Patents

Literature

32results about How to "Small height change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

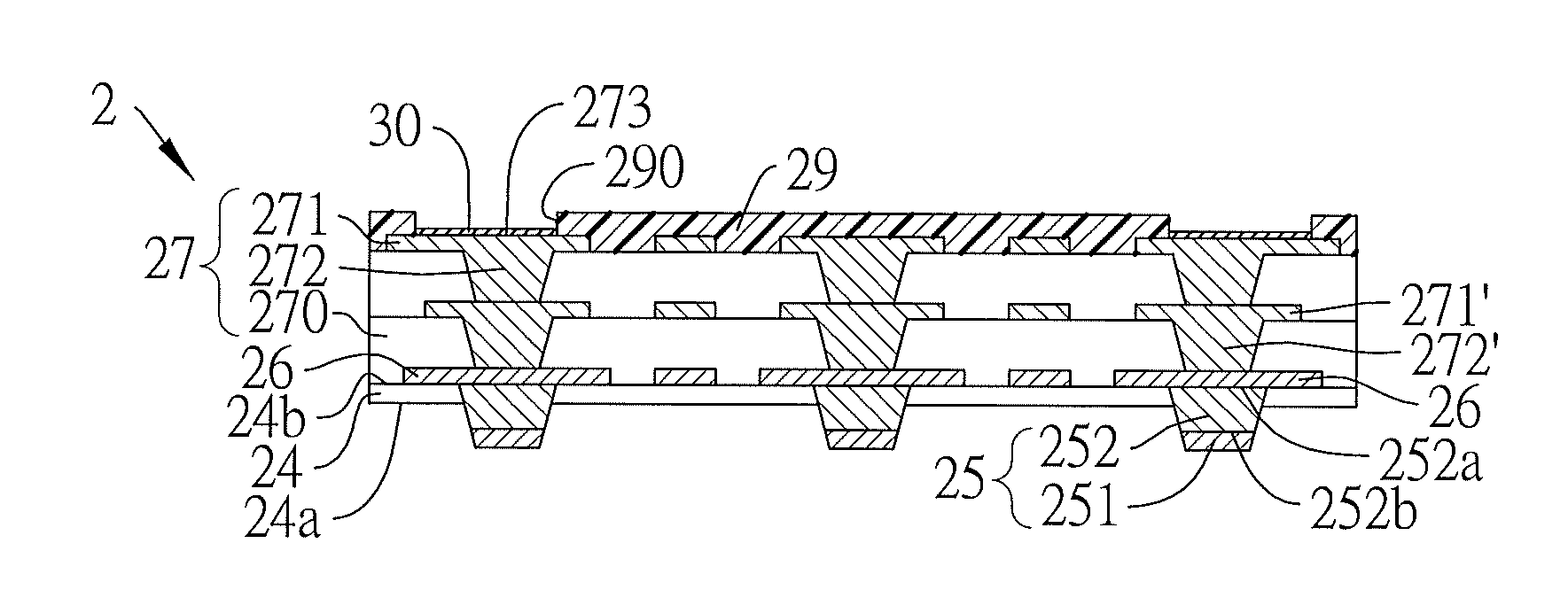

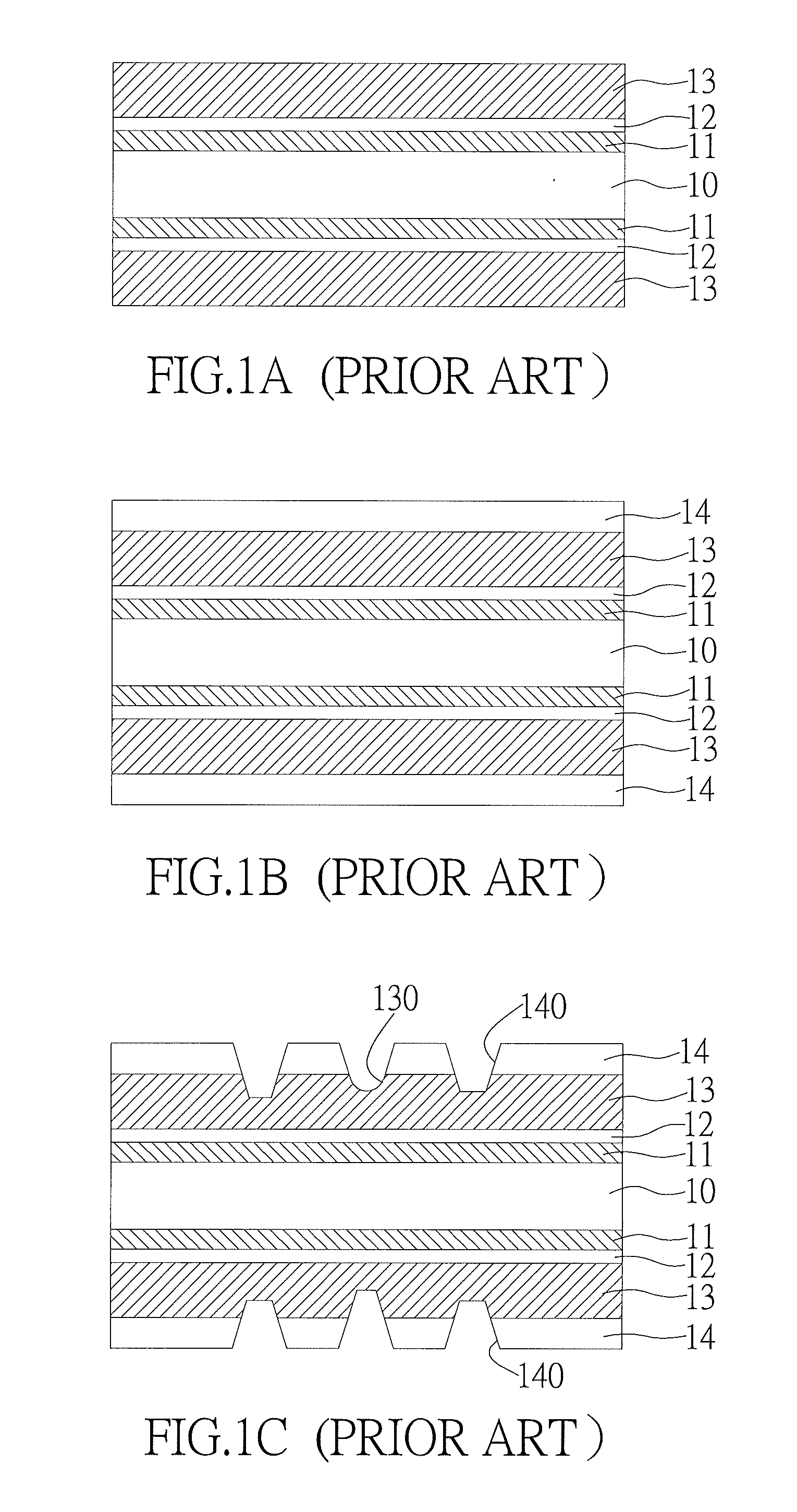

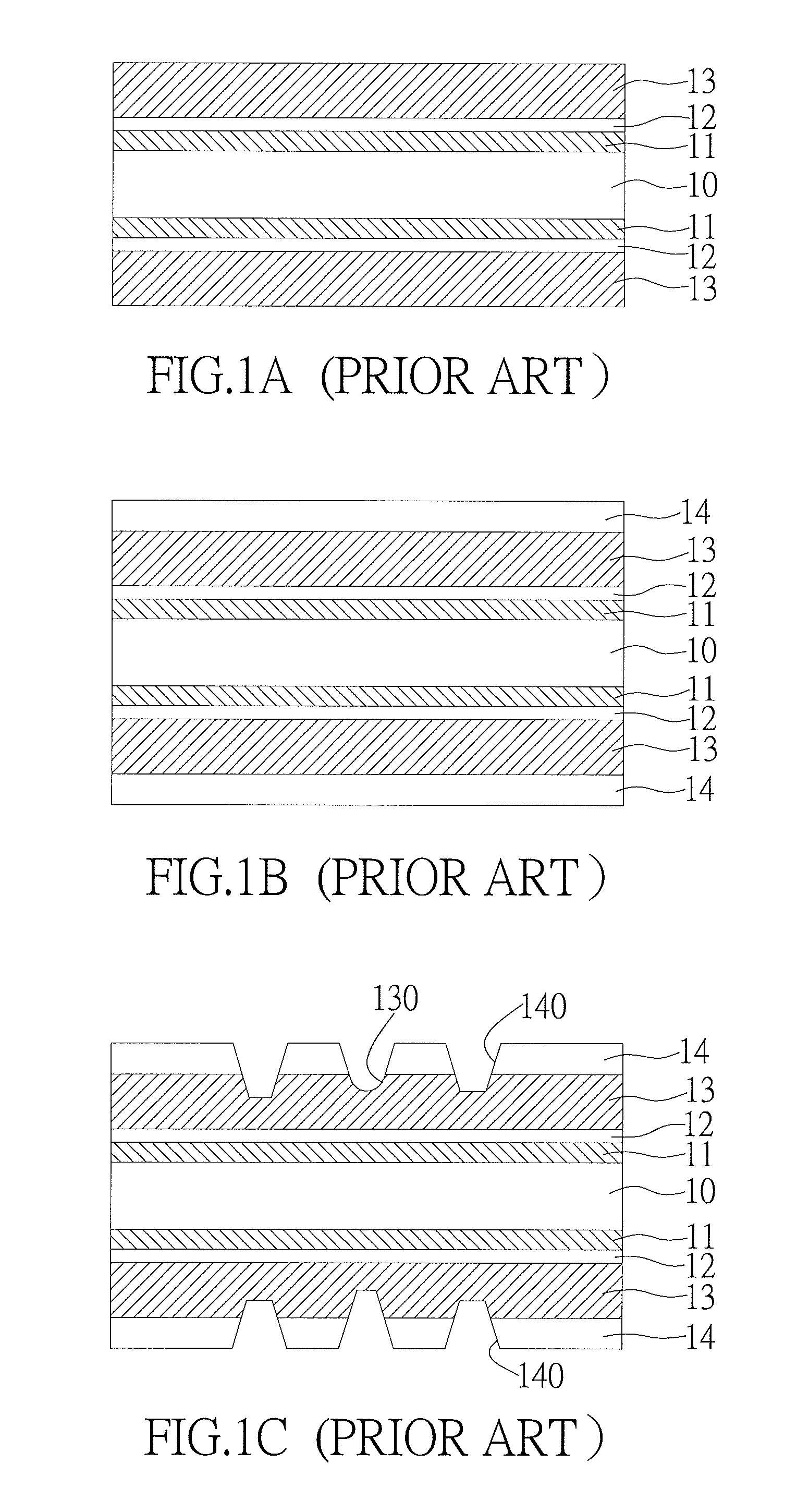

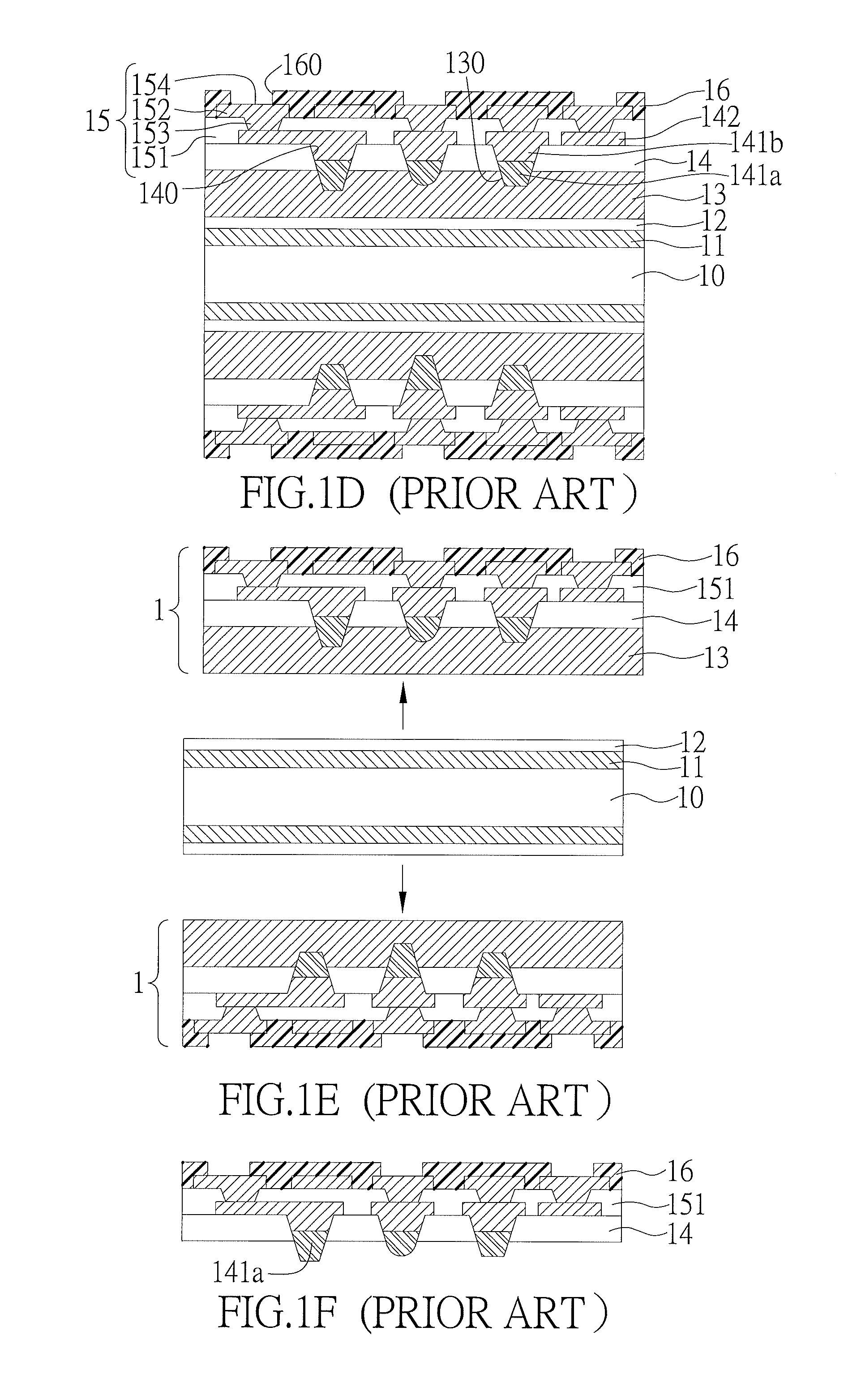

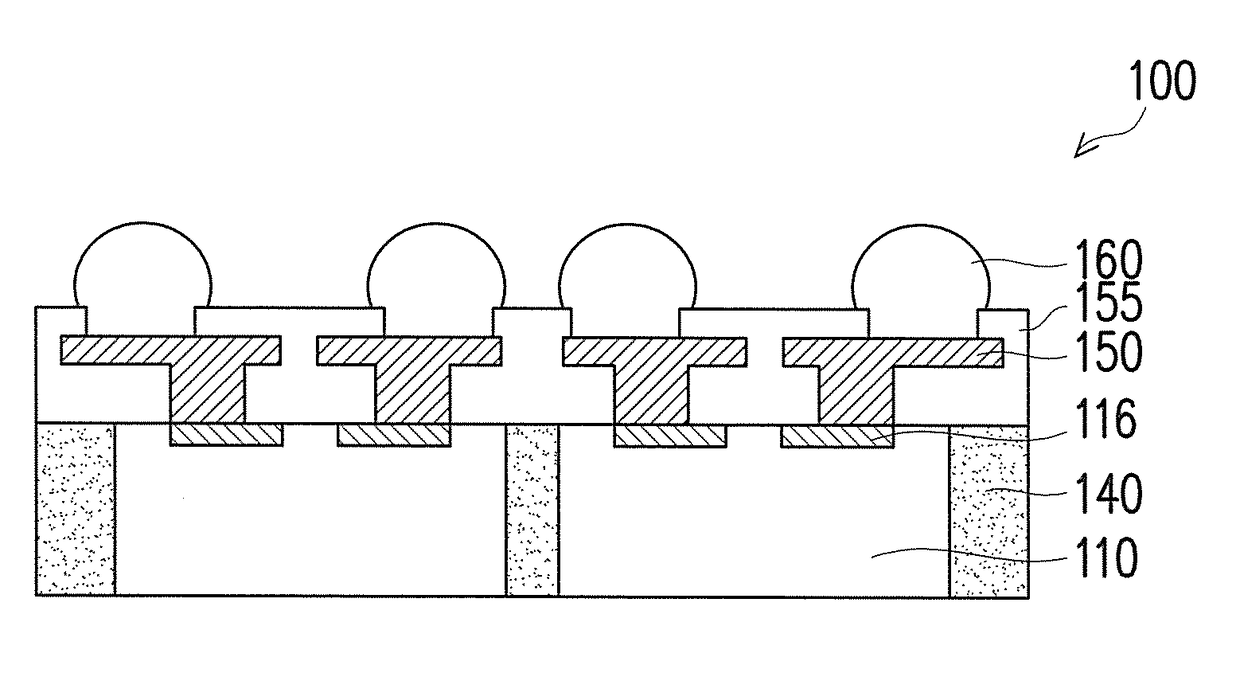

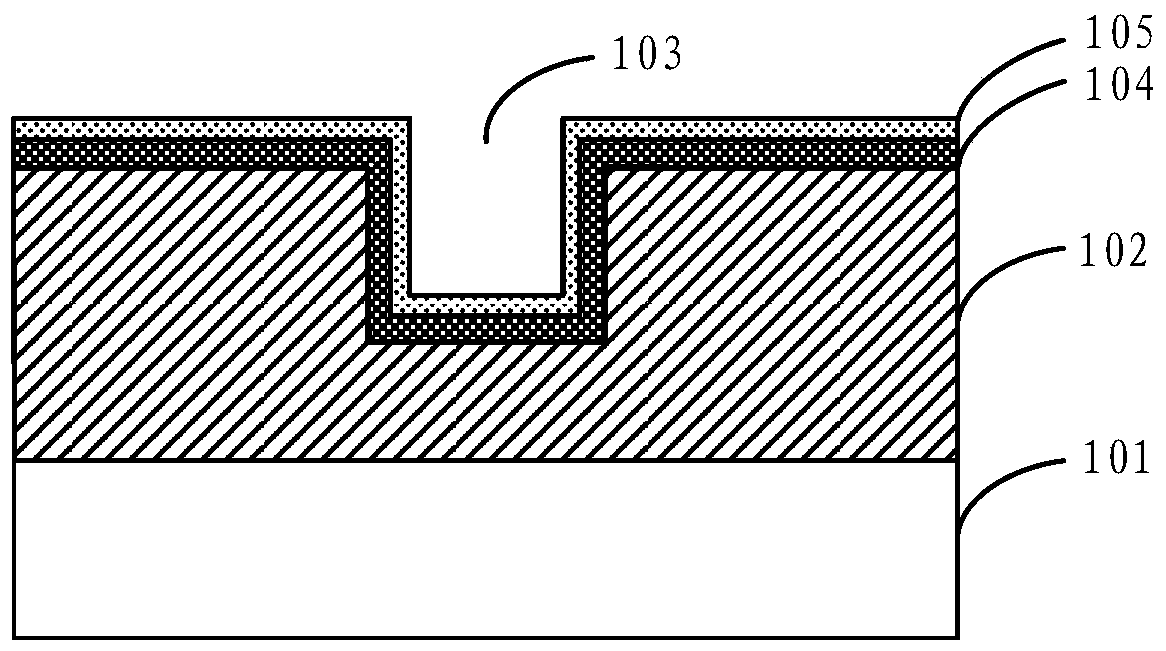

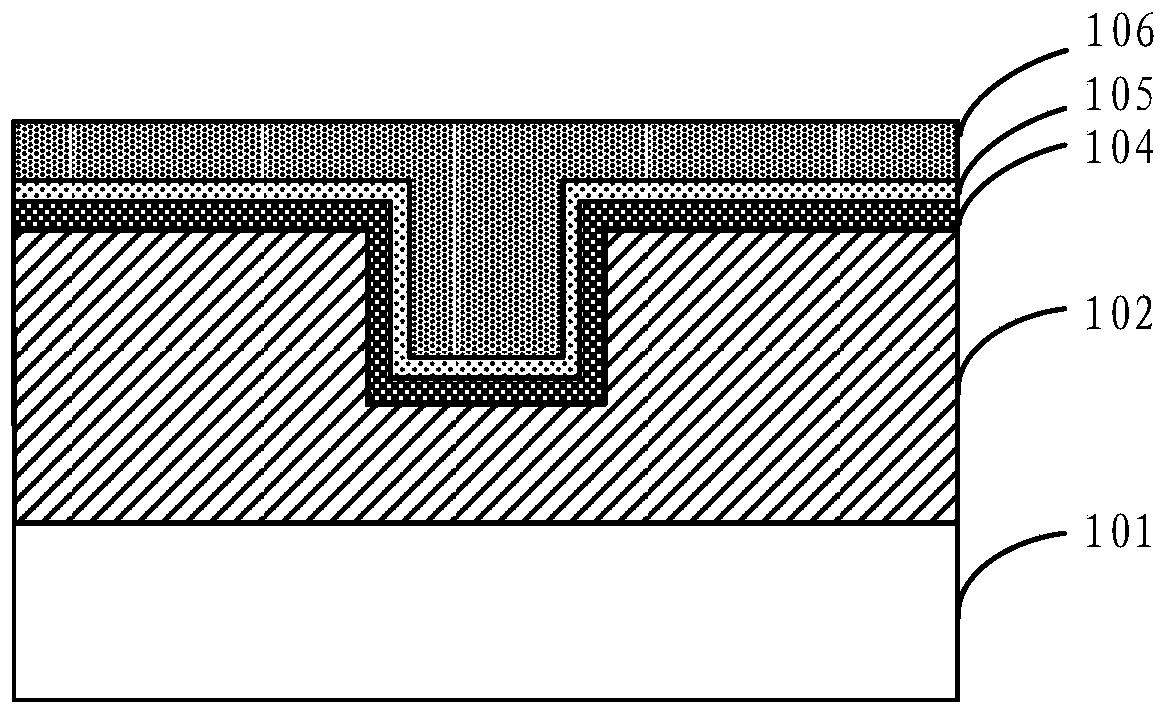

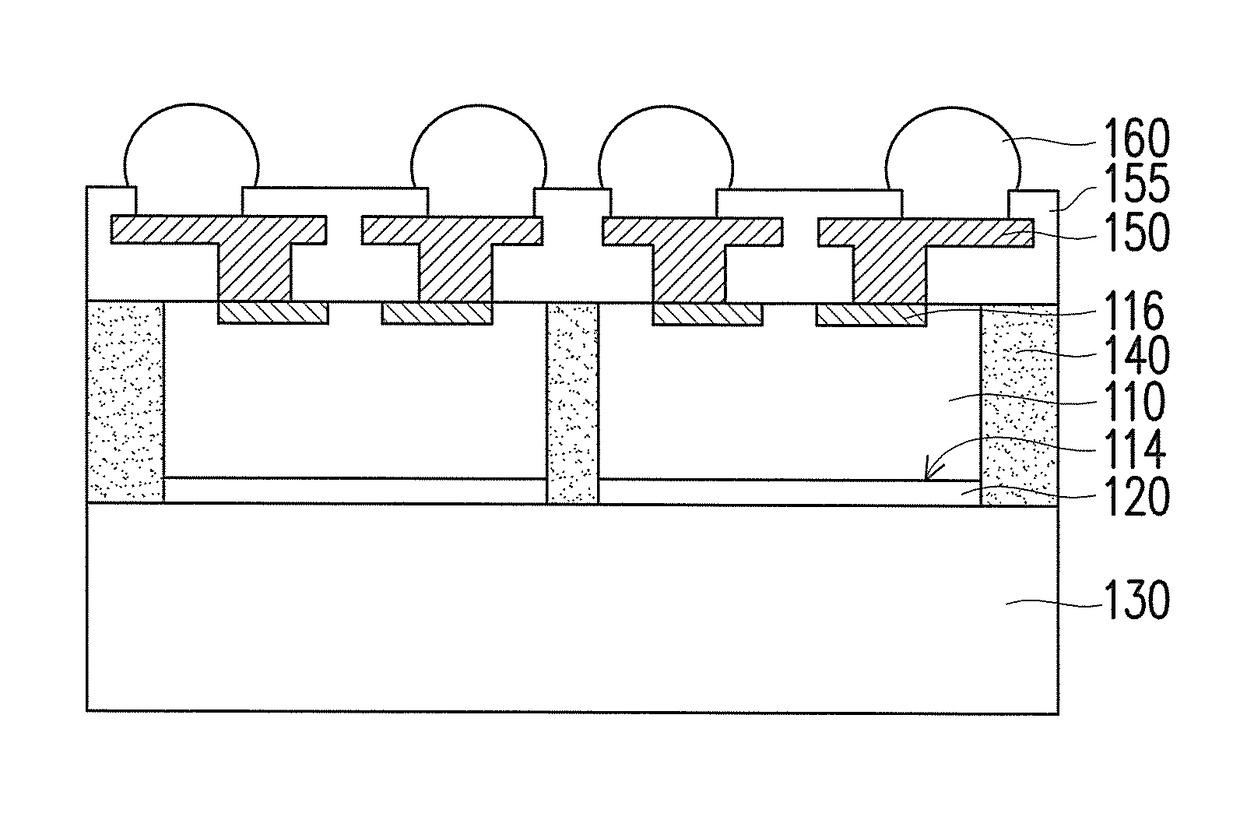

Coreless packaging substrate and method for fabricating the same

ActiveUS20110042128A1Control deviationControl valueElectrically conductive connectionsPrinted circuit aspectsEngineeringUltra fine

A coreless packaging substrate includes: a substrate body including an auxiliary dielectric layer having opposing first and second surfaces, an inner wiring formed on the second surface, and a built-up structure formed on both the second surface of the auxiliary dielectric layer and the inner wiring; and a plurality of conductive bumps including metal pillars having opposing first and second ends and a solder layer formed on the first end, wherein the second ends of the metal pillars are disposed in the auxiliary dielectric layer and electrically connecting with the inner wiring, and the first ends of the metal pillars with the solder layer protrude from the first surface of the auxiliary dielectric layer, thereby achieving ultra-fine pitch and even-height conductive bumps. A method for fabricating the coreless packaging substrate as described above is further provided.

