Machine for testing extensible plastic films for packaging

A film and machine technology, applied in the field of testing machines, can solve the problems of expensive film characteristic testing, film manufacturers and film users can not use, can not be used, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

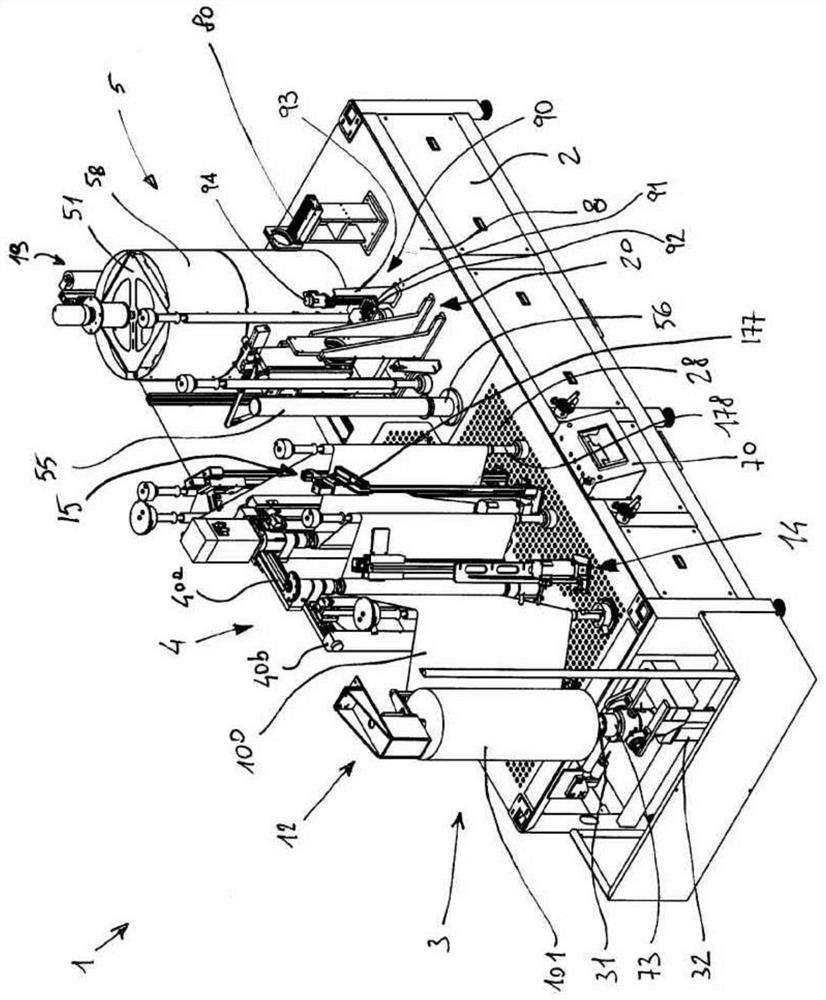

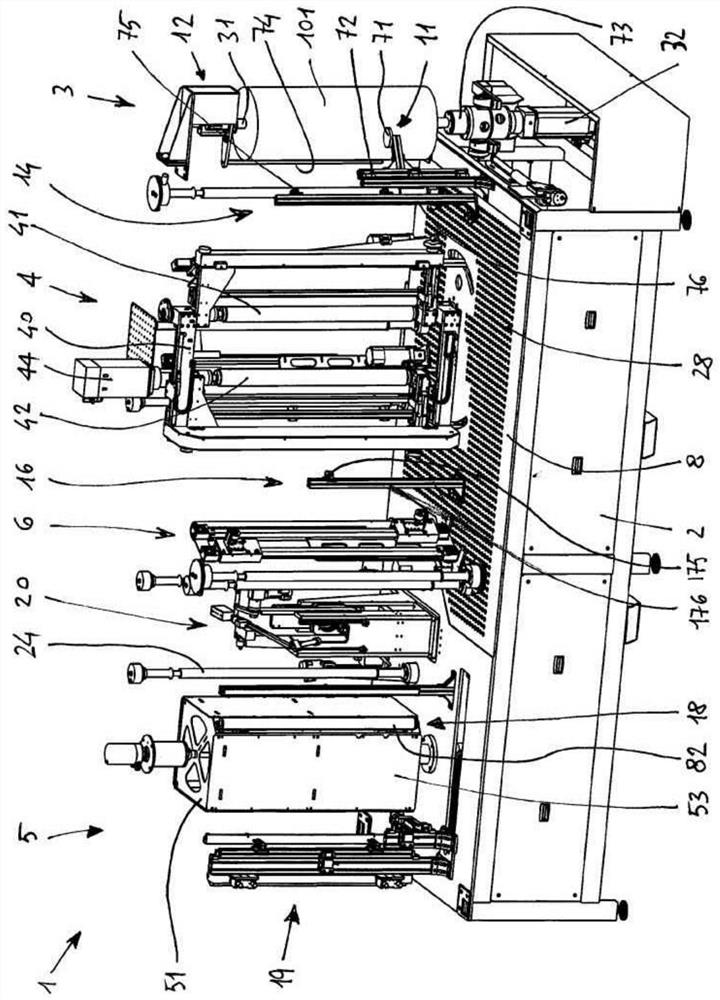

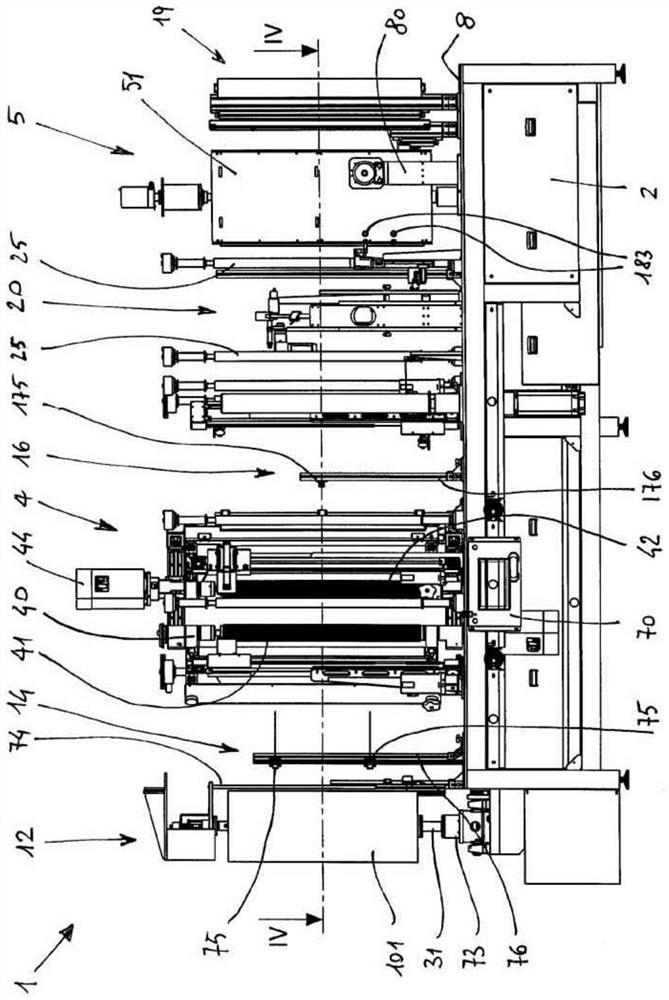

[0042] refer to Figure 1 to Figure 16 , shows a testing machine 1 according to the invention arranged to perform a number of measurements and tests on a film 100 made of plastic to determine its mechanical and physical properties. For example, film 100 is a cold stretchable plastic film type used for wrapping and wrapping objects, packages, products, etc. grouped and arranged in superimposed layers on a pallet to form a pallet load. Schematically, the testing machine 1 comprises a basic structure 2 provided with a support plane 8, an uncoiling station 3, a pre-tensioning station 4, a winding station 5, a plurality of measuring groups 11-16, a plurality of testing groups 17-20, and a plurality of guide rollers 21-24.

[0043] The uncoiling station 3 is provided with unwinding rollers 31 which are driven and / or controlled to rotate about a respective longitudinal axis (in particular almost perpendicular to the support plane 8 ) by a first drive 32 and arranged to support the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com