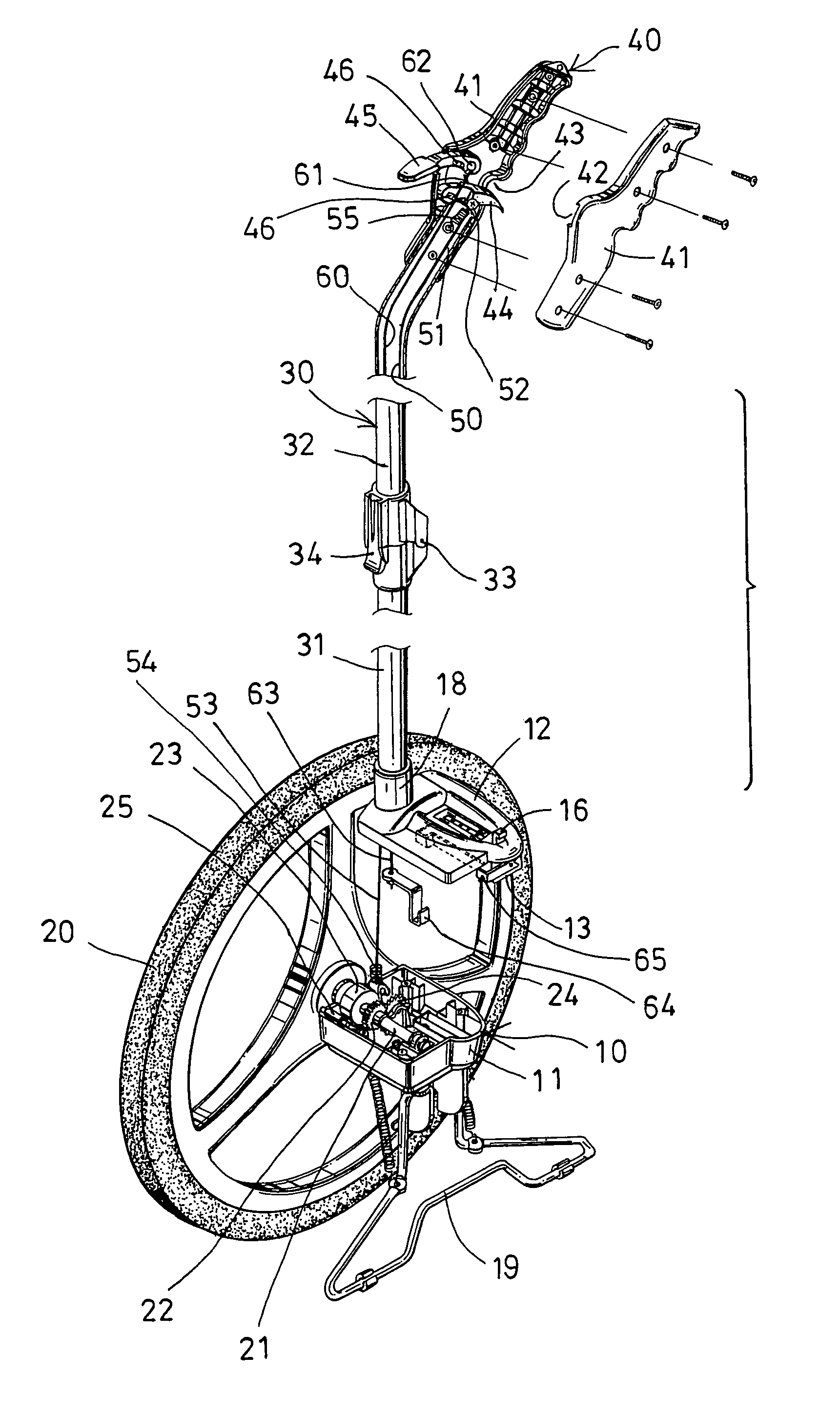

Patents

Literature

298results about "Electrical/magnetic length/width measurements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

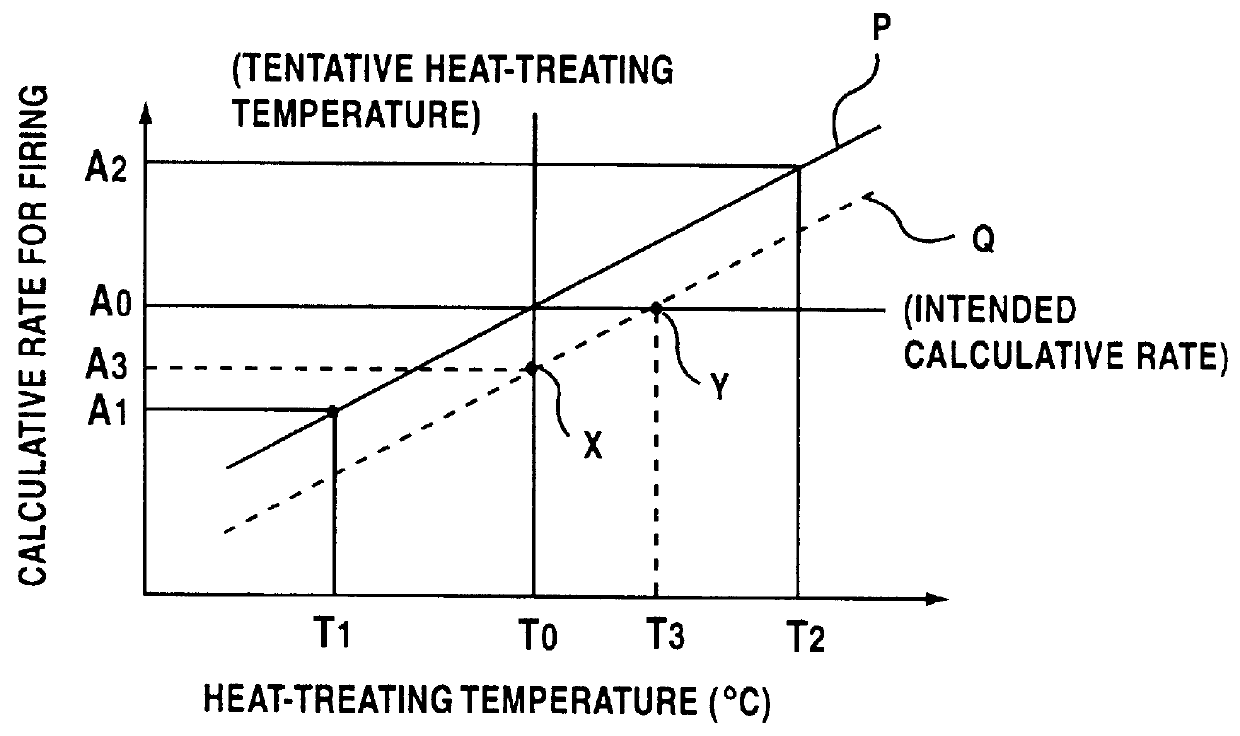

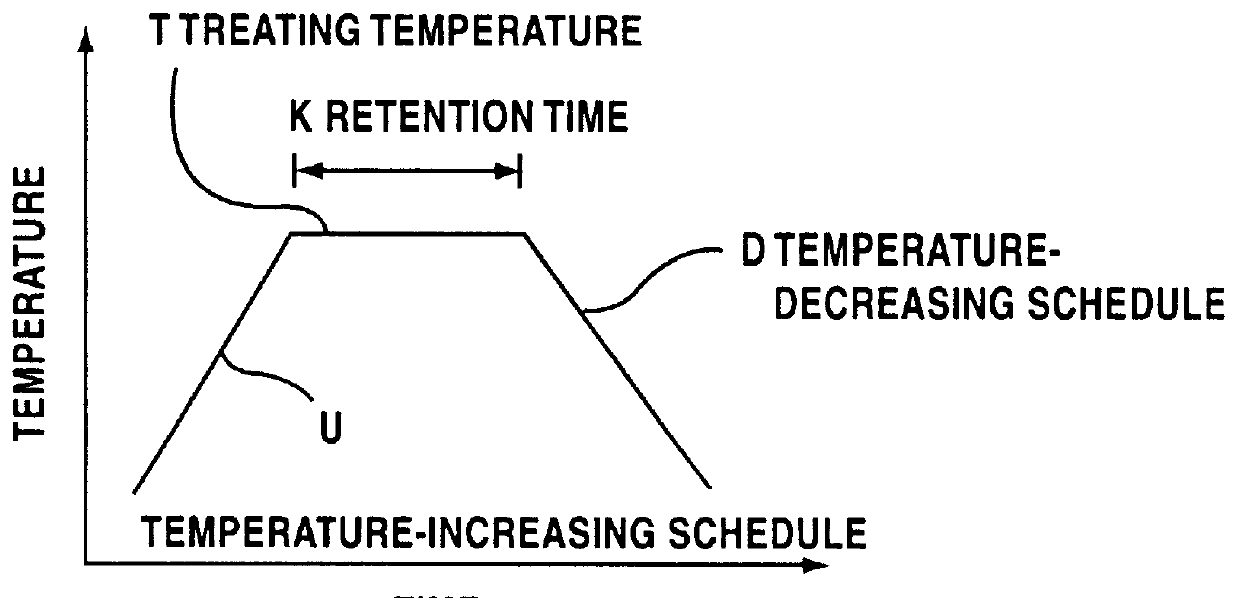

Method for controlling firing shrinkage of ceramic green body

A method of controlling the amount of firing shrinkage of a ceramic green body prepared by molding a ceramic powder (A) to a desired value A1 by heat treating the powder at a temperature T1 that provides the firing shrinkage A1 at a predetermined firing temperature. The temperature T1 is determined based on an established correlation between an amount of firing shrinkage at the predetermined firing temperature and a heat-treatment temperature of a powder (B) having a composition similar to that of the powder (A) in such an extent that a total amount of a greatest common content of an individual component common between the powders (A) and (B) in terms of percent is 90% by weight or more, and satisfying such a relation that the spherical diameter of powder (A) is within a range of + / - 30% relative to the spherical diameter (Rs) of the powder (B) and that its average degree of aggregation (+E,uns x+EE ) is within the range from +E,fra 1 / 2+EE fold to 2 fold relative to the average degree of aggregation (+E,uns x+EE ) of the powder (B).