Owner:UNIMICRON TECH CORP

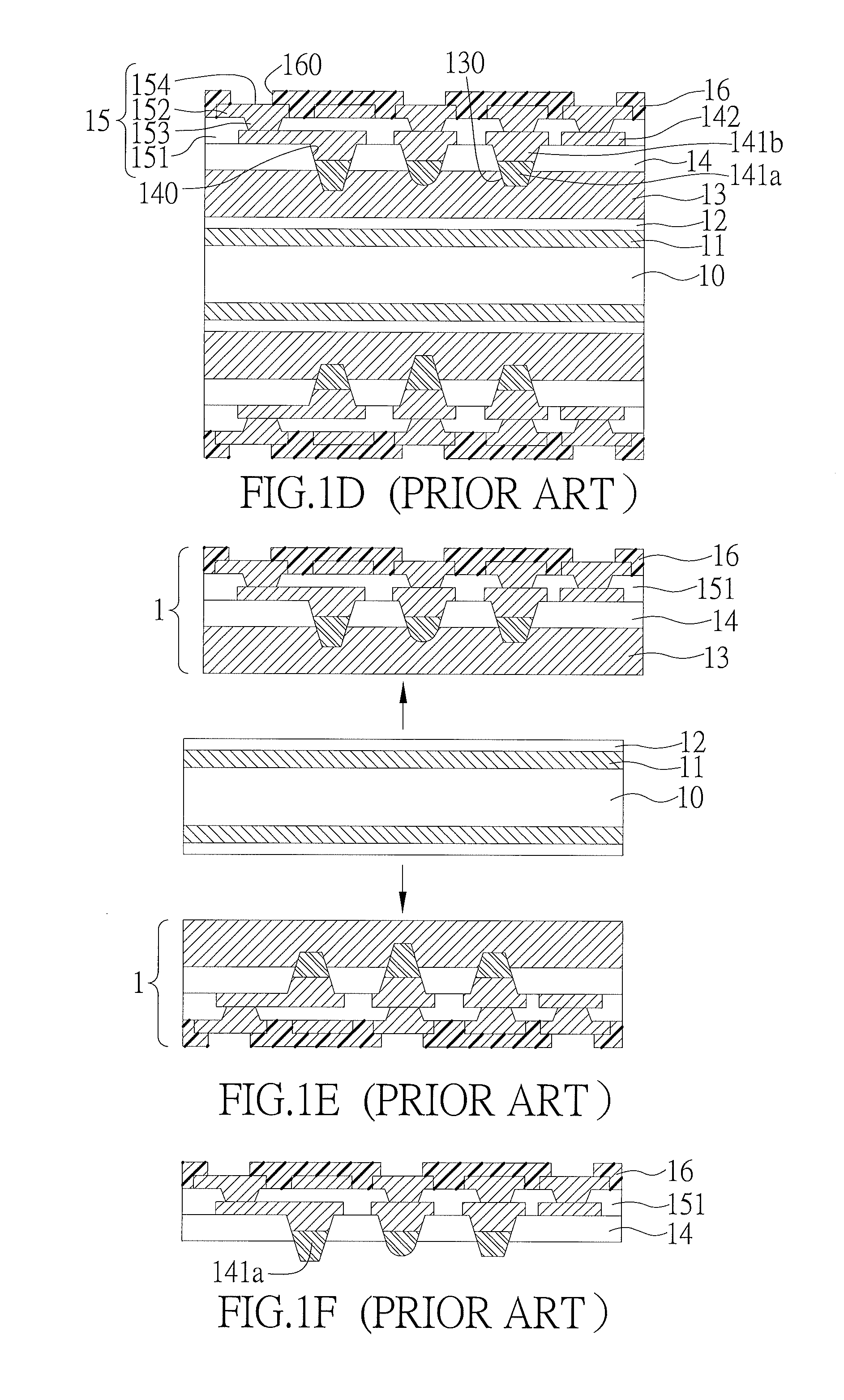

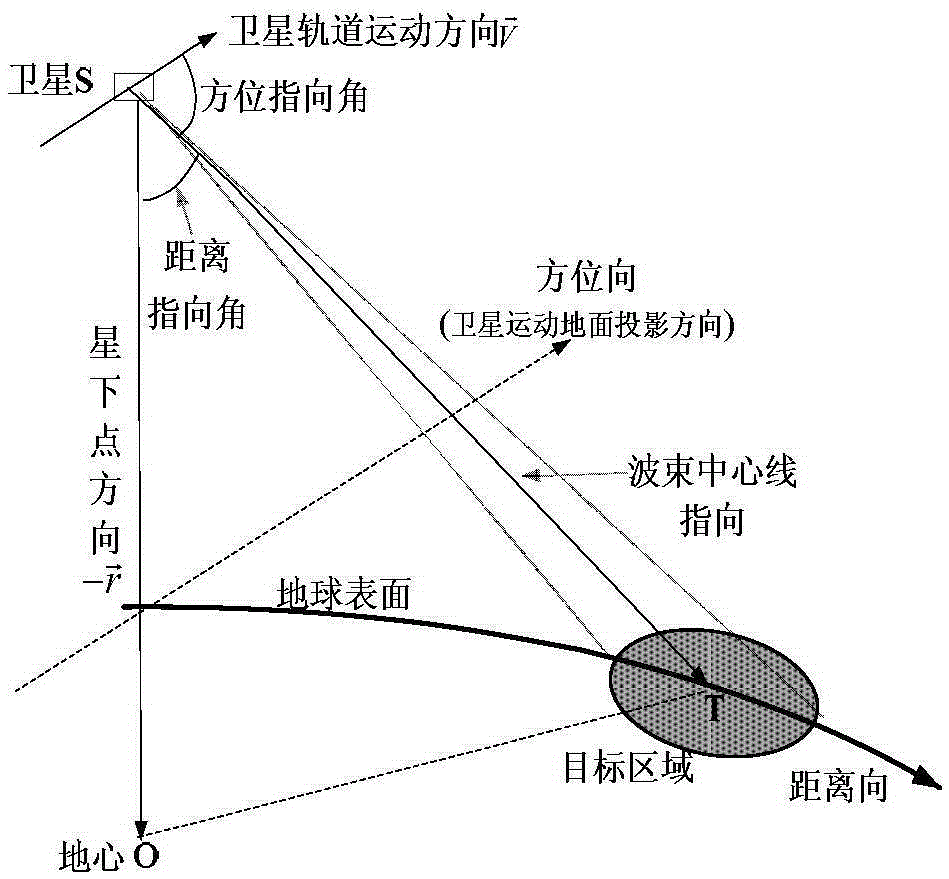

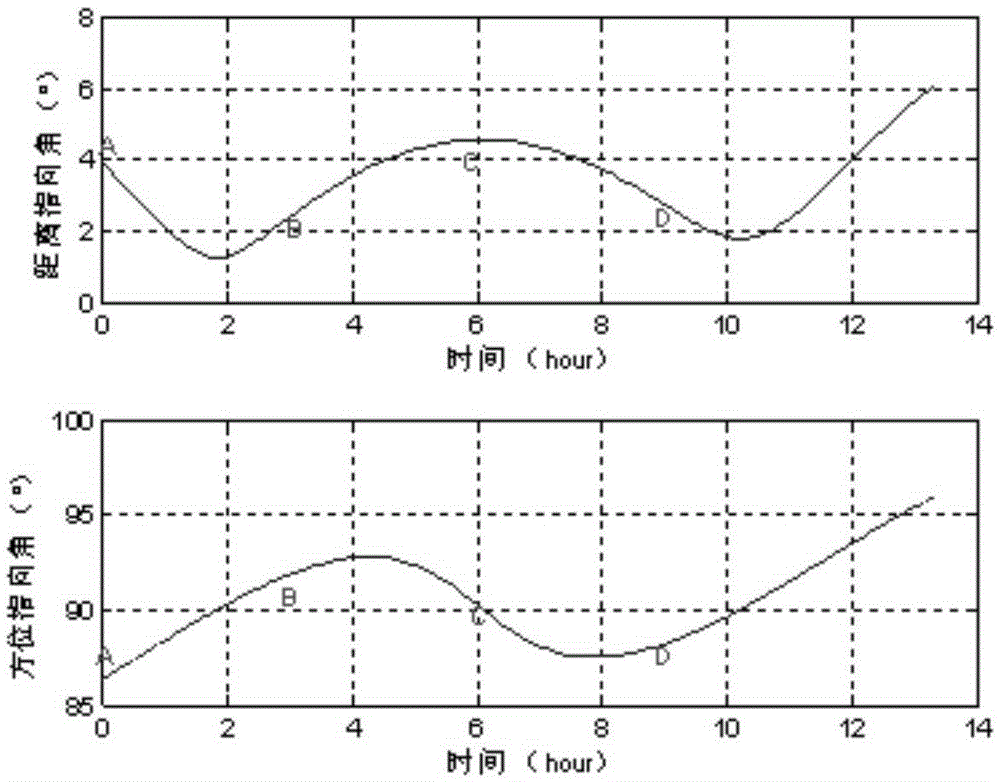

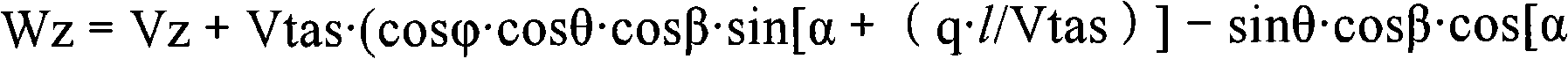

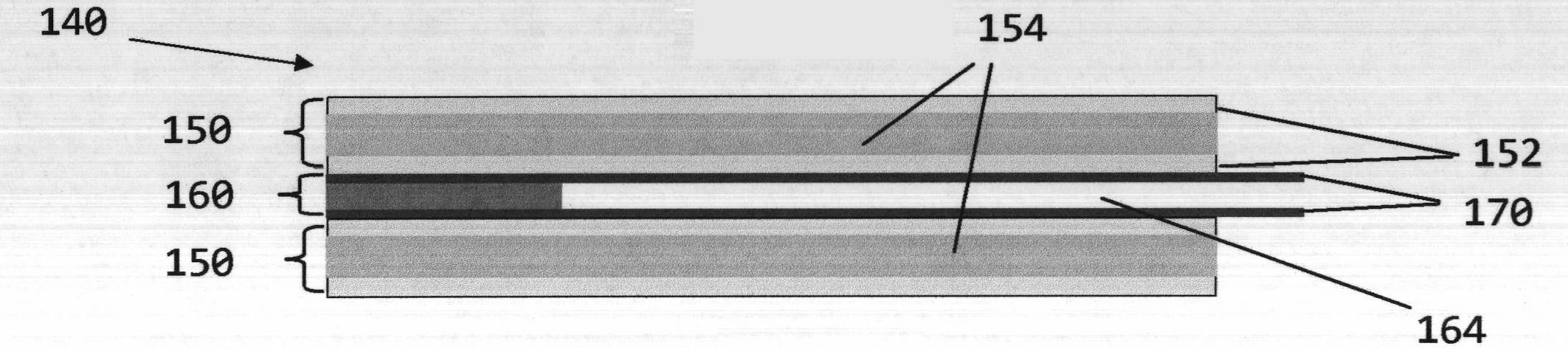

Geosynchronous orbit circular track SAR imaging method using beam pointing control

InactiveCN105403888AEasy to handleSmall height changeRadio wave reradiation/reflectionGeosynchronous satelliteRadar

The invention belongs to the technical field of synthetic aperture radar and particularly relates to a geosynchronous orbit circular track SAR imaging method using beam pointing control. By using such a method, a circular track geosynchronous satellite having a 8-shaped sub satellite point locus is taken as a radar platform, 12 hours corresponding to the half 8 shape where an object to be observed is arranged are regarded as an imaging period, the two-dimension antenna wave beam directional control is carried out in the imaging period by means of a stepping technique, so that the satellite can be in the corresponding movement process of the half 8-shaped sub satellite point locus, the antenna wave beam can always point to the imaged ground object to be observed, the 360-degree relative movement of radar relative to the object is formed, and the circular track SAR imaging based on the geosynchronous orbit satellite platform is realized.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

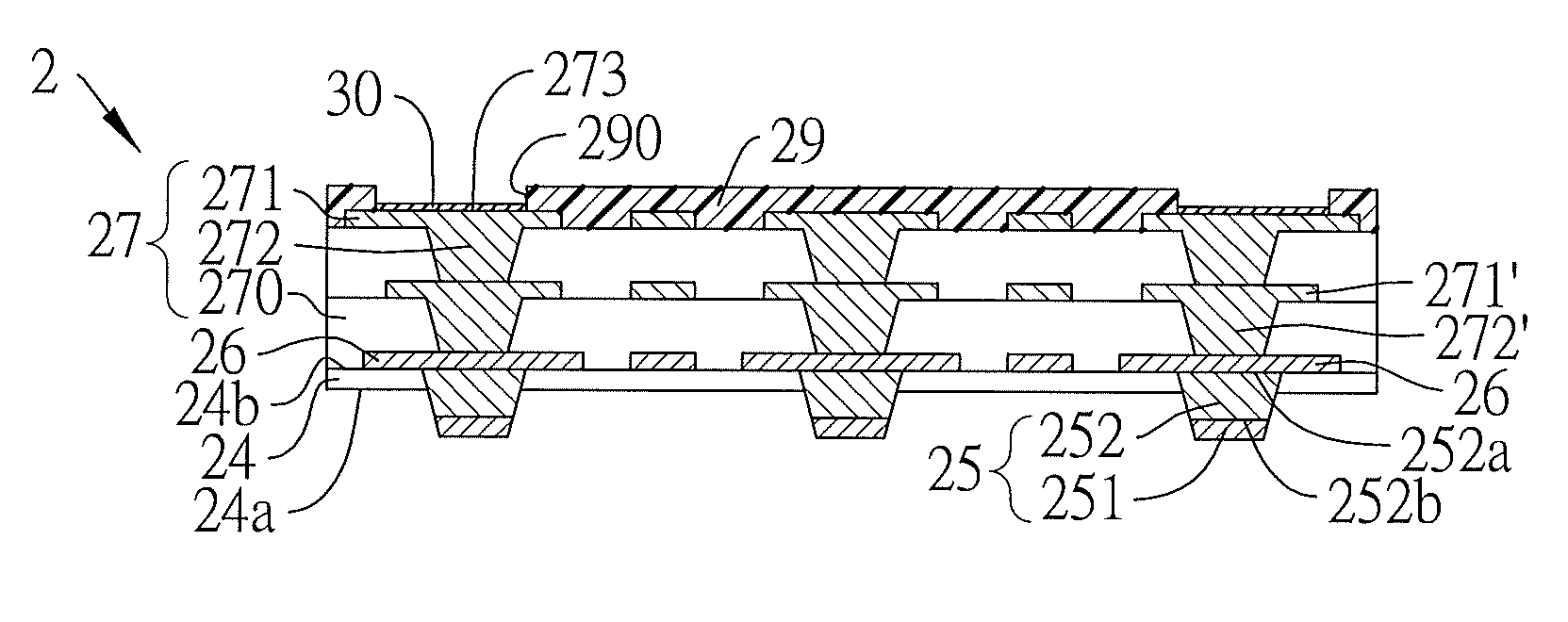

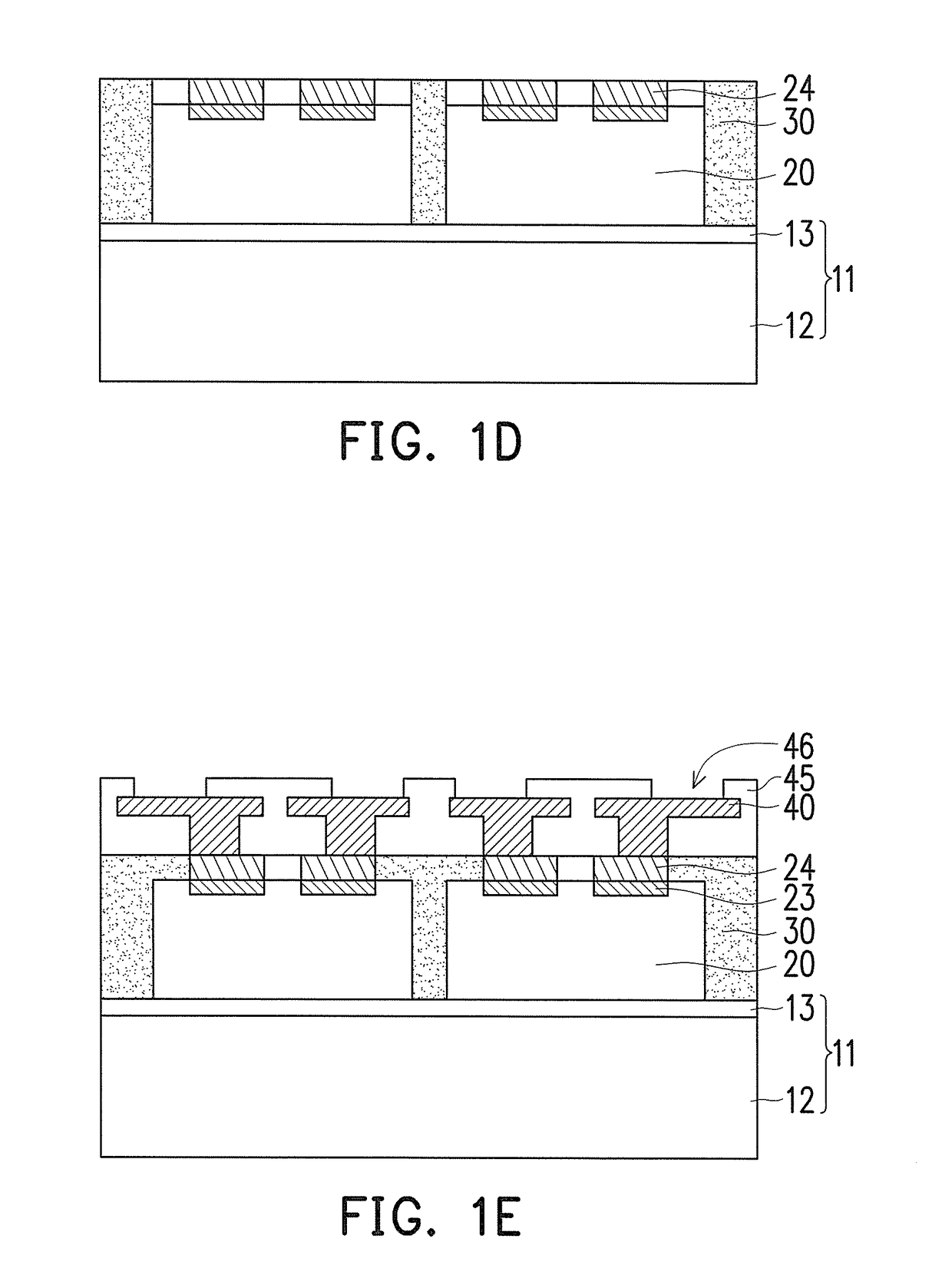

Coreless packaging substrate and method for fabricating the same

ActiveUS8227711B2Effective valueSmall height changeElectrically conductive connectionsPrinted circuit aspectsUltra fineDielectric layer

A coreless packaging substrate includes: a substrate body including an auxiliary dielectric layer having opposing first and second surfaces, an inner wiring formed on the second surface, and a built-up structure formed on both the second surface of the auxiliary dielectric layer and the inner wiring; and a plurality of conductive bumps including metal pillars having opposing first and second ends and a solder layer formed on the first end, wherein the second ends of the metal pillars are disposed in the auxiliary dielectric layer and electrically connecting with the inner wiring, and the first ends of the metal pillars with the solder layer protrude from the first surface of the auxiliary dielectric layer, thereby achieving ultra-fine pitch and even-height conductive bumps. A method for fabricating the coreless packaging substrate as described above is further provided.

Owner:UNIMICRON TECH CORP

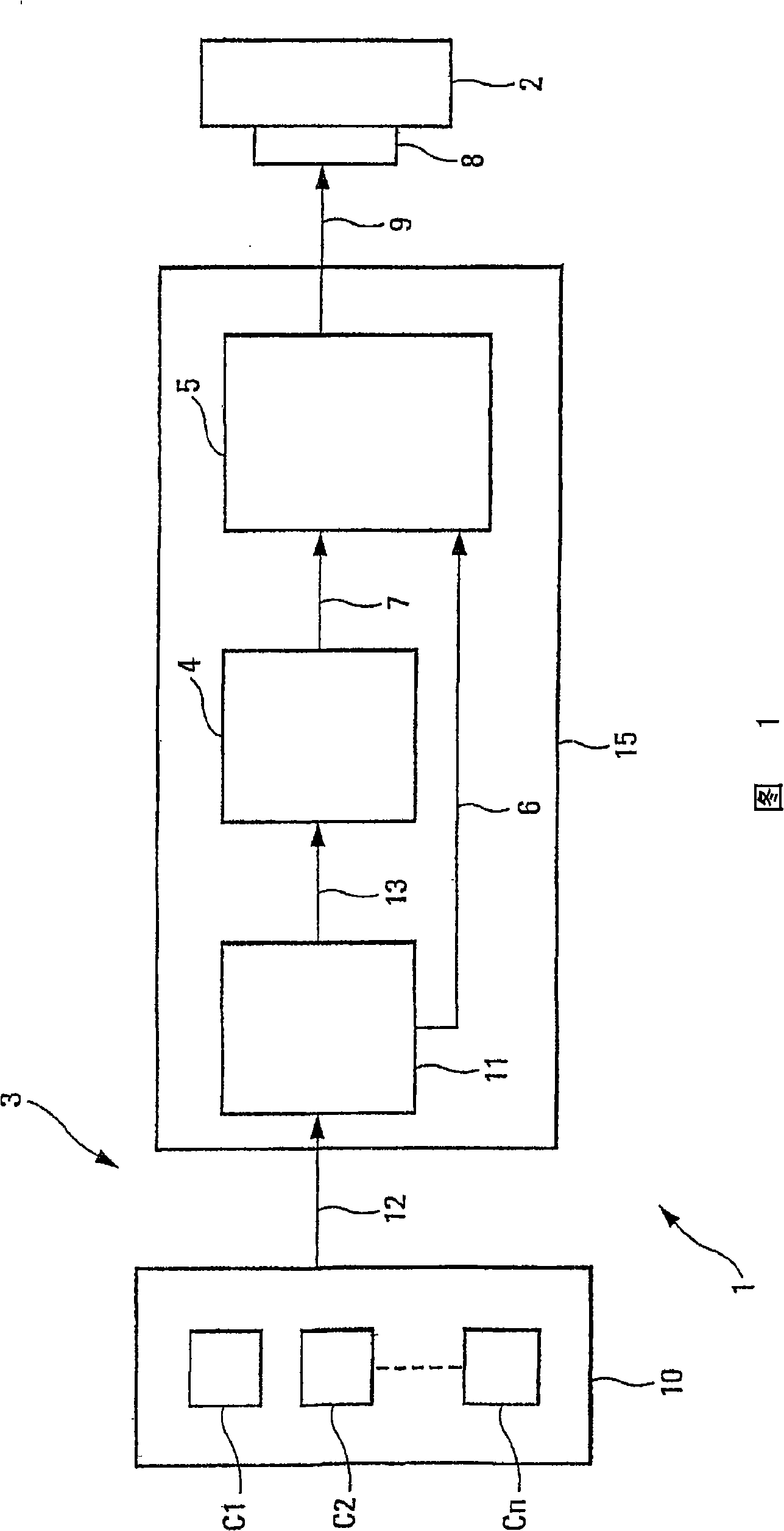

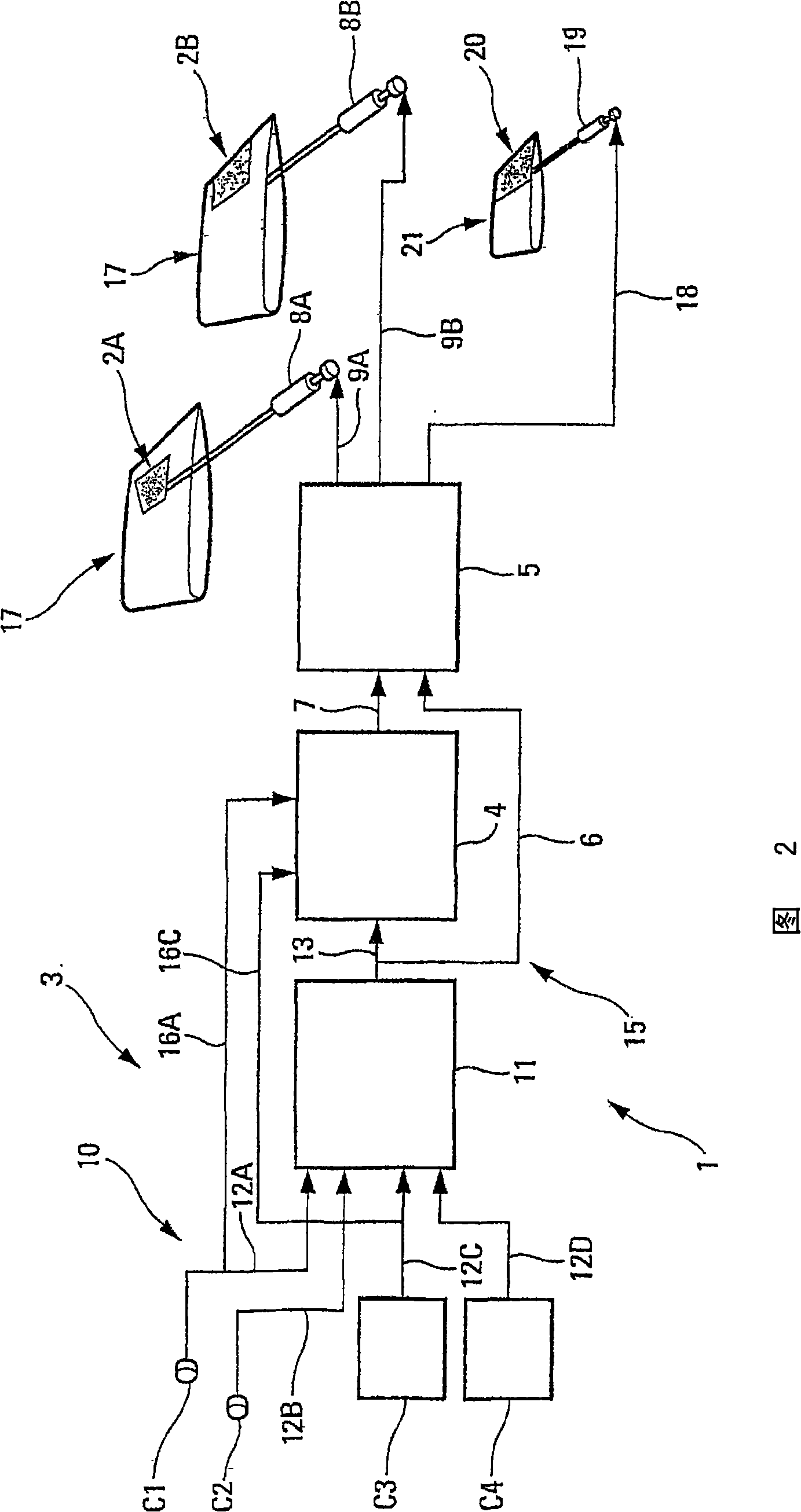

Method and device for attenuating on an aircraft the effects of a vertical turbulence

ActiveCN101283319AMagnitude of reduced vertical load factorSmall height changeActuated automaticallyAltitude or depth controlWind componentAerospace engineering

The invention concerns a device (1) comprising means (4) for determining automatically, using a vertical wind component, a level of severity concerning a vertical turbulence, and means (5) for computing automatically, using said vertical wind component, a control instruction for a controllable member (2), which enables the amplitude of load factors generated on the aircraft by the vertical turbulence to be minimized.

Owner:AIRBUS OPERATIONS (SAS)

High reflective object surface light field deflection technique measuring system and method

ActiveCN105806257AEasy to identify lightImprove computing efficiencyUsing optical meansPhysicsAccuracy and precision

The invention relates to a high reflective object surface light field deflection technique measuring system and method, and is used for three-dimensional reconstruction of the high reflective object surface, the system adopts a light ray reflection principle to acquire normal information of the high reflective object surface and curved surface information, the system is projected by the light field, and the system is sensed through the light ray. The correspondence of an incident ray and a reflection ray are determined through a phase retrieval method, and 3D points on the to-be-detected object surface are calculated. According to the invention, compared with the common phase deflection technique, the system and the method does not have non-unique normal problem, and in light field camera mode, the system has higher response characteristics for object surface height variation, can get higher measuring precision and can fill the blank of domestic and overseas deflection technique measuring system based on light field.

Owner:SHANGHAI UNIV

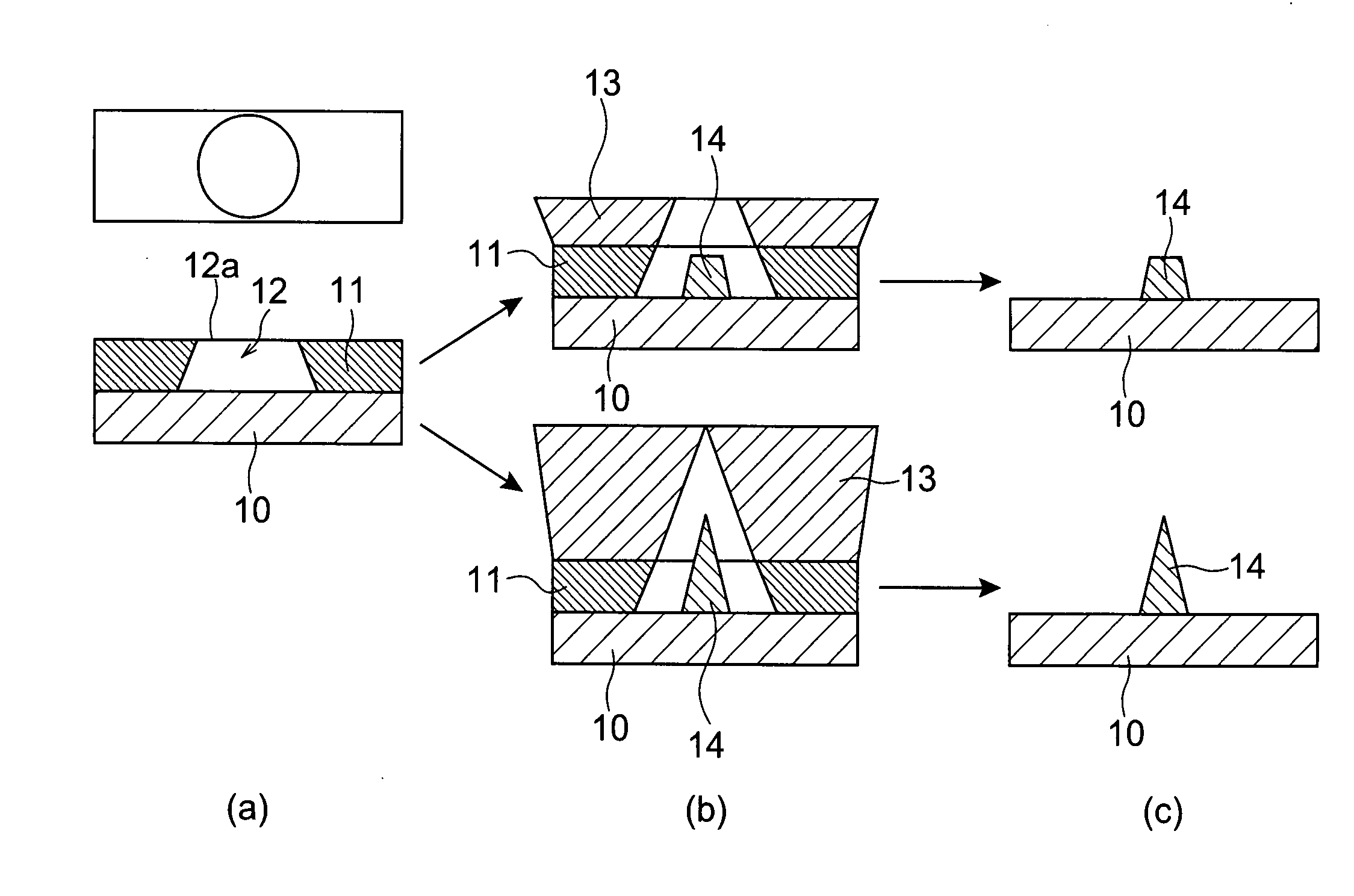

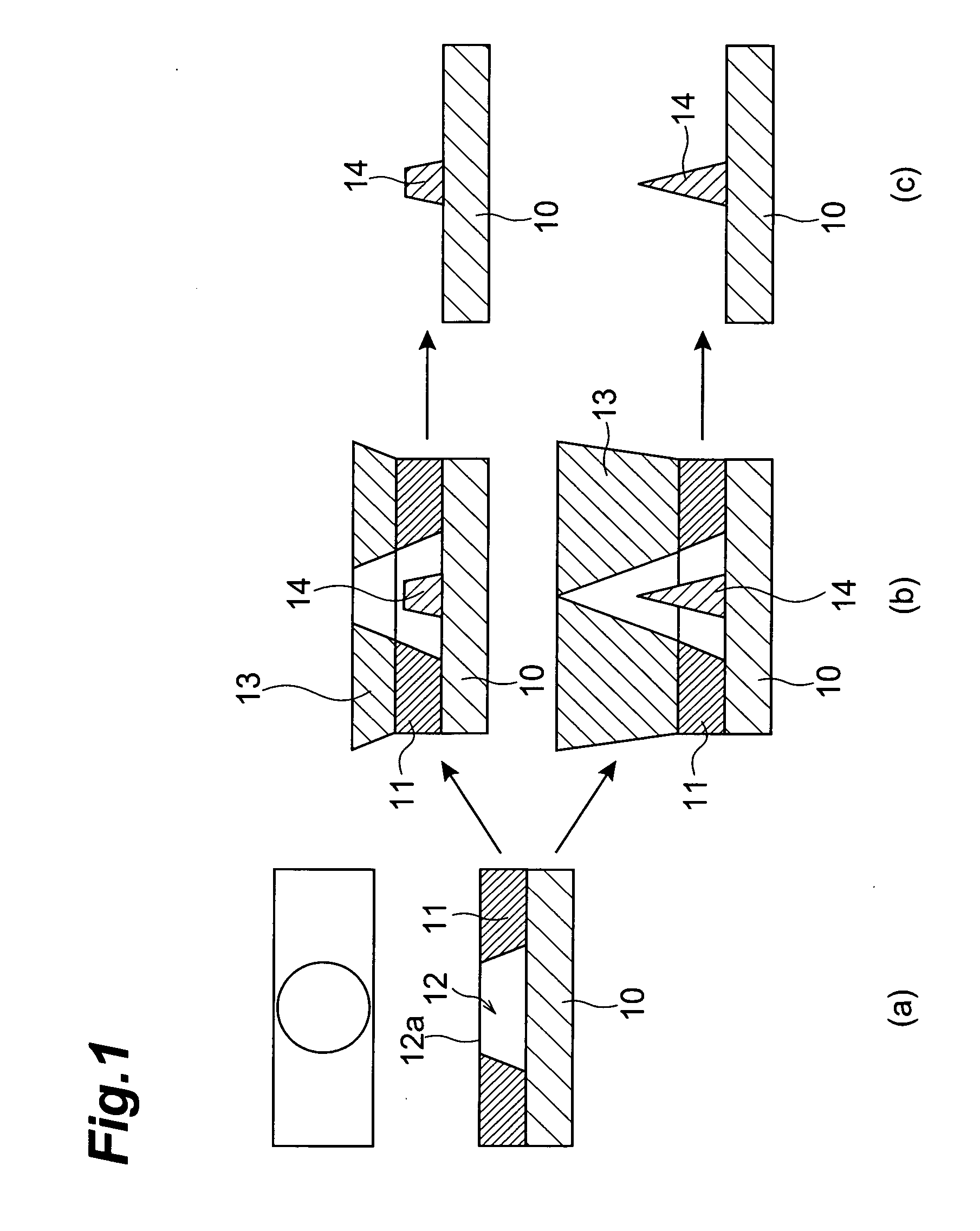

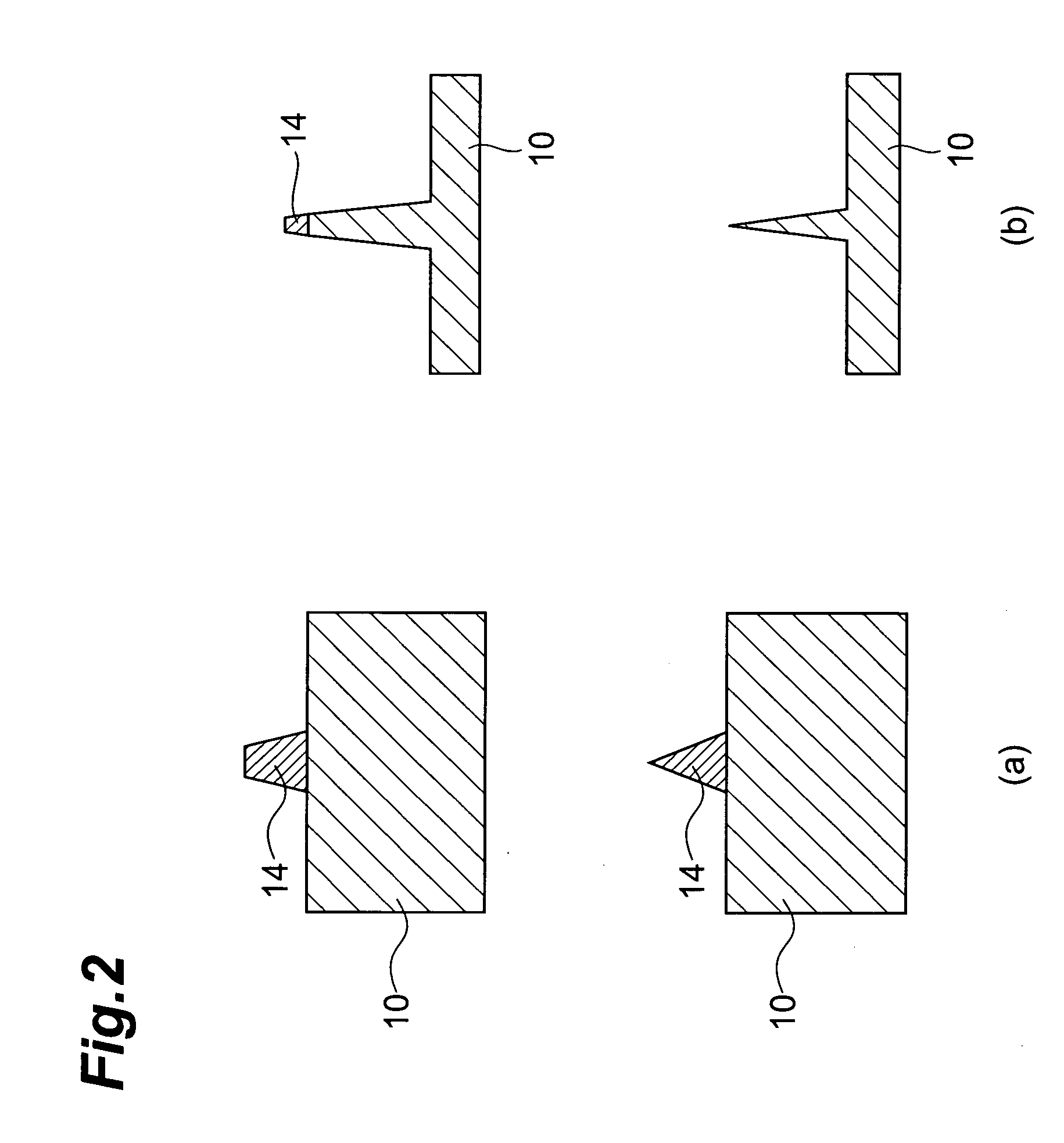

Method for Forming Carbonaceous Material Protrusion and Carbonaceous Material Protrusion

