Single phase capacitor motor and manufacturing method thereof

A capacitor and single-phase technology, which is applied in the field of single-phase capacitor motors and its production, can solve problems such as the complex structure of single-phase capacitor motors, and achieve the effects of simple and reasonable structure, reduced production costs, and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

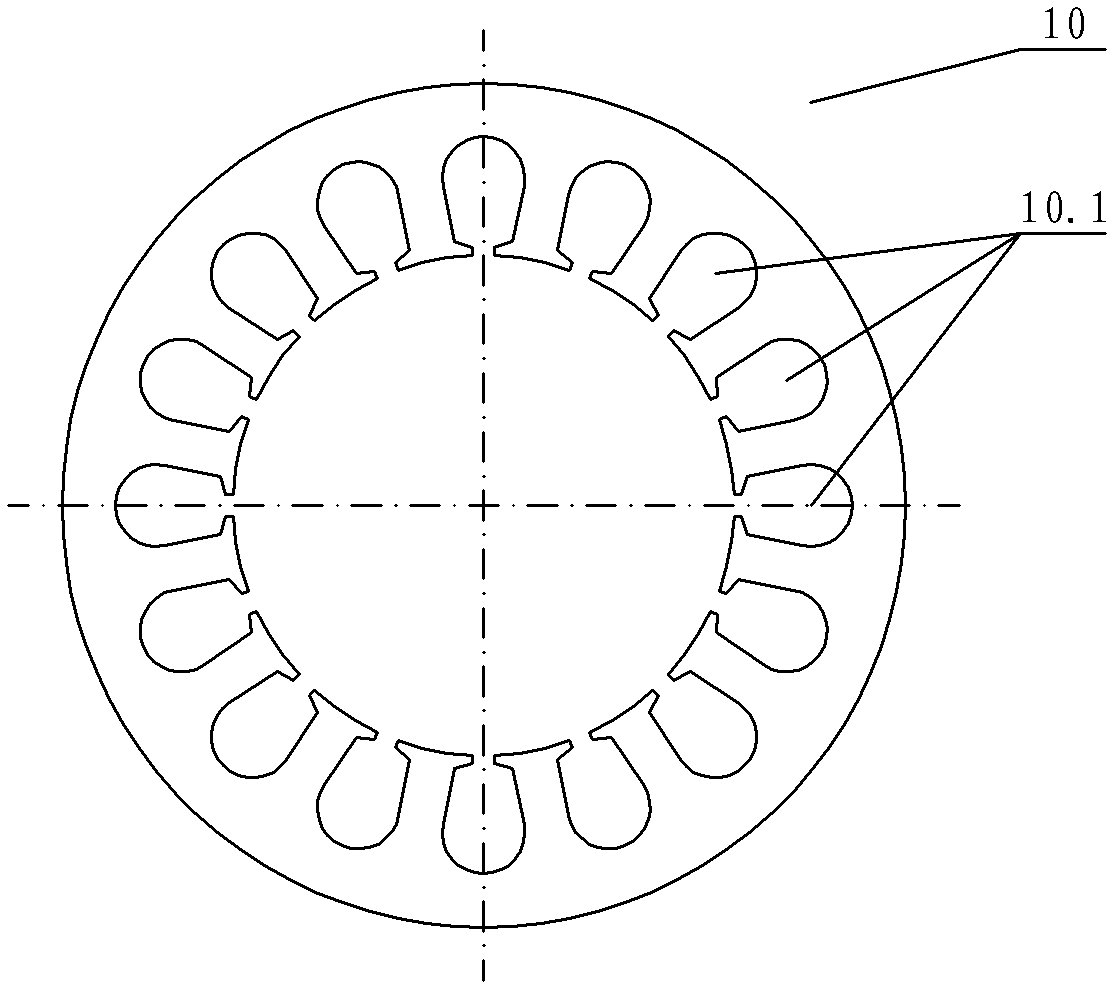

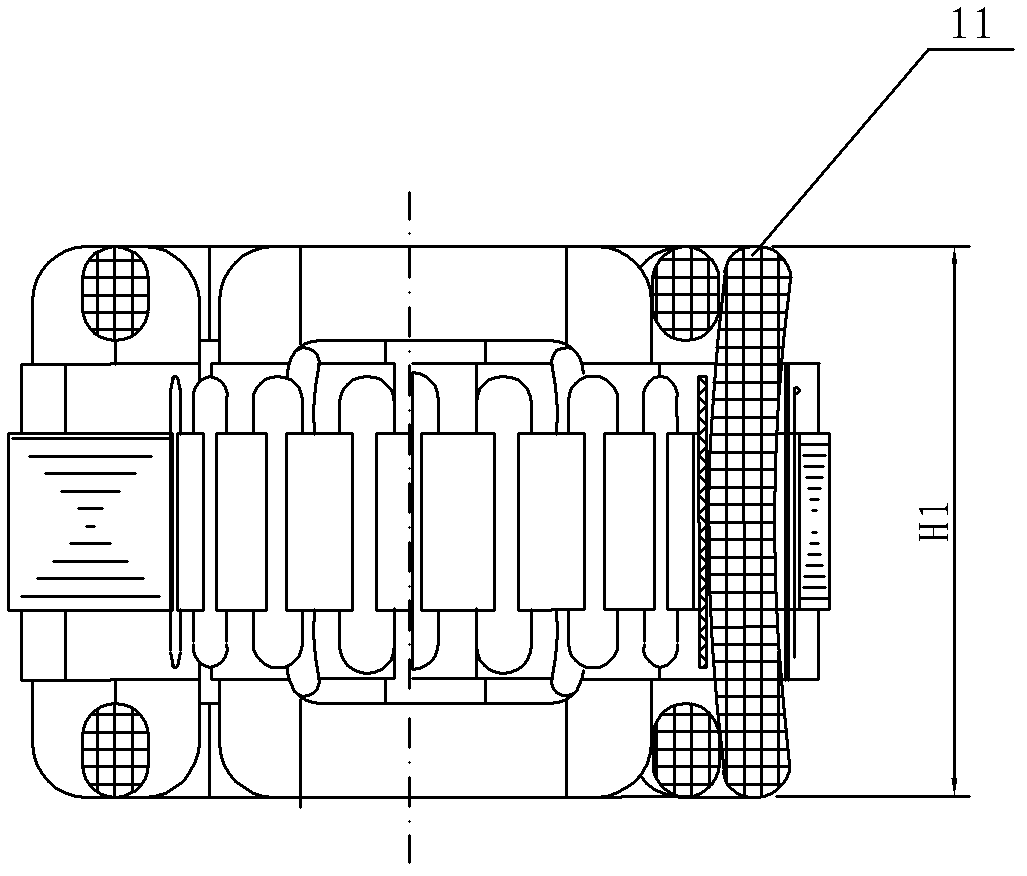

