High reflective object surface light field deflection technique measuring system and method

A technology of object surface and measurement system, applied in measurement devices, optical devices, instruments, etc., can solve problems such as reducing measurement accuracy, solving 'non-unique normals, increasing guide rail motion errors, etc., to achieve convenient and convenient light field decoding. Light recognition, high computational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

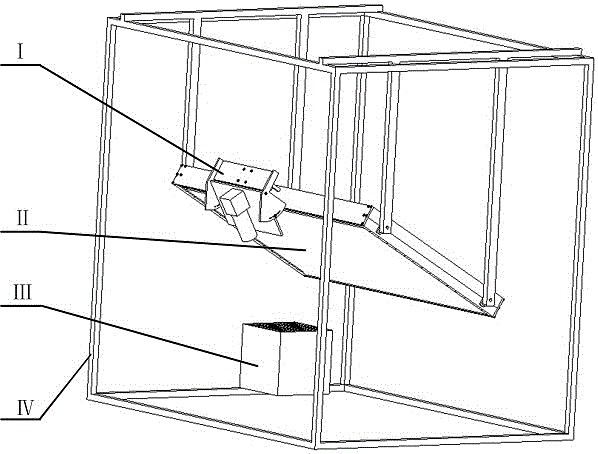

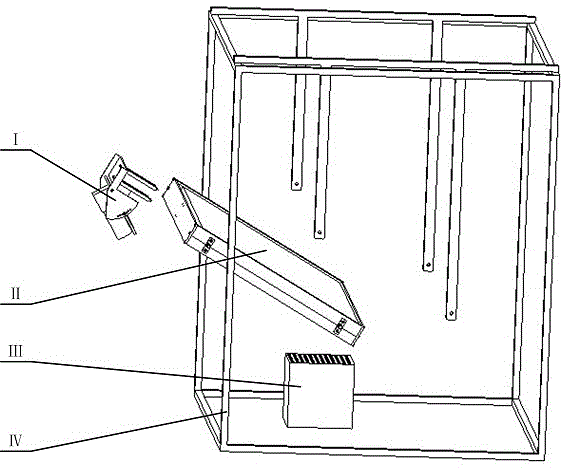

[0034] 1. See Figure 1~Figure 6 , the light field deflection measurement system for the surface of highly reflective objects, including light field projection system II, light perception system I, outer frame IV and object to be measured III; the light field perception system I is supported by one of the camera angle adjustment plates 5 threaded connections are fixed on a dual-display connection upper cover 12 in the light field projection system II; the light field projection system II is fixed on the outer frame IV through 4 connecting pieces 6 threaded connections; the object to be measured III is placed In the light field perception system I, the area where the field of view of camera 1 intersects with the projection area of the light field projection system II.

Embodiment 2

[0035] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the special features are as follows:

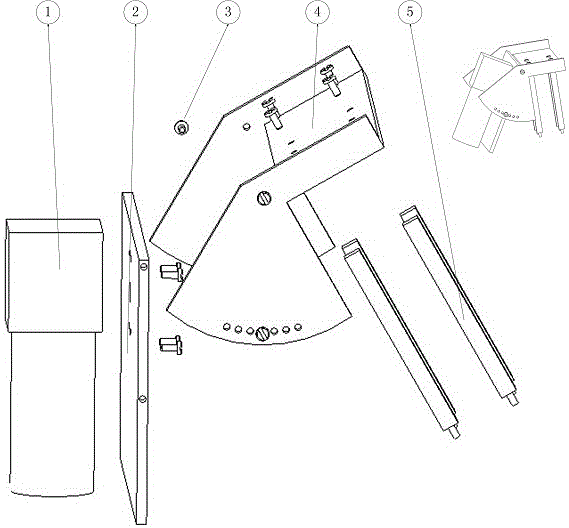

[0036] The light field sensing system I has an ordinary camera or a light field camera 1 with a small aperture, the camera 1 is fixed on the camera support plate 2 by screws 3, and the camera support plate 2 is fixed on the camera by screws 3 On the angle adjustment plate 4, the camera angle adjustment plate 4 is fixed on the camera angle adjustment plate support 5 through the screw 3; the light field projected by the light field projection system II is obtained by shooting the light reflected from the surface of the object III to be measured by the camera 1.

[0037]The light field projection system II: a front display 9 is inserted in a front display left card slot 7 and a front display right card slot 13, and the two card slots 9 and 13 are fixed on a dual display connection by screws 3 The cover plate 12 and a dual display are connected on the lower cover ...

Embodiment 3

[0042] see Figure 7~Figure 9 , the highly reflective object surface light field deflection measurement system and method, using the above system to operate, is characterized in that the operation steps are as follows: First, the projection light field is coded by a time-sharing method, the front display shows the modulated image, and the rear display is all white and highlighted, The camera shoots the pattern reflected by the object to be measured, and the phase information of the surface of the object to be measured is obtained by phase recovery for the pattern captured by the camera. The rear display displays the modulated image, and the front display is all white and highlighted. The camera shoots the reflected pattern of the object to be measured. The phase information of the surface of the object to be measured is obtained by phase recovery for the pattern captured by the camera; secondly, the phase information of the surface of the object to be measured obtained by two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com