InactiveUS20080044647A1High uniformity of projection heightGood reproducibilityNanostructure manufactureSemiconductor/solid-state device manufacturingResistMaterial Protrusion

This method of forming a carbonaceous material projection structure includes: the step of applying a resist 11 onto a diamond substrate 10; the step of forming holes 12 in the applied resist 11, the holes 12 being provided according to a predetermined arrangement, a wall 12b of each of the holes 12 being inversely tapered from an aperture 12a toward a bottom; the step of depositing a mask material through the aperture 12a to form a mask deposition 14 in each of the holes 12; the step of lifting off a mask material 13 deposited on the resist 11 together with the resist 11; and etching the diamond substrate 10 using the mask deposition 14 as a mask to form a carbonaceous material projection.

Owner:SUMITOMO ELECTRIC IND LTD

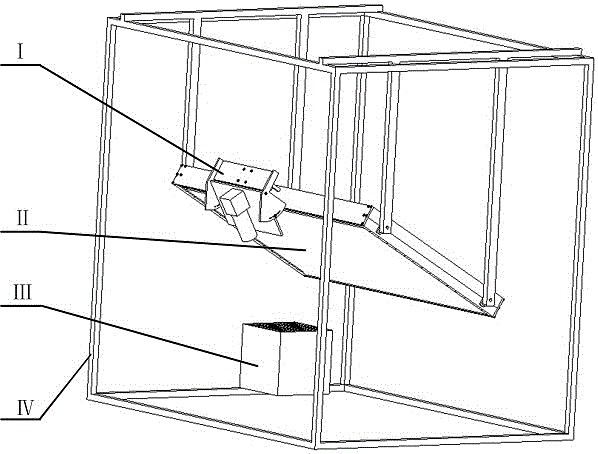

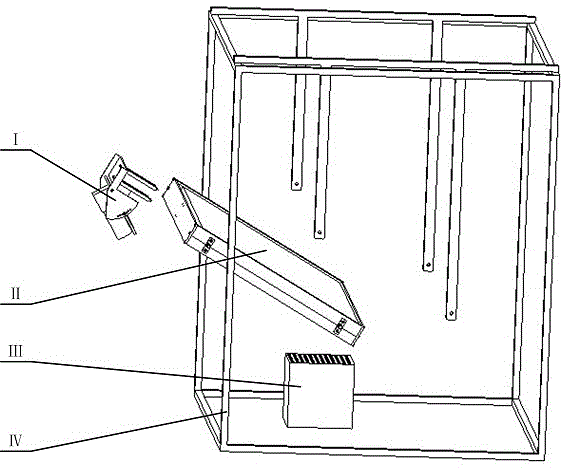

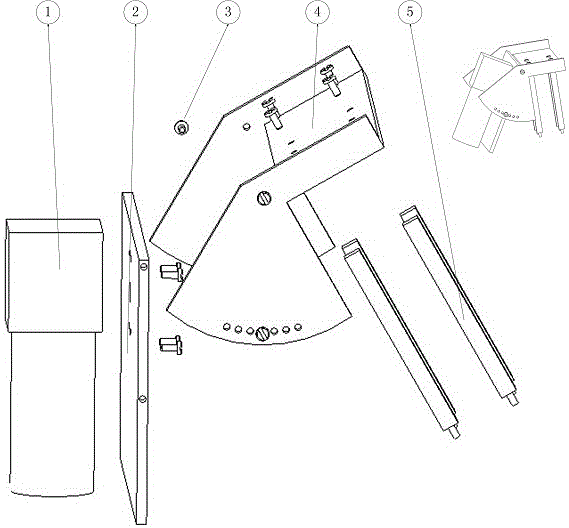

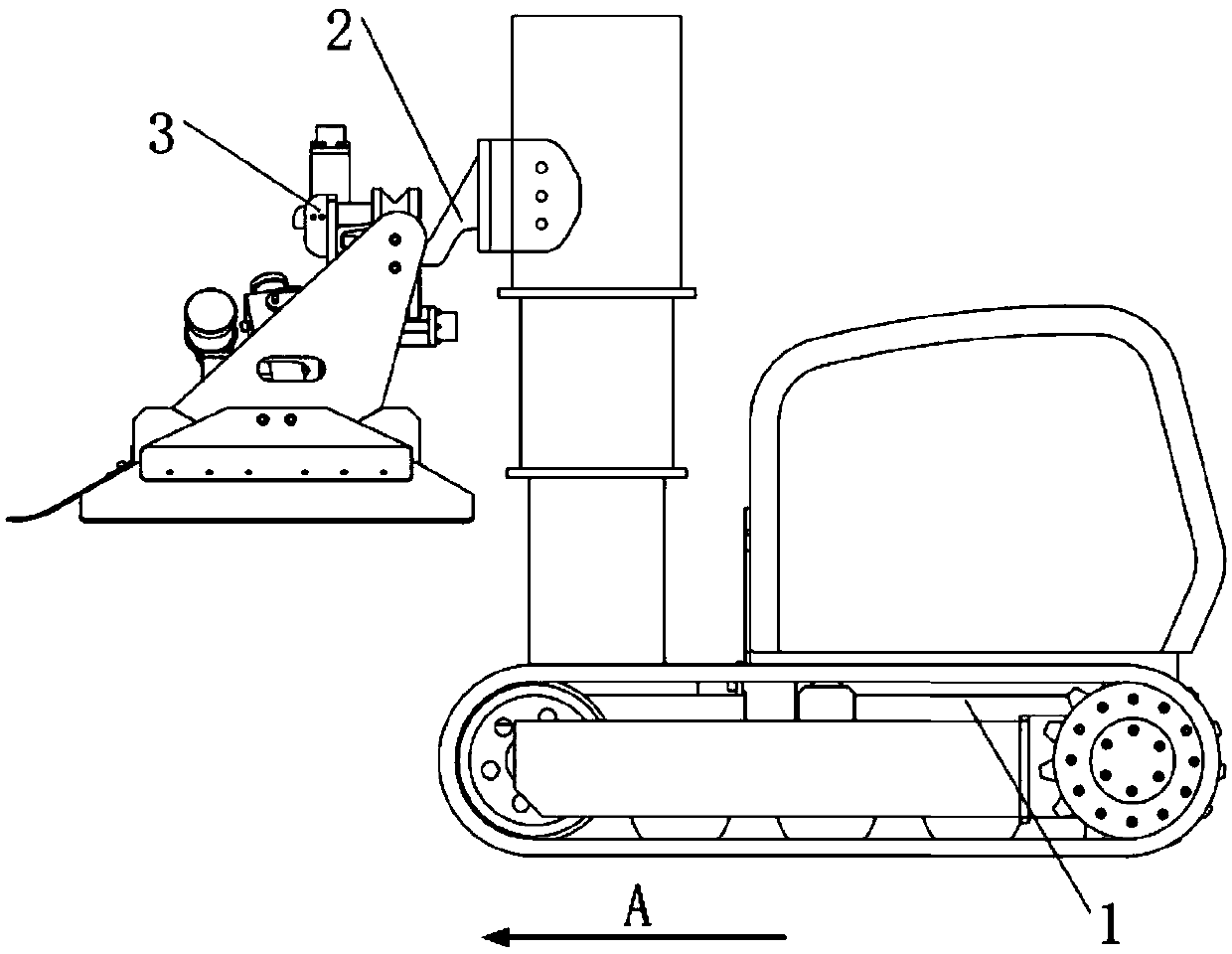

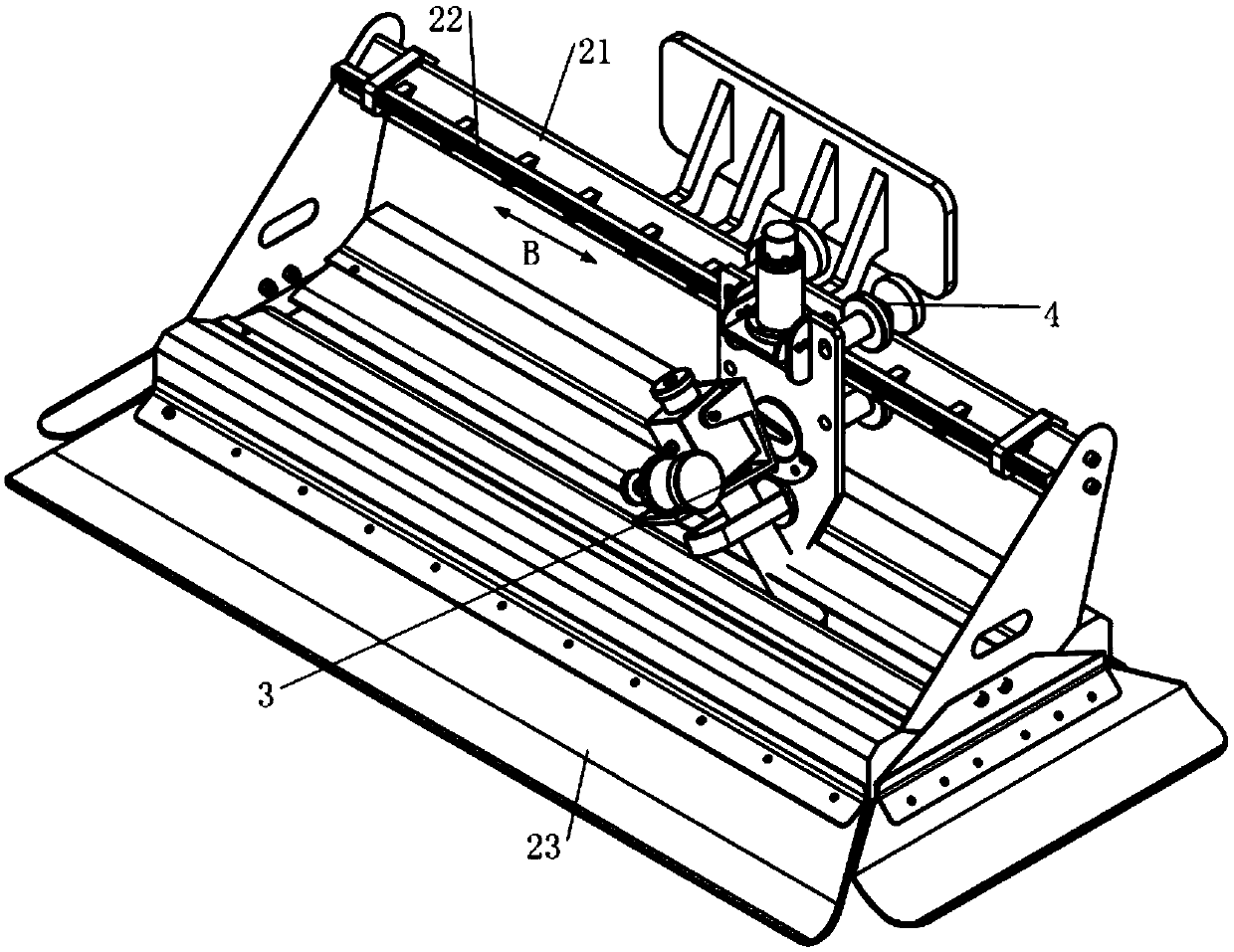

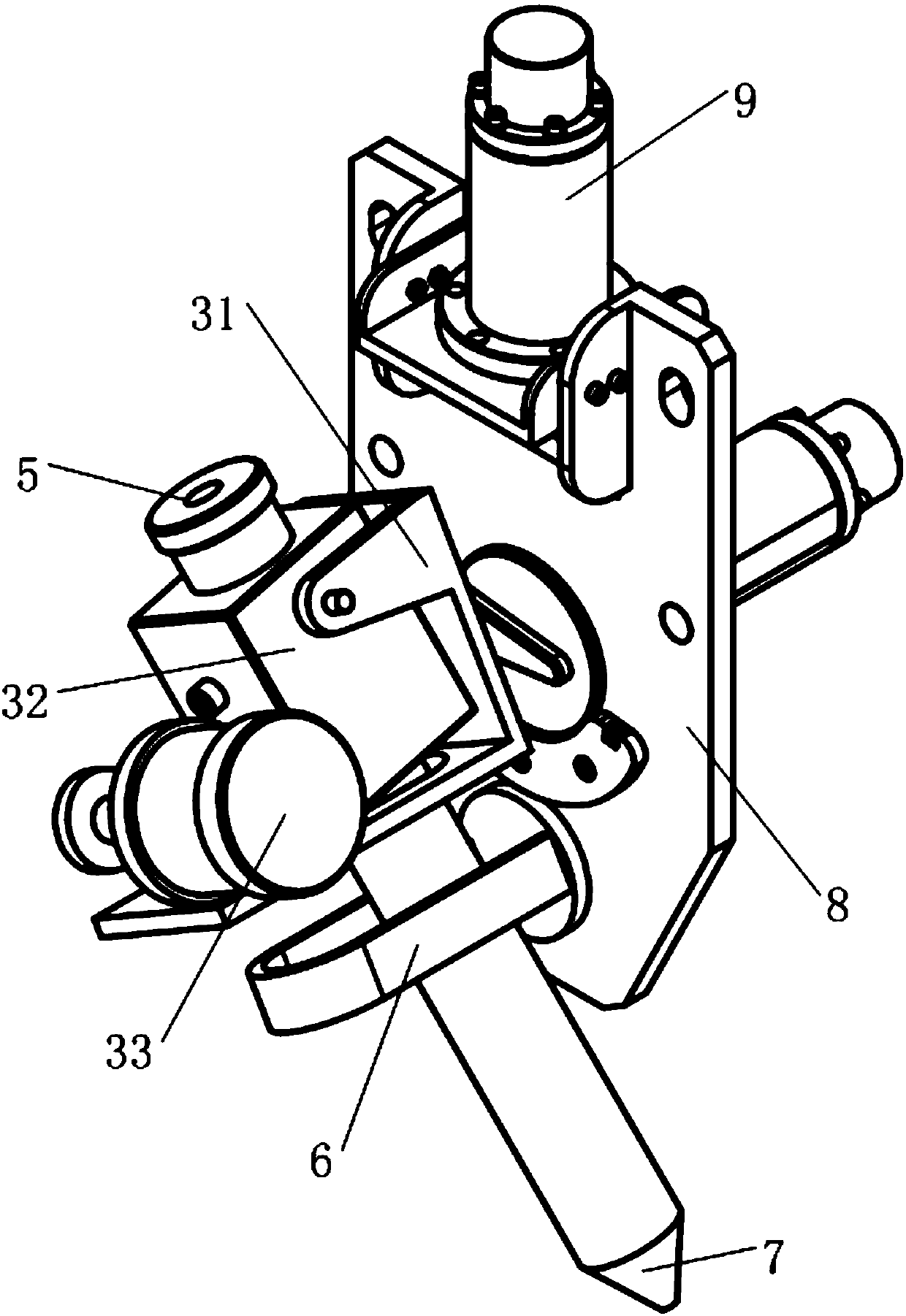

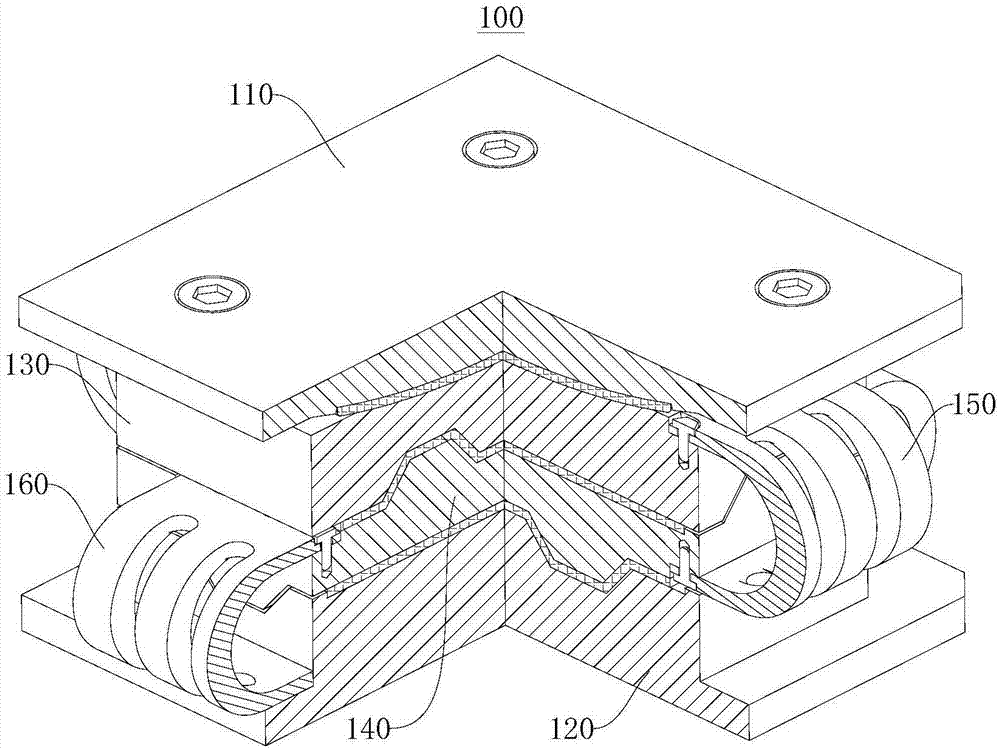

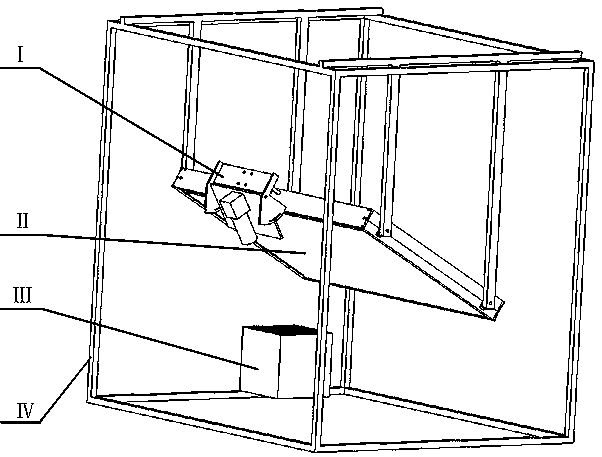

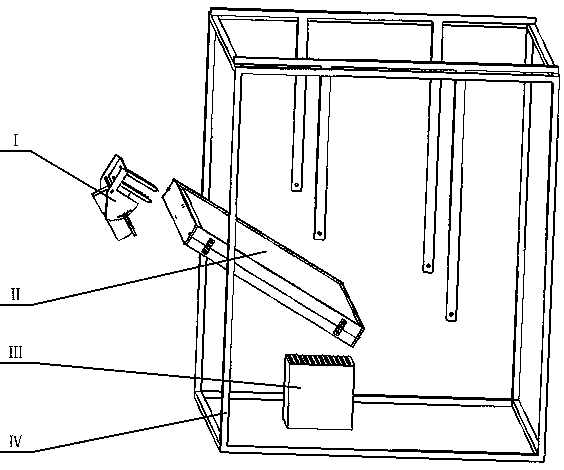

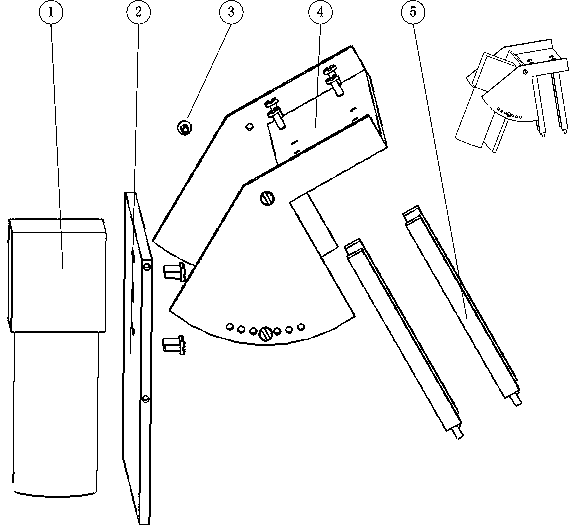

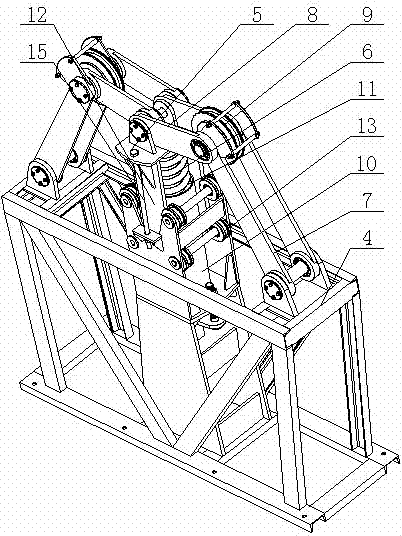

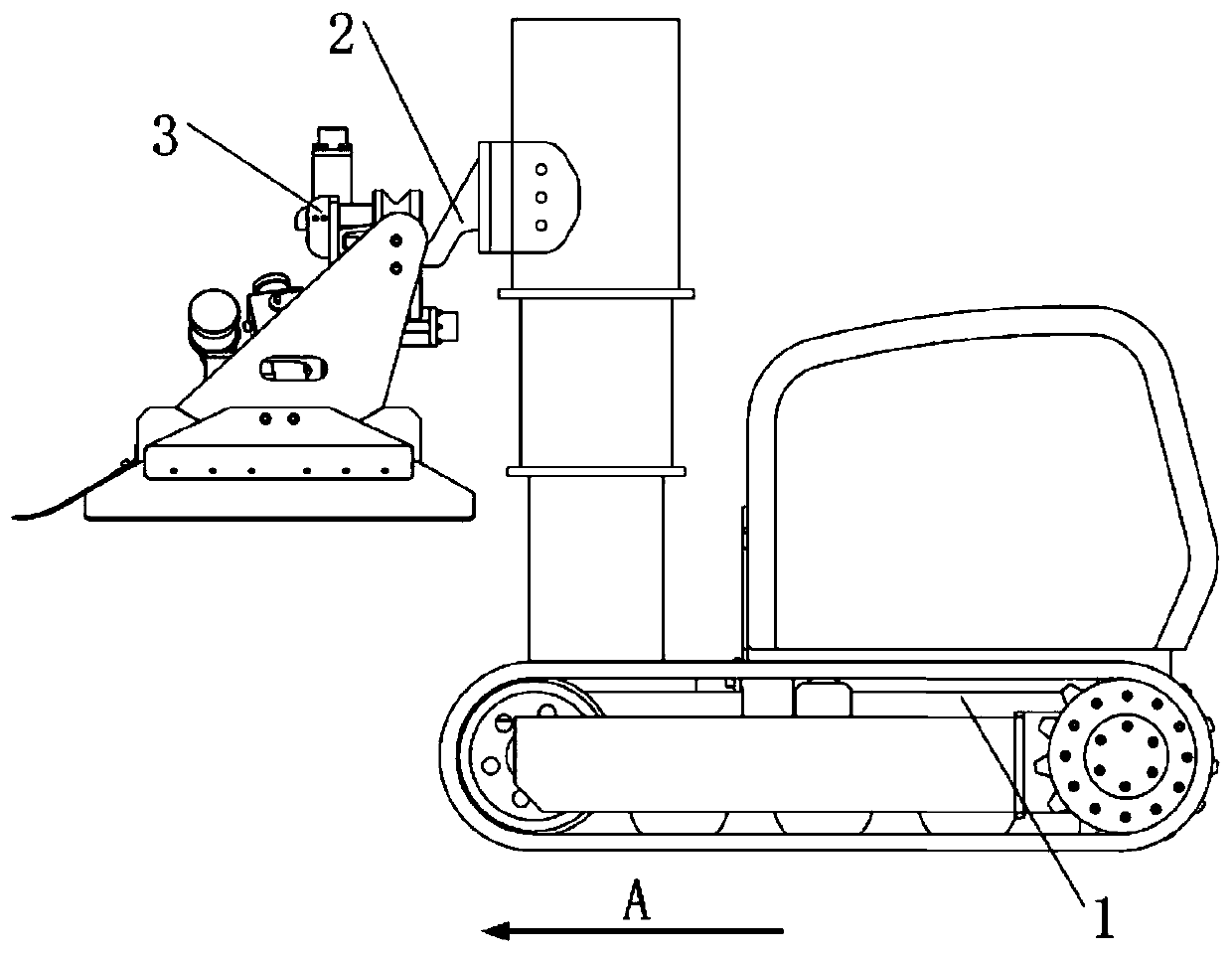

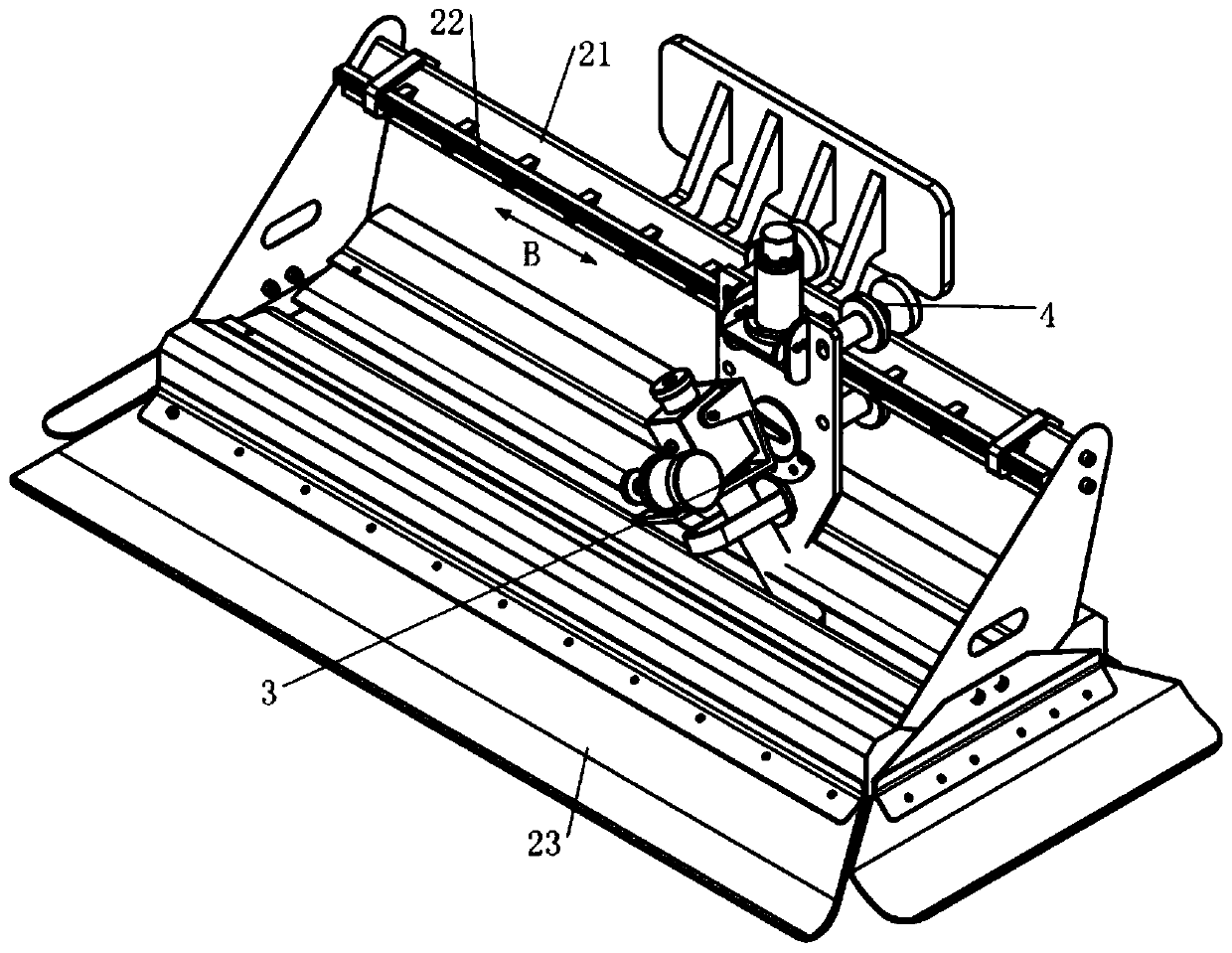

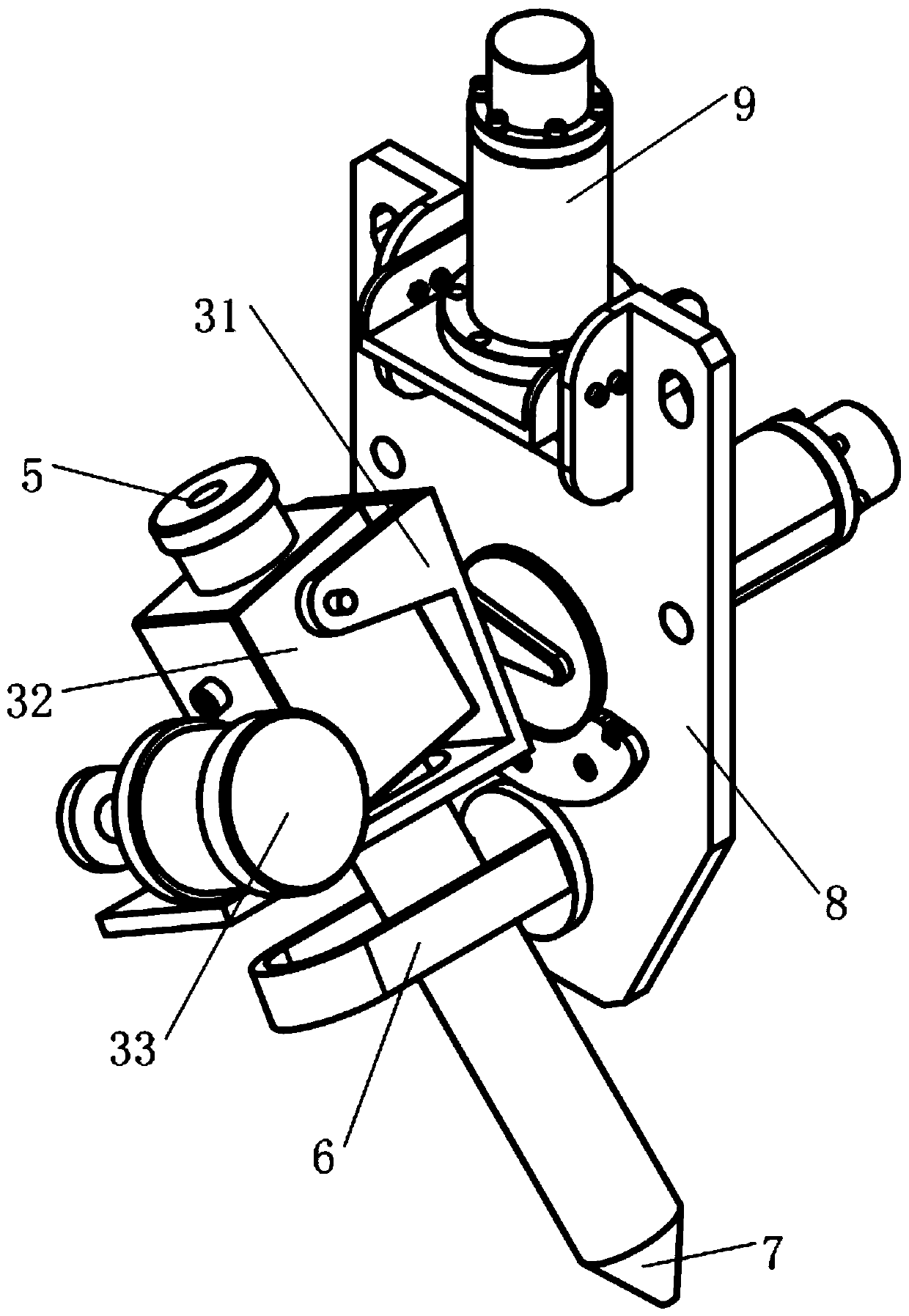

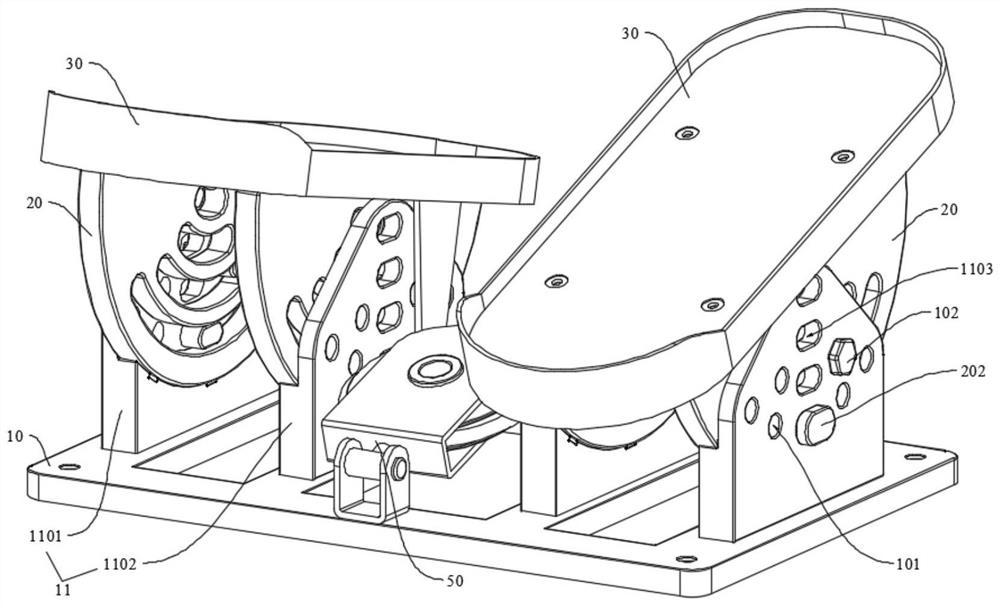

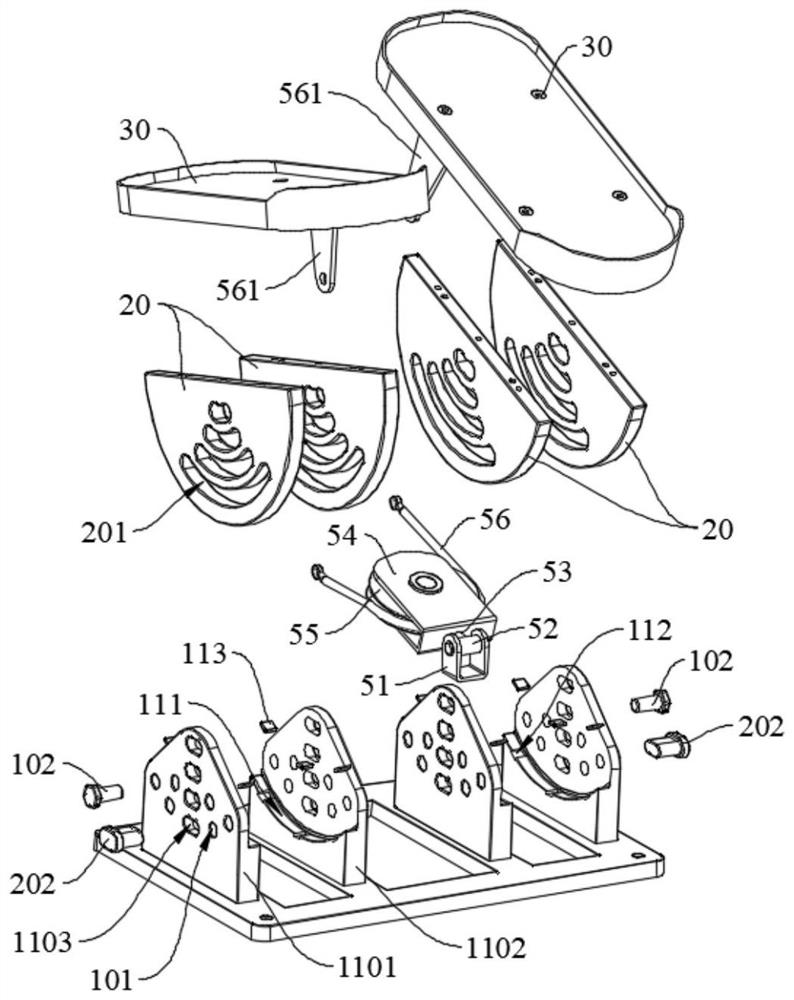

Swing spray gun and water jet equipment

ActiveCN108677672AExtended service lifeImprove work efficiencyRoads maintainenceHigh pressure waterHigh pressure

