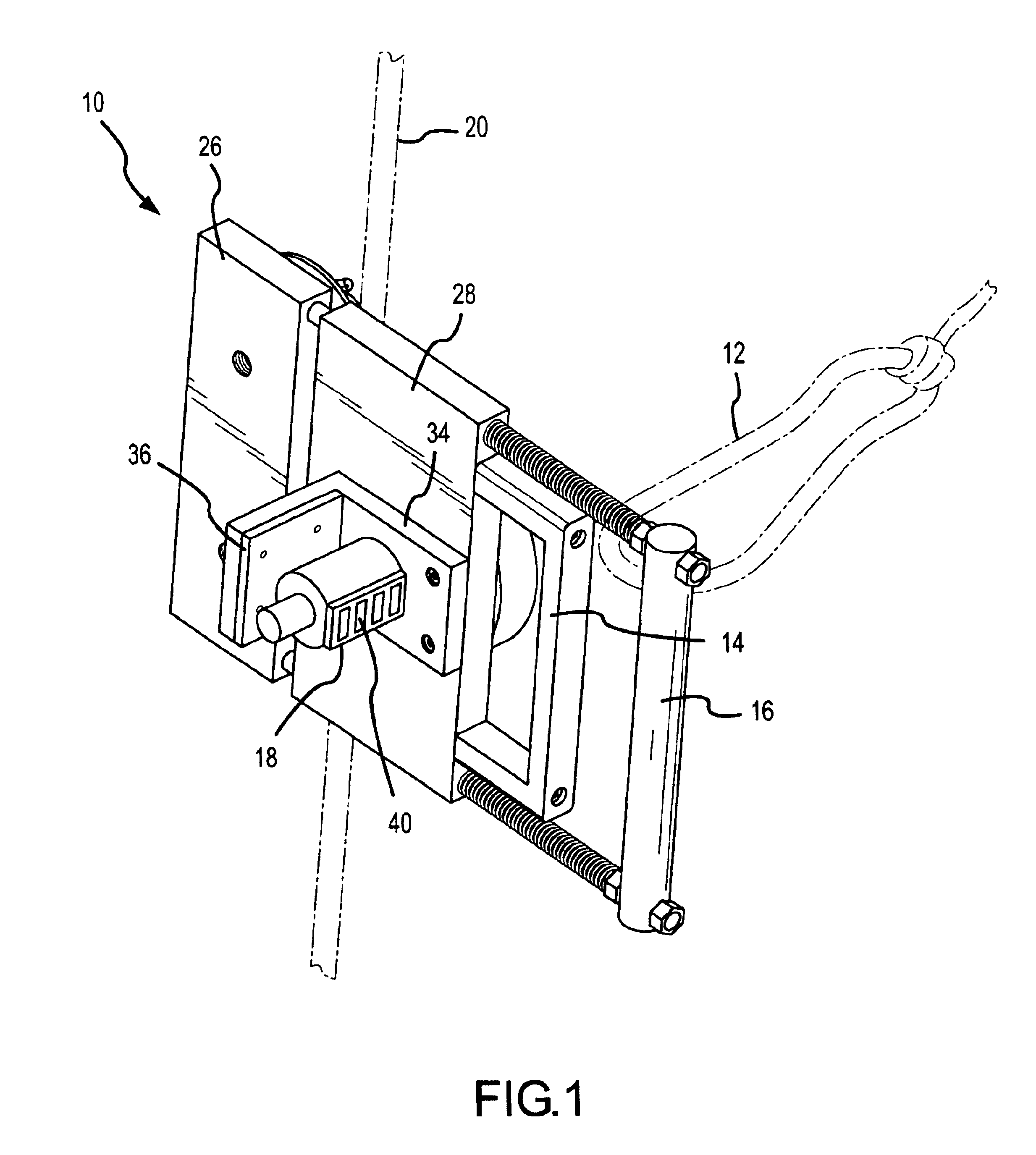

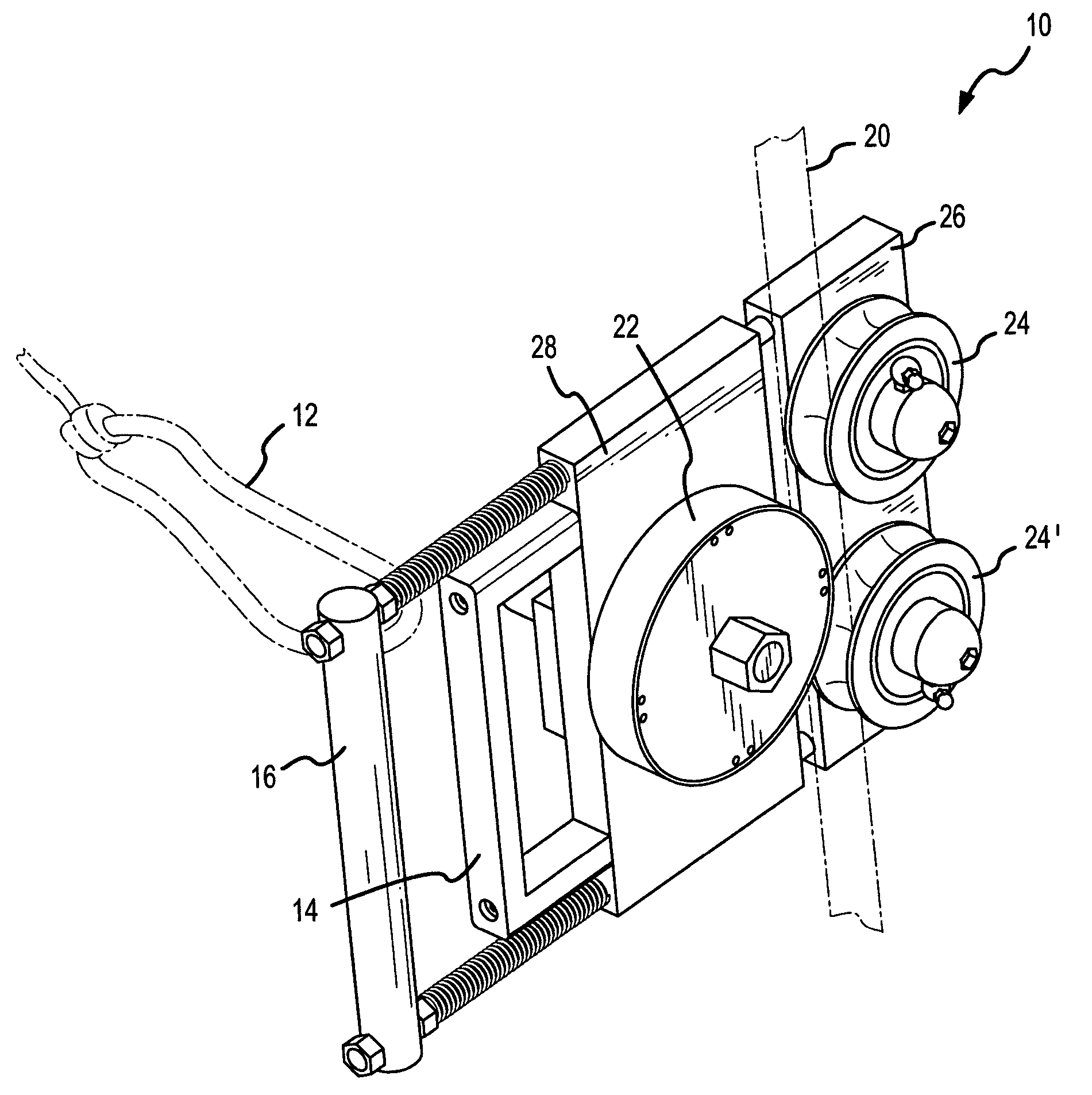

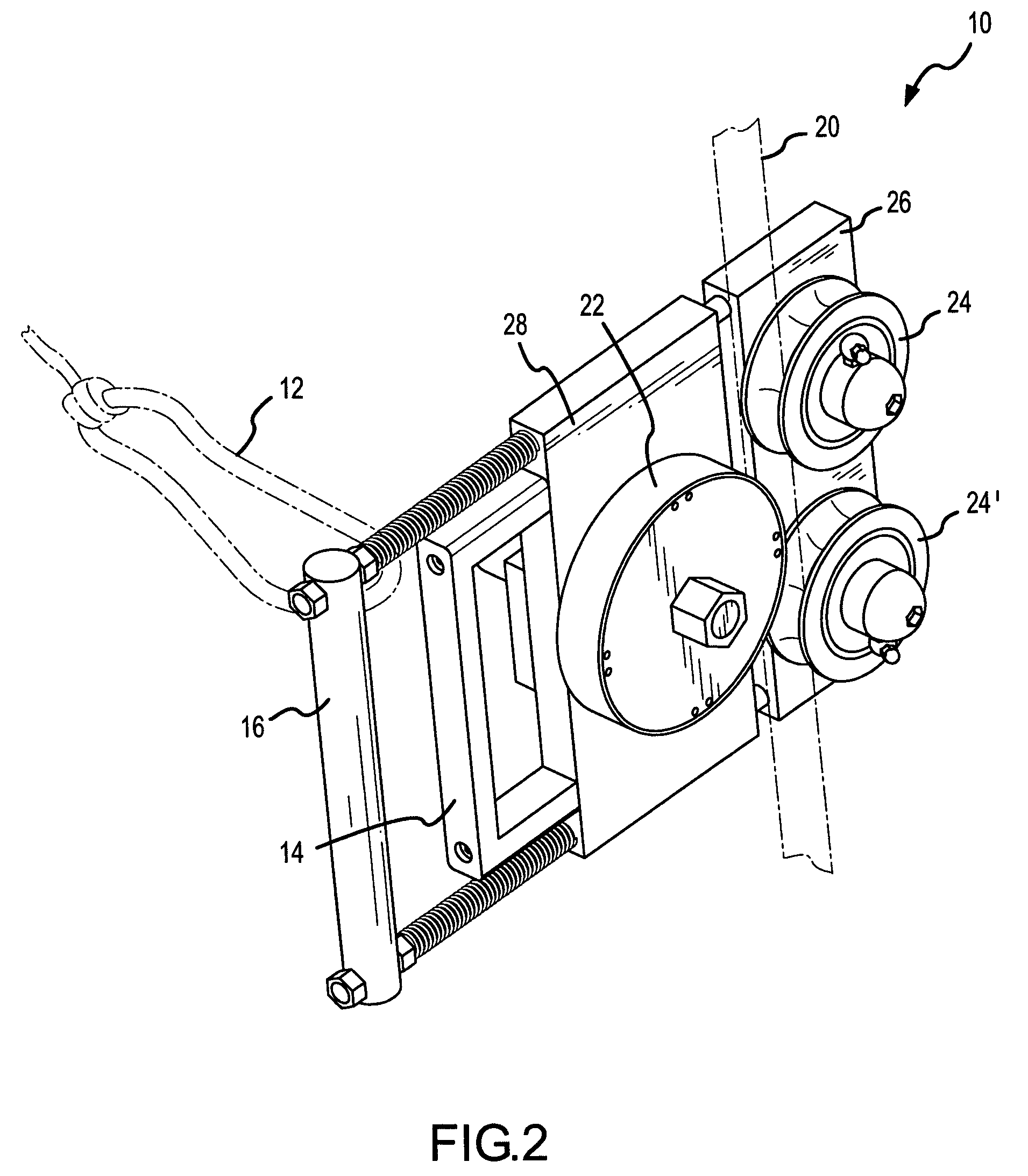

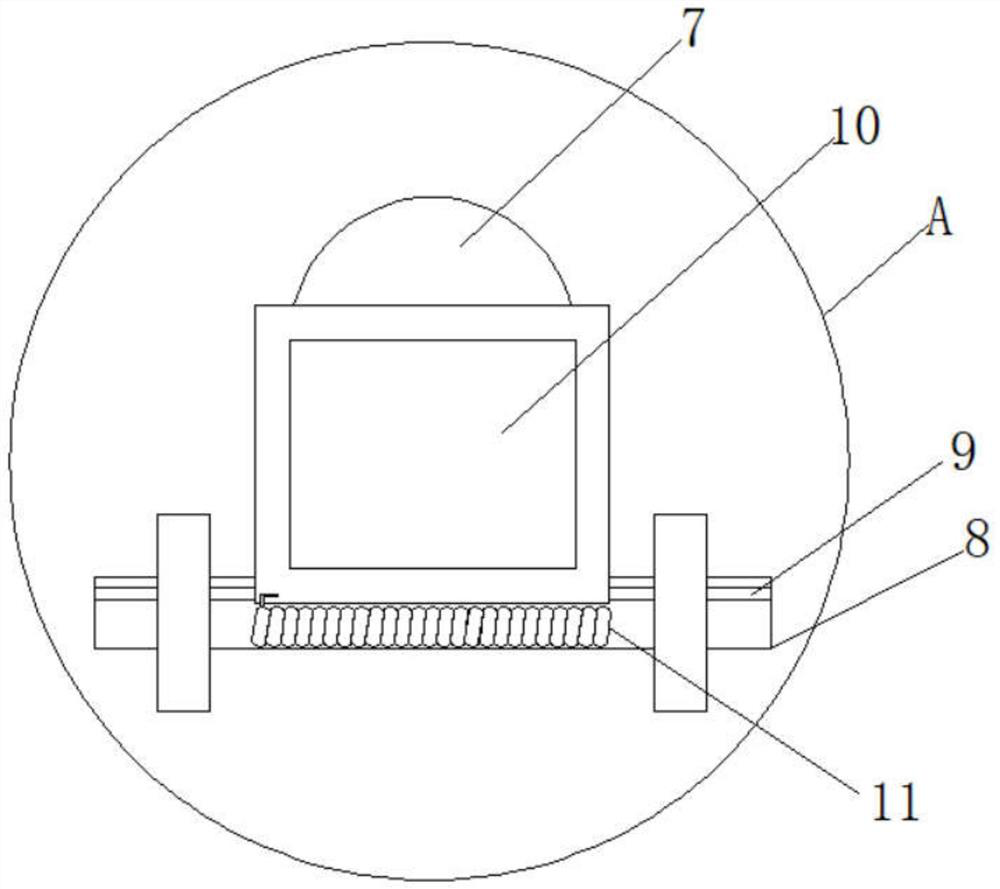

Handheld Measuring Device

InactiveUS20150192400A1Provide convenienceExact lengthMeasuring wheelsMechanical length measurementsLocking mechanismHand held

A handheld measuring device is provided that facilitates measurement of elongated articles such as wire, rope, cable, tubing, and the like. The device includes a housing having an upper and a lower roller that are adapted to bear against an article to be measured. The lower roller is connected to a counter assembly and the upper roller is rotatably supported within a clevis and affixed to a plunger assembly. A spring biased locking mechanism locks the plunger assembly in place as the article to be measured is drawn between the rollers. The counter assembly registers a linear distance traveled by the lower roller for accurate measurement of the work piece. The device can be deployed in one hand and is suitable to be carried on one's person when not in use. The housing facilitates insertion of a work piece while the rollers and clevis member prevent separation from the rollers.

Owner:RADO ROBERT JOSEPH

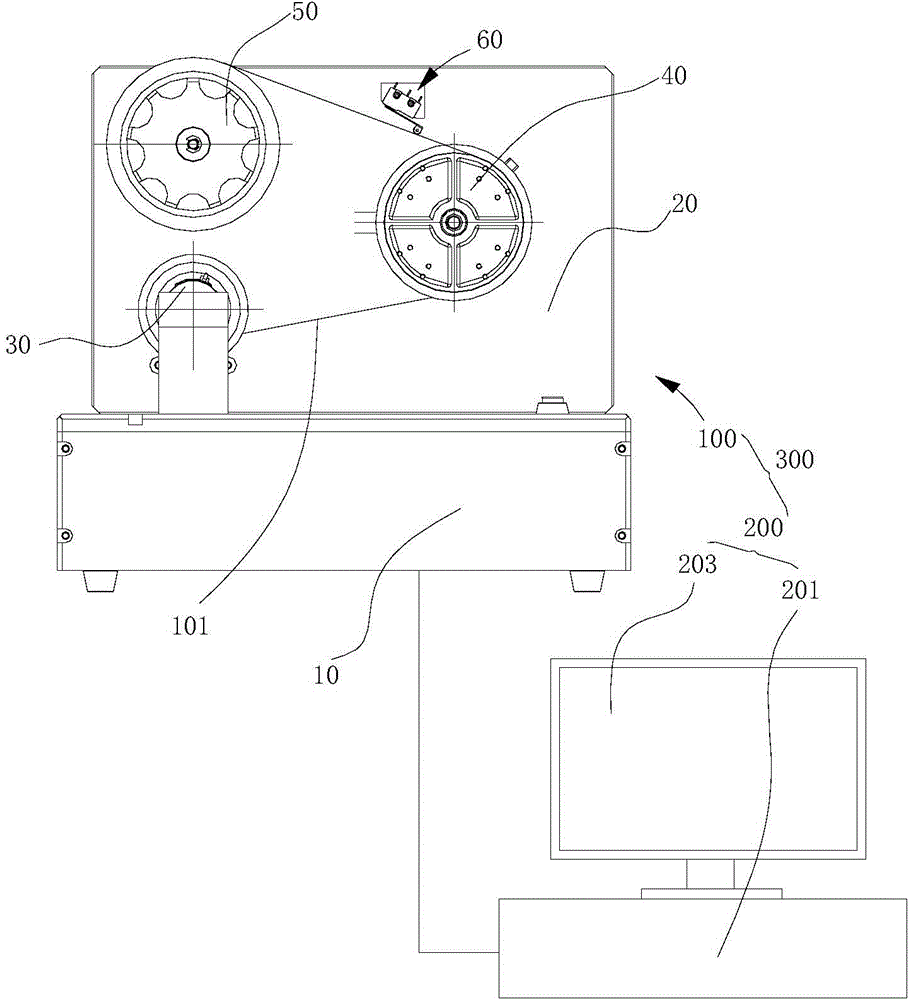

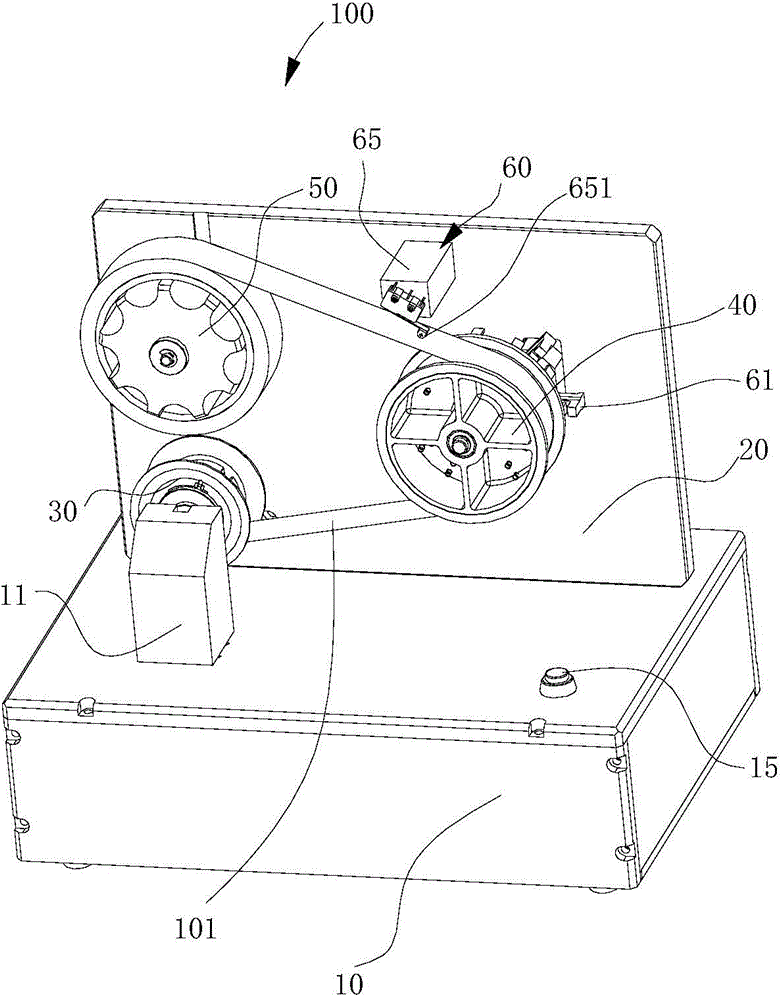

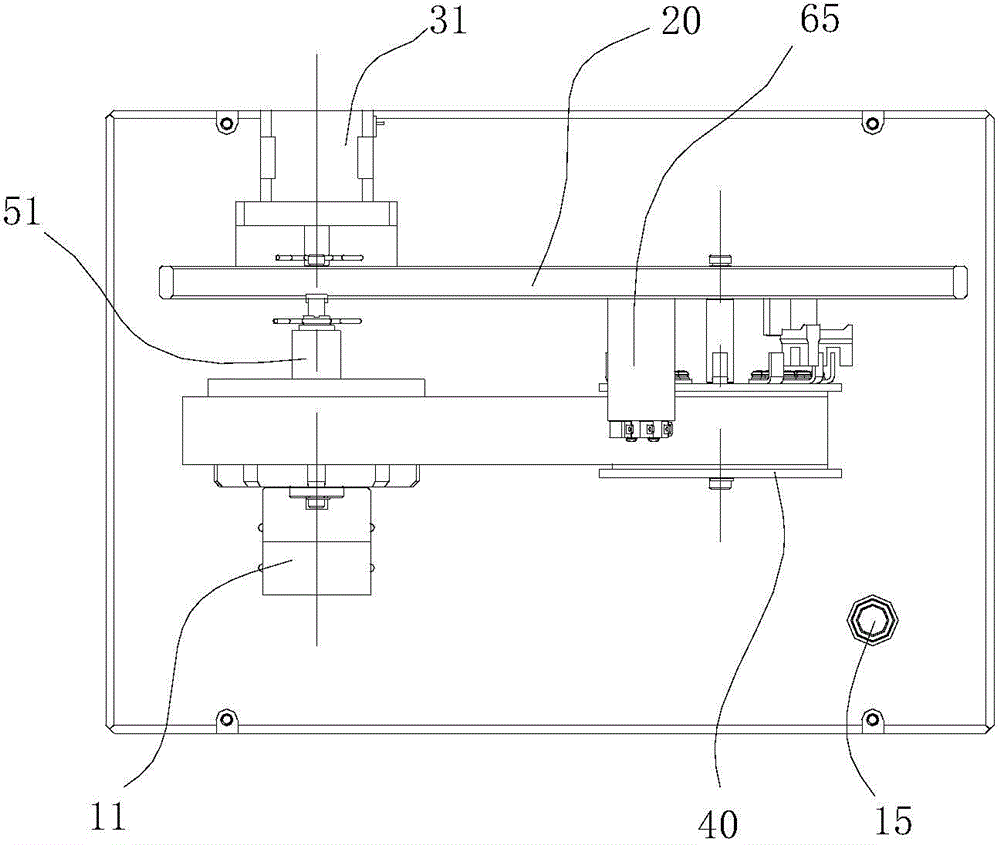

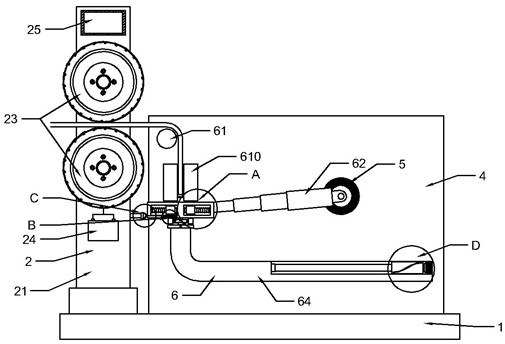

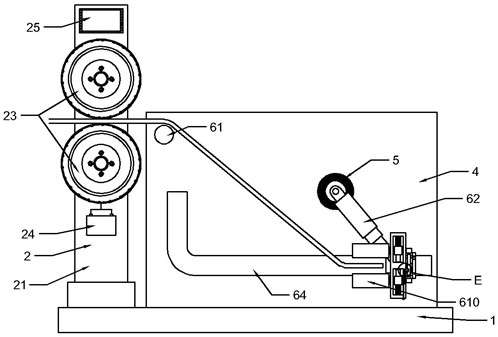

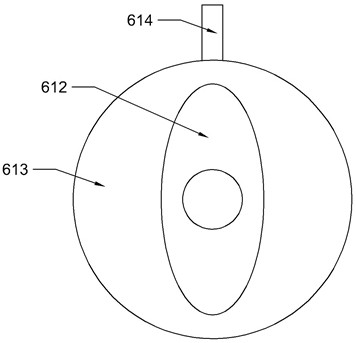

Bank note coiling band measurement equipment and method

PendingCN104567775AImprove measurement efficiencyMechanical length measurementsArticle deliveryWind componentEngineering

The invention relates to bank note coiling band measurement equipment and a bank note coiling band measurement method. The equipment comprises a measuring mechanism and a data processing terminal, wherein the measuring mechanism comprises a supporting frame, a winding component, a measuring wheel, a rotating wheel and a sensing component; the winding component comprises a rotating driving piece arranged on the supporting frame, and a winding wheel connected with the rotating driving piece; the measuring wheel and the winding wheel as well as the rotating wheel and the winding wheel are arranged at an interval; the measuring wheel and the rotating wheel are arranged on the supporting frame; the winding wheel, the measuring wheel and the rotating wheel form a triangular profile; the sensing component comprises a micro switch and a photoelectric disconnection sensor which are arranged on the supporting frame, and a sensor induction piece; the data processing terminal comprises a data processor electrically connected with the micro switch and a photoelectric disconnection sensor, and an output part electrically connected with the data processor. The bank note coiling band measurement equipment is high in efficiency.

Owner:SHENZHEN YIHUA COMP +2

Tool for Fast Detection of Worm Length

ActiveCN110057269AQuality improvementPrevent inflowMachine part testingMechanical length measurementsEngineeringOil storage

The present invention discloses a tool for fast detection of worm length, the tool comprises a base and a cover mounted on the base. Inner side wall of the cover is in rotatory connection with a second rotary rod through a bearing seat, lower end of the second rotary rod is in fixed connection with a fixed seat, the worm is clamped inside the fixed seat by a clamping mechanism, a scale is fixedlyinstalled on inner side wall of the cover, an oil storage barrel is fixedly installed on inner side wall of the cover, the oil storage barrel is filled with lubricating oil, and an oil outlet pipe isinstalled at bottom of the oil storage barrel. The tool can take the lead in realizing demonstration of working state of the worm through cooperation of the clamping mechanism and a simulated workingmechanism, so that detecting personnels can directly observe smoothness and occlusion tightness of meshing transmission between worm wheels and the worm through naked eyes, thereby worms that are outof specification are removed, greatly improving quality of worms leaving factory, preventing defective products from flowing into the market, and improving market reputation for enterprises to a certain extent.