Owner:NGK INSULATORS LTD

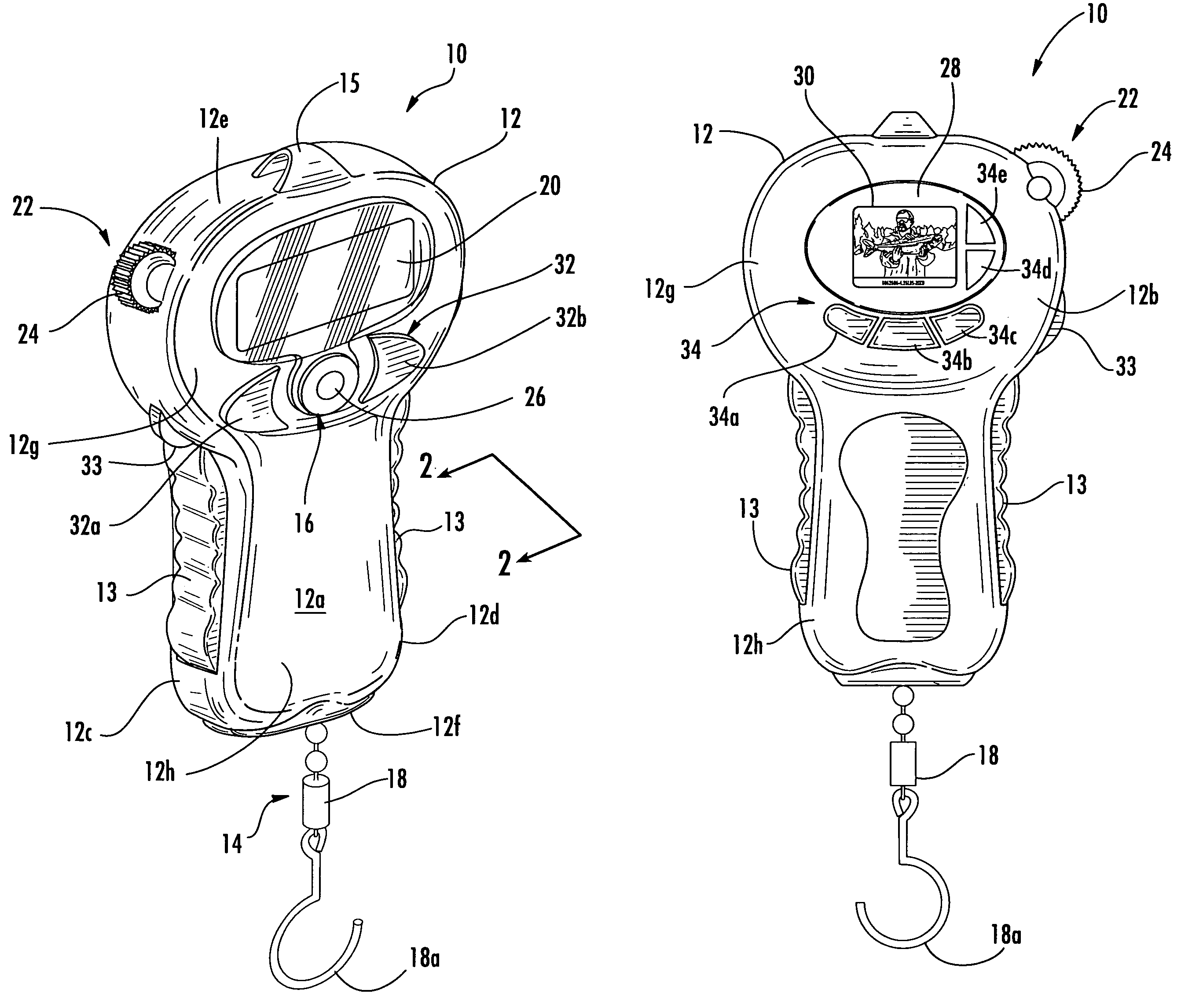

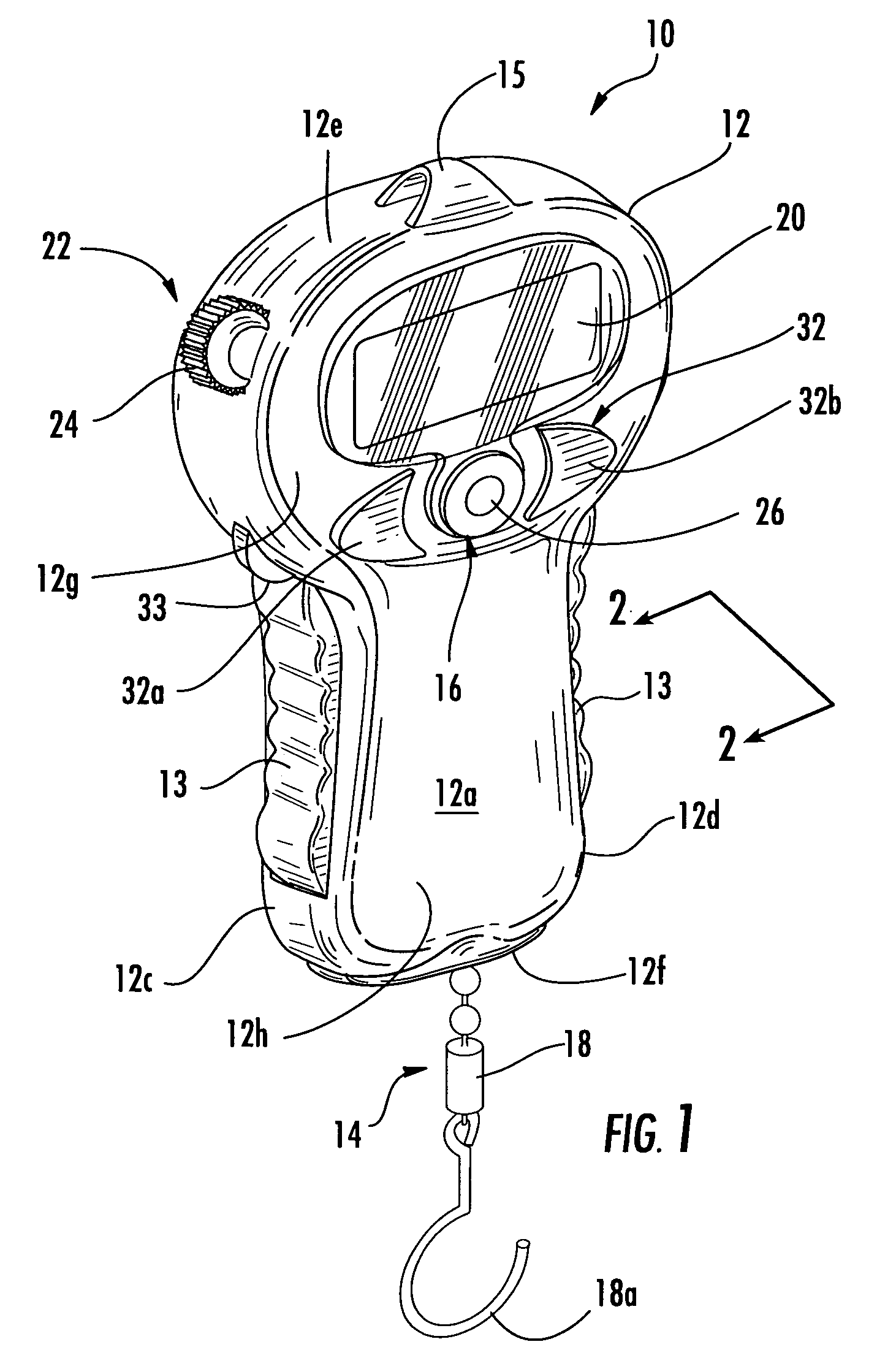

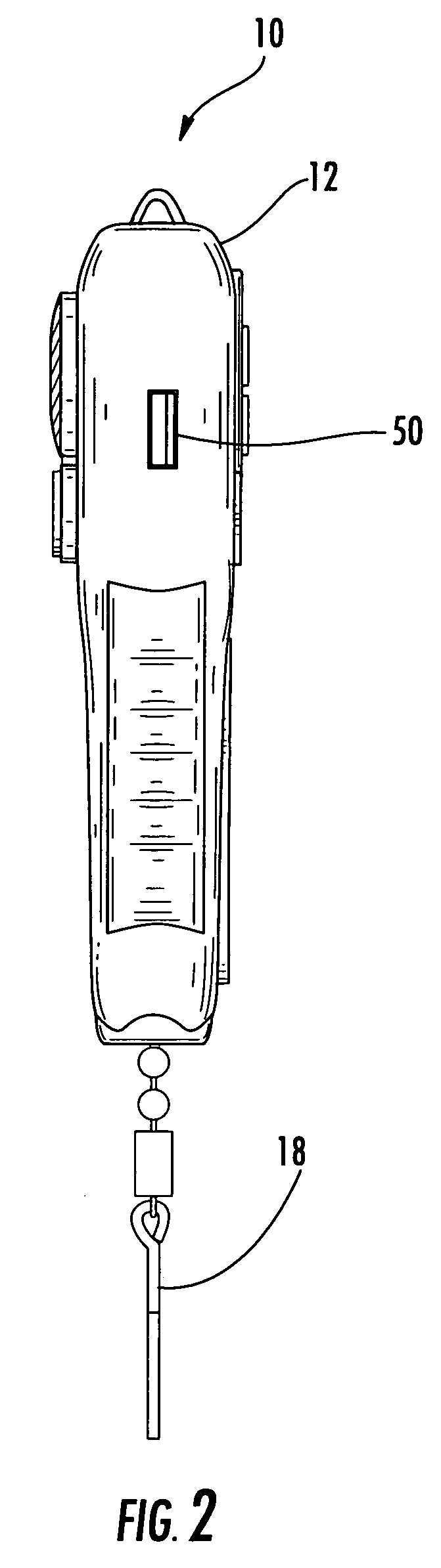

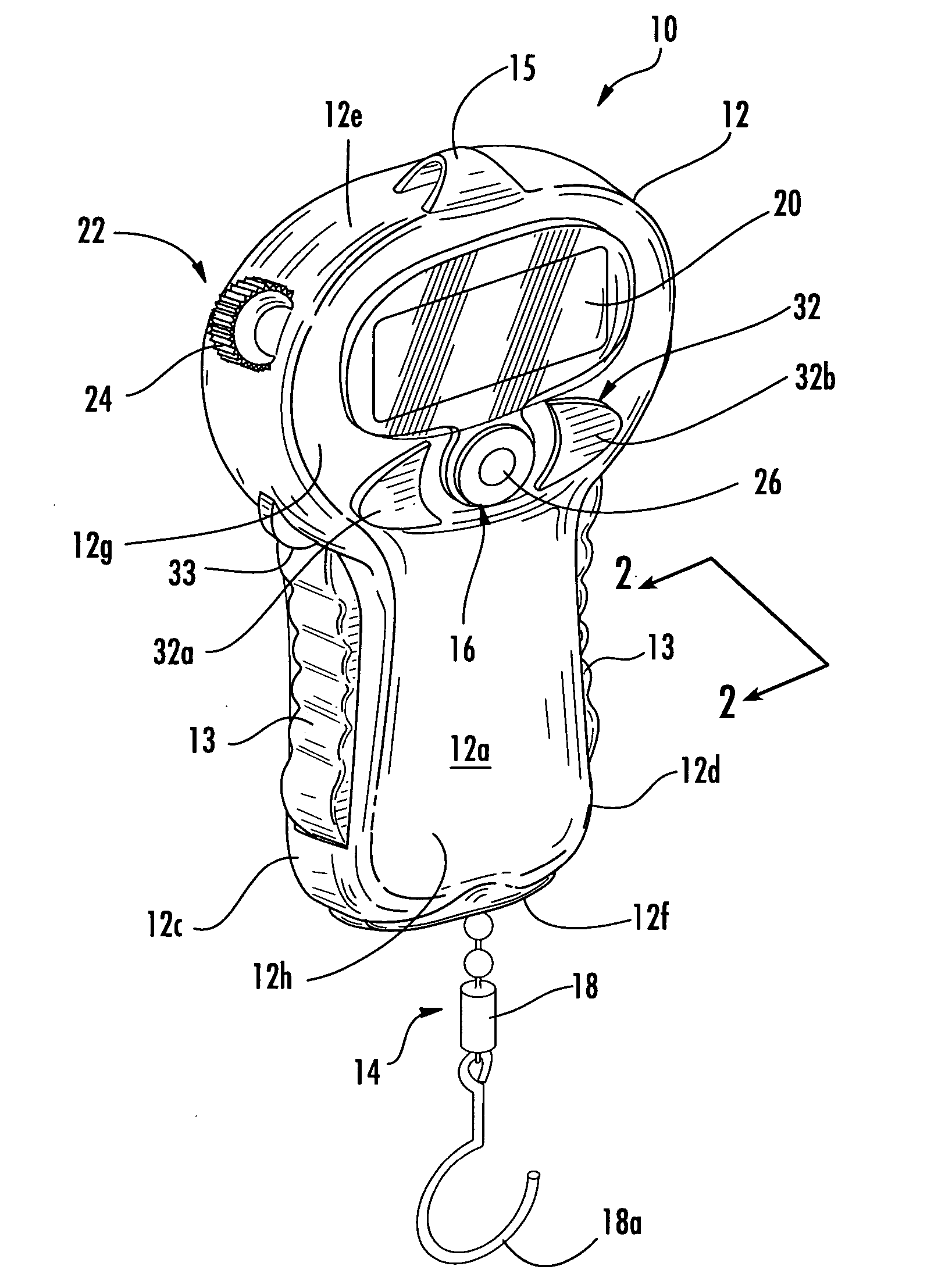

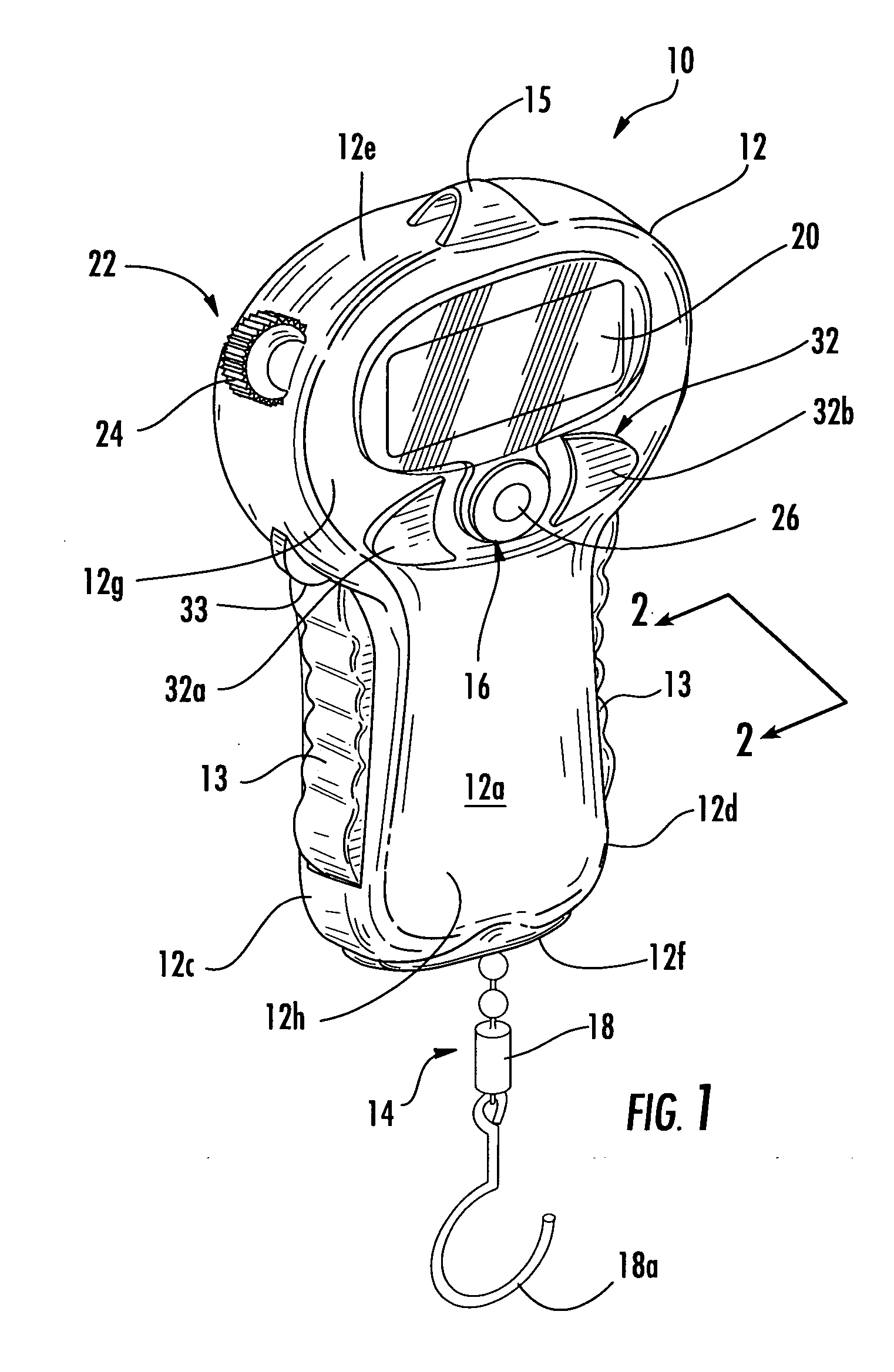

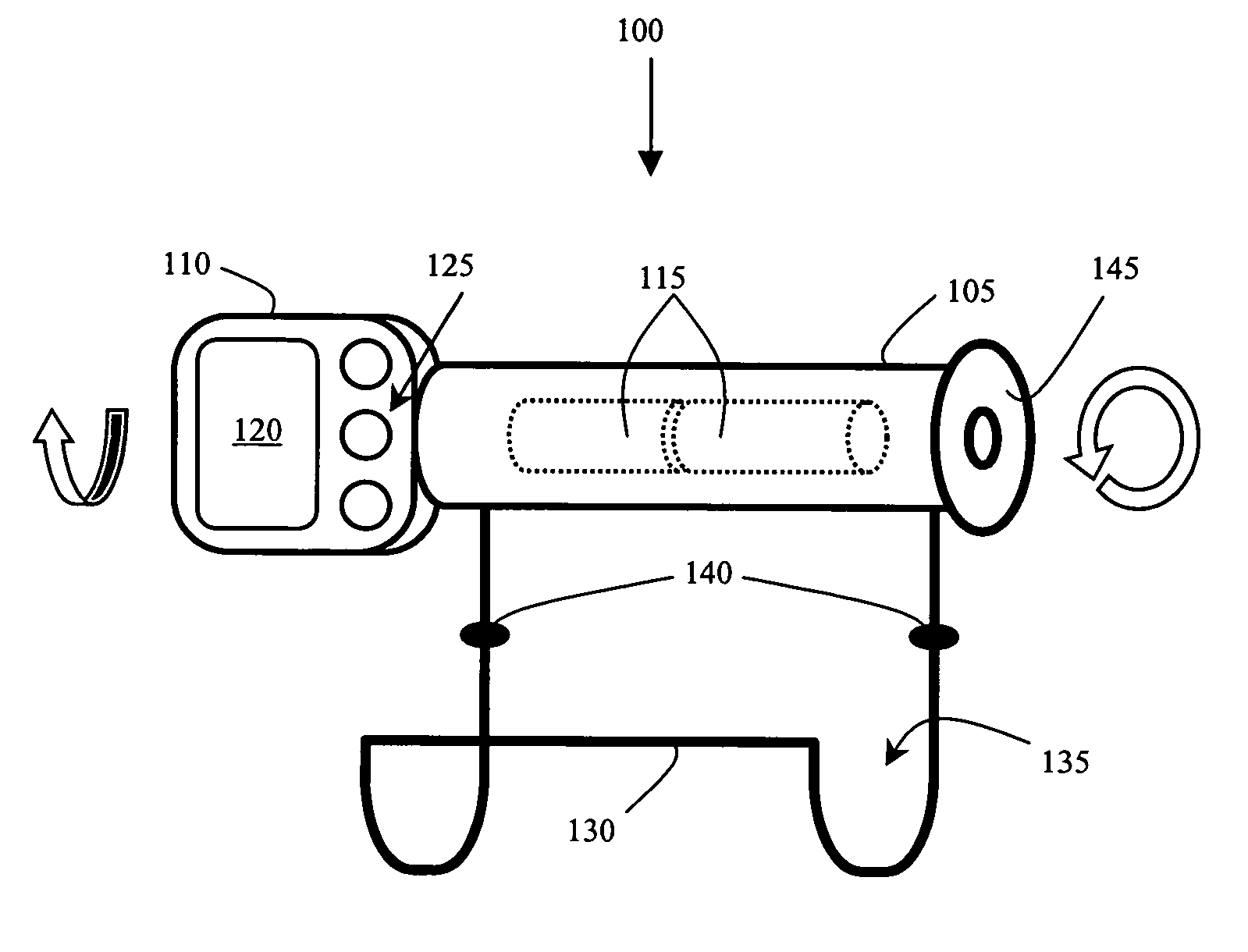

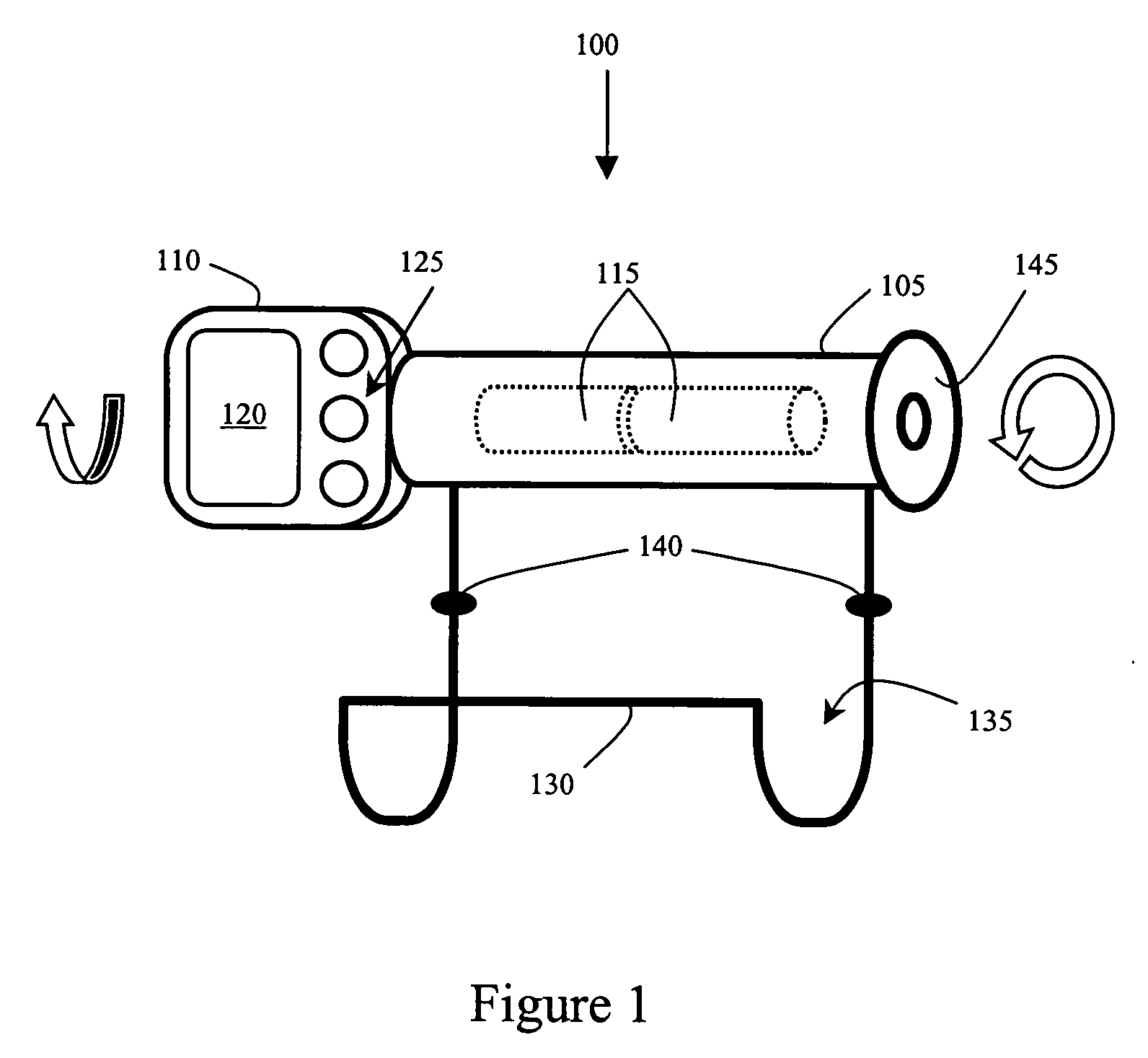

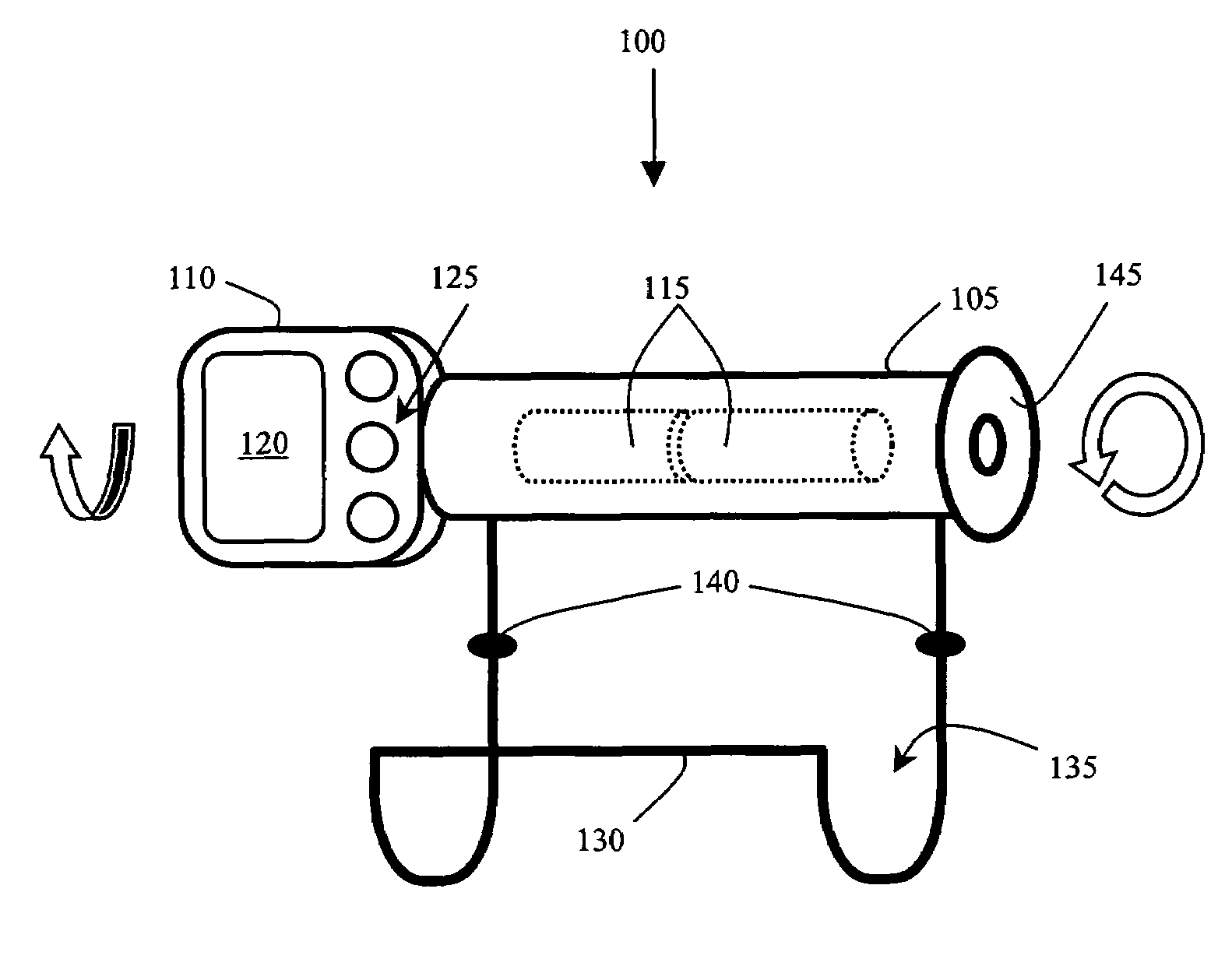

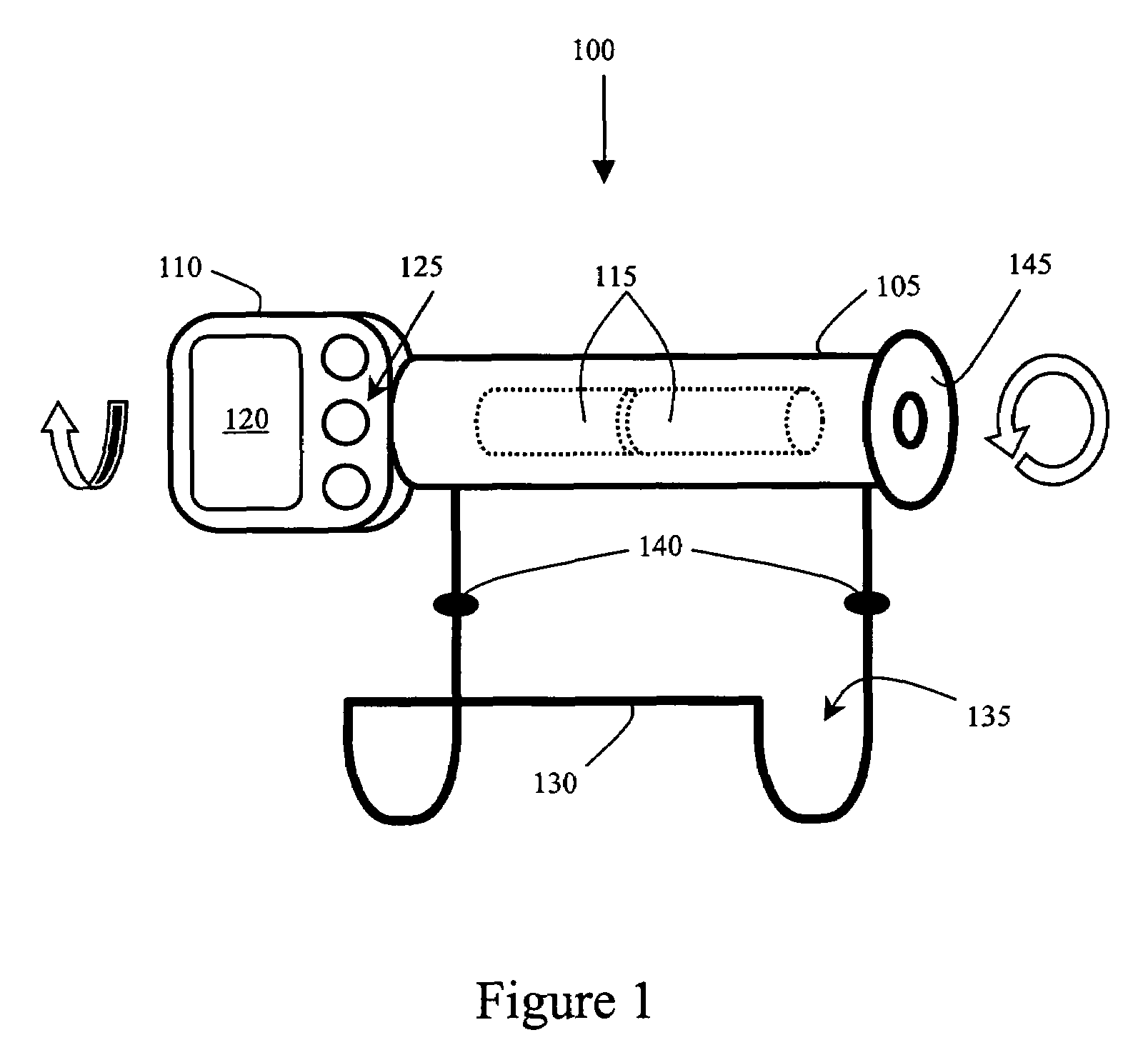

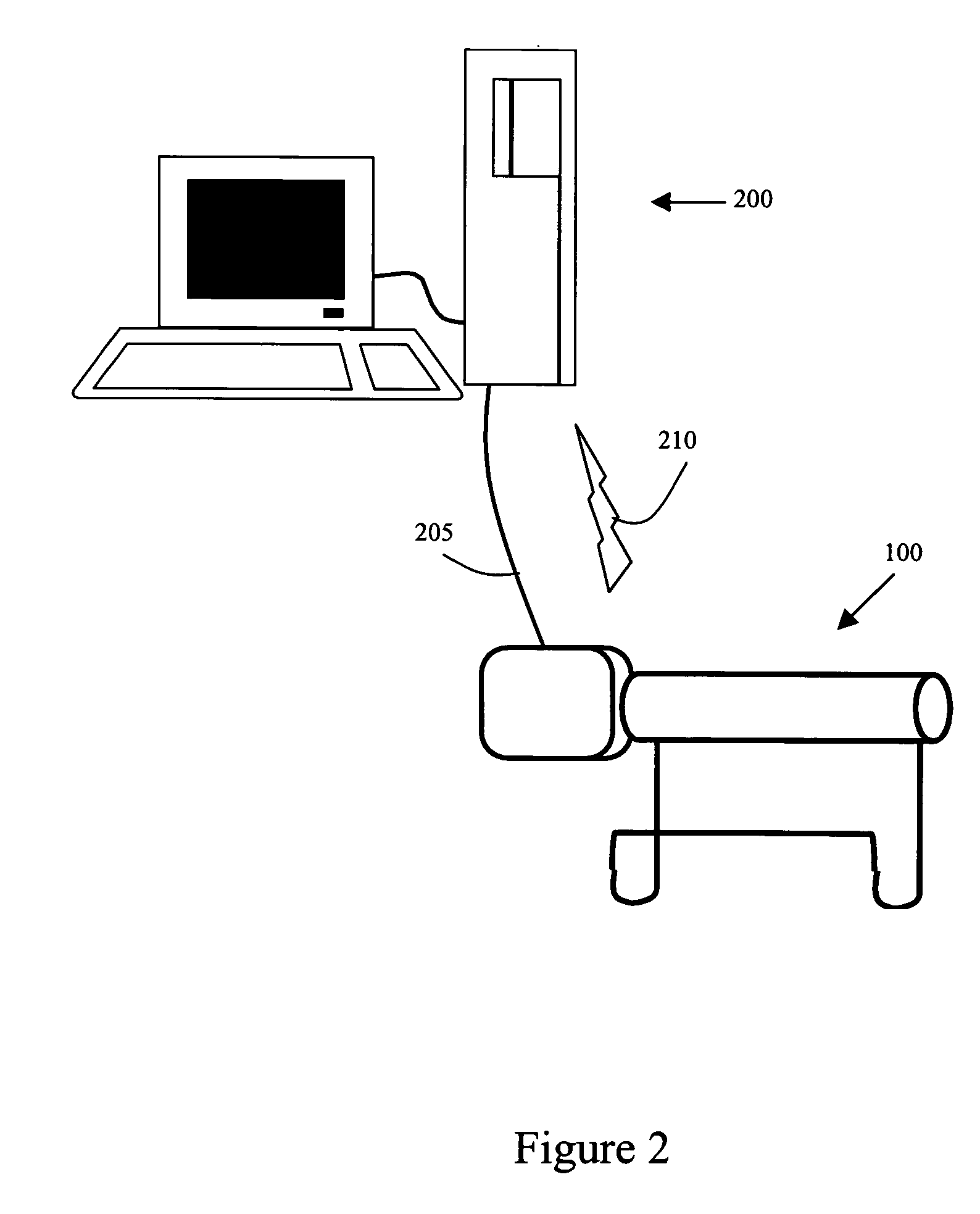

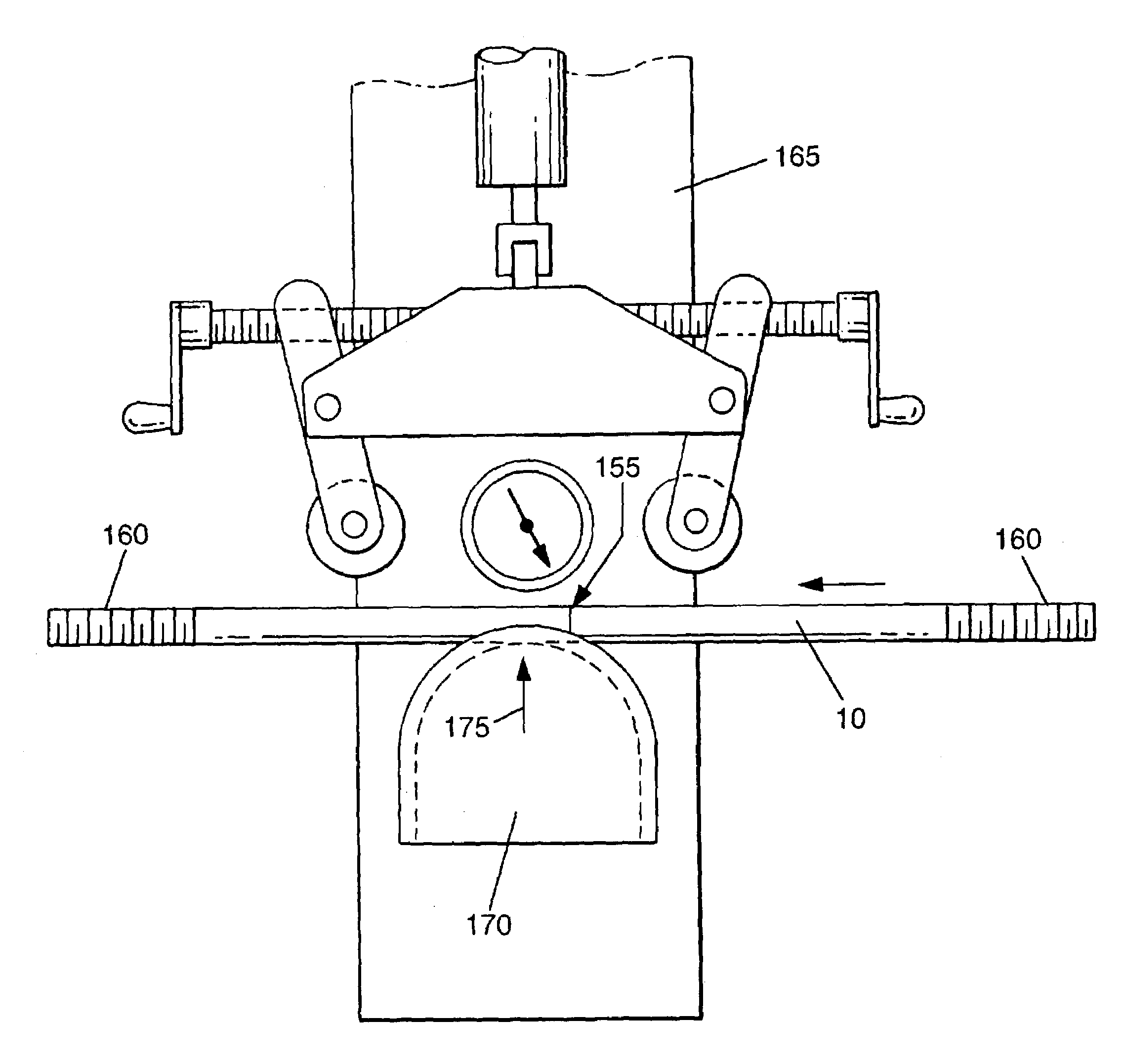

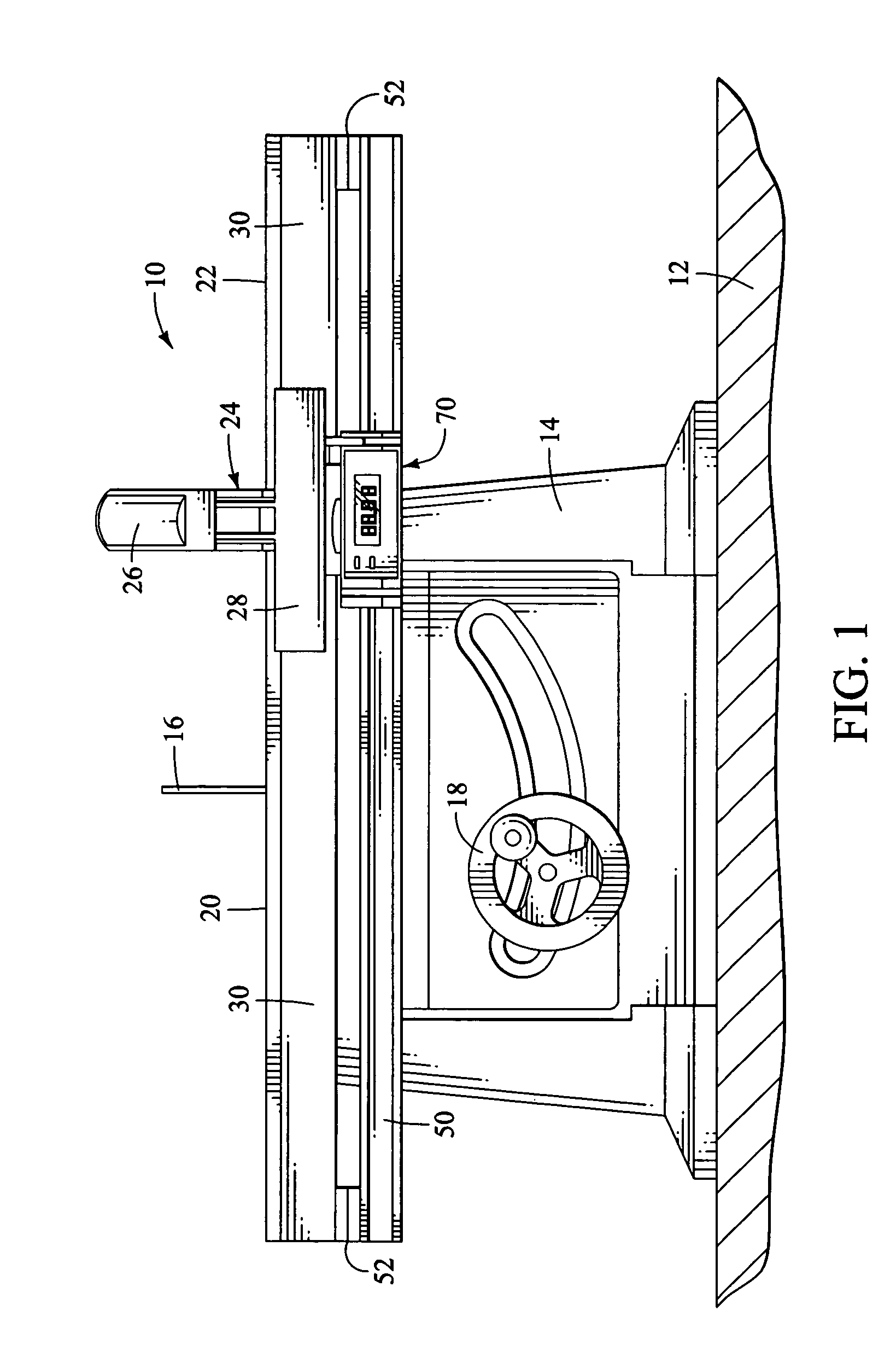

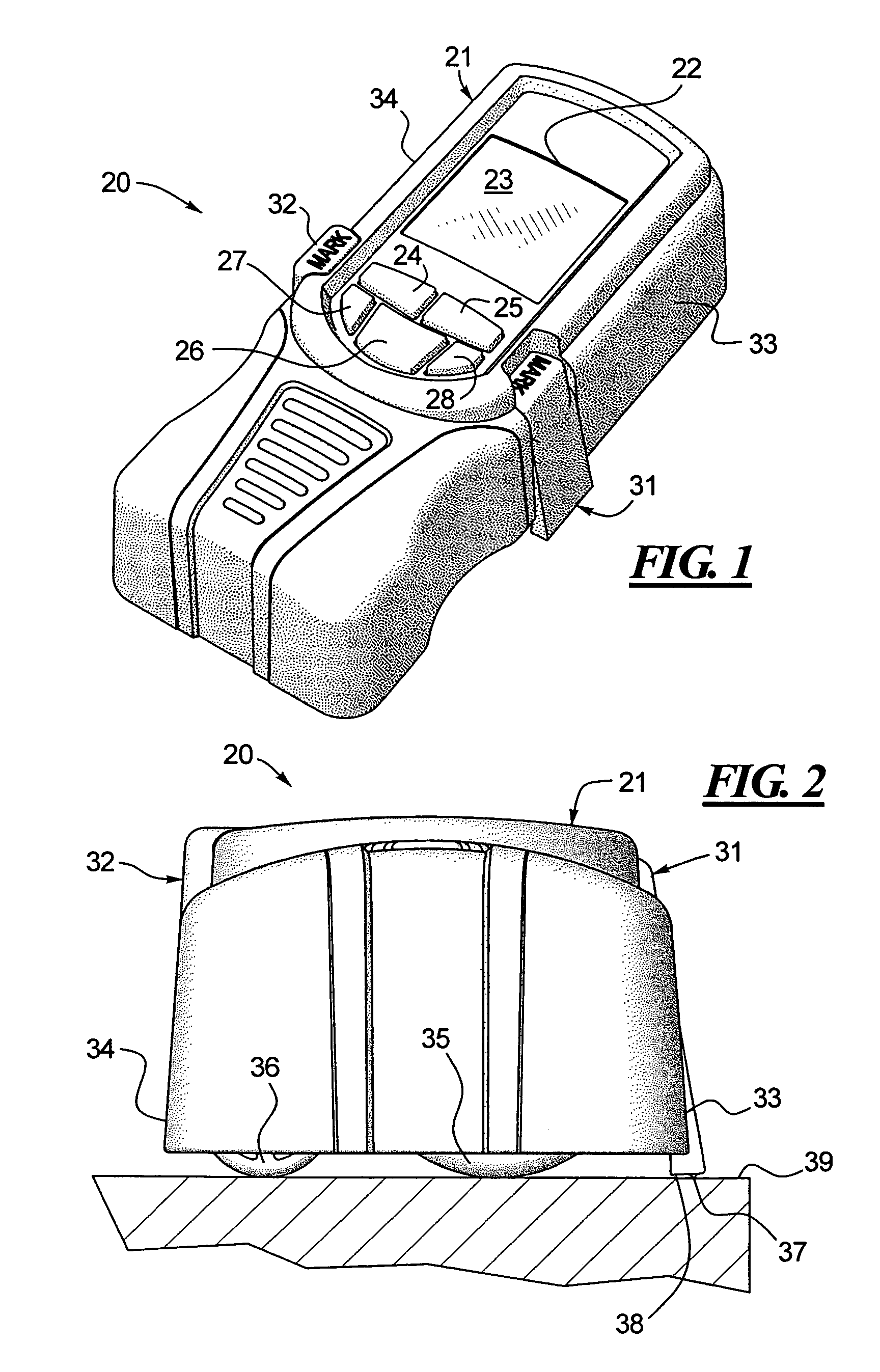

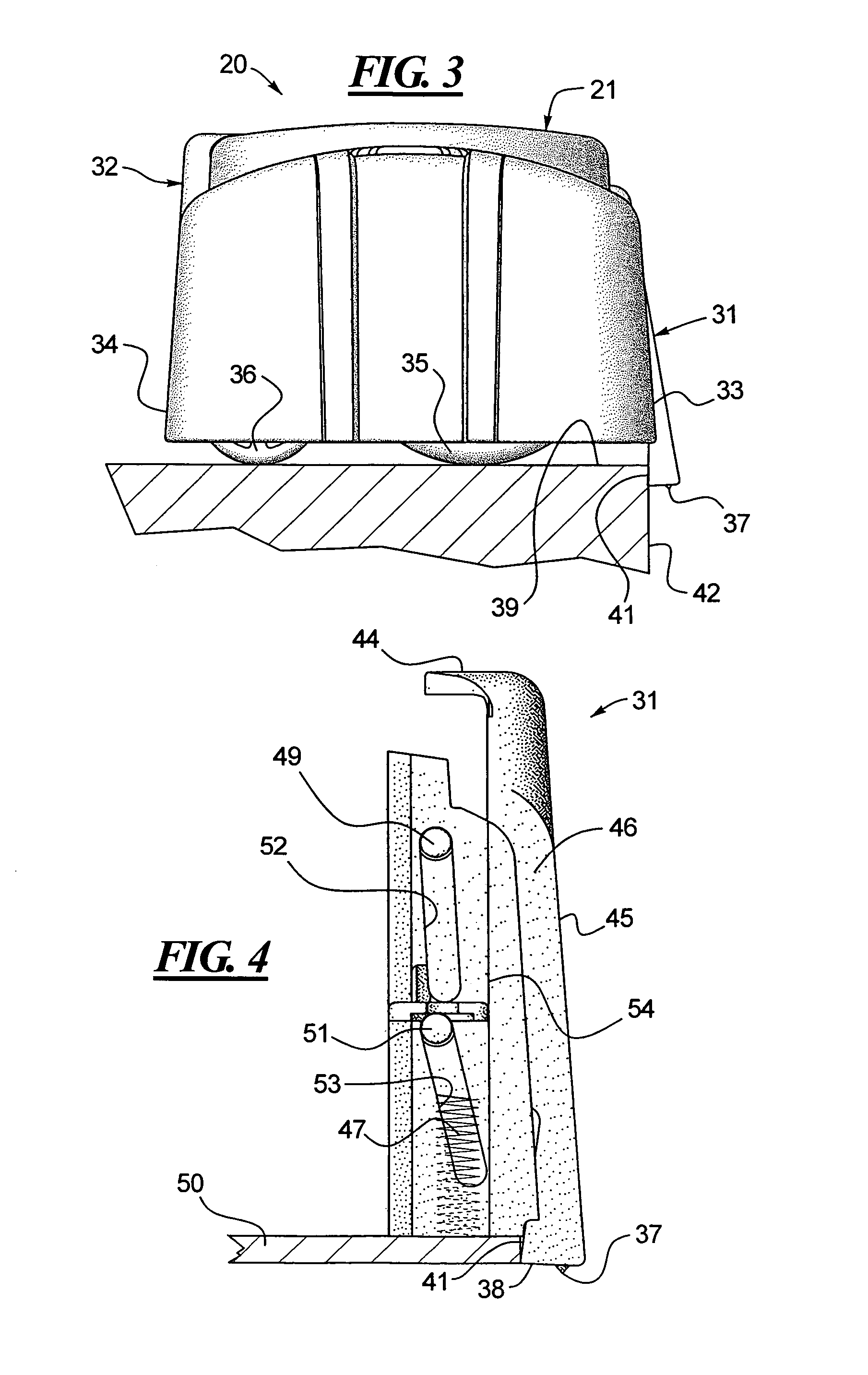

Handheld fish measuring apparatus with integral camera

A handheld apparatus for measuring fish, game, and the like is provided and includes a scale, a camera, and a length measuring device. The scale includes a support member that extends outwardly from the apparatus housing, and a display that is visible through the housing. The support member is configured to suspend an object therefrom for weighing via the scale, and the display is configured to display the weight of an object suspended from the support member. The length measurement device is configured to measure the length of an object and the display is configured to display the length of an object measured by the length measurement device. The camera includes a lens, an image sensor configured to capture images obtained via the lens, and a camera display. The camera display displays an image of an object taken by the camera with weight and / or length information for the object.

