Control method for testing and determining length of raw material thread of rewinding vehicle and control device used thereof

A control method and raw material yarn technology, applied in the direction of electromagnetic measuring device, using electric/magnetic device to transfer sensing components, thin material processing, etc., can solve the loss of two-for-one twisting machine, large power loss, unsatisfactory use effect, and insufficient control Accurate and other issues, to achieve the effect of shortening working time, facilitating popularization and application, and improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

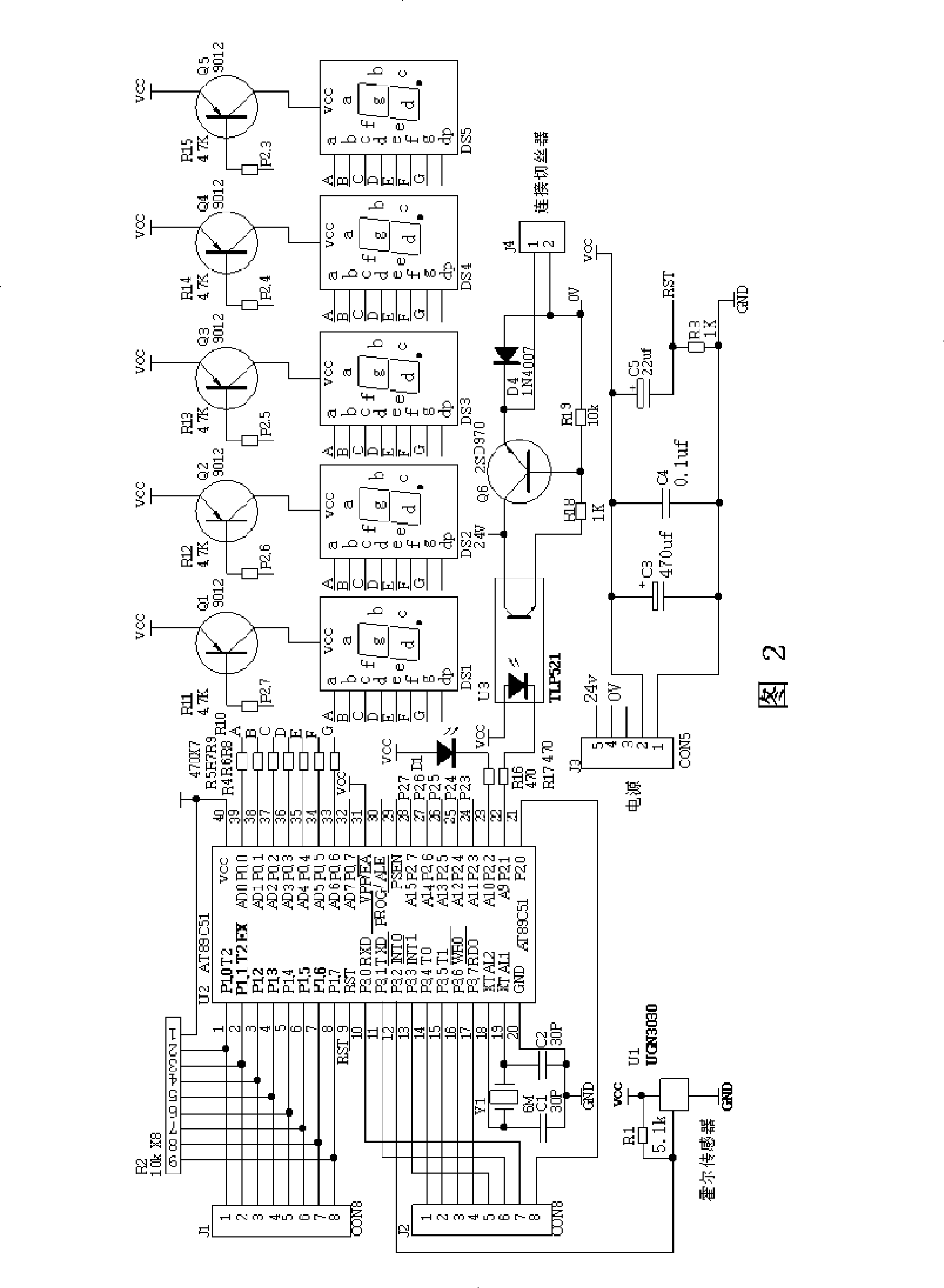

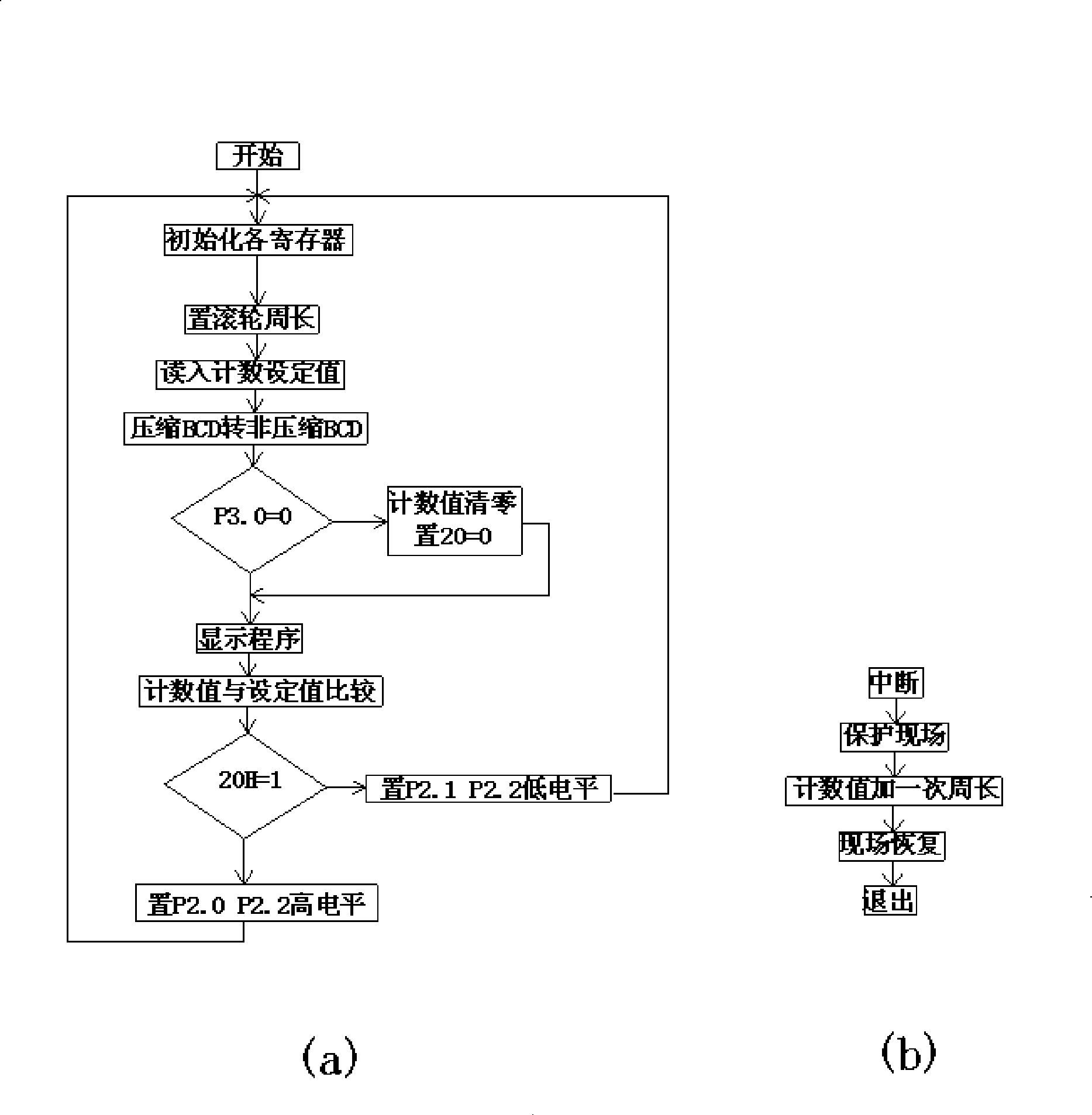

[0012] Embodiment of the present invention: a control method for measuring and determining the length of the raw material yarn of the winding car. The method is to install a round roller equipped with a magnetic block on each spindle of the winding car, and the raw material silk rolls against the round roller, and the winding of the raw material silk on the round roller is greater than or equal to 80% of the circumference of the round roller. %. When the raw material wire is wound, the round roller is driven to rotate, and the pulse signal is detected by the Hall sensor installed on the corresponding position of the magnetic block on the round roller, and the detected pulse signal is input to the signal processing device, which counts and The count value is compared with the set value, and when the count value reaches the set value, a control signal is output to cut off the raw material wire.