Owner:日照新睿招商发展有限公司

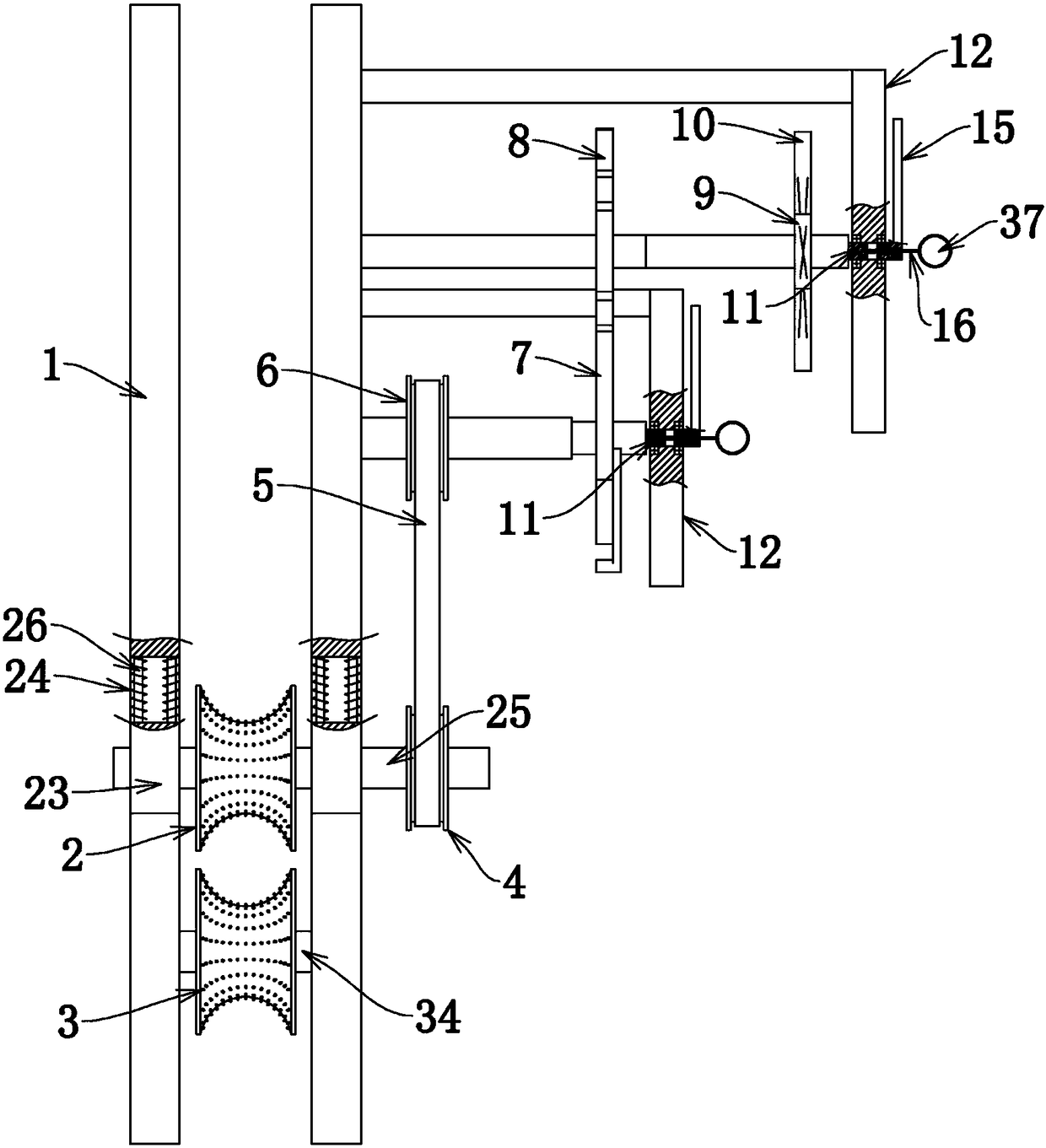

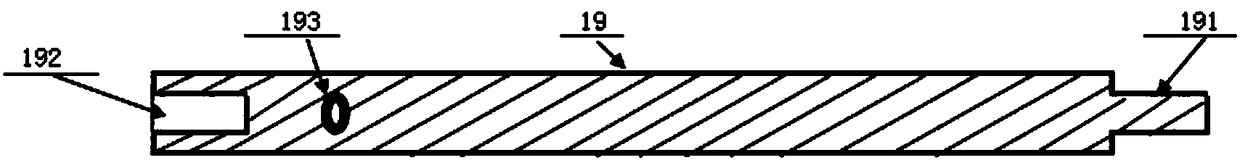

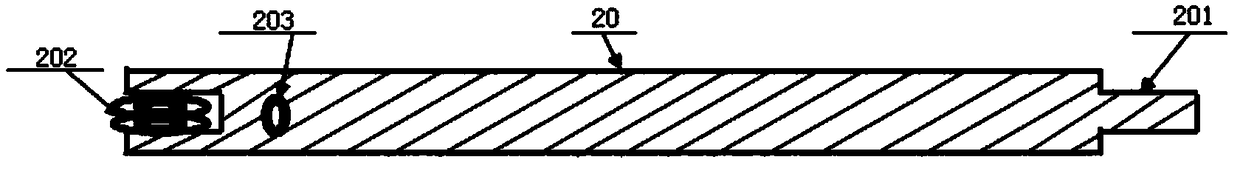

Stay rope displacement sensor integrated with error compensation technology, and preparation method thereof

InactiveCN106247897AHigh precisionOmit the process of decodingMechanical length measurementsMicrocomputerMicrocontroller

The invention discloses a stay rope displacement sensor integrated with an error compensation technology, and a preparation method thereof. The stay rope displacement sensor comprises a mechanical body, a shaft coupling, an encoder installation seat, a multi-turn absolute encoder based on an SSI interface, a connection cable and a single-chip microcomputer processing module. When a steel wire rope on the mechanical body is drawn out, the steel wire rope drives a main shaft to rotate, the main shaft drives the multi-turn absolute encoder to rotate, the multi-turn absolute encoder outputs electric signals with angle information in a rotation process, the single-chip microcomputer processing module reads the electric signals output by the multi-turn absolute encoder, afterwards, angle data is decoded into displacement information, after original displacement information is calibrated, an error model is constructed according to a least square method, and the error model is embedded into the single-chip microcomputer processing module. The stay rope displacement sensor integrated with the single-chip microcomputer processing module has the advantage of directly outputting a displacement quantity, omits a user decoding process, at the same time, greatly improves the precision of the stay rope displacement sensor after the output displacement information is subjected to error compensation correction.

Owner:JIUJIANG HANTANG OPTOELECTRONICS TRANSMISSION TECH CO LTD

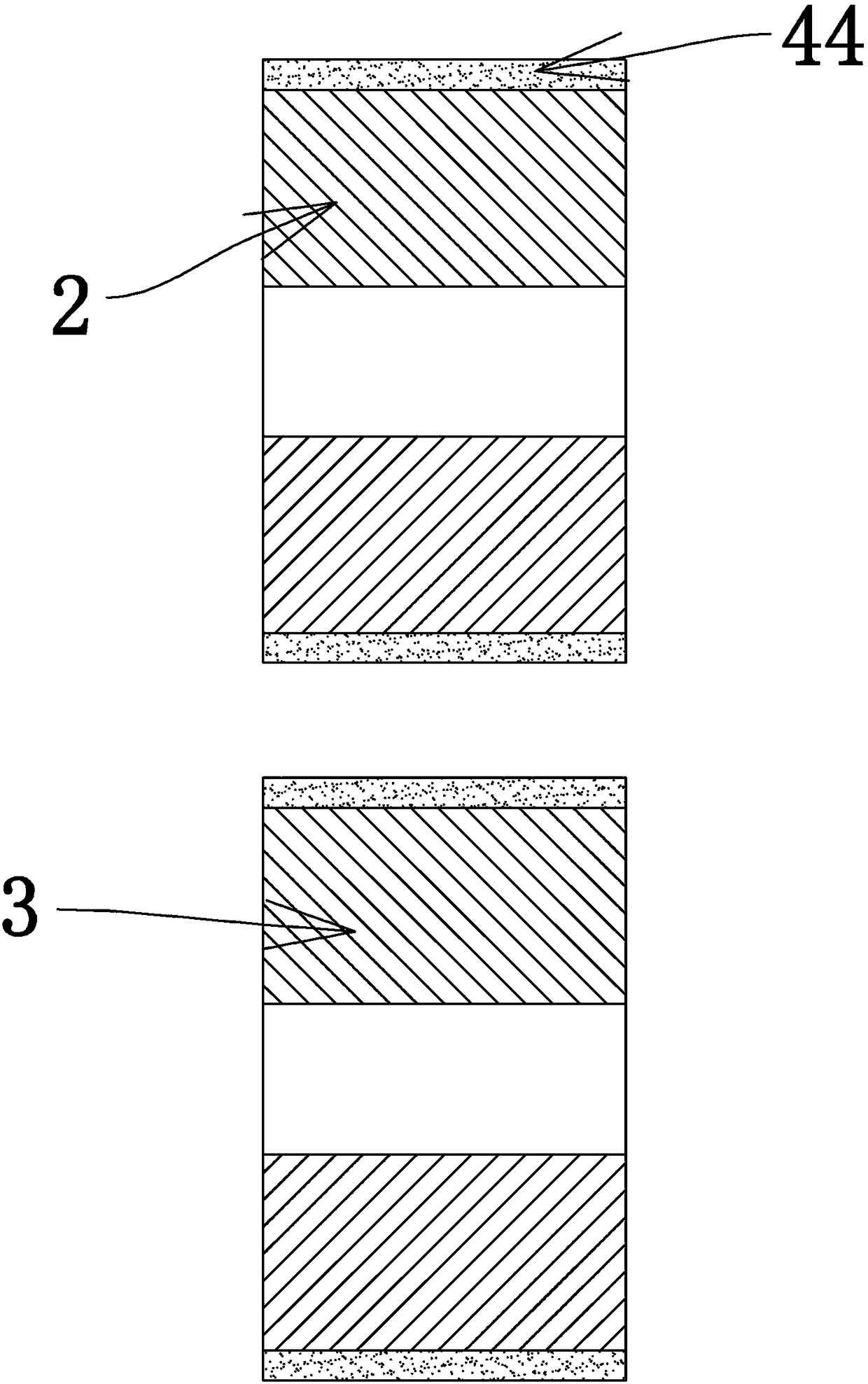

Bearing device for fixed length moving cutting of textile fabric

ActiveCN106498694ASimple structureEasy to operateSevering textilesMechanical length measurementsEngineeringMechanical engineering

The invention discloses a bearing device for fixed length moving cutting of a textile fabric. The bearing device comprises a strip-shaped bearing base. A strip-shaped hollow shell is fixedly connected to the upper surface of the strip-shaped bearing base. A first semicircular through groove is formed in the upper surface of the strip-shaped hollow shell. A first semicircular uncovered shell is embedded into the first semicircular through groove. A plurality of first rotating circular shafts are arranged at one end of the upper surface of the first semicircular uncovered shell. The multiple first rotating circular shafts are sleeved with a second semicircular bottomless shell matched with the first semicircular uncovered shell, a bearing mechanism is arranged inside the first semicircular uncovered shell, a moving cutting mechanism is arranged on the front surface of the strip-shaped hollow shell, a moving mechanism is arranged on the lower surface of the strip-shaped bearing base, a measuring mechanism is arranged on the front surface of the second semicircular bottomless shell, and a controller is arranged on the side surface of the strip-shaped hollow shell. The bearing device has the advantages of being simple in structure and high in practicability.

Owner:江西求学纺织科技有限公司

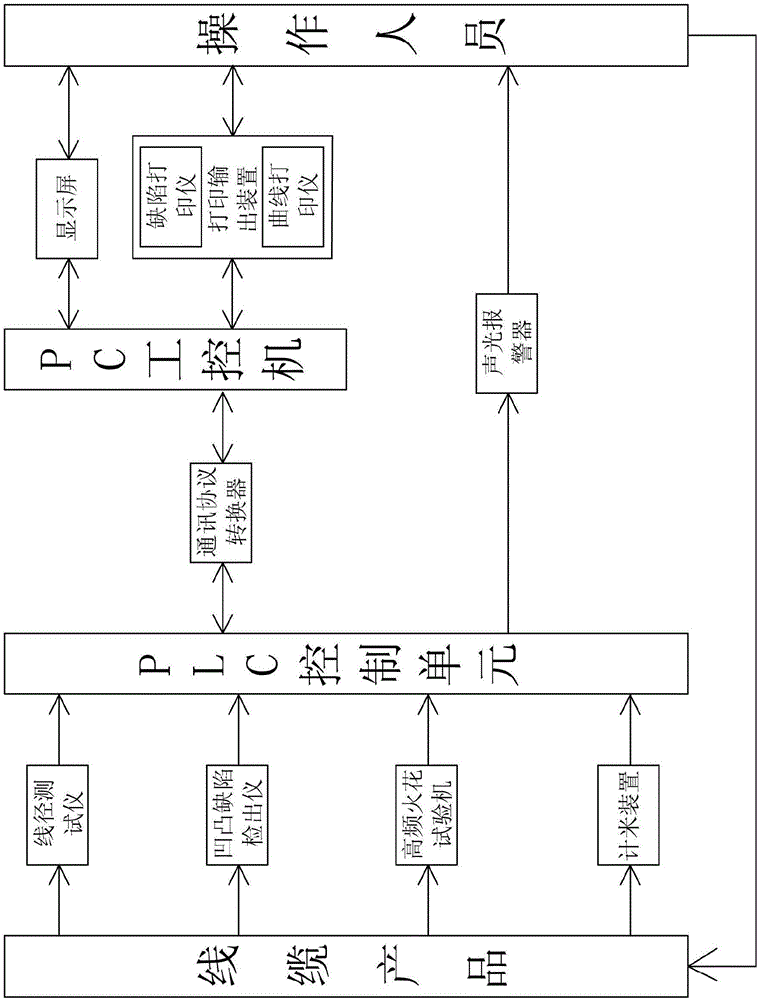

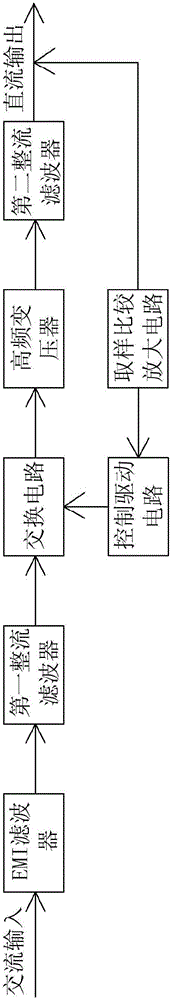

Cable on-line detection system

PendingCN106840075AReduce workloadEasy to observeMaterial breakdown voltageMechanical length measurementsEngineeringOutput device

The invention provides a cable on-line detection system and belongs to the technical field of cable inspection systems. The system includes a cable diameter tester, a high-frequency spark testing machine, a concave-convex defect detection apparatus, a meter counting device, a PLC control unit, a communication protocol converter, a PC industrial personal computer and an audible and visual alarm; the high-frequency spark testing machine, the concave-convex defect detection apparatus, the cable diameter tester and the meter counting device are connected with the PLC control unit respectively, the PLC control unit is connected with the communication protocol converter and the audible and visual alarm, the communication protocol converter is connected with the PC industrial personal computer, and the PC industrial personal computer is provided with a display screen and a printing output device. The system has the advantages that operators do not need to often go to a site to check whether the current state is within a controlled range or not, the automation of cable on-line detection is achieved, the production efficiency is improved, the workload of the operators is reduced, the PC industrial personal computer is used for displaying the state in real time and recording and storing data, and it is convenient for the operators to check the current state of a product, find a problem timely and solve the problem in the short time.

Owner:SUZHOU CABLEPLUS PHOTOELECTRIC TECH

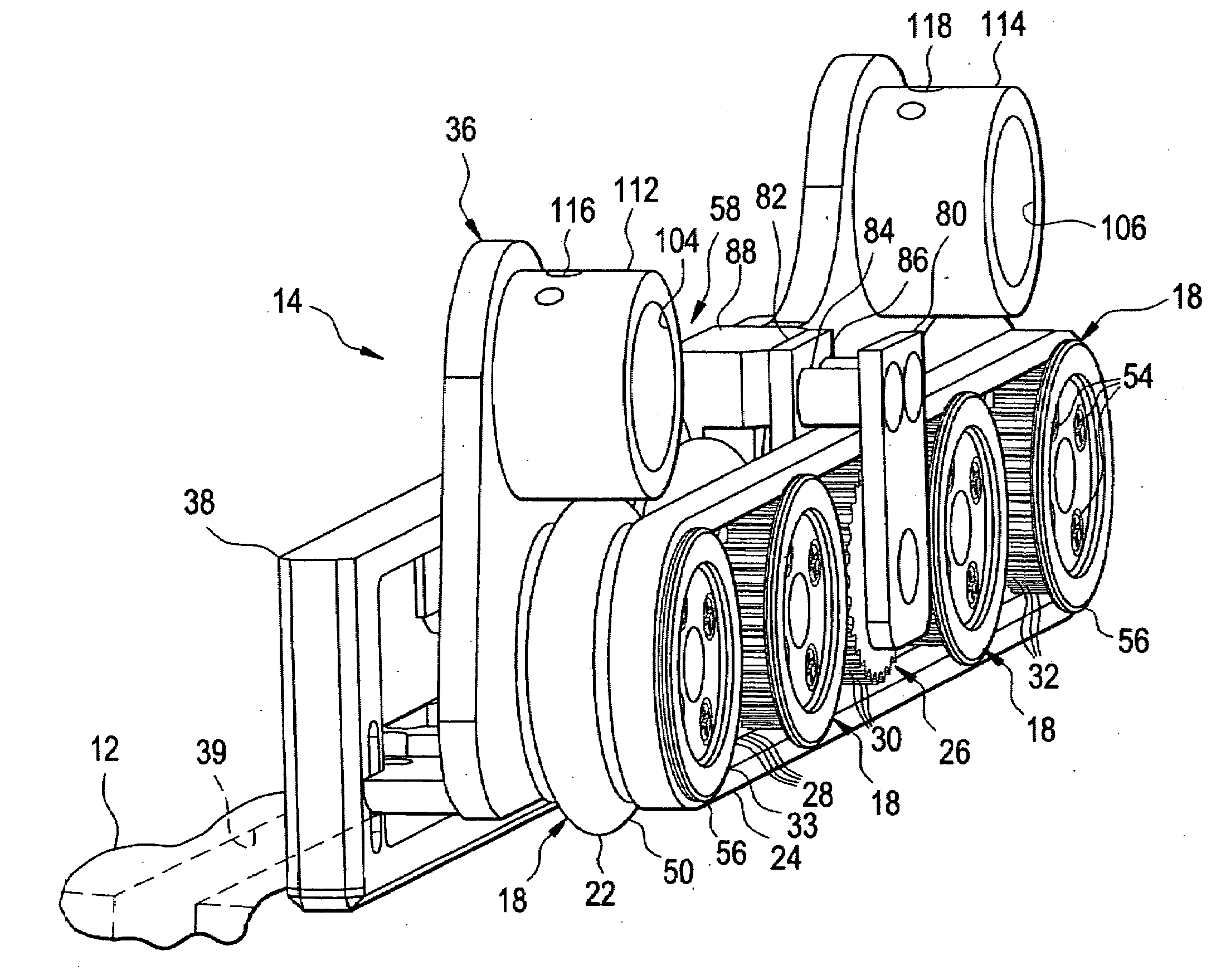

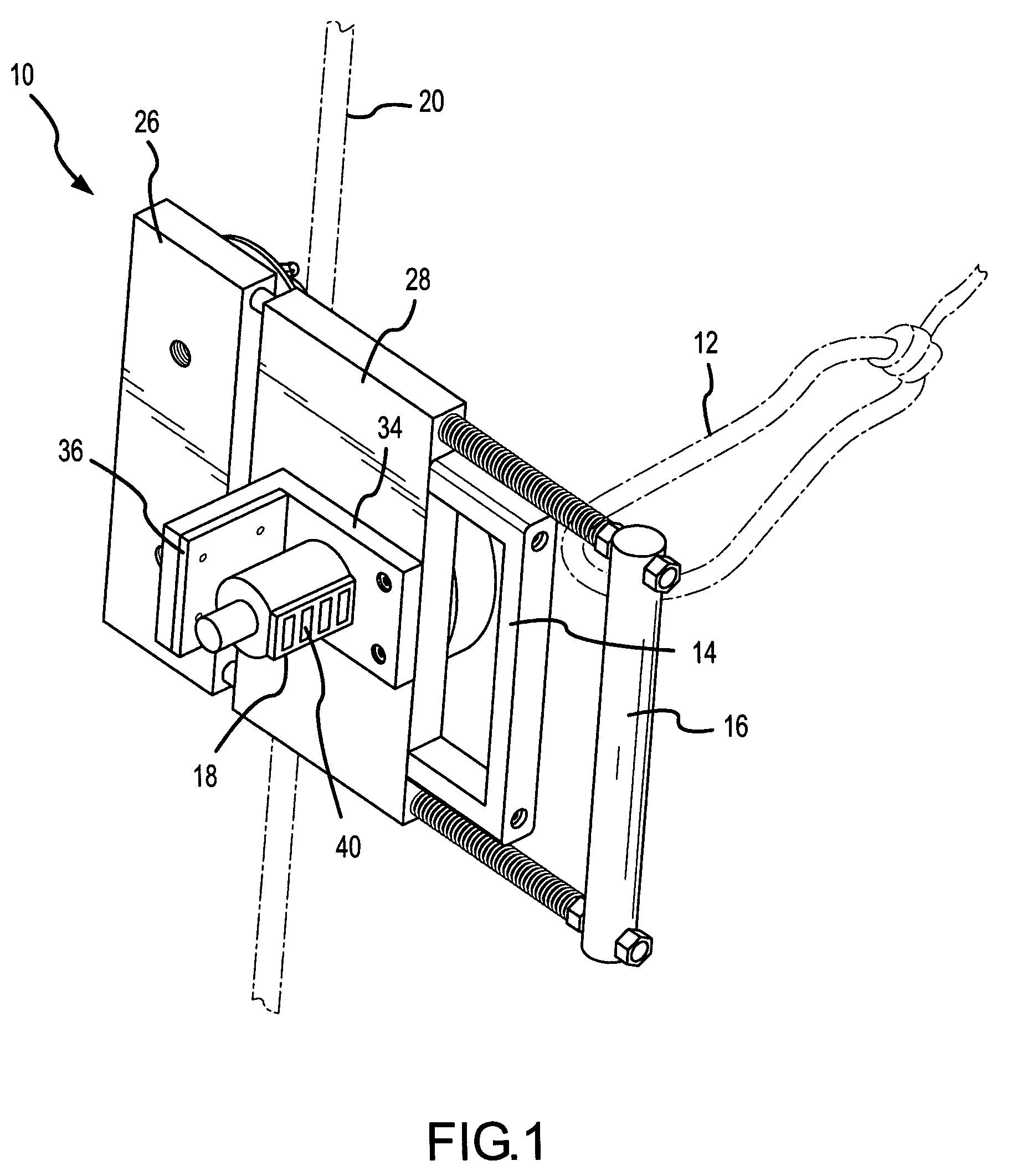

Method and apparatus for linear measurement of a stator core

A linear measurement device for a stator core inspection system includes a plurality of wheels rotatably mounted to a frame. Each of the wheels has a contact surface and a hub portion. The linear measurement device further includes an encoder gear rotatably mounted to the frame. The linear measurement device further includes a sensor configured to generate a signal indicative of rotation of the encoder gear. The linear measurement device further includes a belt configured to engage the hub portion of each wheel and the encoder gear, and rotation of one wheel causing synchronous rotation of the encoder gear and the other wheels.

Owner:GENERAL ELECTRIC CO

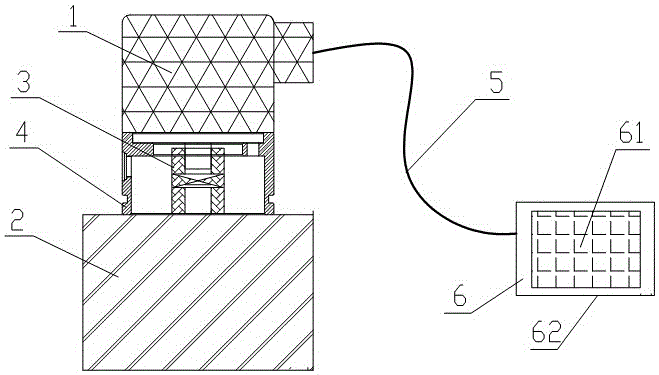

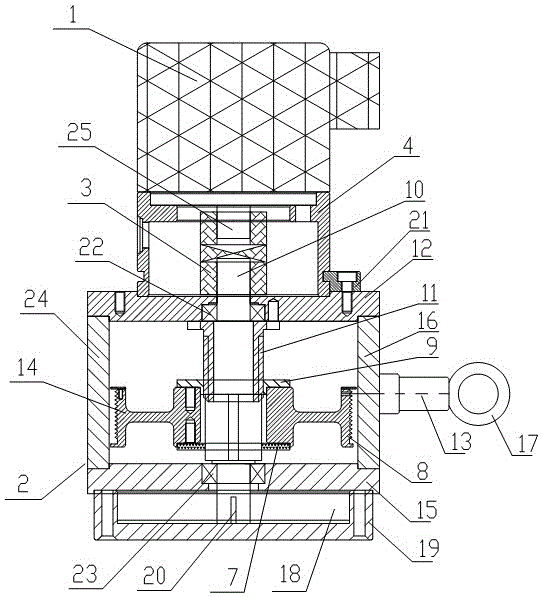

Cable length meter

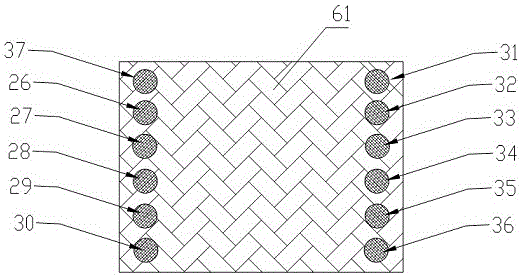

InactiveCN109297389APrevent slippingAvoid misalignmentMechanical length measurementsEngineeringFlexible cable

The invention discloses a cable length meter, comprising a n-shaped frame, a guiding mechanism, a pressing adjustment mechanism, and a metering mechanism. The n-shaped frame consists of a horizontal top plate, a horizontal bottom plate, and a connecting plate vertically disposed between the top plate and the bottom plate. The guiding mechanism is located in the n-shaped frame and comprises a supporting shaft, a plurality of guiding wheels, a cylinder, an inverted U-shaped limiting member, and an abutting member. The pressing adjustment mechanism is located in the n-shaped frame and comprises apair of fixed cylinders vertically fixed on the top plate, a pressure roller and a spring disposed between a pair of the fixed cylinders. The metering mechanism is located in the n-shaped frame and comprises a positioning shaft vertically arranged on the bottom plate, a meter wheel rotatably disposed on the positioning shaft, and a meter connected to the meter wheel. According to the cable lengthmeter, a flexible cable whose length need to be measured is straightened to avoid slipping and misalignment of the cable when passing through the meter wheel, so that a measurement result has high accuracy and small error.

Owner:王学睿

Depthometer

A depthometer for measuring a length of an elongate line. A main wheel is mounted upon a main body component and is in communication with a registering mechanism. Line guides are mounted upon a lower body component. An inner handle connected to the main body component is pulled toward an outer handle connected to the lower body component, in opposition to a spring-like force in the opposite direction, to open the depthometer and position a line within the depthometer. The main body component is automatically moved towards the lower body component via a spring-like force when the inner handle is released, thereby engaging the line in the depthometer in the installed position.