Owner:PROPEL IP

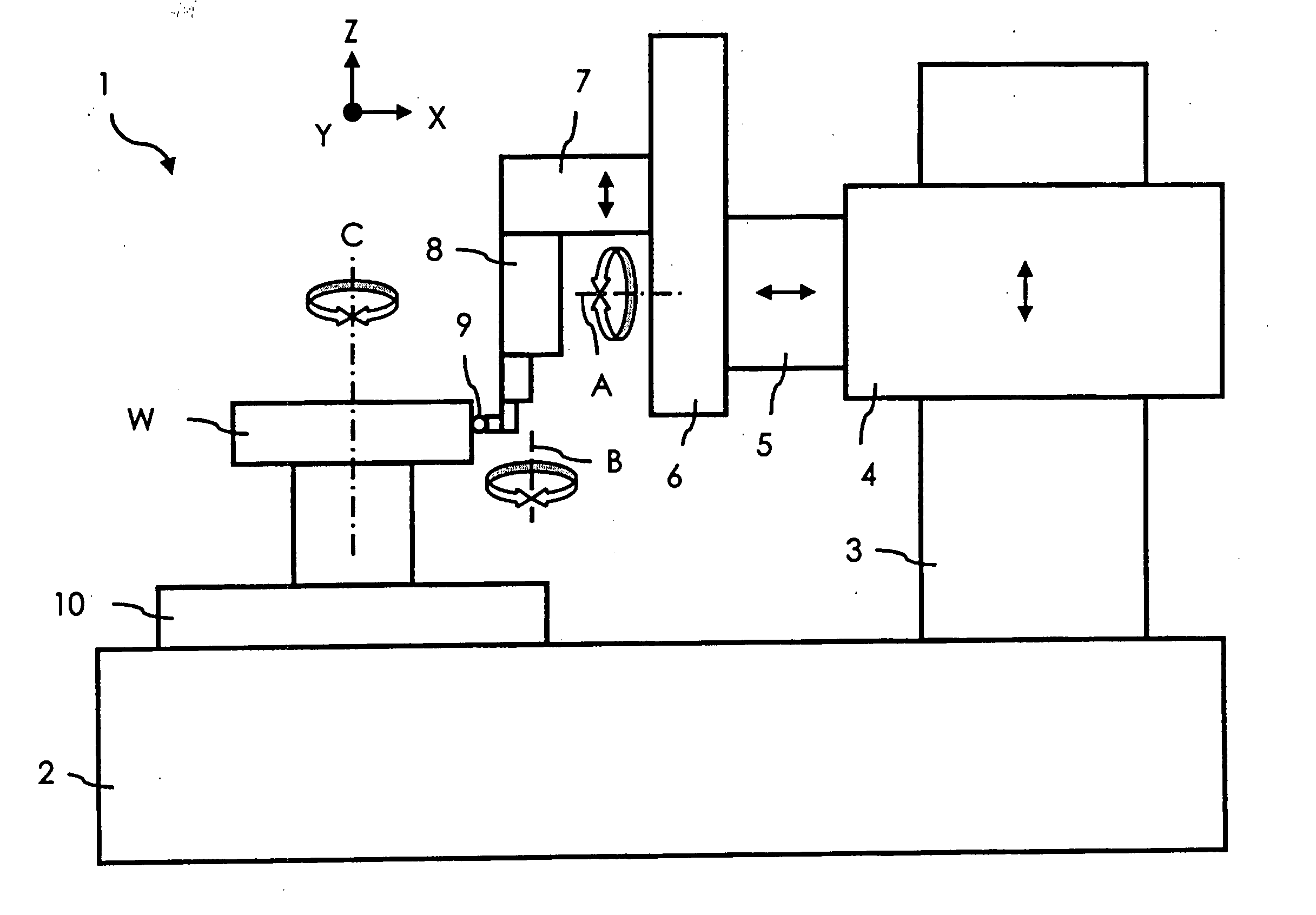

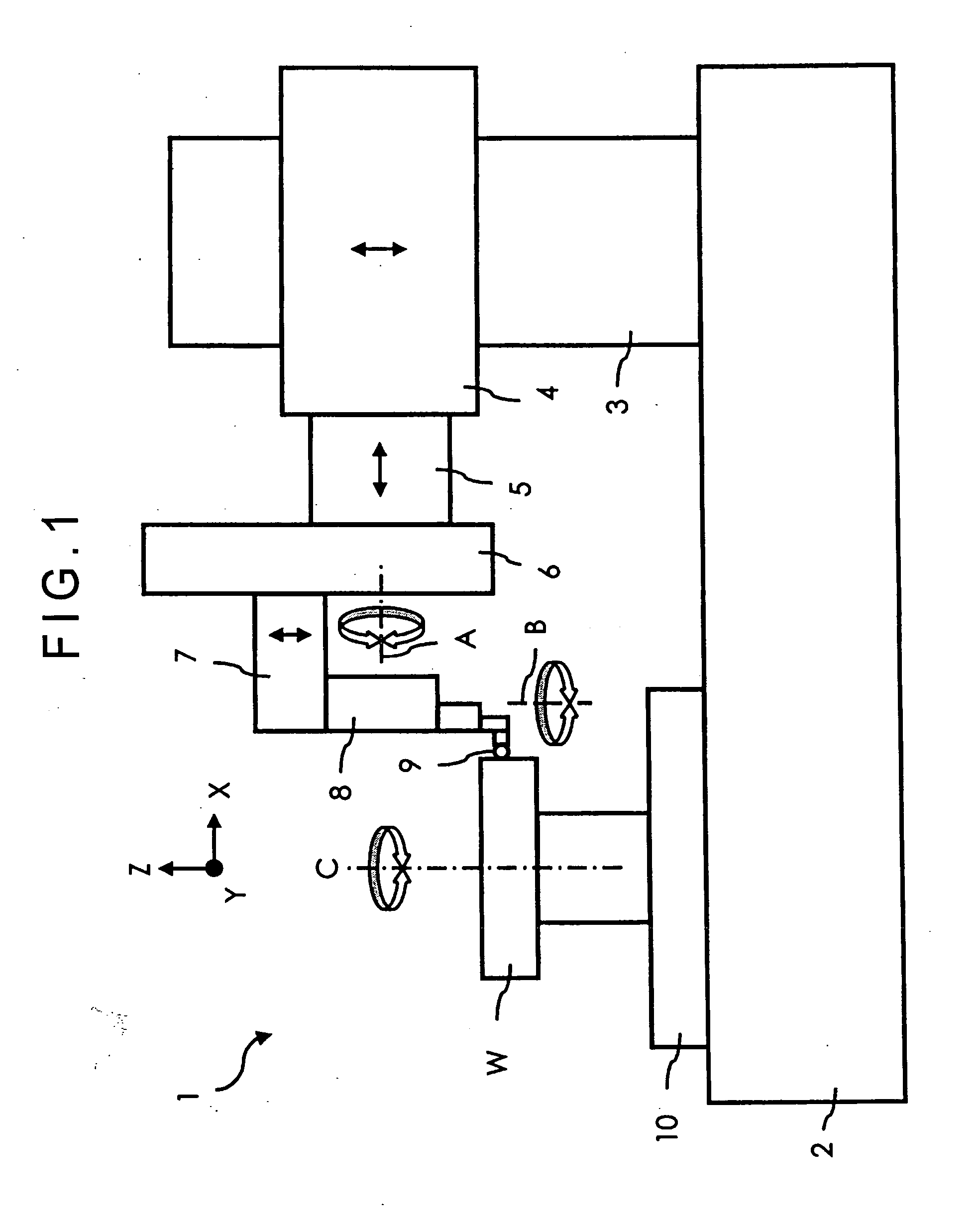

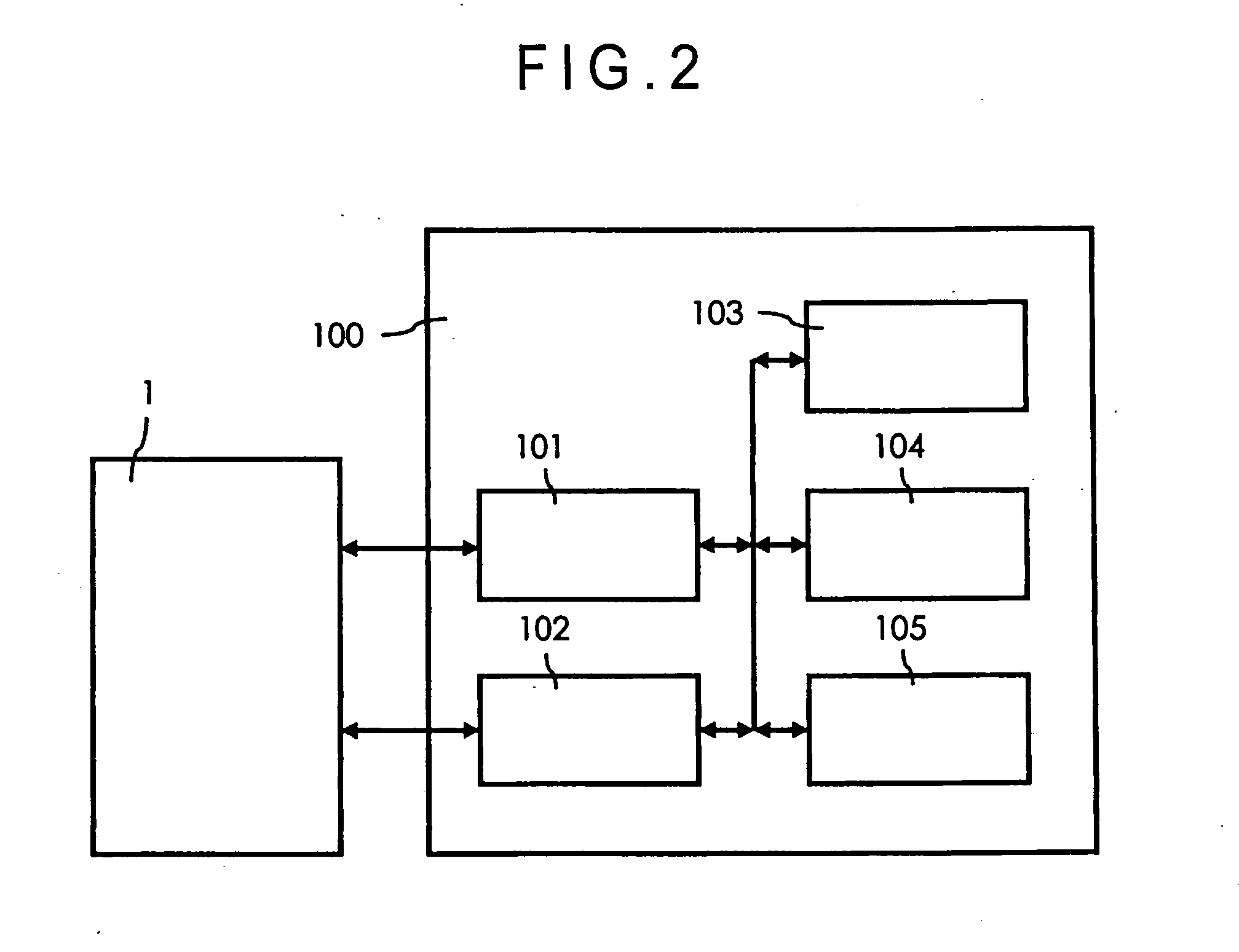

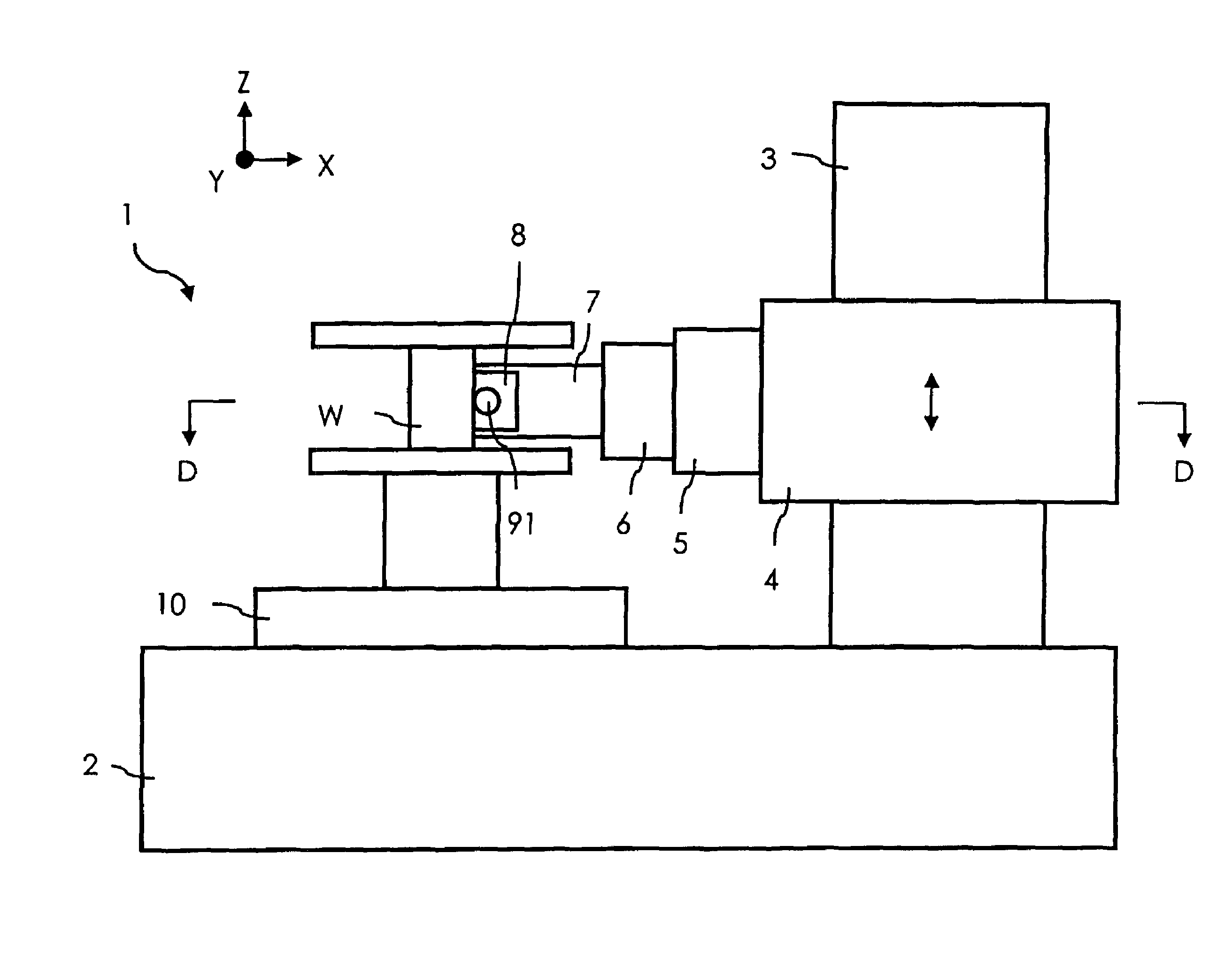

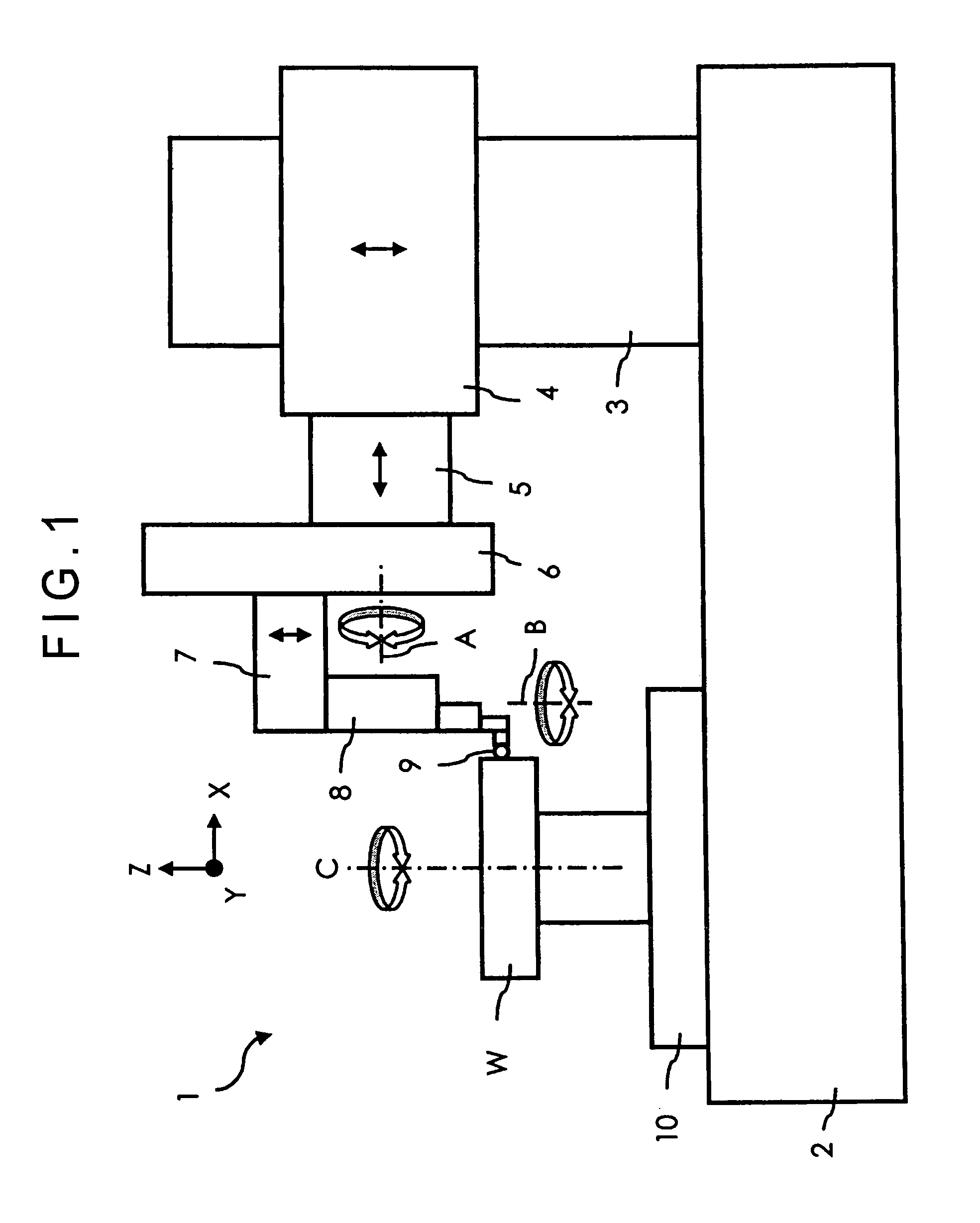

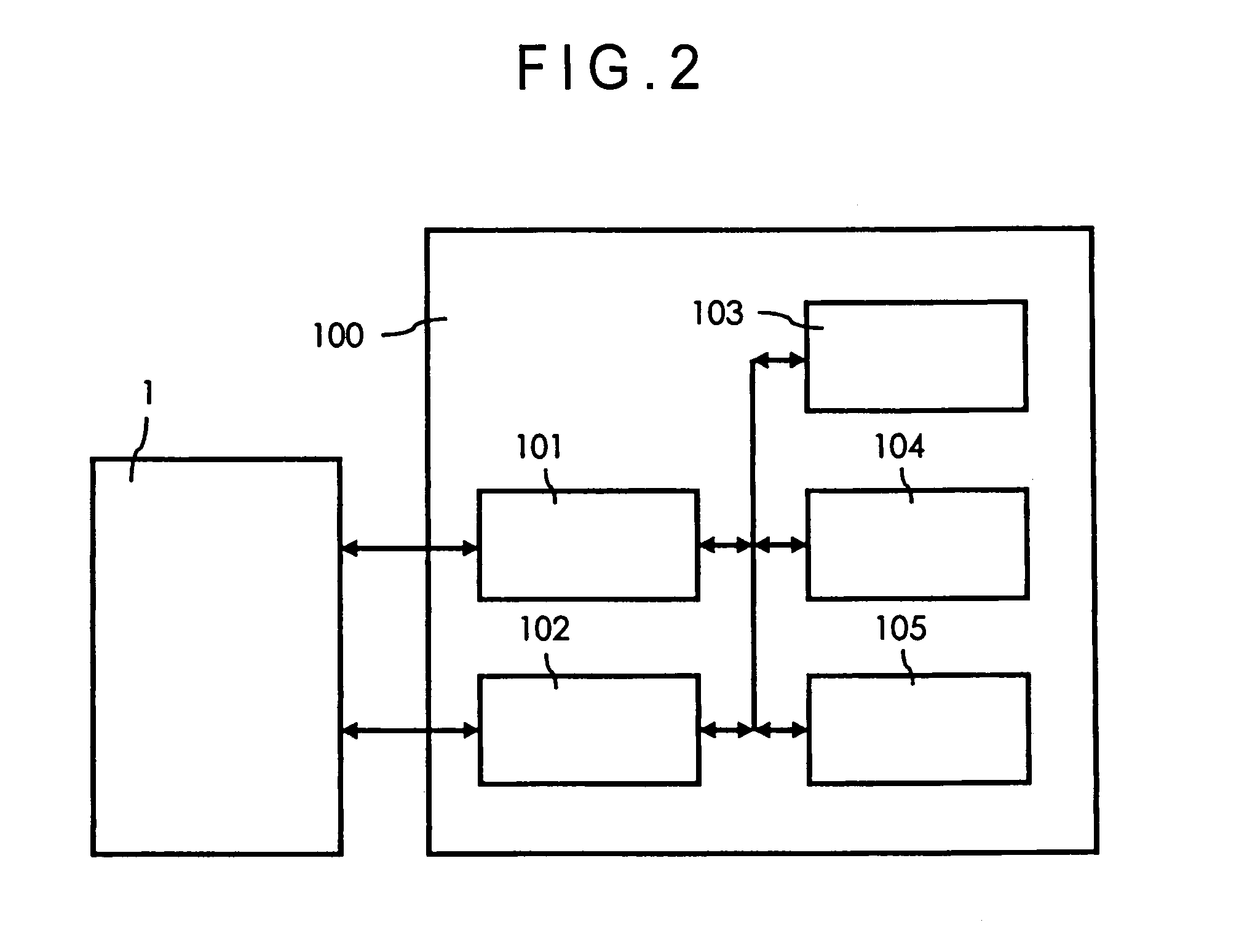

Width-measuring method and surface texture measuring instrument

ActiveUS20050132591A1Easy to measureSimple and accurate measurementMechanical counters/curvatures measurementsMechanical diameter measurementsMeasuring instrumentSurface roughness

A surface texture measuring instrument has a rotary table on which a workpiece is rotatably mounted, a Z-axis slider capable of moving in a Z-axis direction parallel to a rotation axis of the rotary table, an X-axis slider that is held by the Z-axis slider and is advanceable and retractable in an X-axis direction orthogonal to the rotation axis, a first arm that is held by the X-axis slider and is rotatable around a center line parallel to the X-axis, a second arm that is held by the first arm and is advanceable and retractable in a direction orthogonal to the X-axis, and a detector held by the second arm to measure a surface texture of the workpiece.

Owner:MITUTOYO CORP

Handheld fish measuring apparatus with integral camera

A handheld apparatus for measuring fish, game, and the like is provided and includes a scale, a camera, and a length measuring device. The scale includes a support member that extends outwardly from the apparatus housing, and a display that is visible through the housing. The support member is configured to suspend an object therefrom for weighing via the scale, and the display is configured to display the weight of an object suspended from the support member. The length measurement device is configured to measure the length of an object and the display is configured to display the length of an object measured by the length measurement device. The camera includes a lens, an image sensor configured to capture images obtained via the lens, and a camera display. The camera display displays an image of an object taken by the camera with weight and / or length information for the object.

Owner:PROPEL IP

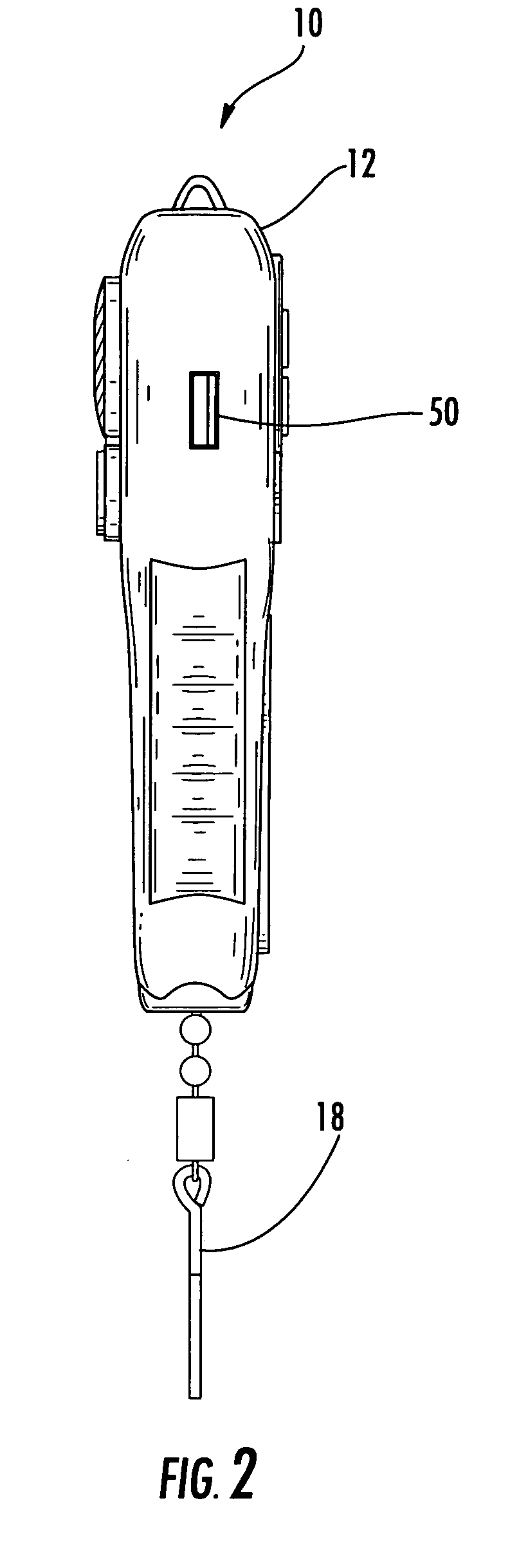

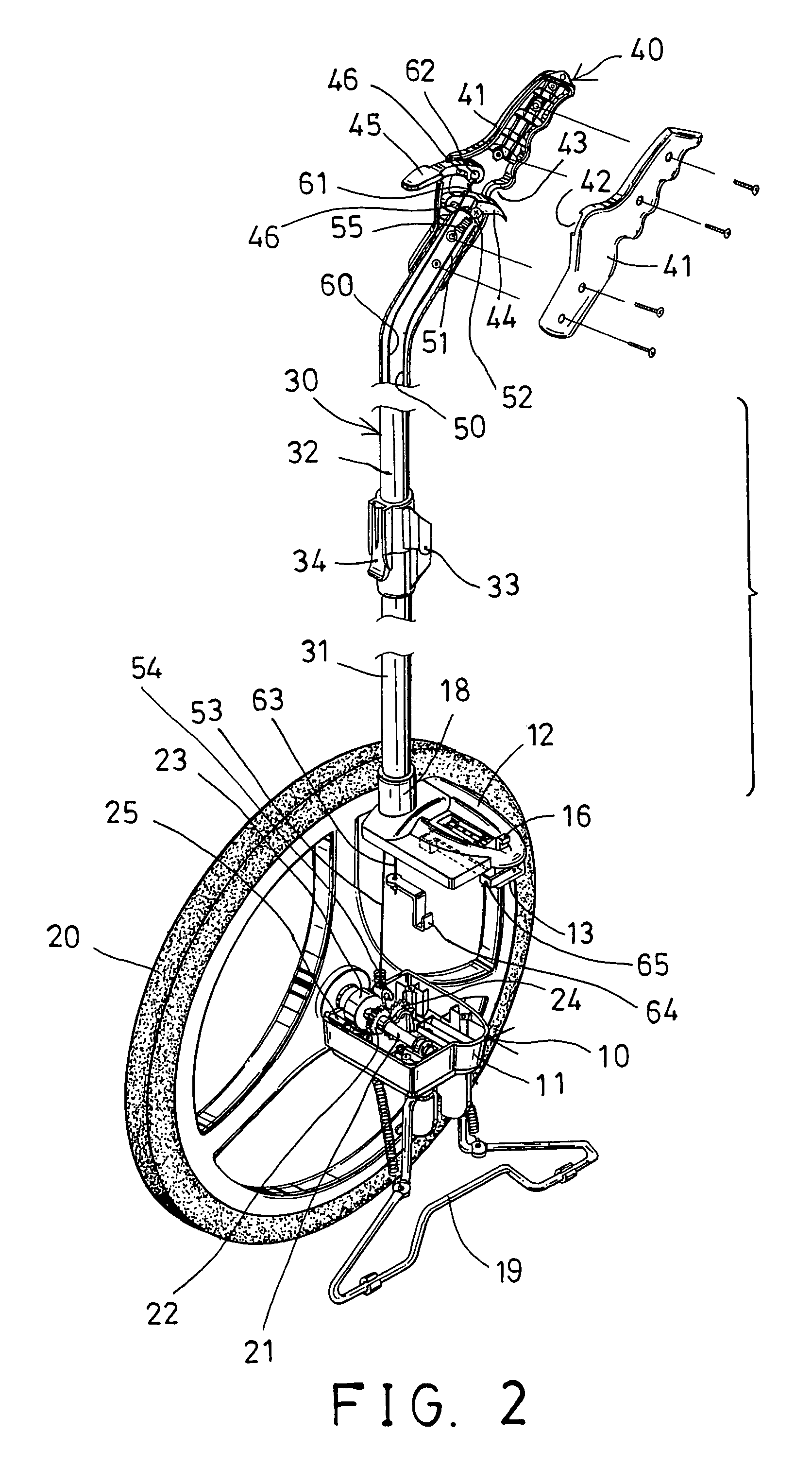

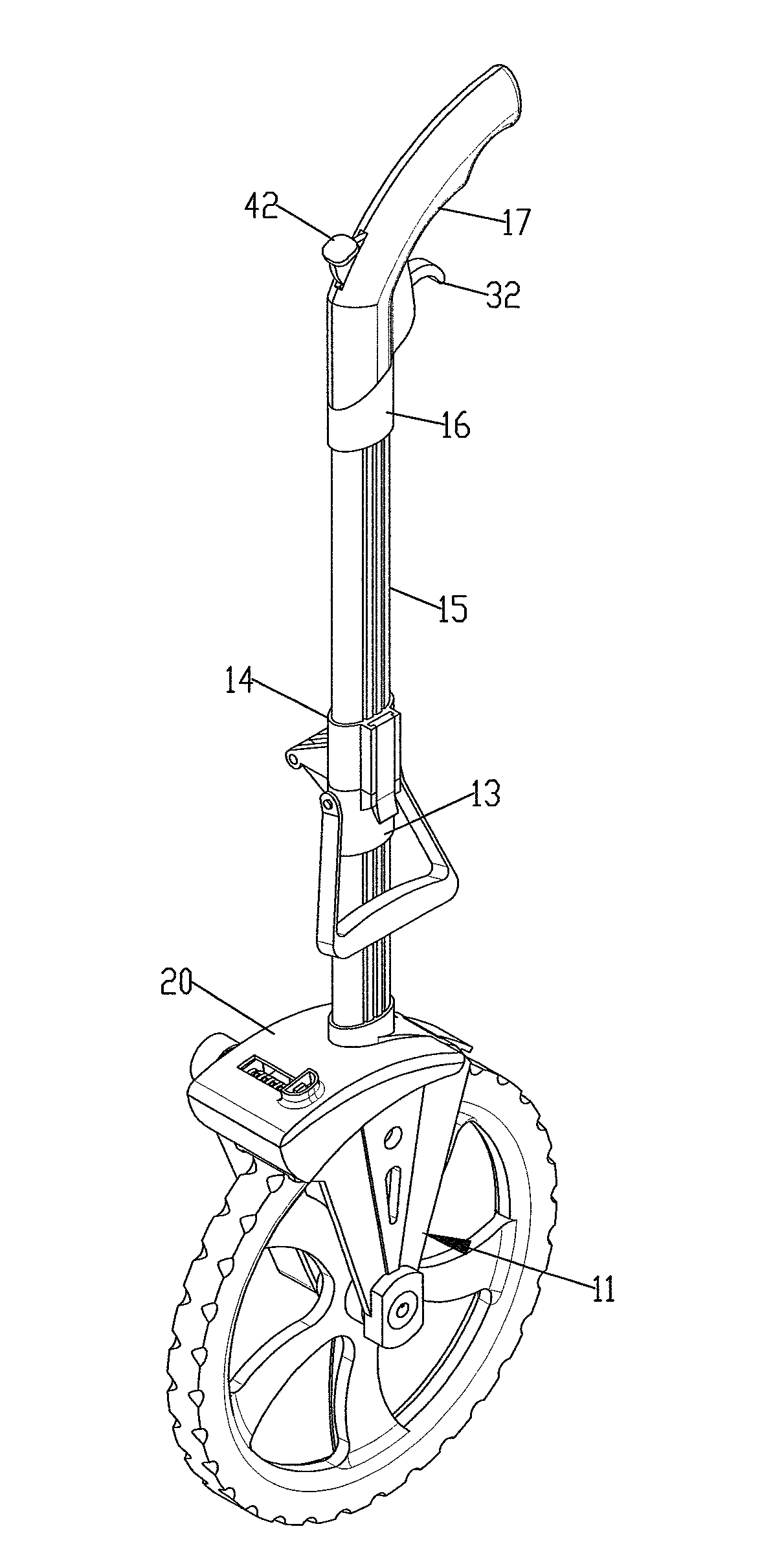

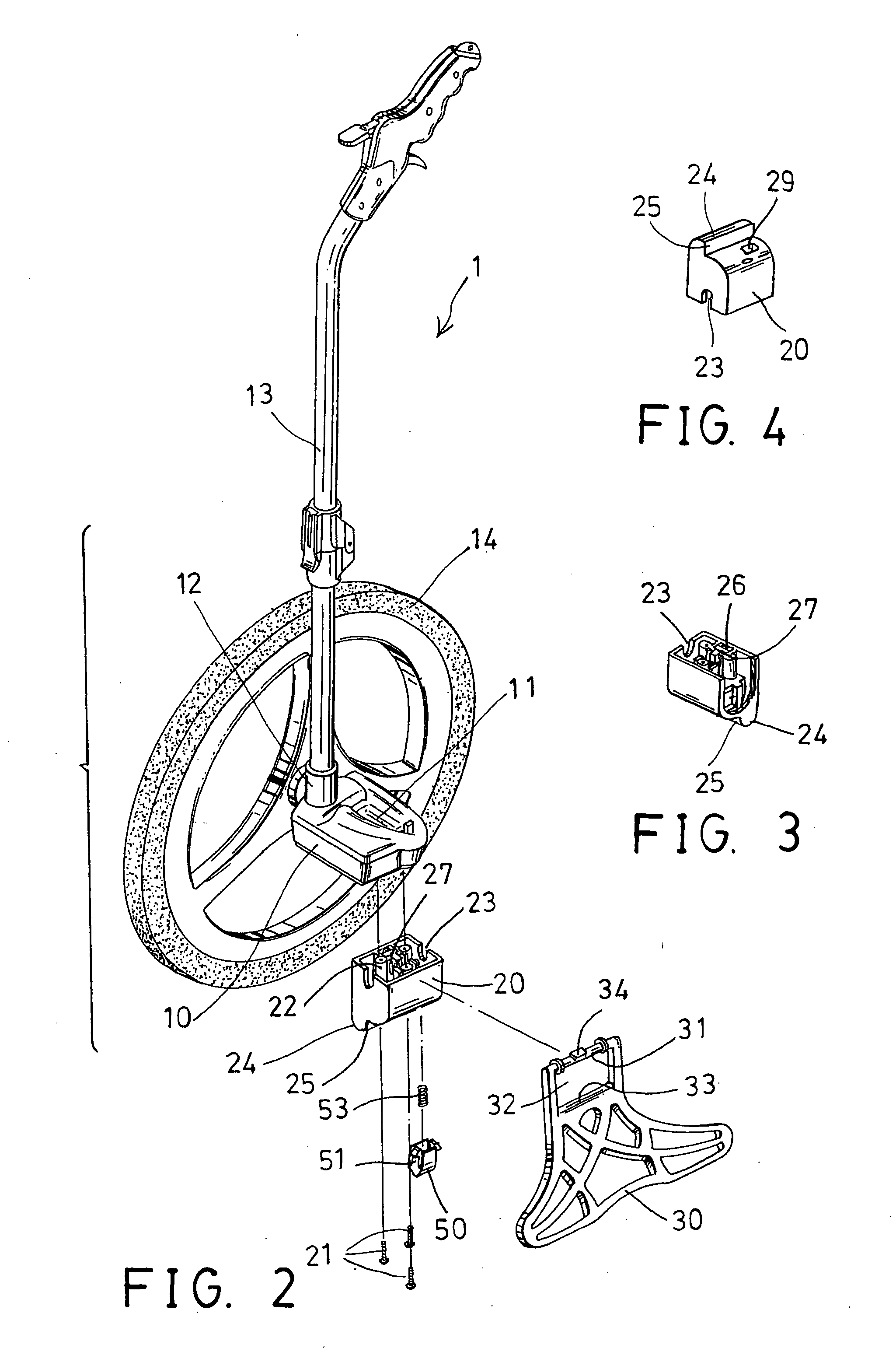

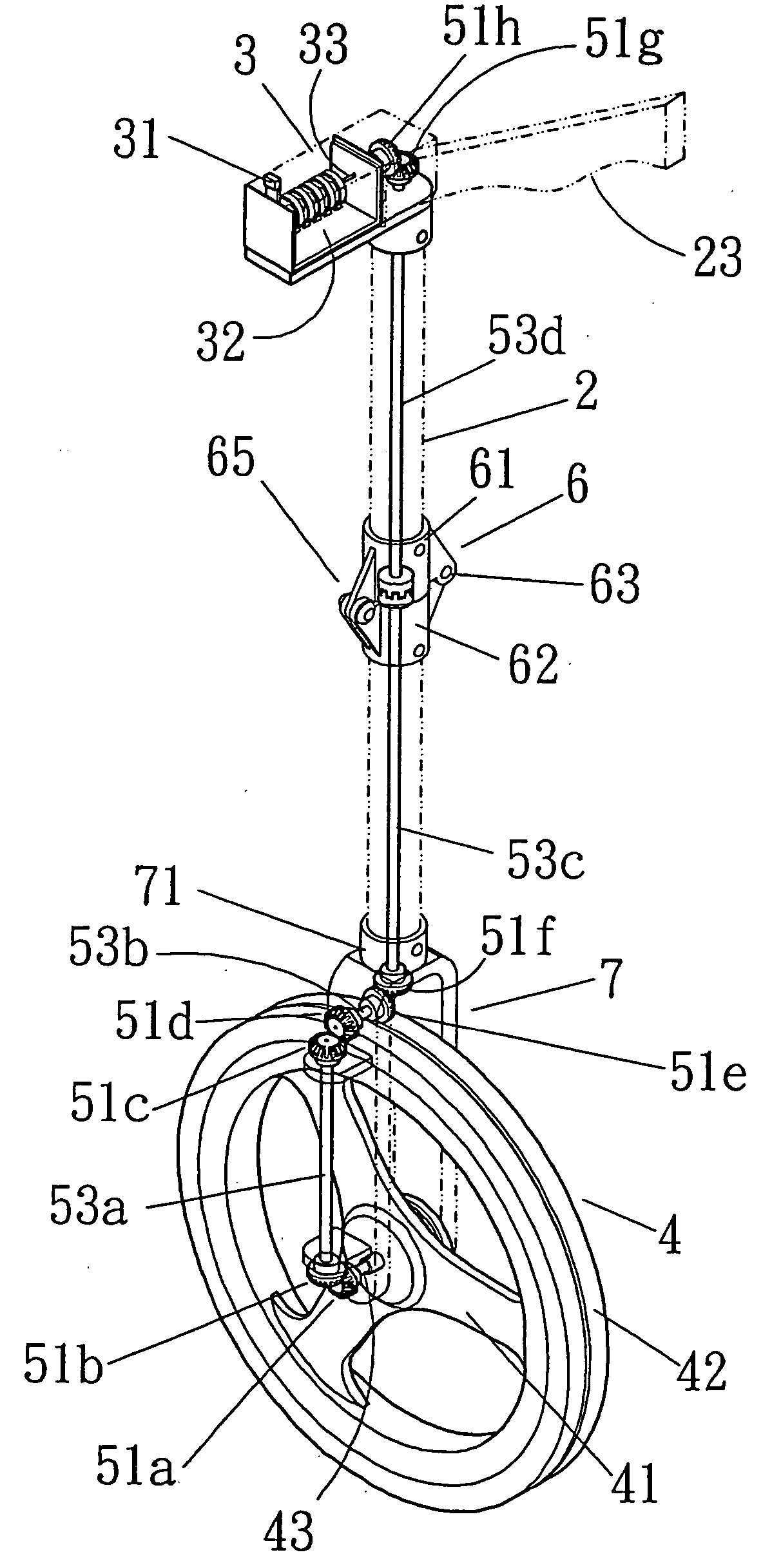

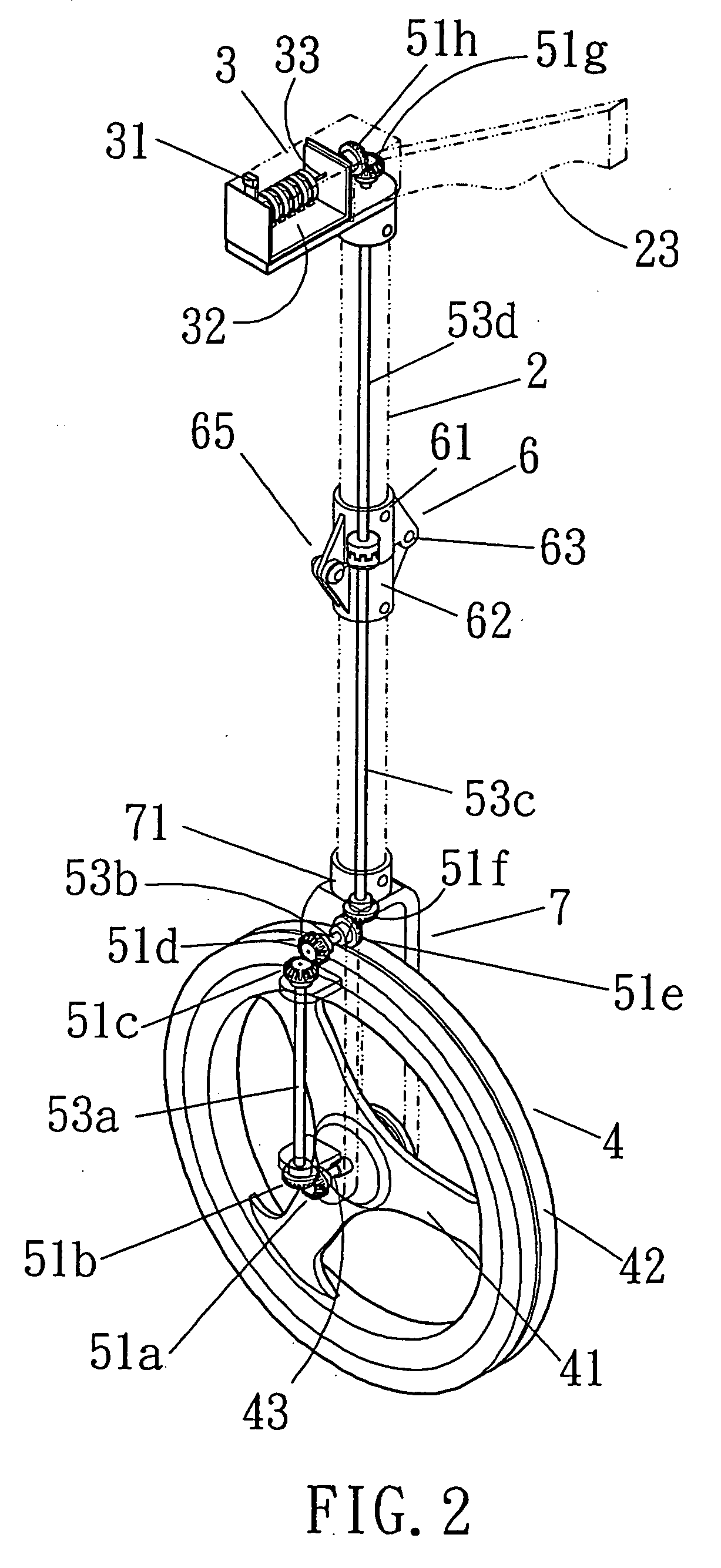

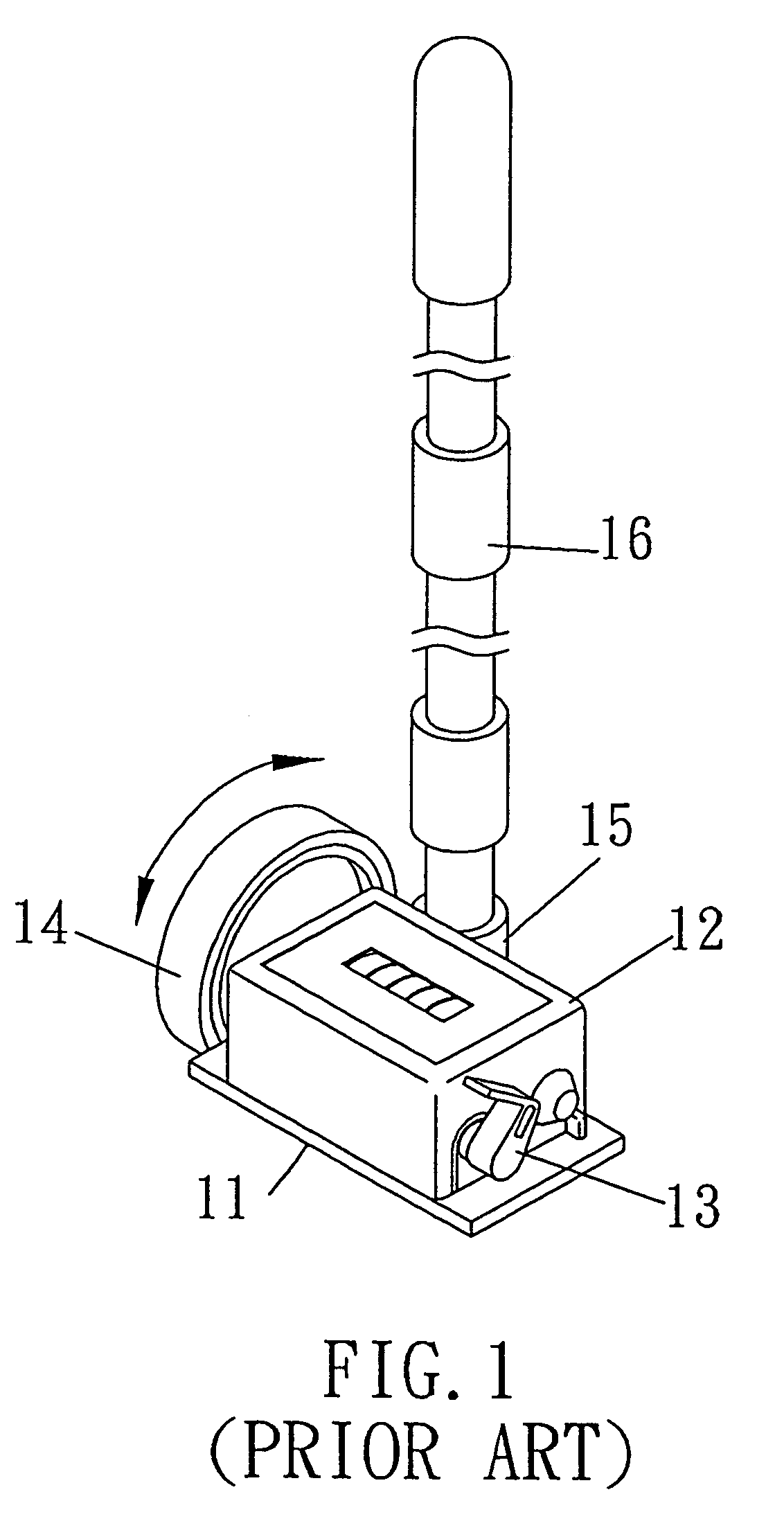

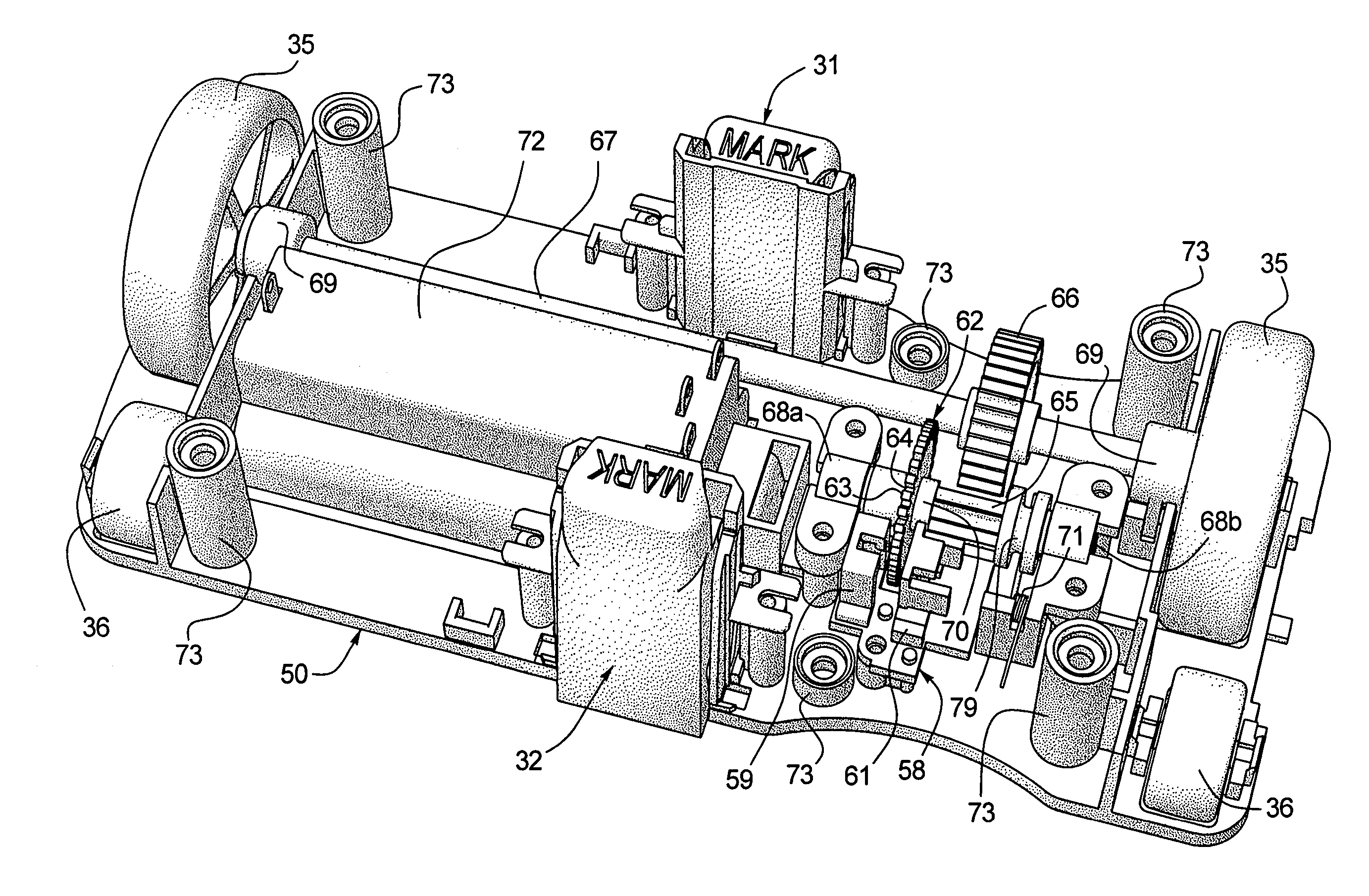

Distance measuring device

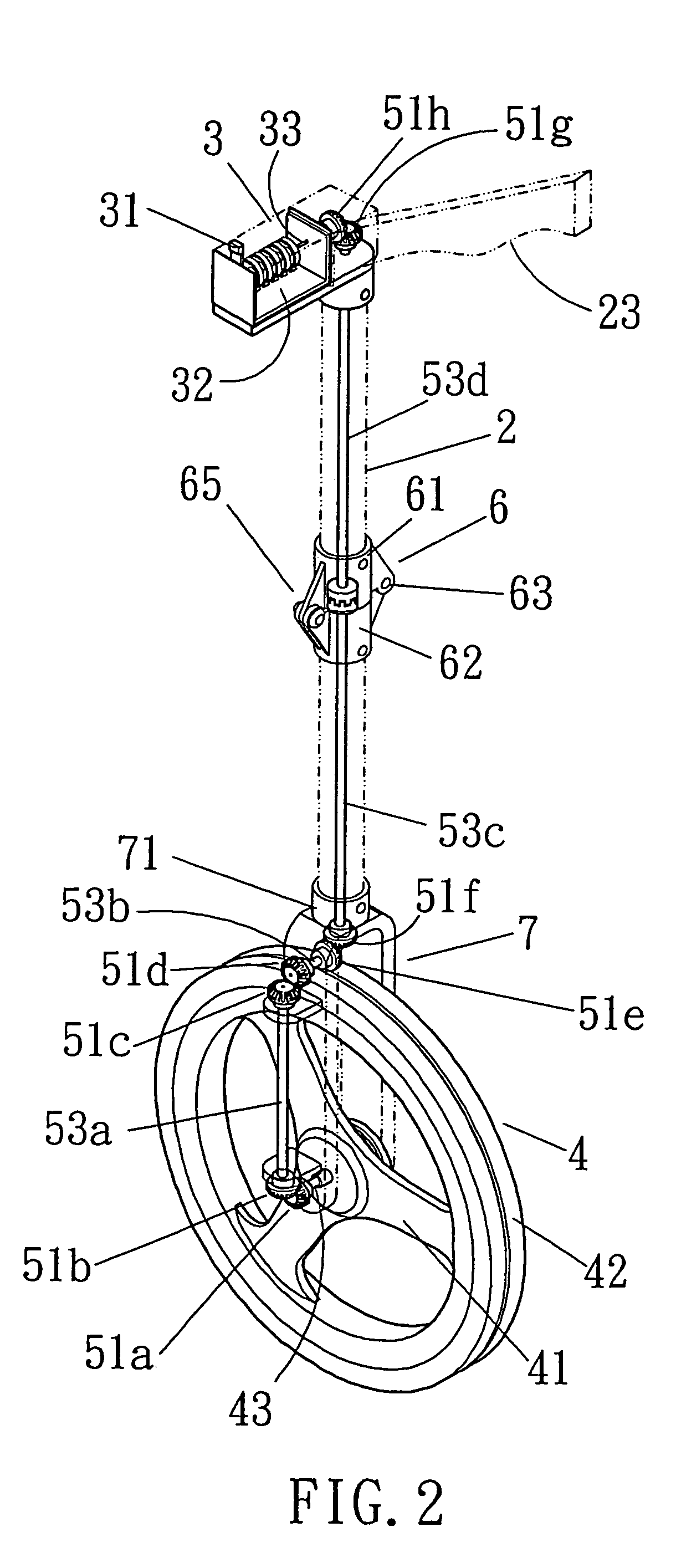

A distance measuring device includes a housing having a distance meter, a measuring wheel having a wheel axle rotatably engaged into the housing and coupled to the distance meter. A brake wheel is disposed on the wheel axle. A brake arm is pivotally secured in the housing and movable to engage with the brake wheel for braking the brake wheel. A pole includes a foldable structure, a handle is disposed on top of the pole, a brake lever and a handgrip are pivotally secured to the handle and extended out of the handle for being actuated by users, and coupled to the brake arm and the distance meter with flexible brake cable and a flexible wire, which allow the segments of the pole to be folded relative to each other.