The invention provides a swing spray gun and water jet equipment. The swing spray gun comprises a base, a bearing seat, a jet pipe and a third driving device, wherein the bearing seat is driven by a second driving device to rotate around a first axis relative to the base; the jet pipe is rotatably mounted on the bearing seat around a second axis, the top end of the jet pipe is connected with a high-pressure water source, and a nozzle located at the bottom of the jet pipe faces the layer to be treated; and third driving device is installed on the bearing seat, an eccentric structure is arrangedon an output shaft parallel to the second axis, an eccentric protrusion of the eccentric structure is hinged to a connecting rod, the other end of the connecting rod is hinged to the jet pipe, and the hinged position and the second axis position are arranged at intervals by a set distance to form a crank-rocker mechanism. According to the design, swing amplitude of the nozzle can be increased firstly, and then the working efficiency of the jet pipe during a single stroke can be increased; secondly, the same swing amplitude requires less driving force and prolongs the service life of the thirddriving device; and in addition, an injection pipe returns to the initial position in the non-working state without shaking, and the performance and reliability of the device are ensured.

Owner:CITIC HEAVY INDUSTRIES CO LTD

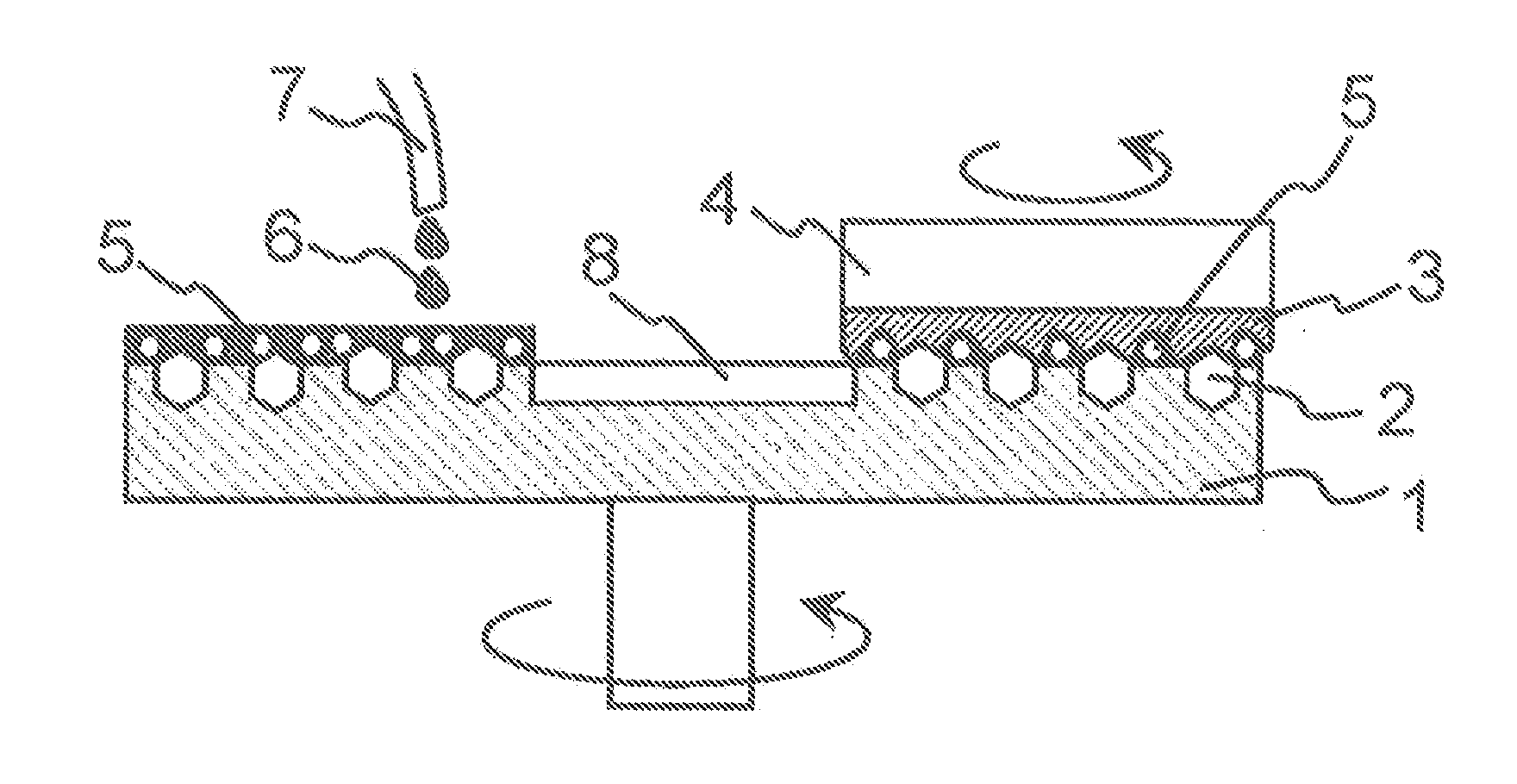

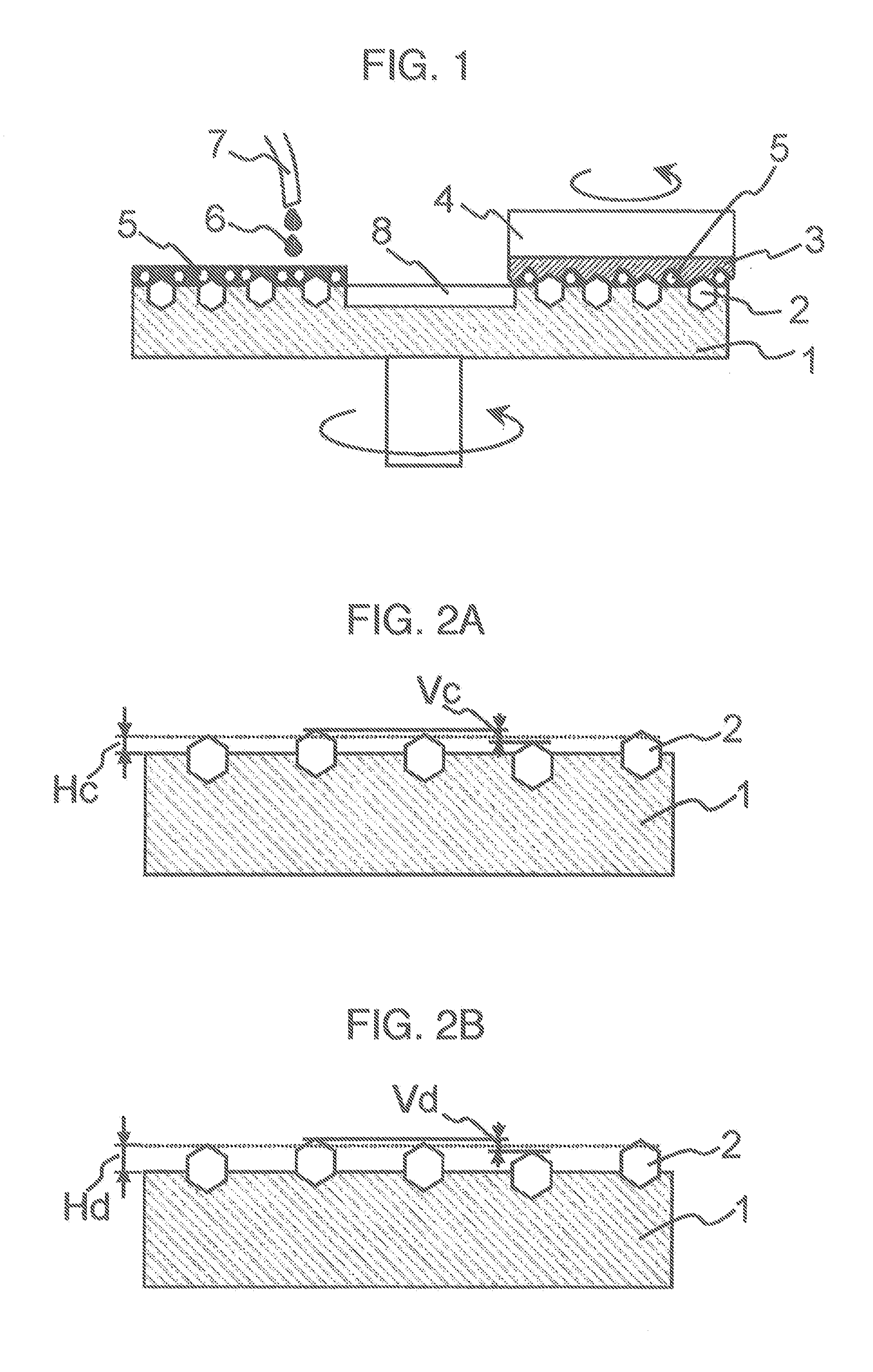

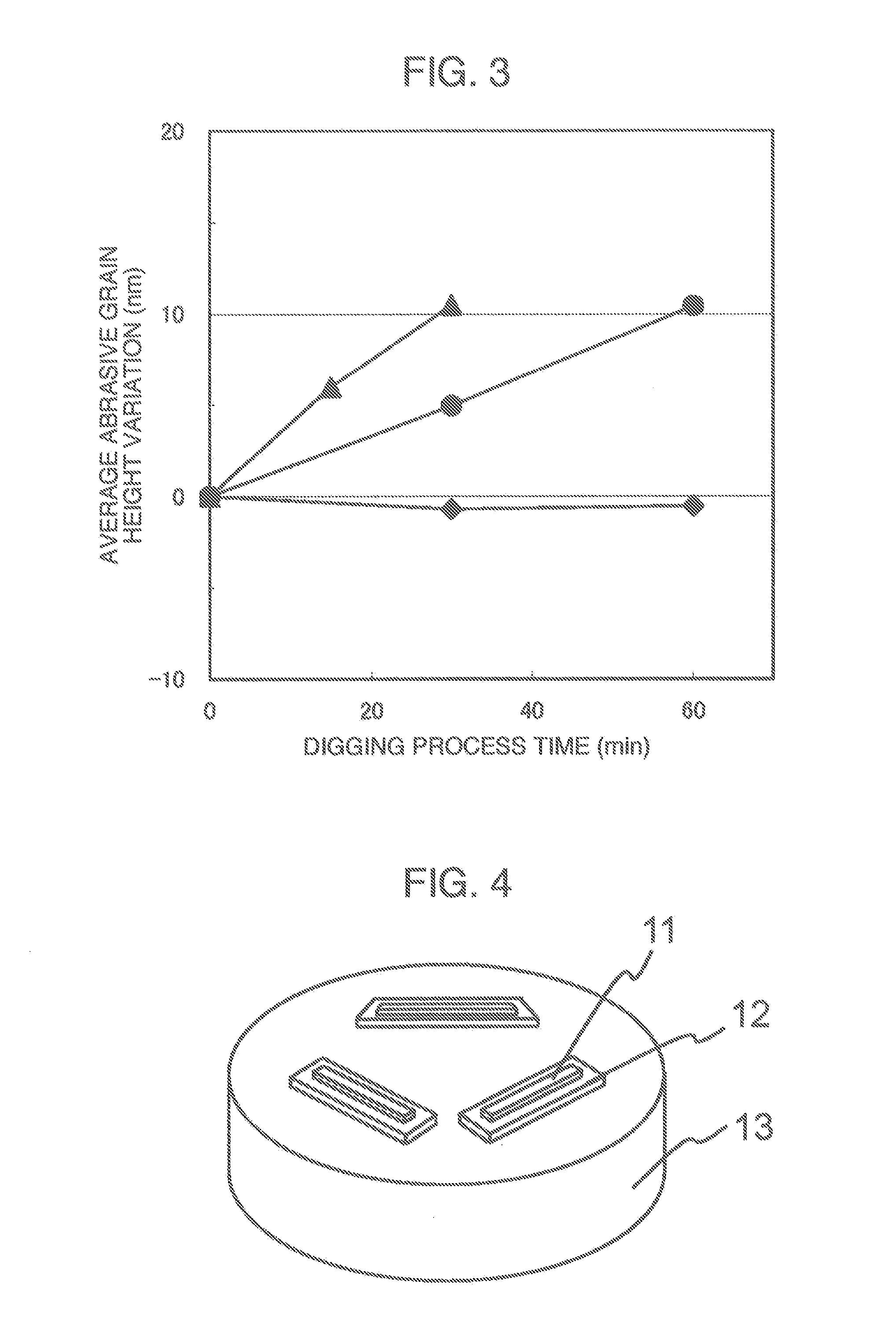

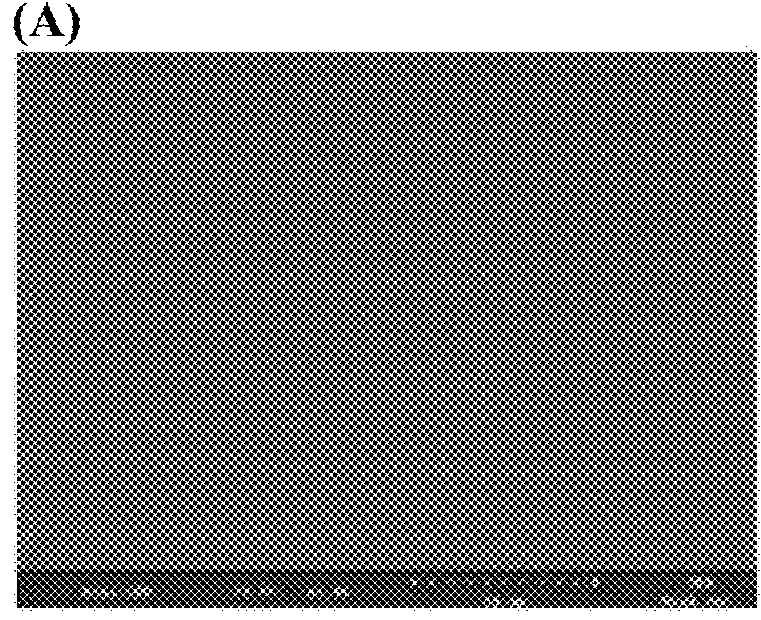

Method of Manufacturing Lapping Plate, and Method of Manufacturing Magnetic Head Slider using the Lapping Plate

InactiveUS20110239444A1Large abrasive grain heightSmall height variationElectrical transducersHeads using thin filmsMetallurgyAir bearing surface

A method of manufacturing a lapping plate which has abrasive grains fixed in the plate and which is used for lapping of the air bearing surface of a magnetic head. Abrasive grains fixed in the lapping plate are subjected to an abrasive digging process to selectively lap the surface of the lapping plate in the vicinity of the abrasive grains, and the dug abrasive grains are subjected to an equalization process to make their abrasive grain heights equal.