Owner:ROBERTS DANNY

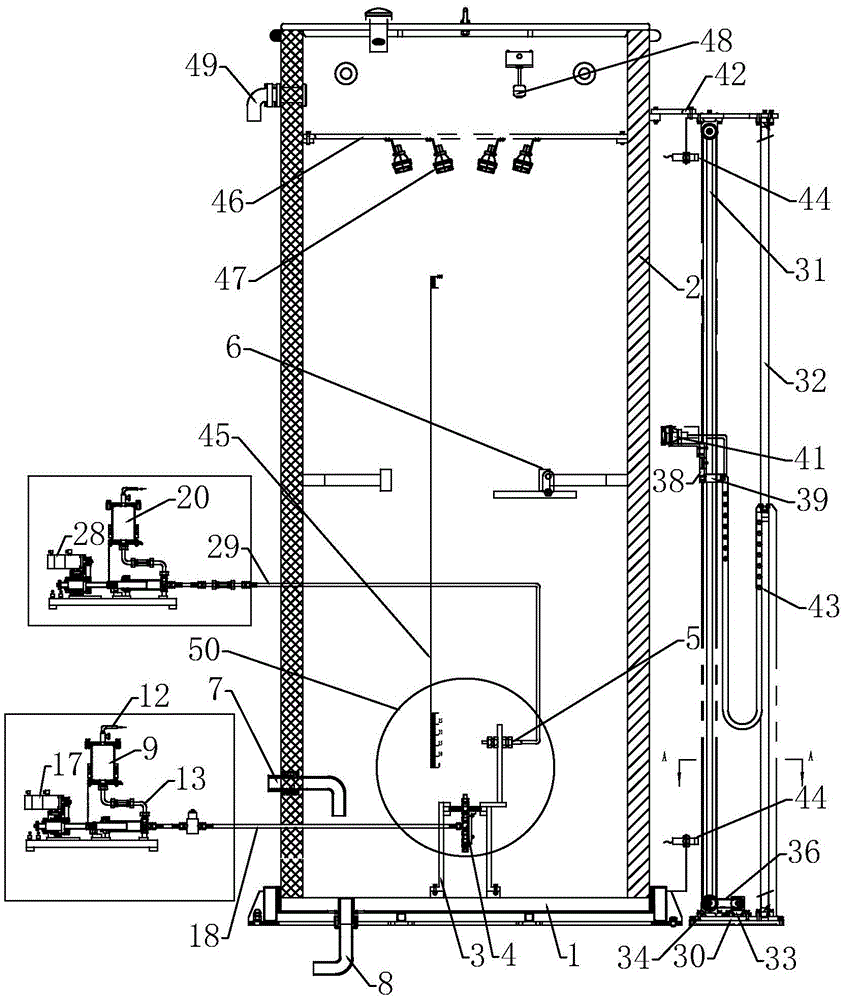

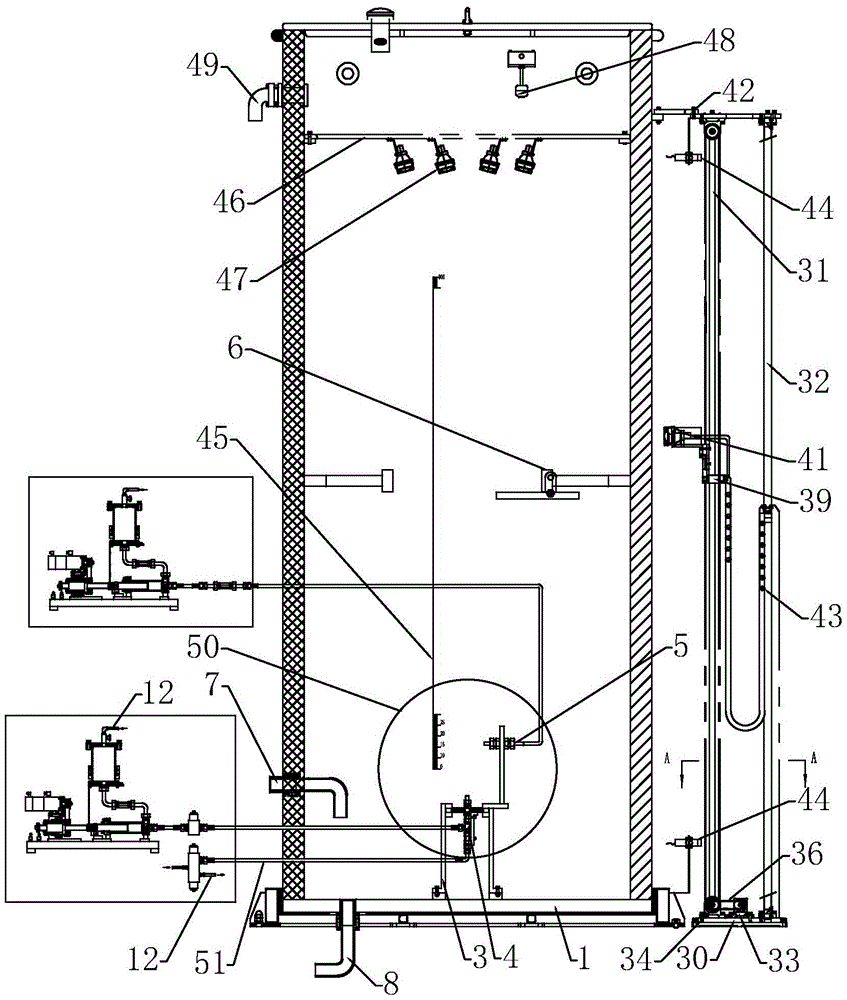

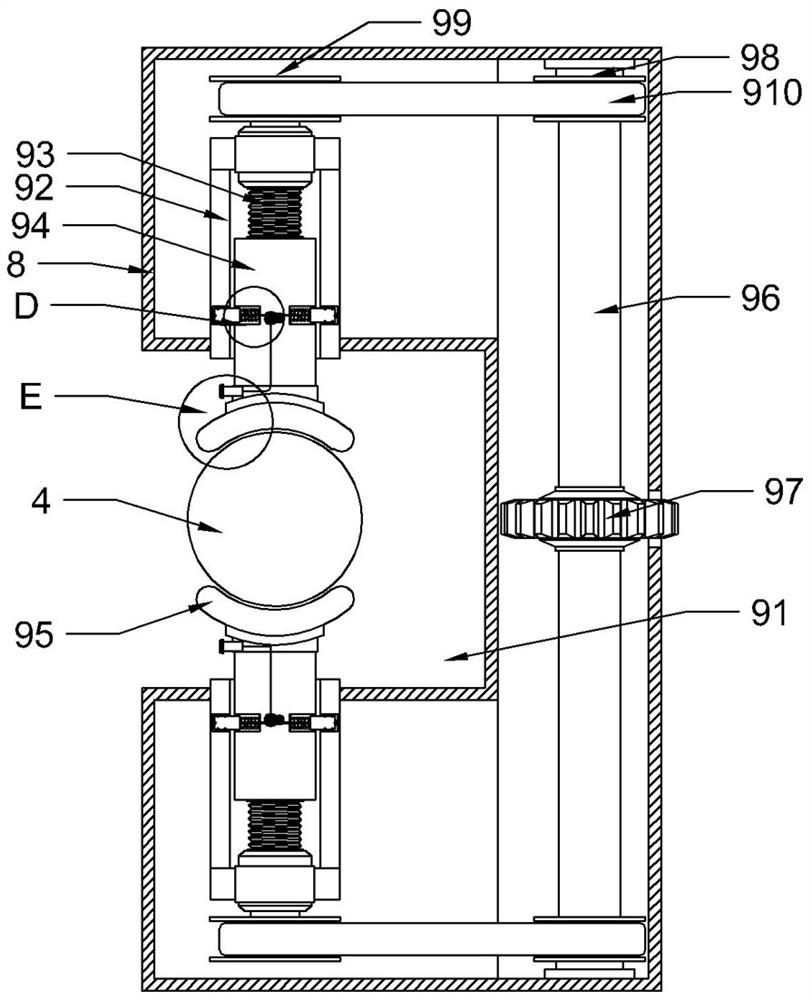

Vertical simulation device and simulation method of submarine spilled oil

InactiveCN105527291AGuaranteed clarityImprove clarityMechanical area measurementsInvestigating moving fluids/granular solidsSpray nozzleSubmarine

The invention relates to the technical field of marine environment simulation test equipment, and in particular to a vertical simulation device and a simulation method of submarine environment spilled oil. The vertical simulation device of submarine environment spilled oil comprises a main body water channel, wherein a fixed chassis is arranged at the bottom of the main body water channel; a support frame is arranged at the internal bottom of the main body water channel; an ejector is arranged on the support frame; an oil dispersant nozzle is arranged above the right side of the support frame; a laser particle instrument is arranged at the middle part of the main body water channel above the ejector; an oiling unit connected with an inlet of the ejector is arranged on the external left side of the main body water channel; an oil dispersant injecting unit is arranged on the external left side of the main body water channel above the oiling unit; a lifting high-speed camera system is arranged on the external right side of the main body water channel; all the laser particle instrument, the oiling unit, the oil dispersant injecting unit and the lifting high-speed camera system are connected with a controller. The vertical simulation device of submarine environment spilled oil is scientific in design, and capable of simulating the vertical migrating and diffusing process regularities of submarine spilled oil and other pollutants in water body at different injecting speeds and simulating the existing mechanism and conditions of submerged oil contaminates.

Owner:NORTH CHINA SEA ENVIRONMENTAL MONITORING CENT OF STATE OCEANIC ADMINISTATION +1

Depthometer

A depthometer for measuring a length of an elongate line. A main wheel is mounted upon a main body component and is in communication with a registering mechanism. Line guides are mounted upon a lower body component. An inner handle connected to the main body component is pulled toward an outer handle connected to the lower body component, in opposition to a spring-like force in the opposite direction, to open the depthometer and position a line within the depthometer. The main body component is automatically moved towards the lower body component via a spring-like force when the inner handle is released, thereby engaging the line in the depthometer in the installed position.

Owner:ROBERTS DANNY

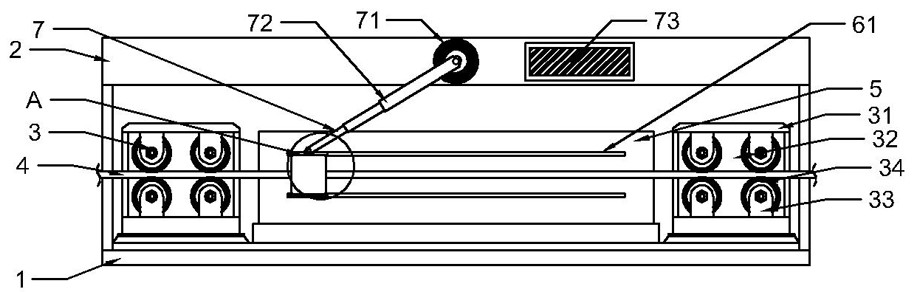

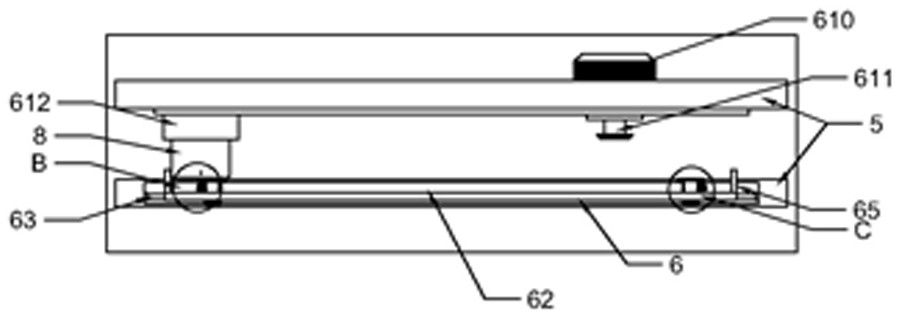

Length metering device for data line production detection

The invention is suitable for the technical field of length metering, and provides a length metering device for data line production detection. The device comprises: a placement plate which is provided with a guiding metering assembly, wherein the data line cooperates with the guiding metering assembly; an operation plate mounted on the placement plate, and provided with a reciprocating motor; and a pulling assembly installed at the output end of the reciprocating motor, wherein when the length metering device for data line production detection is used in cooperation with the reciprocating motor, a data line is arranged in the guiding metering device, the pulling assembly is started, the pulling assembly can pull the data line for transmission according to the preset length, and the data line is arranged in the guiding metering device for data line production detection. In the transmission process, the guiding metering device can measure and count the length of the data line to be transmitted, the single pulling length of the pulling assembly is equal, and the pulled data line can be cut off after single pulling is completed, so that the subsequent data line waits for next pulling.

Owner:SHENZHEN YIHUAXING ELECTRONICS

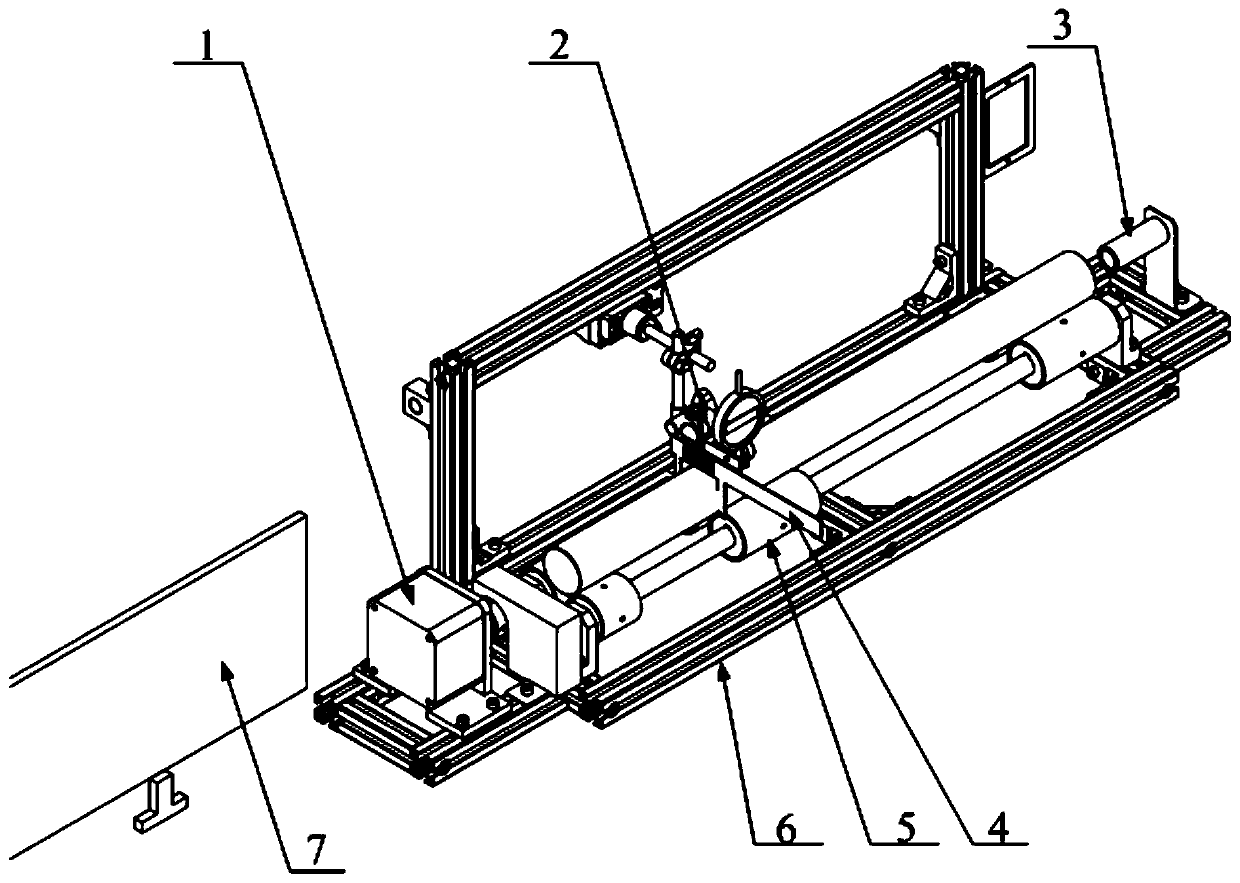

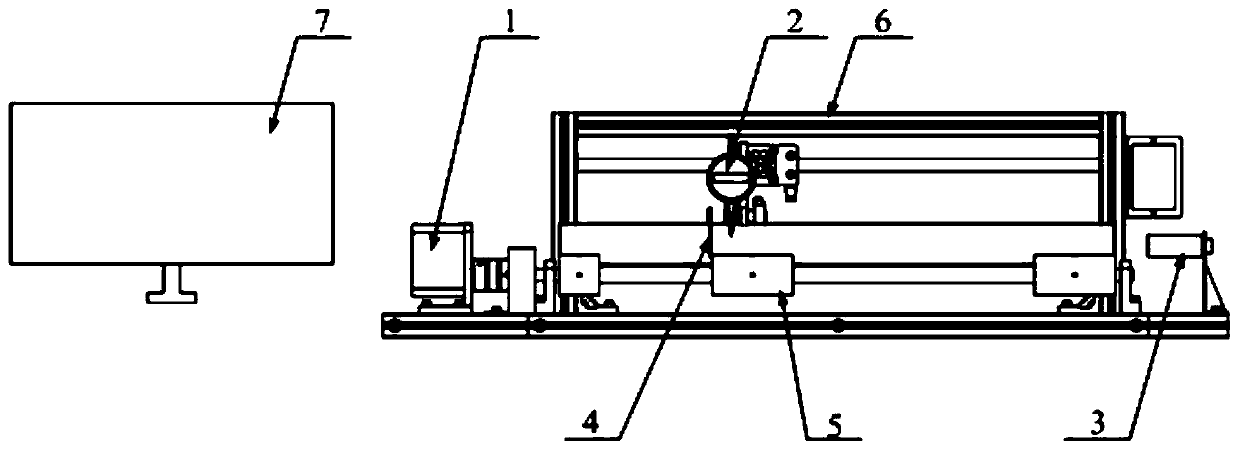

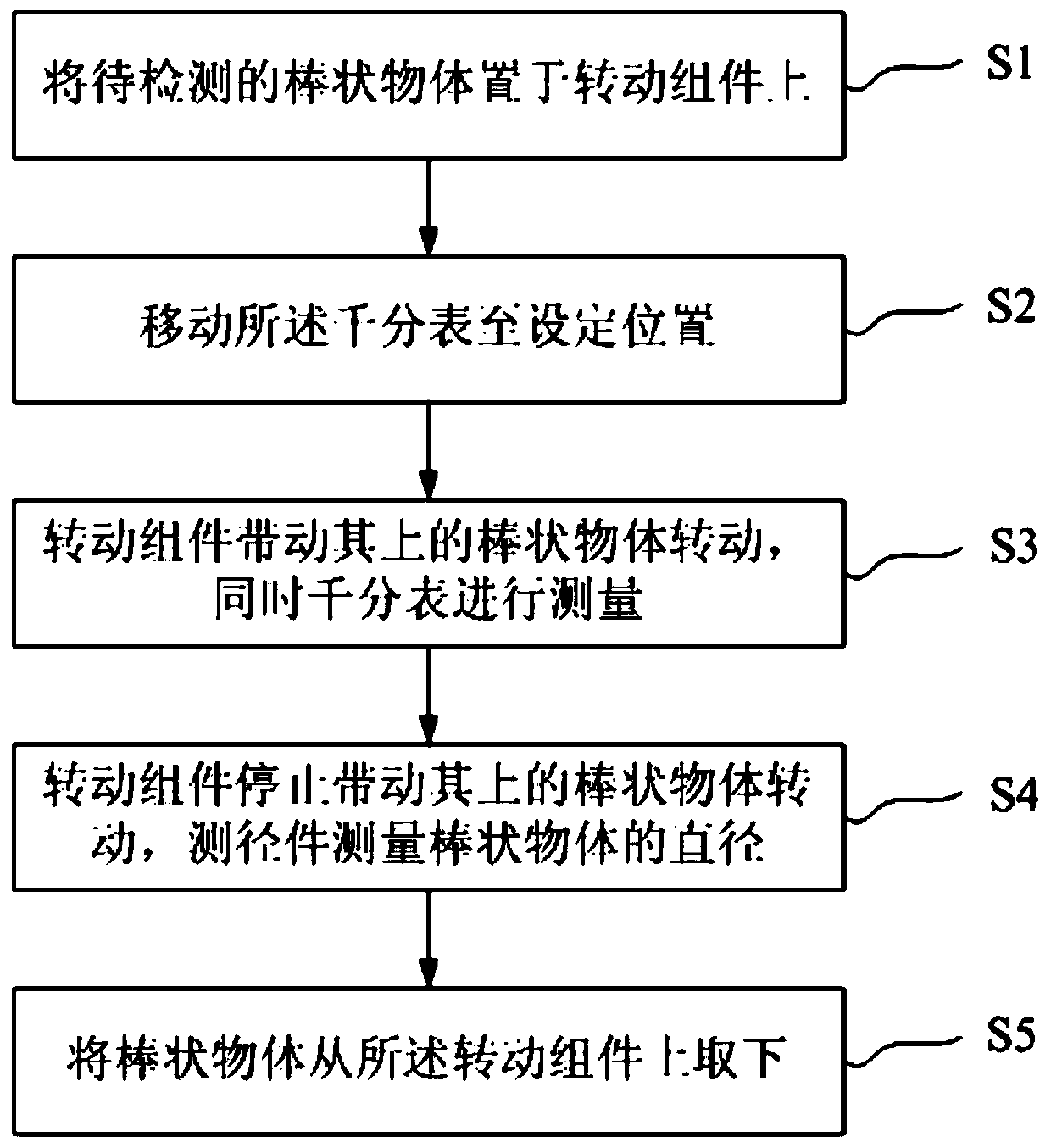

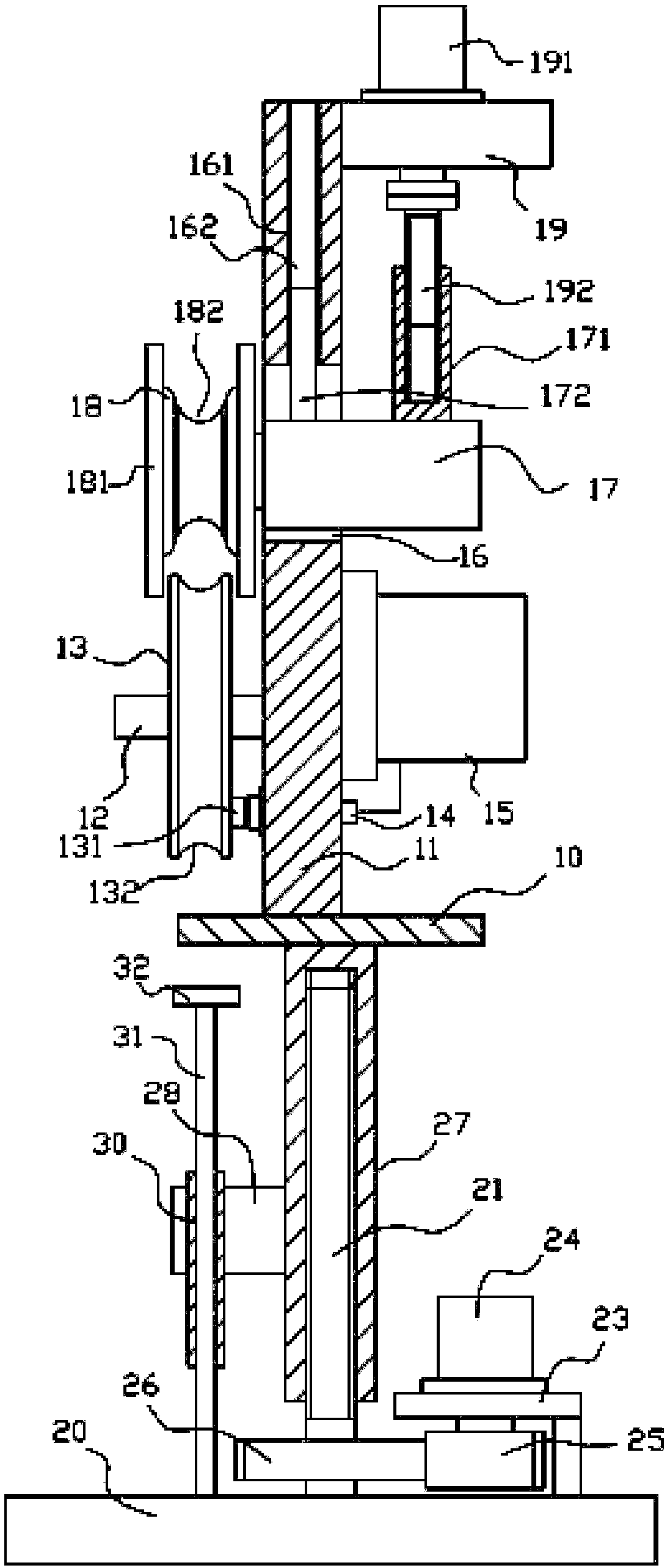

Rod-shaped object detection device, detection method and control system

PendingCN110986857APrevent rotationAvoid dial gaugesMechanical counters/curvatures measurementsMechanical diameter measurementsControl systemStructural engineering

The invention discloses a rod-shaped object detection device, a rod-shaped object detection method and a control system. The rod-shaped object detection device comprises a support; a rotating assemblywhich is arranged on the support and can support and drive a rod-shaped object to rotate; a dial indicator which is installed on the support and can move in the length direction of the rod-shaped object on the rotating assembly; and a diameter measuring piece used for measuring the diameter of the rod-shaped object on the rotating assembly. The structural design of the detection device for the rod-shaped object can effectively solve the problems that the labor intensity is high and the labor cost is high when the rod-shaped object is detected.

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD

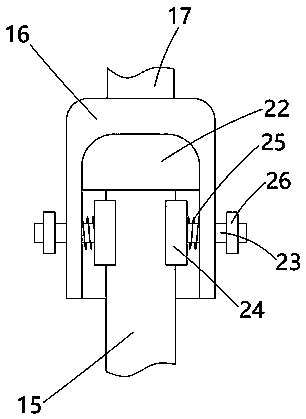

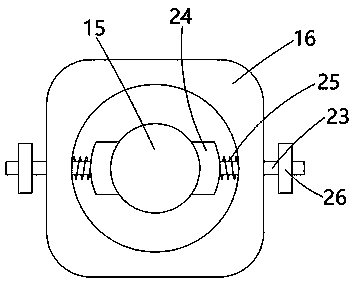

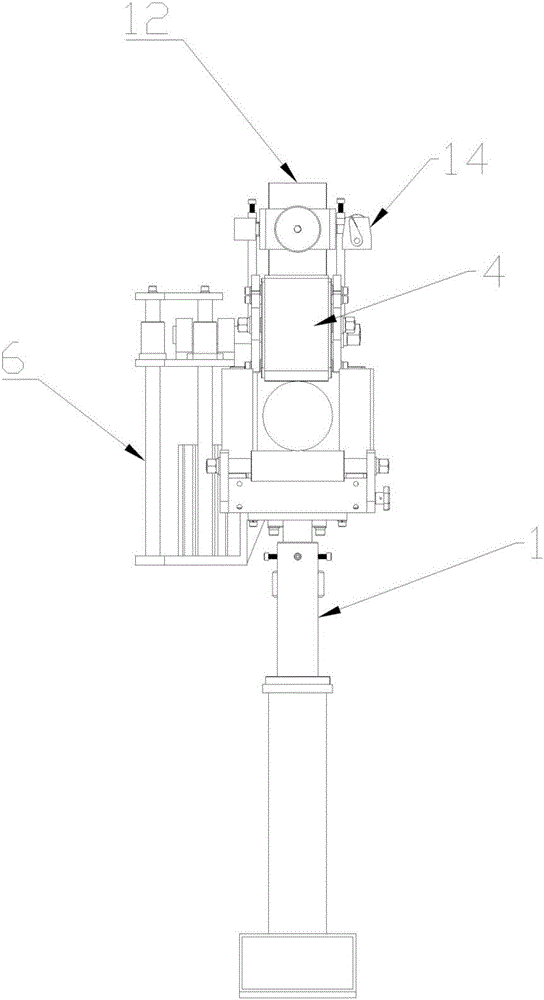

High-low adjustable clamping adjustable cable length meter

InactiveCN109141181AGuaranteed normal position deliverySatisfy the delivery meter counting requirementsMechanical length measurementsEngineeringNormal position

The present invention discloses a high-low adjustable clamping adjustable cable length meter. The high-low adjustable clamping adjustable cable length meter comprises a fixed plate and an installationbottom plate, the top surface of the installation bottom plate is hinged with a vertical adjustable screw, a motor support rack is fixed at the top surface of the installation bottom plate, a liftingmotor is fixed at the top surface of a transverse plate of the motor support rack, the output shaft of the lifting motor penetrates the transverse plate of the motor support rack and is fixed with adrive gear, a transmission gear is fixed at the lower portion of the vertical adjustable screw, the transmission gear is engaged with the drive gear, a vehicle lifting sleeve is in screw connection with the vertical adjustable screw, and a fixed plate is fixed at the top end of the vehicle lifting sleeve; and a vertical main plate is fixed at the top surface of the fixed plate. The high-low adjustable clamping adjustable cable length meter can automatic adjust the high-low position of the upper spacing clamping wheel and can prevent the transmission cable from sliding out from a position between the upper spacing clamping wheel and a meter counting wheel through two spacing circular plates so as to ensure the normal position transmission, and can perform automatic high-low adjustment of the fixed plate so as to meet the meter counting transmission requirements of different heights.