Owner:WANG HUI CHEN

Method and device for testing the tightness of an electric machine stator core

ActiveUS20130047748A1Material analysis using sonic/ultrasonic/infrasonic wavesMagnetic circuitElectric machineEngineering

A method is provided for testing the tightness of an electric machine stator core includes: introducing a test instrument that is connected to a movable support into an air gap between a stator core and a rotor, locally placing the test instrument and locally testing defined zones of the generator stator core. A device for carrying out the method is also provided.

Owner:GENERAL ELECTRIC TECH GMBH

Aweigh we go multi-purpose digital scale

InactiveUS20070045011A1Function increaseEasy to holdMeasuring wheelsUsing electrical meansCommon carrierComputer science

A portable scale that allows travelers to calculate the weight of their luggage and compare the weight against weight limits that are imposed by common carriers. The scale includes circuitry for calculating weight and a memory for storing weight limits. Weight and other information is shown to the user via a display screen. In the preferred embodiment, the scale includes a hook and handle that facilitate weighing suitcases and other objects. The preferred embodiment also includes a digital measuring tape that allows the traveler to check the size of his luggage against size restrictions imposed by common carriers. The scale can also be incorporated into a portable weighing mat, which allows weight to be determined simple by placing the object on the mat. The scale can also be incorporated into the handle of a suitcase wherein the weight of the suitcase is calculated when the suitcase is lifted by its handle.

Owner:DITTRICH JOSEPHINE M +1

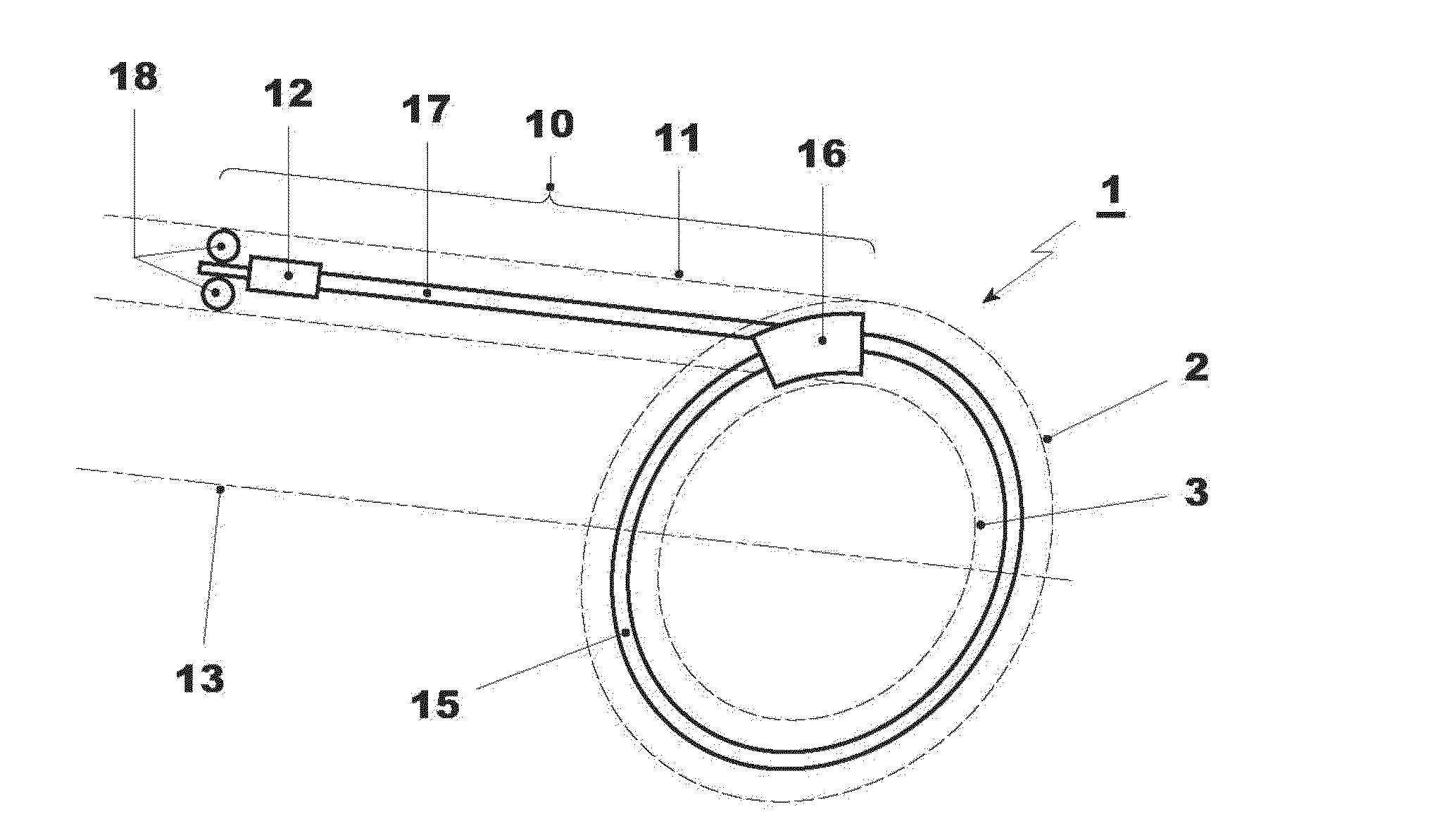

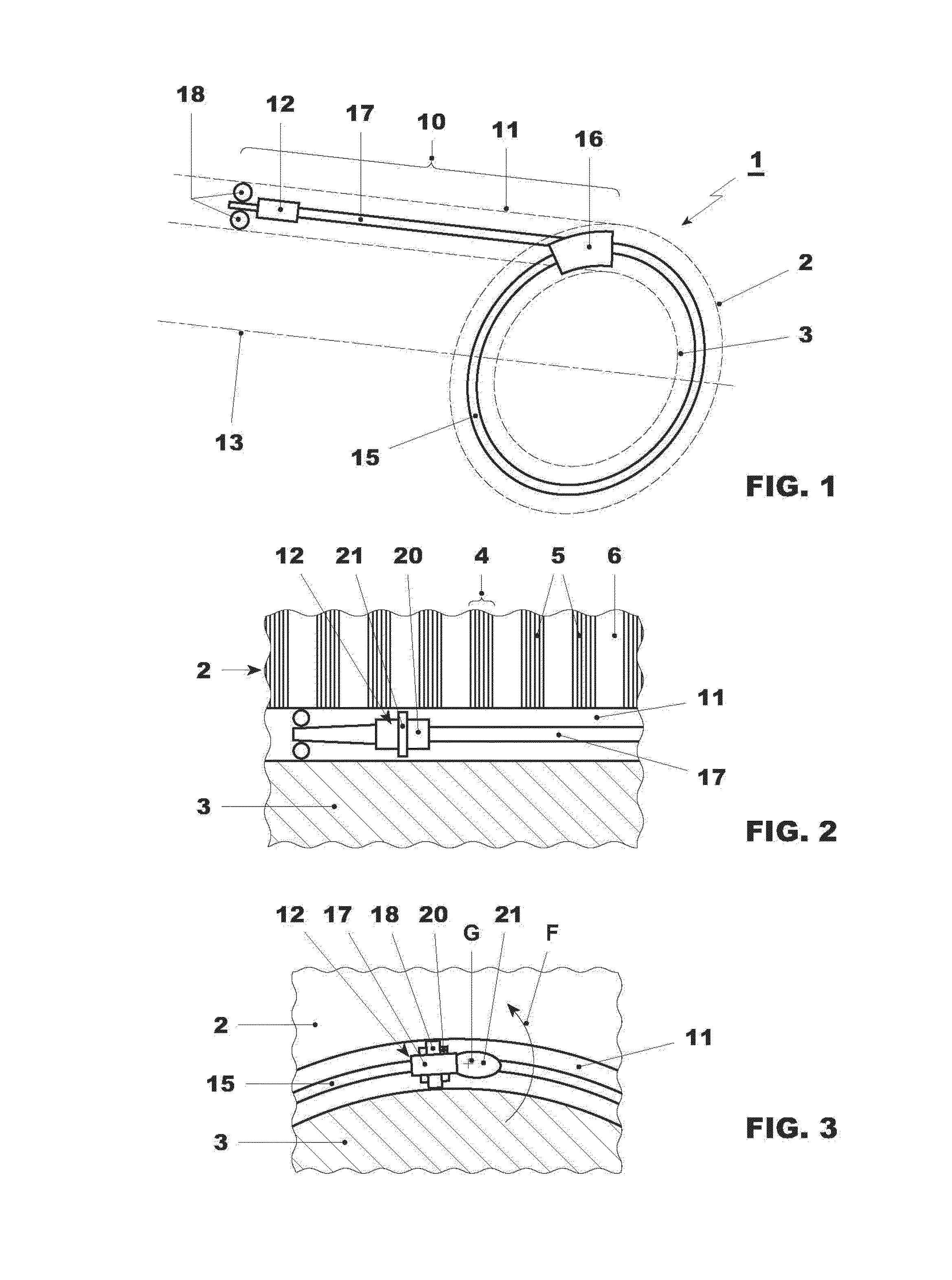

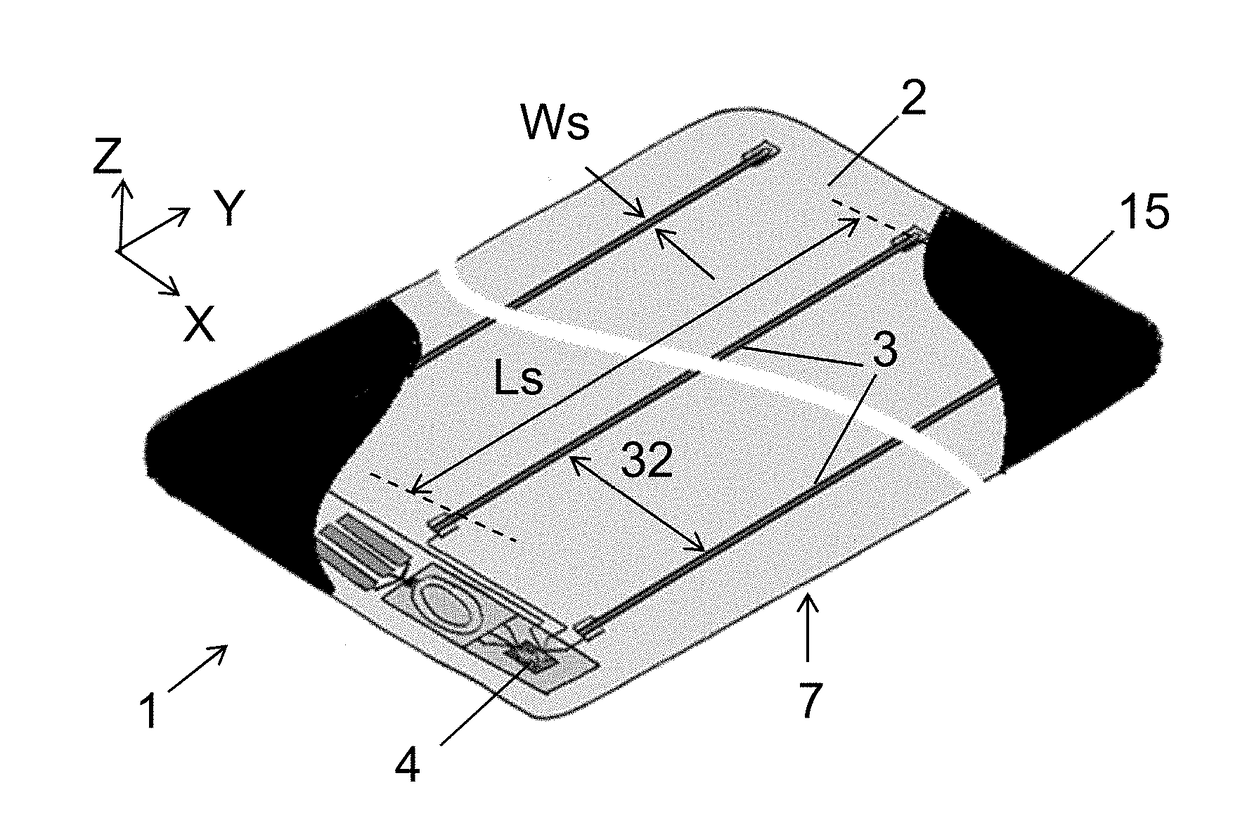

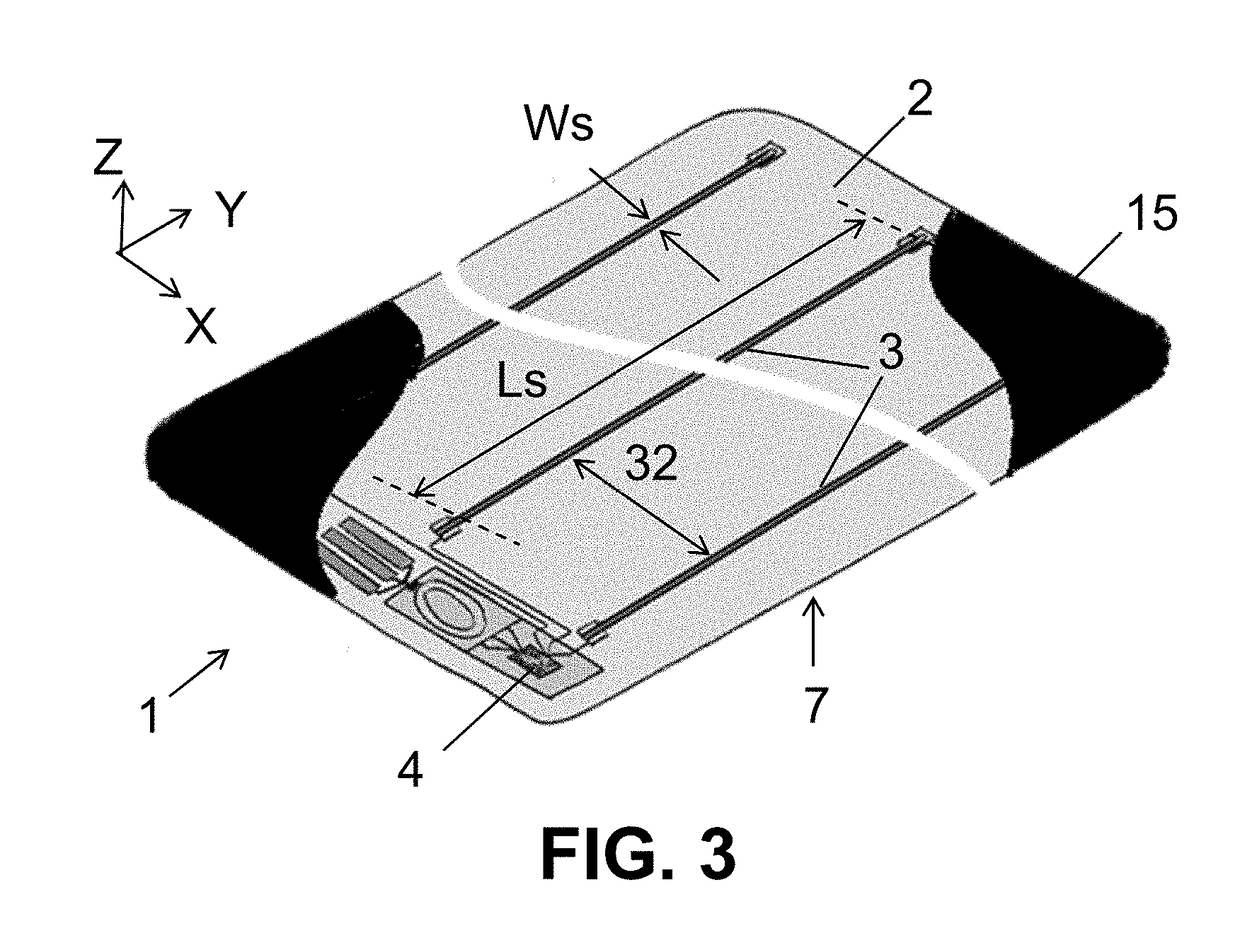

Elastic Sensor

InactiveUS20170265810A1Not to damageAccurate locationAnimal reproductionElectromyographyEngineeringSensor system

A stretchable sensor patch comprising: an elastic film layer with a stretchability of at least 100% and at least one elastic DEAP strip with a stretchability of at least 50%. The sensor patch may comprise an integrated circuit, a memory, an energy source, an adhesion layer for adhesion of the film layer to a skin, and a protective layer. A sensor system with such a sensor patch is also disclosed.