Owner:HITACHI LTD

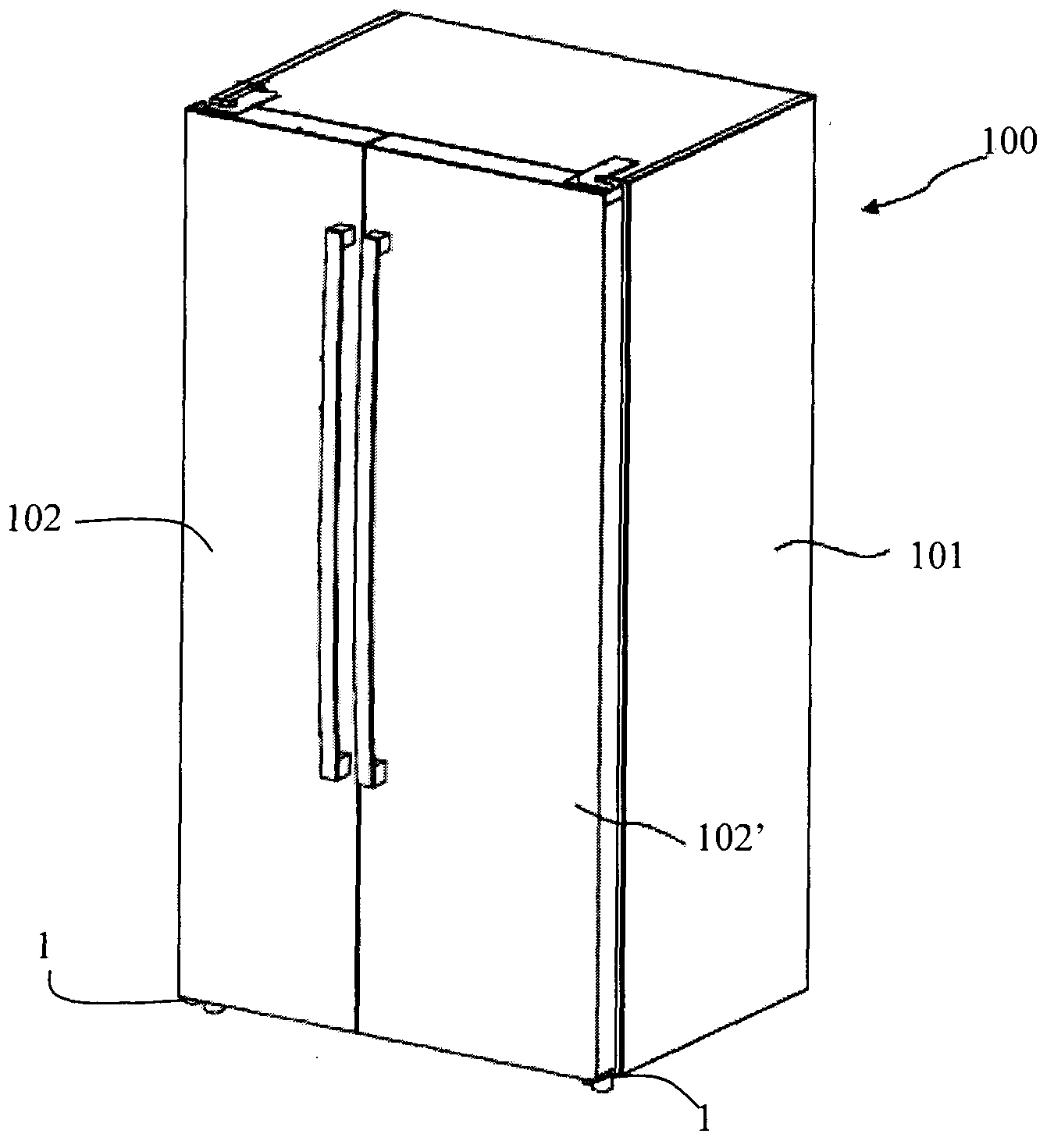

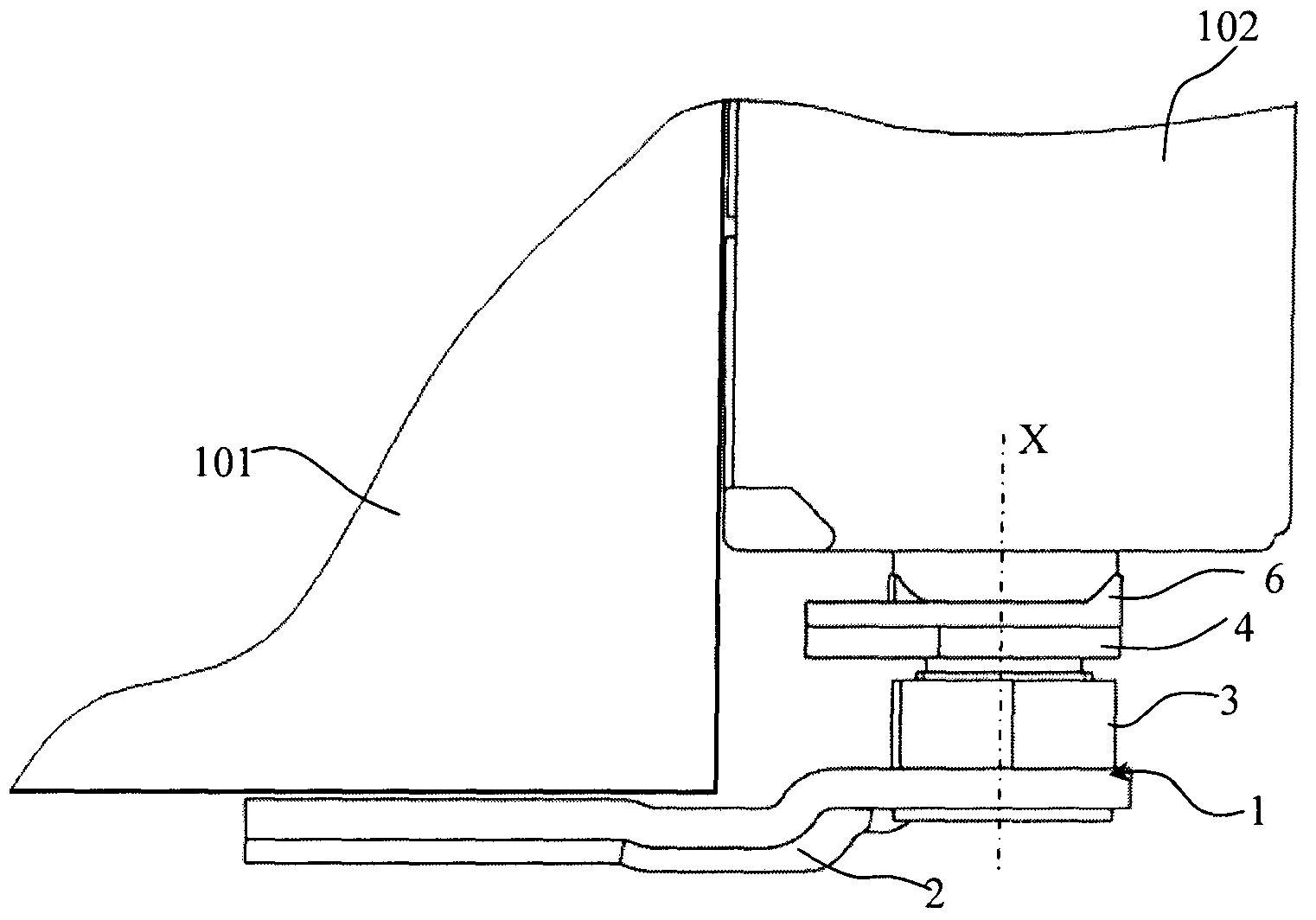

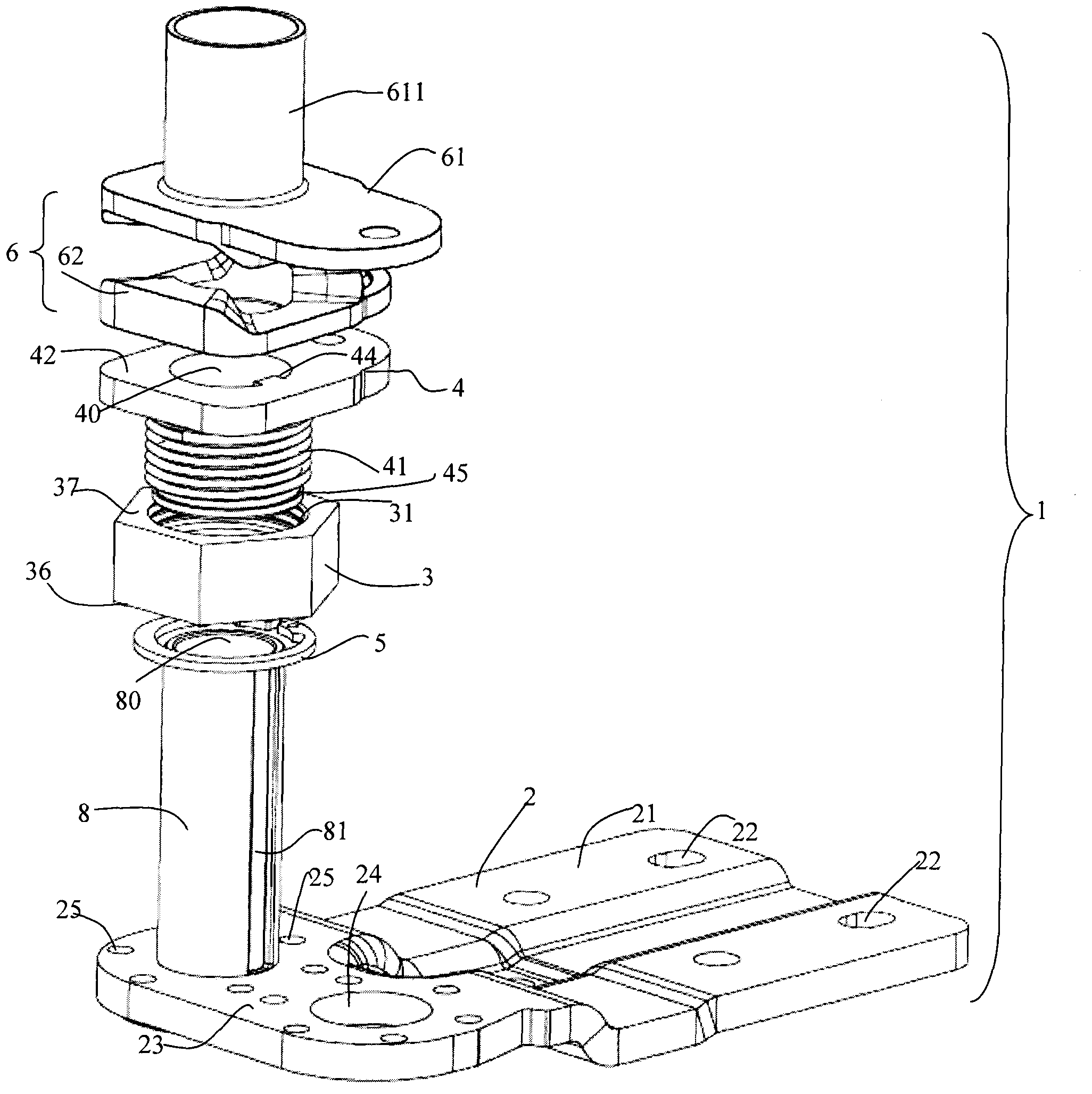

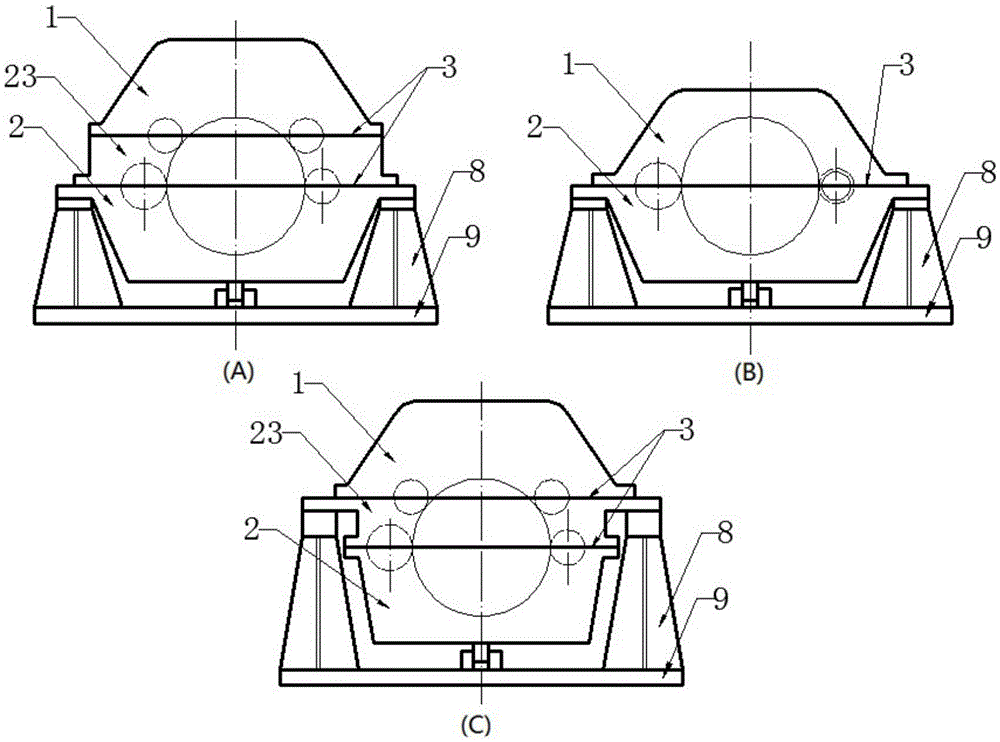

Refrigeration tool with door hinge assembly

ActiveCN103836874AReduces the possibility of accidental rotationSmall height changeLighting and heating apparatusWing accessoriesRefrigerationHinge angle

The invention relates to a refrigeration tool. The refrigeration tool comprises a body, a door and a hinge assembly, wherein the hinge assembly can rotate around the rotating axis, is connected to the door and the body and comprises a regulating part (3), a second thread part (41) and a horizontal wall (23). The regulating part is used for regulating the height of the door relative to the body and provided with a first thread part (31) and an end wall (36) which is at least approximately parallel to the horizontal plane. When the regulating part (3) rotates around the rotating axis, one of the first thread part and the second thread part can move in the vertical direction along the other of the first thread part and the second thread part. At least a part of one of the horizontal wall and the end wall (36) is located on the other of the horizontal wall and the end wall. According to the scheme, one of the end wall and the horizontal wall is provided with at least one concave part (25), the other of the end wall and the horizontal wall is provided with at least one convex part (35), and each convex part (35) selectively drops into or being moved out of the at least one concave part.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU

Axis height adjustable gear box supporting structure

ActiveCN105626838AReduce the temperatureSmall height changeGearboxesGear lubrication/coolingImpellerGear wheel

The invention relates to an axis height adjustable gear box supporting structure which is characterized in that for a unit integrating a gear box and a multistage turbomachine, a position neighboring a split plane of the gear box is supported by a bracket; a sliding pin structure is arranged on the contact surface of the supported position; the bottom surface of a lower box body of the gear box is fit with a bottom plate of the bracket by a guide stand plate; and heat exchange pipelines and temperature sensors are arranged on the bracket. With the adoption of the axis height adjustable gear box supporting structure, the offset of the axis of each gear shaft in an operating process can be controlled conveniently; the heights of the axes are hardly changed with the change of the temperature of a box body; the influence of thermal expansion on the unit is reduced; the operating stability and energy conversion efficiency of the unit are improved; and the axis height adjustable gear box supporting structure is applicable to various gear box type turbomachine units.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

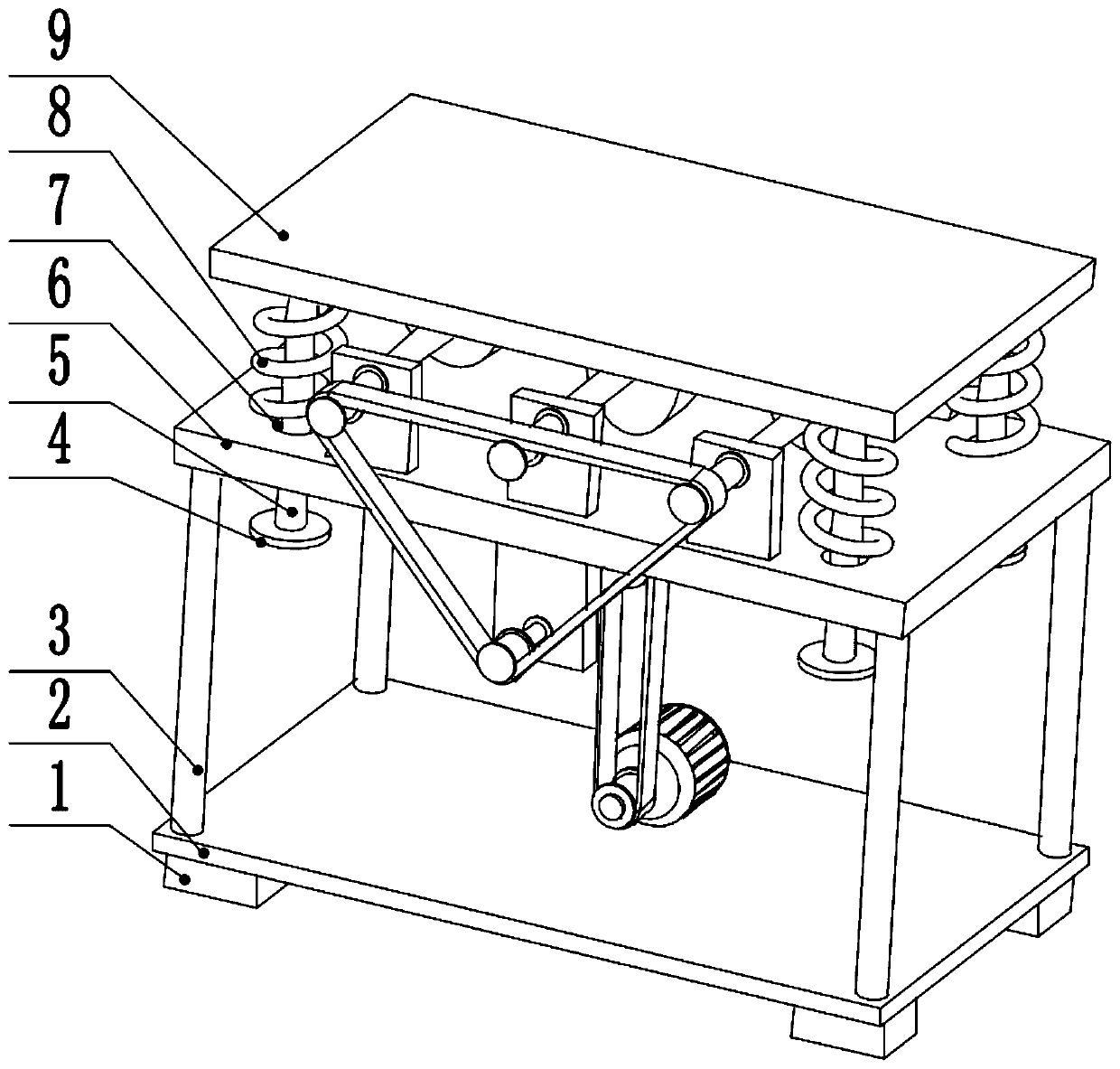

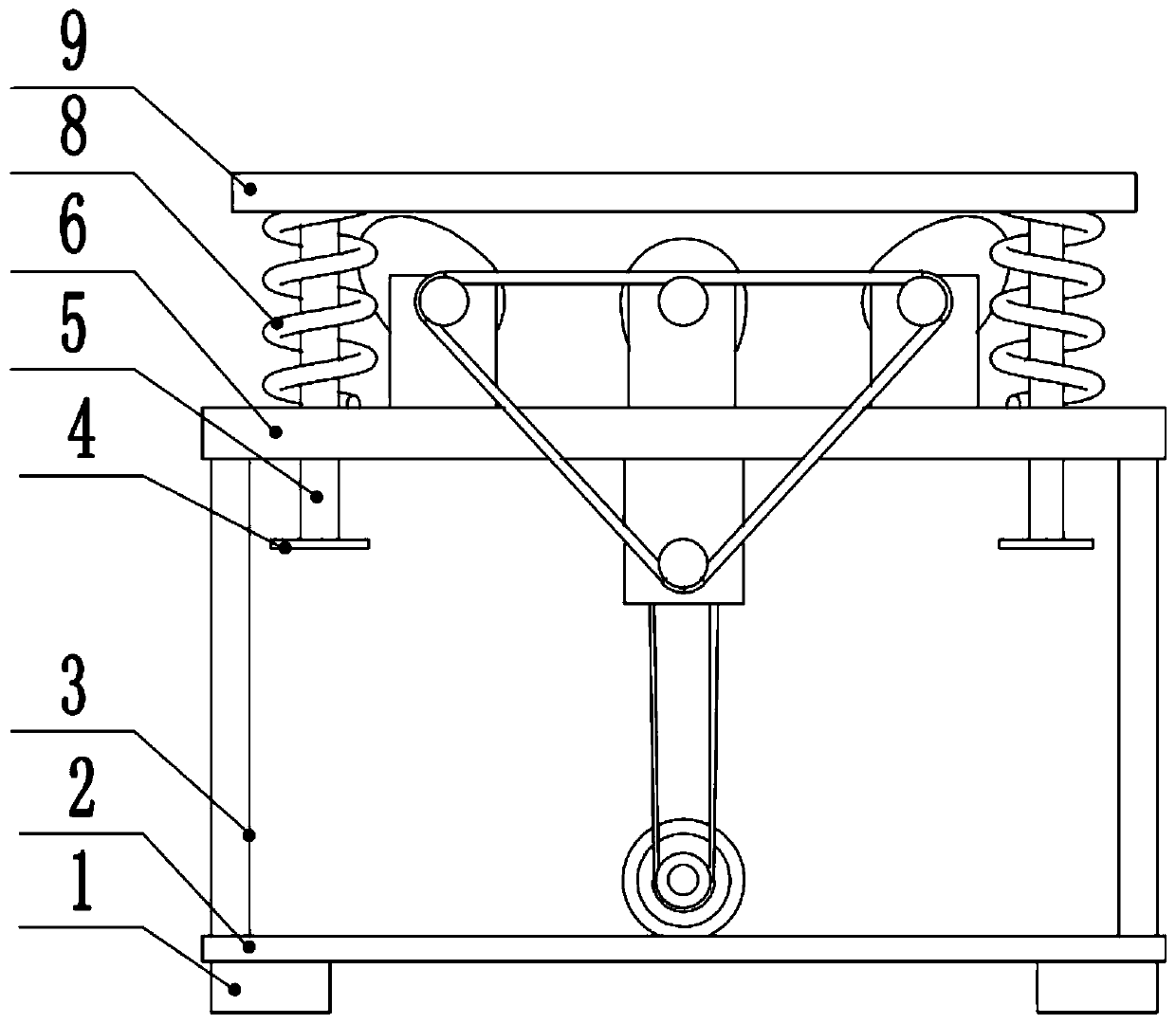

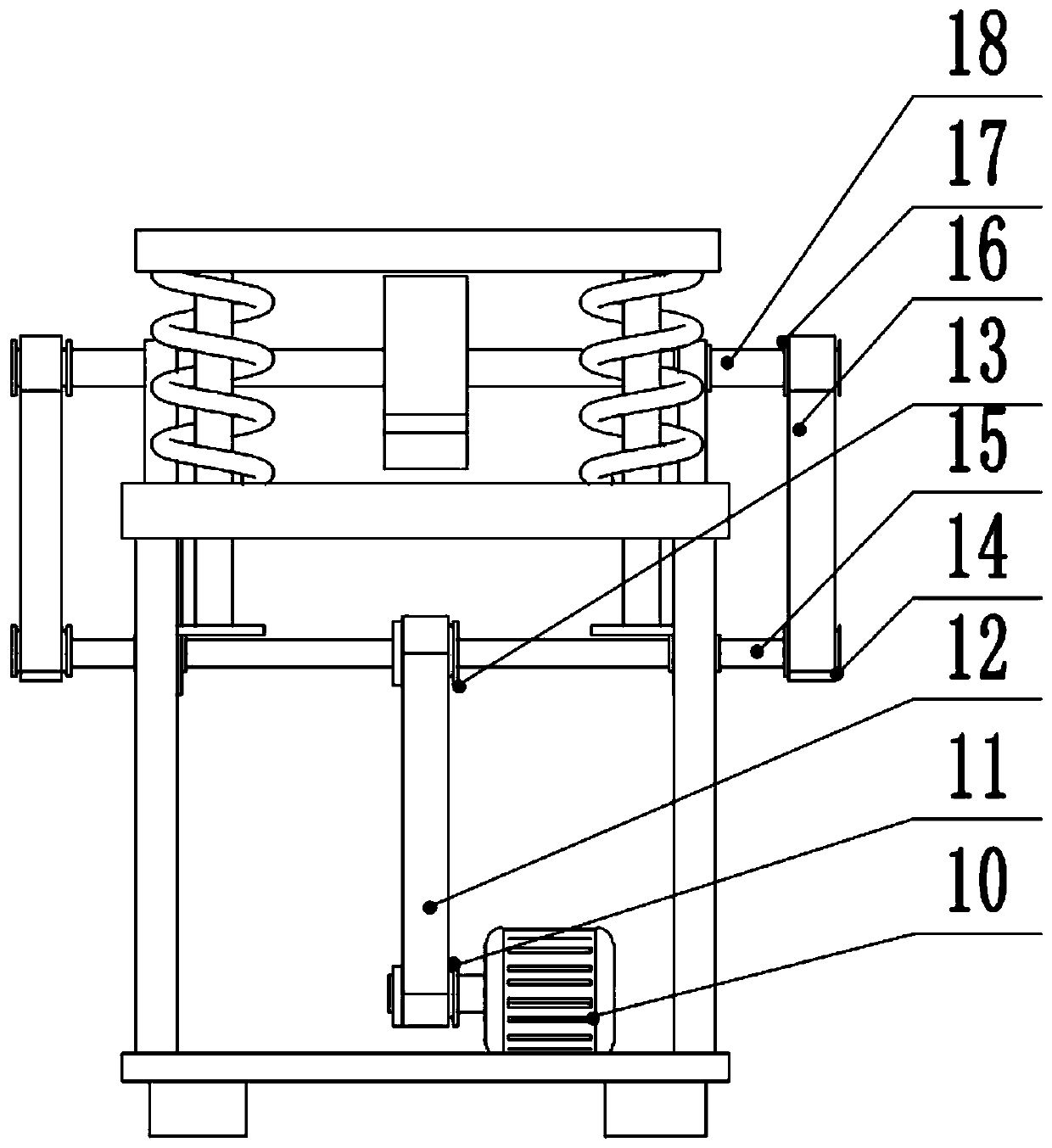

Vibrating device for forming of ceramic structural components

InactiveCN110948644AHigh vibration frequencyIncrease contact frequencyCeramic shaping apparatusElectric machineryDrive motor

The invention relates to the technical filed of ceramic machining, and discloses a vibrating device for forming of ceramic structural components. The vibrating device comprises a bottom plate; supporting columns are arranged on the left and right sides of the upper surface of the bottom plate; a mounting plate is arranged at the upper parts of the supporting columns; through holes are formed in the left and right sides of the mounting plate; guiding rods are connected in the middles of the through holes in a penetrating manner; a supporting plate is arranged at the upper ends of the guiding rods; a driving motor is arranged in the middle of the bottom plate; an output shaft of the driving motor is fixedly connected with a first belt pulley; the first belt pulley is connected with a secondbelt pulley through a first belt; the second belt pulley is fixedly connected in the middle of a spindle; third belt pulleys are arranged on the front and back sides of the spindle; the third belt pulleys are connected with fourth belt pulleys through second belts; the fourth belt pulleys are fixedly connected with the front and back ends of rotating shafts; and cams are arranged in the middles ofthe rotating shafts. The invention is applicable to the vibrating device for forming of the ceramic structural components. One driving motor is arranged to drive the three rotating shafts to rotate simultaneously, so that the three cams begins to rotate simultaneously, and the contact frequency between the cams and the supporting plate is increased.

Owner:淄博松阳锆业科技有限公司

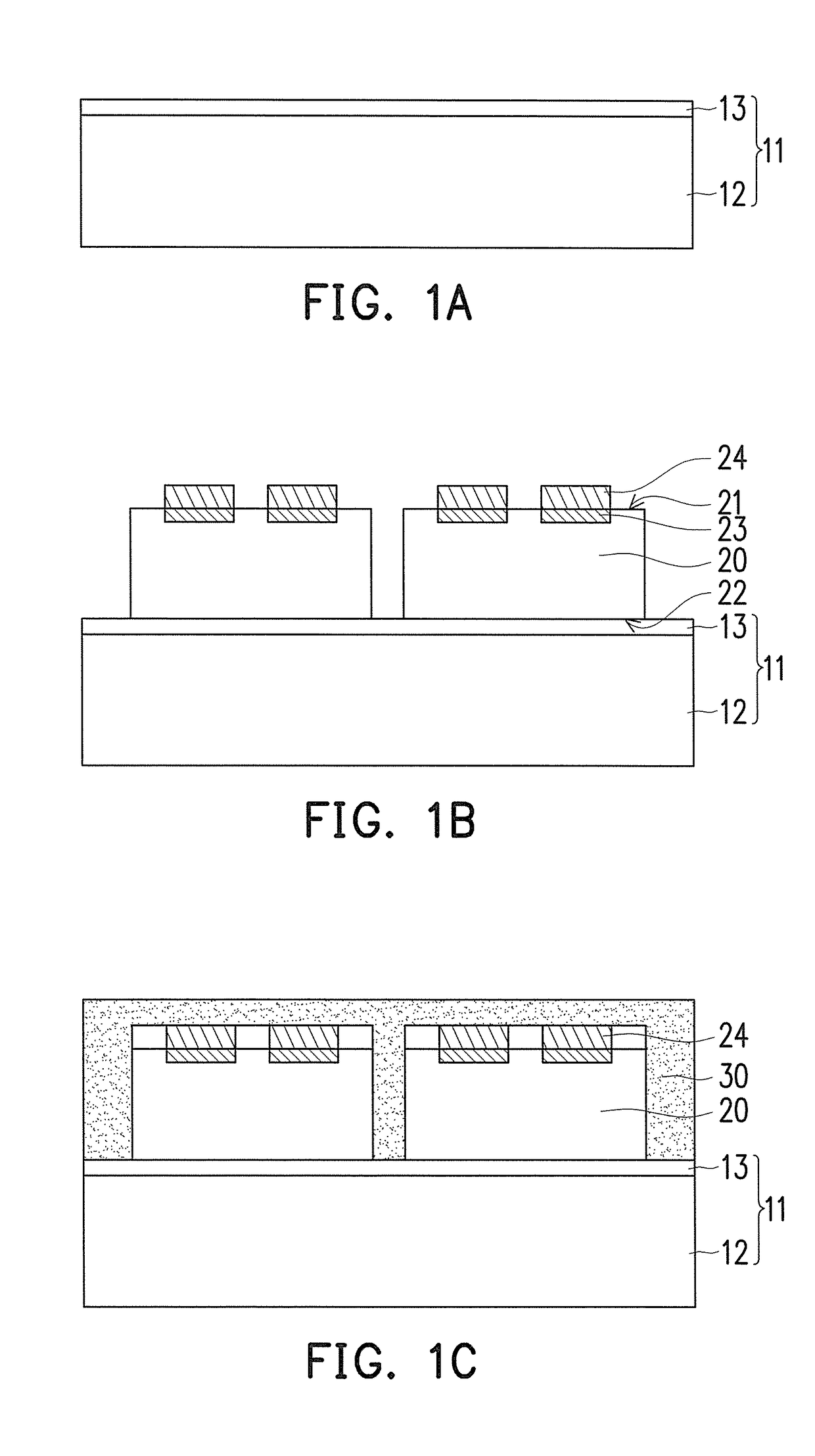

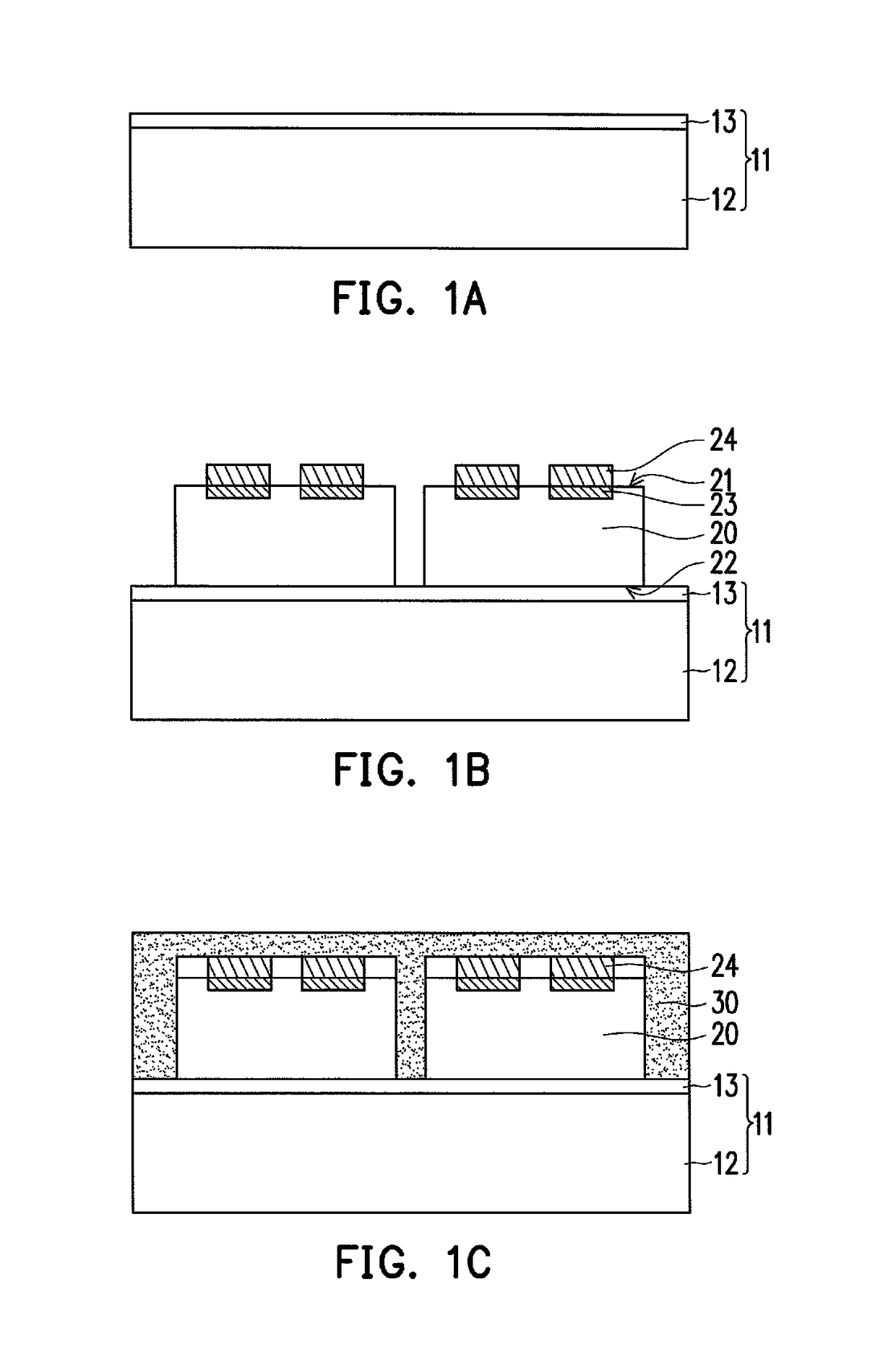

Manufacturing method of wafer level package structure

ActiveUS20170229425A1Low manufacturing costLess processingSemiconductor/solid-state device detailsSolid-state devicesRedistribution layerWafer-level packaging

A manufacturing method of a wafer level package structure includes the following steps. A chip is disposed on a supporting board, wherein the chip includes an active surface and a back surface opposite to the active surface, and a plurality of pads on the active surface, and the back surface of the chip is adhered to the supporting board through a die attach film (DAF). A molding is disposed on the supporting board to perform a wafer level exposed die molding procedure on the chip, wherein the molding surrounds the chip, and the pads of the chip are exposed out of the molding. A redistribution layer (RDL) is formed on the active surface of the chip, wherein the RDL is electrically connected to the pads. The supporting board and the DAF are removed from the chip.