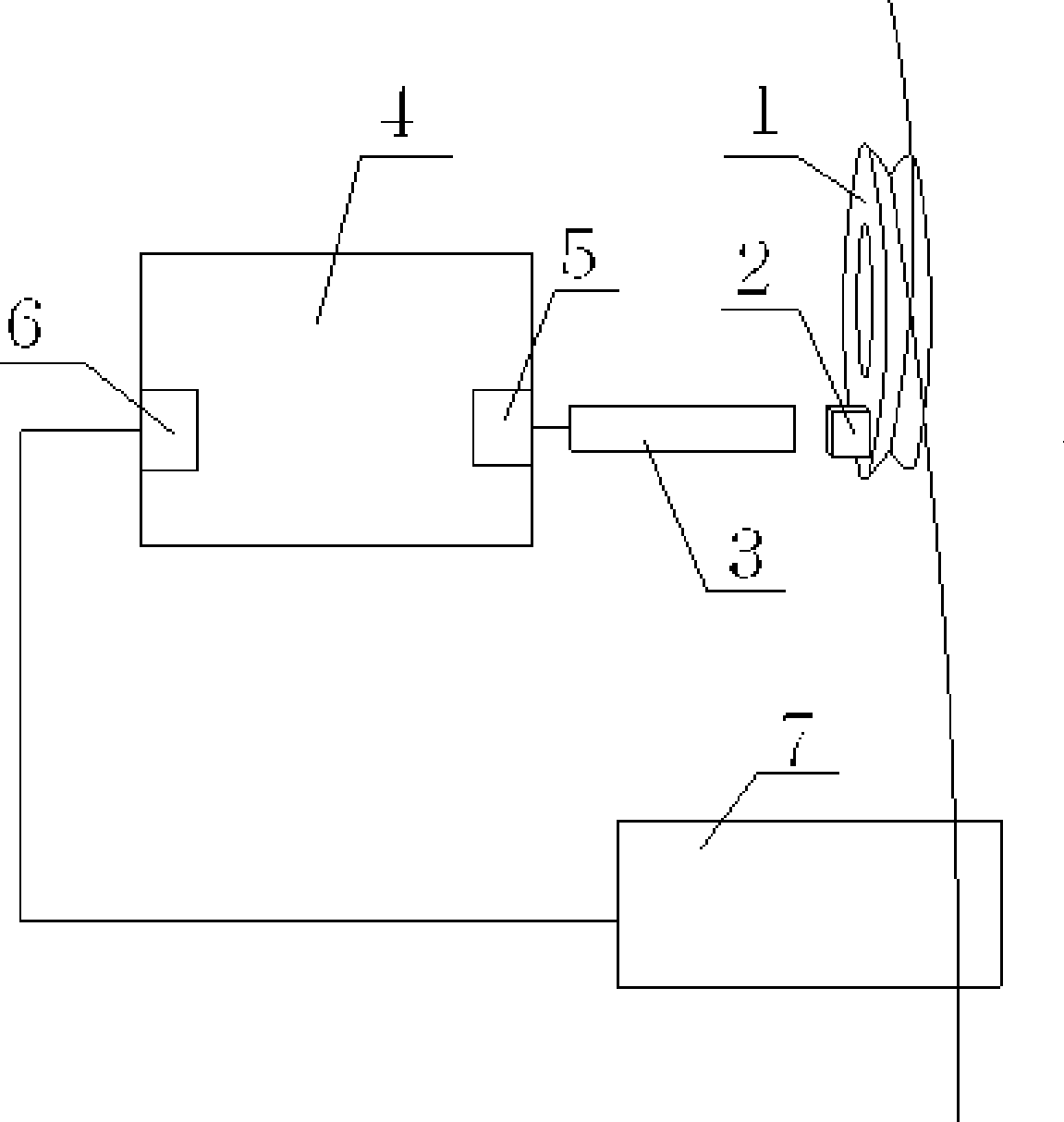

[0013] Applied devices when using the above method, such as figure 1 As shown, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com