Owner:叶佑君

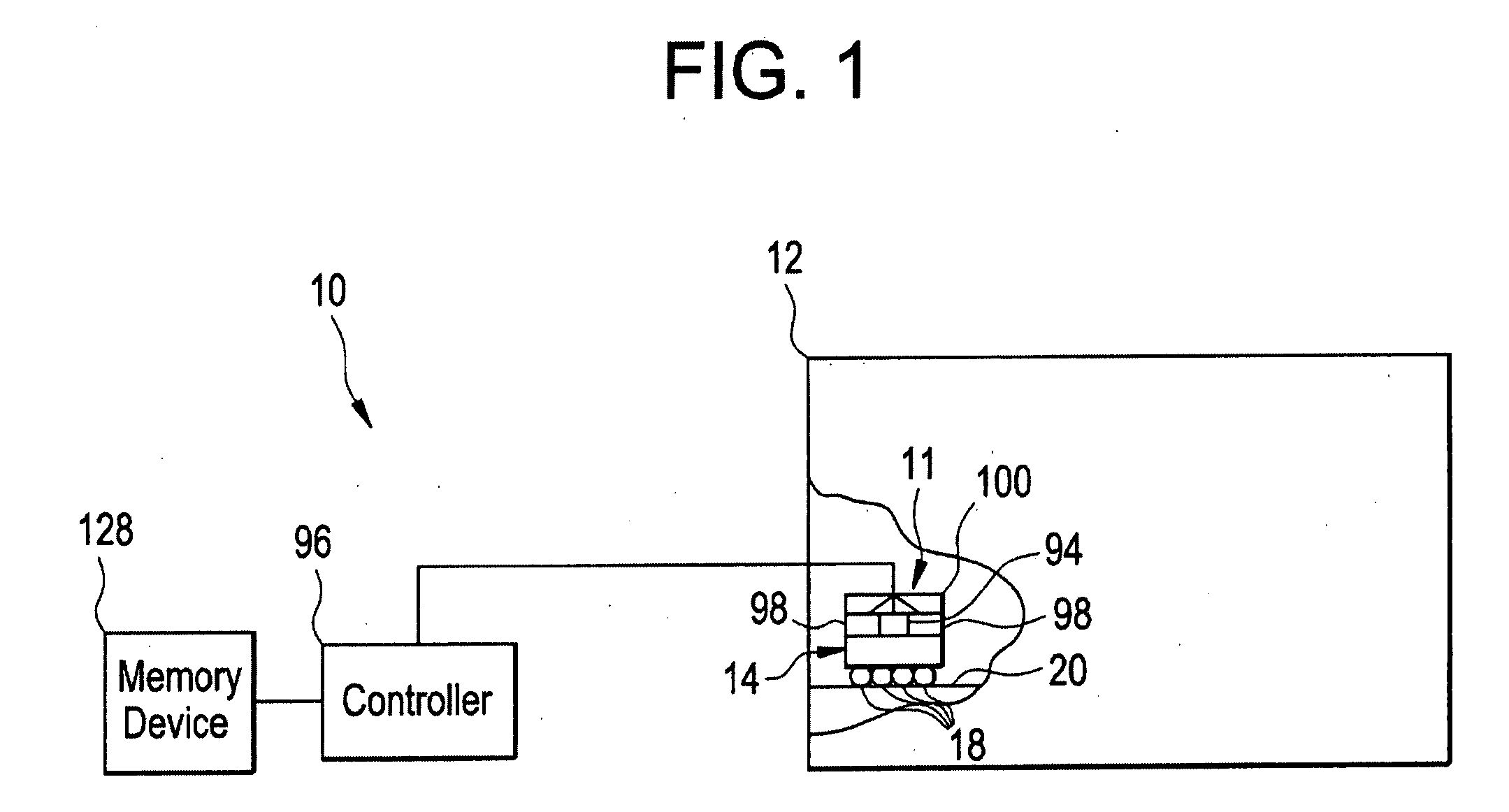

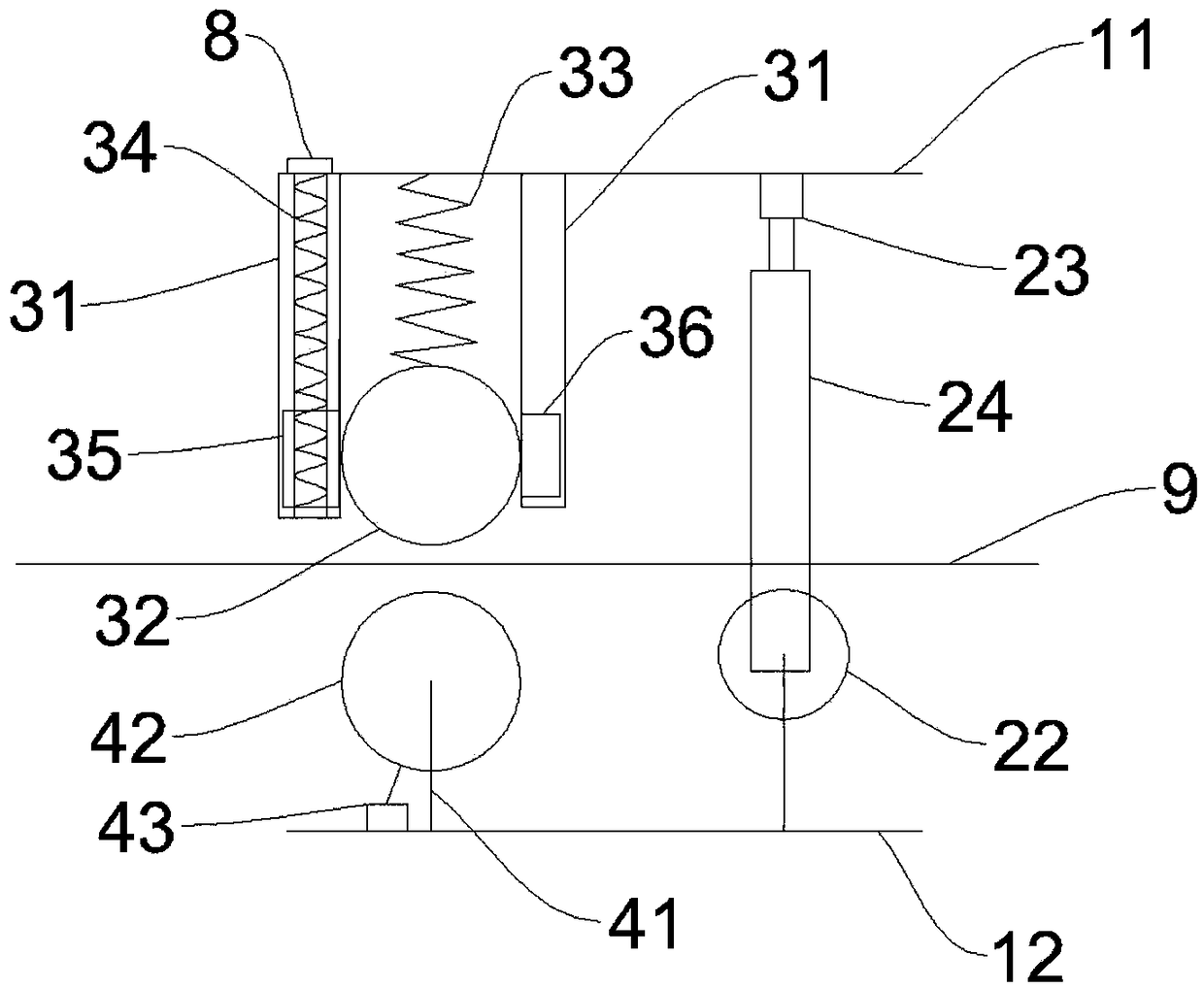

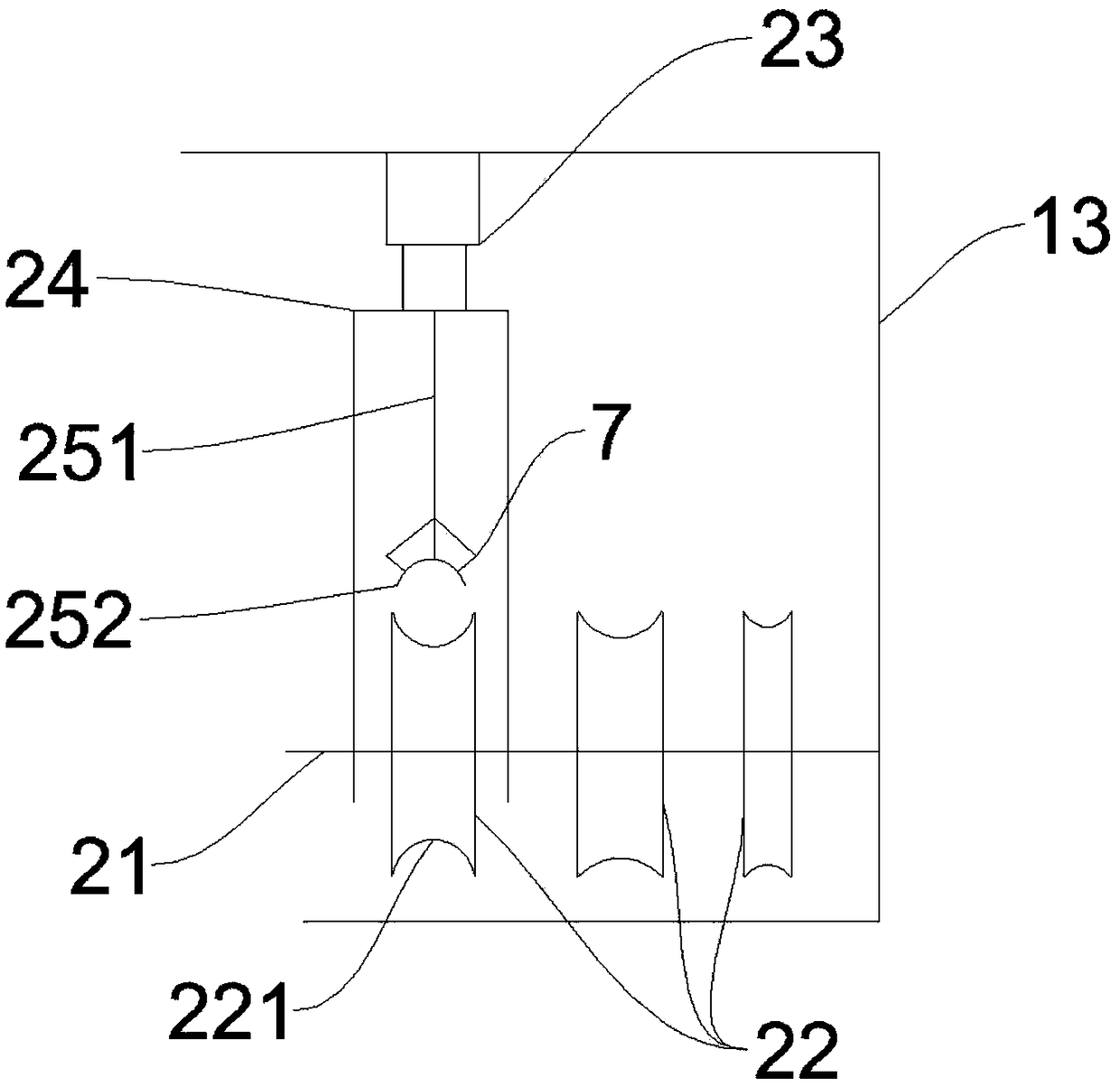

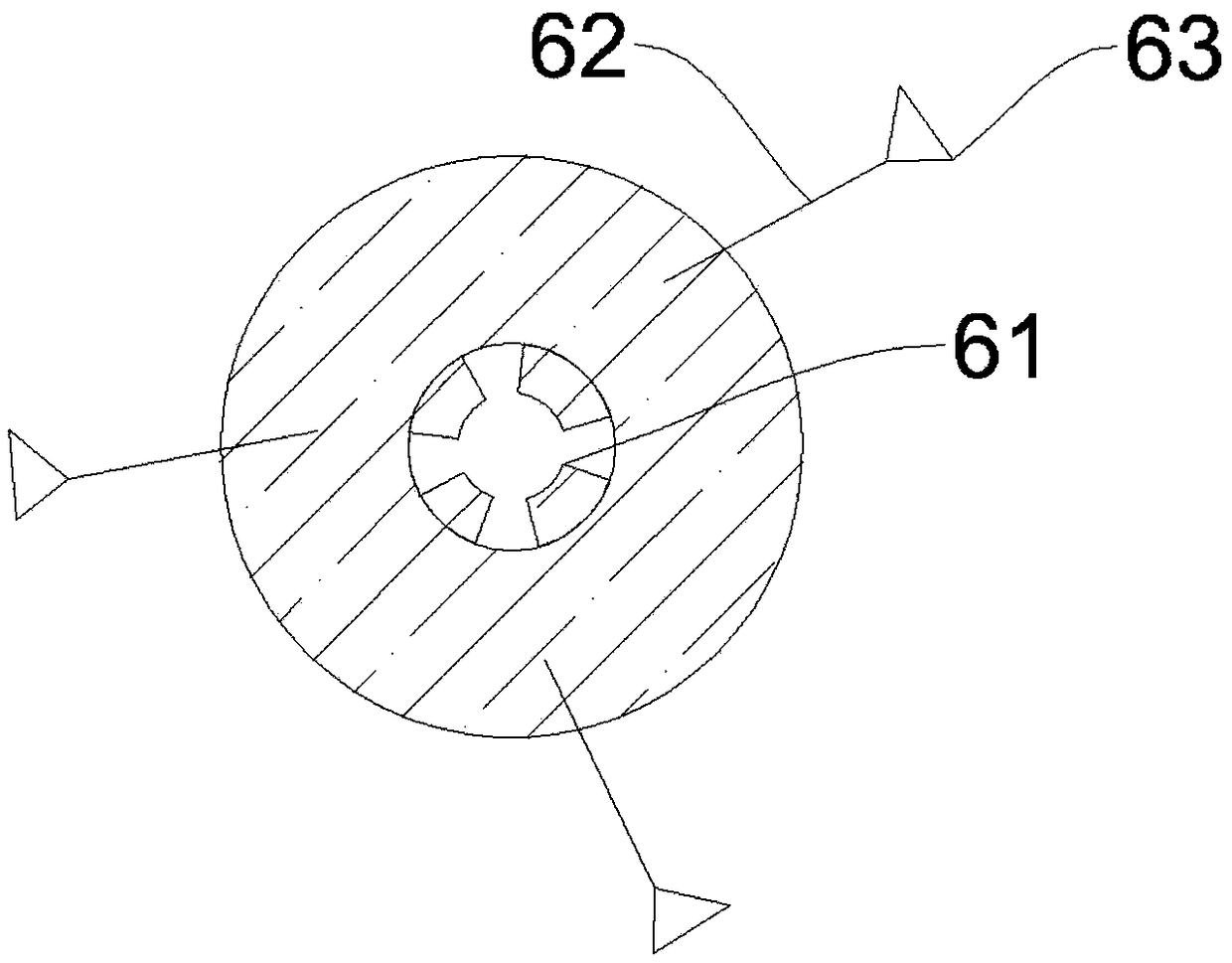

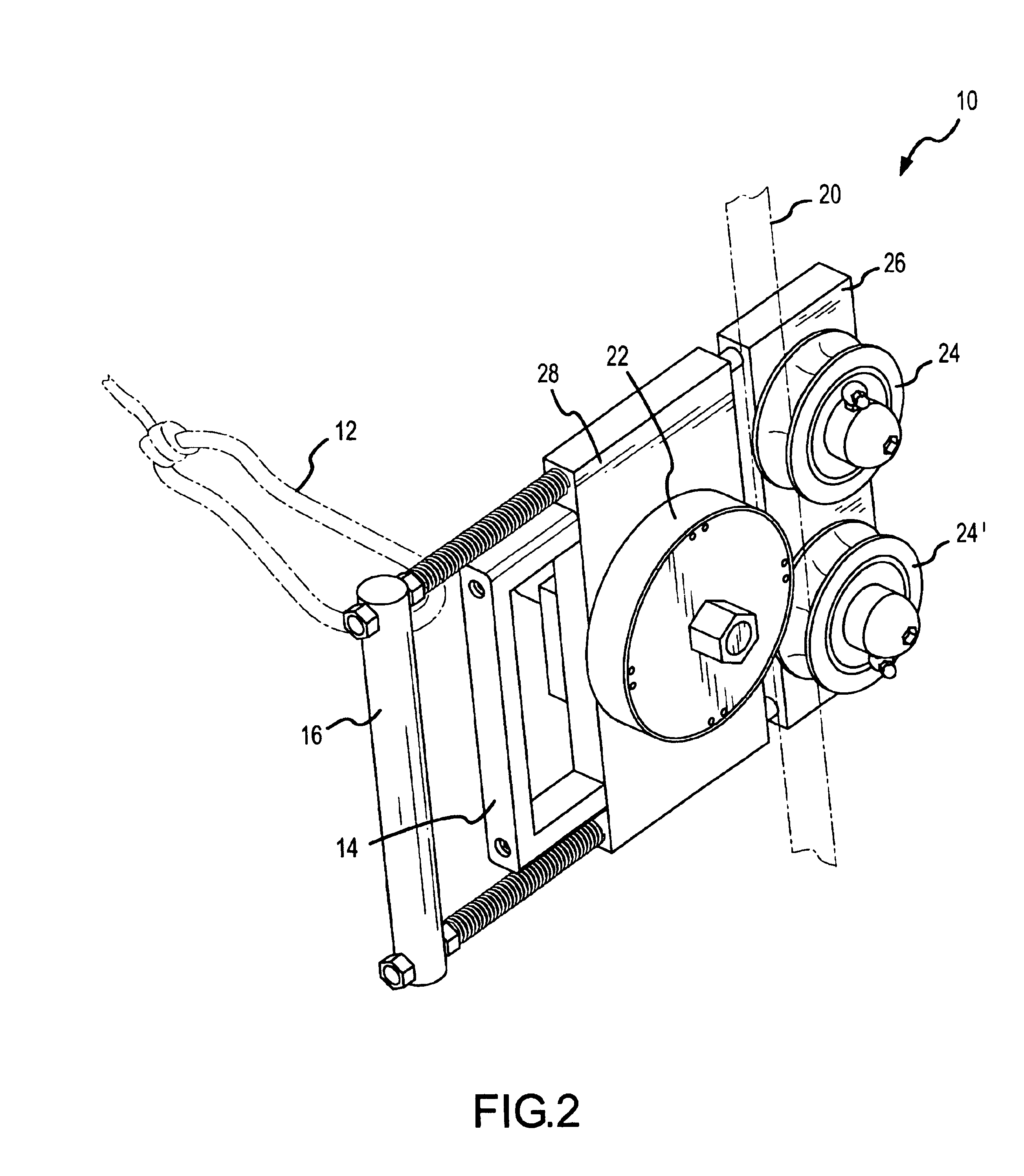

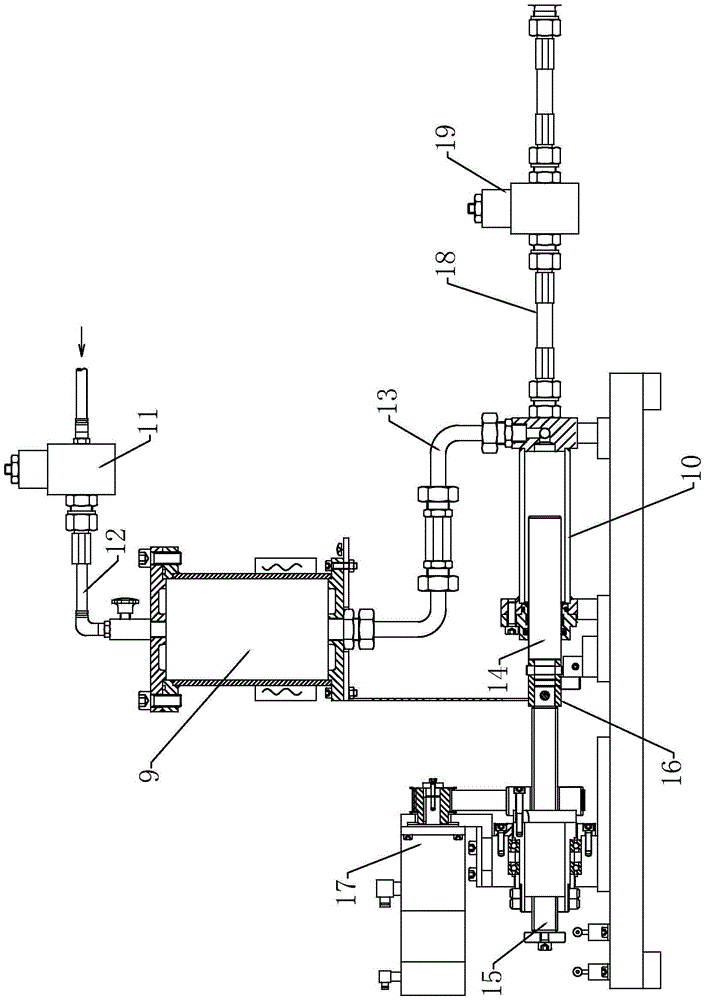

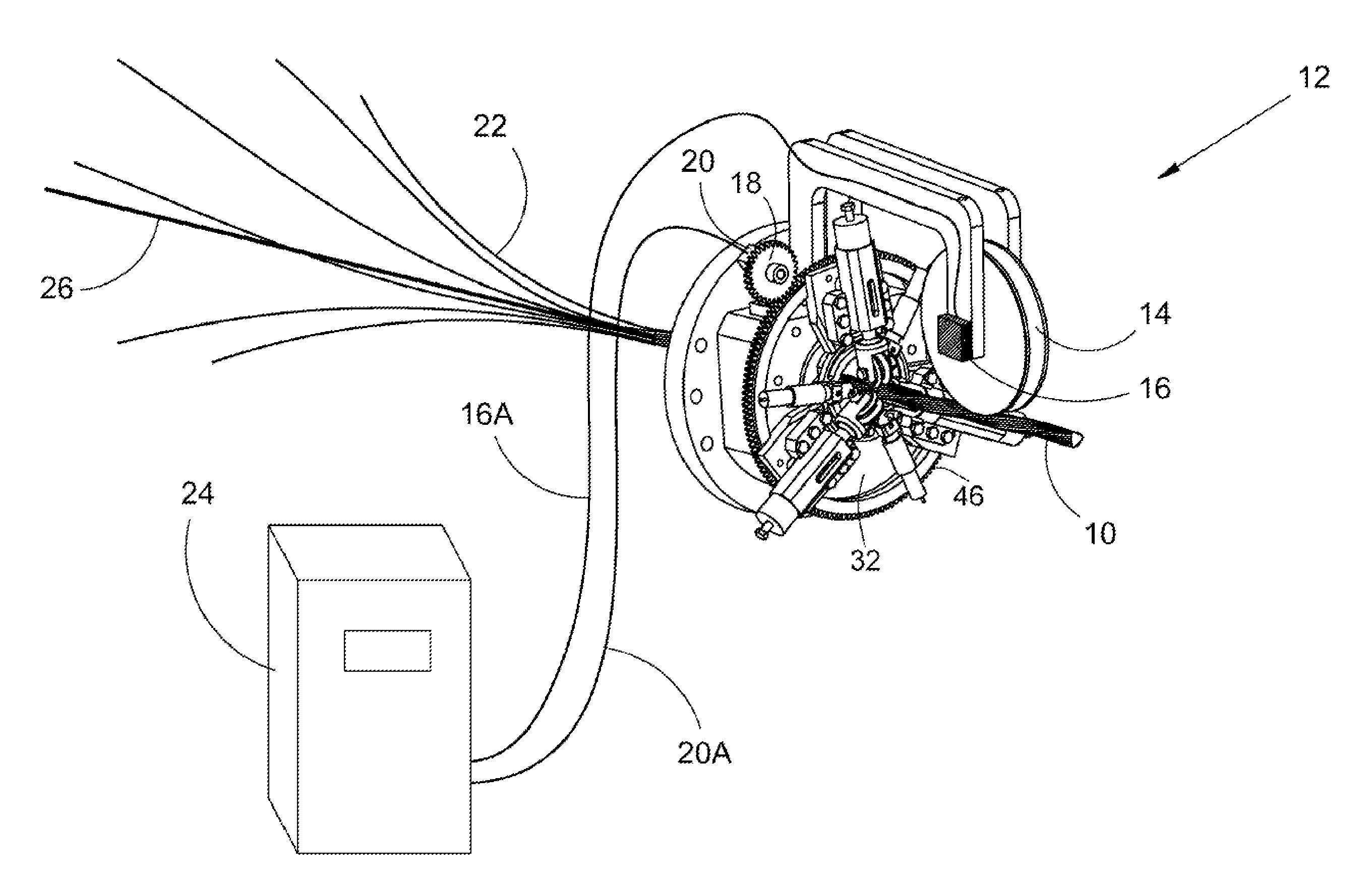

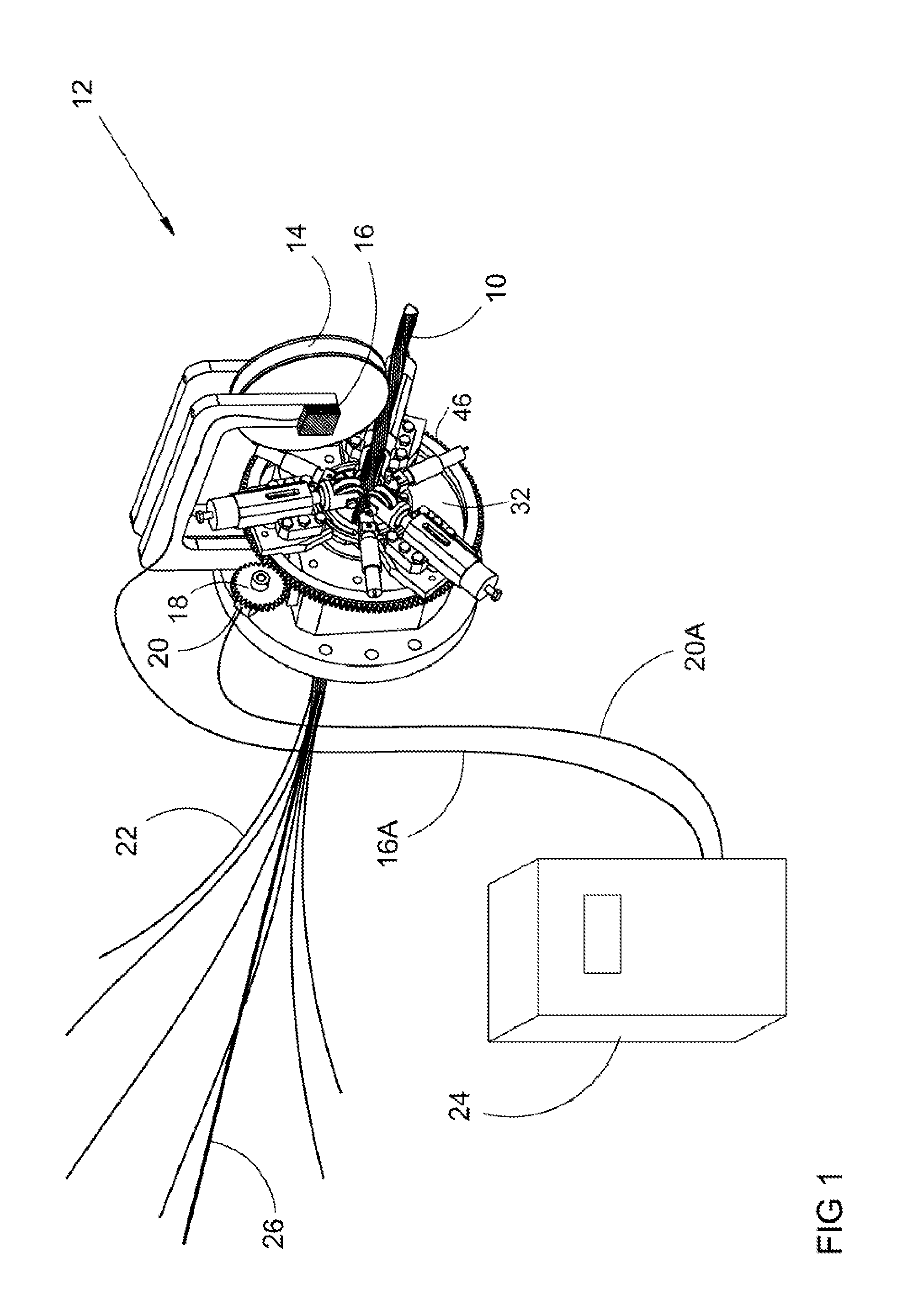

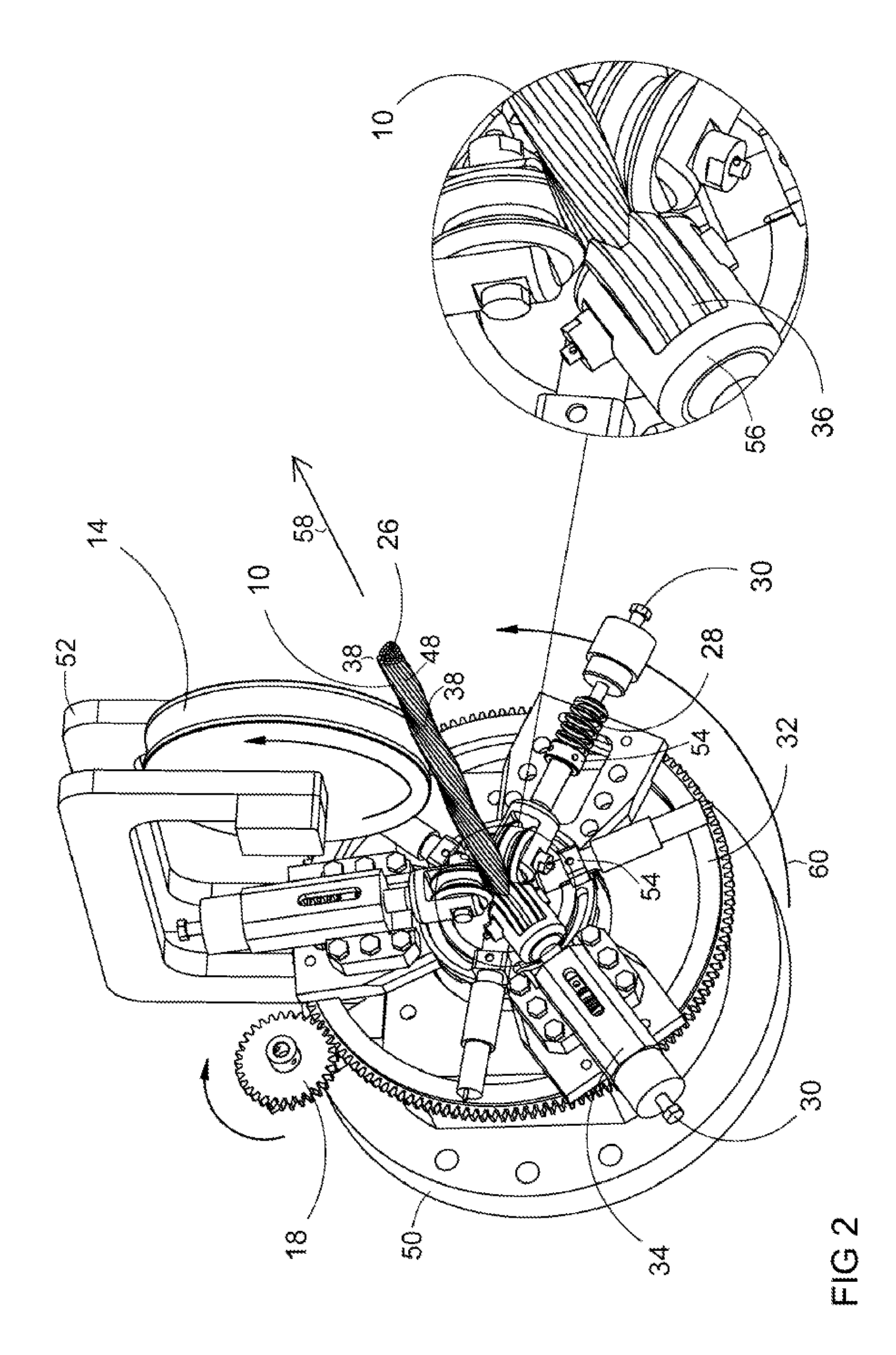

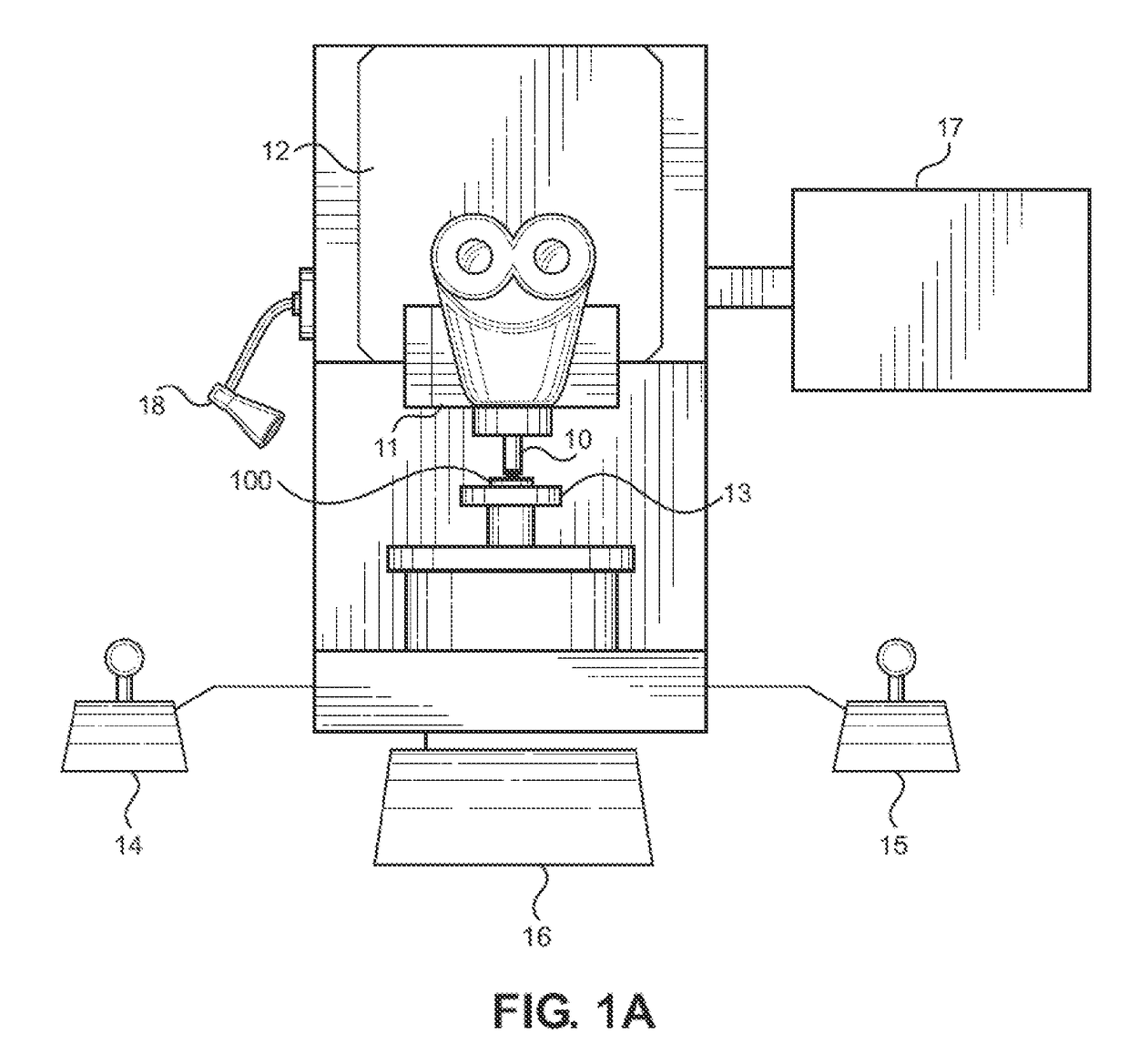

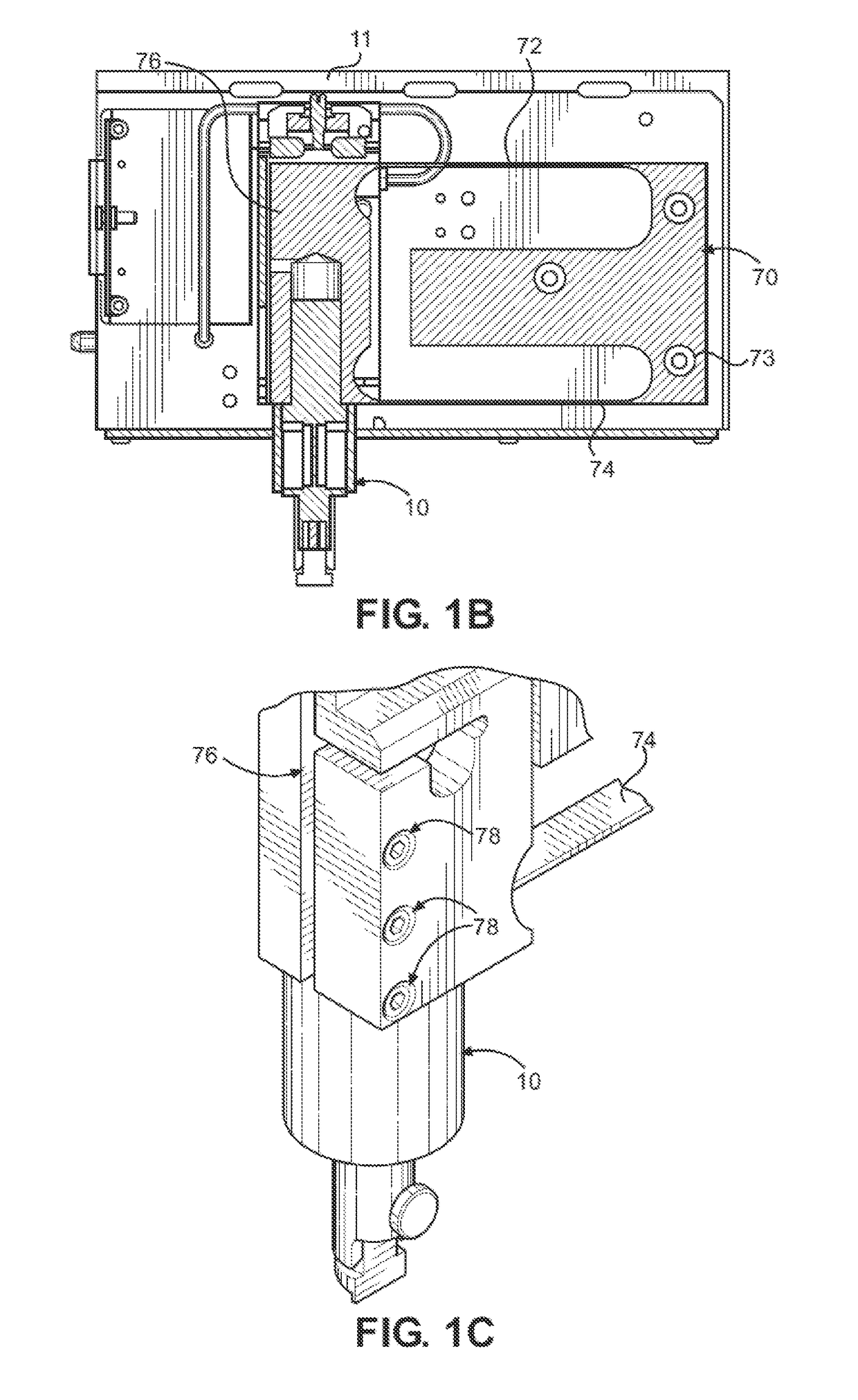

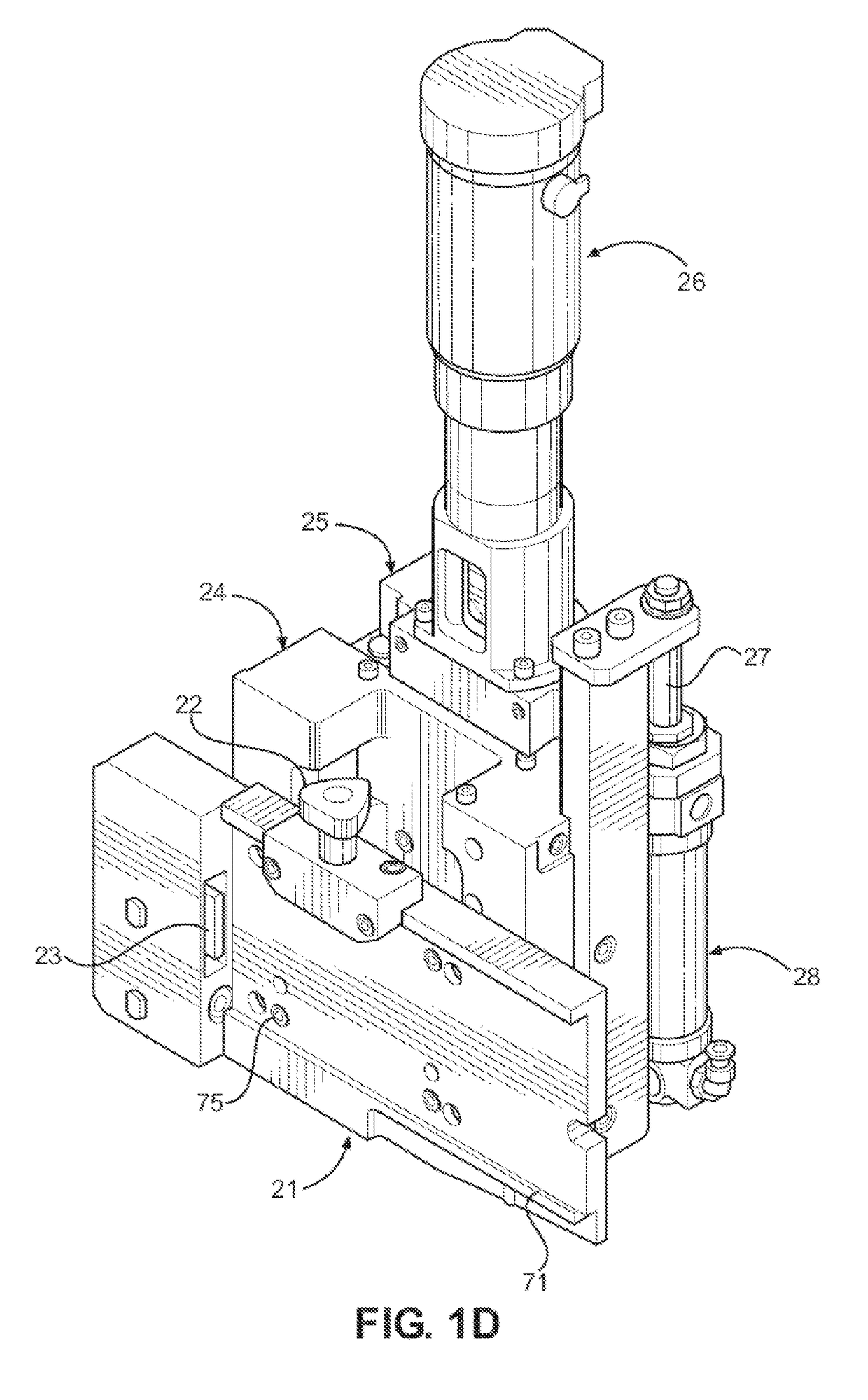

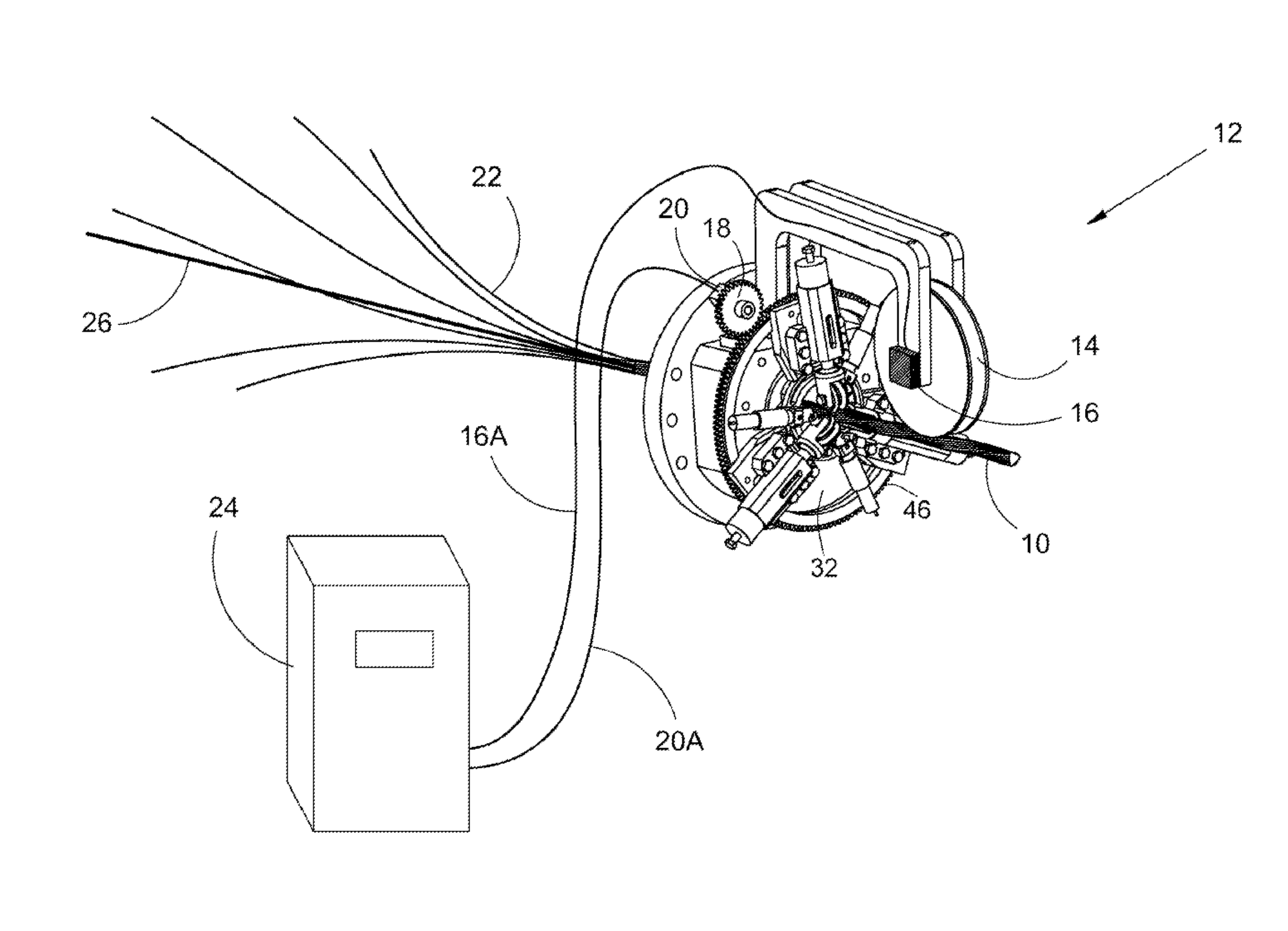

System and method for measuring geometry of non-circular twisted strand during stranding process

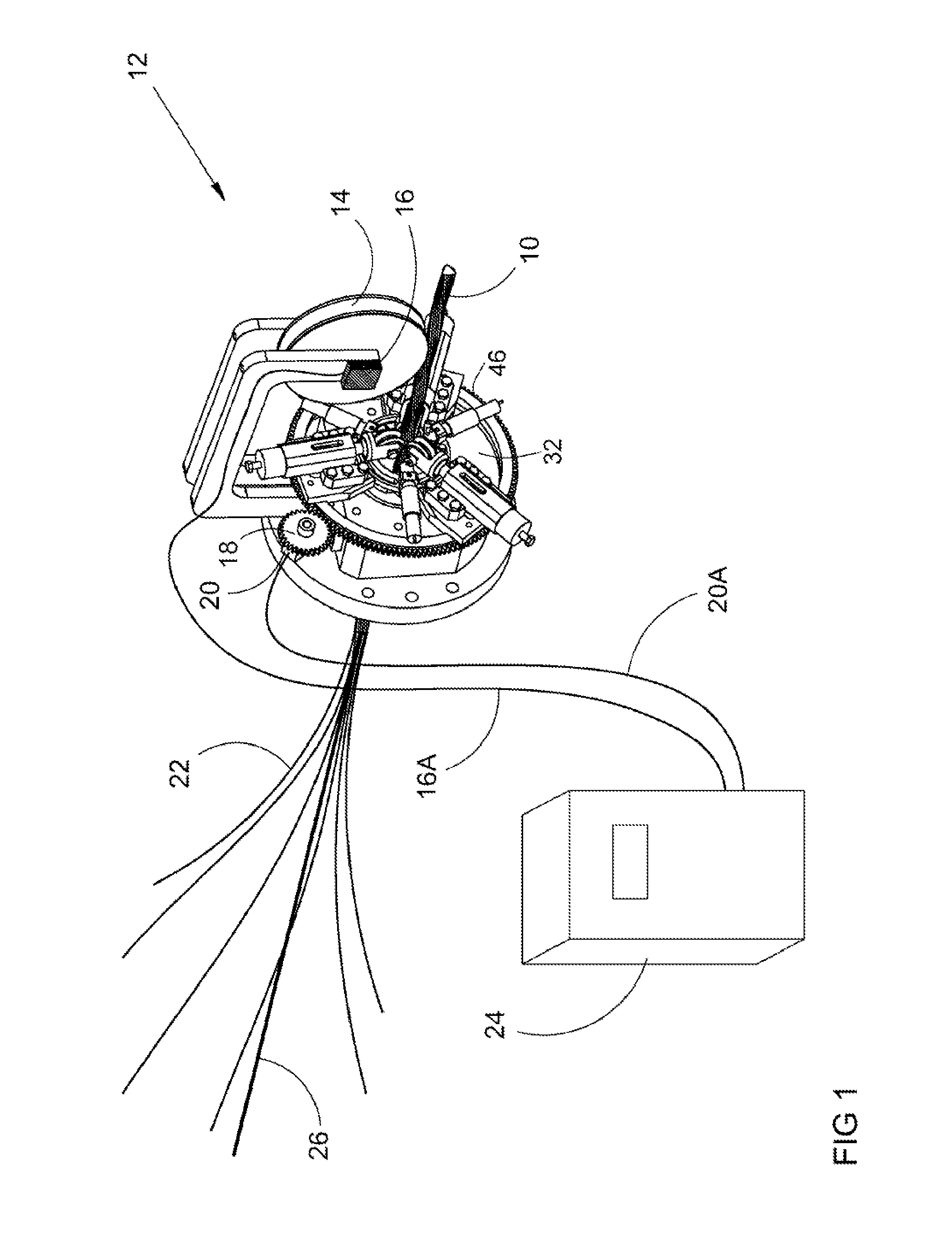

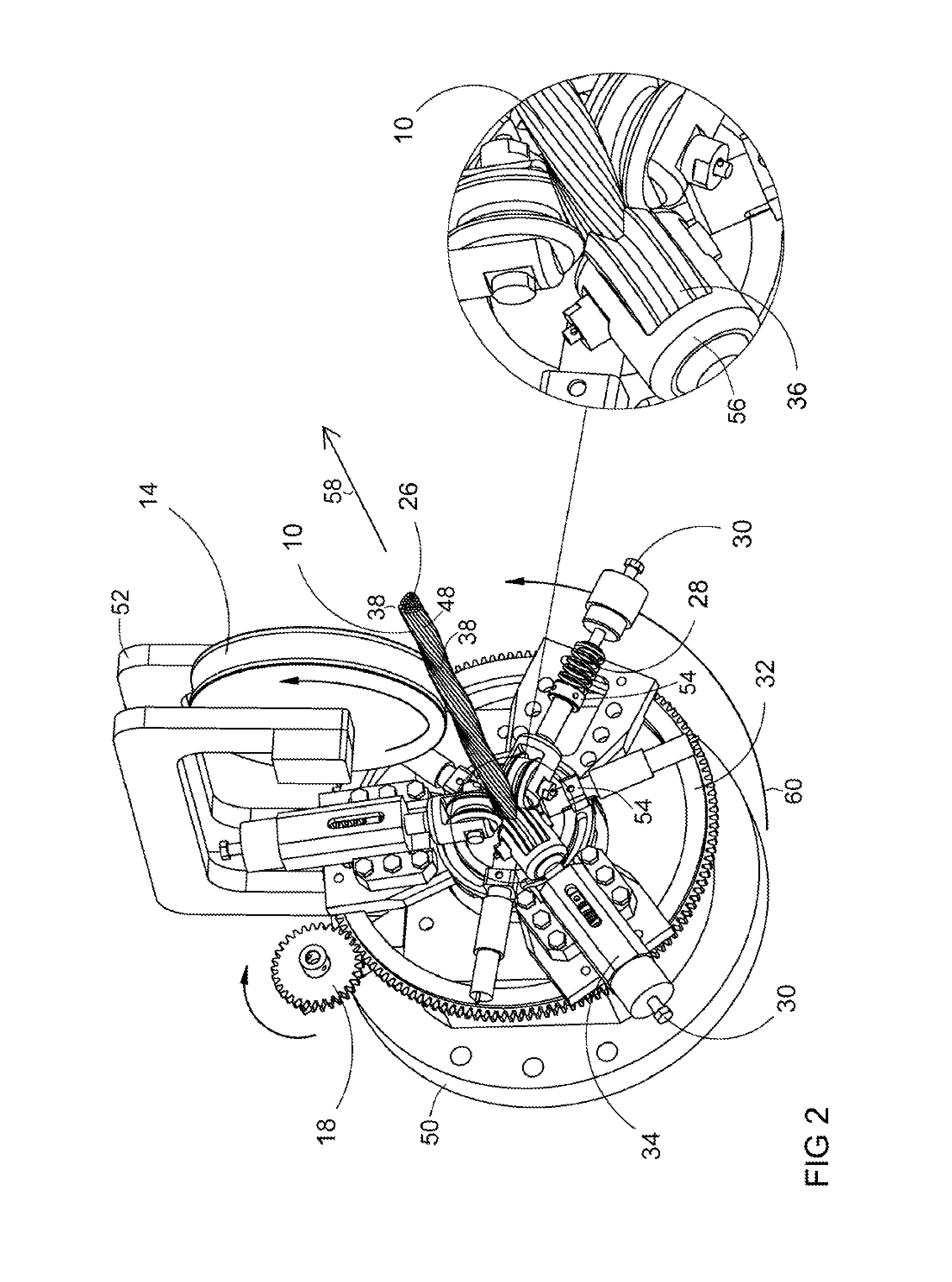

ActiveUS20140366392A1ControlMechanical counters/curvatures measurementsEngineeringLinear displacement

A system (12) for measuring geometry of a non-circular twisted strand (10) during a stranding process, the system comprising: a pulley (14), for being rotated by linear displacement of the strand (10) induced by the stranding process; a first encoder (16), for measuring the rotation of the pulley (14), thereby measuring the linear displacement of the strand (10); at least one embracing element (36), for embracing a vertex (38) or another zone (48) of the strand (10), for being rotated perpendicular (60) to the longitudinal position (58) of the strand (10), the embracing obtained by the non-circular character of the strand (10) rather than by friction, thereby allowing sliding the at least one embracing element (36) therealong; and a second encoder (20), for measuring the rotation of the at least one embracing element (36), thereby measuring the twist character of the strand (10).

Owner:ASHKENAZI RONEN

Bond test apparatus and method

ActiveUS20190056307A1Electrical testingMaterial strength using tensile/compressive forcesEngineeringBending stiffness

A bond test apparatus comprises a test tool assembly 200 comprising a test tool 40 configured to contact a bond during a bond test, a flexure 80 coupled to the test tool assembly, and a sensor. The sensor is configured to provide a measurement of a displacement of a first end of the flexure 80 relative to a second end of the flexure on application of a force to the flexure, and a processor is configured to receive a displacement signal from the sensor and, based on the displacement signal and optionally a known stiffness of the flexure, to determine the force on the flexure. A cartridge for a bond test apparatus, a method of measuring a force in a bond test apparatus, and a method of measuring the closing force on the jaws of a bond test tool are also provided.