Owner:BAINISHA CVBA

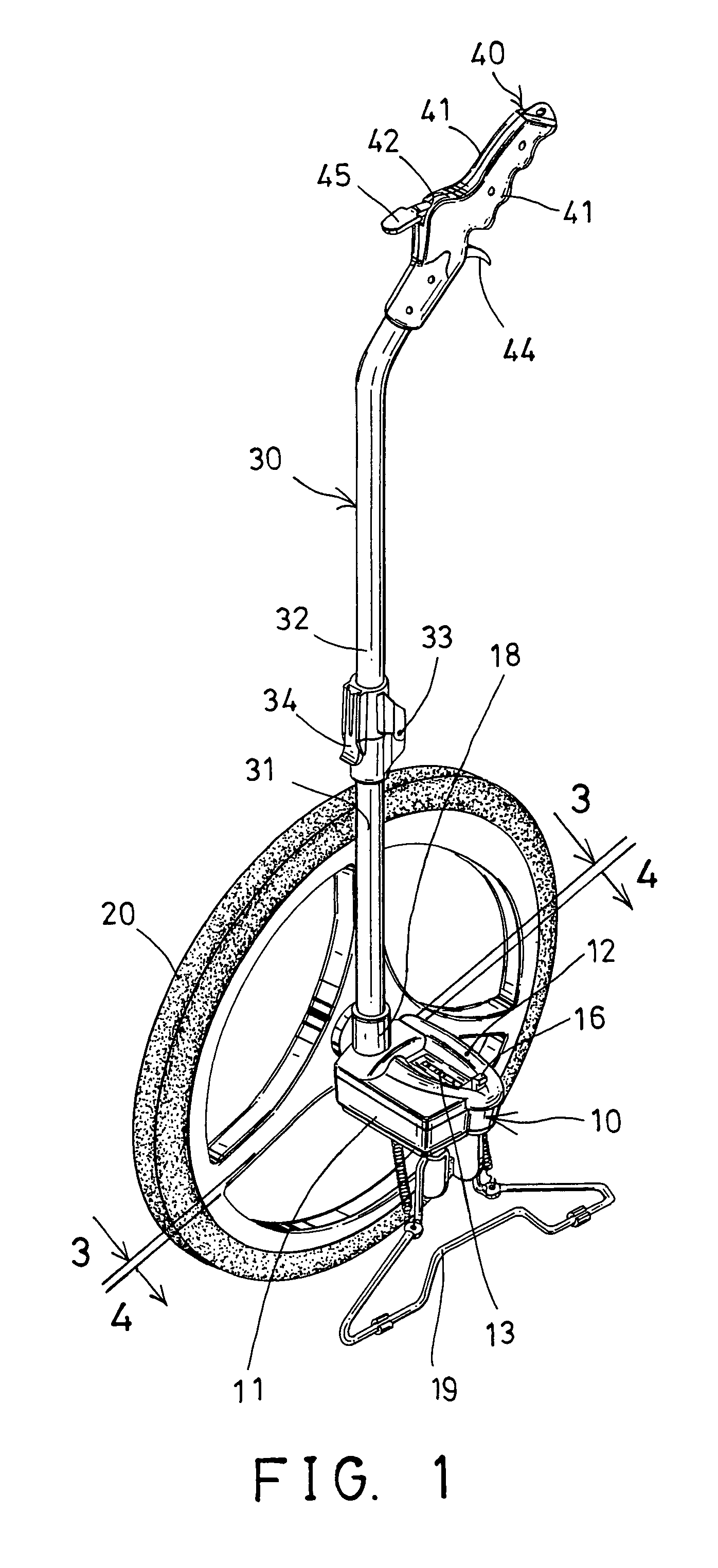

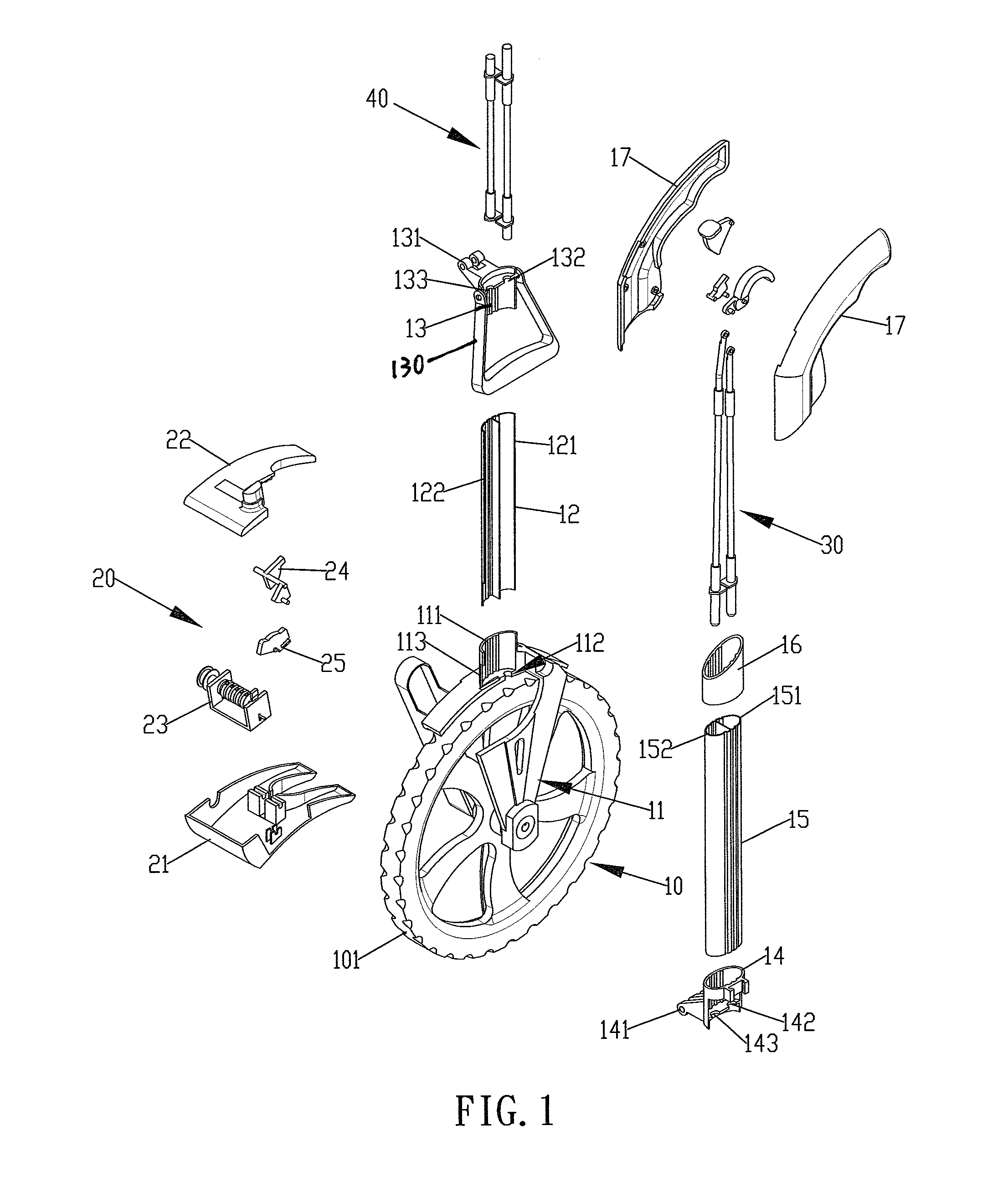

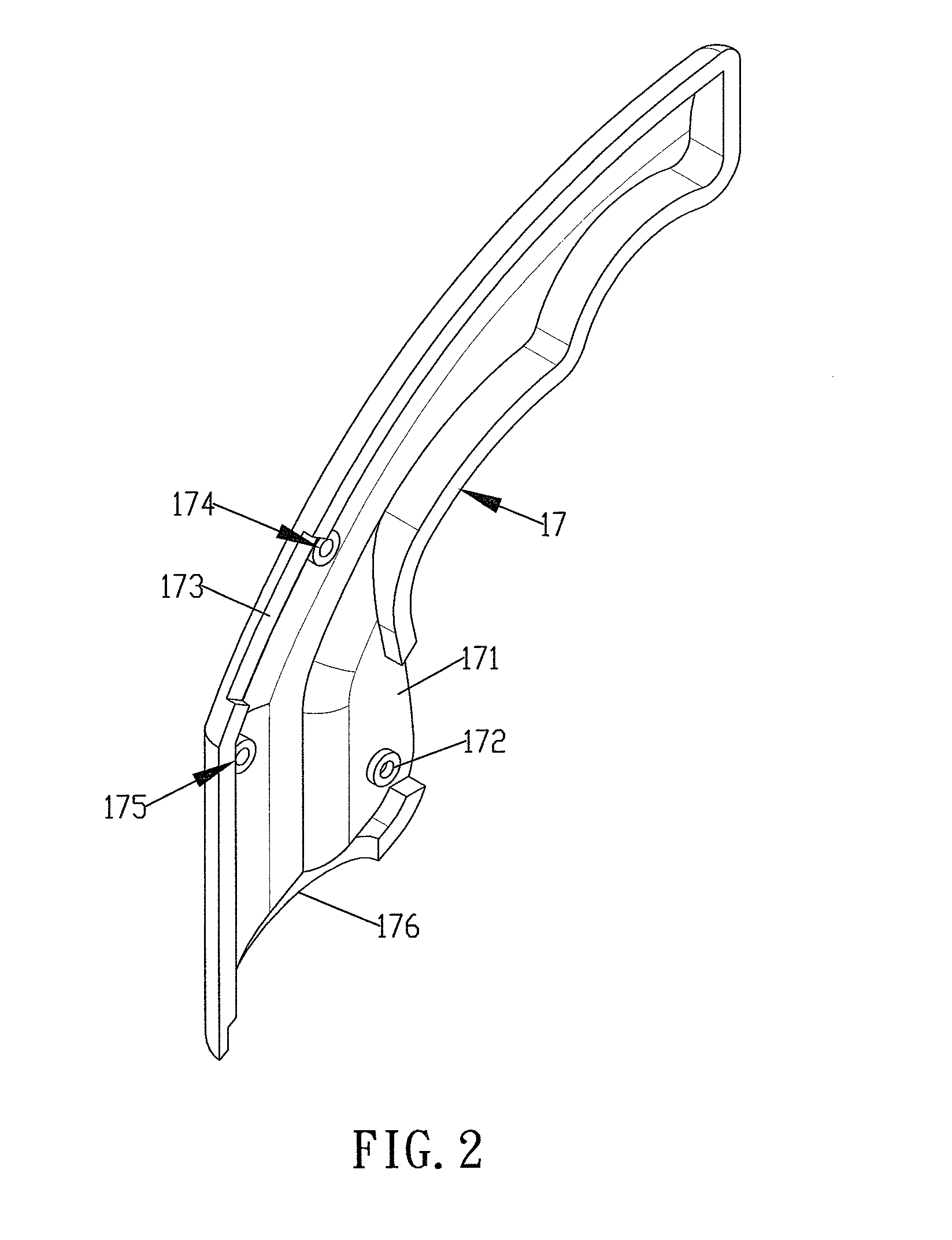

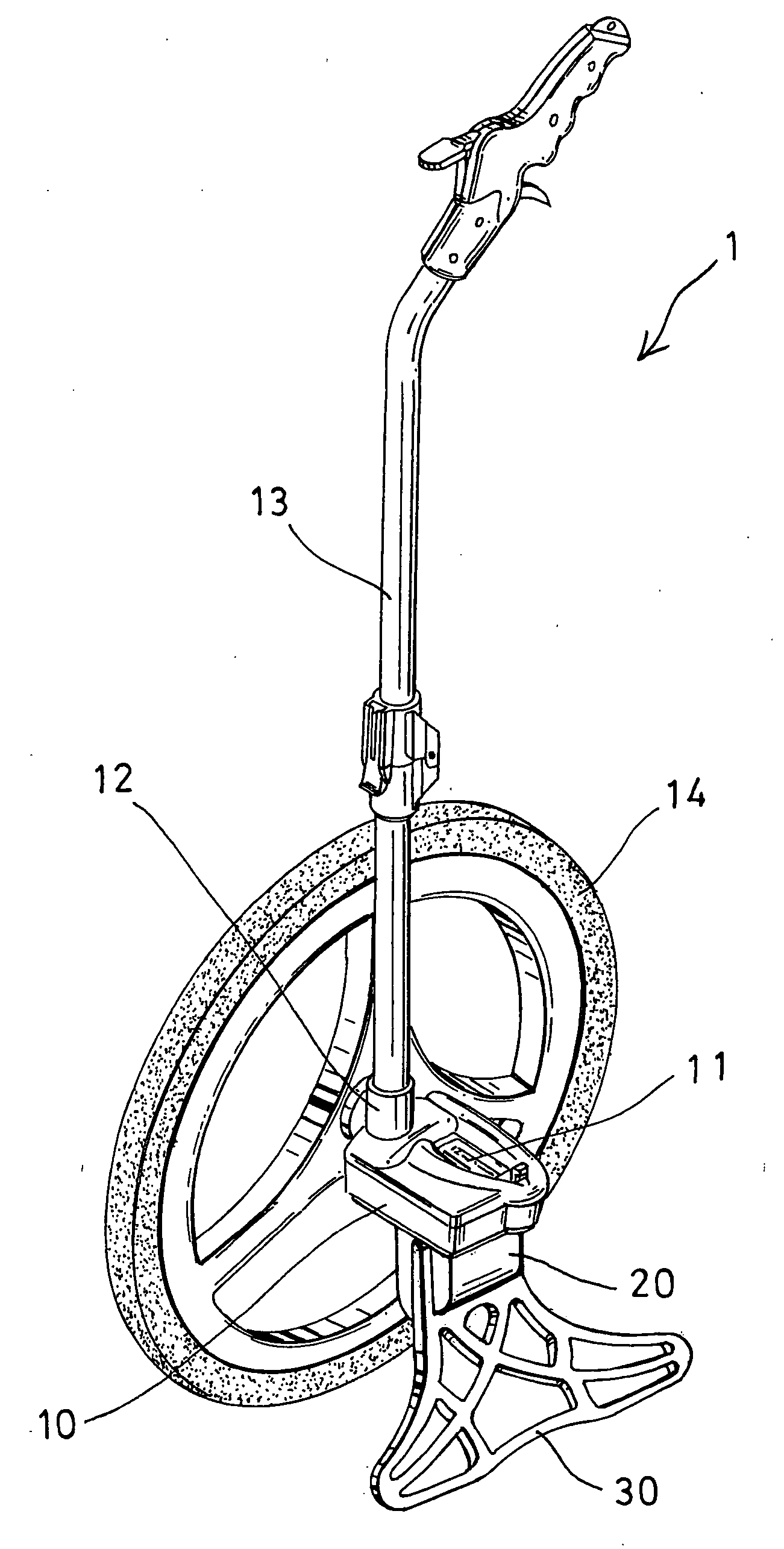

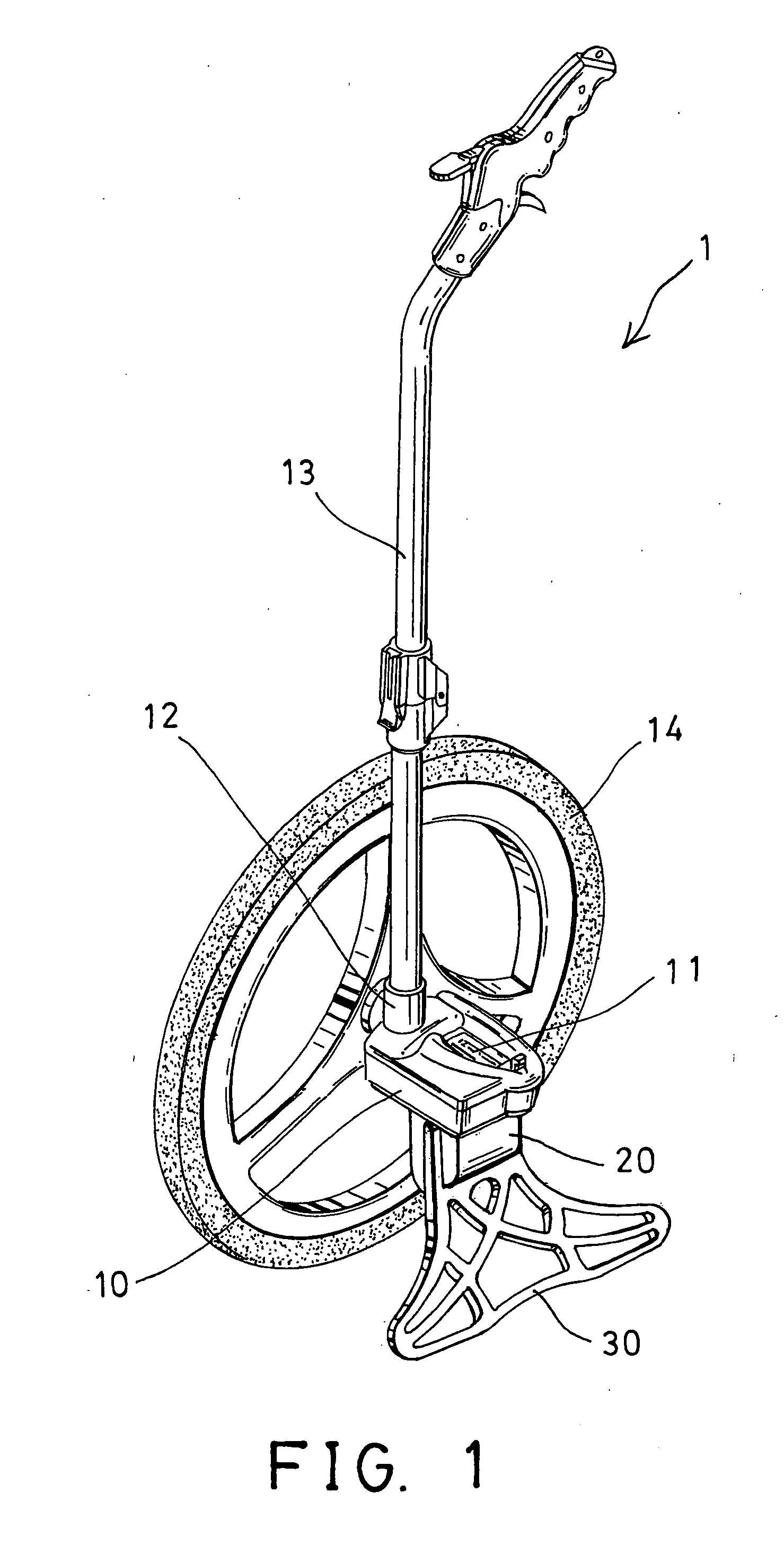

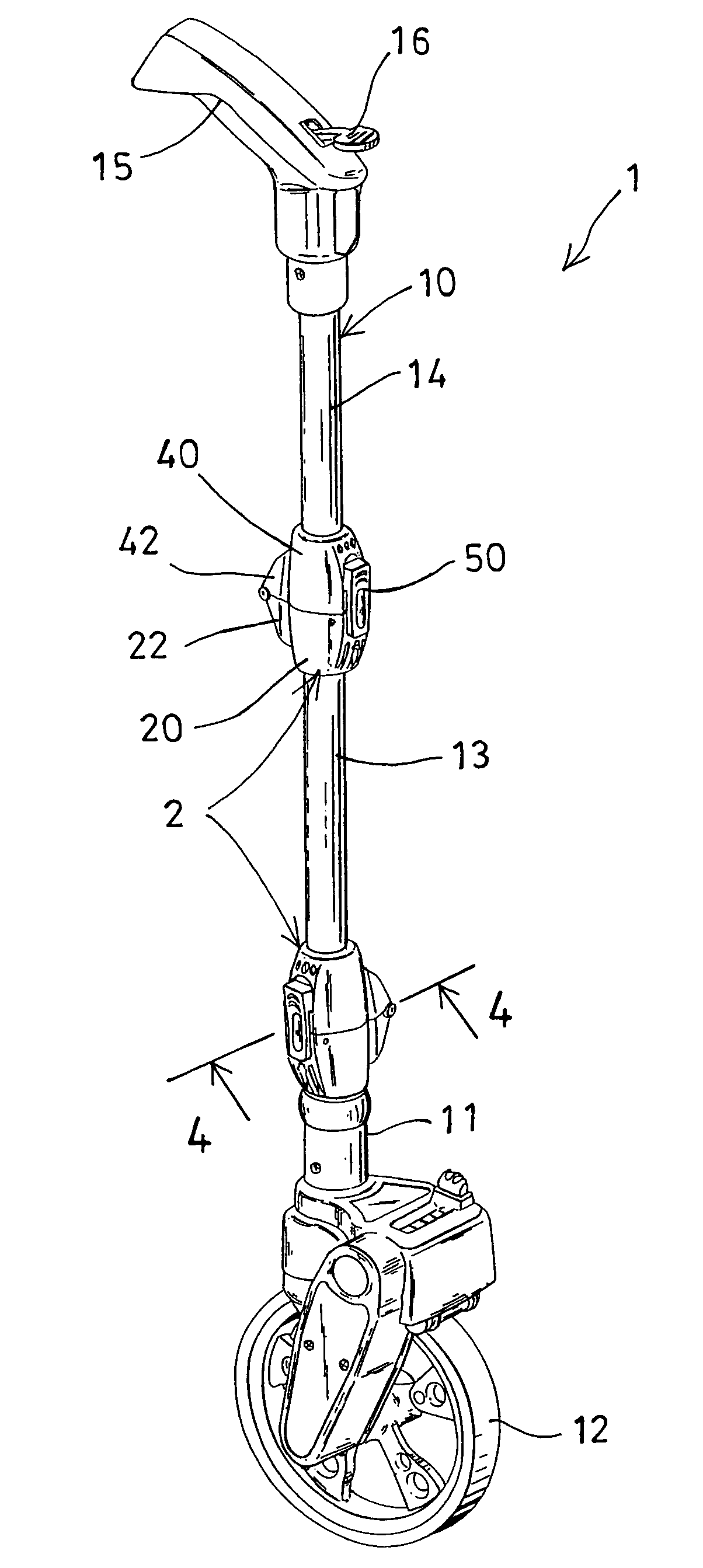

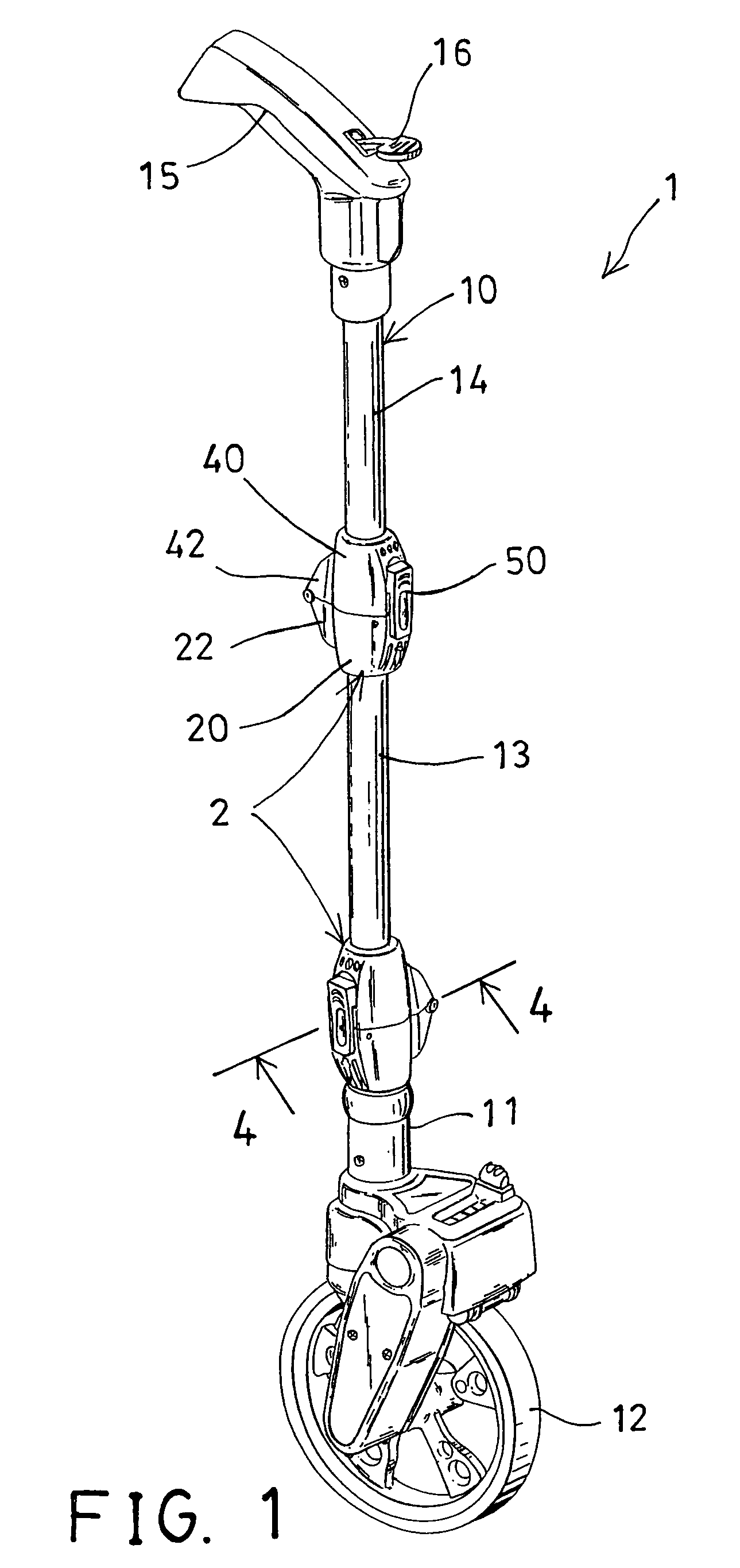

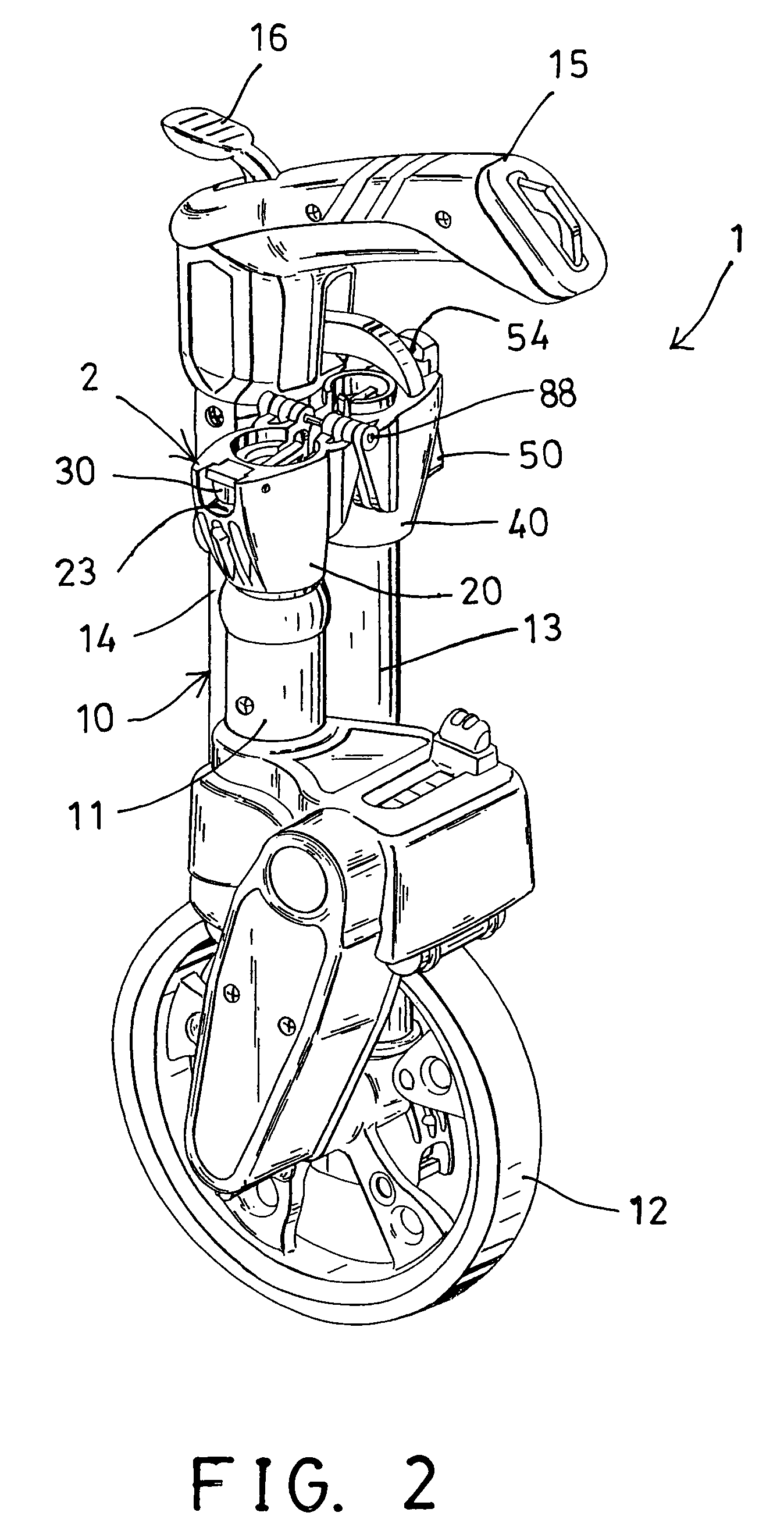

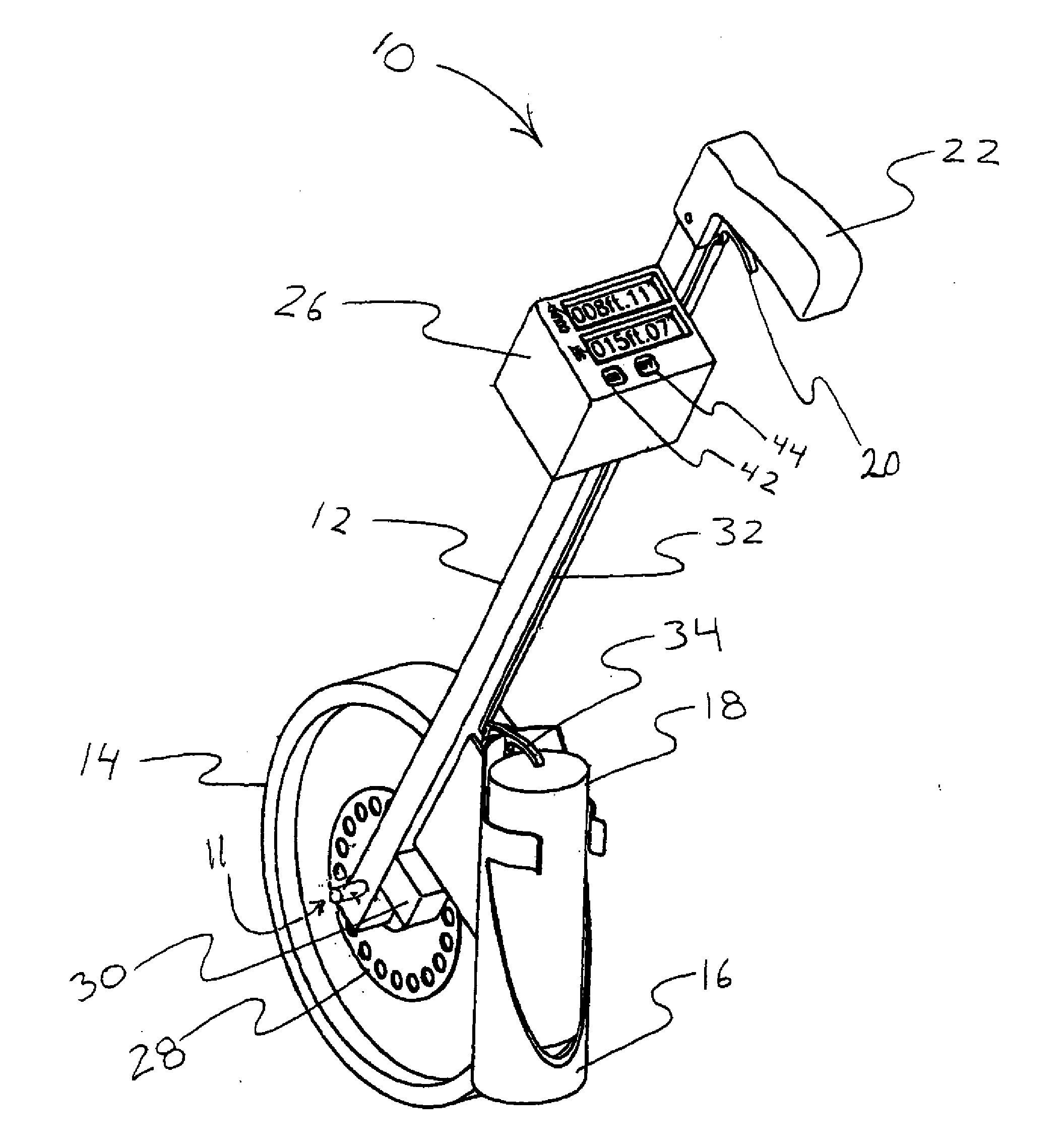

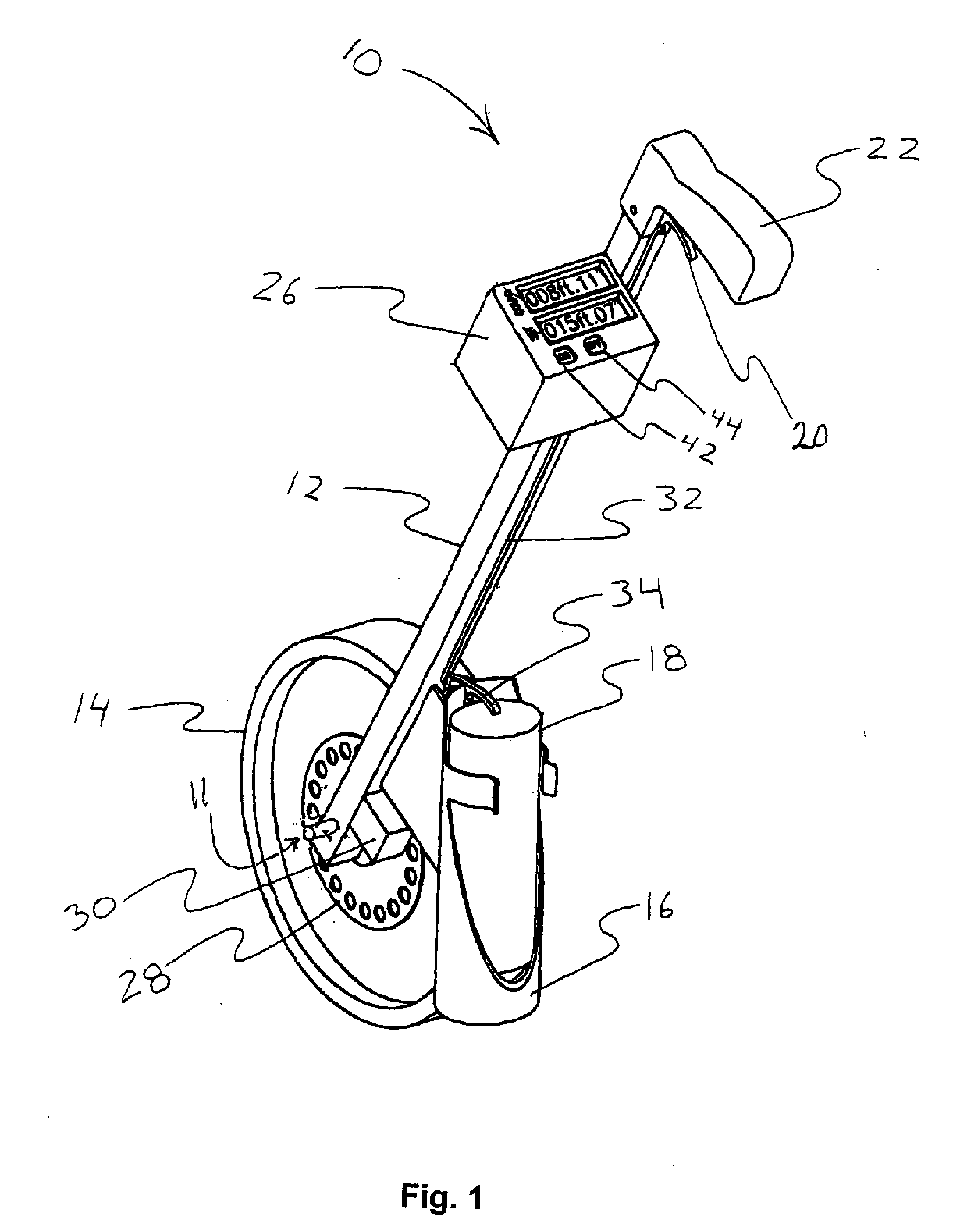

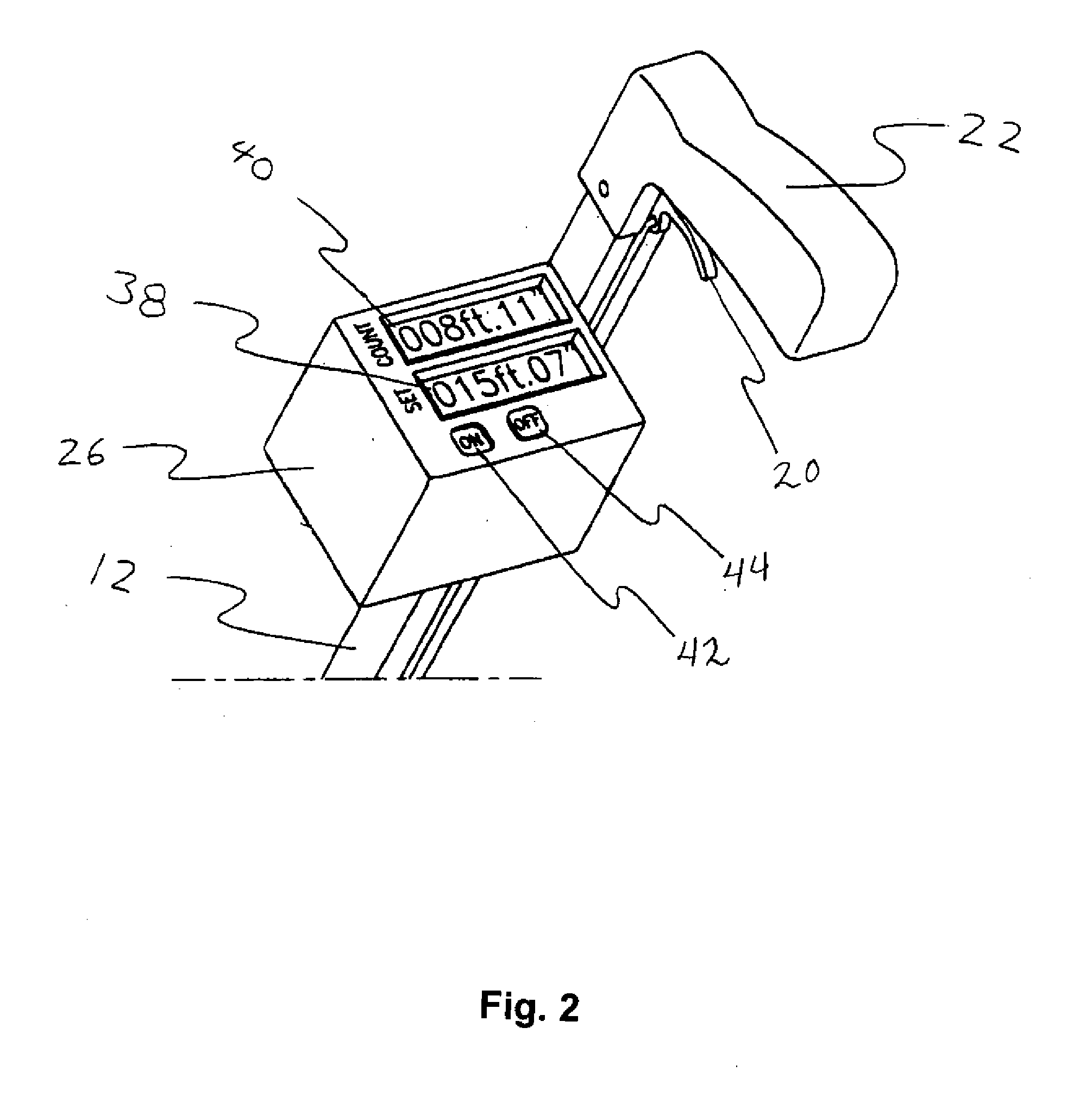

Wheeled distance measuring device

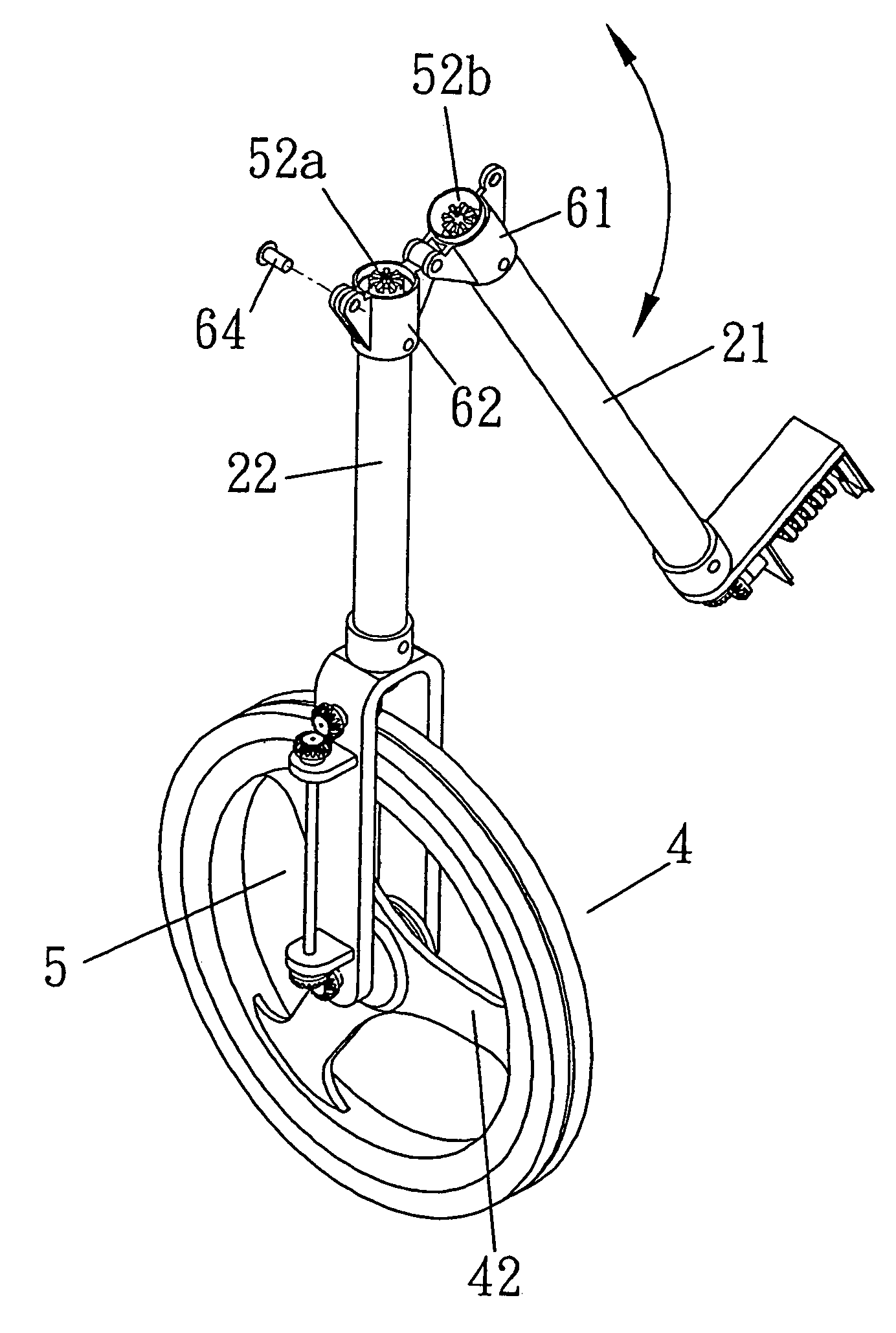

A wheeled distance measuring device includes a wheel unit having a wheel and a front fork with which the wheel is rotatably connected. A pole unit is connected to the front fork and a handle is connected to a top of the pole unit. A measuring unit is connected to a side of the front fork and a brake unit and an initialization unit are connected to the measuring unit. The brake unit and the initialization unit have a brake key and an initialization key received in the handle. Two respective rods are connected to the brake and initialization keys respectively and extend through the pole unit and connected to the measuring unit. By operating the brake key and the initialization key, the wheel can be braked and the measuring unit can be initialized respectively.

Owner:TECHTRONIC POWER TOOLS TECHNOLOGY LTD

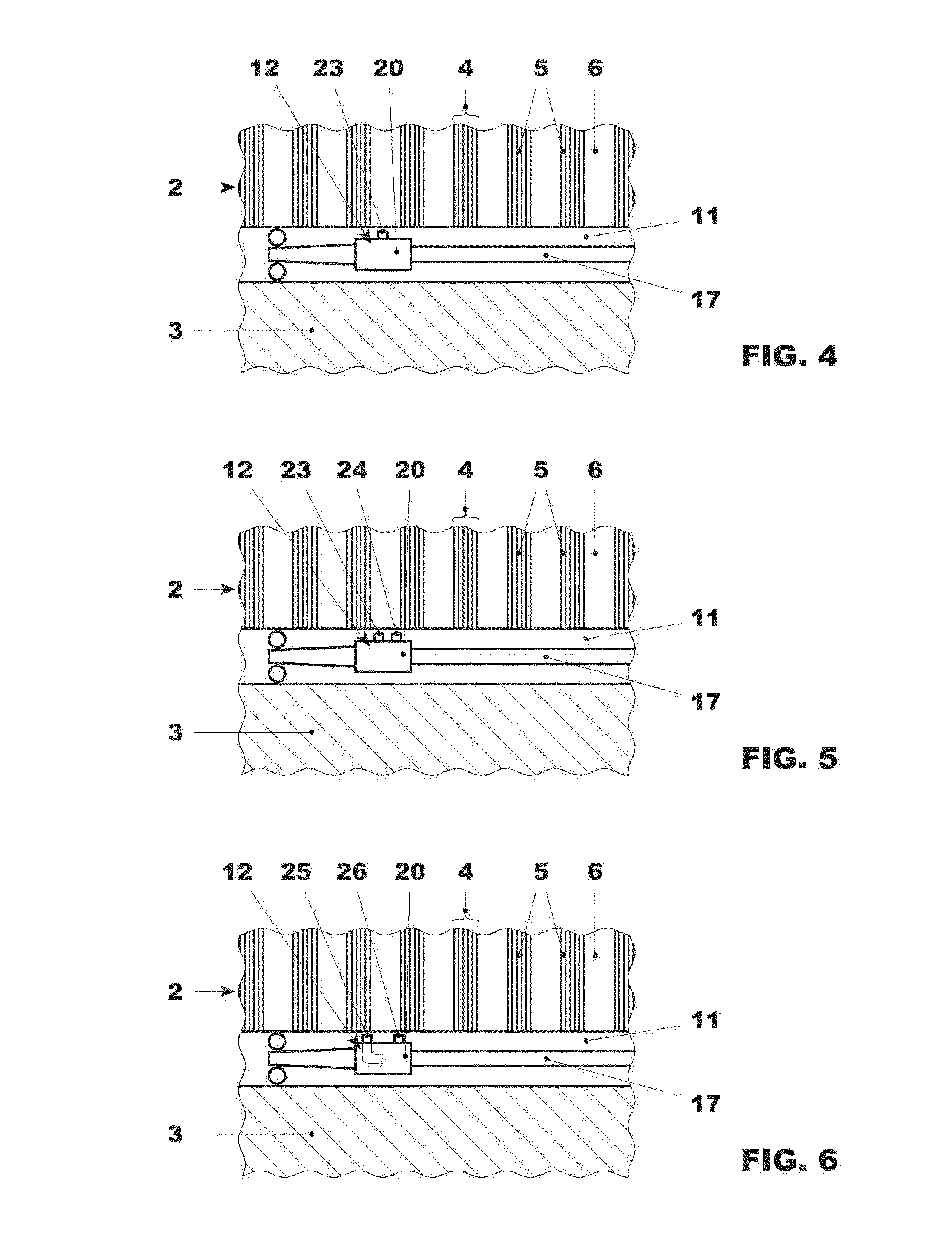

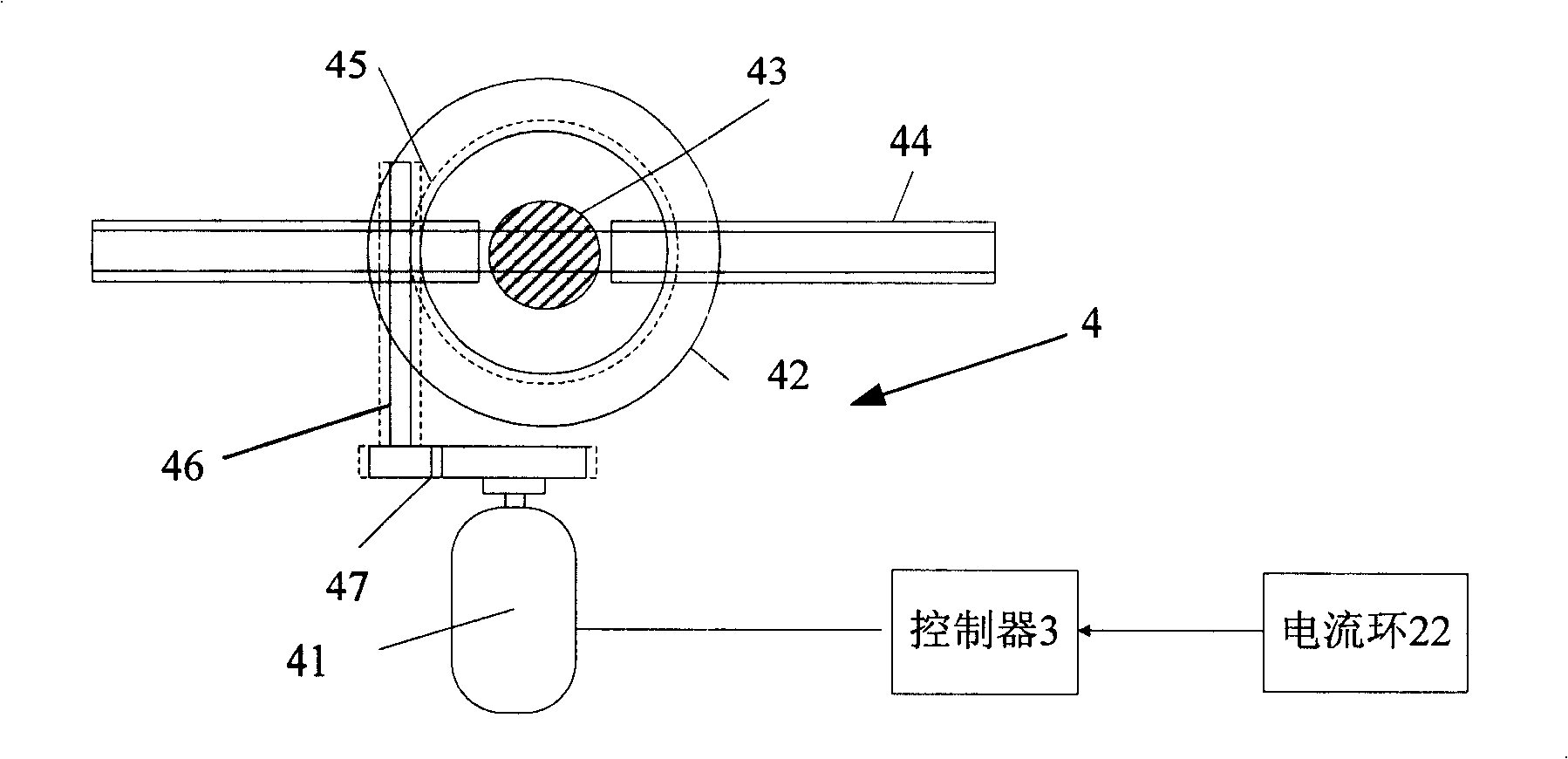

Apparatus and method for automatically correcting error of conveyer belt

InactiveCN101244777AImprove reliabilityImprove work efficiencyConveyorsRollersControl theoryControl engineering

The invention provides a device capable of automatically rectifying the deviation of the conveyer belt according to the deviation sensing signals. The device comprises: a deviation sensing device which can detect the deviation of the conveyer belt and send out the deviation signal; a processor which is connected with the deviation sensing device and can receive the deviation signal; a deviation rectification mechanism which is connected with the processor and adjusts the conveyer belt to the proper position according to the deviation signal under the control of the processor. The invention also discloses the automatic deviation rectifying method of the device. The rectifying device can carry out the quantitative detection for the deviation of the conveyer belt, convert the detected deviation into a real-time continuous deviation signal and automatically adjust the conveyer belt to the working position under the control of a controller, without need for stopping the conveyor, so as to improve the work efficiency and reliability of the conveyer greatly.

