Automatic production device for fan housings

A technology of production equipment and fan cover, which is applied in the field of automatic production equipment of fan cover, can solve the problems of restricting the development of enterprises, high error rate of manual operation, low efficiency, etc., and achieve the goal of improving yield and quality, reducing human error, and accurate positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

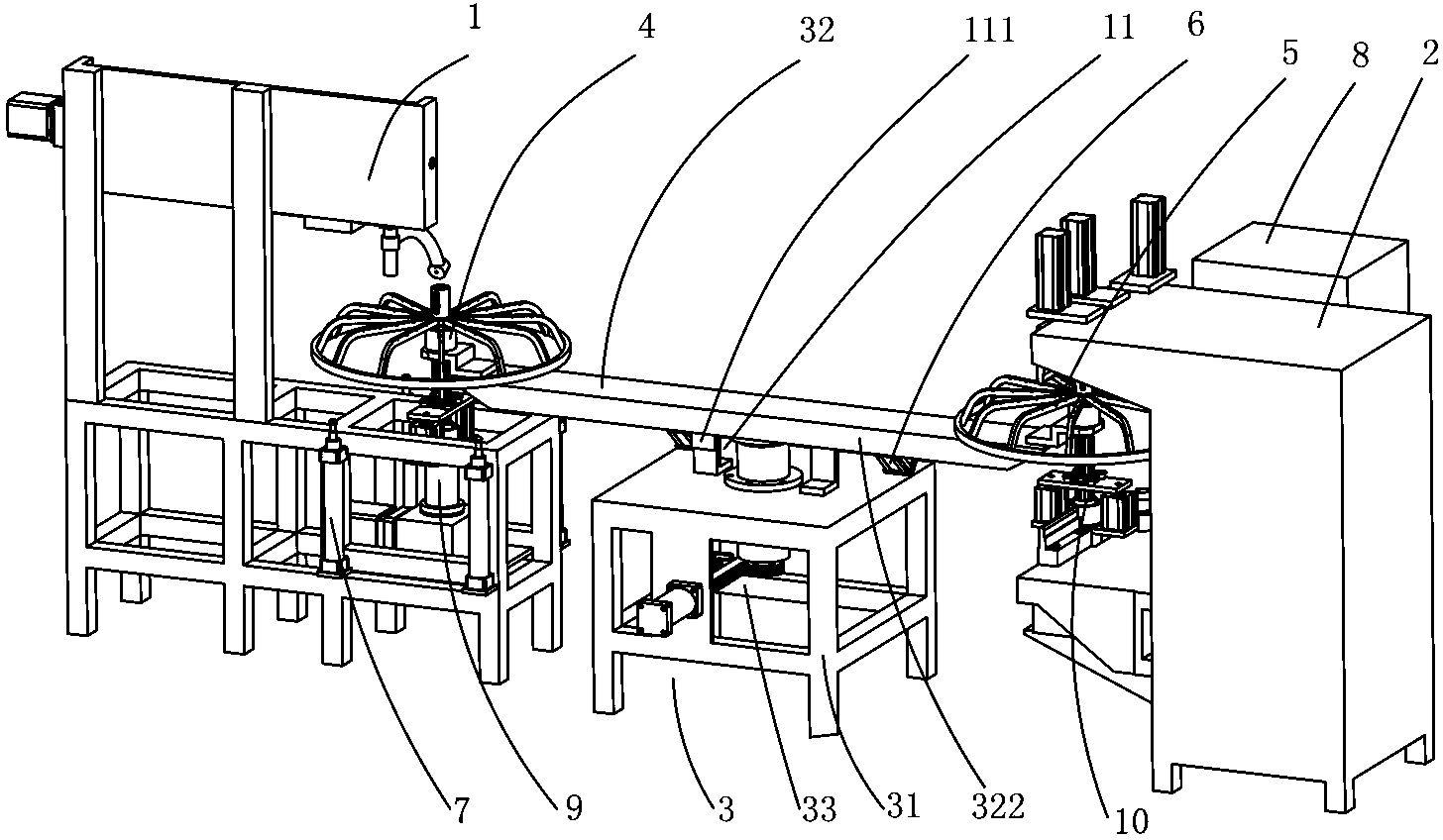

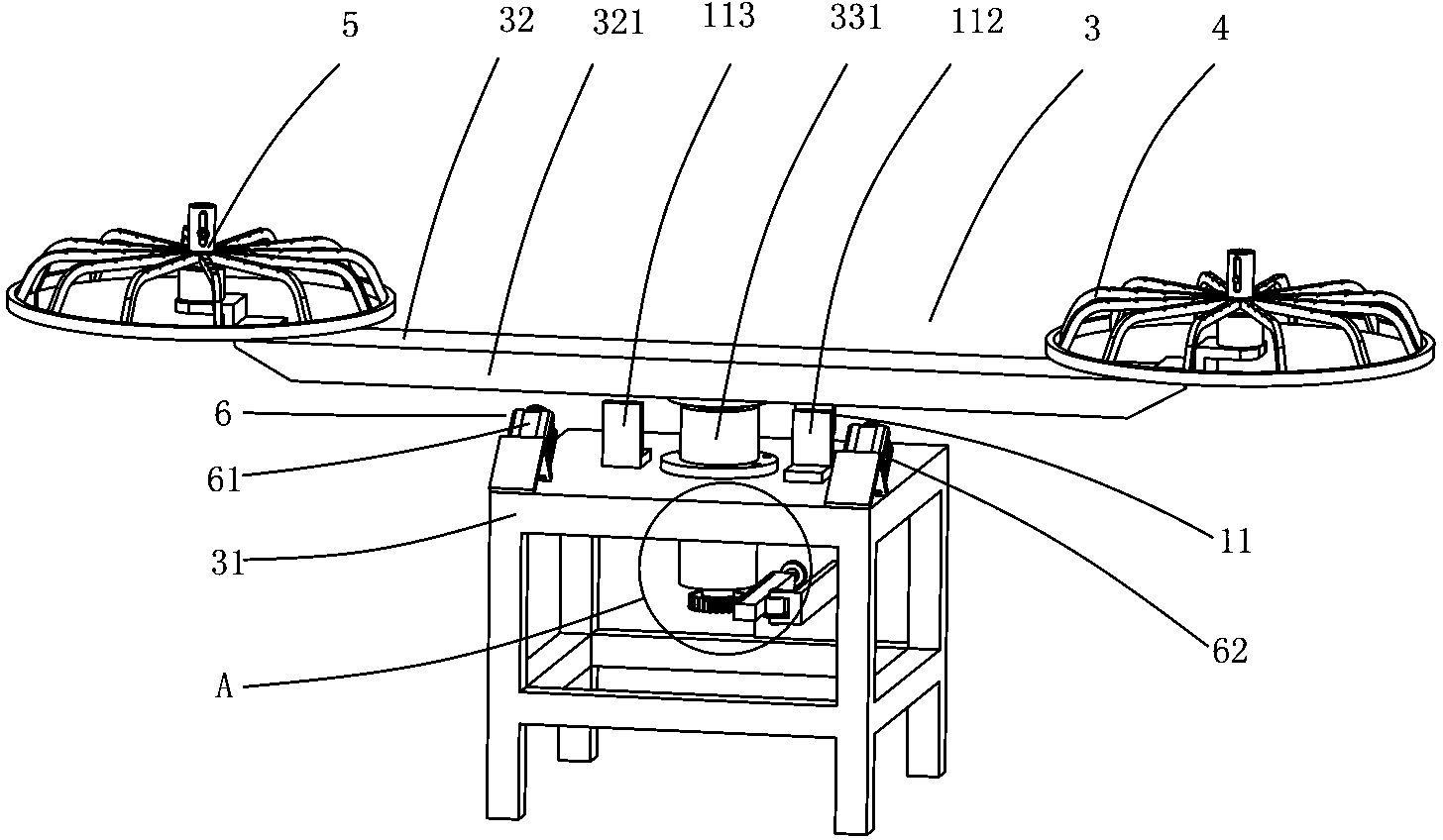