Owner:NORDSON CORP

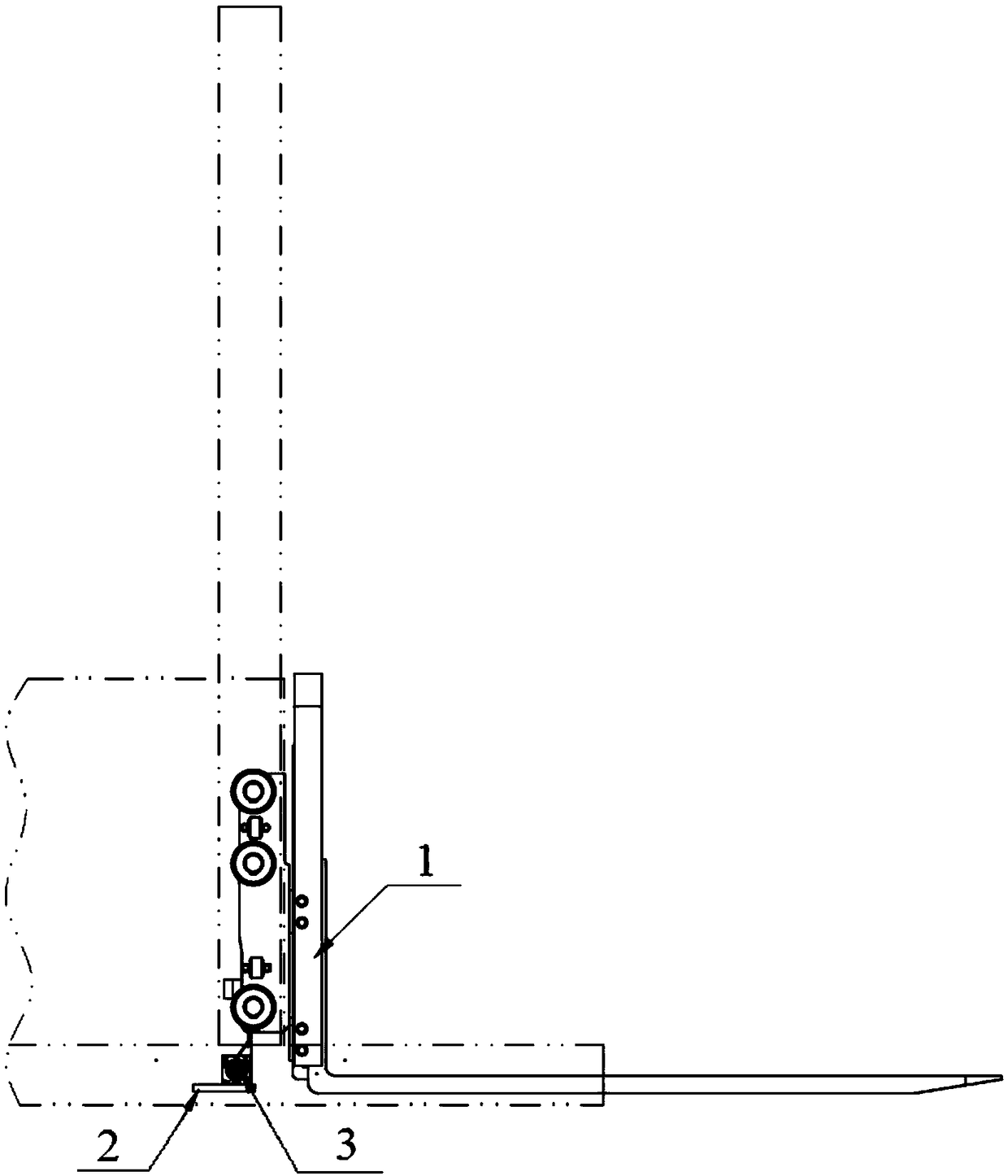

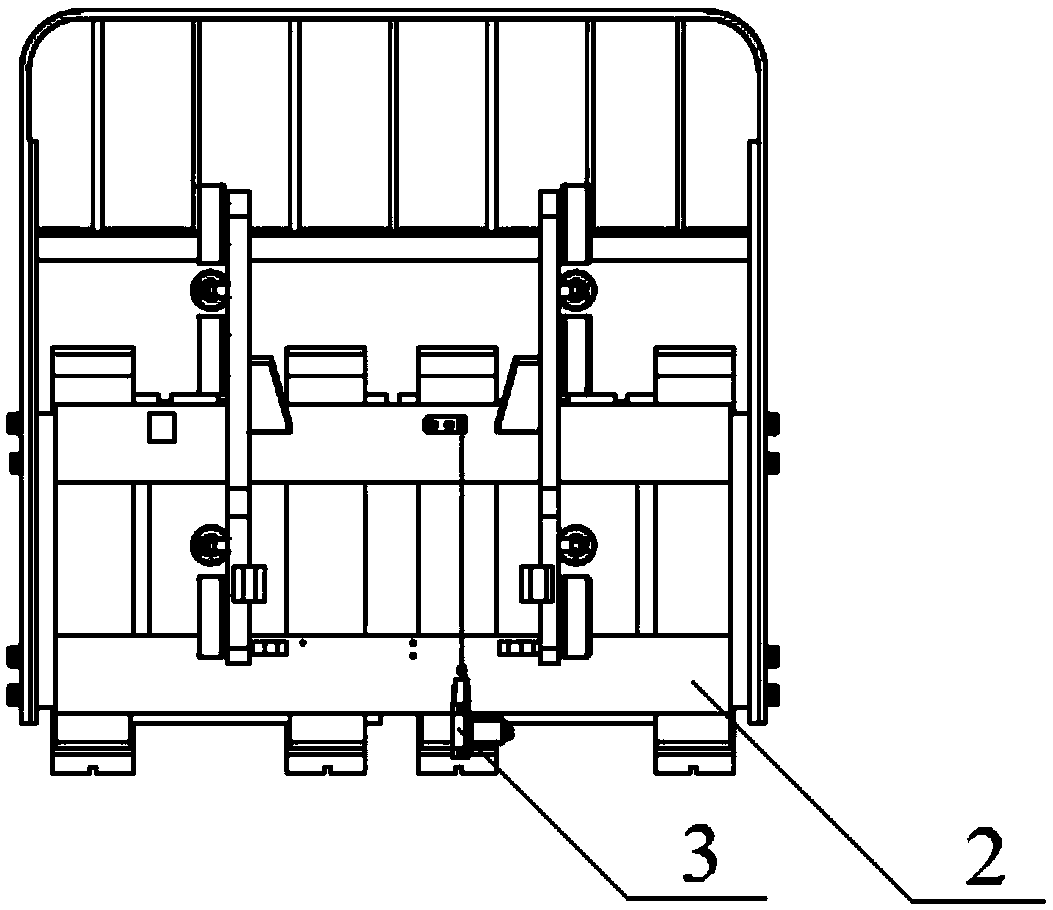

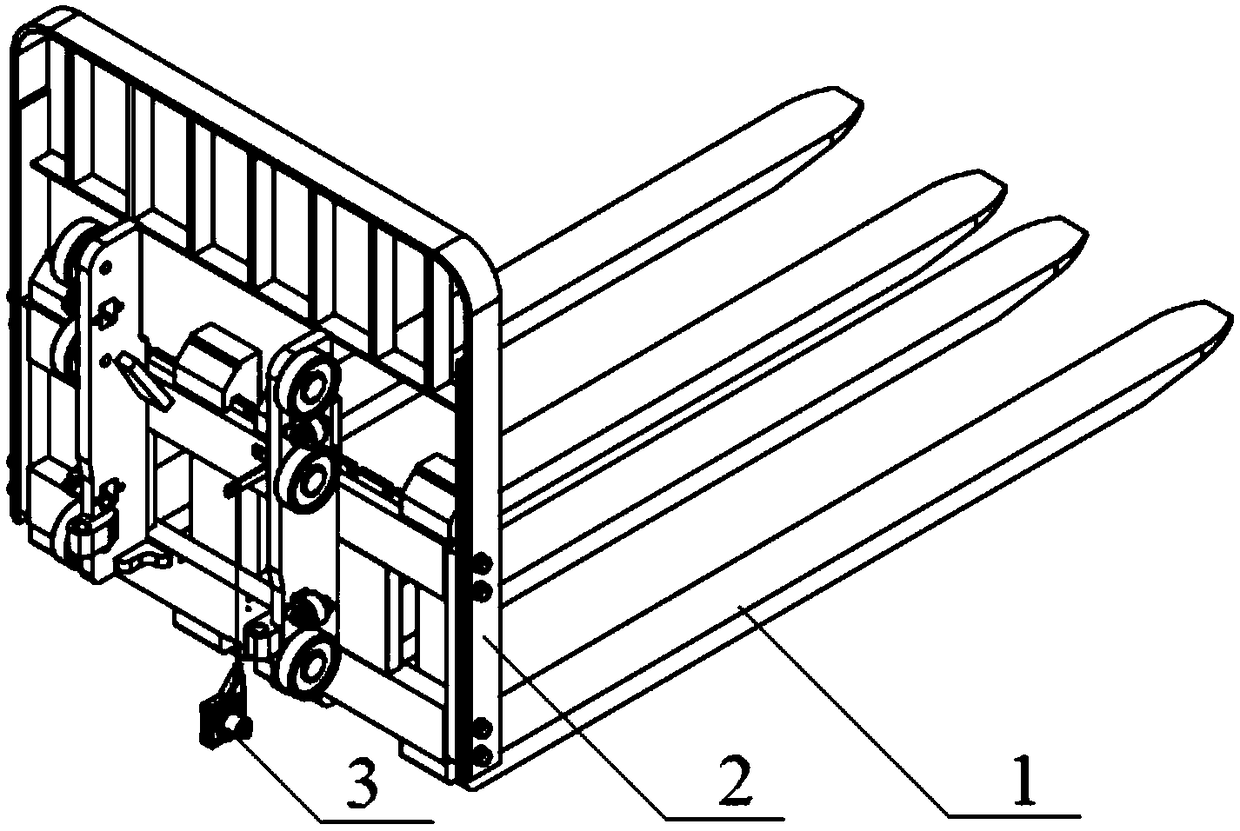

Fork height monitoring device

The invention provides a fork height monitoring device. Real-time lifting height information of a fork is converted into an electrical signal by a pull rope displacement sensor; the electrical signalis transmitted to a display control device; the display control device calculates real-time height of the fork according to the electrical signal received, and displays the real-time height via a screen; finally, an operator may monitor in real time and accurately know the lifting height information of the fork.

