Self-resetting friction damping shock absorber and shock absorbing bridge

A technology of frictional damping and shock-absorbing bearings, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problems of affecting driving safety, large structure size, and high cost, so as to improve the level of energy consumption and reset energy, and extend the self- The effect of vibration period and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

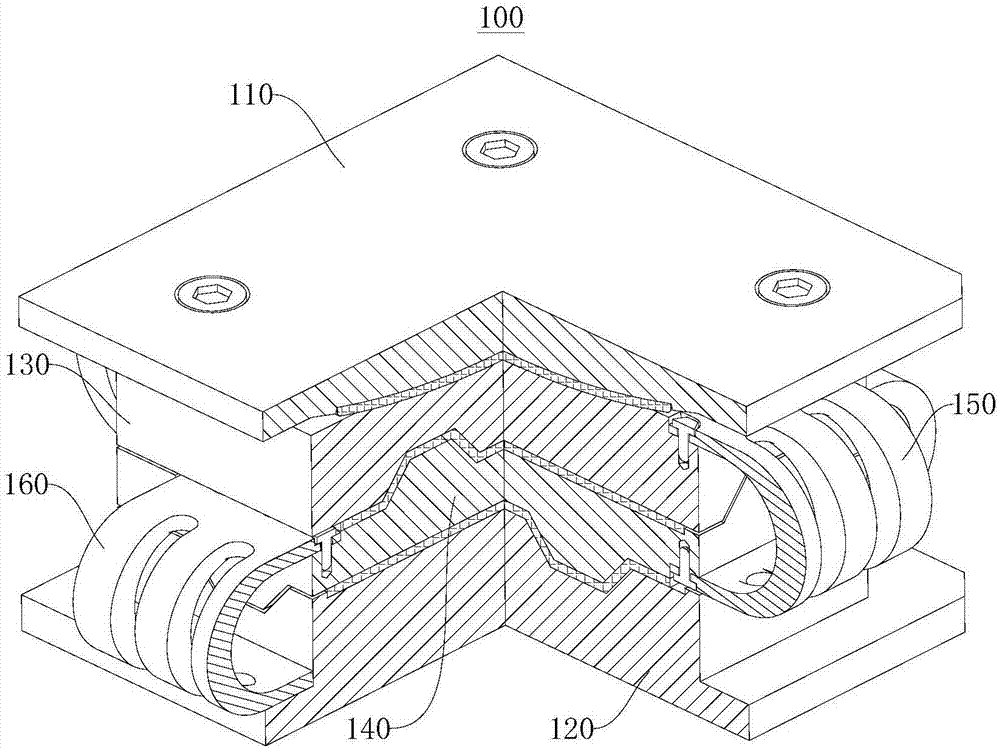

[0038] see figure 1 and figure 2 , the present embodiment provides a self-resetting frictional damping shock-absorbing support 100, which has a simple structure and can effectively improve horizontal energy consumption and reset capability without affecting the overall mechanical structure of the bridge.