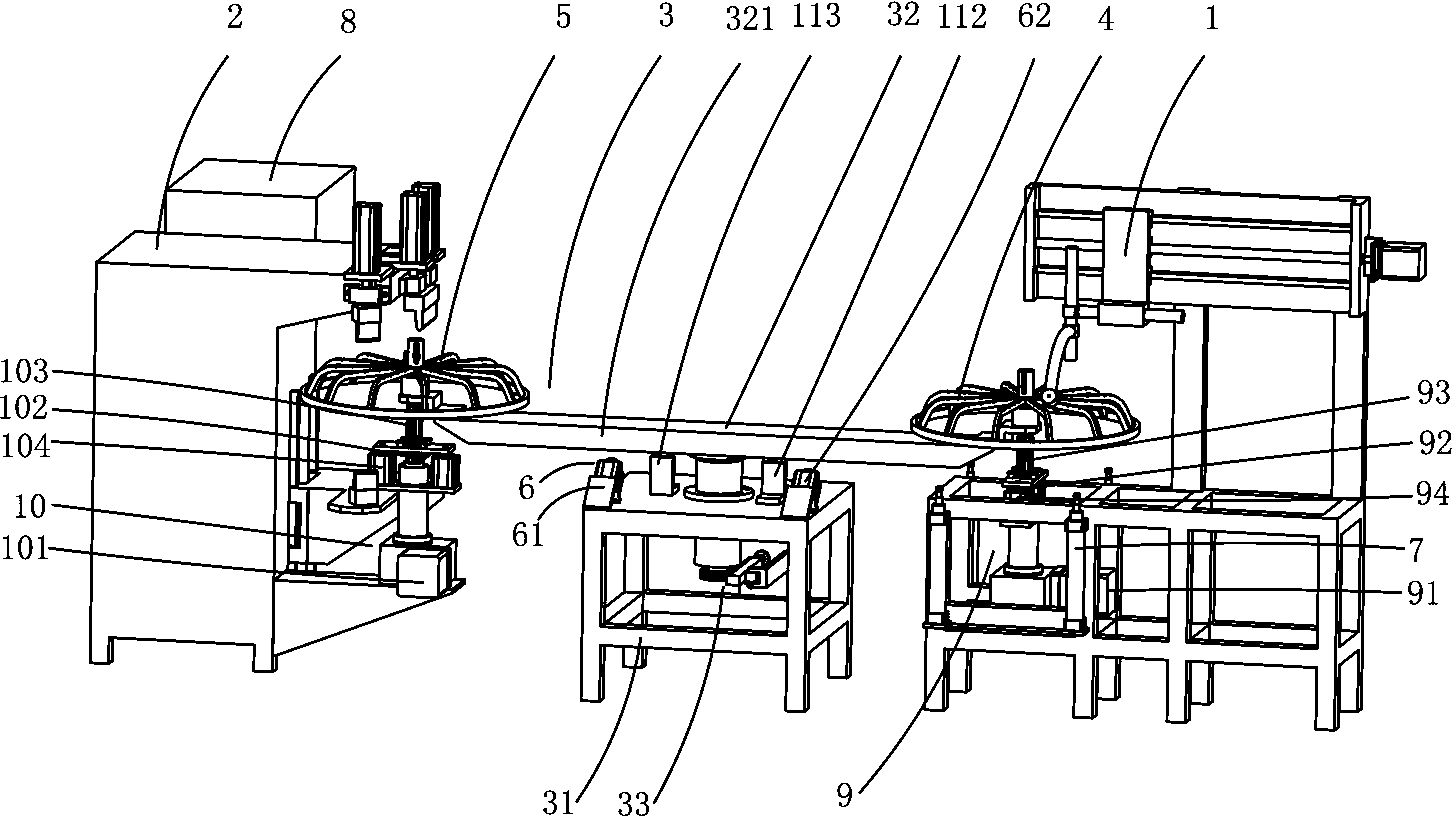

[0025] Below in conjunction with accompanying drawing, the present invention will be further described, Figure 1 to Figure 7 Shows a preferred embodiment of the present invention, which is mainly used for the manufacture of fan covers or other circular screen covers, which includes a winding part 1 and a welding part 2, and the winding part 1 and the welding part 2 A rotating part 3 capable of forward and reverse rotation is connected, and the two ends of the rotating part 3 are provided with a first processing module 4 and a second processing module 5 for installing workpieces. The first processing module 4 The second processing module 5 can be rotated onto the winding part 1 or the welding part 2 through the rotating part 3, and the first processing module 4 and the second processing module 5 are respectively positioned on the winding part on the rotating part 3 1 or the positioning device 6 used on the welding part 2, and the winding part 1 is provided with the workpieces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com