Owner:HANGCHA GRP +1

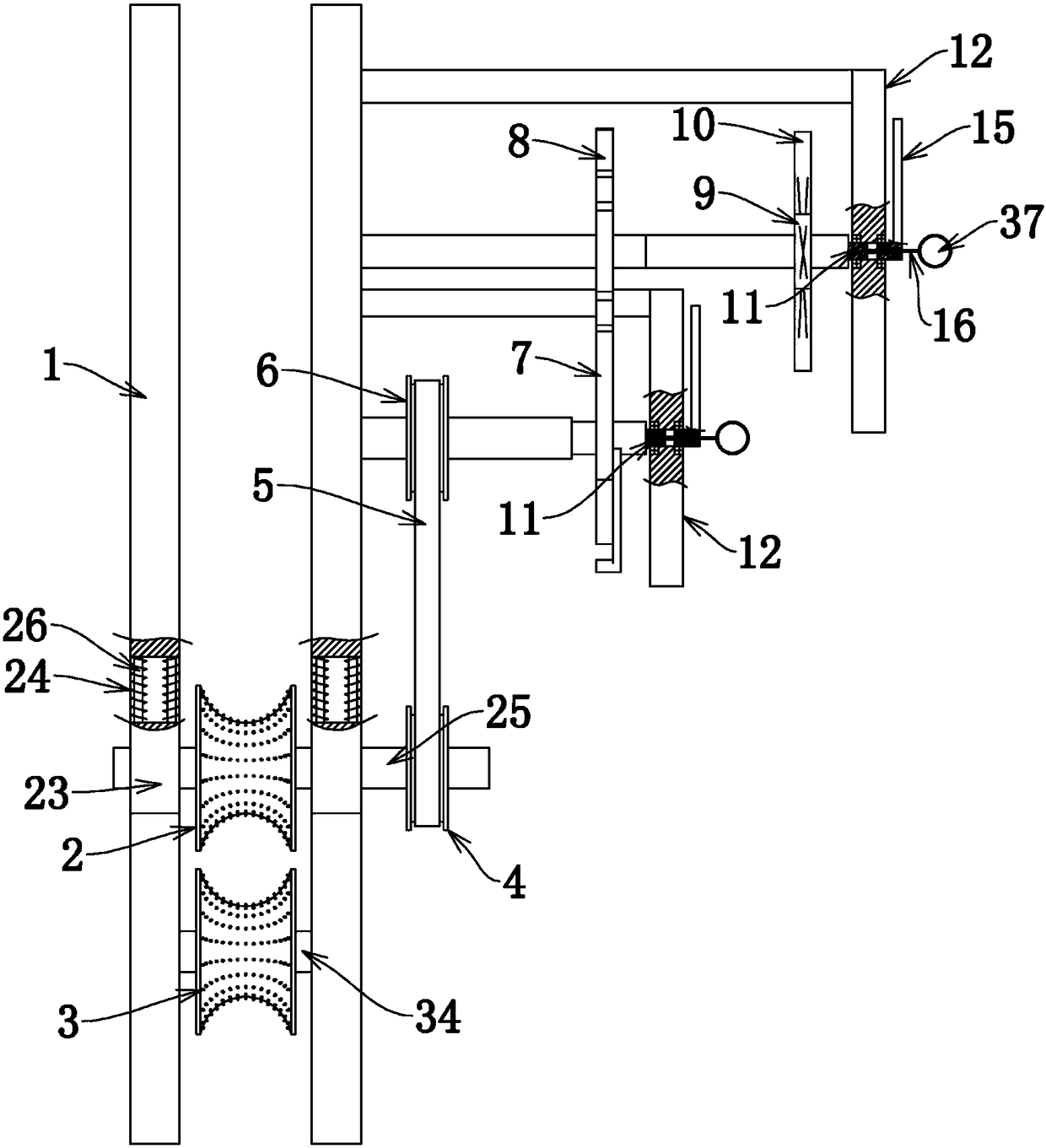

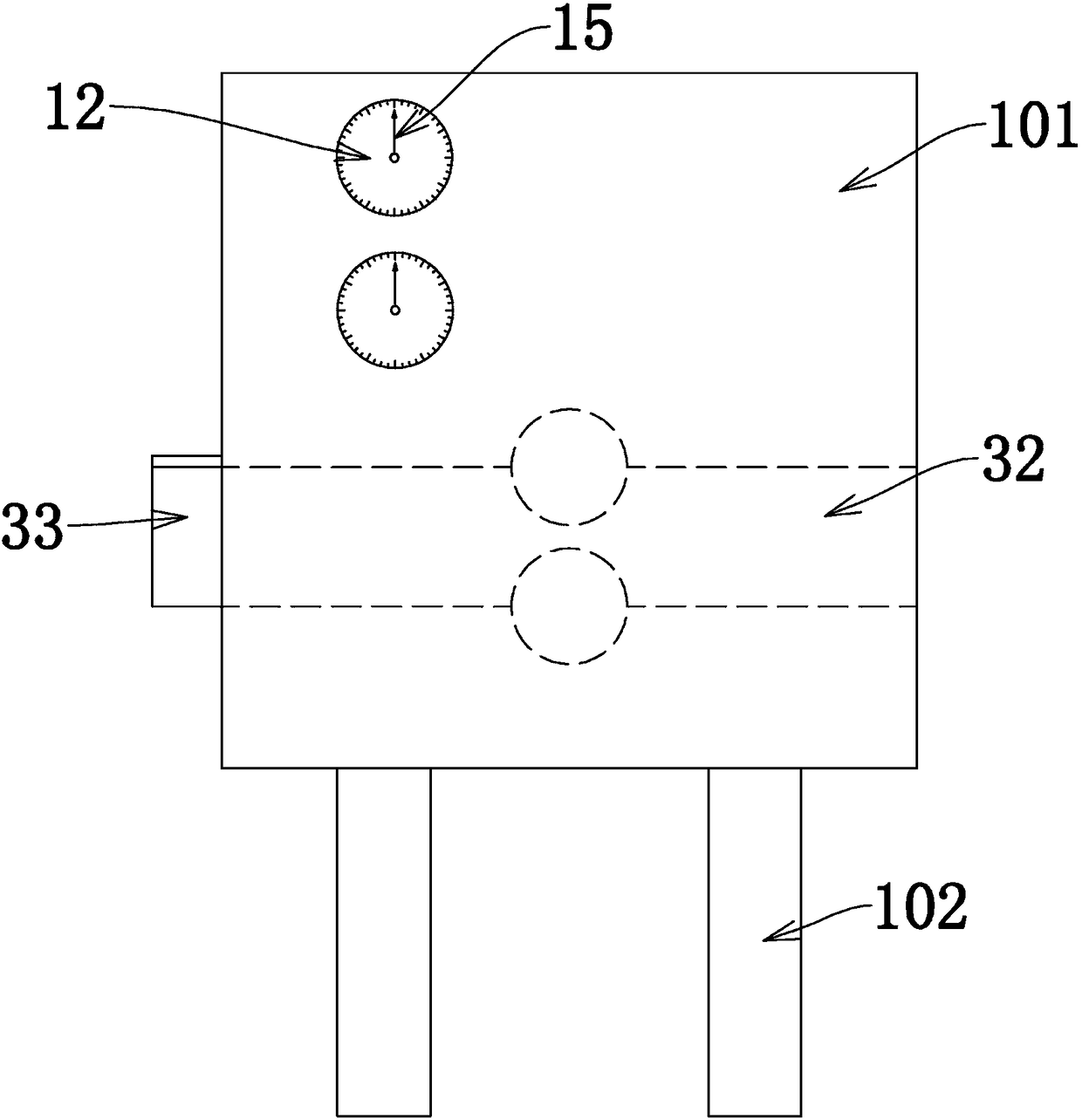

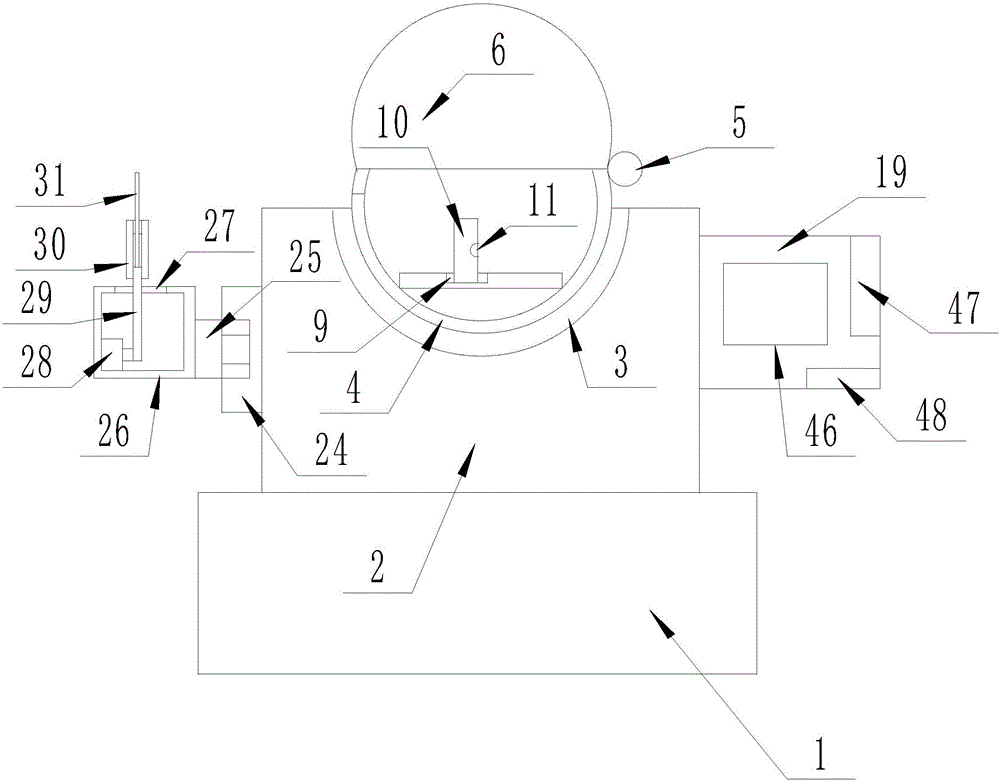

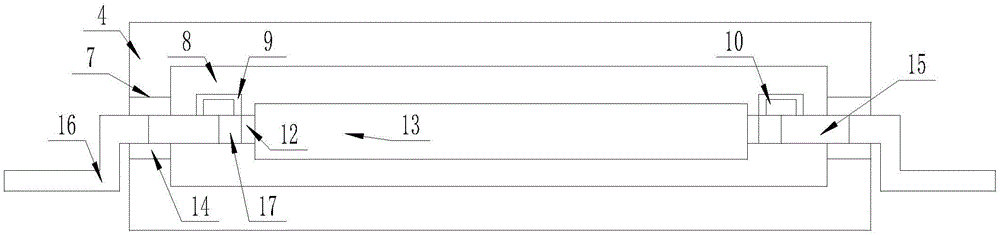

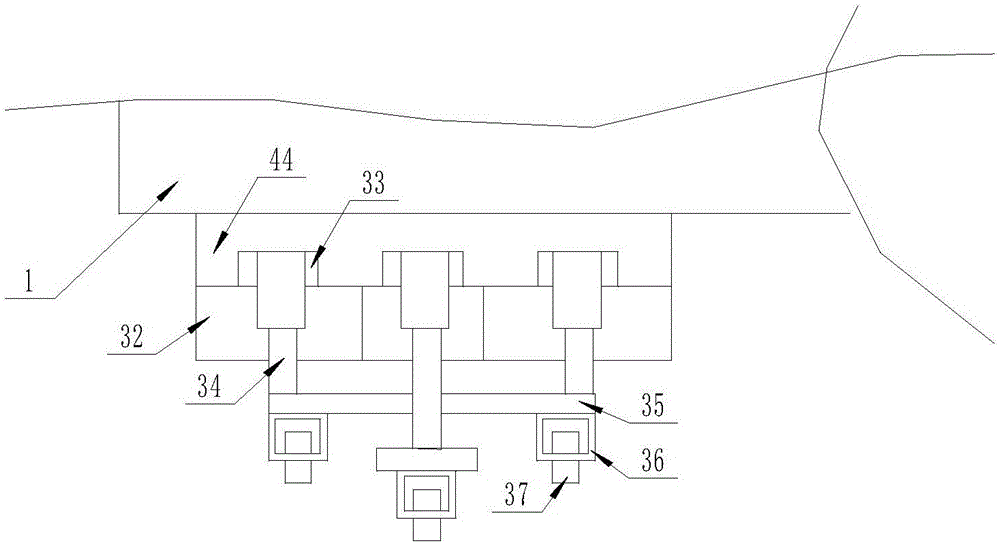

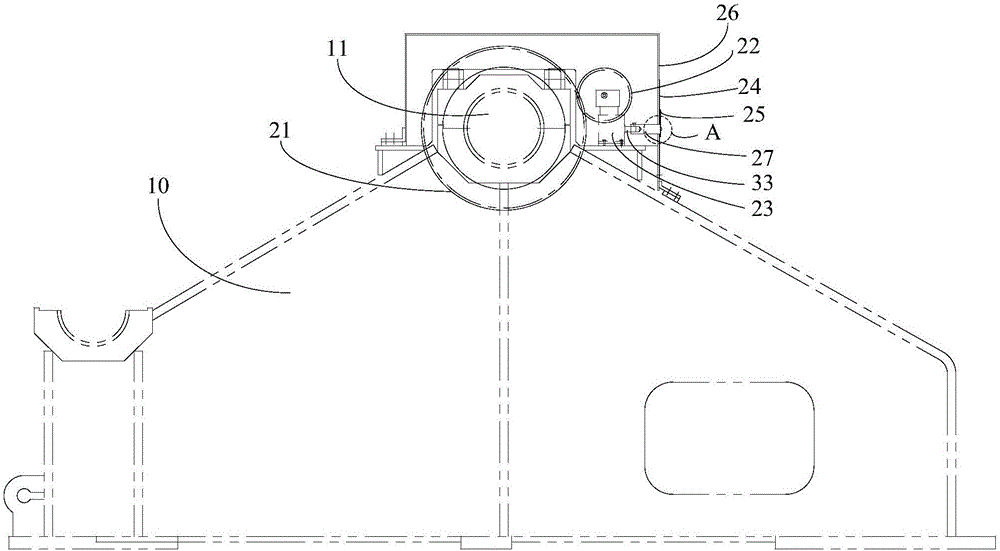

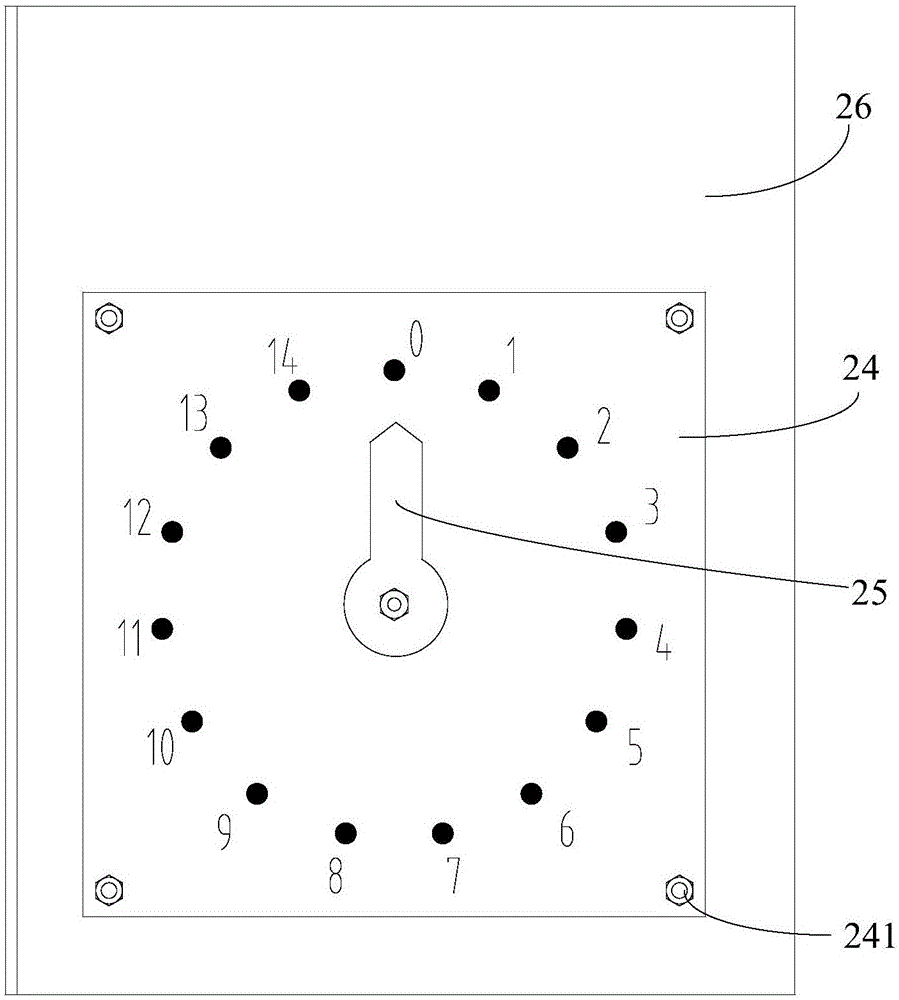

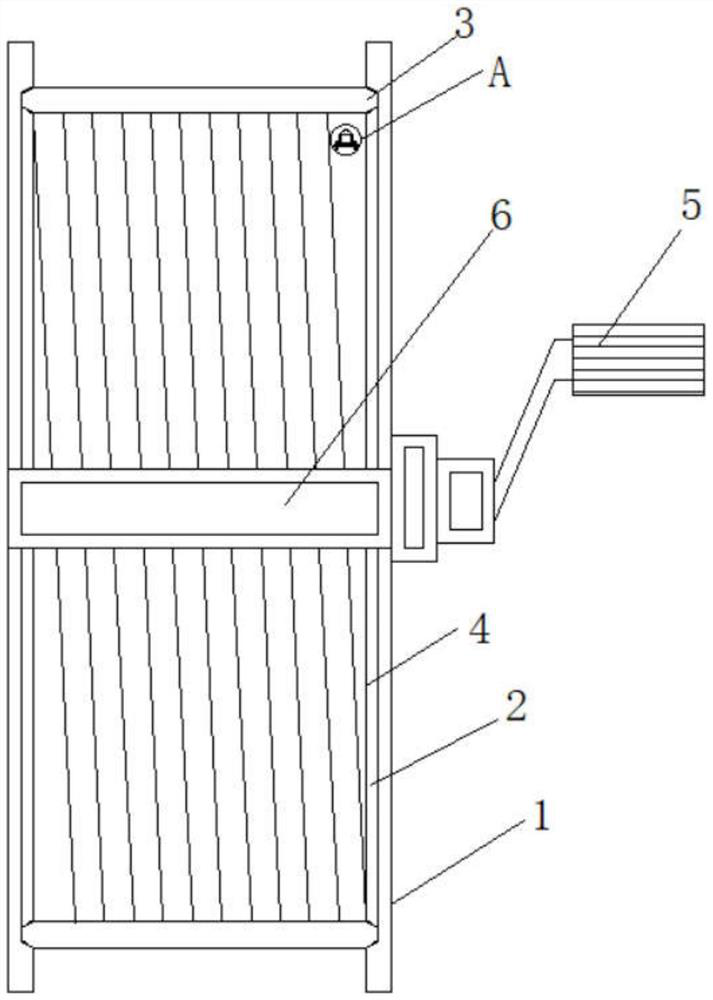

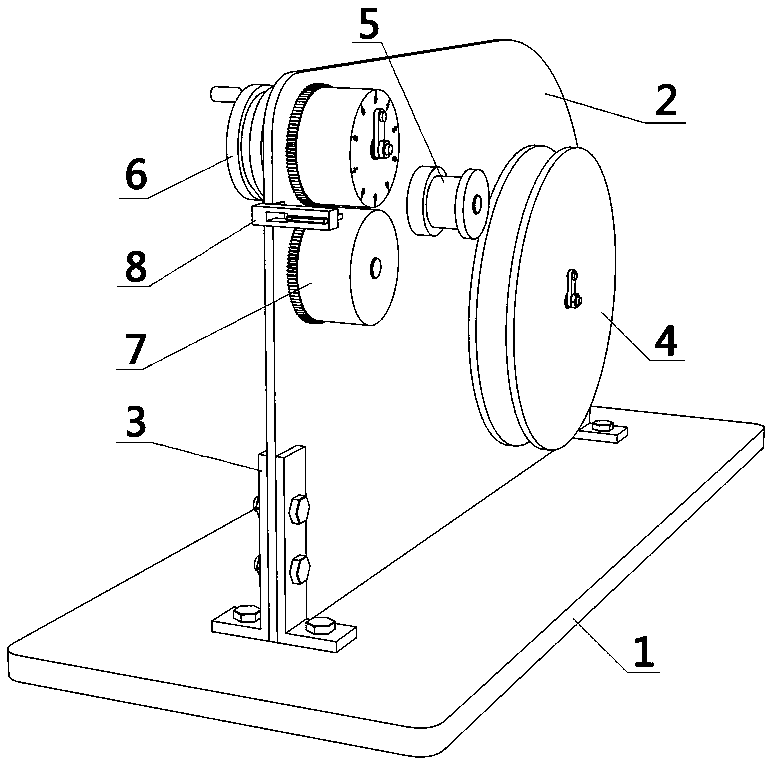

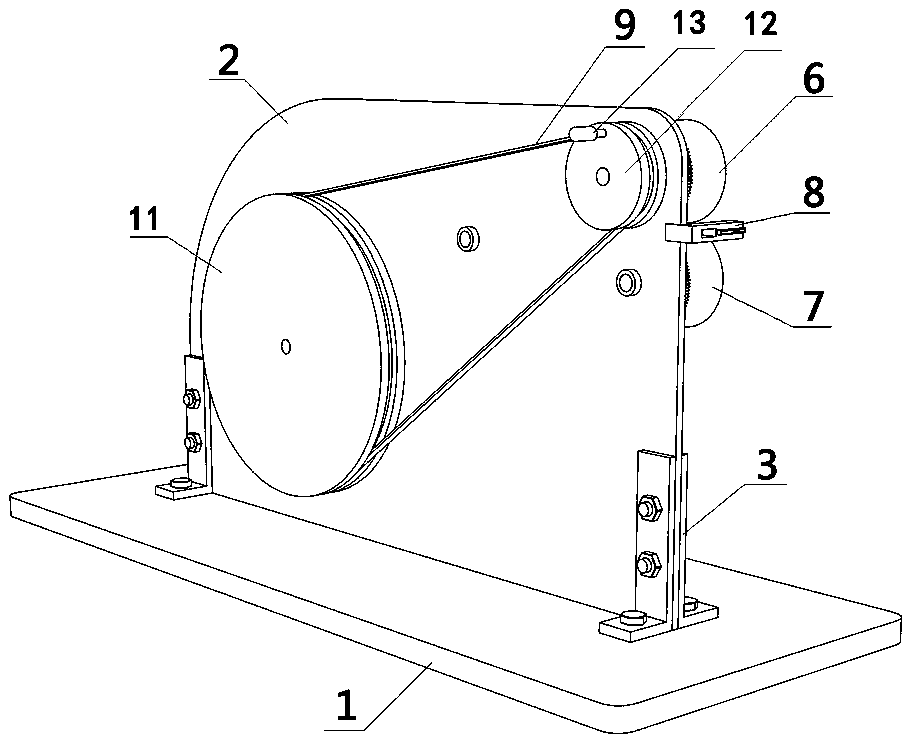

Road and bridge construction measurement device

ActiveCN108286925AReduce labor intensityEasy to useMechanical length measurementsMeasurement deviceEconomic benefits

The present invention provides a road and bridge construction measurement device. The problems are effectively solved that errors are large, labor intensity is high, the efficiency is low and economicbenefit is lost when manual length measurement is performed. The method provided by the invention reduces the consumption of raw materials, saves the labor and save the cost so as to improve the economic benefit. The method employs a mechanical structure to achieve measurement of the length of a steel strand with no need for electric energy so as to facilitate usage in the construction process, have convenient and accurate measurement and low worker labor intensity and be suitable for batch measurement of the steel strand, after the steel strand reaches a predetermined length, a runner can belocked and is not rotated, the length of the steel strand is a required length, and after the a structure on a graduated disc is set, the method can automatically obtain the steel strand with the required length.

Owner:郝铭

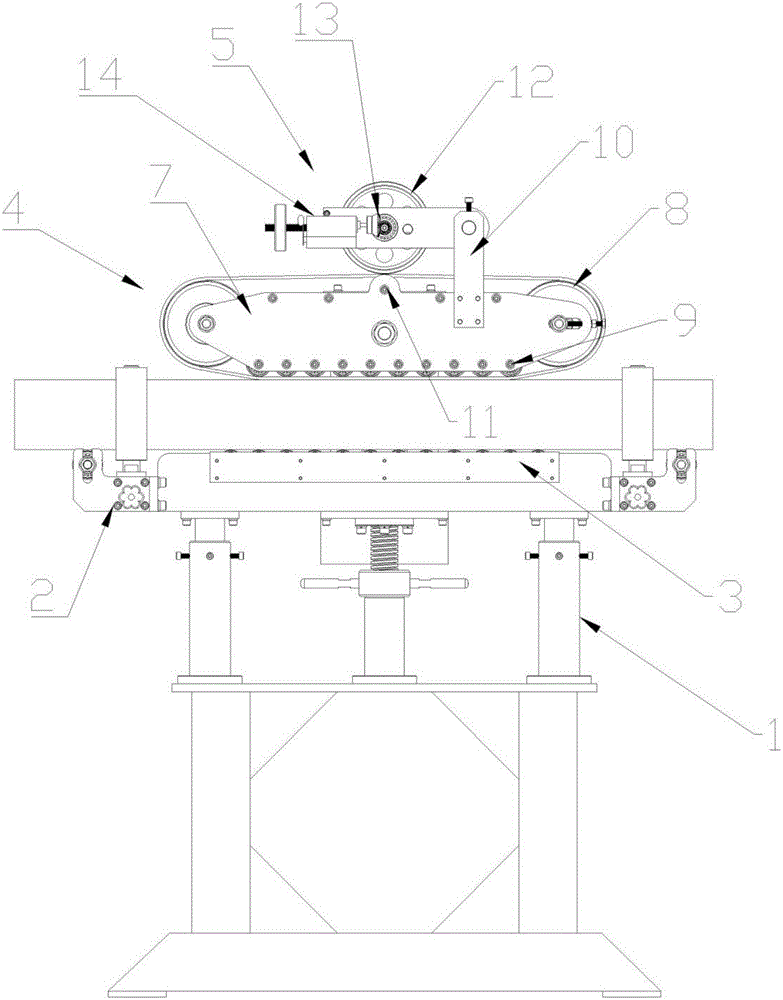

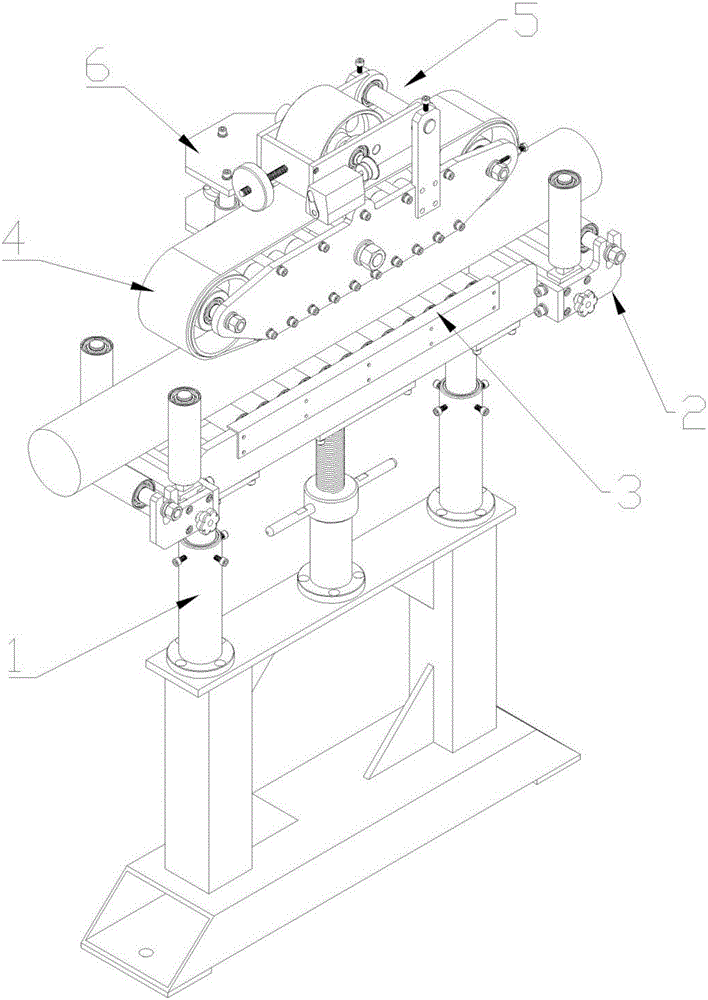

Novel length counter

InactiveCN106643416AIncrease contact areaPrevent slippingFilament handlingMechanical length measurementsEngineeringMechanical engineering

The invention discloses a novel length counter. A lifting fixed device is provided with guide apparatuses, a lower support roller apparatus, and a lifting apparatus. The guide apparatuses are disposed at two ends of the lower support roller apparatus, and the upper part of the lifting apparatus is provided with an upper compression roller apparatus. A material channel is formed between the lower support roller apparatus and the upper compression roller apparatus, and a length counting apparatus is disposed above the upper compression roller apparatus. The upper compression roller apparatus and the length counting apparatus rotate synchronously. The overall height of the length counting apparatus is adjusted through the lifting fixed device. The height of the upper compression roller apparatus is adjusted through the lifting fixed device, thereby changing the size of the material channel between the lower support roller apparatus and the upper compression roller apparatus. The length counter increases the contact area through an array roller transmission cable, and prevents the slipping. A length counting standard wheel and an array roller rotate synchronously, and the operation distance of the cable is recorded, thereby improving the counting precision. The central height where the cable passes is adjusted through the lifting fixed device. The size of the material channel is changed through the lifting device, thereby enlarging the application range of the length counter.

Owner:WUXI NANFANG ELECTROTECHN MACHINERY

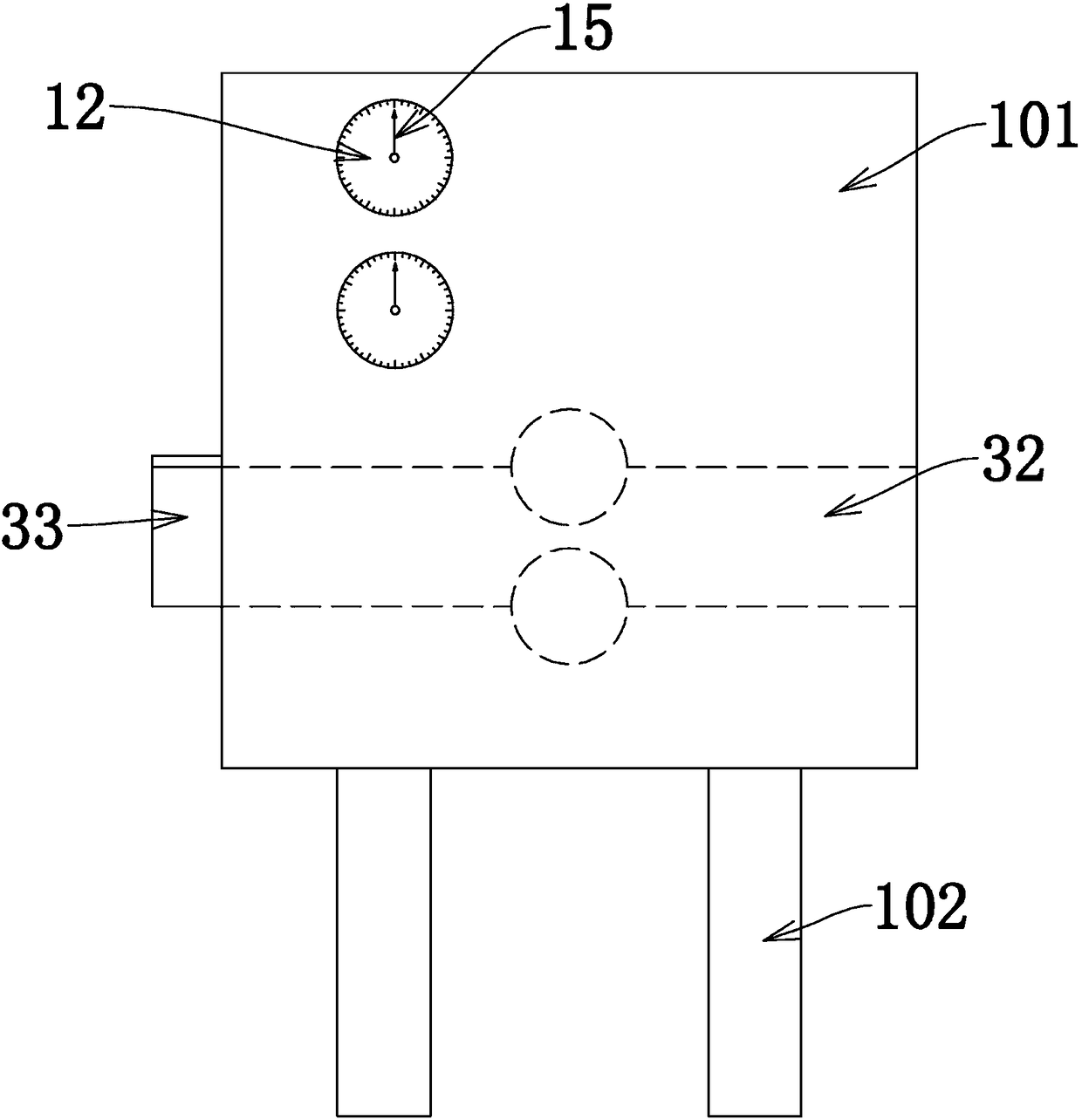

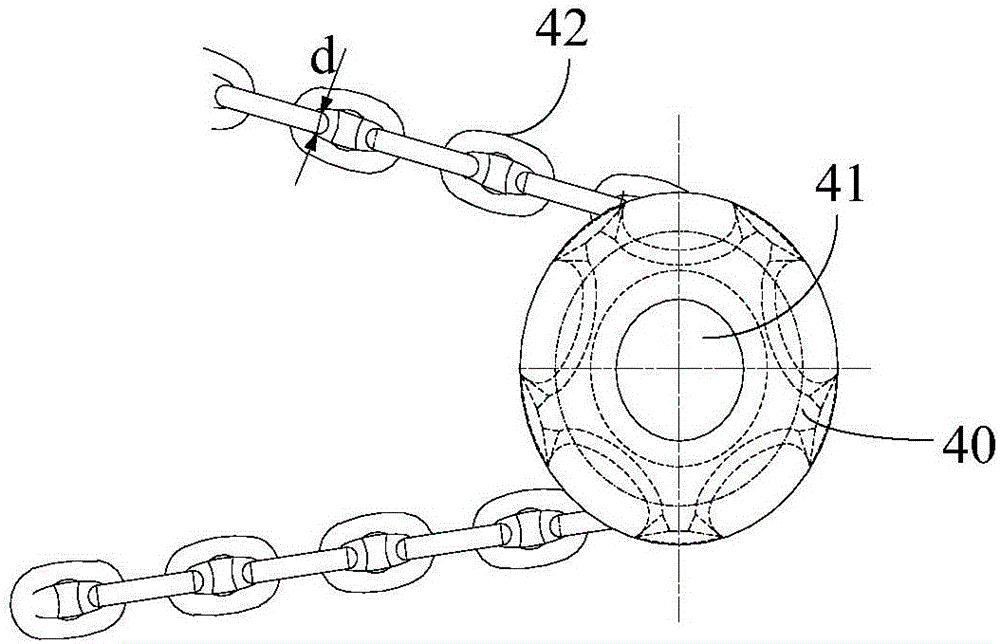

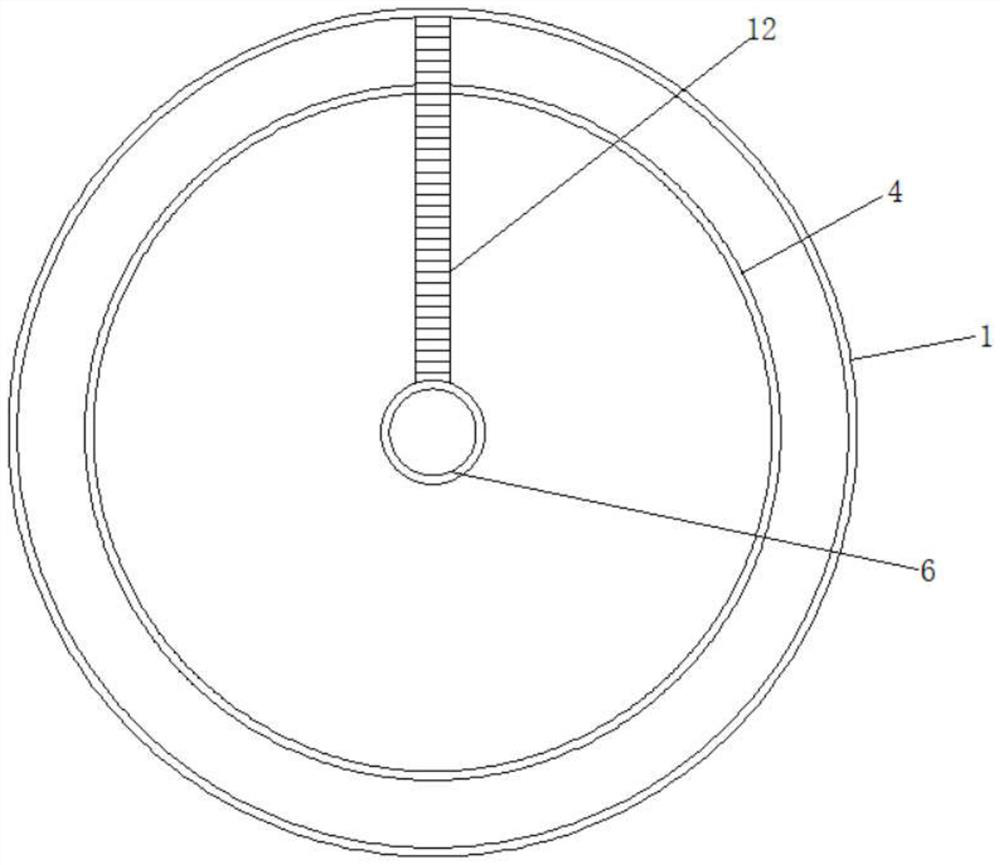

Anchor chain length indicating device

InactiveCN106802122AAvoid the problem of inaccurate lengthWaterborne vesselsMechanical length measurementsGear wheelReduction drive

The present invention discloses an anchor chain length indicating device, and belongs to the ship machinery technology field. The device comprises a first gear, a second gears, a decelerator, a pointer and a dial which are coaxially arranged on the rotation shaft of a cable lifter. The second gear is arranged on the input shaft of the decelerator, the second gear is engaged with the first gear, and the pointer is vertically connected with the output shaft of the decelerator. The scales showing the length of the anchor chain are distributed on the dial, and the scales are arranged all around the output shaft of the decelerator so as to obtain the length of the released anchor chain through the scales indicated by the pointer when the cable lifter rotates and avoid the problem that the length of the released anchor chain is not accurate through visual estimation.

Owner:WUHAN MARINE MACHINERY PLANT

System and method for measuring geometry of non-circular twisted strand during stranding process

A system (12) for measuring geometry of a non-circular twisted strand (10) during a stranding process, the system comprising: a pulley (14), for being rotated by linear displacement of the strand (10) induced by the stranding process; a first encoder (16), for measuring the rotation of the pulley (14), thereby measuring the linear displacement of the strand (10); at least one embracing element (36), for embracing a vertex (38) or another zone (48) of the strand (10), for being rotated perpendicular (60) to the longitudinal position (58) of the strand (10), the embracing obtained by the non-circular character of the strand (10) rather than by friction, thereby allowing sliding the at least one embracing element (36) therealong; and a second encoder (20), for measuring the rotation of the at least one embracing element (36), thereby measuring the twist character of the strand (10).