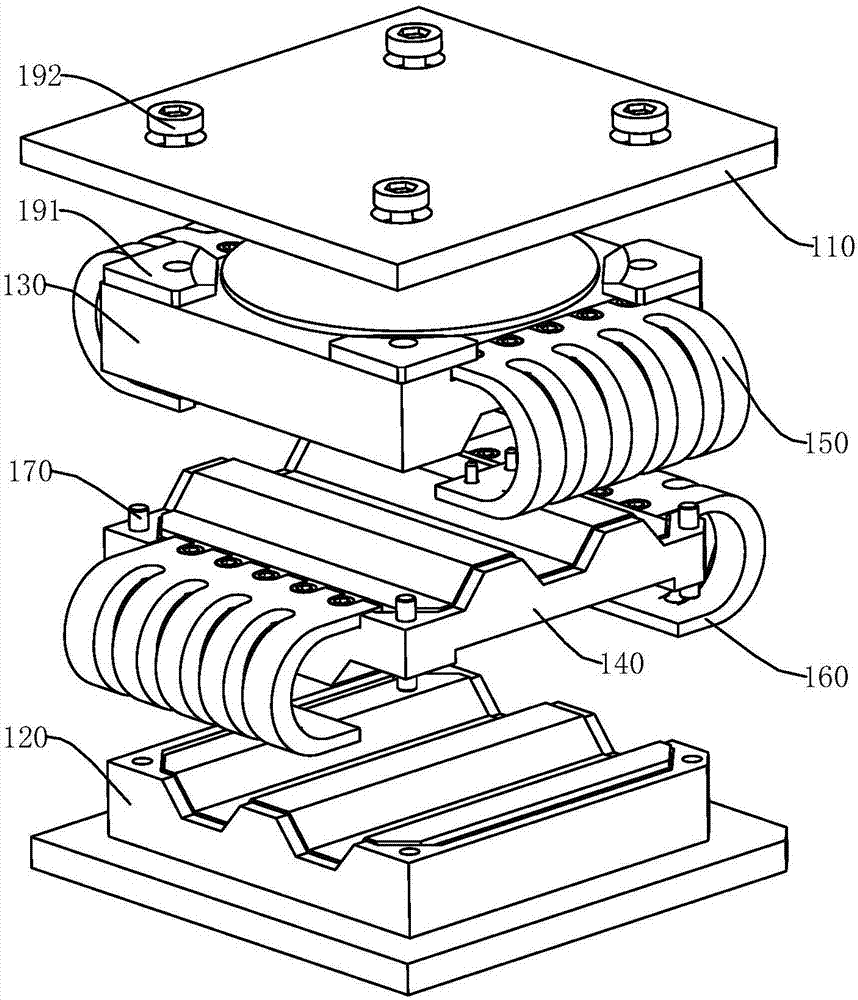

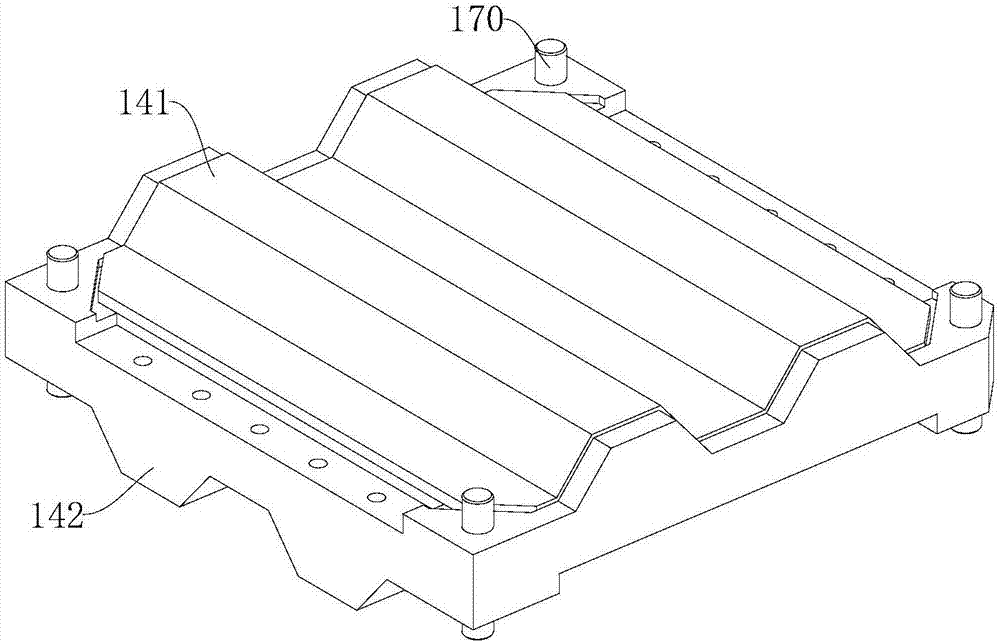

[0039] The self-resetting friction damping shock absorber 100 provided in this embodiment includes a first seat plate 110, a second seat plate 120, a support panel 130, a friction member 140, a first shock absorber 150 and a second shock absorber 160 . The first support plate 110 is connected to the support panel 130, and the two ends of the friction member 140 are respectively connected to the end of the support panel 130 away from the first support plate 110 and the second support plate 120, and the friction member 140 can be opposite to the support panel 130 and the second seat plate 120 to slide. One end of the first shock absorber 150 is connected to the friction me...

no. 2 example

[0068] This embodiment provides a shock-absorbing bridge (not shown in the figure), including a bridge body (not shown in the figure), a pier column (not shown in the figure), and the self-resetting frictional damping shock-absorbing bearing 100 provided in the first embodiment. The self-resetting frictional damping shock absorber 100 includes a first seat plate 110 , a second seat plate 120 , a support panel 130 , a friction member 140 , a first shock absorber 150 and a second shock absorber 160 . The first support plate 110 is connected to the support panel 130, and the two ends of the friction member 140 are respectively connected to the end of the support panel 130 away from the first support plate 110 and the second support plate 120, and the friction member 140 can be opposite to the support panel 130 and the second seat plate 120 to slide. One end of the first shock absorber 150 is connected to the friction member 140 , and the other end of the first shock absorber 150 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com