Owner:POWERTECH TECHNOLOGY

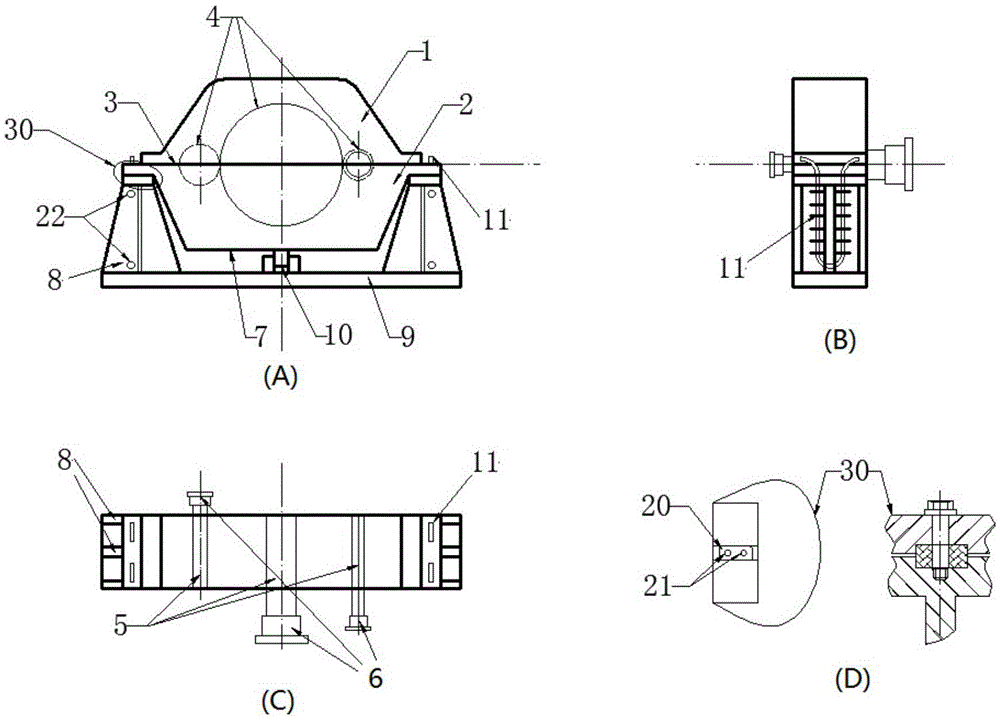

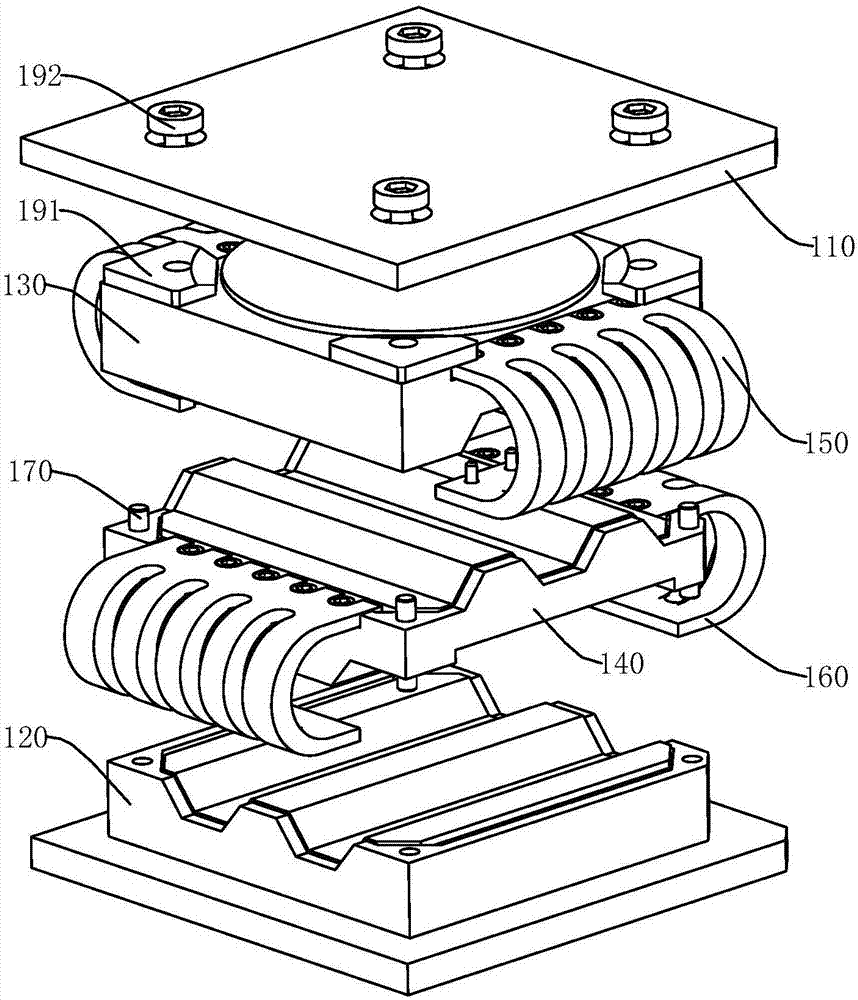

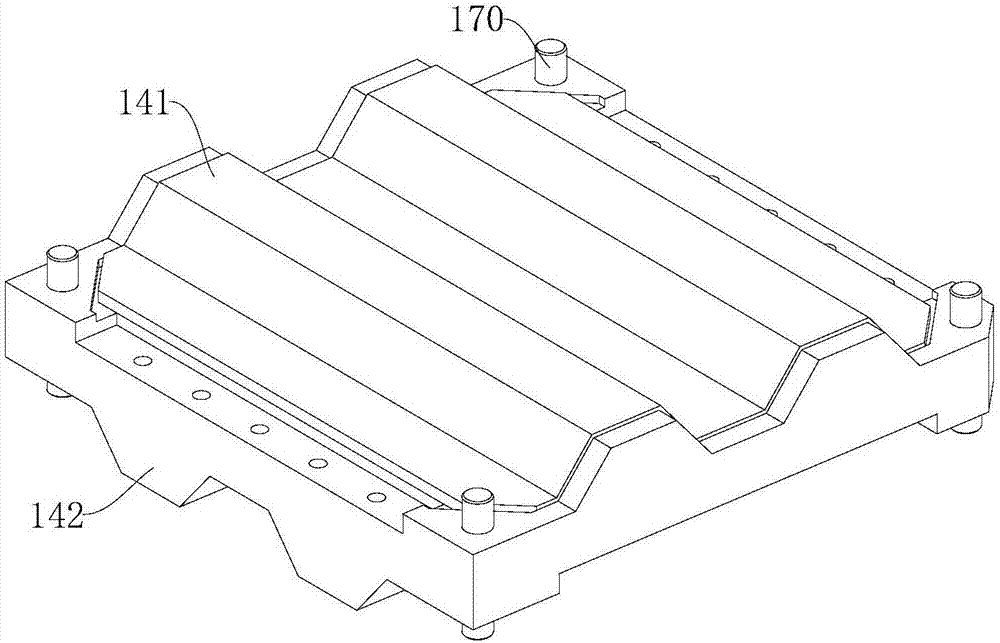

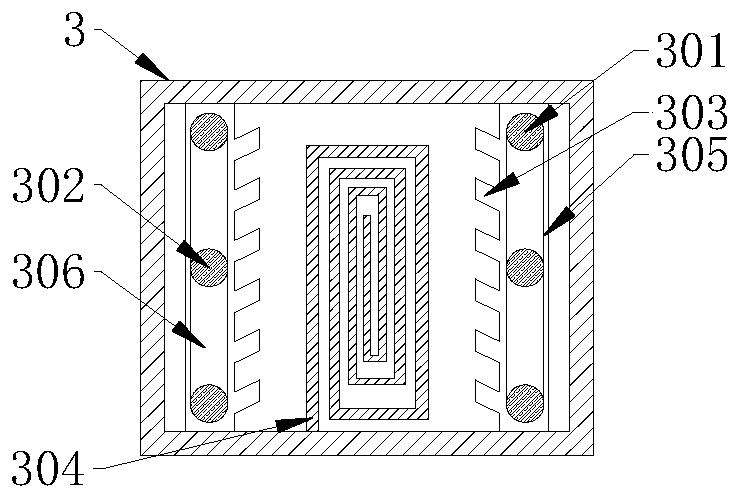

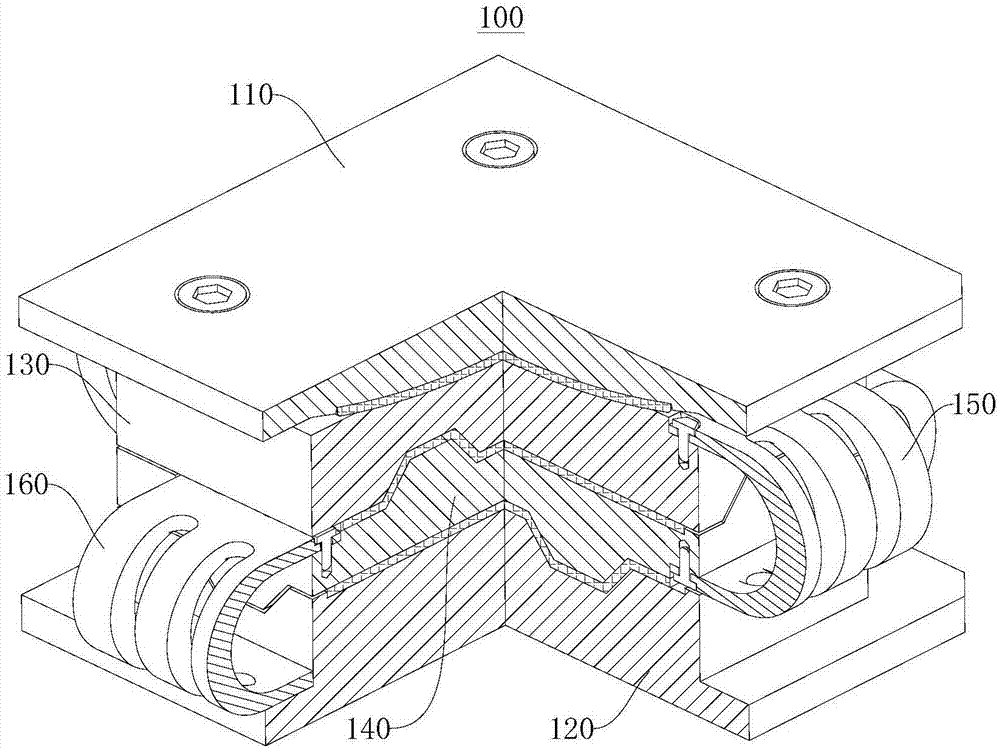

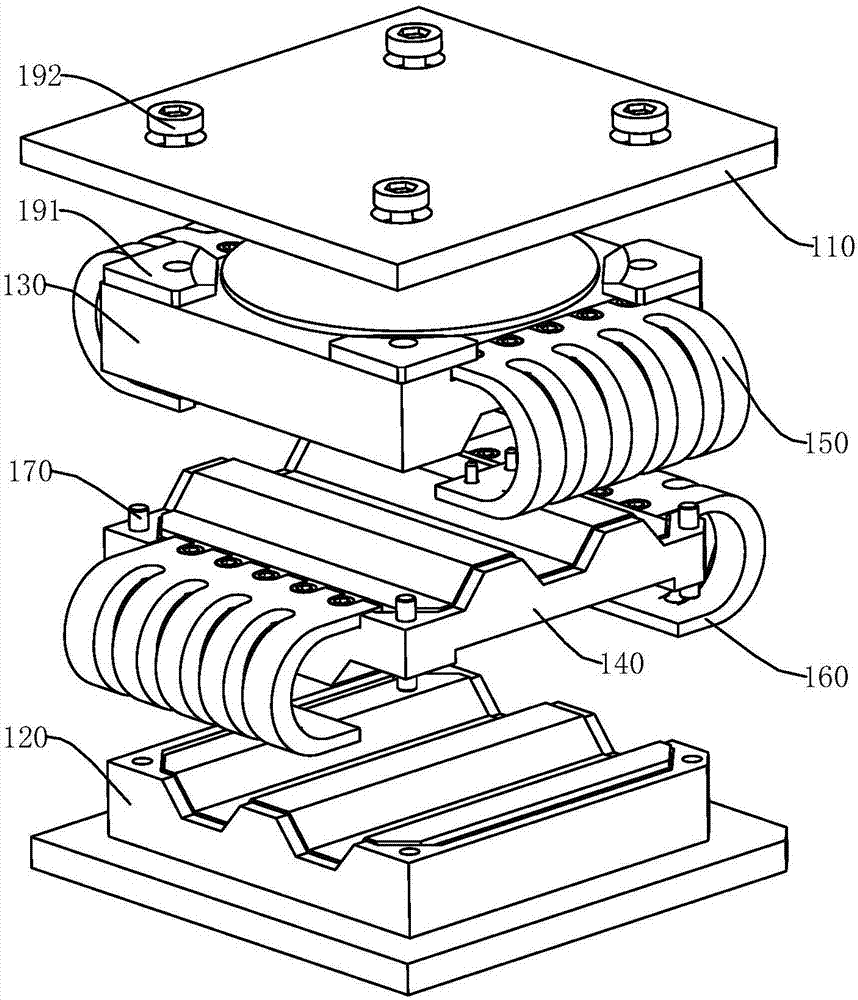

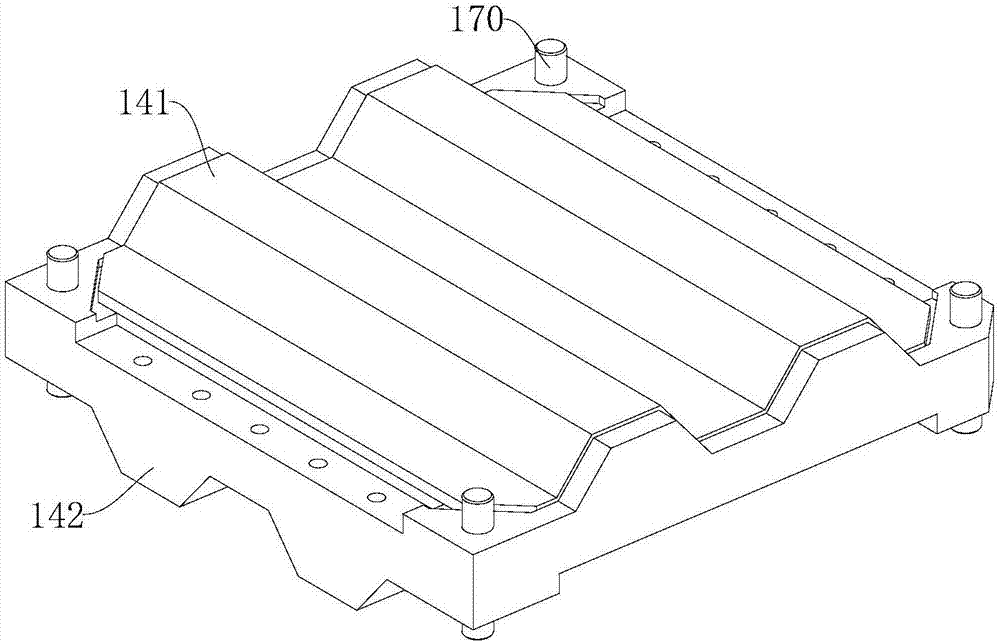

Self-reset friction damping shock mount and damping bridge

ActiveCN107268431AGuaranteed normal functioningExtend the basic natural vibration periodBridge structural detailsHysteresisShock mount

The invention discloses a self-reset friction damping shock mount and a damping bridge, and relates to the technical field of damping. The self-reset friction damping shock mount comprises a first mount plate, a second mount plate, a supporting face plate, a friction piece, a first damping piece and a second damping piece. The first mount plate is connected with the supporting face plate. The two ends of the friction piece are connected with the end, away from the first mount plate, of the supporting face plate and the second mount plate respectively. The friction piece can slide relative to the supporting face plate and the second mount plate for friction energy consumption and damping. The two ends of the first damping piece are connected with the friction piece and the supporting face plate respectively. The two ends of the second damping piece are connected with the friction piece and the second mount plate respectively. Damping and resetting of the two damping pieces are realized through damping hysteresis. The invention further provides the damping bridge. The self-reset friction damping shock mount and the damping bridge are simple in structure, horizontal energy consumption and reset capacity can be effectively improved, and the mechanical structure of the bridge is not influenced.

Owner:SICHUAN UNIV

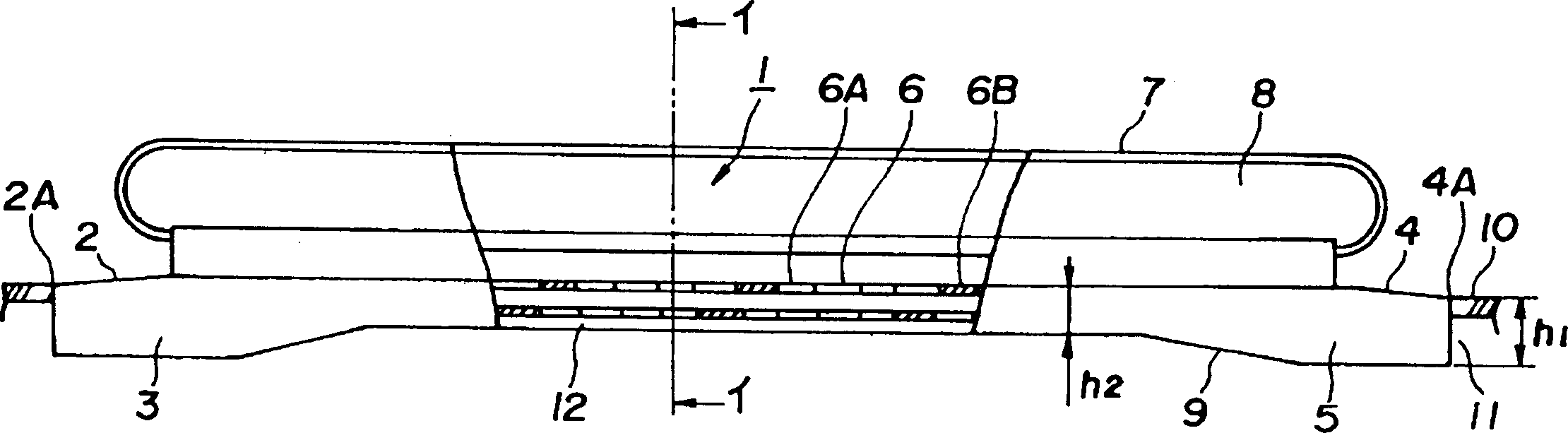

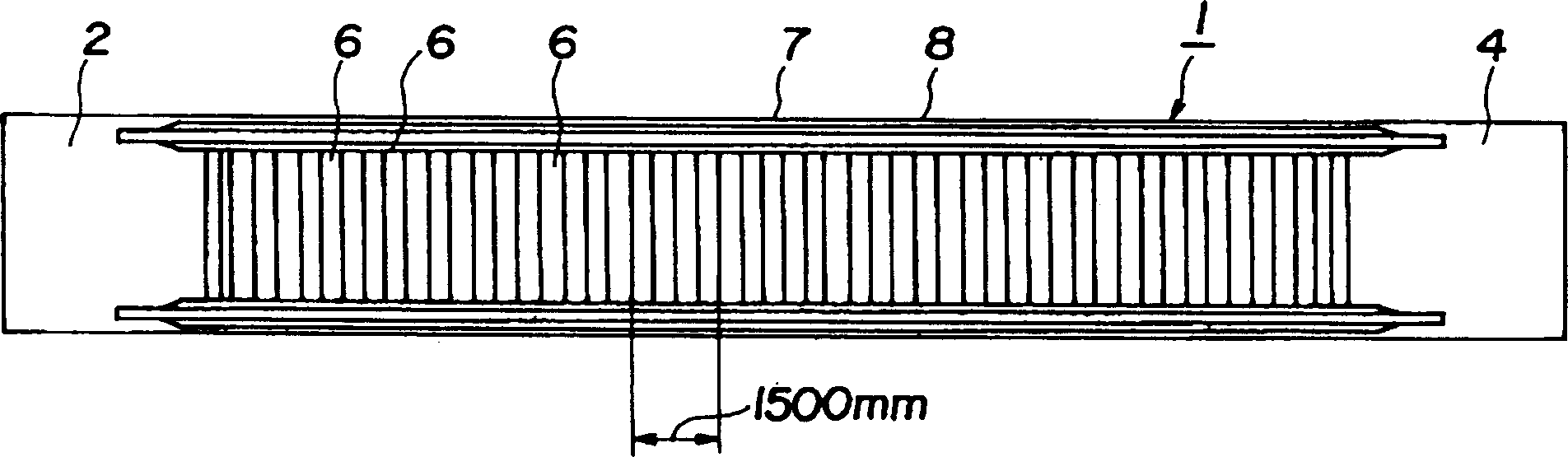

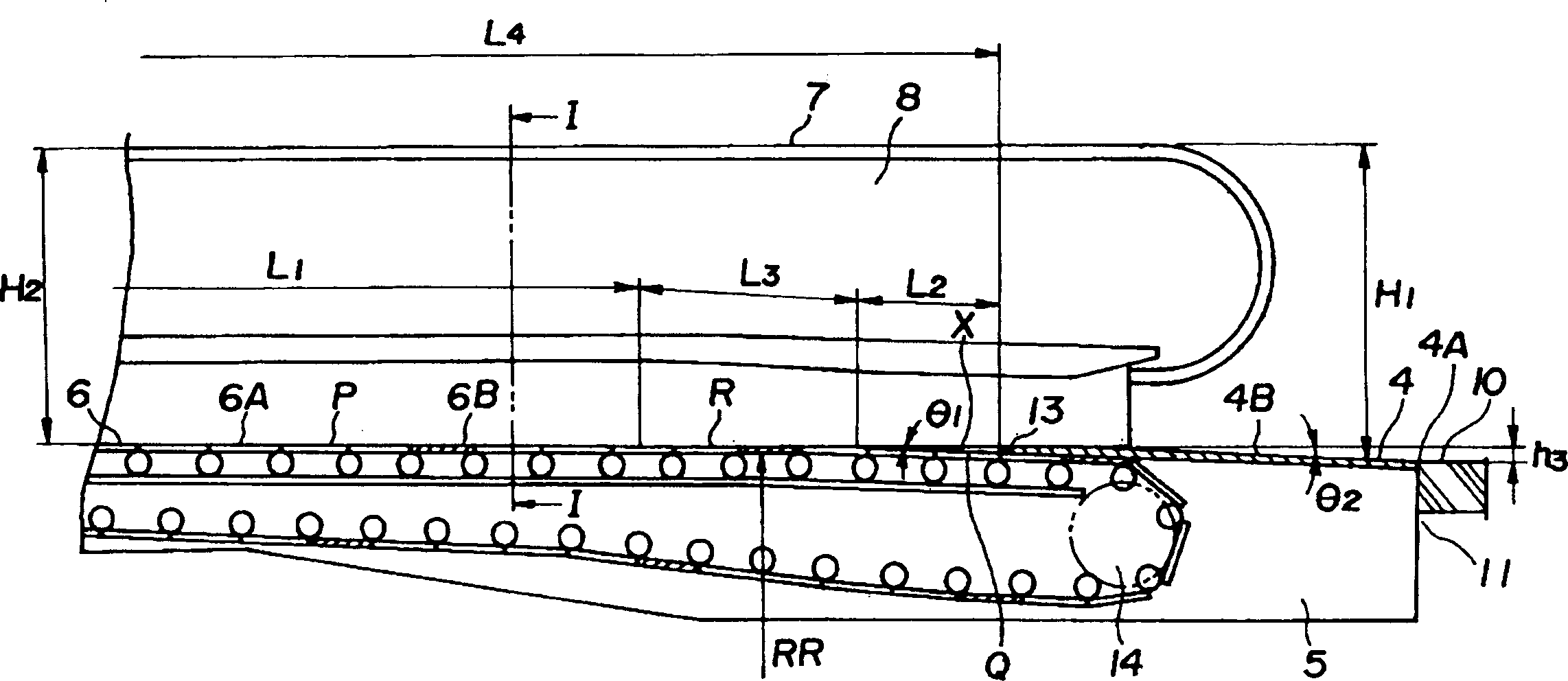

Automatic foot path

The pallet 6 moving substantially horizontally to convey a passenger is composed of ordinary color pallets 6A and colored pallets 6B arranged at a predetermined interval. A height position of a substantially horizontal main moving road surface P of the pallet 6 is substantially the same as a height position of a top face of a getting-on-and-off floor 4 upper face or is slightly higher than the latter position. An inclined road surface Q on which a getting-on-and-off floor 4 side is lower than the main moving road surface P is provided in a part where the pallet 6 comes in and out of the getting-on-and-off floor 4. An inclined floor surface 4B which is continuous with the inclined road surface Q and on which an anti-pallet side becomes low is provided on the getting-on-and-off floor 4. To provide a moving sidewalk allowing a passenger, in particular, a wheelchair user to move smoothly between a pallet and a floor side and capable of easily determining operation of the pallet and reducing thickness of a device.

Owner:HITACHI LTD

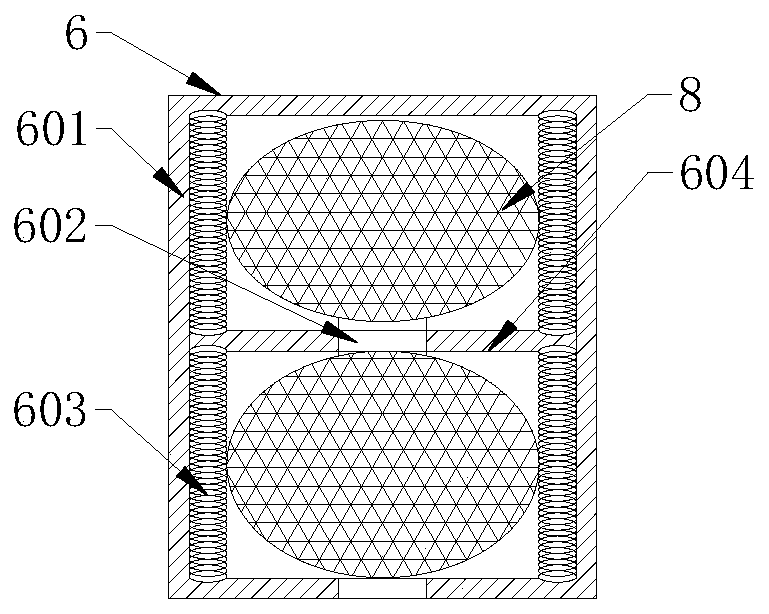

Low-speed damping mechanism of deceleration strip

The invention relates to the technical field of traffic safety, and discloses a low-speed damping mechanism of a deceleration strip, the low-speed damping mechanism comprises a shell, the upper end of an inner cavity of the shell is movably sleeved with a movable block, the cross section of the movable block is T-shaped, and the lower end of the movable block is provided with a first movable cavity. By arranging the low-speed damping mechanism, when a vehicle passes through the deceleration strip at a low speed, after a tire is pressed on the upper surface of the movable block, air at the lower end of the movable block moves downwards into the air cavity through the vent hole when the movable block overcomes the elastic force of the first spring, so that the movable block moves downwards by a certain distance; therefore, the gradient of the deceleration strip on the road surface is reduced, the vibration amplitude is small when a vehicle with a low speed passes through the deceleration strip, and when the vehicle passes through the deceleration strip at a high speed, air at the lower end of the movable block cannot quickly move into the air cavity due to the small hole diameter of the vent hole, so that the height change amplitude of the movable block is small. Therefore, the effect of warning deceleration is achieved.