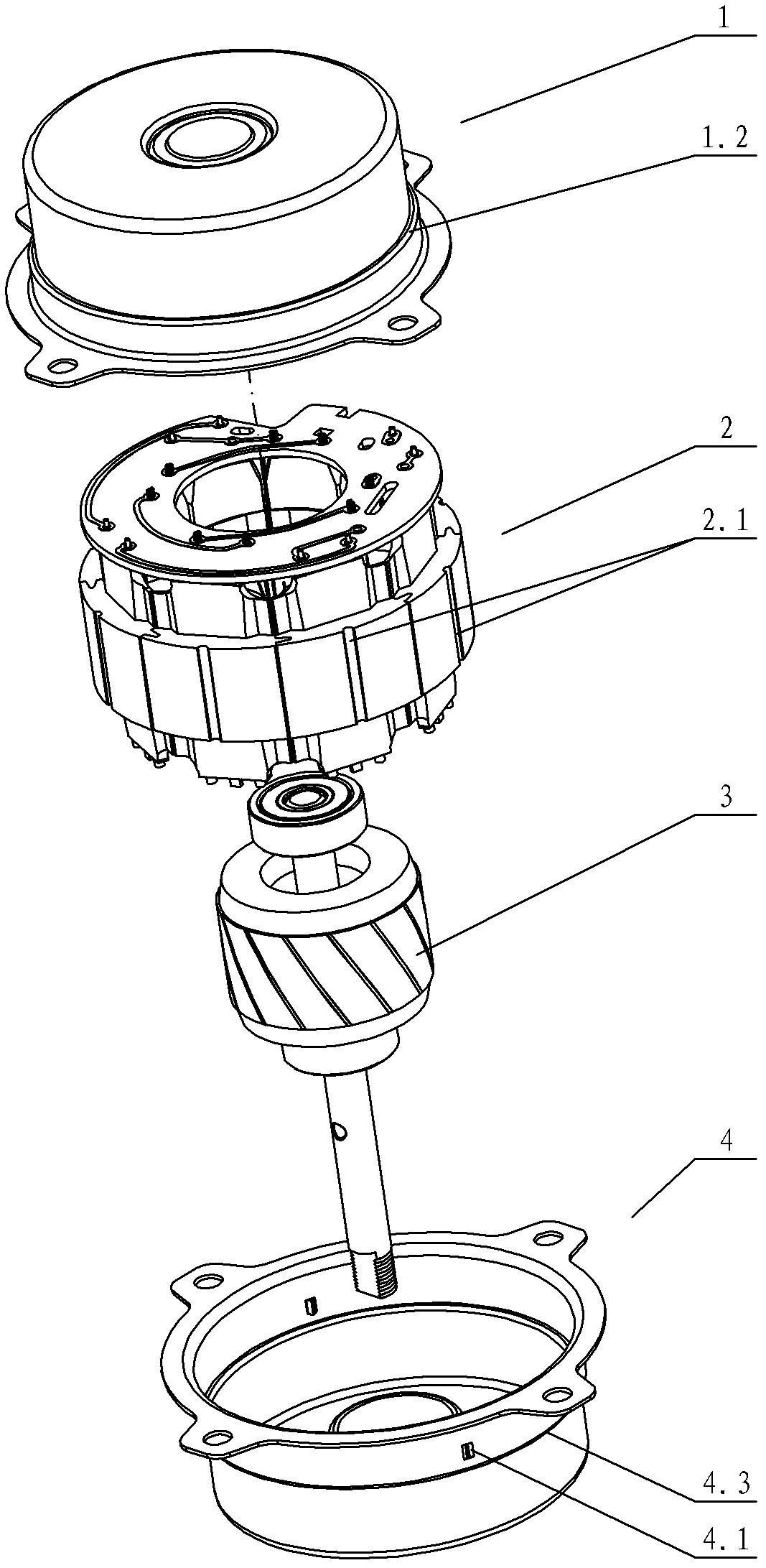

[0032] see Figure 3-Figure 10 , the single-phase capacitor motor includes a stator 2 and a rotor 3 arranged in a casing, the casing is jointly surrounded by a rear cover 1 and a front cover 4, and the stator 2 includes N main coil winding assemblies 5 and N The auxiliary coil winding assembly 6, the main coil winding assembly 5 and the auxiliary coil winding assembly 6 are alternately arranged to form a ring-shaped stator 2, each of the main coil winding assembly 5 and the auxiliary coil winding assembly 6 includes a coil wound on the stator The winding 7 on the iron core 5.2, where N is the number of stator poles of the motor. For example, a 4-pole motor = 4 primary coil winding assemblies + 4 secondary coil winding assemblies. N primary coil winding assemblies 5 and N secondary coil winding assemblies 6 are relatively independent, see Figure 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com