An automatic following obstacle-crossing vehicle

An automatic following and obstacle technology, applied in the direction of motor vehicles, non-electric variable control, vehicle position/route/height control, etc., can solve the problem of stable obstacle-crossing performance, poor carrying capacity, high requirements on the road surface environment, and the inability to realize automatic handling, etc. problems, to achieve good obstacle-surpassing performance and carrying stability, low requirements on road conditions, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Such as figure 1 As shown, the present invention provides an auto-following obstacle-crossing vehicle, which is used to automatically follow a target to move under multiple road conditions, and includes at least one inner planetary compound gear train unit 1, and the inner planetary compound gear train unit 1 It is used to walk and jump over obstacles when encountering obstacles.

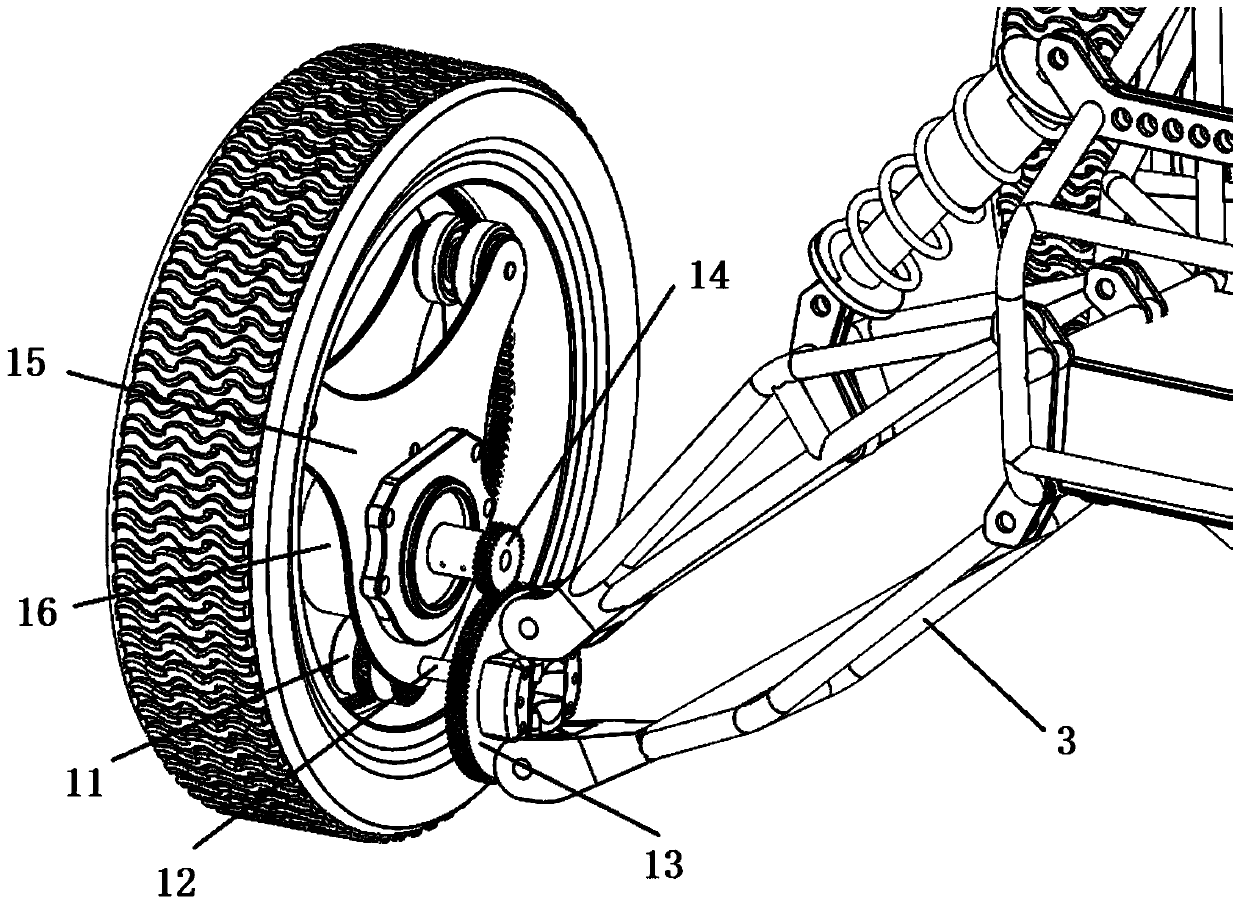

[0031] Combine Figure 2 to Figure 6 As shown, the inner planetary compound gear train unit 1 includes:

[0032] A ring gear 18, which is arranged on the inner surface of a tire 19 and rotates at the same speed as the tire 19;

[0033] A main bearing wheel 11, the main bearing wheel 11 is coaxially provided with a gear 111 meshing with the ring gear, the main bearing wheel 11 rotates at the same speed as the gear 111, and the main bearing wheel 11 can Rolling and sliding around the inner surface 191 of the tire 19, while at the same time, the gear 111 rotates relative to the ring gear 18;

[0034] A...