Owner:SHANGHAI MARITIME UNIVERSITY

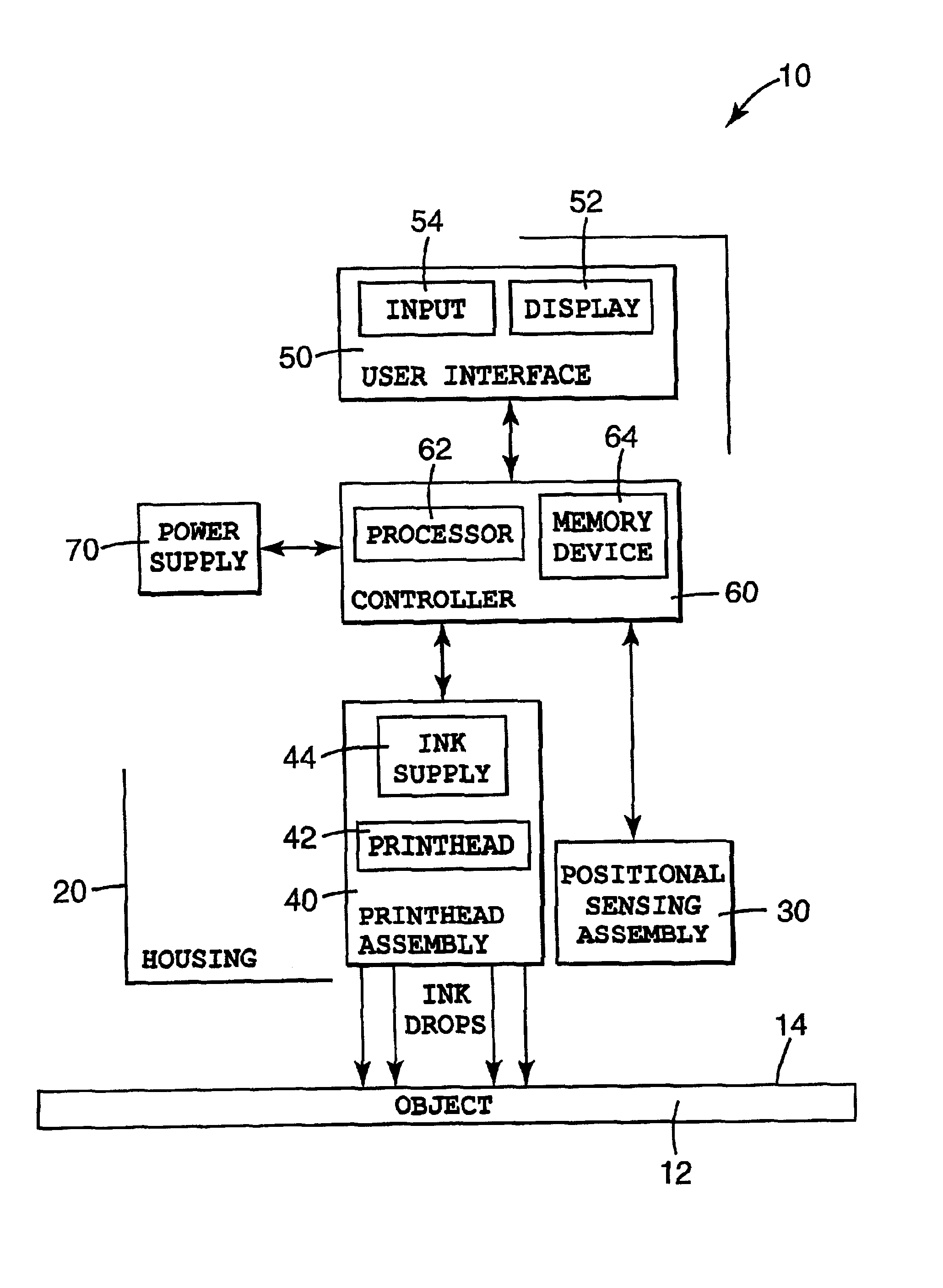

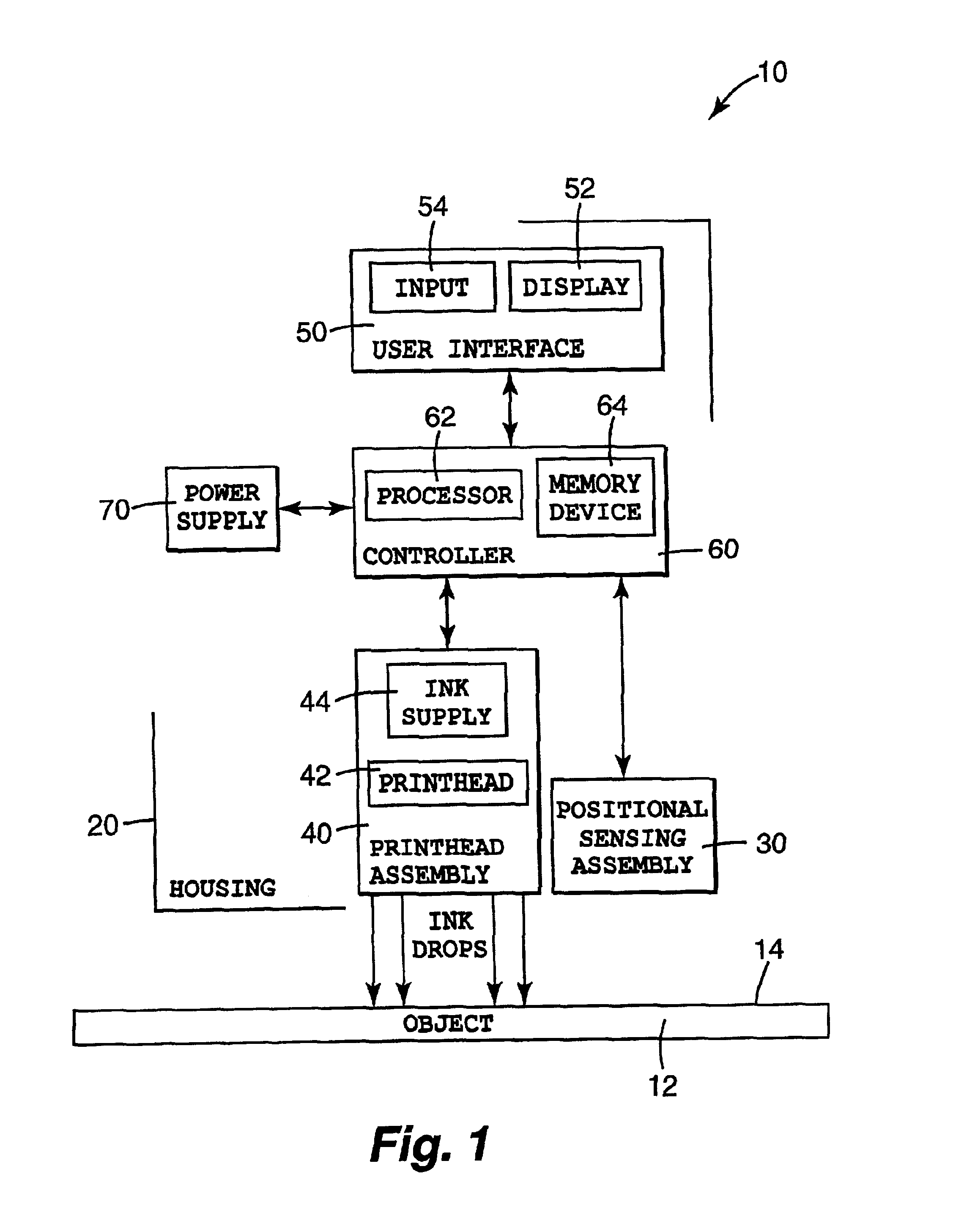

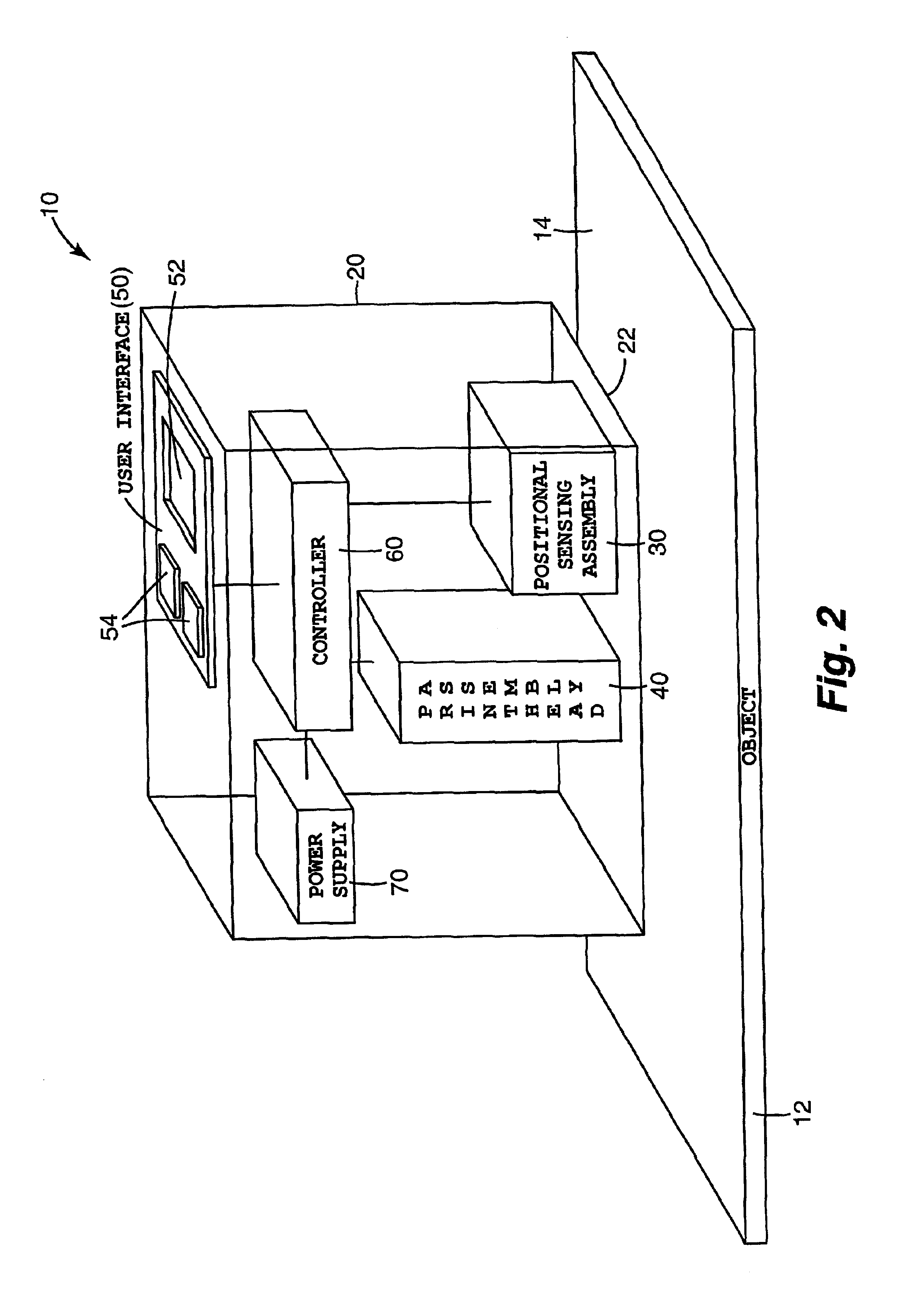

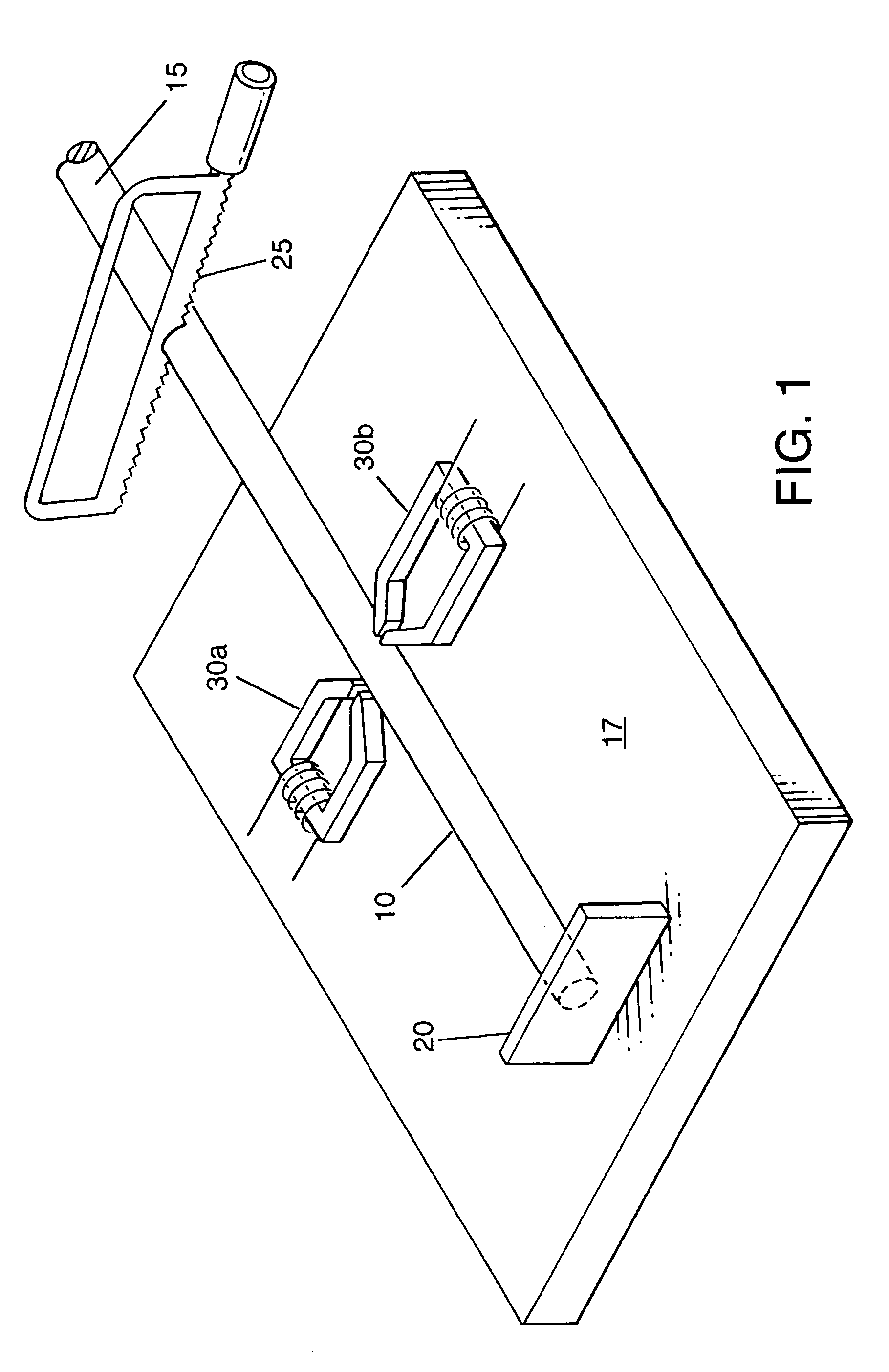

Measurement and marking device

A measurement and marking device includes a housing, a positional sensing assembly mounted in the housing, a printhead assembly mounted in the housing, and a controller mounted in the housing and communicating with the positional sensing assembly and the printhead assembly. The positional sensing assembly is adapted to sense a position of the housing relative to an object as the housing is moved along a surface of the object and the printhead assembly is adapted to print on the surface of the object as the housing is moved along the surface of the object. As such, the controller is adapted to operate the printhead assembly to print a mark on the surface of the object based on the position of the housing relative to the object as the housing is moved along the surface of the object.

Owner:HEWLETT PACKARD DEV CO LP

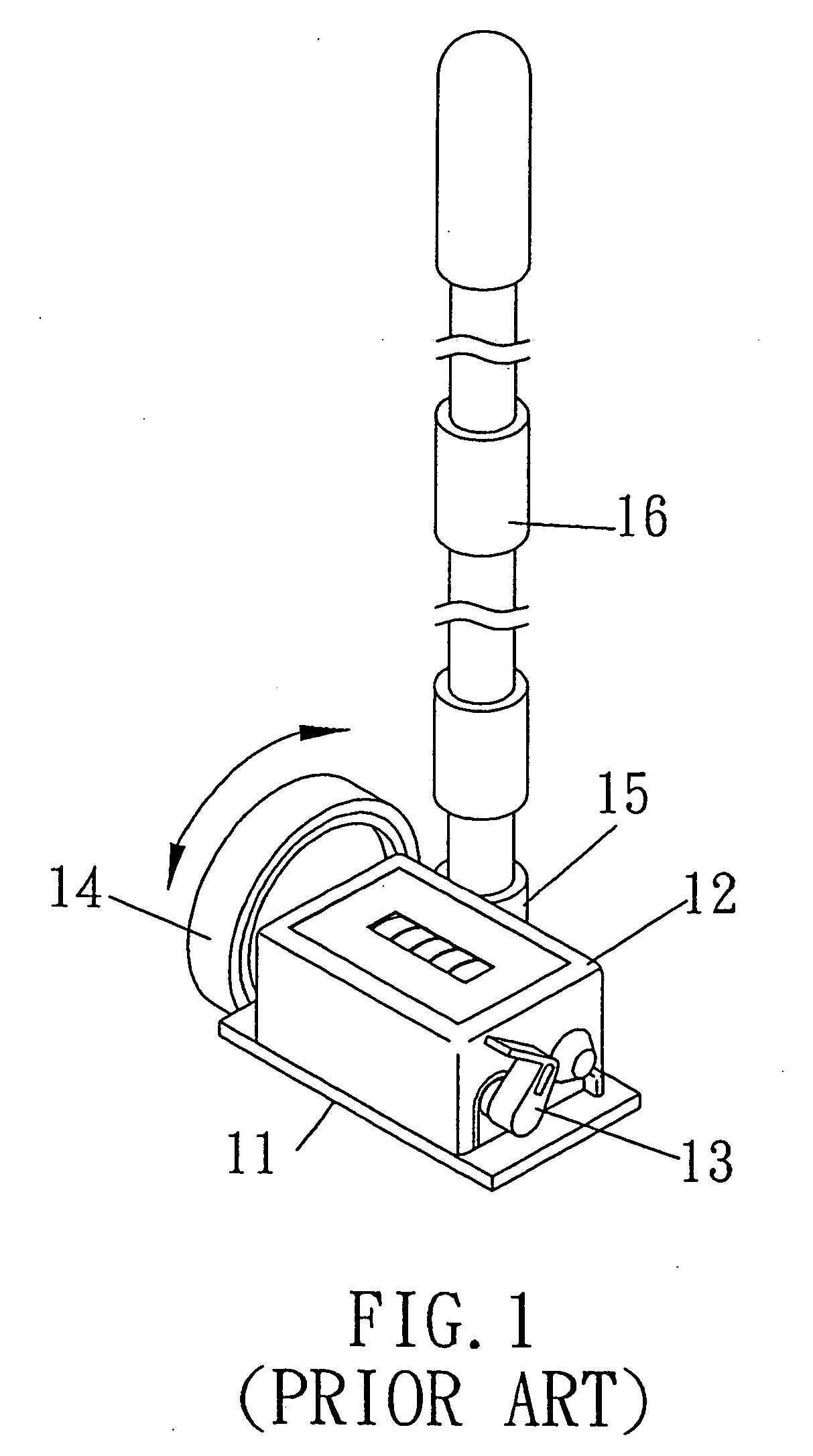

Wheeled distance measuring device

InactiveUS20070084076A1Prevent fallingRestrict movementMeasuring wheelsUsing electrical meansEngineeringCam

A wheeled distance measuring device includes a wheel rotatably attached to a housing, a casing secured to the housing and having a protrusion to form an anchoring shoulder, and a stand having a shaft rotatably attached to the casing and having an anchoring edge for engaging with the protrusion of the casing and for positioning the stand to the casing at a downward working position. The casing includes a spring-biased latch extendible out to selectively engage with the stand, and to further position the stand to the casing at the downward working position. The casing includes an actuator biased to engage with a cam member of the stand, for selectively positioning the stand to the casing.

Owner:WANG HUI CHEN

Multi-purpose digital scale for travelers

InactiveUS7238895B2Easy to holdEasy to grip handleMeasuring wheelsUsing electrical meansCommon carrierComputer science

A portable scale that allows travelers to calculate the weight of their luggage and compare the weight against weight limits that are imposed by common carriers. The scale includes circuitry for calculating weight and a memory for storing weight limits. Weight and other information is shown to the user via a display screen. In the preferred embodiment, the scale includes a hook and handle that facilitate weighing suitcases and other objects. The preferred embodiment also includes a digital measuring tape that allows the traveler to check the size of his luggage against size restrictions imposed by common carriers. The scale can also be incorporated into a portable weighing mat, which allows weight to be determined simple by placing the object on the mat. The scale can also be incorporated into the handle of a suitcase wherein the weight of the suitcase is calculated when the suitcase is lifted by its handle.

Owner:DITTRICH JOSEPHINE M +1

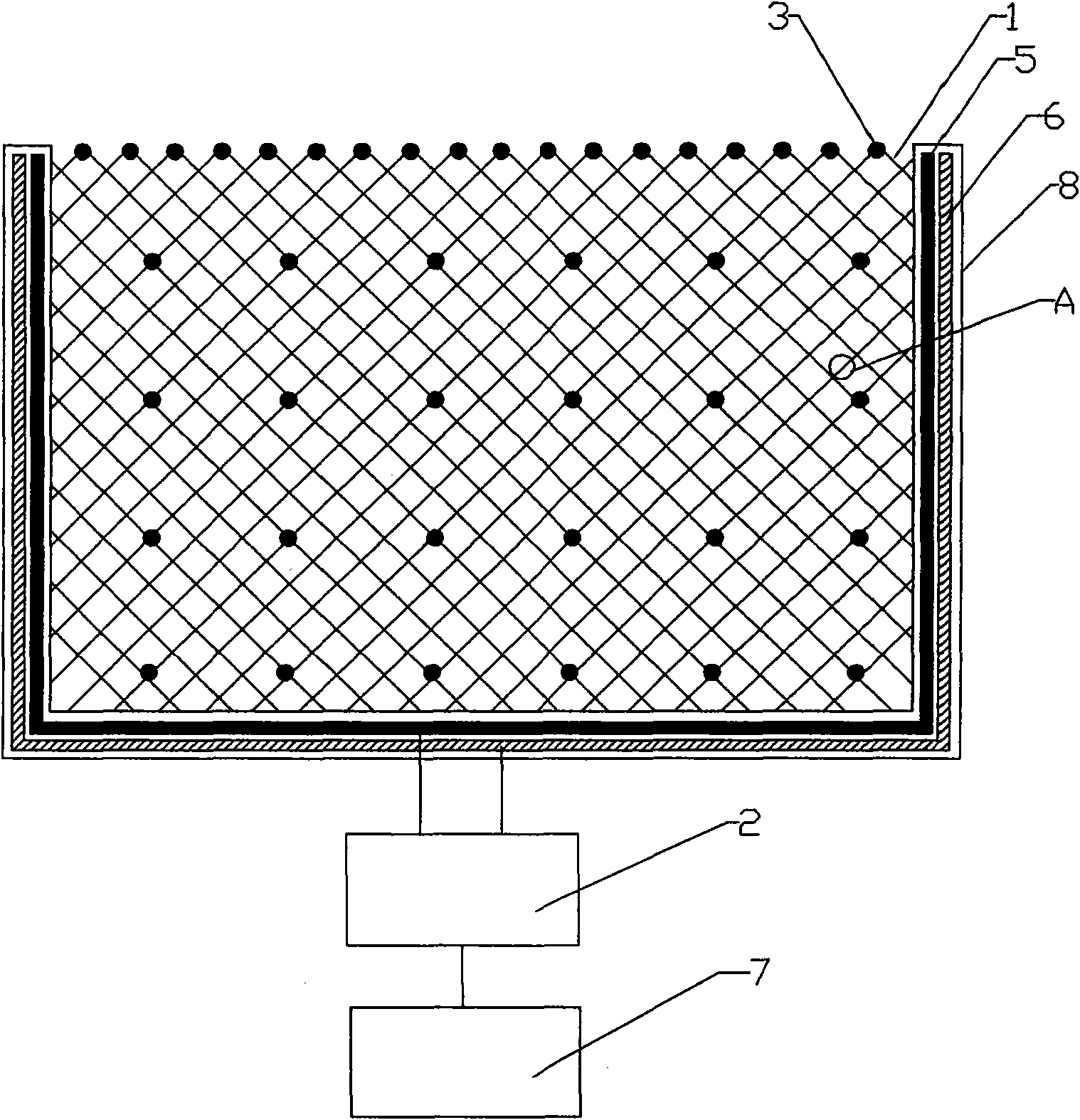

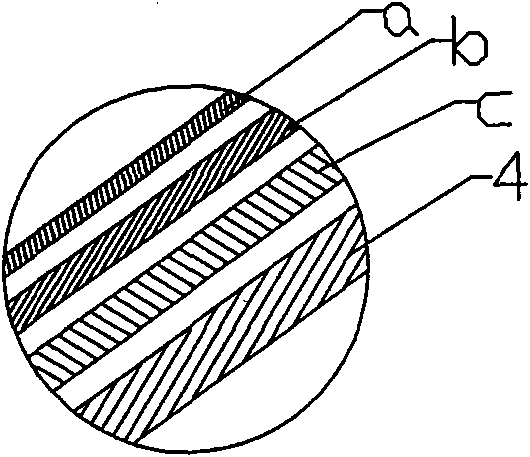

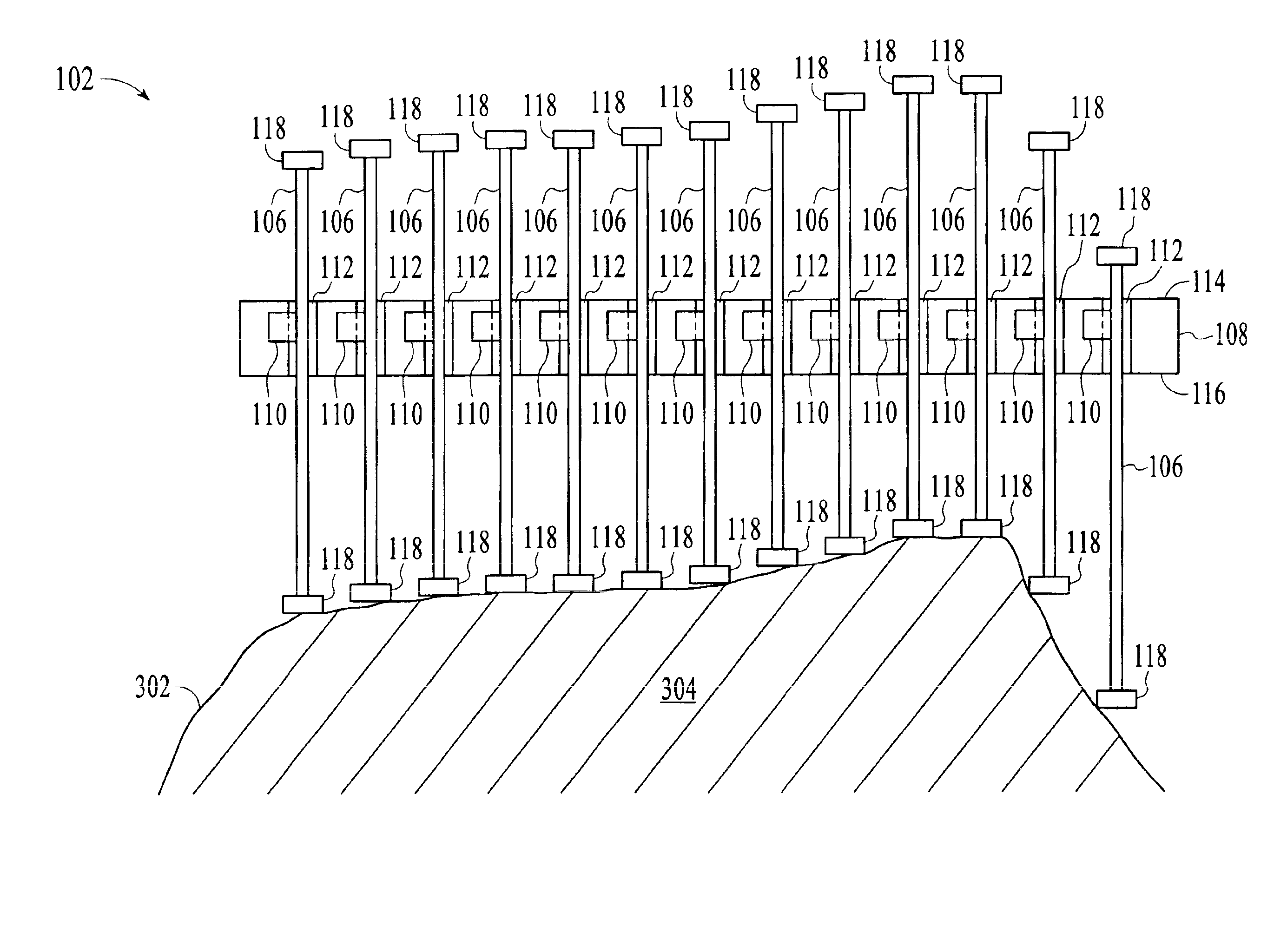

System for monitoring crack of piezoelectric-array converged alertness network structure and monitoring and installing methods

InactiveCN101561430APrecise structureEasy to useMaterial analysis by electric/magnetic meansForce measurement using piezo-electric devicesElectricityMonitoring system

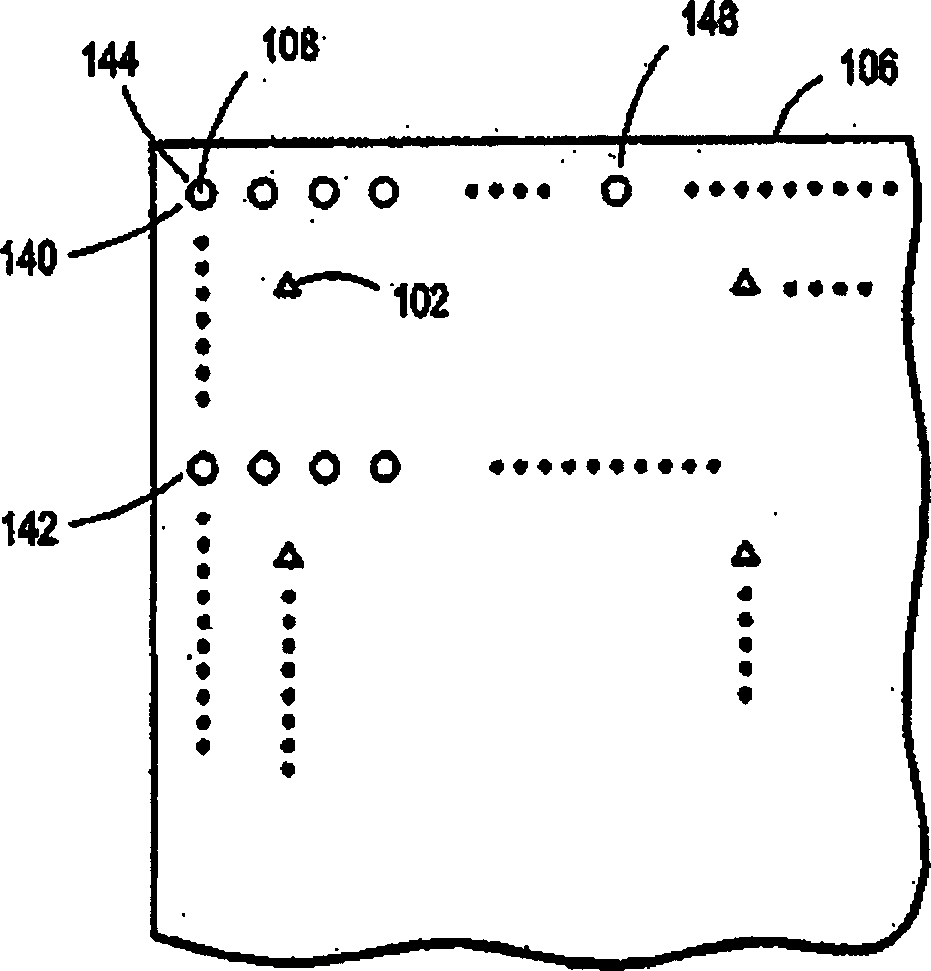

The invention discloses a system for monitoring crack of piezoelectric-array converged alertness-network structure; on the basis of a bionic monitoring unit formed by the crossing of a plurality of mutually-insulated alertness lines, a piezoelectric array consisting of piezoelectric sensing elements is added; therefore, not only structural surface crack is accurately judged by the monitoring of the alertness line, but also structural internal stress field quantity is judged by piezoelectric signals of the piezoelectric elements, thereby acquiring analysis results such as potential bearing capacity and hazardous state pre-judgment before the crack appears and the depth and structural stress release state after the crack appears. The system can realize all-around and tri-dimensional damage detection of the engineering structure, which is a monitoring system with reliable use, high efficiency, low cost and correct result; simultaneously, the invention also discloses monitoring and installing methods of the piezoelectric-array converged alertness network structure crack monitoring system.

