Special measuring device for building design

A measurement device and architectural design technology, applied in the direction of measurement devices, mechanical measurement devices, and mechanical devices, can solve the problems of high labor intensity, loss of economic benefits, low efficiency, etc., and achieve low labor intensity for workers, convenient and accurate measurement, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

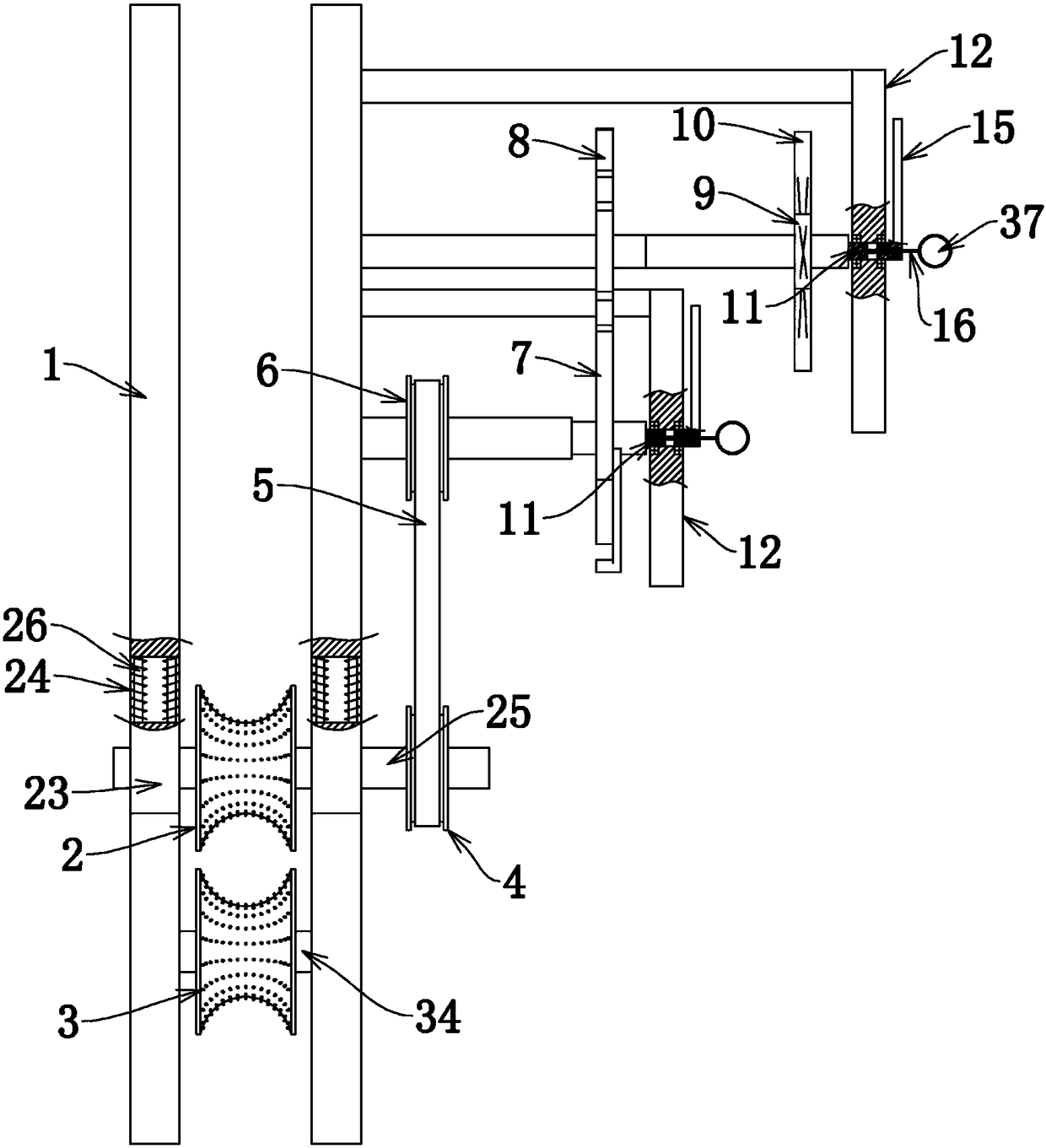

Embodiment 1

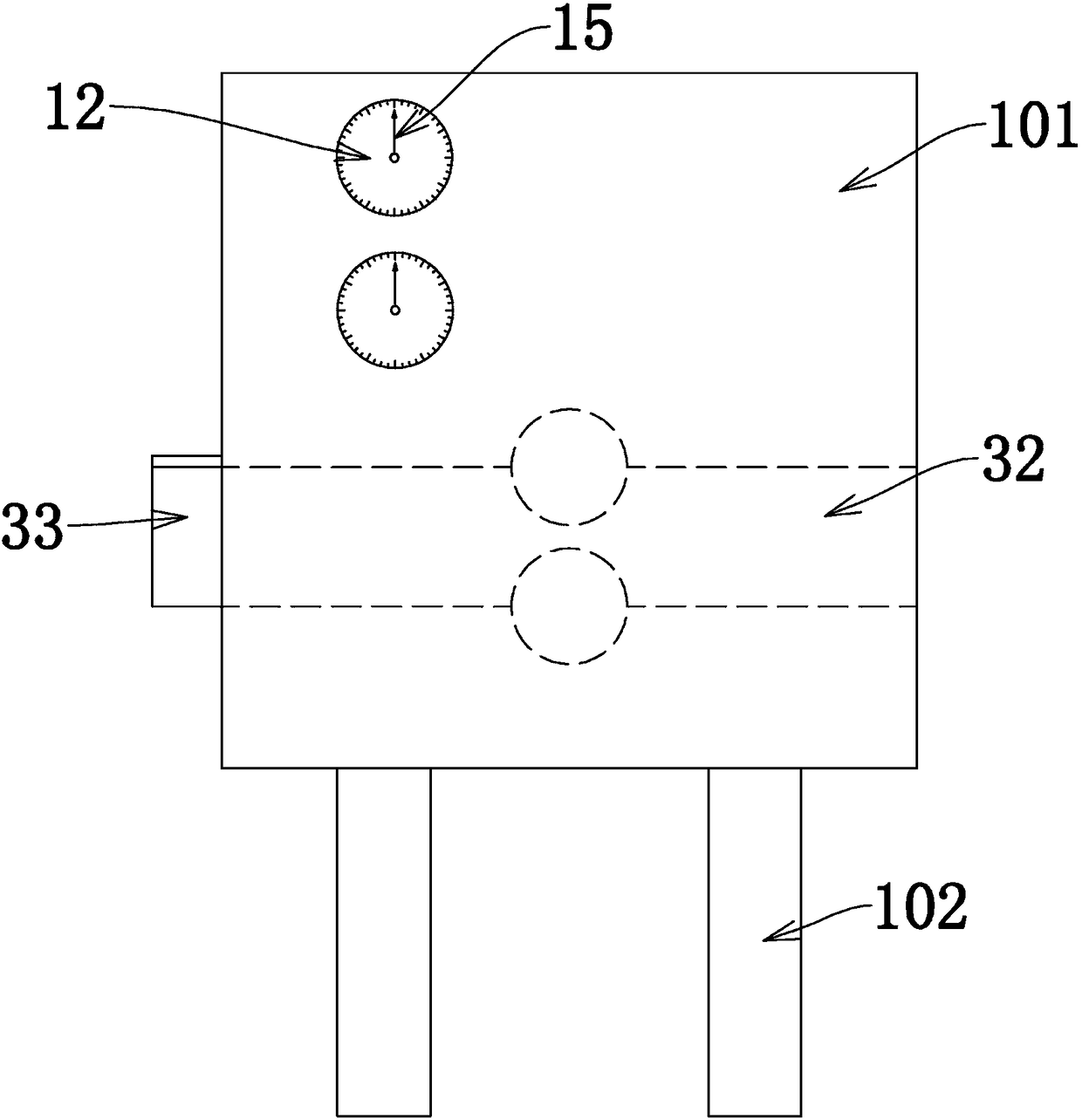

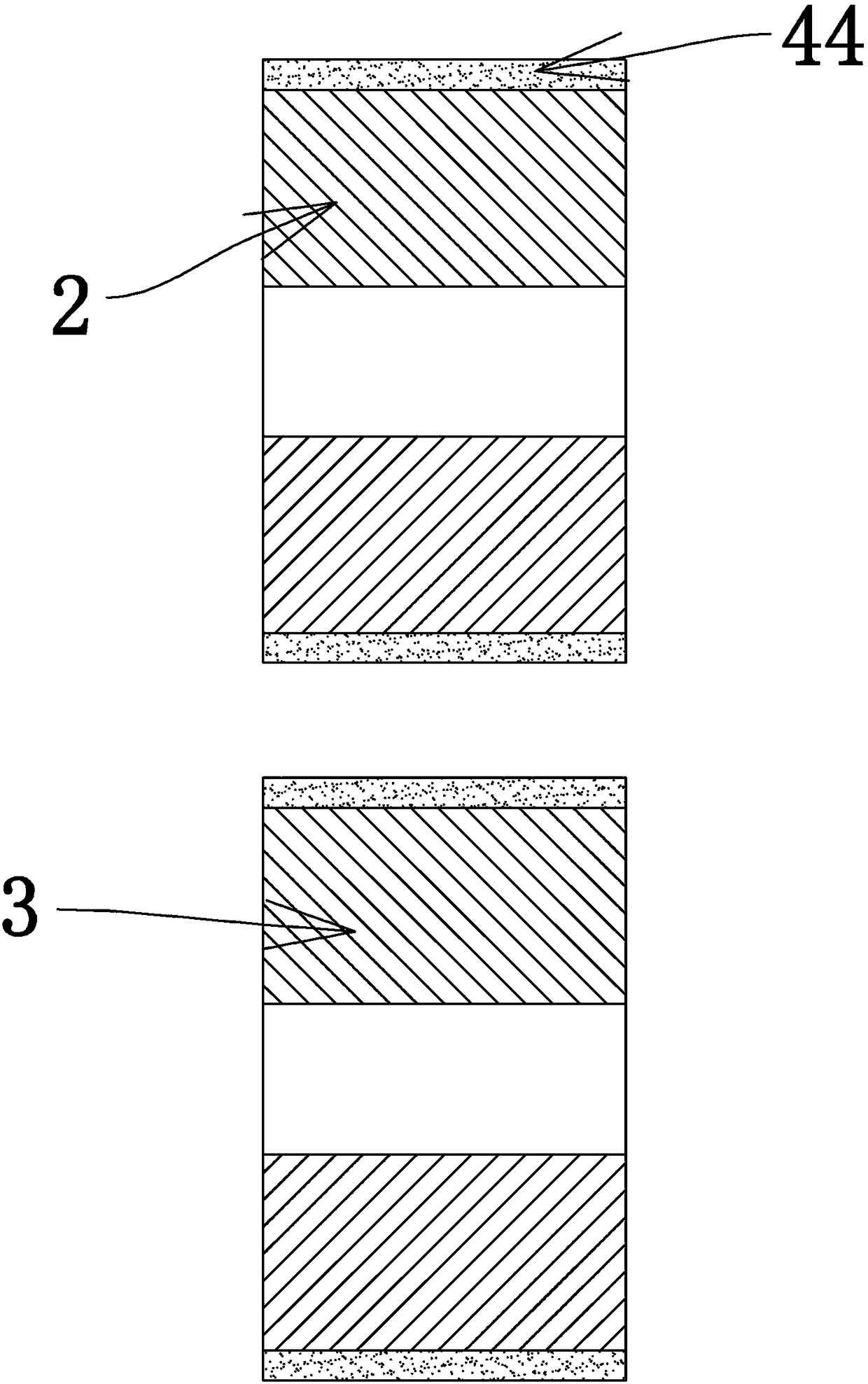

[0037] Embodiment 1 includes a frame 1, the frame 1 includes a casing 101 and legs 102 arranged in a rectangular arrangement at the bottom of the casing 101, the frame 1 is provided with a first wheel 2, the first A second runner 3 is rotatably connected to the frame 1 below the runner 2, and steel strands can pass between the first runner 2 and the second runner 3. The first rotation 2 and the second runner 3 They are all arranged in the housing 101, and there is an elastic mechanism between the first runner 2 and the frame 1 so that the first runner 2 can move up and down and has a downward pressure. During