Magnetic sensor

A technology of magnetic sensors and magnetoresistive effect elements, applied in the field of magnetic sensors, can solve problems such as difficulty in obtaining sensor characteristics, complicated manufacturing process, and rising manufacturing costs, and achieve the goals of easy manufacturing process, high-precision sensor characteristics, and reduced manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

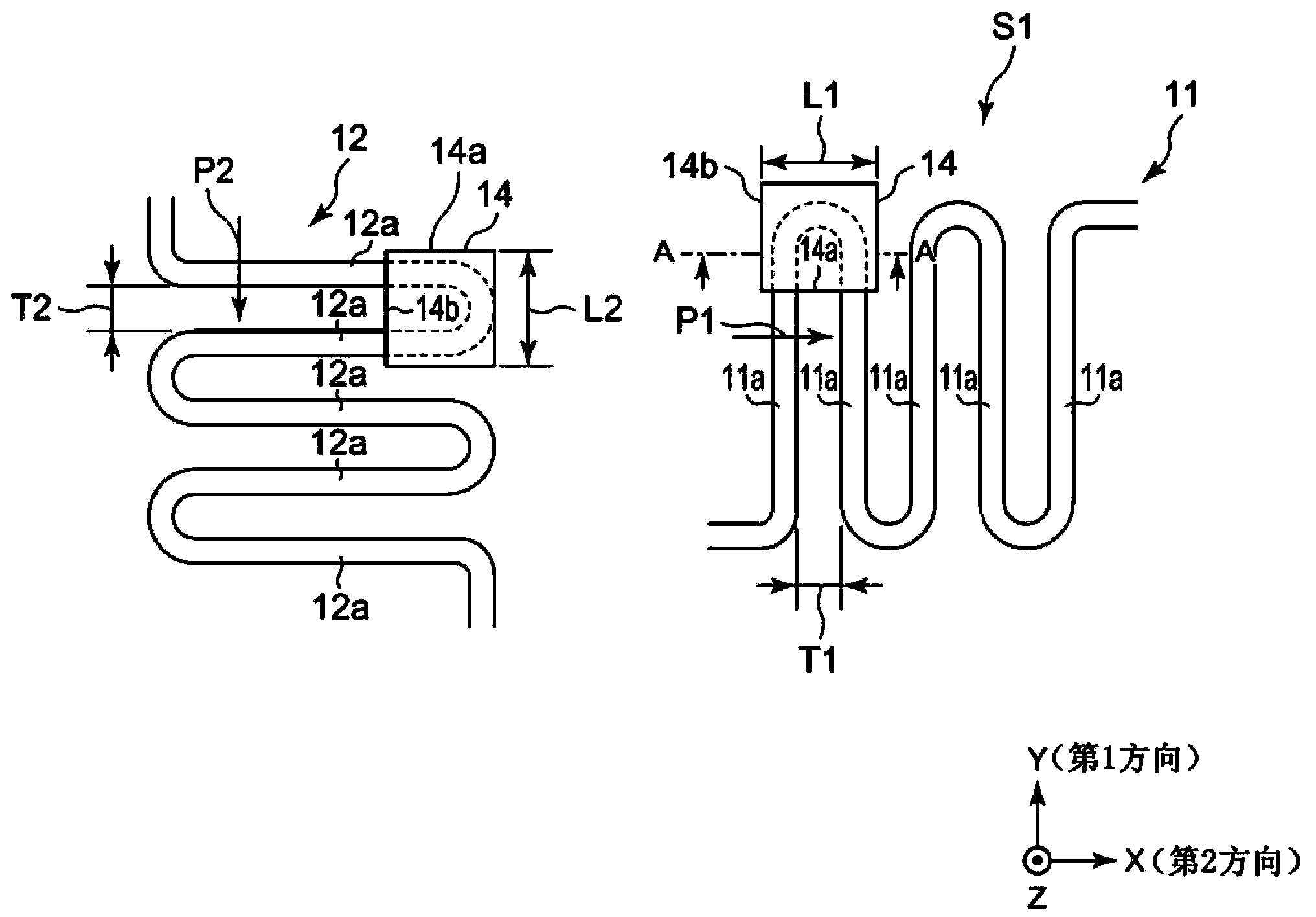

[0037] figure 1 It is a plan view showing an example of a first element and a second element mounted in the magnetic sensor of the first embodiment.

[0038] here, in figure 1 In the first embodiment shown, the Y direction is defined as a first direction, and the X direction perpendicular to the Y direction is defined as a second direction. The X direction and the Y direction represent two directions orthogonal to each other in a plane. On the other hand, the Z direction represents a height direction (thickness direction) perpendicular to both of the X direction and the Y direction.

[0039] In the magnetic sensor S1, a plurality of meander elements 11, 12 are formed on the same substrate.

[0040] The meander element 11 is a first element, and is sometimes referred to as a first element 11 hereinafter. In addition, the meander element 12 is a second element, and may be referred to as a second element 12 hereinafter.

[0041] Such as figure 1 As shown, the first element ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com