Owner:CHONGQING JIAOTONG UNIVERSITY

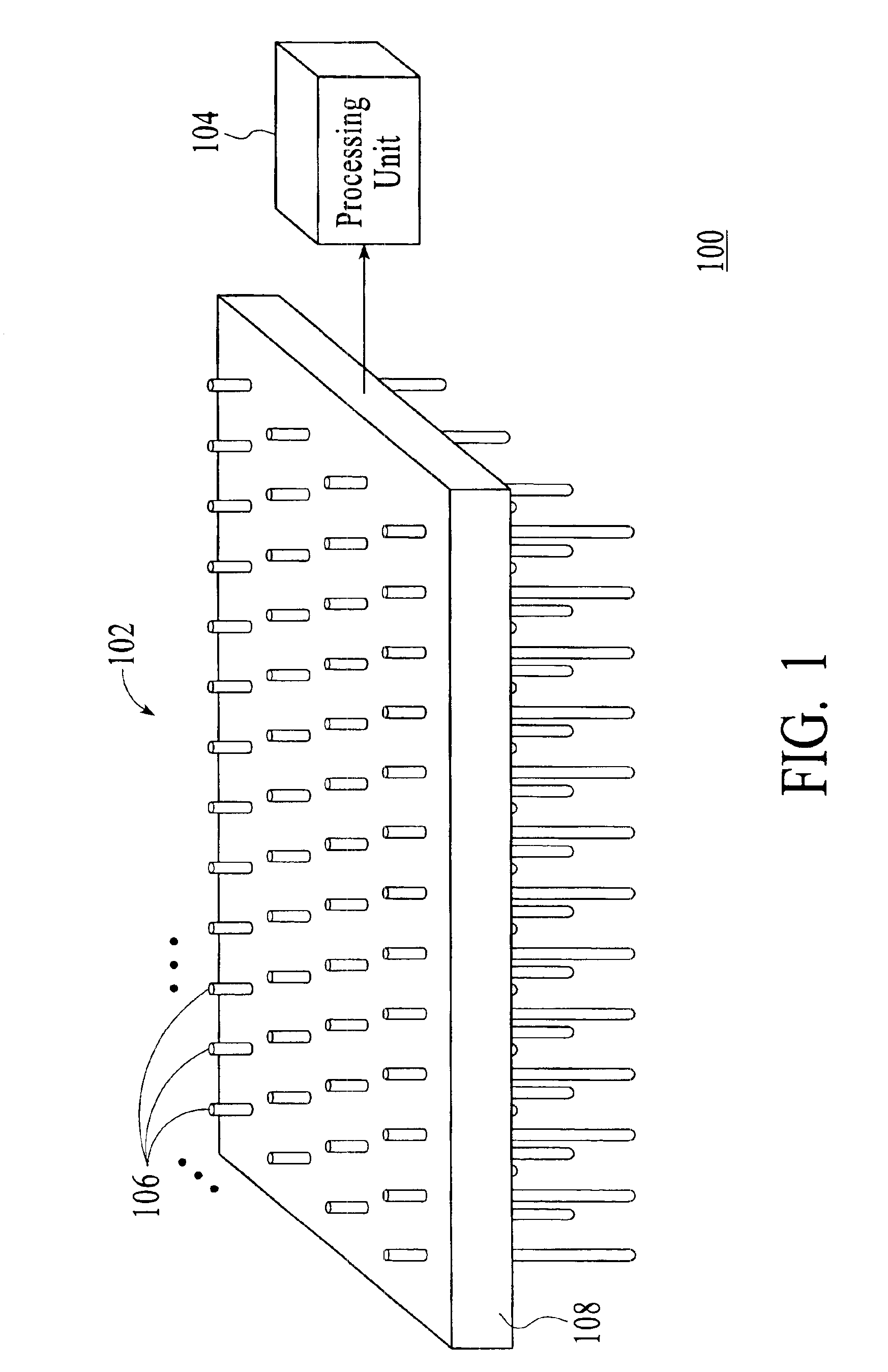

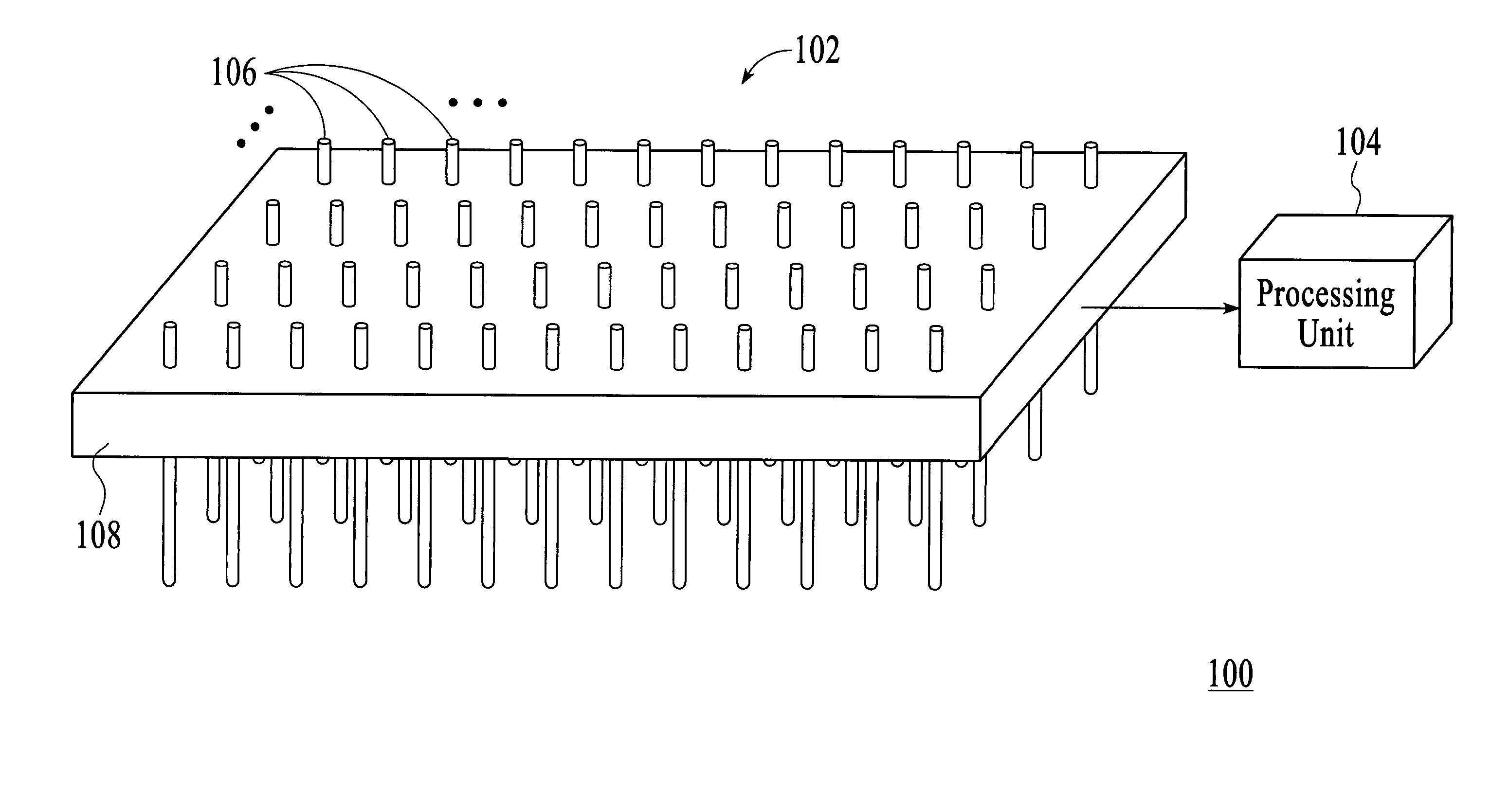

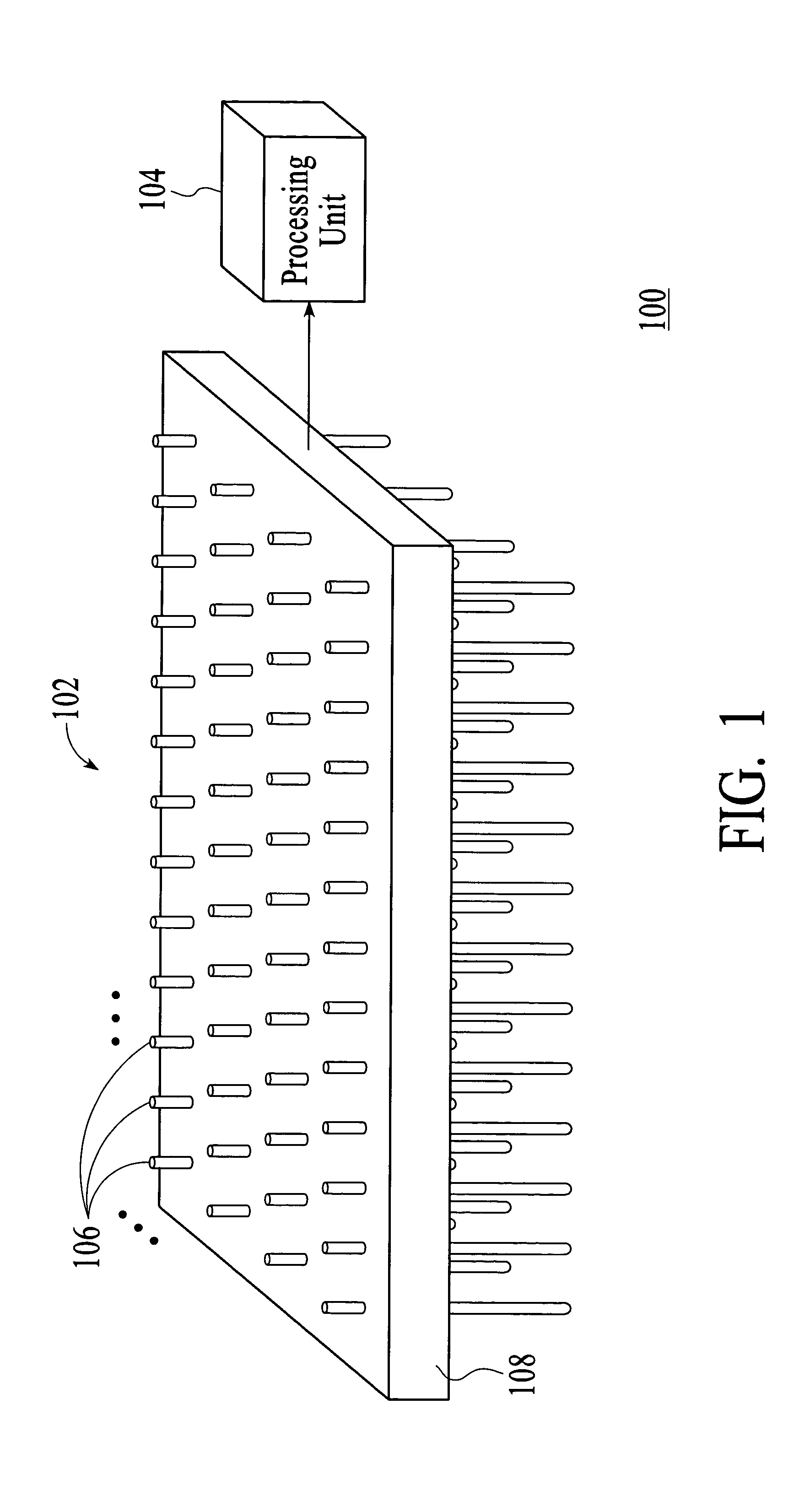

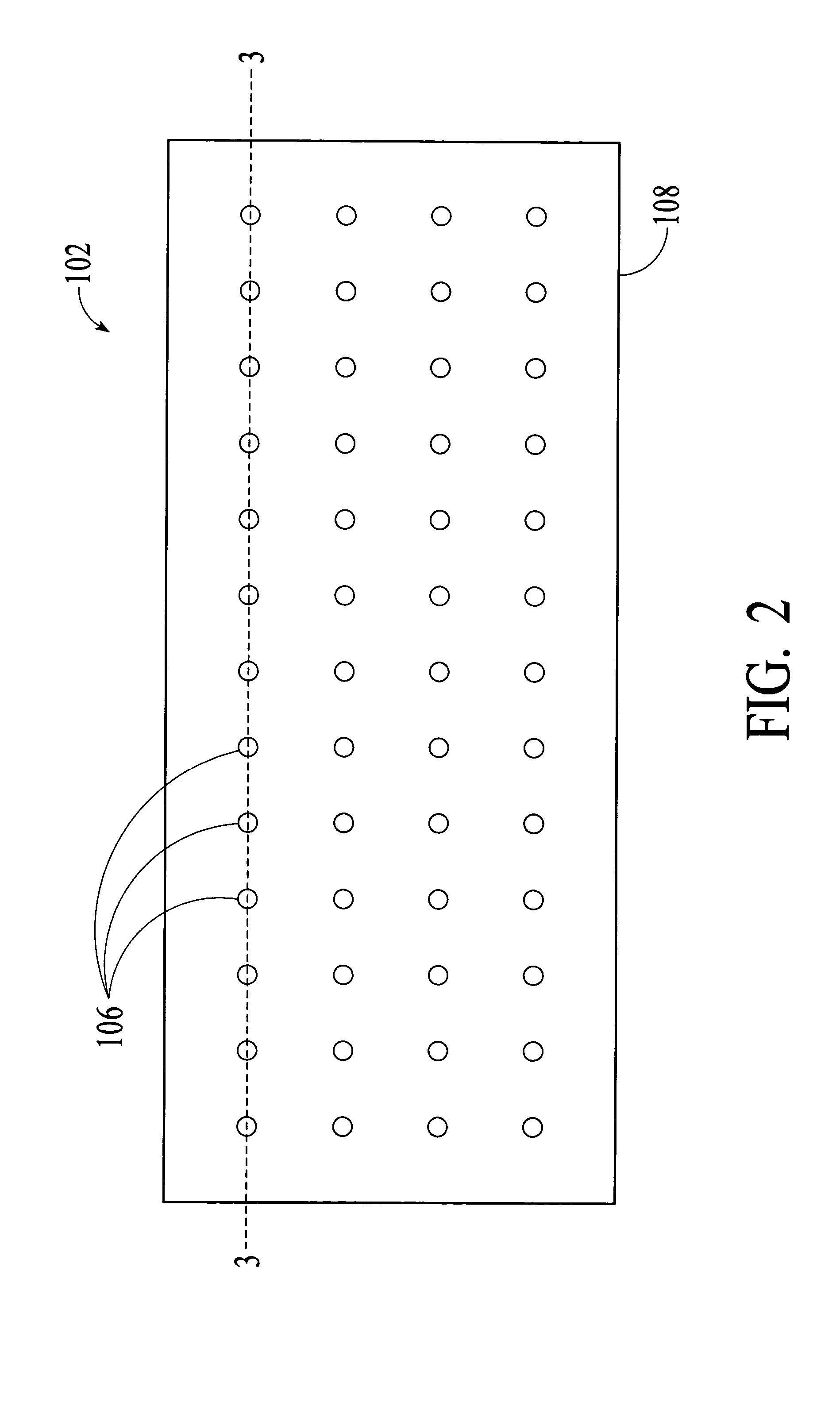

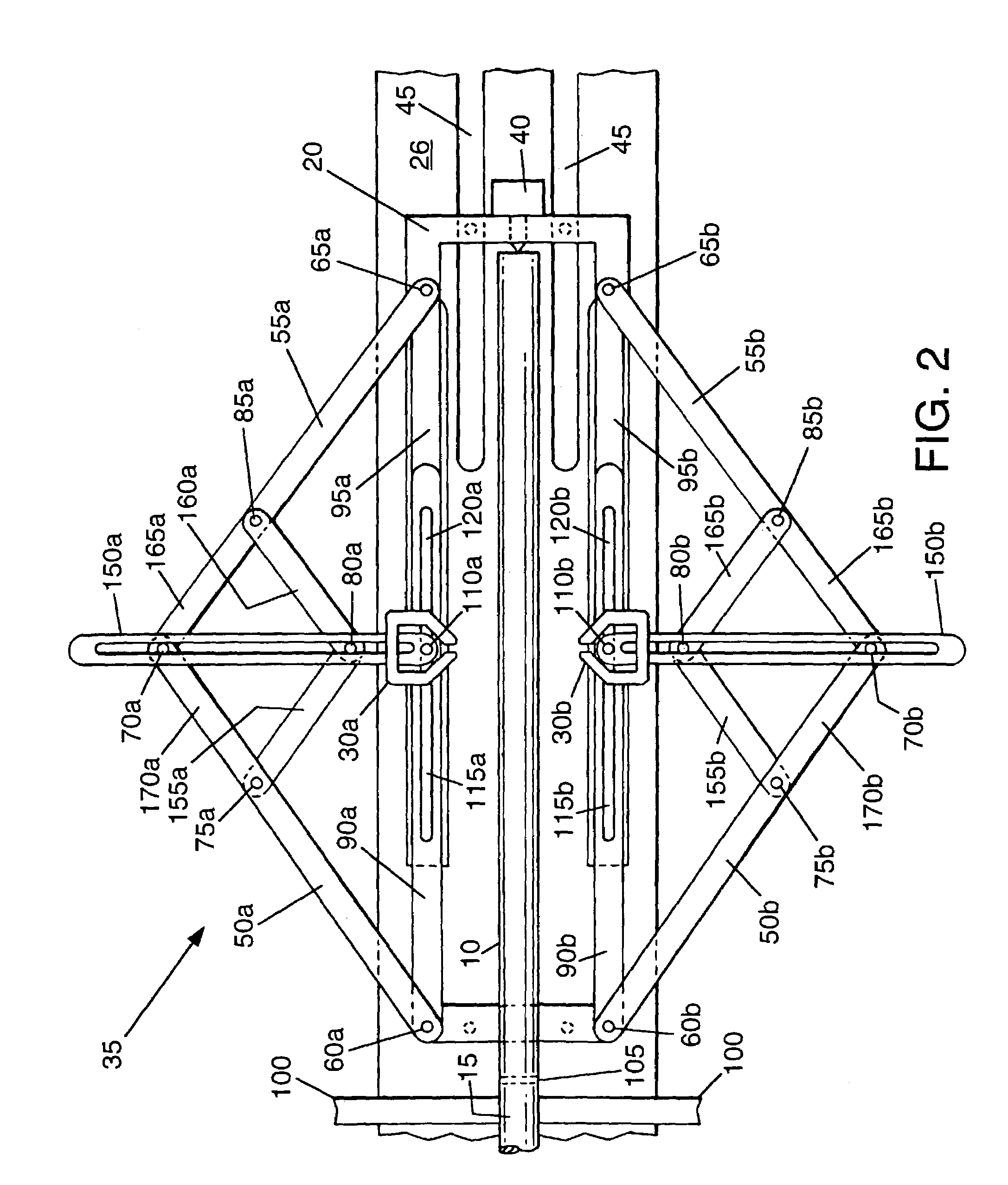

System and method for measuring three-dimensional objects using displacements of elongate measuring members

InactiveUS6907672B2Short processFeeler-pin gaugesUsing subsonic/sonic/ultrasonic vibration meansClassical mechanics

Owner:HEWLETT PACKARD DEV CO LP

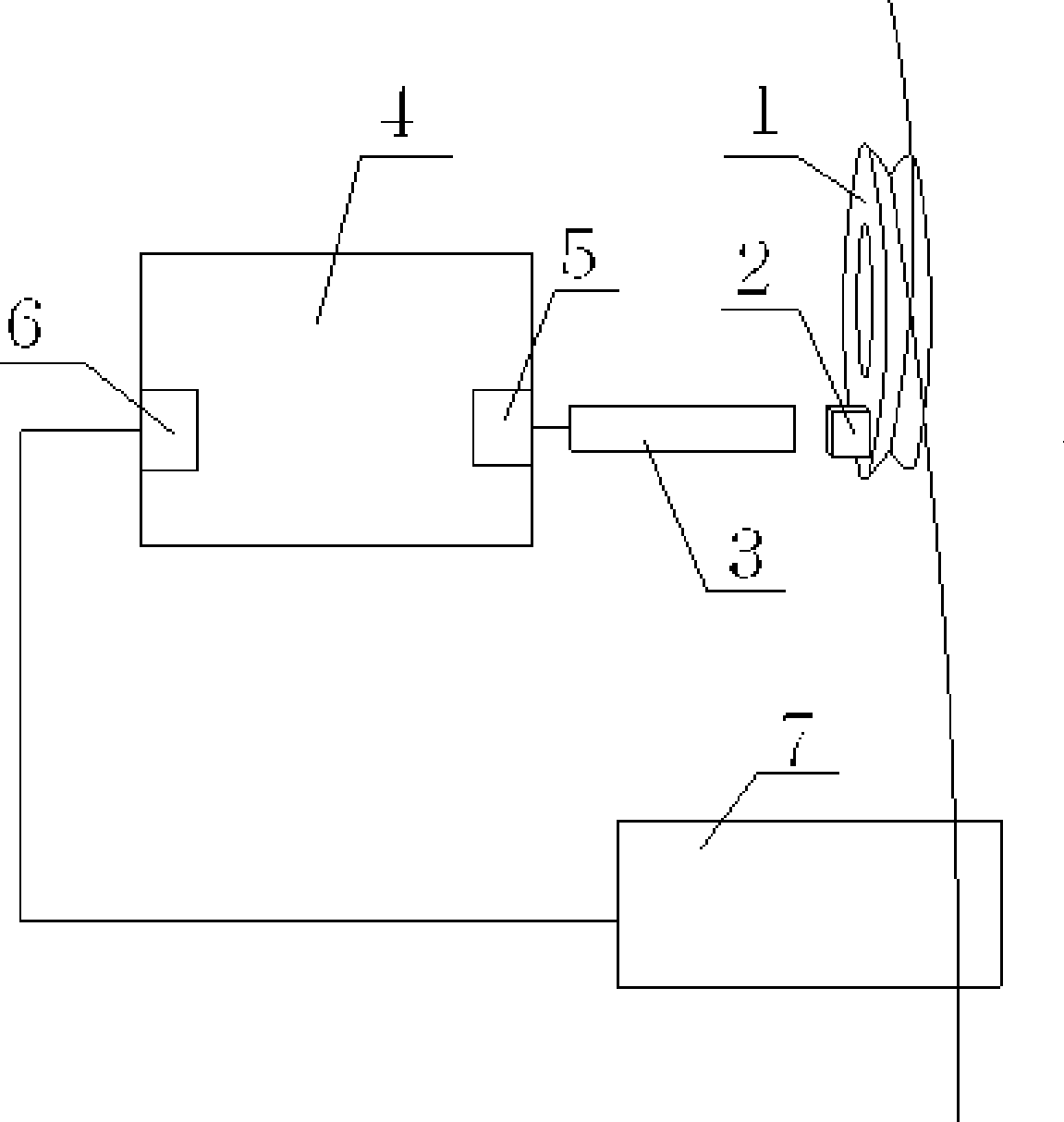

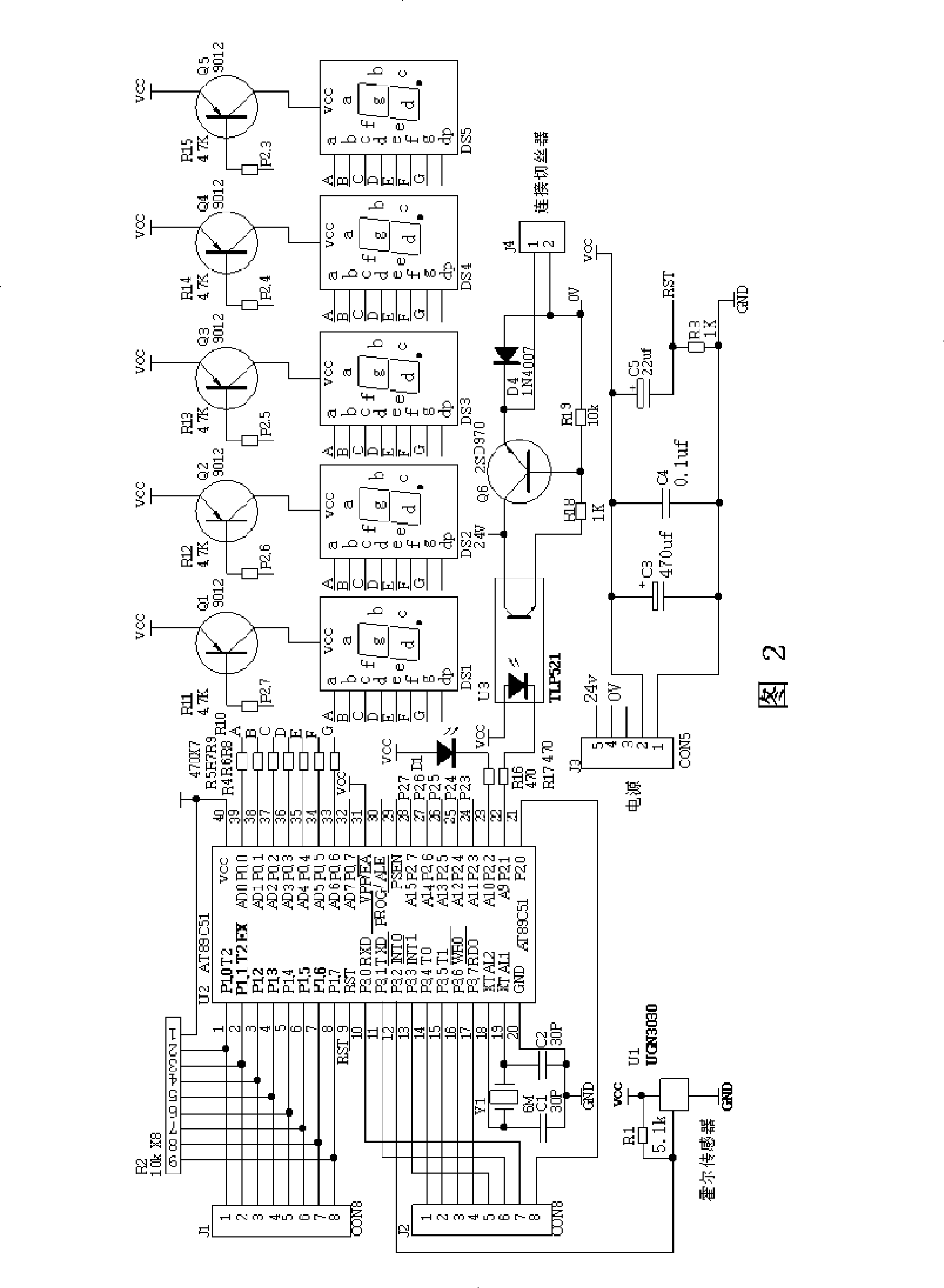

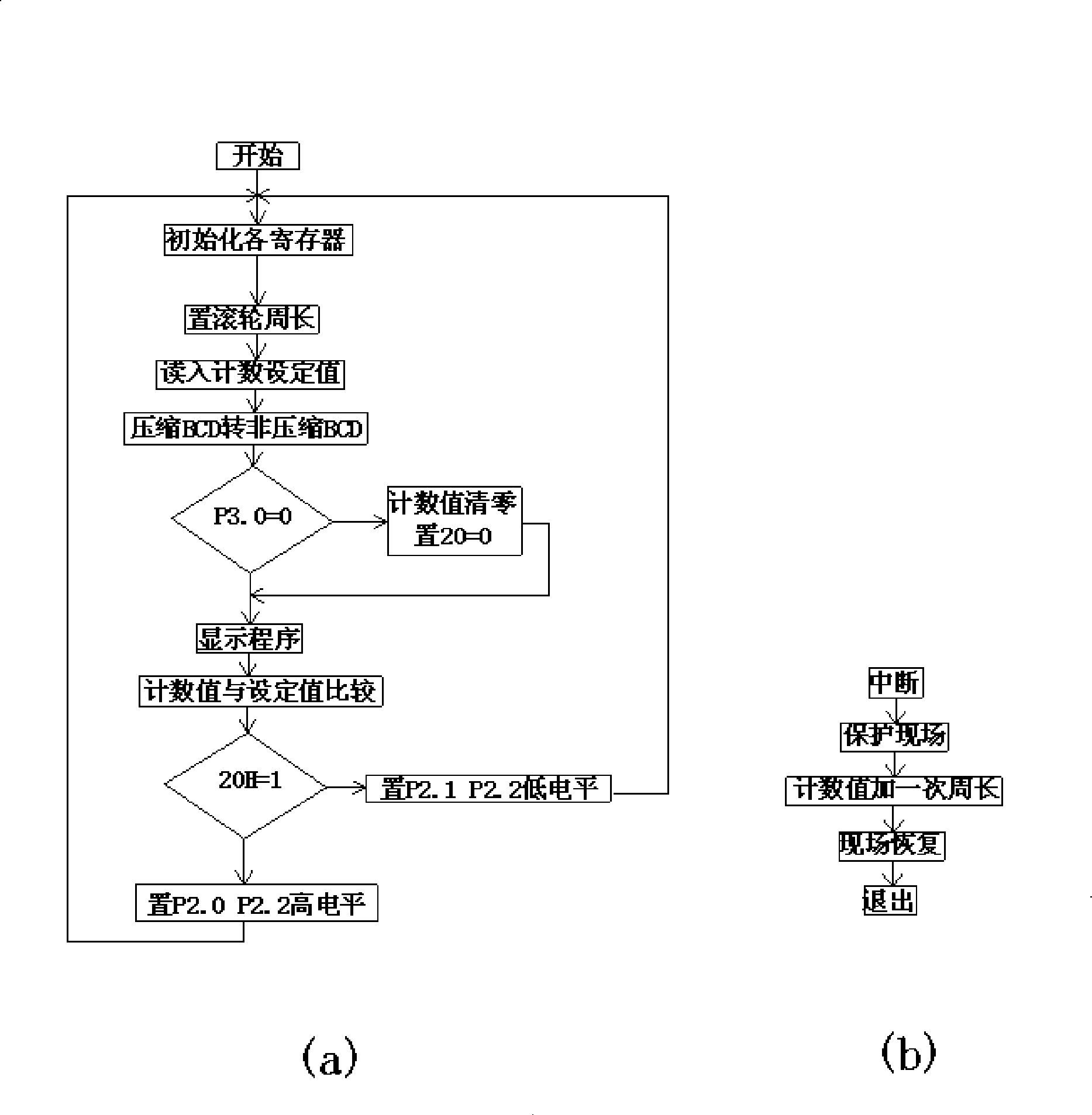

Control method for testing and determining length of raw material thread of rewinding vehicle and control device used thereof

InactiveCN101428717AImproved winding length accuracyGuaranteed lossFilament handlingTextiles and paperBobbinControl signal

The invention discloses a winding car raw material wire fixed length control method, which is characterized in that the method comprises the following steps: mounting a circle roller which is equipped with a magnet block on spindles of the winding car; coiling the raw material wire against the circle roller; driving the circle roller to rotate when the raw material wire is wound; and mounting a hull sensor in the position corresponding to the magnet block on the circle roller to detect an impulse signal, further outputting the impulse signal in a signal processing device; counting, comparing the count value with the setting value by the signal processing device; and outputting the control signal and cutting off the raw material wire when the count value reaches the setting value. By adopting the proper method and device to control the coiling length of the raw material wire on the straight bobbin, the invention not only improves the control precision, and reduces the energy loss, but also has the advantages of simple structure, easy operation and low manufacturing cost.

Owner:HUZHOU JINGCHENG TEXTILE

Wheel vehicle measuring apparatus

InactiveUS20060156573A1Accurate measurementImprove ease of useMeasuring wheelsUsing electrical meansMechanical engineeringWheel and axle

Owner:INDEX MEASURING TAPE

Wheeled distance measuring device

ActiveUS7555846B1Efficient foldingSelectively and solidly coupled togetherMeasuring wheelsUsing electrical meansDrop-shapedElectrical and Electronics engineering

A wheeled distance measuring device includes a longitudinal pole having two segments, a housing and a casing attached to the segments and pivotally coupled together, a latch device pivotally attached to the housing and having a latch, and a lock device pivotally attached to the casing and having a catch for engaging with the latch of the latch device and for detachably securing the segments together. The casing includes a chamber formed by a wall for receiving the lock device, and a channel formed in the wall for pivotally engaging with a water-drop-shaped pivot member of the lock device and for pivotally attaching and coupling the lock device to the casing.

Owner:WANG CHENG LIN

System and method for measuring three-dimensional objects using displacements of elongate measuring members

InactiveUS20050076521A1Shorter measuring processShort processFeeler-pin gaugesUsing subsonic/sonic/ultrasonic vibration meansClassical mechanics

A system and method for measuring a three-dimensional object uses a number of elongate measuring members that can be displaced with respect to a base in response to a surface of the object. The displaced distances of the elongate measuring members due to the surface of the object are then determined. The displaced distances are measurements of the object surface.

Owner:HEWLETT PACKARD DEV CO LP

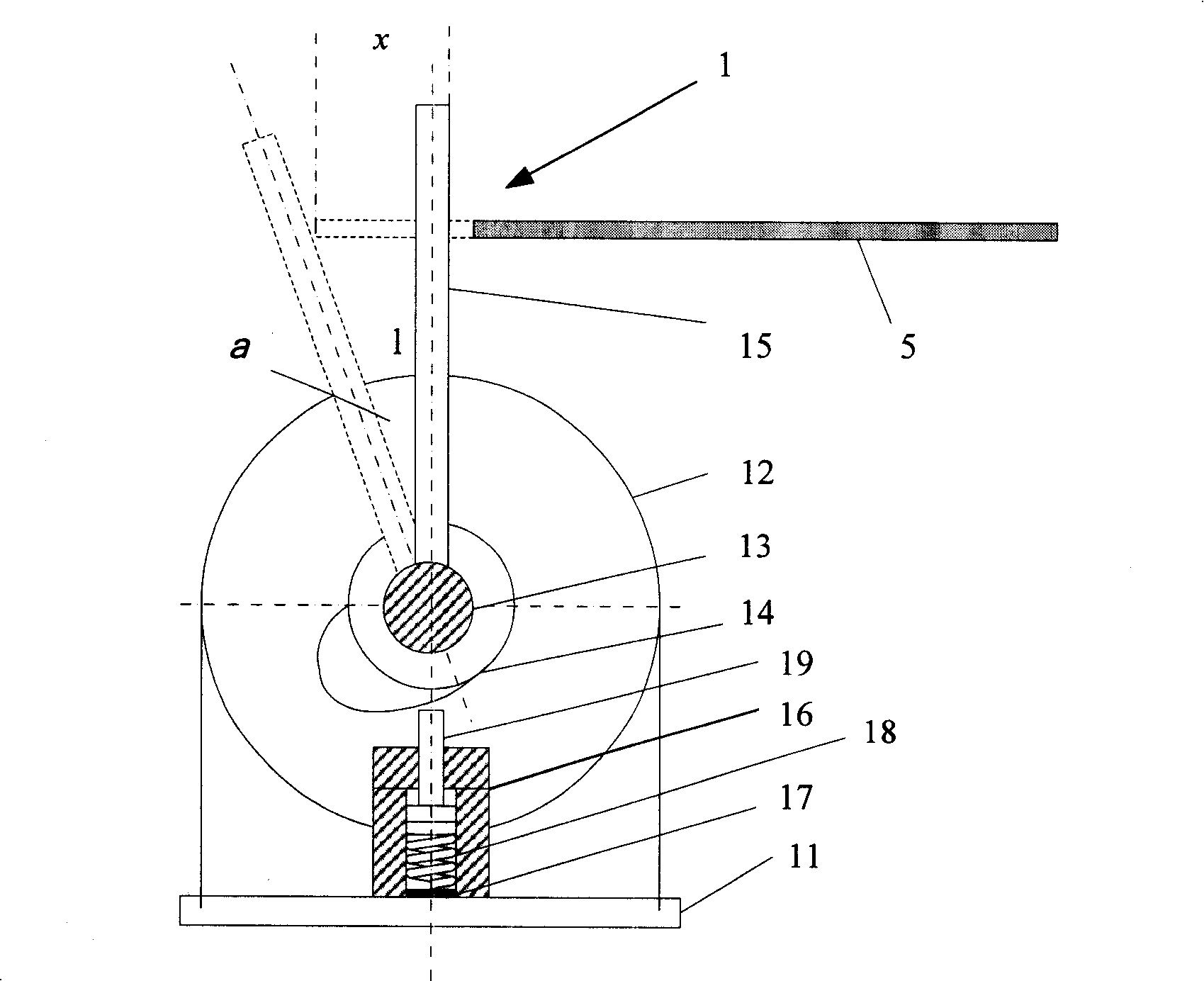

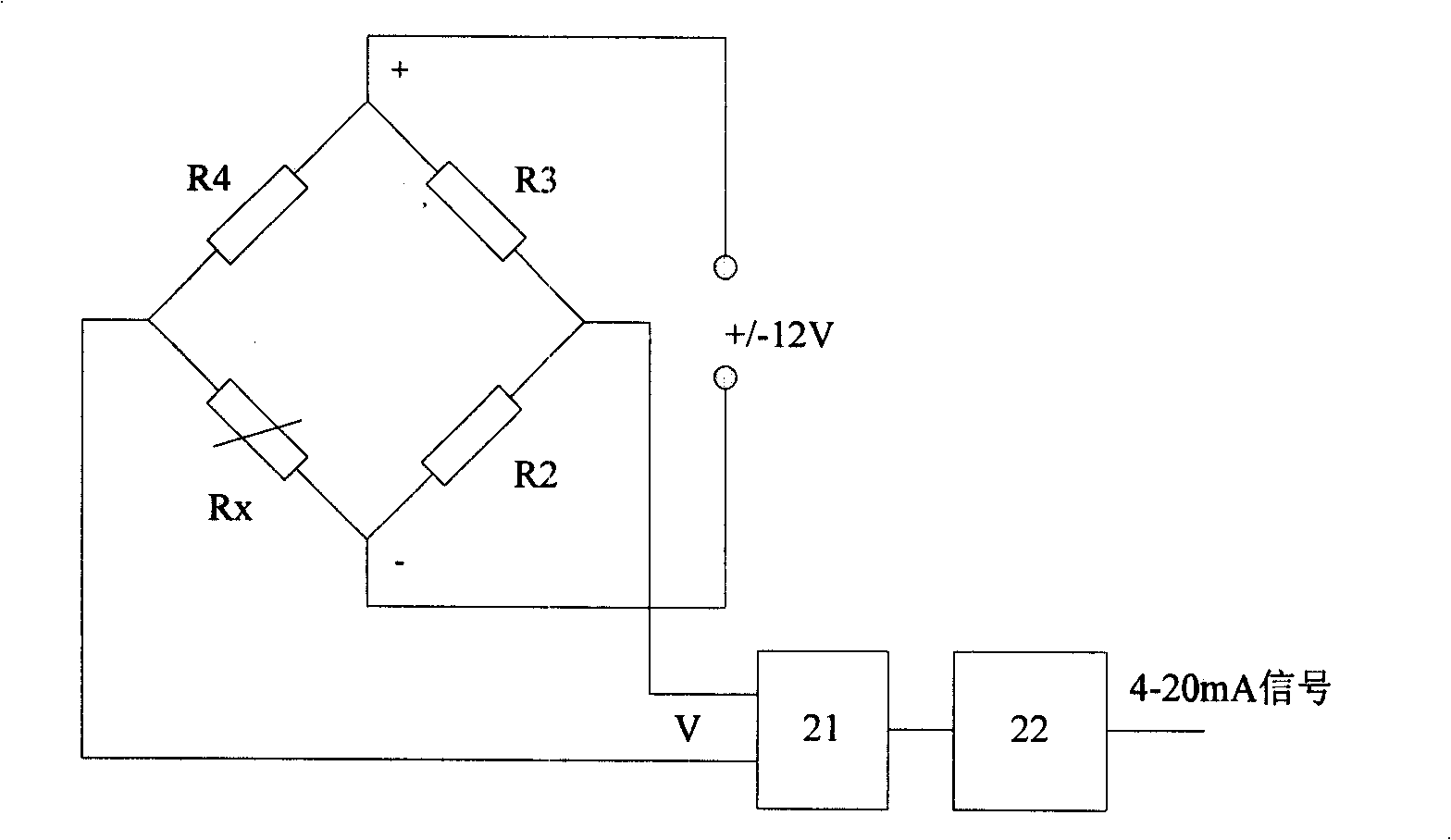

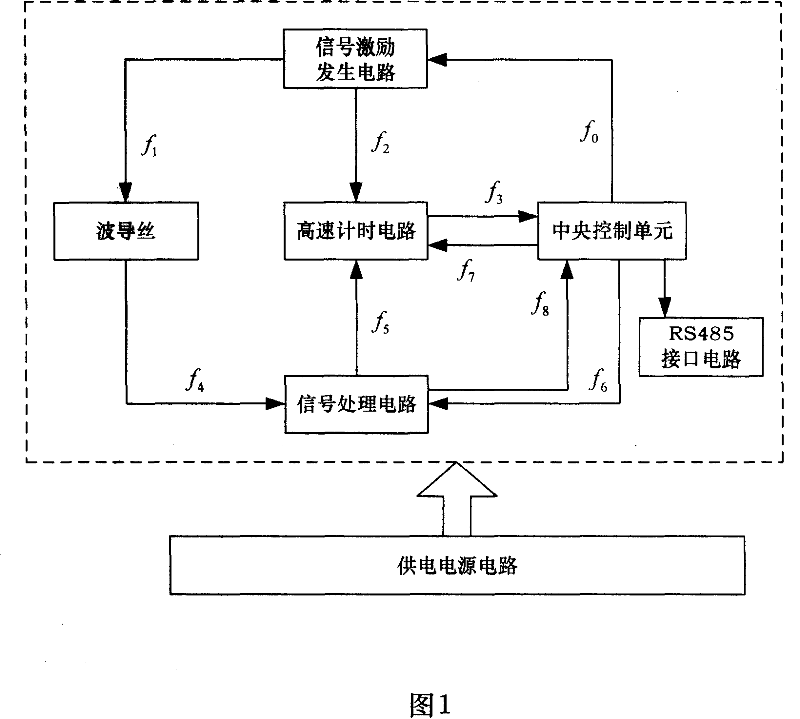

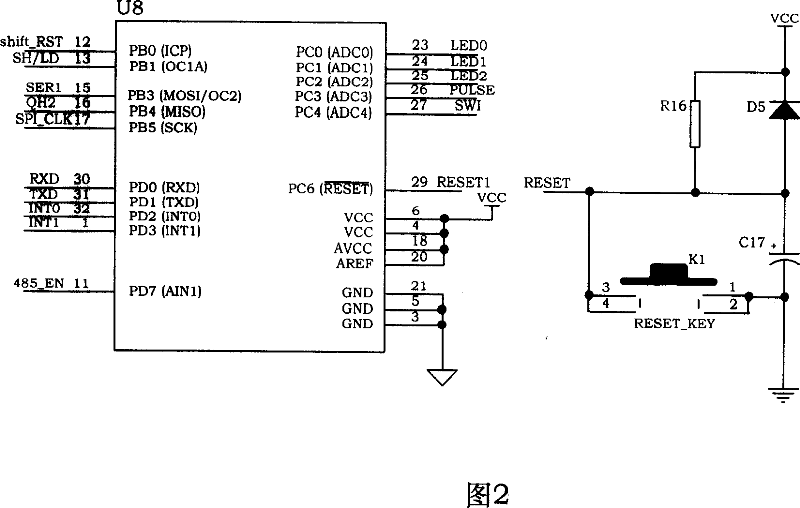

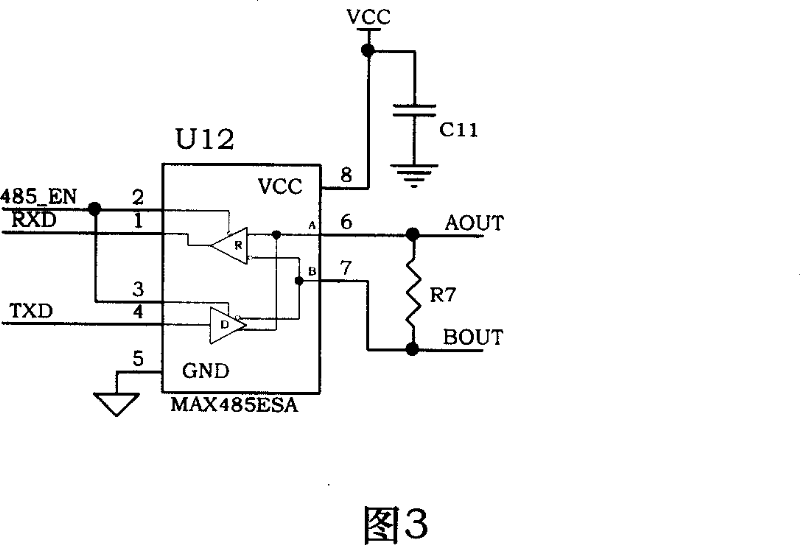

Magnetostrictive displacement sensor

InactiveCN101038151AHigh measurement accuracyHigh resolutionElectrical/magnetic length/width measurementsSignal processing circuitsSignal generator

The present invention discloses a magnetoconstriction type displacement sensor which measures the displacement by using a time-difference displacement measuring method. A torsional wave is generated by crossing two different magnetic field and then the transmitting time of the torsional wave is computed, thus the displacement measuring can be performed indirectly and accurately. The magnetoconstriction type displacement sensor consists of a center control unit, a drive signal generator, a signal processing circuit, a high-speed timing circuit, a RS485 interface circuit, a power supply circuit and the wave guide filament.

Owner:BEIHANG UNIV

Magnetic marker for manufacturing processes and identification of finished workpieces

InactiveUS7065994B1Efficient productionEasy alignmentShaping safety devicesElectric/magnetic position measurementsMagnetic markerHigh energy

A permanent invisible magnetic marking and positioning system of unfinished steel rods, spring steel bars, workpieces, and the like. A midpoint or center of the rod, bar or workpiece is automatically located and a high-energy pulse is applied for an embedded magnetic marker in the workpiece. Meanwhile, the magnetizing heads can also be repositioned to various points on a workpiece for imparting manufacturing and product identification data. In the case of leaf springs, the center of a spring steel bar is located a magnetic marker is embedded there. A high-energy rectangular pulse imparts a permanent invisible magnetic marks and data. The embedded indicators having peak magnetic strength allow manual or automatic positioning for perfect alignment in bending, tapping and other forming processes.