Owner:淮北平坤锂电池科技有限公司

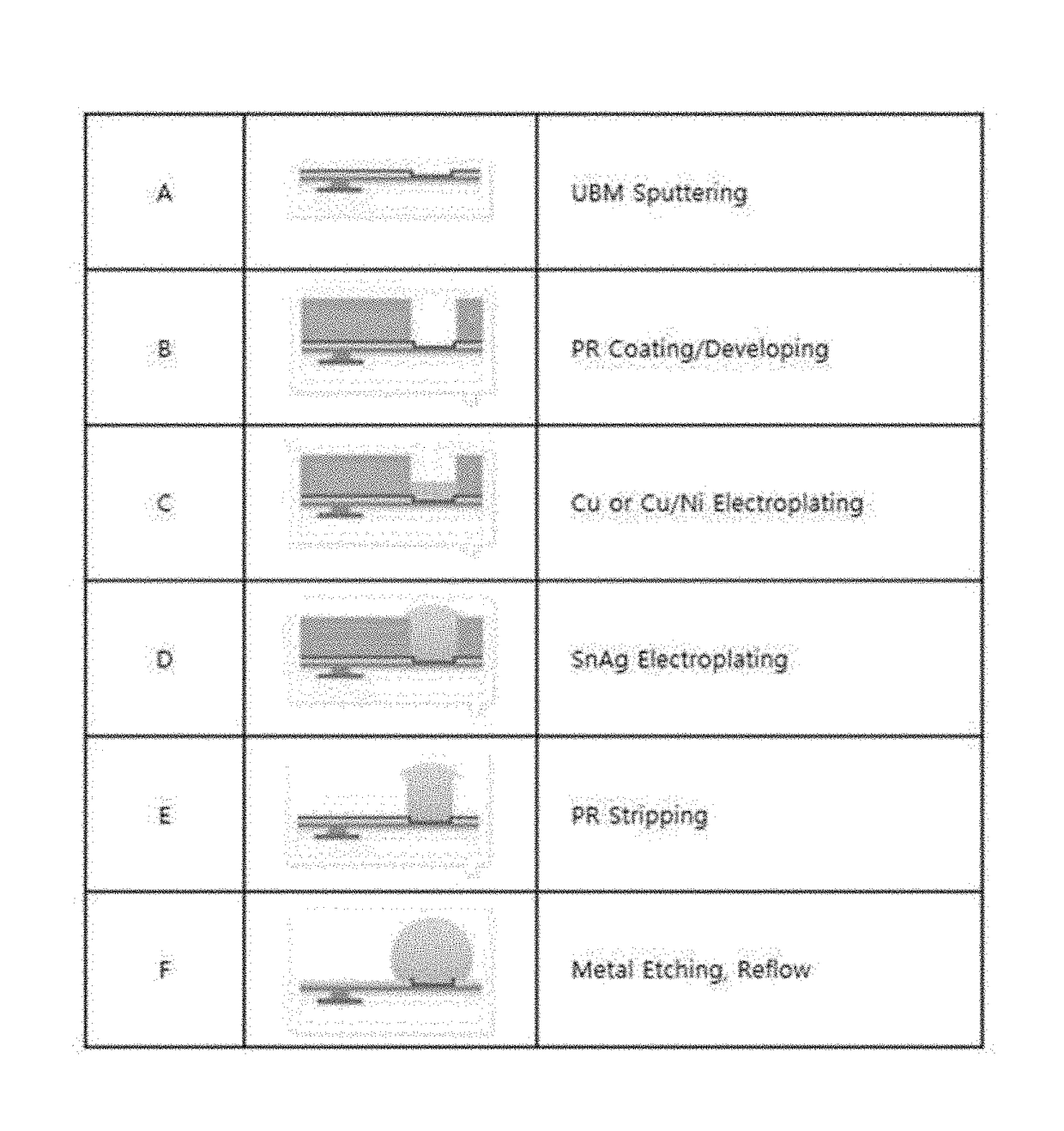

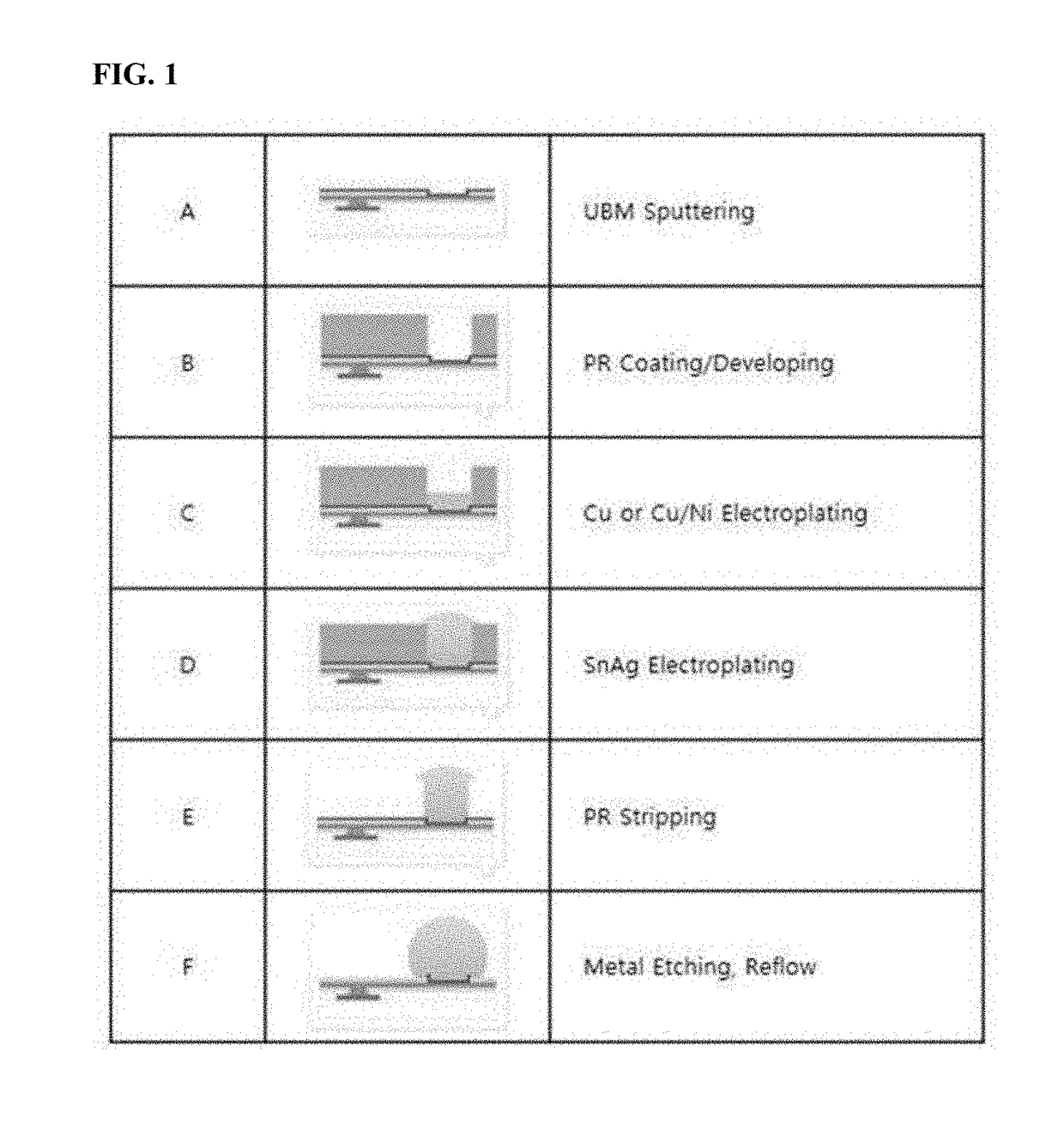

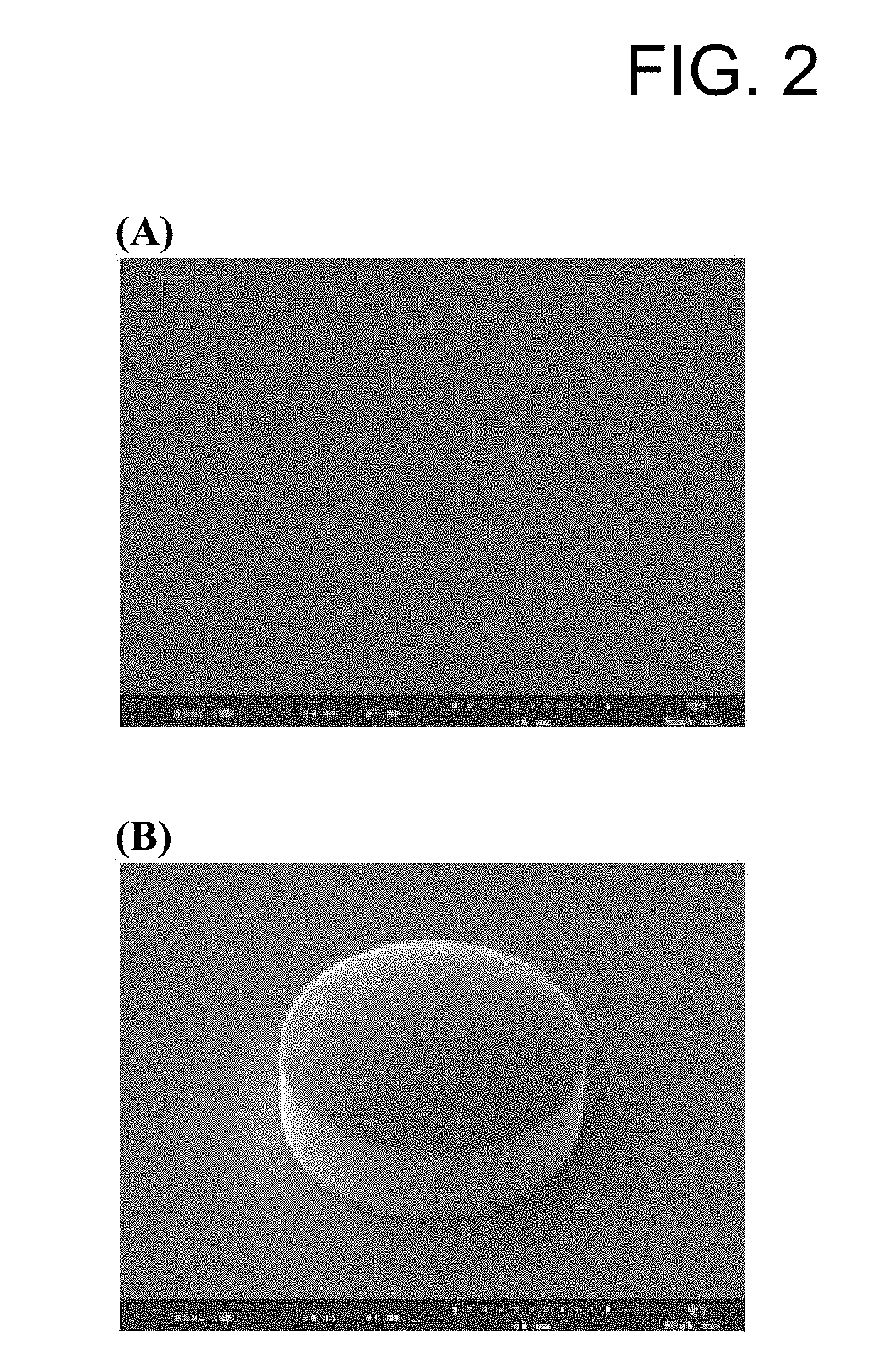

Tin alloy electroplating solution for solder bumps including perfluoroalkyl surfactant

ActiveUS20160035685A1Good spreadabilityIncrease surface tensionSemiconductor/solid-state device detailsSolid-state devicesEtherAlloy

Disclosed is a tin-based electroplating solution for forming solder bumps of a flip chip package. The tin-based electroplating solution includes tin methanesulfonate, silver methanesulfonate, methanesulfonic acid, a fluorinated surfactant, an aromatic polyoxyalkylene ether, and water. Also disclosed is a method for forming solder bumps by using the electroplating solution. The method includes (1) electroplating a silicon wafer having a protective layer through which an electrode pad is exposed and an under bump metallurgy (UBM) layer with a copper or copper / nickel plating solution to form copper or copper / nickel pillars on the under bump metallurgy layer and (2) electroplating the pillars with the tin-based electroplating solution to form solder bumps.

Owner:APCT

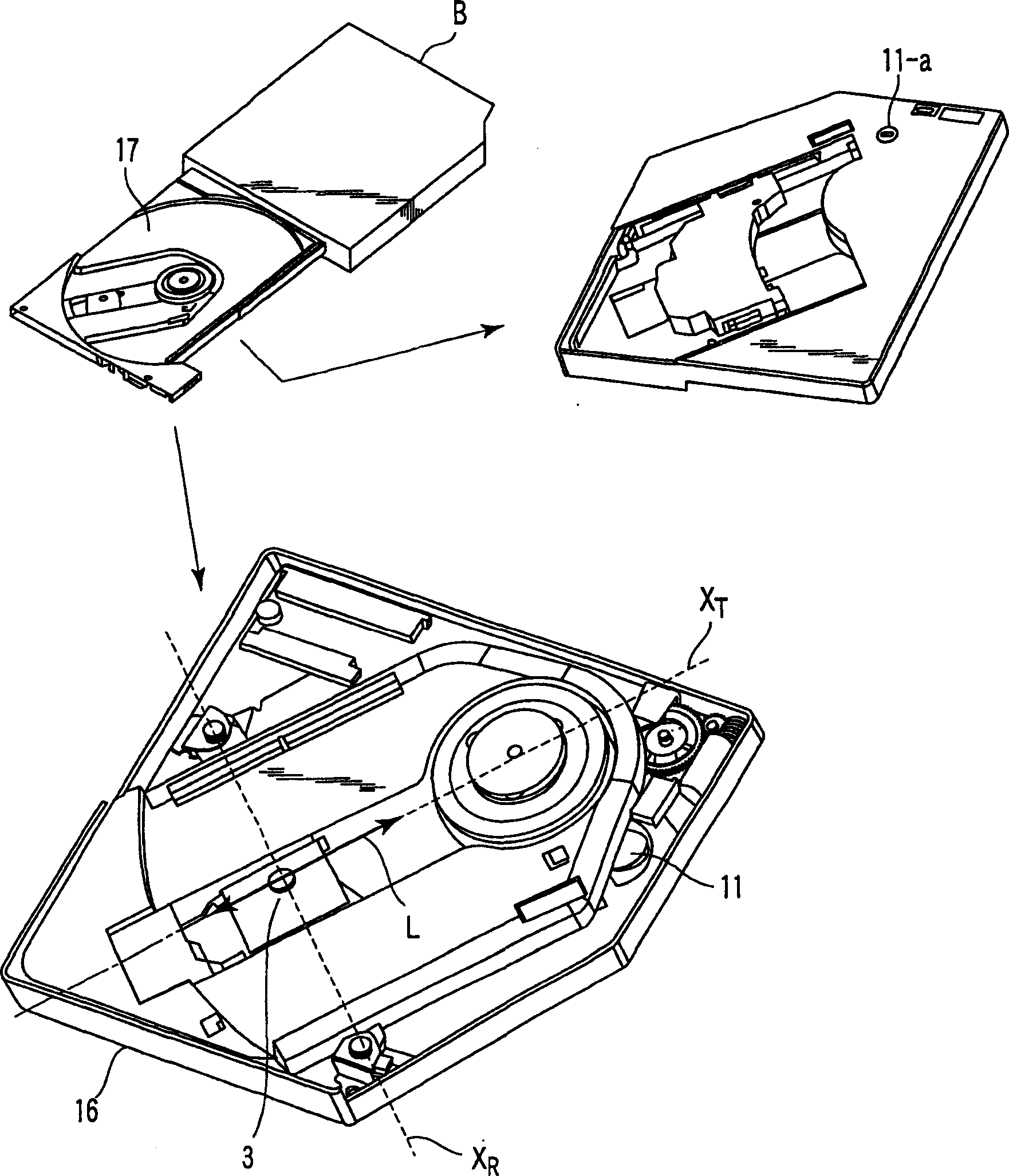

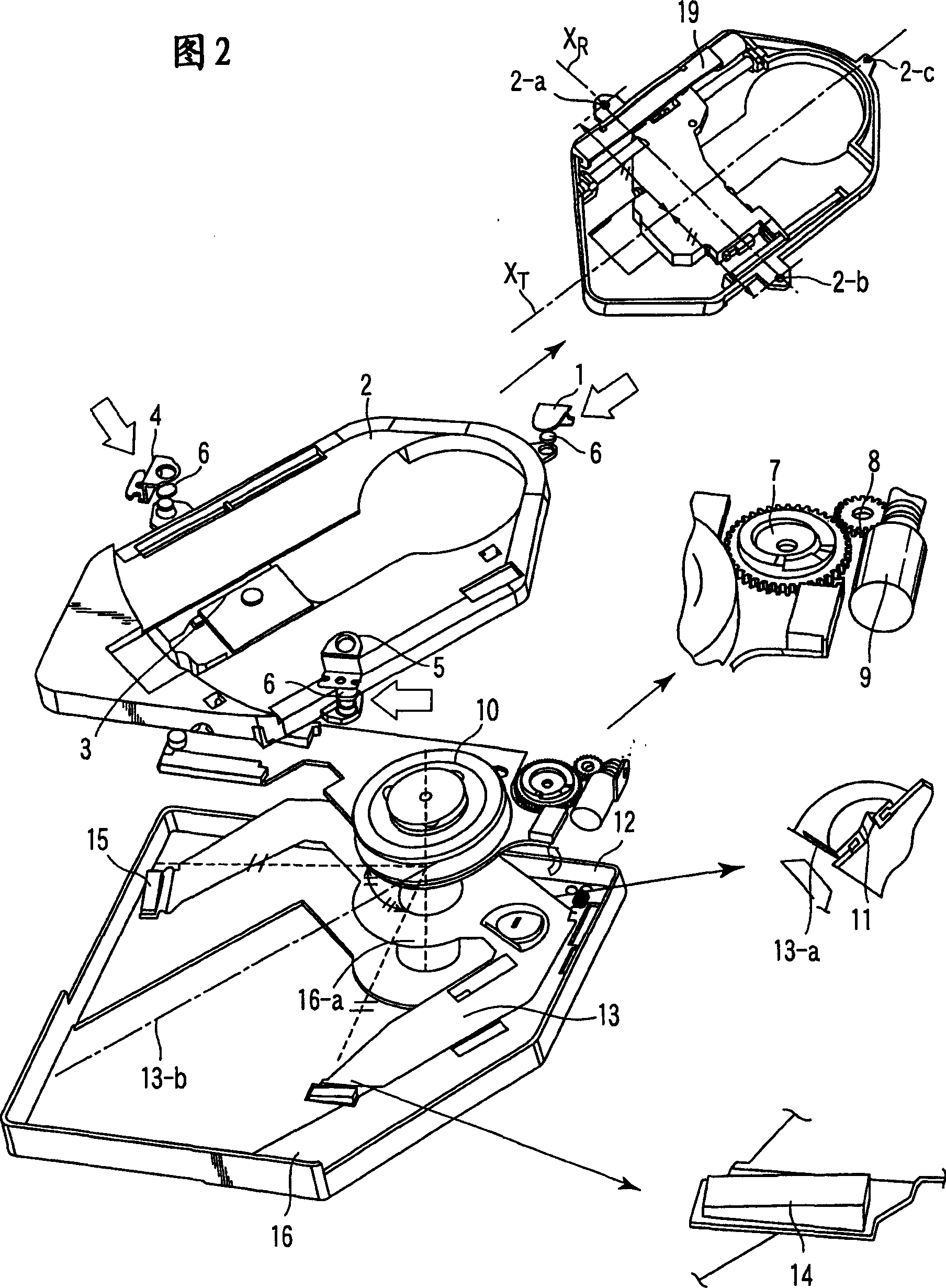

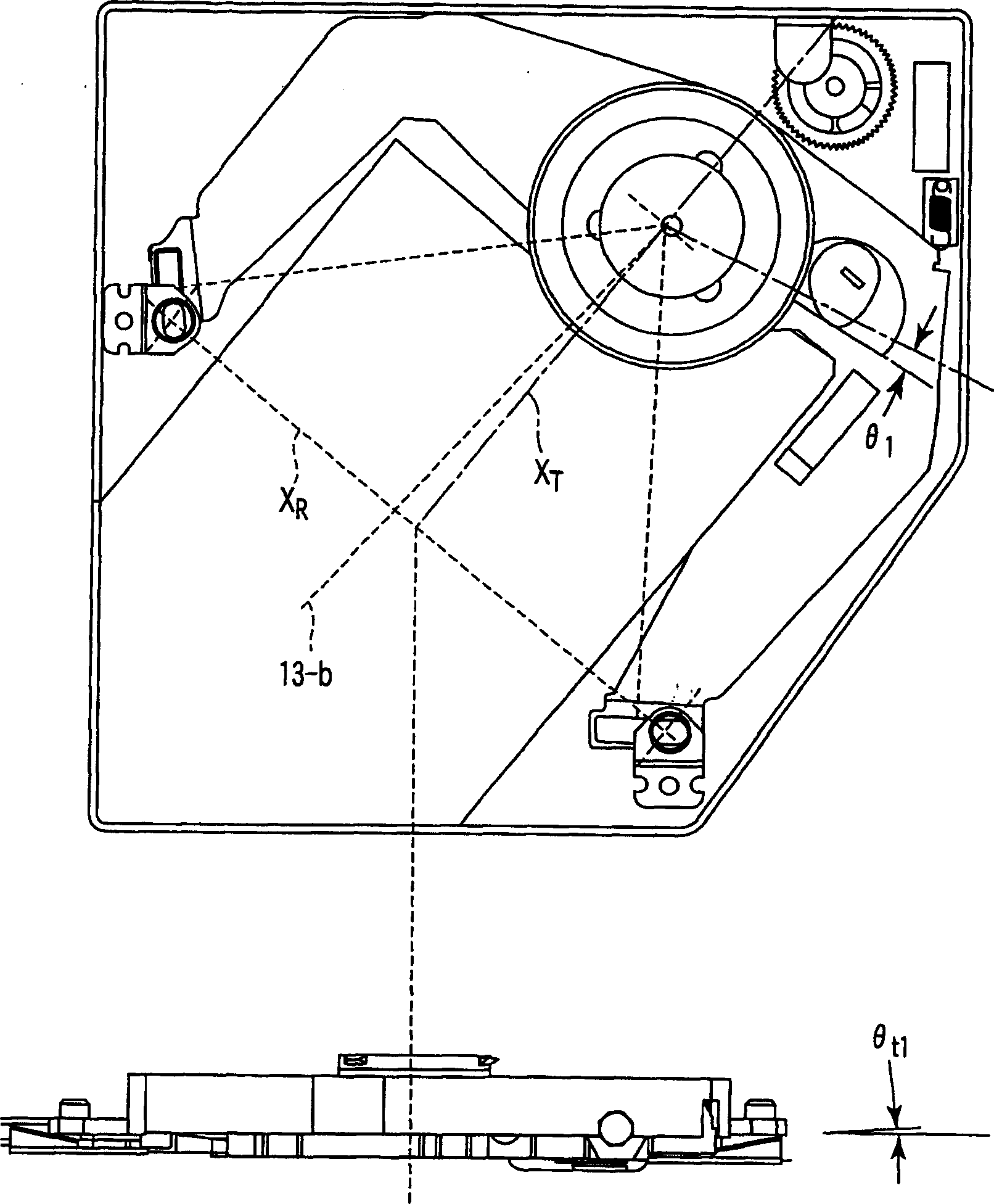

Optical disk apparatus

InactiveCN1467713AEasy to adjustSmall height changeRecord information storageRecording on magnetic disksRotational axisOptical pickup

An optical disk apparatus includes a main chassis and a sub-chassis provided on a drawer, and has a skew adjusting mechanism of the main chassis and the sub-chassis which is skew-adjusted with reference to a rotational axis in tangential direction XT, which is parallel to a spot trajectory L of an optical pickup and located in the vicinity of the spot trajectory L, and a rotational axis in radial direction XR perpendicular to the rotational axis in tangential direction XT. This enables the skew adjustment in which a change in height of the optical pickup is small during the adjustment and distortion is small.

Owner:KK TOSHIBA

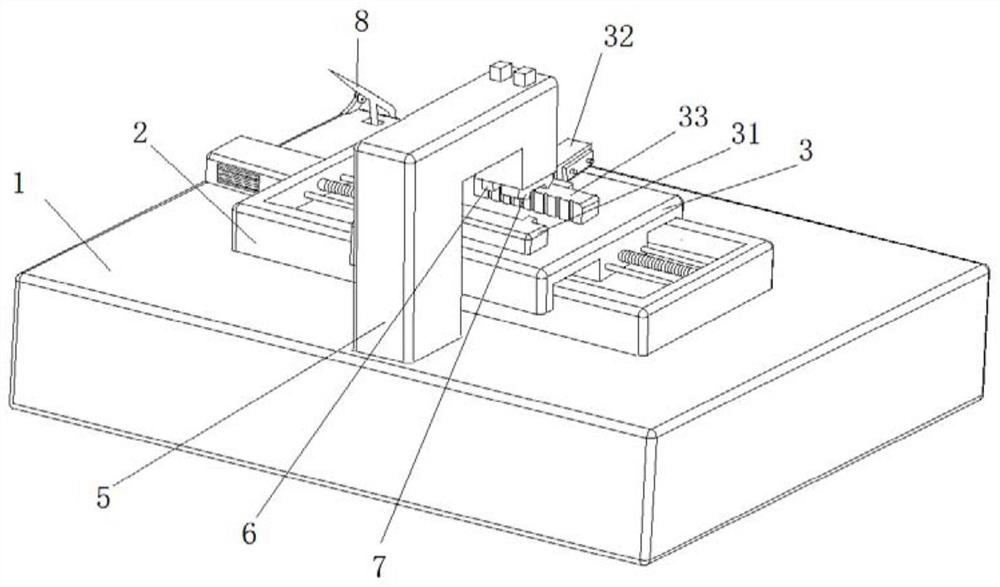

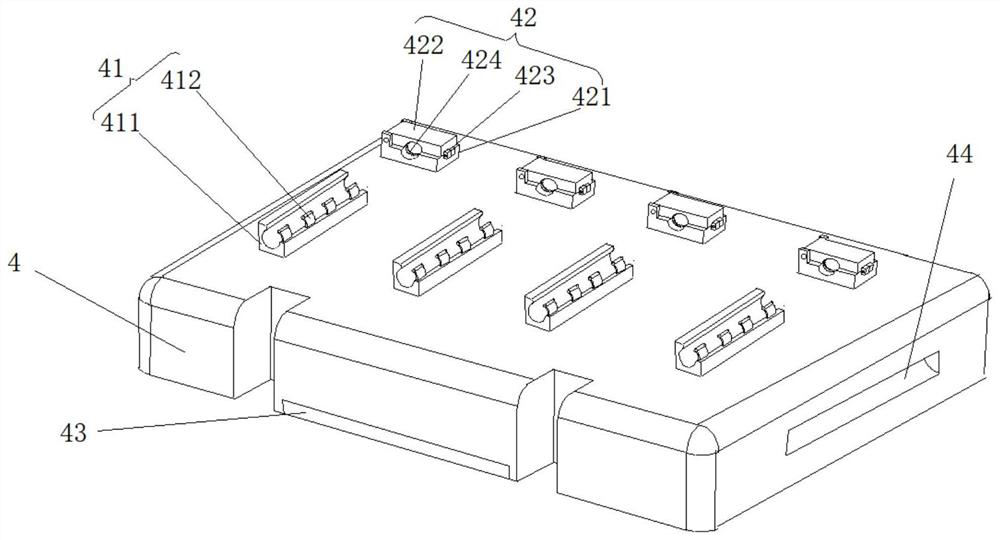

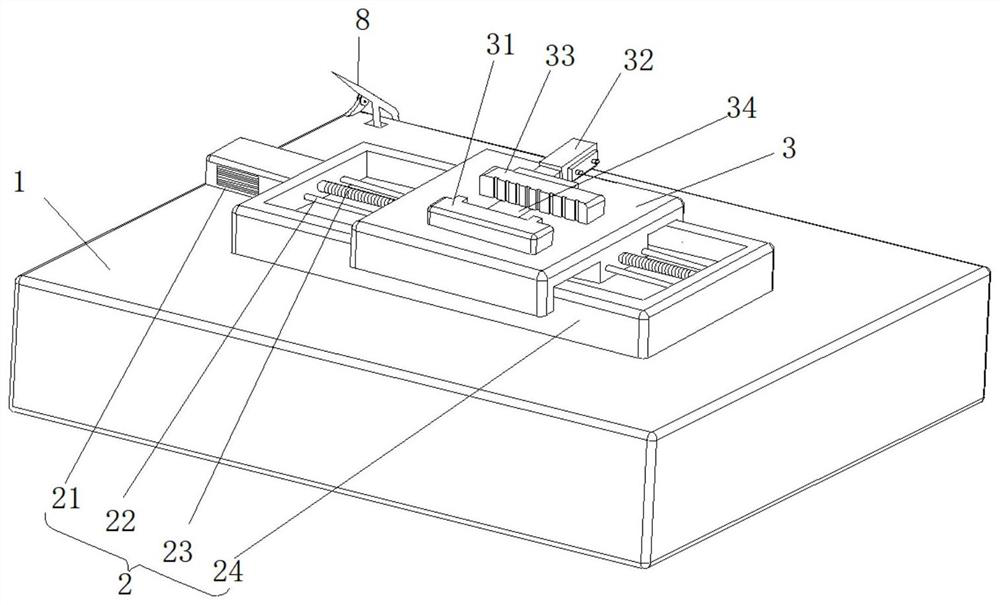

Automatic control welding platform for coaxial cable and 2M joint

ActiveCN111843096AGuarantee welding qualityAvoid separationSoldering auxillary devicesCoaxial cableAutomatic control

The invention discloses an automatic control welding platform for a coaxial cable and a 2M joint and belongs to the technical field of circuit welding equipment. The automatic control welding platformfor the coaxial cable and the 2M joint comprises a machine table, a servo guide rail, a movable seat, a clamp seat, 2M elastic clamps, coaxial cable clamps, a support frame, extending-and-contractingarms, a welding mechanism and a structured light locating and distance measurement mechanism. The machine table is provided with the servo guide rail. The movable seat is arranged on the servo guiderail in a sliding manner. The clamp seat is detachably fixed to the movable seat and provided with the 2M elastic clamps and the coaxial cable clamps. The support frame is fixed to the machine table and provided with the two extending-and-contracting arms. The two extending-and-contracting arms are connected with the welding mechanism and the structured light locating and distance measurement mechanism correspondingly. The automatic control welding platform for the coaxial cable and the 2M joint has the beneficial effects that welding precision and welding efficiency are high, operation is convenient to conduct, and the automatic control welding platform is applicable to massive coaxial cable and 2M joint welding.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

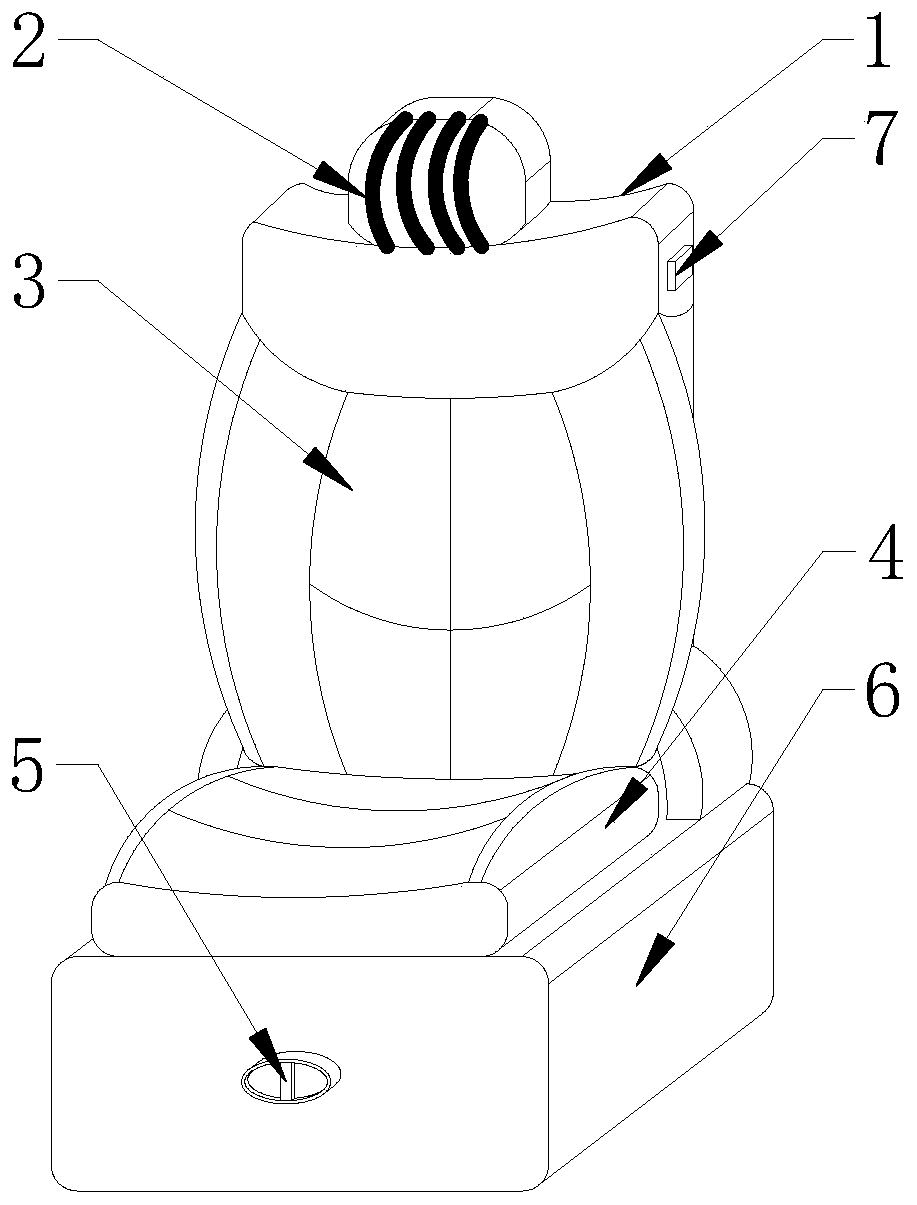

Adjustable safety seat

InactiveCN110370997ARest comfortablyImprove driving feelingSeat heating/ventillating devicesPedestrian/occupant safety arrangementBack restsEngineering

The invention discloses an adjustable safety seat which comprises a safety seat main body, a headrest and an adjustable backrest; the headrest is fixedly connected to the top of the safety seat main body; the adjustable backrest is fixedly connected to the bottom of the headrest; an adjusting rod is fixedly connected to one side of the interior of the adjustable backrest; fixing wheels are fixedlyconnected to the middle part of the adjusting rod; fixed teeth are fixedly connected to one side of the adjusting rod; connecting belts are movably connected to one side of the interior of the adjustable backrest; and a heating pipe is fixedly connected to the middle part of the interior of the adjustable backrest. The heating pipe can heat the seat for a user to improve the use feeling of the user in winter, an pneumatic pump can perform inflation and exhaust on an air bag to improve the safety of the seat, and the adjustable backrest enables the user to freely adjust a height and an angle of the seat to greatly satisfy the use feeling of the user, so that the adjustable safety seat is convenient to use, high in safety and suitable for the field of automobile accessories and has a wide development prospect in the future.