use, the steel strand Enter from the entrance of the housing 101, and then enter between the first runner 2 and the second runner 3, the interval between the first runner 2 and the second runner 3 in the initial state is less than the diameter of the steel strand, And because the surface of the first runner 2 and the second runner 3 facing the entrance is an arc surface, ...

Embodiment 2

[0038] Embodiment 2, on the basis of Embodiment 1, the two ends of the first runner 2 are rotatably connected with a bearing seat 23 via a first rotating shaft 25, and the bearing seat 23 is vertically slidably connected to the frame 1. The upper end of the bearing seat 23 is connected with the second compression spring 24 whose other end is connected on the frame 1, constituting an elastic force device. Specifically, a first rotating shaft 25 is fixedly connected to both ends of the first rotating wheel 2, and a bearing housing 23 is rotationally connected to both ends of the first rotating shaft 25, and a plurality of sliding rods 26 are vertically slidingly connected in the bearing housing 23, and the sliding rods 26 The upper and lower ends of the upper and lower ends are respectively fixed on the frame 1, and the two ends of the slide bar 26 are respectively fixed on the second stage clip 24 at the upper end of the bearing on the frame 1. When the steel strand continuousl...

Embodiment 3

[0039] Embodiment 3, on the basis of Embodiment 1, the tensioning device of the belt 5 includes a sleeve 27 fixed on the frame 1, and the sleeve 27 is axially slidably connected with a movable rod 28, and the movable rod 28 free ends are connected with a base bar 29 perpendicular thereto, and the front and rear ends of the base bar 29 are respectively connected with vertical support bars 30, and also include a tension pulley 31 connected to the belt 5, the tension pulley The two ends of 31 are rotatably connected to two supporting rods 30 respectively, and a tension spring 44 sleeved on the movable rod 28 is connected between the sleeve 27 and the base rod 29 . The belt 5 tensioning device makes when the first pulley 4 follows the first runner 2 and jumps up and down, the belt 5 between the first pulley 4 and the second belt 6 is always stretched, and will not slip, which improves the measurement precision.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com