Owner:DANKO DONALD M +1

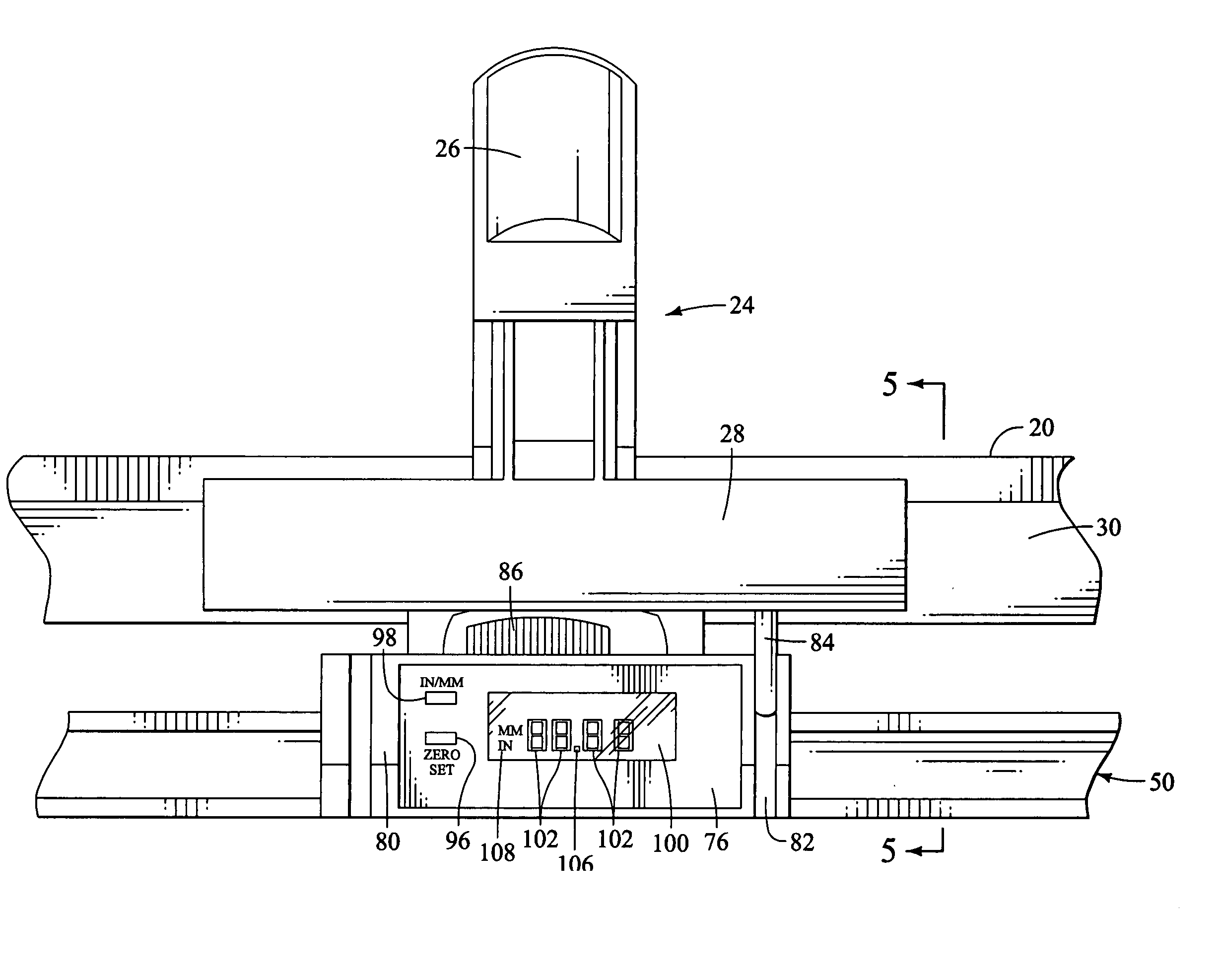

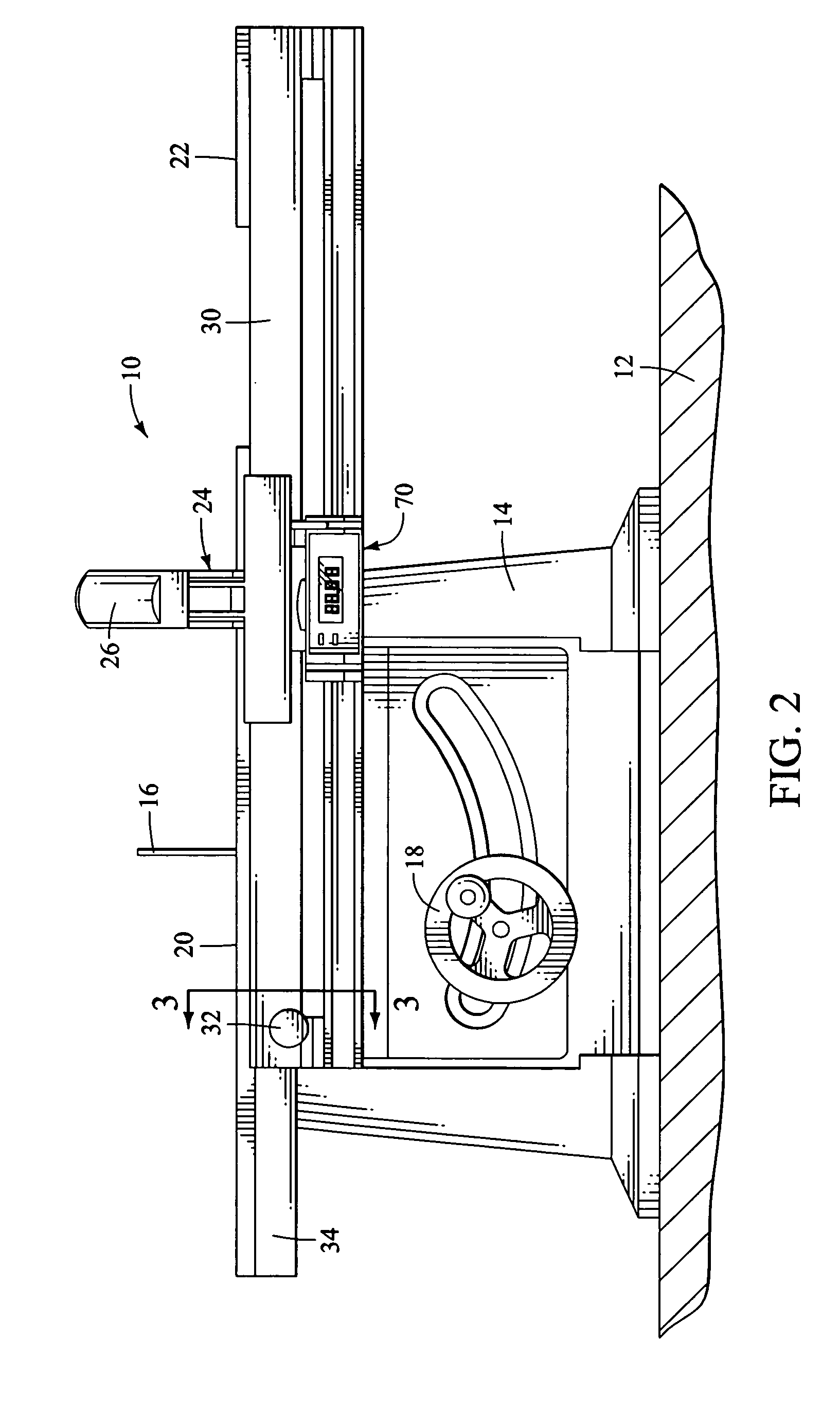

Table saw having a measurement and display system

InactiveUS7231858B2Increase effective sizeIncrease rangeMetal sawing devicesWalking sticksVia fenceEngineering

A table saw having various embodiments of a measurement and display system. Several embodiments have at least one fence rail on which a removable fence is movably supported and comprise an elongated sensor strip that is located adjacent the fence rail and a sensing unit that is supported and positioned adjacent to the sensor strip and is capable of providing an electrical signal to a display unit that is indicative of the position of the sensor unit relative to the elongated sensor strip. A processing unit is operatively connected to the sensing unit and display unit to provide a digital readout of the position of the sensing unit. A switch is connected to the processing unit and is adapted to provide a zero or reference setting position.

Owner:CREDO TECH CORP

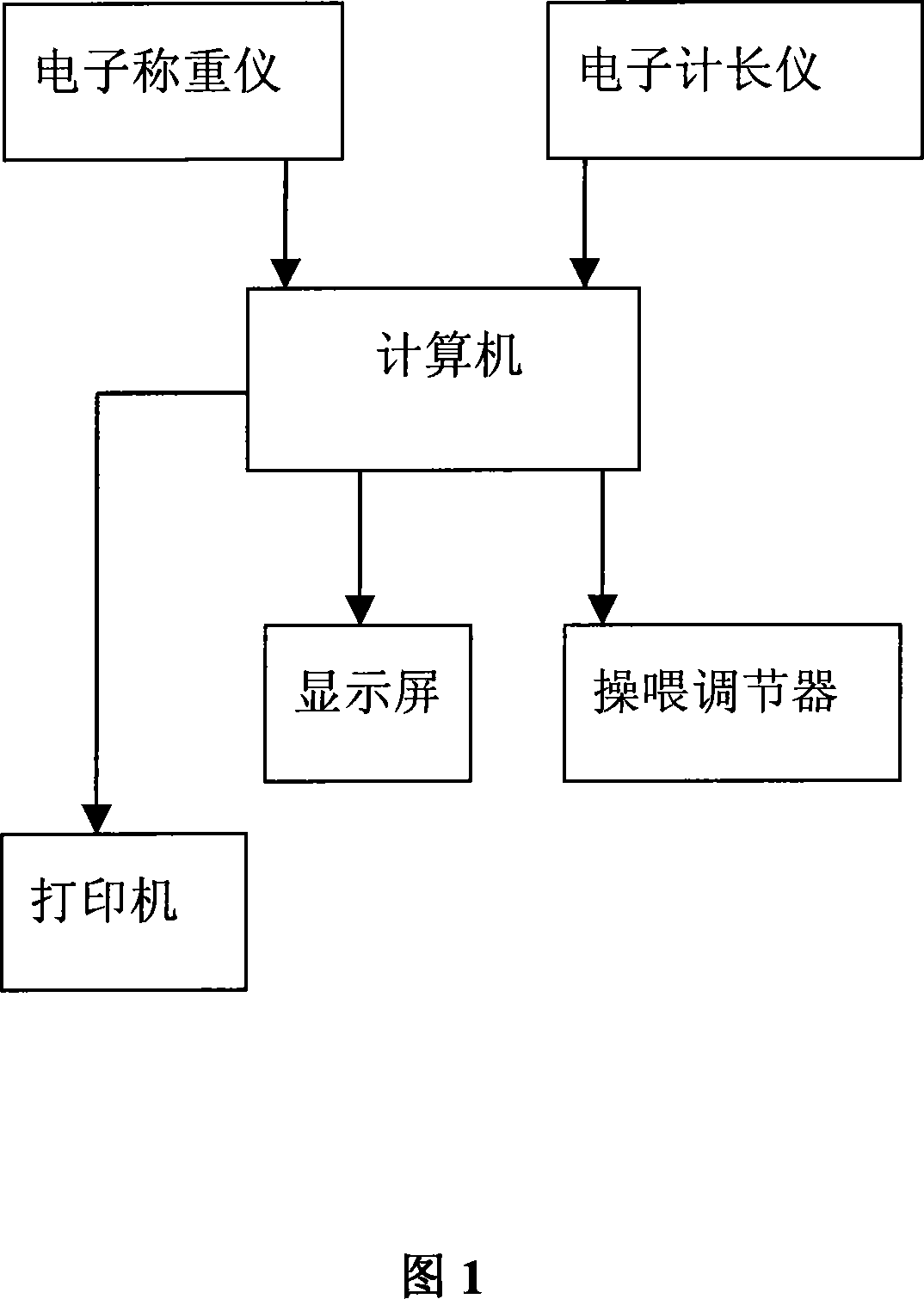

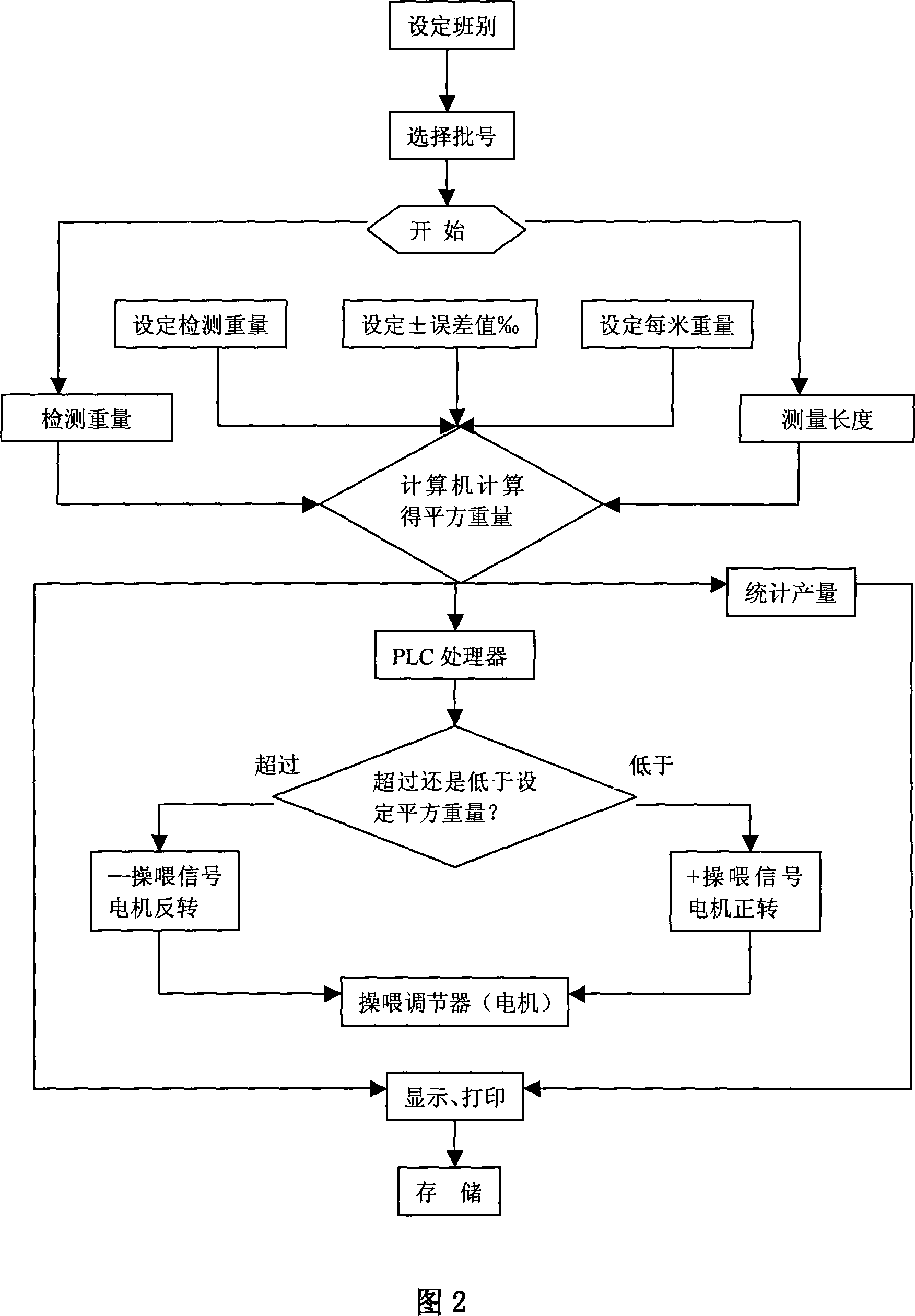

Weight-per-meter measuring device and method for fabric setting

InactiveCN101021042AManual control error is largeImprove efficiencyInspecting textilesHeating/cooling textile fabricsAutomatic controlDisplay device

The present invention discloses weight-per-meter measuring device and method for fabric setting, and relates to detection technology. The weight-per-meter measuring device includes one electronic weighing instrument, one electronic length instrument, one operating and regulating unit, a display, a printer and a computer with corresponding software. Under the control of the computer, the weight-per-meter measuring device measures the length and the weight of the set fabric, calculates the square weight, compares with the standard amount and regulates. The present invention has easy manufacture, high precision, fast regulation, automatic control, high efficiency and other advantages.

Owner:上海好力纺织机电设备有限公司

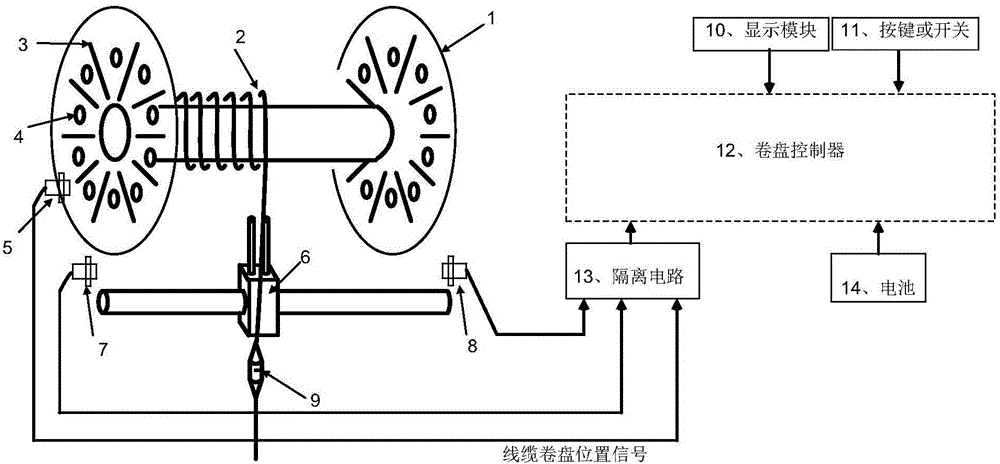

Emergency lighting cable pay-off and take-up length measuring device and method

ActiveCN105936448AAccurate measurementEliminate measurement effectsFilament handlingUsing electrical meansLocation detectionEffect light

The invention discloses an emergency lighting cable pay-off and take-up length measuring device which comprises a reel controller, a cable reel and a winding displacement device. The reel controller controls rotation of the cable reel, a pulse identifier for identifying the rotation turn numbers of the cable reel is arranged on the cable reel, a proximity switch for identifying the pulse identifier is arranged on one side or two sides of the cable reel, position switches are arranged at two ends of the winding displacement device, both the proximity switch and the position switches are connected with the reel controller, and the reel controller is connected with a display module. The emergency lighting cable pay-off and take-up length measuring device gives consideration to the influence on the pay-off and take-up length of different layer numbers during winding, so that the cable pay-off and take-up length measurement is accurate. The influence on the measurement of cable diameter change caused by cable connection is eliminated, and the device is suitable for multiple-section cable connection. By combining a simple position detecting device and a proposed computing method, the cable length can be accurately measured in real time. The position detection of the reel is achieved by utilizing reinforcing ribs or detection holes of the cable reel, and the costs of the device are reduced.

Owner:SHANDONG ACAD OF SCI INST OF AUTOMATION

Measuring roller and spray device

A measuring device includes a frame, a rolling wheel carried by the frame, measuring means for determining a distance traveled by the wheel, and signal means responsive to the measuring means for indicating when the wheel has traveled a preselected set distance. The measuring device may also include marking means such as spray paint, a braking mechanism, and a sonar position indicator.

Owner:WATKINS NATHAN P

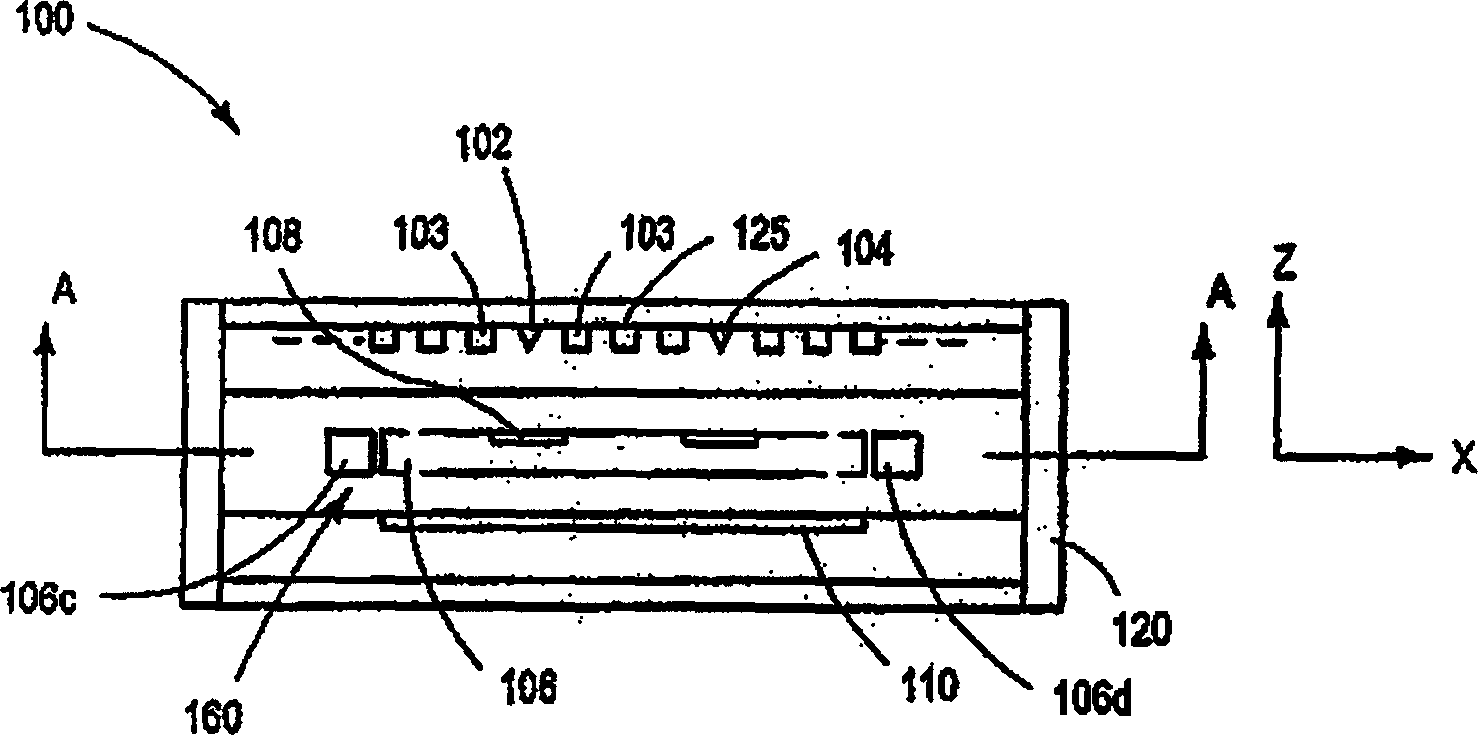

Position sensor based on capacity

InactiveCN1497237AAvoid overwriting by mistakeHigh resolutionResistance/reactance/impedenceUsing electrical meansRelative motionControl theory

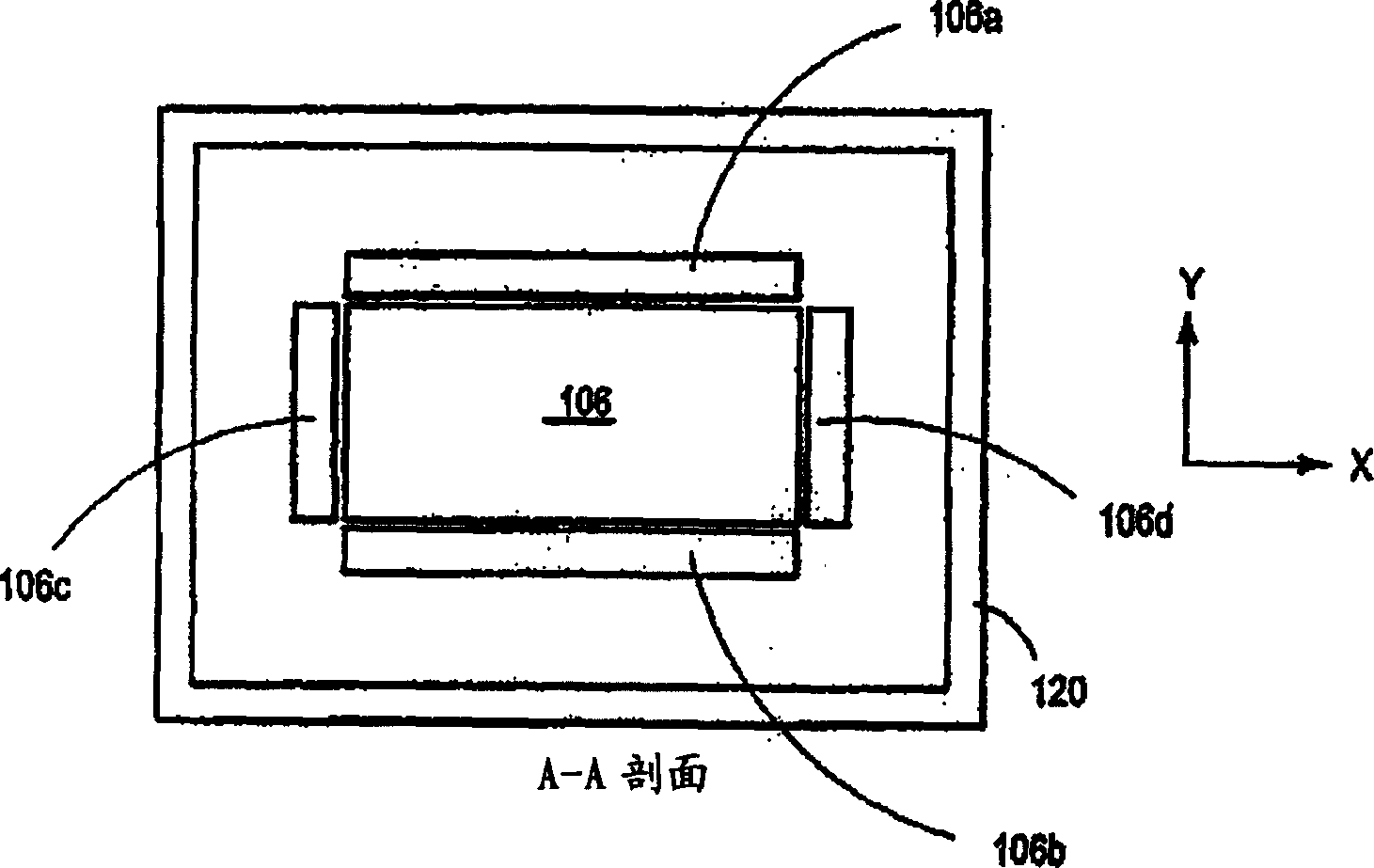

A position sensor 160, 162, 210, 260 for use in connection with a movable system having a pair of objects 106, 120 that are configured to move relative to one another along an axis through an operative range of motion. The position sensor includes a first plate 178, 180, 222, 226, 266, 268 secured to one of the objects and a pair of second plates 166, 168, 172, 174, 214, 216, 220, 262, 264 secured to the other of the objects. The second plates are adjacent each other and coplanar. The first plate and second plates are configured so that the second plates are spaced from and parallel to the first plate as the objects move relative to one another along the axis. The first plate and second plates are configured so that they form two variable, spaced-plate capacitors 192, 194, 240, 242, 244, 246 having capacitances that vary as the objects move relative to one another within the operative range along the axis. The position sensor is configured to use the capacitances to generate output usable to determine relative position of the objects along the axis.

Owner:HEWLETT PACKARD CO

Wheel vehicle measuring apparatus

InactiveUS7111412B2Accurate measurementImprove ease of useMeasuring wheelsUsing electrical meansEngineeringRotation cycle

Owner:INDEX MEASURING TAPE

Width-measuring method and surface texture measuring instrument

ActiveUS7036238B2Scan accuratelyIncrease the areaMechanical counters/curvatures measurementsMechanical diameter measurementsRotary stageMeasuring instrument

Owner:MITUTOYO CORP

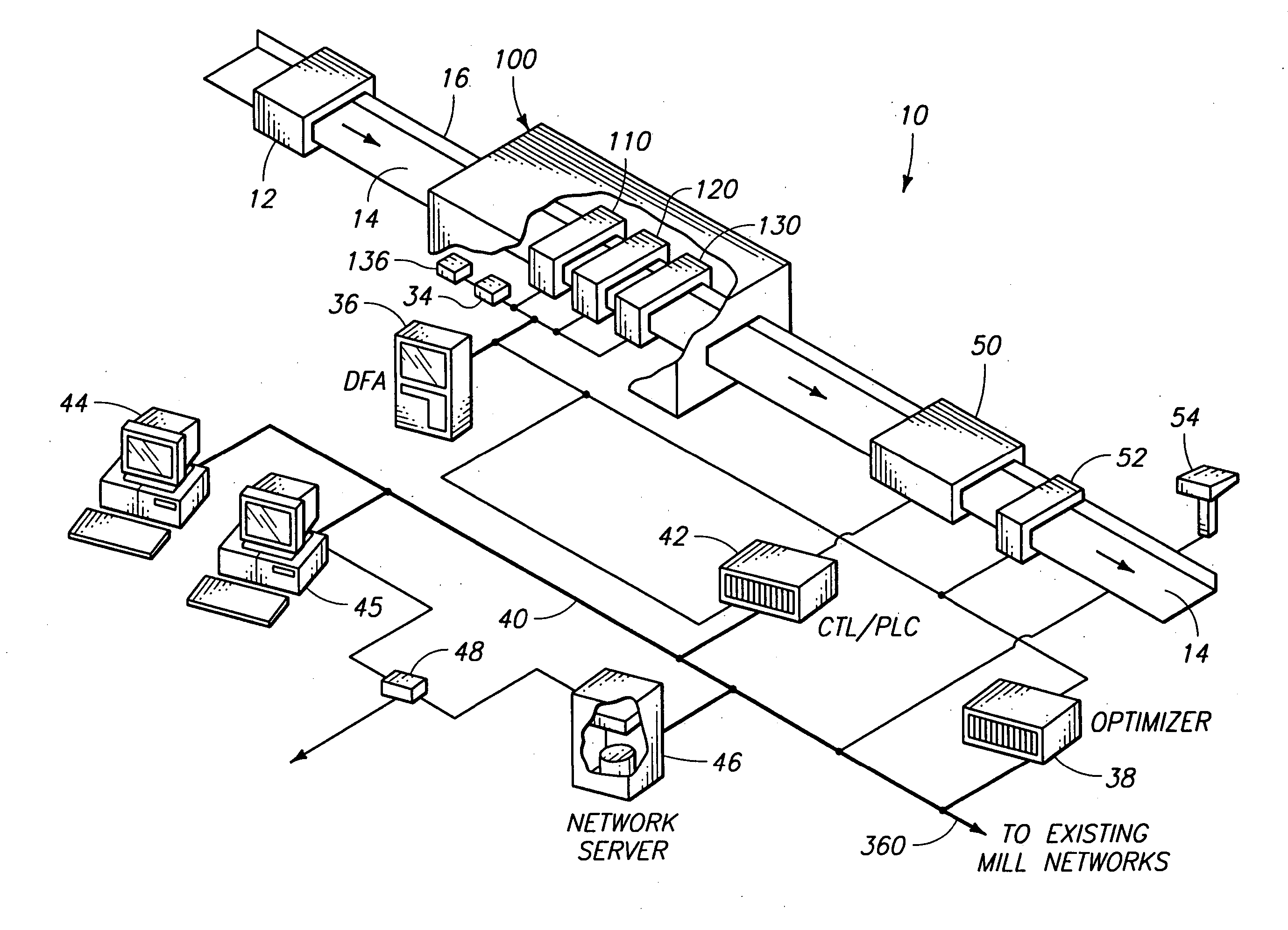

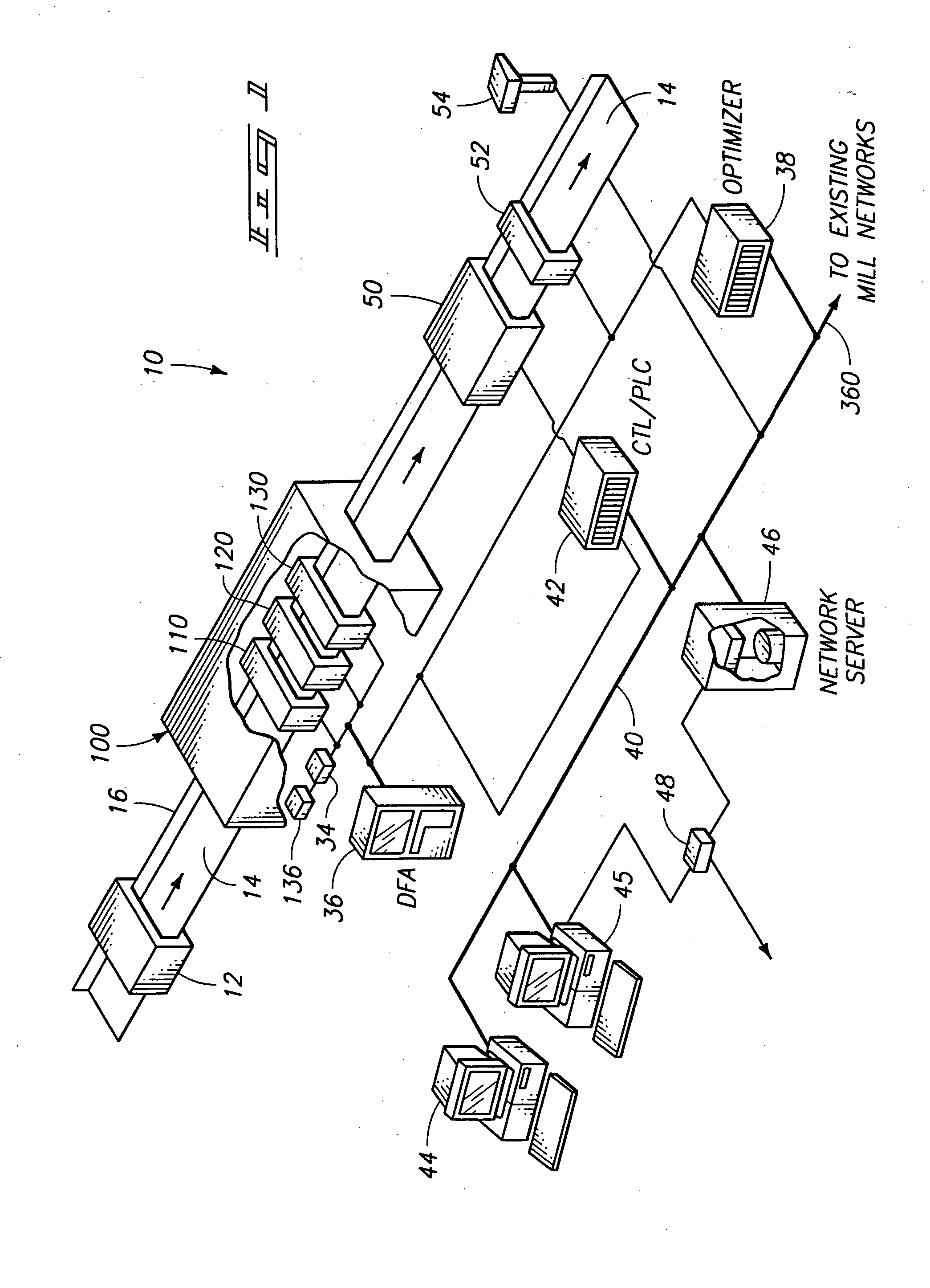

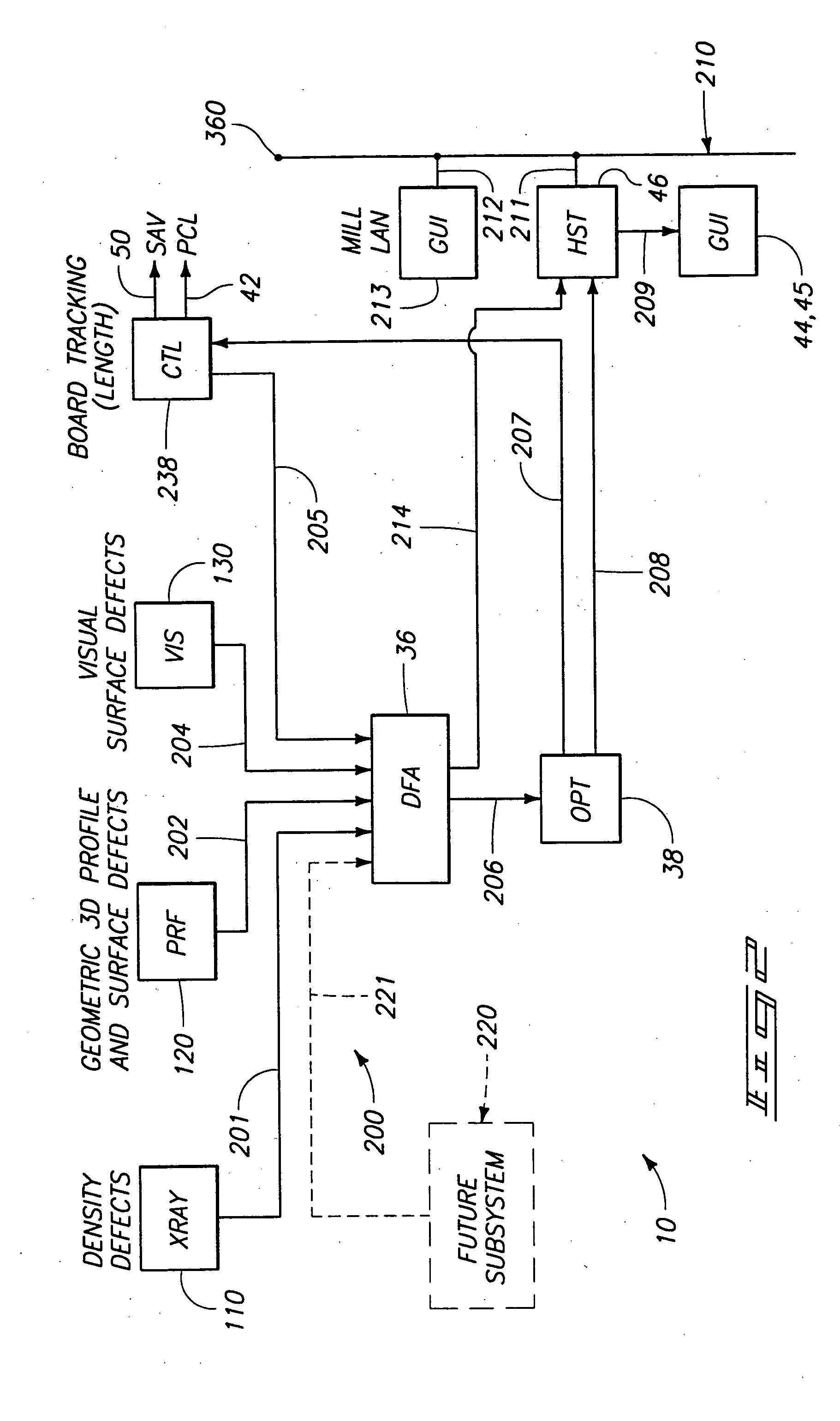

Method and apparatus for improved inspection classification of attributes of a workpiece

InactiveUS20050021280A1Linear/angular speed measurementFluid speed measurementKinematicsAngular velocity

An apparatus for detecting the probable existence, location, and type of defects in a workpiece is described. The apparatus includes a sensor subsystem, an optimizer, a control subsystem, and a computer system having a processor and computer readable memory. Sensor subsystem senses a first section of the workpiece and produces signals corresponding to a physical characteristic of the workpiece. The computer system is configured to generate a workpiece model based on the signals produced by the sensor subsystem. In an alternate embodiment, a defect assembler can be provided to merge signals from a plurality of sensor subsystems. The defect assembler can also be configured to generate the workpiece data model. The optimizer is configured to generate workpiece segmentation recommendations based on the workpiece data model. The processor is configured with a first producer thread program which, in response to the receipt of a first set of signals by the computer system, receives a data subscription request from a subsystem which uses data and transmits the signals from the computer readable memory to the generator of the data subscription request. The processor is further configured to generate a second producer thread in response to storage of a second set of signals in the computer readable memory. The second producer thread is configured to receive one of the data subscription requests and selectively send the second set of signals to the generator of the data subscription request. A tracking device for tracking selective kinematics of a workpiece moving through a plant is also disclosed. The tracking device includes an encoder wheel configured to tangentially contact a workpiece and rotate at an angular velocity coincident with the linear velocity of the workpiece. The tracking apparatus further includes a drive mechanism for driving the encoder wheel at a first angular velocity approaching the angular velocity of the encoder wheel which is coincident with the linear velocity of the workpiece. The tracking device also includes a signal generator configured to interact with the encoder wheel and generate a signal in response to the angular velocity of the encoder wheel. The tracking apparatus can be incorporated into the apparatus for detecting defects within a workpiece by providing the signal from the signal generator to the control subsystem.

Owner:USNRKOCKUMS CANCAR

Rolling electronic length measuring device

InactiveUS7036241B2Prevent reboundGood for scrollingMeasuring wheelsUsing electrical meansMeasurement deviceControl theory

An electronic measuring device is disclosed which includes a pair of wheels connected to an axle that passes through a drive gear. The drive gear is enmeshed to a second gear which, in turn, is coaxially connected to an encoder disk. The encoder disk has spaced-apart fins around its outer periphery. As the wheels turn and the encoder disk rotates, the fins and openings between the fins pass between an emitter and a receiver. The emitter and receiver are linked to a controller which calculates the distance traversed by the wheels based upon the number of fins that pass between the emitter and receiver, or with an active counting system (ACS). The controller also includes functions to establish start and stop points for a measurement and an easy means for dividing a measured distance into equal parts or segments and a means for marking the boundary points that define the segments when the measuring device is rolled back across the measured distance. The device can be used on both planar and non-planar surfaces.

Owner:IRWIN IND TOOL CO

Popular searches

Circuit susbtrate materials Multilayer circuit manufacture Claywares Color television details Other angling devices Weighing auxillary devices Mechanical measuring arrangements Special purpose weighing apparatus Electric/magnetic roughness/irregularity measurements Mechanical roughness/irregularity measurements

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com