Owner:诸暨市领跑管理咨询事务所

A light field deflection measurement system and method for a highly reflective object surface

ActiveCN105806257BEasy to identify lightImprove computing efficiencyUsing optical meansLight-field cameraPhase retrieval

The invention relates to a high reflective object surface light field deflection technique measuring system and method, and is used for three-dimensional reconstruction of the high reflective object surface, the system adopts a light ray reflection principle to acquire normal information of the high reflective object surface and curved surface information, the system is projected by the light field, and the system is sensed through the light ray. The correspondence of an incident ray and a reflection ray are determined through a phase retrieval method, and 3D points on the to-be-detected object surface are calculated. According to the invention, compared with the common phase deflection technique, the system and the method does not have non-unique normal problem, and in light field camera mode, the system has higher response characteristics for object surface height variation, can get higher measuring precision and can fill the blank of domestic and overseas deflection technique measuring system based on light field.

Owner:SHANGHAI UNIV

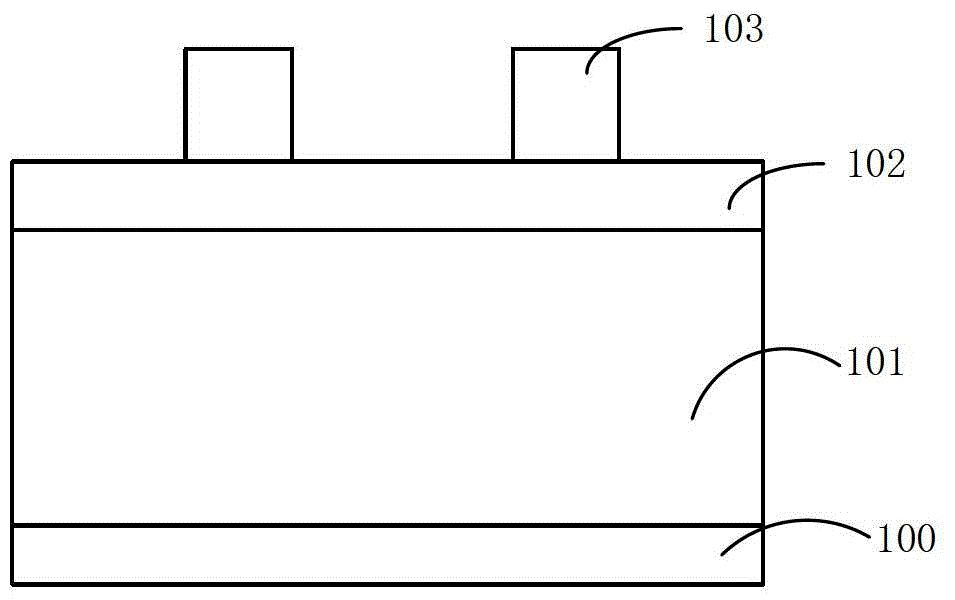

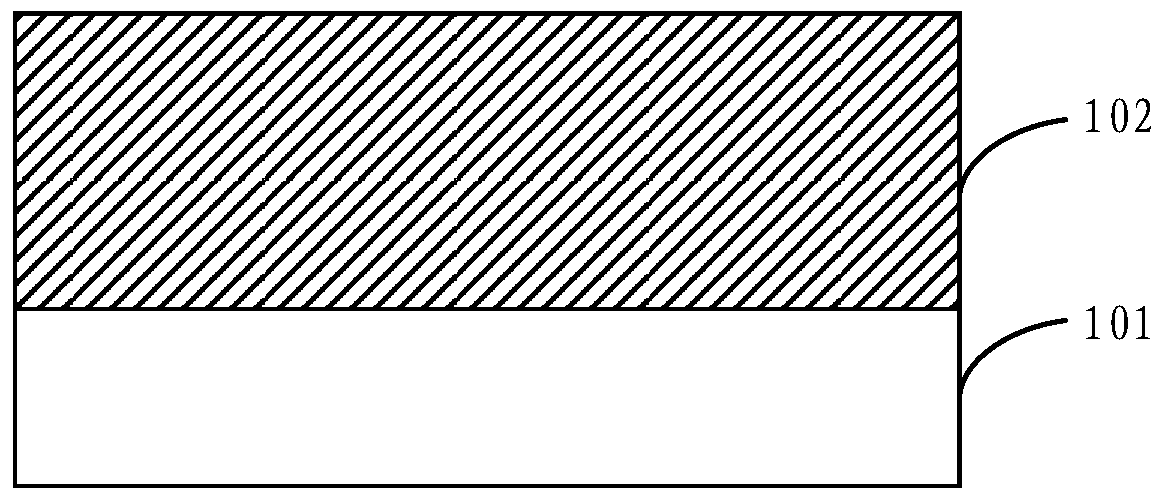

A kind of method of making finfet semiconductor device

ActiveCN104347413BSmall height changeAvoid Process VariabilitySemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringPartial filling

The invention relates to a method for manufacturing a FinFET semiconductor device. The method includes the following steps: providing a semiconductor substrate; forming a hard mask layer with a shallow groove pattern on the semiconductor substrate; etching the semiconductor substrate so as to form shallow grooves and fins between the shallow grooves; depositing a first oxide layer on the semiconductor substrate so as to fill the shallow grooves partly; depositing a groove stop layer on the first oxide layer; depositing a second oxide layer on the groove stop layer; executing a first flattening step and stopping at the groove stop layer at the tops of the fins; executing a second flattening step and stopping at the hard mask layer; and back-etching the second oxide layer in the shallow grooves so as to expose the groove stop layer in the shallow grooves. According to the method, the technology change of back-etching of the oxide layers can be well controlled.

Owner:SEMICON MFG INT (SHANGHAI) CORP

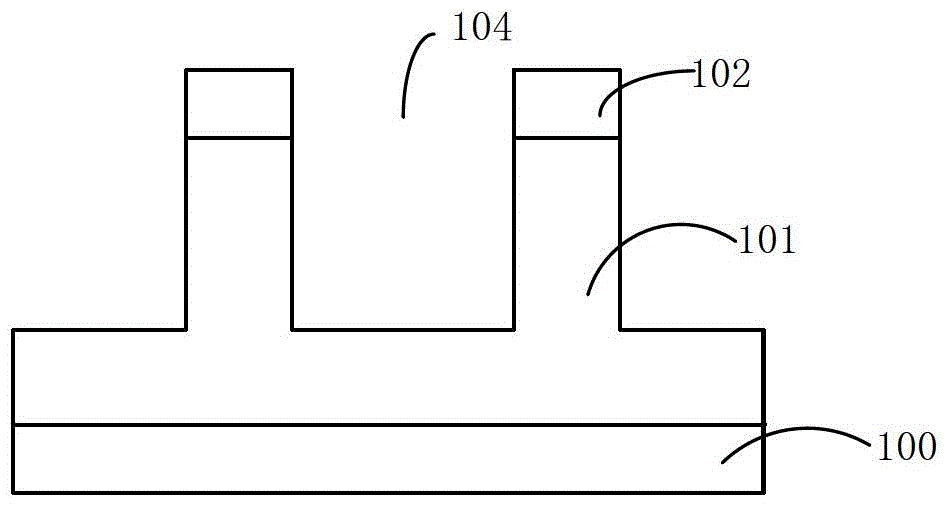

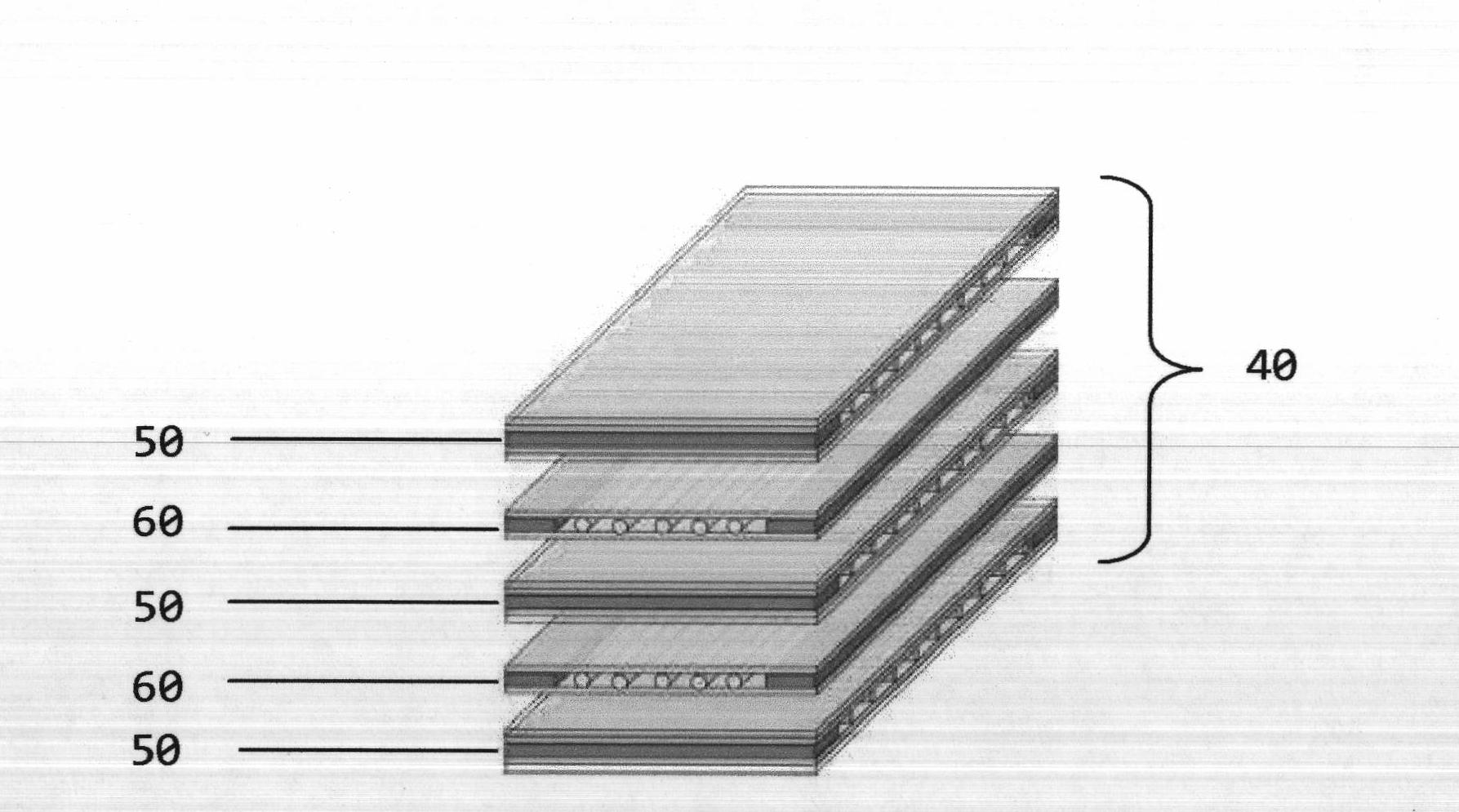

Water vapor transfer-separator plate arrangement

ActiveCN102610836AReduce configurationReduce the overall heightFinal product manufactureWater management in fuel cellsFuel cellsWater vapor

The arrangement (140) has separator plates (150, 160) defining a region of a wet-side flow channel (154). Water vapor transfer (WVT) membranes (170) are arranged on surfaces of the separator plates so that a region of a common, planar, dry-side flow channel (164) is formed between the transfer membranes. Edge strips are positioned between the membranes so that the dry-side flow channel region is formed. A thickness of the dry-side flow channel region is defined by the strips. An individual support e.g. thread, is positioned below the dry-side flow channel region. An independent claim is also included for a method for manufacturing a WVT arrangement. The thread is made of plastic, distributed adhesive or glass.

Owner:GM GLOBAL TECH OPERATIONS LLC

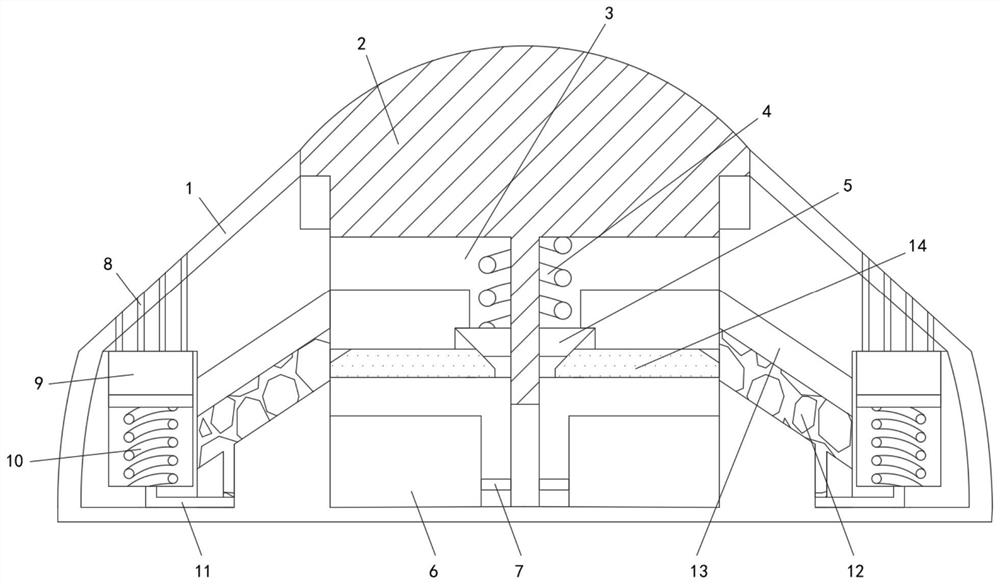

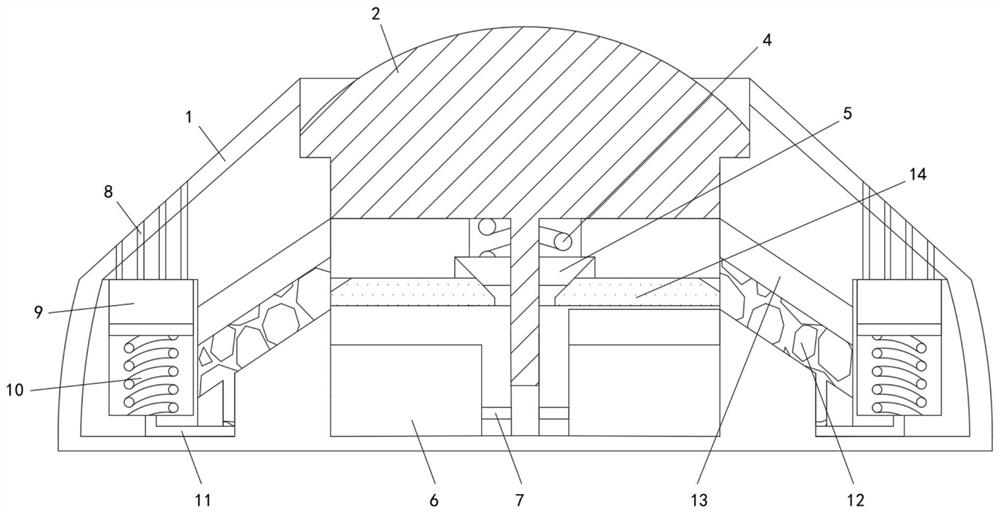

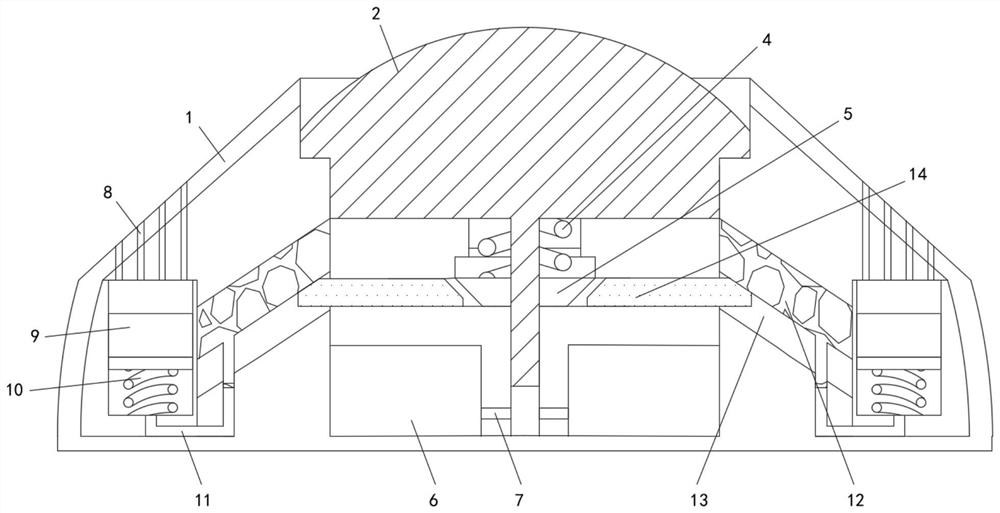

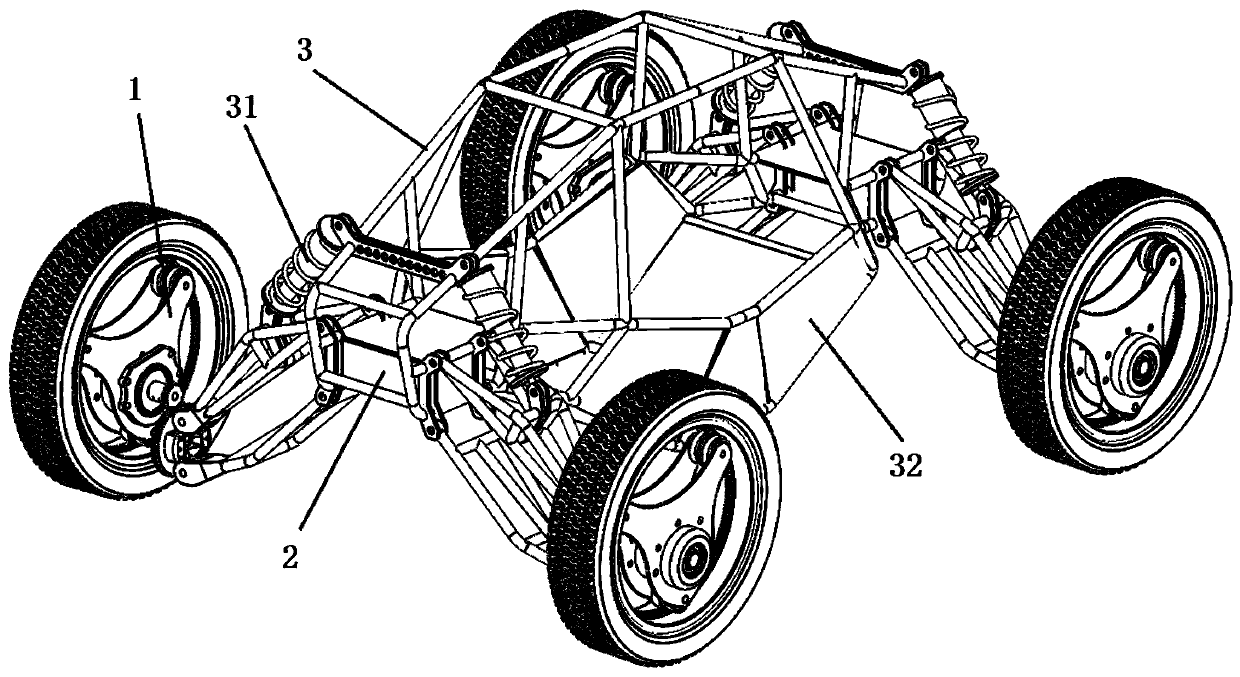

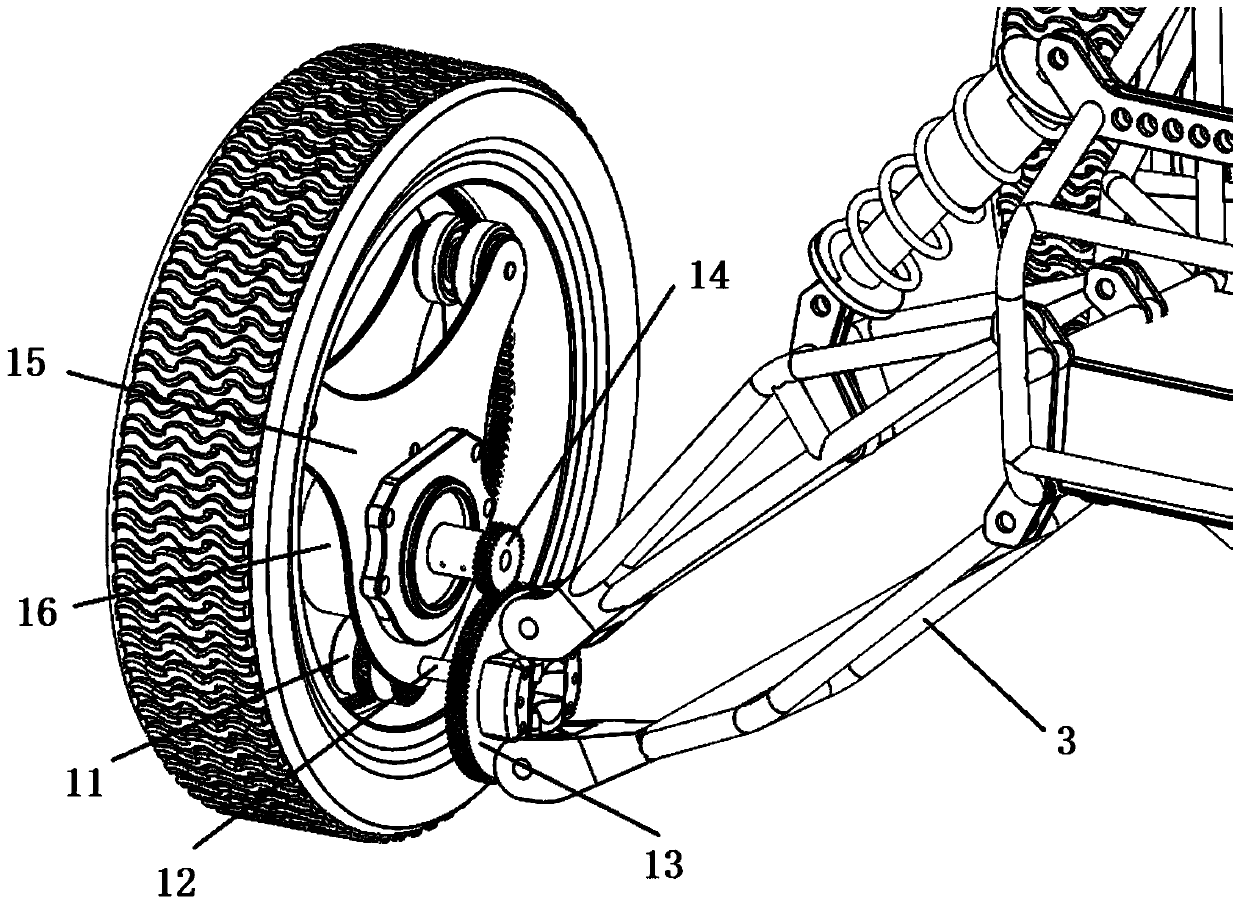

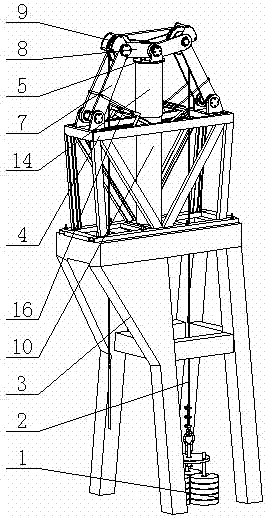

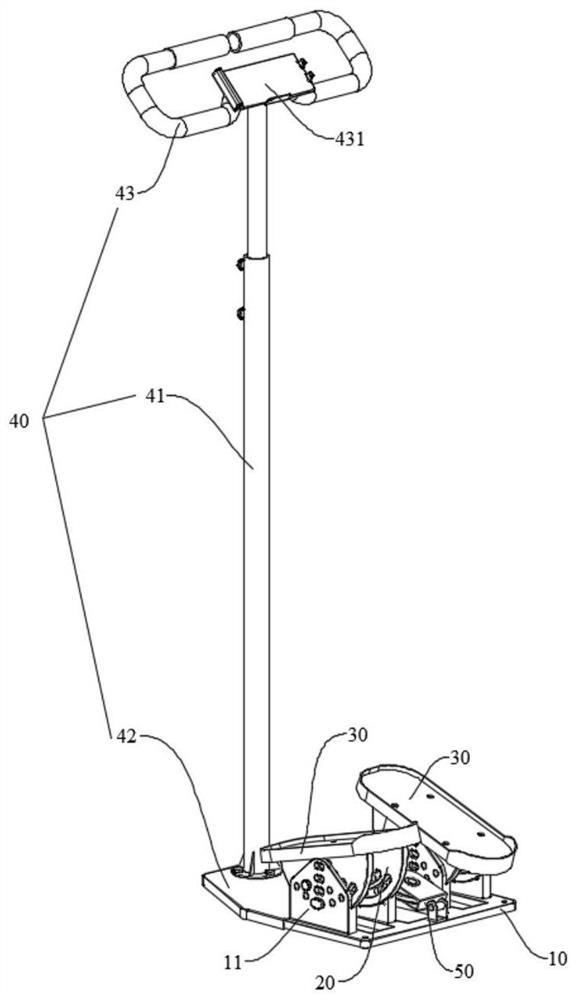

An automatic following obstacle-crossing vehicle

ActiveCN107380289BReduce the burden onDefy gravityPosition/course control in two dimensionsVehiclesGear wheelRoad surface

The invention provides an automatic-following obstacle crossing vehicle comprising at least one inner planet type compound gear train unit. Each inner planet type compound gear train unit comprises an inner gear ring, a main bearing wheel, and a power device. The inner gear rings are arranged on the inner surfaces of tires, and the inner gear rings and the tires rotate in the same speed; the main bearing wheels are provided with gears engaged with the inner gear rings coaxially and can slide around the inner surfaces of the tires in a rolling mode; the power devices are used for driving force transmitting mechanisms and transmitting the rotating force to the main bearing wheels and the gears; and the main bearing wheels and the gears are connected with exterior loads through pin shafts. The automatic-following obstacle crossing vehicle can effectively cross an obstacle with the loads, the requirement for the pavement condition in the carrying process is low, the load weight is high, and excellent performance is achieved.

Owner:玄智(深圳)科技有限公司

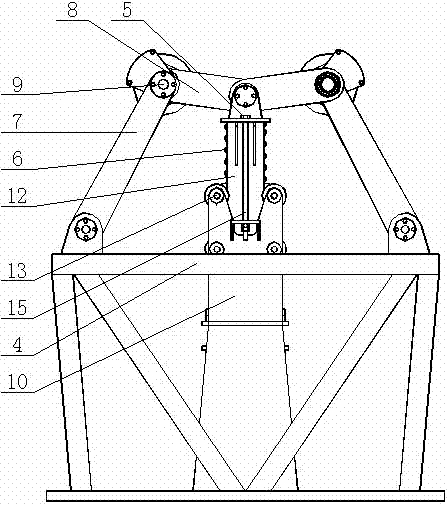

Gravity loading mechanism of high pressure extrusion mill

The invention discloses a gravity loading mechanism of a high pressure extrusion mill. The gravity loading mechanism comprises a heavy loading block, a wire rope connected with the heavy loading block, a bracket used for supporting the wire rope to suspend the heavy loading block, and a buffering device arranged on the top of the bracket, wherein the wire rope bypasses the buffering device to buffer the height change of the heavy loading block caused by retreat of the a buffering roller. The integral function of the gravity loading mechanism of high pressure extrusion mill disclosed by the invention is similar to that of a hydraulic loading mechanism of a high pressure double-roller extrusion mill in the prior art, however, the integral system damp of the gravity loading mechanism provided by the invention is smaller than that of the hydraulic loading mechanism, so that the response speed can be greatly improved.

Owner:铜陵迈臣机电科技有限责任公司

Copper interconnection structure, manufacturing method thereof, and electronic device

ActiveCN105489549BSmall height changeAvoid damageSemiconductor/solid-state device detailsSolid-state devicesCopper interconnectMoisture absorption

Owner:SEMICON MFG INT (SHANGHAI) CORP

A swinging spray gun and water jet equipment

The invention provides a swing spray gun and water jet equipment. The swing spray gun comprises a base, a bearing seat, a jet pipe and a third driving device, wherein the bearing seat is driven by a second driving device to rotate around a first axis relative to the base; the jet pipe is rotatably mounted on the bearing seat around a second axis, the top end of the jet pipe is connected with a high-pressure water source, and a nozzle located at the bottom of the jet pipe faces the layer to be treated; and third driving device is installed on the bearing seat, an eccentric structure is arrangedon an output shaft parallel to the second axis, an eccentric protrusion of the eccentric structure is hinged to a connecting rod, the other end of the connecting rod is hinged to the jet pipe, and the hinged position and the second axis position are arranged at intervals by a set distance to form a crank-rocker mechanism. According to the design, swing amplitude of the nozzle can be increased firstly, and then the working efficiency of the jet pipe during a single stroke can be increased; secondly, the same swing amplitude requires less driving force and prolongs the service life of the thirddriving device; and in addition, an injection pipe returns to the initial position in the non-working state without shaking, and the performance and reliability of the device are ensured.

Owner:CITIC HEAVY INDUSTRIES CO LTD

Tin alloy electroplating solution for solder bumps including perfluoroalkyl surfactant

ActiveUS9871010B2Improve flatnessSmall height changeSemiconductor/solid-state device detailsSolid-state devicesAlloyUnder bump metallurgy

Disclosed is a tin-based electroplating solution for forming solder bumps of a flip chip package. The tin-based electroplating solution includes tin methanesulfonate, silver methanesulfonate, methanesulfonic acid, a fluorinated surfactant, an aromatic polyoxyalkylene ether, and water. Also disclosed is a method for forming solder bumps by using the electroplating solution. The method includes (1) electroplating a silicon wafer having a protective layer through which an electrode pad is exposed and an under bump metallurgy (UBM) layer with a copper or copper / nickel plating solution to form copper or copper / nickel pillars on the under bump metallurgy layer and (2) electroplating the pillars with the tin-based electroplating solution to form solder bumps.

Owner:APCT

Self-resetting friction damping shock absorber and shock absorbing bridge

ActiveCN107268431BGuaranteed normal functioningExtend the basic natural vibration periodBridge structural detailsEngineeringSurface plate

Owner:SICHUAN UNIV

Tendon pulling plate for ankle pump movement

PendingCN114849149ASmall height changeSmooth experienceMuscle exercising devicesMovement coordination devicesMuscle strainsEngineering

The invention provides an ankle pump movement tendon stretching plate which comprises a base, auxiliary supporting pieces are arranged on the two sides of the base, and an arc groove is formed in each auxiliary supporting piece; the arc surfaces of the cylindrical surface supporting pieces are in relative sliding connection with the arc grooves in the auxiliary supporting pieces; and the two pedals are fixedly connected with the two cylindrical surface supporting pieces correspondingly, and the rotation centers of the pedals are located in the middle positions of the pedals. According to the muscle and ligament state of a user, the muscle stretching angle can be automatically adjusted, the situation that the muscle stretching angle of the user is too large, and consequently the muscle is pulled is avoided, and the functions that the muscle stretching angle is controllable, muscle stretching is conducted on the two legs respectively, and ankle pump movement is conducted are achieved.

Owner:合肥辩日医疗科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com