Embodiment 2

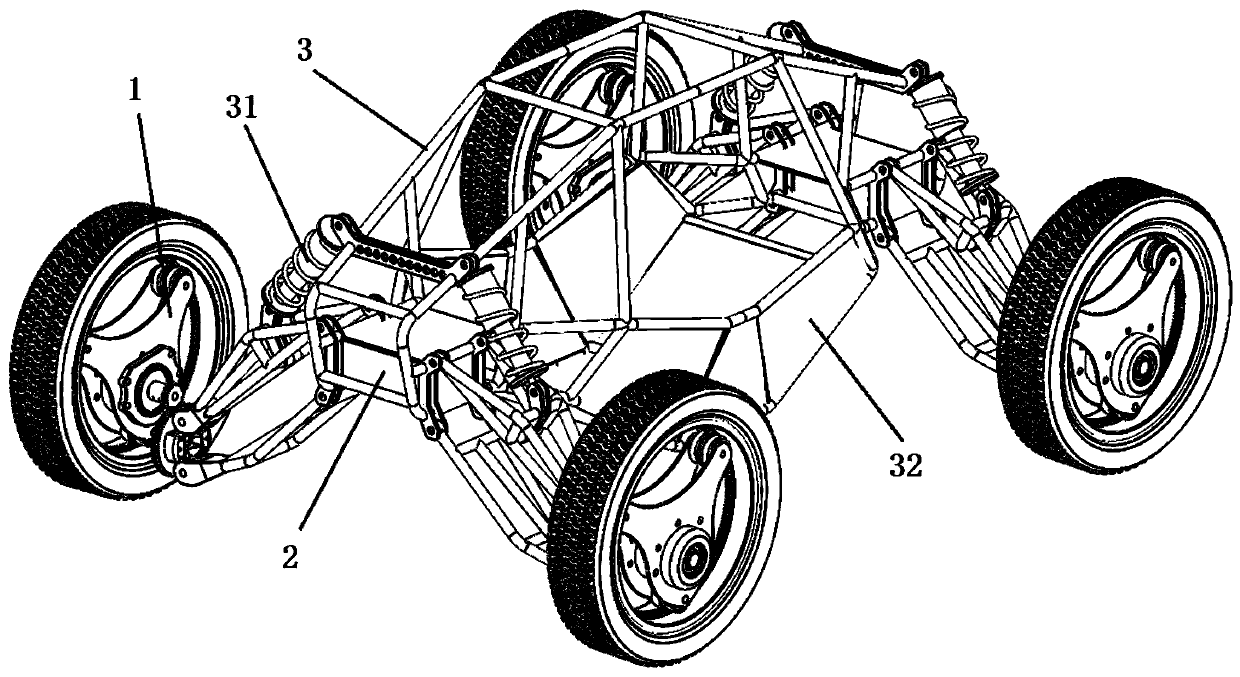

[0044] As with the auto-following obstacle-crossing vehicle described above, this embodiment differs from it in that the auto-following obstacle-crossing vehicle further includes a frame 3, and the frame 3 is connected with four sets of the inner planetary composite The wheel train unit 1, four groups of the inner planetary compound wheel train unit 1 are respectively placed at the four corners of the frame 3, thereby forming a basic vehicle structure.

[0045] Preferably, the frame 3 is provided with a shelf 32, and the shelf 32 can carry goods.

[0046] Preferably, the frame 3 is provided with a suspension device 31, and the suspension device 31 acts as a shock absorber for the shelf 32 to reduce the bumps of the goods.

[0047] Preferably, the four groups of the inner planetary compound gear train units 1 are independently driven and the suspension device 31 is respectively installed.

[0048] Preferably, the external load includes the frame 3, the shelf 32 and goods.

Embodiment 3

[0050] As mentioned above, the automatic following obstacle-crossing vehicle is different from this embodiment in that it combines Figure 7a to Figure 7f As shown, the automatic following obstacle crossing vehicle can realize the obstacle crossing function. Take climbing stairs as an example, the specific climbing process is as follows:

[0051] Such as Figure 7a As shown, when on flat ground, due to the gravity effect of the external load, the main bearing wheels 11 and the gears 111 of the four sets of the inner planetary compound gear train unit 1 are located on the inner surface 191 of the tire 19 The line connecting the center of the main bearing wheel 11 and the center of the tire 19 is approximately perpendicular to the ground;

[0052] Such as Figure 7b As shown, when the two groups of the inner planetary compound gear train unit 1 at the front encounter an obstacle, the tire 19 stops rotating, and then the ring gear 18 stops rotating. In this case, the The gear 111 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com