Owner:ASHKENAZI RONEN

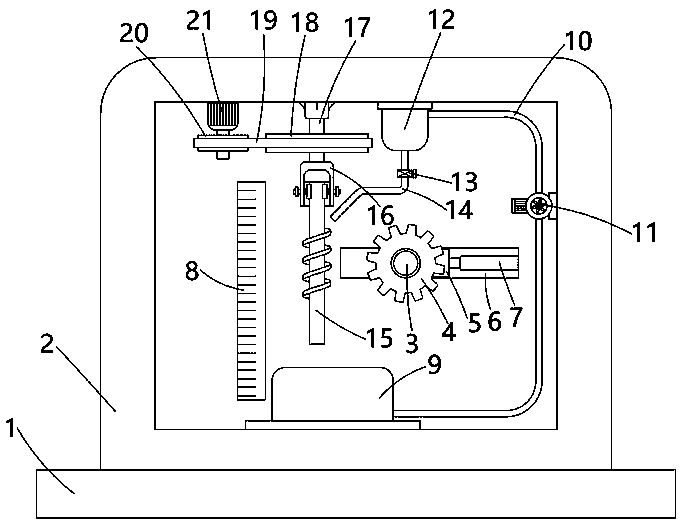

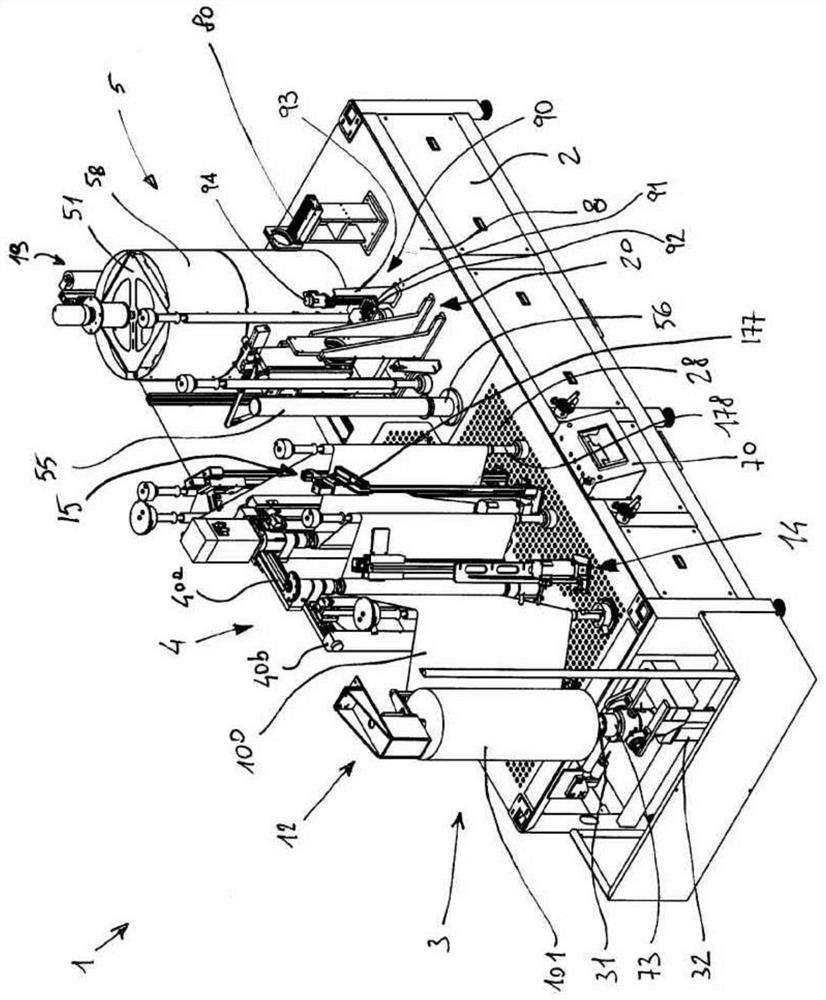

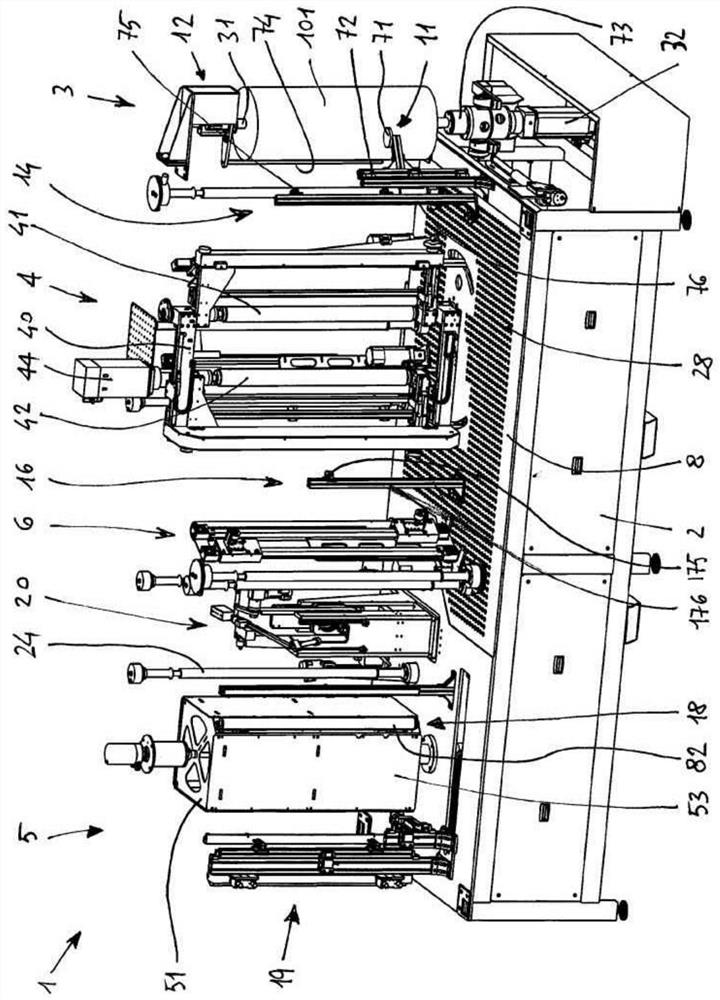

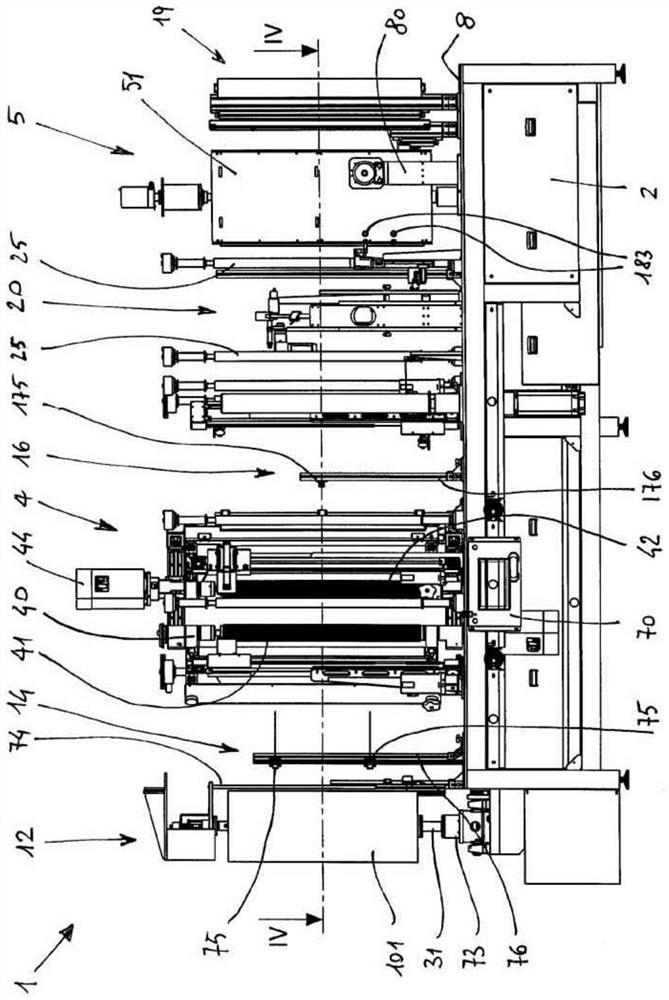

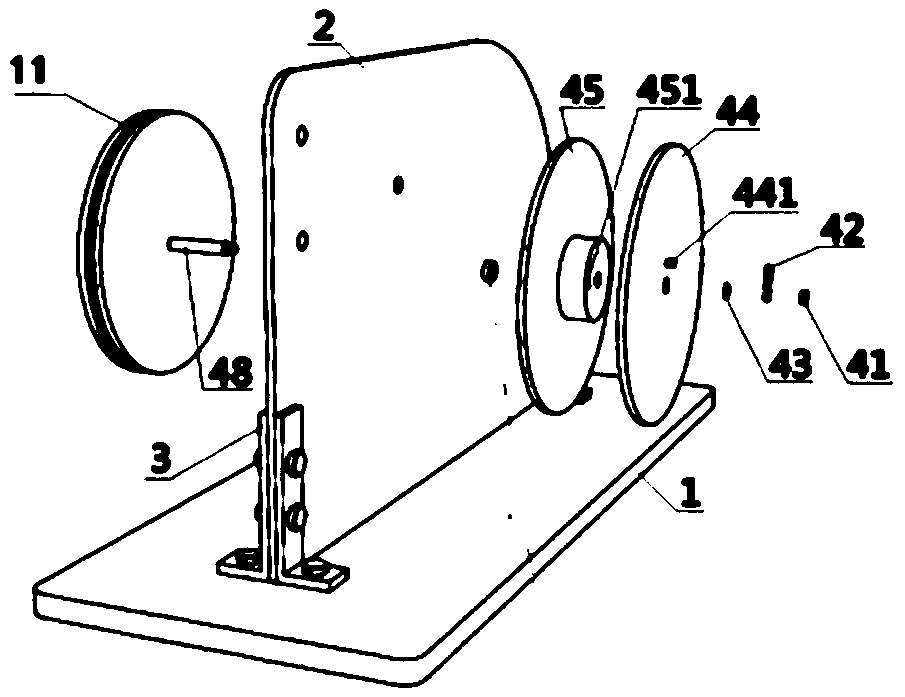

Machine for testing extensible plastic films for packaging

A testing machine (1) to perform a plurality of measurements and / or tests on a film (100) made of plastics in order to determine mechanical and physical properties of the film (100), comprises a basicstructure (2) provided with a supporting plane (8); an unwinding station (3) provided with an unwinding roller (31) driven and / or controlled in rotation about a respective longitudinal axis by firstdriving means (32) and arranged to support a reel (101) of the film (100); a pre- stretching station (4) arranged to unwind the film (100) from the reel (101) with a preset unwinding speed and to pre-stretch the film (100) of a preset percentage, the pre-stretching station (4) comprises a couple of pre-stretching rollers (41; 42) driven in rotation about respective longitudinal axes by second driving means (43, 44) and a plurality of return rollers (45, 46, 47) to deviate and wrap the film (100) on the pre- stretching rollers (41, 42) according to a predetermined pre-stretching path; the pre-stretching rollers (41, 42) and return rollers (45, 46, 47) are interchangeable and adjustably positionable to change the pre-stretching path; the testing machine (1) further comprises a wrapping station (5) provided with a testing drum (51) driven and / or controlled in rotation about a respective longitudinal axis by third driving means (52) and arranged to be wrapped at least partially by the film(100) coming out from the pre-stretching station (4); a plurality of guiding rollers (21-24) to lead the film (100) along an unwinding path from the unwinding station (3) to the pre-stretching station (4) and from the latter to the wrapping station (5), the guiding rollers (21-24) being interchangeable and reversibly and adjustably mountable to the supporting plane (8) to change the unwinding path; a plurality of measuring groups (11-16) to perform a plurality of respective measurements at least of dimensional and / or physical parameters of the reel (101) and of the film (100) and reversibly and adjustably mountable to the supporting plane (8) depending on the unwinding path; a plurality of testing groups (17-20) provided with respective means to interact with the film and perform respective tests and measurements on the film (100) in order to determine mechanical and physical properties of the latter.

Owner:AETNA GROUP

Wire and cable length metering device

InactiveCN112254612APrevent fallingEasy to observe readingsMechanical length measurementsElectric machineGear wheel

The wire and cable length metering device comprises a machine body, an electric heating pipe and a motor, wherein the electric heating pipe is arranged in the machine body, the motor is arranged on the right side of the machine body, the output end of the motor is connected with a threaded rod, a discharging port is formed in the left side of the machine body, a feeding port is formed in the rightside of the top end of the machine body, a water inlet is formed in the left side of the top end of the machine body, a control button is arranged on the outer wall of the water inlet, the control button is fixedly connected with one end of a first rotating shaft, a first gear is welded to the other end of the first rotating shaft, the first gear is in meshed connection with a second gear, and one end of a second rotating shaft is welded to the top end of the second gear. By arranging the torsion spring, the rotating plate and the second rotating shaft, the rotating plate can fix a wire and acable, calculation errors caused by falling during winding are prevented, and by arranging the graduated scale on the fixing plate, people can conveniently observe and read.

Owner:GAOYOU DINGTIAN HIGH MOLECULAR MATERIAL CO LTD

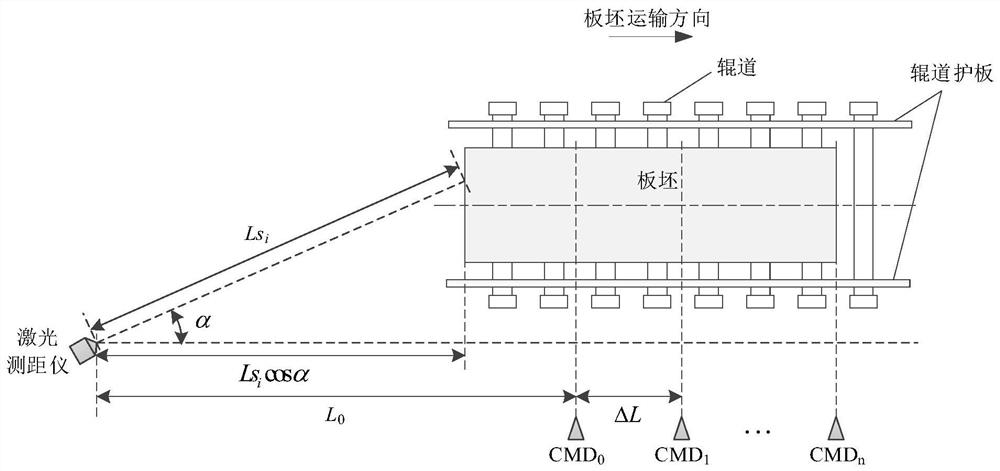

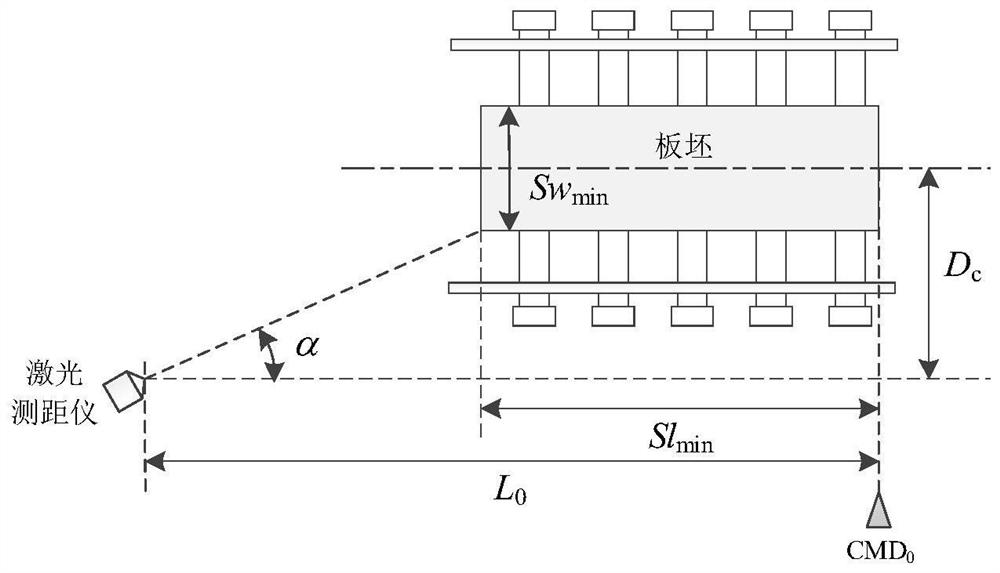

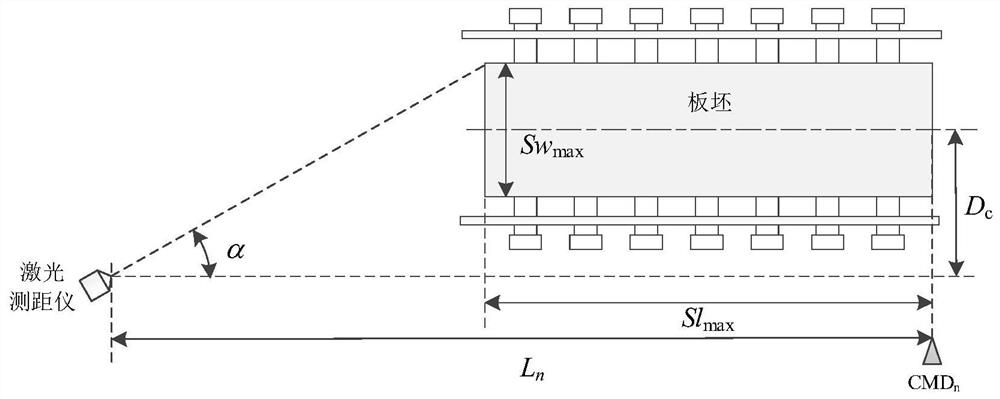

Online automatic measurement method for length of stokehole plate blank

ActiveCN111795632AGuaranteed stabilityGuaranteed reliabilityMechanical length measurementsLaser rangingEngineering

The invention provides an online automatic measurement method for the length of a stokehole plate blank, which belongs to the technical field of metal processing. According to the method, a laser range finder and a plurality of cold metal detectors are mounted on a stokehole plate blank conveying roller way to realize online automatic measurement of the length of a plate blank; firstly, the plateblank is conveyed in a roller way conveying process; when a rising edge signal of a cold metal detector is received each time, the laser range finder measurement data at the moment are locked and stored, then the effectiveness of the laser range finder measurement data is judged, and finally the actual length of the plate blank is calculated according to the geometrical relationship among the laser range finder, the plate blank and the cold metal detectors. The equipment investment is low, the measuring method is simple, the length measuring range is large, and meanwhile the length of the plate blank can be measured in the plate blank conveying process.

Owner:北京科技大学设计研究院有限公司

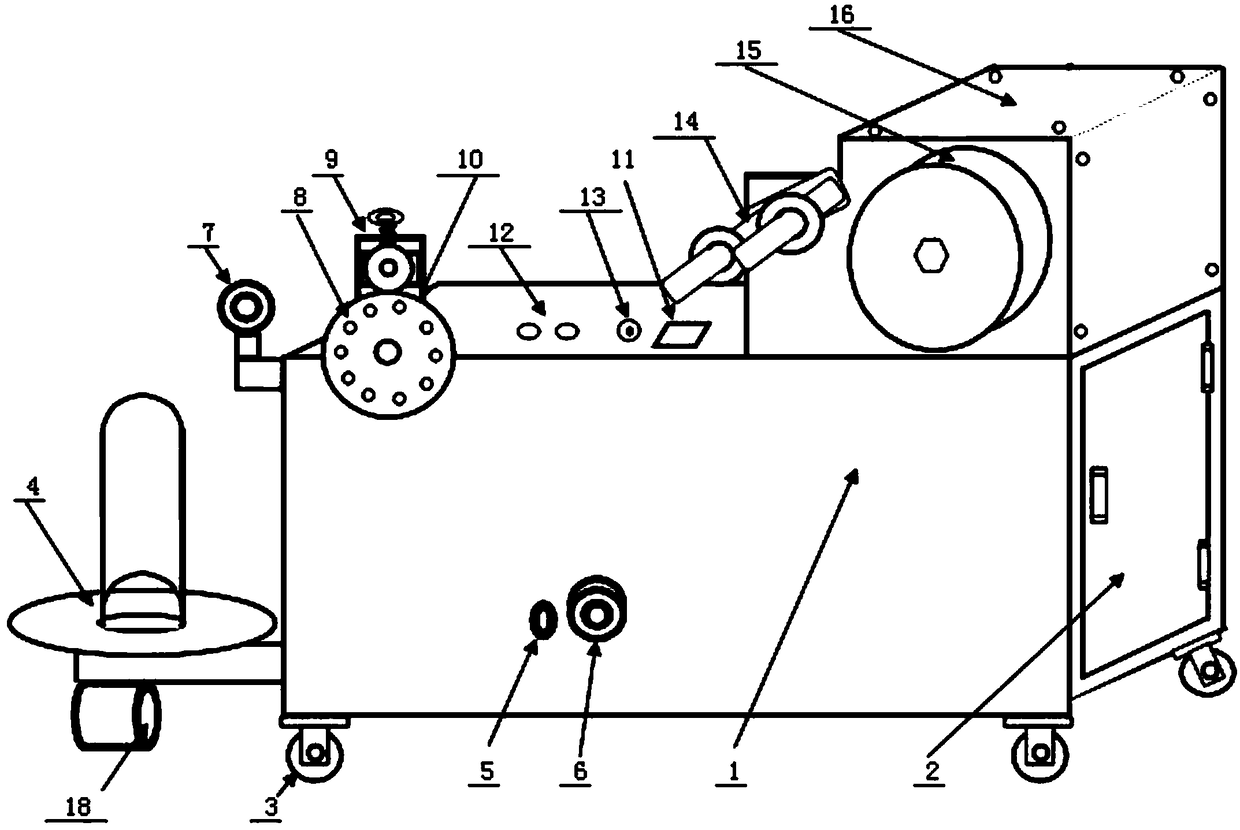

Electric wire net content length measuring machine and use method thereof

PendingCN108562209ANet content length measurement is goodNot affected by ambient humidityFilament handlingMechanical length measurementsElectric machineLength measurement

An electric wire net content length measuring machine comprises a rack, a wire pay-off frame, a wire conduit positive ring, a first guide wheel, a second guide wheel, a metering wheel, a pressing device, a revolution meter, a speed regulating potentiometer, a control switch, an induction counter, a wire arranging device, an opening and closing take-up disc, a motor, an extension tube connecting thread ring, a standard length extension connecting pipe L and a standard length extension connecting pipe A. The motor is located in the rack and connected with the opening and closing take-up disc. The wire arranging device is fixed to the rack and located on the left side of the opening and closing take-up disc. The control switch, the induction counter and the speed regulating potentiometer arearranged on a table top of the rack and located between the metering wheel and the wire arranging device. The electric wire net content length measuring machine is a set of integrated equipment, can randomly move without being limited by occasions, is not influenced by the environment humidity, and is high in length measurement accuracy and small in measurement precision error range, dual diversified standard measurement can be carried out at the same time through two methods, and the electric wire net content length measuring machine is metering equipment very good in net content length measurement.

Owner:广东金华电缆股份有限公司

Length metering device for data line detection

ActiveCN113883984ARealize length measurement workWork benchesMechanical length measurementsControl theoryMechanical engineering

The invention is suitable for the technical field of data line length metering, and provides a length metering device for data line detection. The device comprises: an operation table which is provided with a mounting rack, wherein the operation table is provided with a conduction assembly, and the conduction assembly is internally provided with a data line; a guide plate installed on the operation table, wherein a control assembly is installed on the guide plate; and a driving assembly installed on the installation frame, wherein an installation block is connected to the driving assembly, and a traction assembly is installed on the installation block. When the driving assembly is started, the driving assembly can drive the traction assembly to operate, transmission is carried out in a reciprocating type data line pulling mode through the matching relation between the driving assembly and the control assembly, the transmission length of each time of data line pulling is equal, the transmission length is automatically calculated through the driving assembly according to the number of pulling times, and the length measurement work of the transmitted data line is realized.

Owner:SHENZHEN YIHUAXING ELECTRONICS

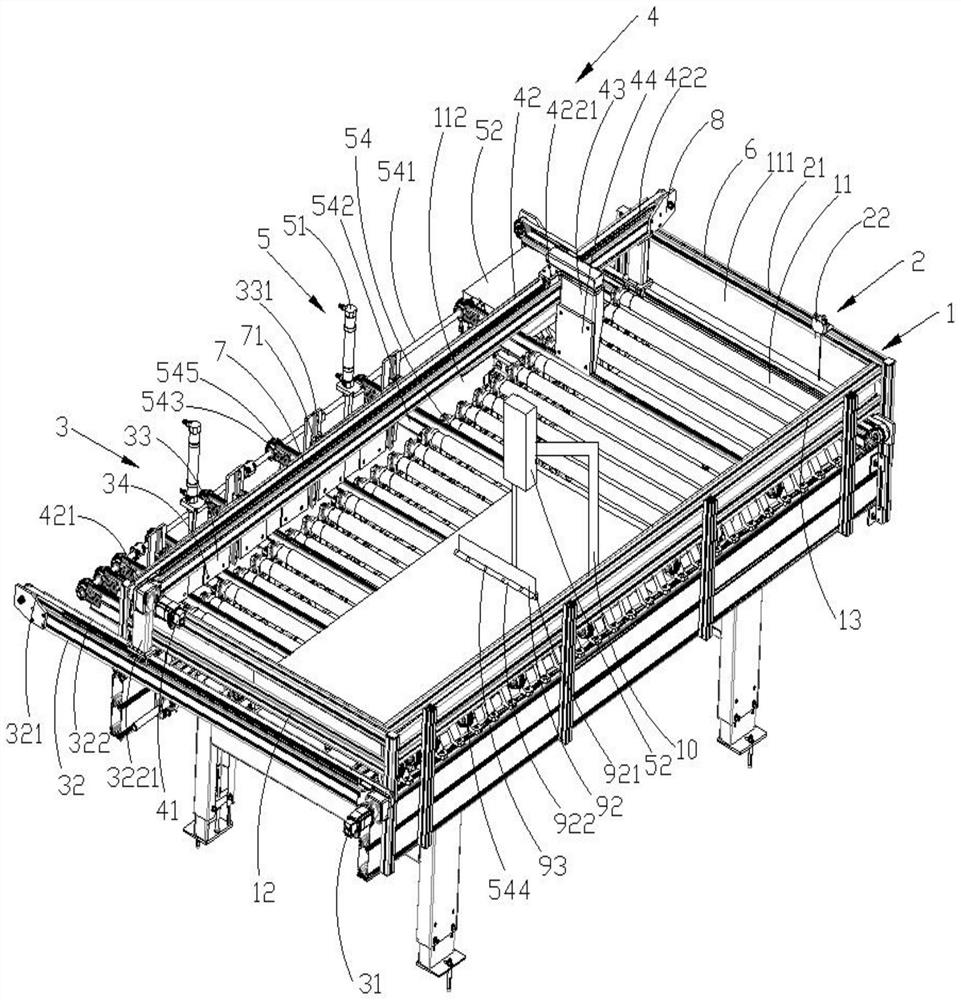

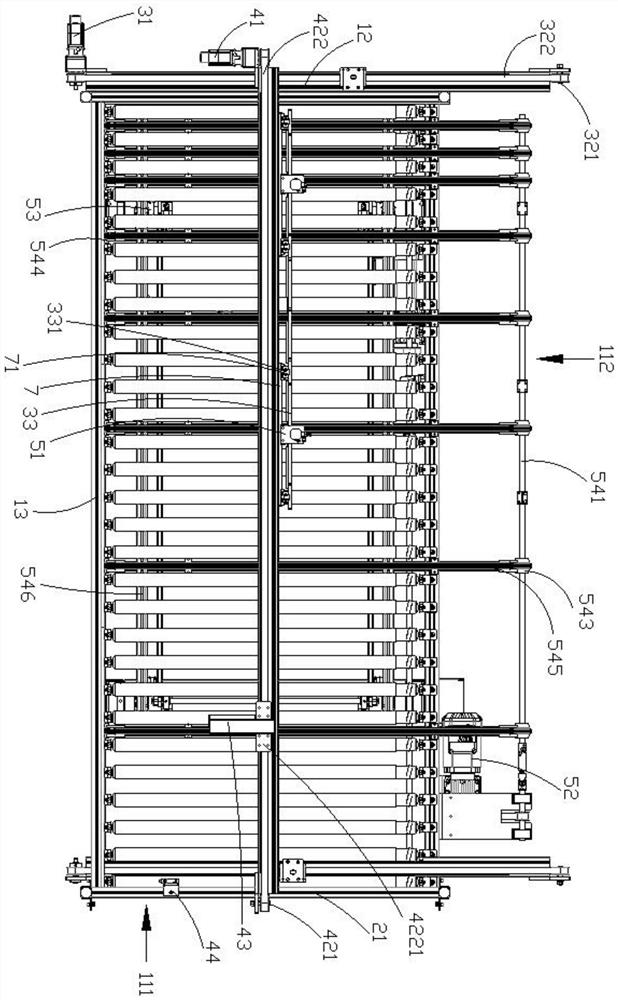

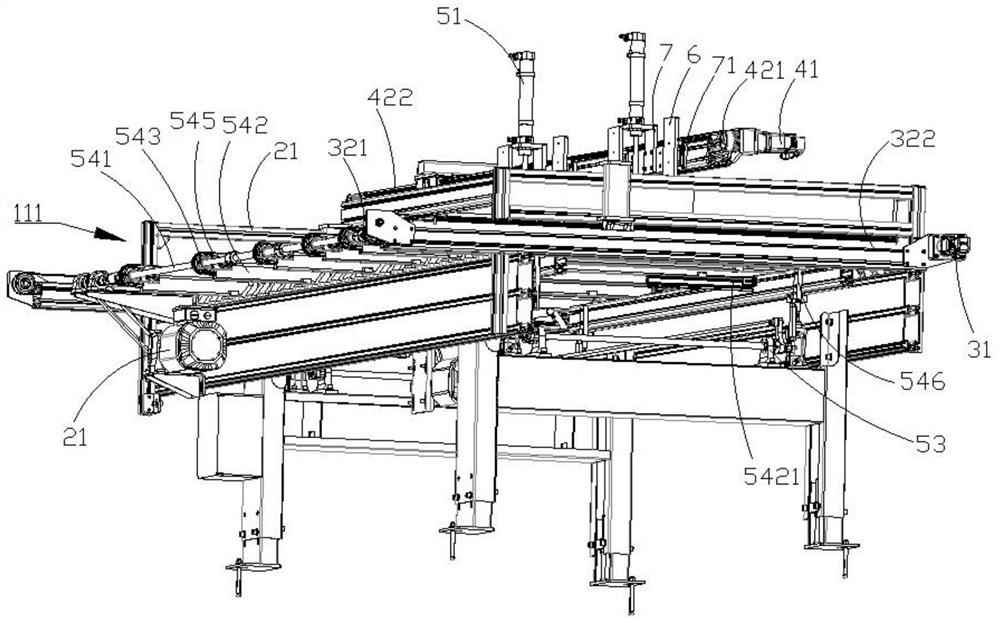

Automatic plate size measuring station and measuring method thereof

ActiveCN112729049ABeautiful packagingCompact structureControl devices for conveyorsMechanical width measurementsProcess engineeringMechanical engineering

The invention relates to the technical field of plate packaging, and in particular, relates to an automatic plate size measuring station and a measuring method thereof. The automatic plate size measuring station comprises a feeding mechanism, a thickness measuring mechanism, a width measuring mechanism, a length measuring mechanism and a discharging mechanism which are used for automatically measuring thickness data, width data and length data of plates respectively. According to the automatic plate size measuring station and the measuring method thereof, the length data, the width data and the thickness data of the plates are measured fully automatically and accurately, manpower is not needed, the labor cost is saved, the production efficiency is improved, the accuracy of the measured data is high, subsequent production of packaging paper of the corresponding size is facilitated, the plates are protected completely, resource waste is avoided, and the packaging appearance of the plates is more exquisite, the automatic plate size measuring station is capable of continuously measuring the plates of various sizes and high in practicability, and all operation in the measuring process is agile in cooperation and high in fluency.

Owner:湖北鑫光智能装备有限公司

Measuring device for wire protection sleeve cutting

PendingCN109397371ASolve the entanglementImprove operational efficiencyMechanical length measurementsMetal working apparatusDrive wheelEngineering

The invention relates a measuring device for wire protection sleeve cutting. The measuring device for wire protection sleeve cutting comprises a supporting mechanism, a material winding and fixing mechanism, a clamping and cutting mechanism and a transmission mechanism, wherein the supporting mechanism comprises an upright supporting plate, the material winding and fixing mechanism and the clamping and cutting mechanism are arranged on one side face of the supporting plate, the transmission mechanism is arranged on the other side face of the supporting plate; the material winding and fixing mechanism comprises a feeding wheel mechanism and a transition wheel; the clamping and cutting mechanism comprises a pair of clamping wheels and a discharging bayonet mechanism, each of the pair of clamping wheels comprises a driving wheel mechanism and a driven wheel mechanism, and a measuring scale is arranged on the axial end face of a driving wheel of the driving wheel mechanism; the transmission mechanism is a belt transmission mechanism. During use, the coiled wire protective sleeve is fixed on the material winding and fixing mechanism, and the pull-out wire protection sleeve is wound around the transition wheel and is sent into a pair of clamping wheels; and under the action of the belt transmission mechanism, through the measurement of the driving wheel, the discharge clamping opening is used for outputting a wire protection sleeve with a qualified length.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Popular searches

Using optical means Tension measurement Electrical/magnetic length/width measurements Surveying instruments Material testing goods Optically investigating flaws/contamination Material analysis by optical means Rope making machines Converting sensor output mechanically Structural/machines measurement

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com