Concentrically-split-type stator and stator winding centralized assembling method

A stator winding and split technology is applied in the field of concentric split stator and stator winding centralized assembly method, which can solve problems such as large labor costs, achieve high work efficiency, reduce material costs, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further described below in conjunction with accompanying drawing.

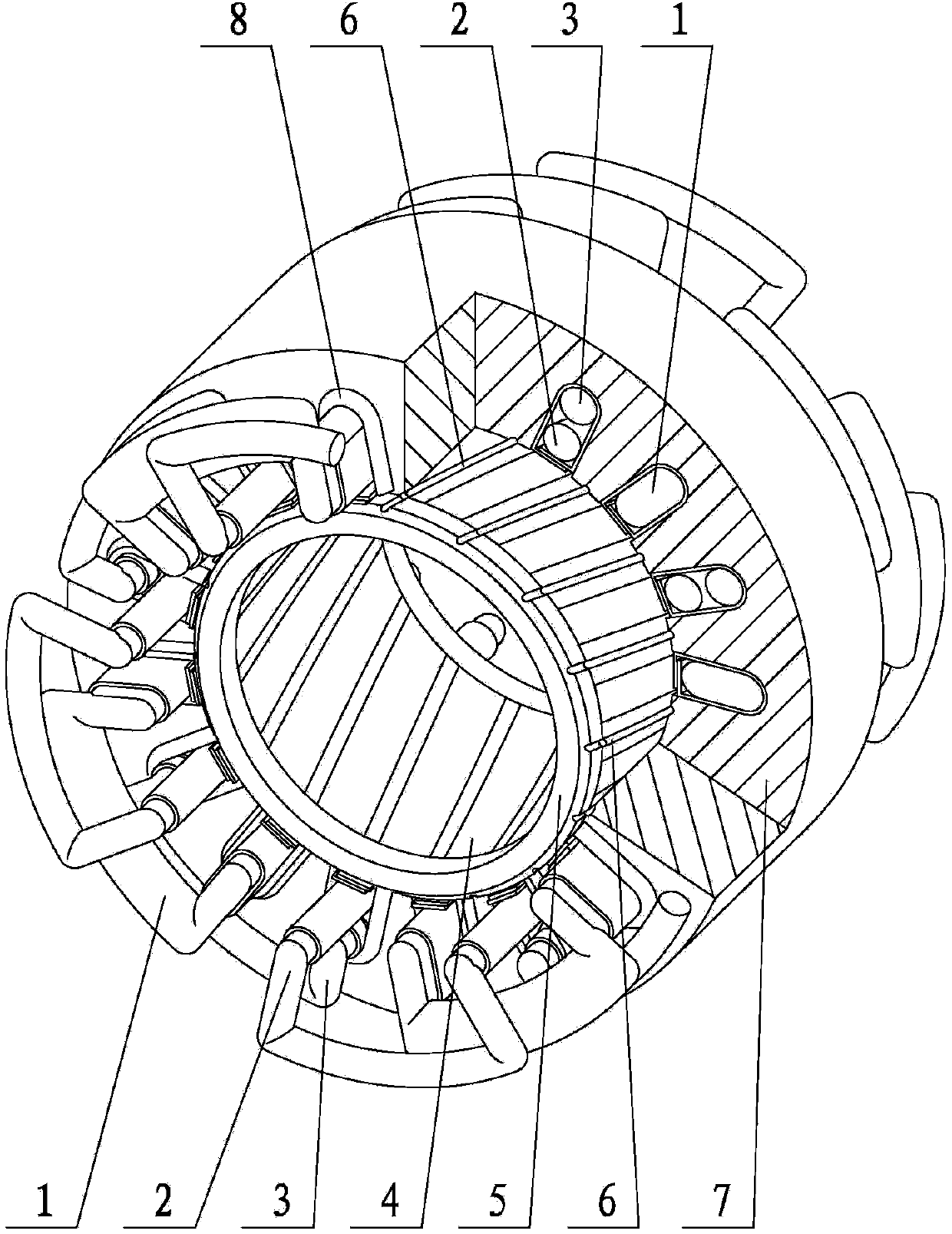

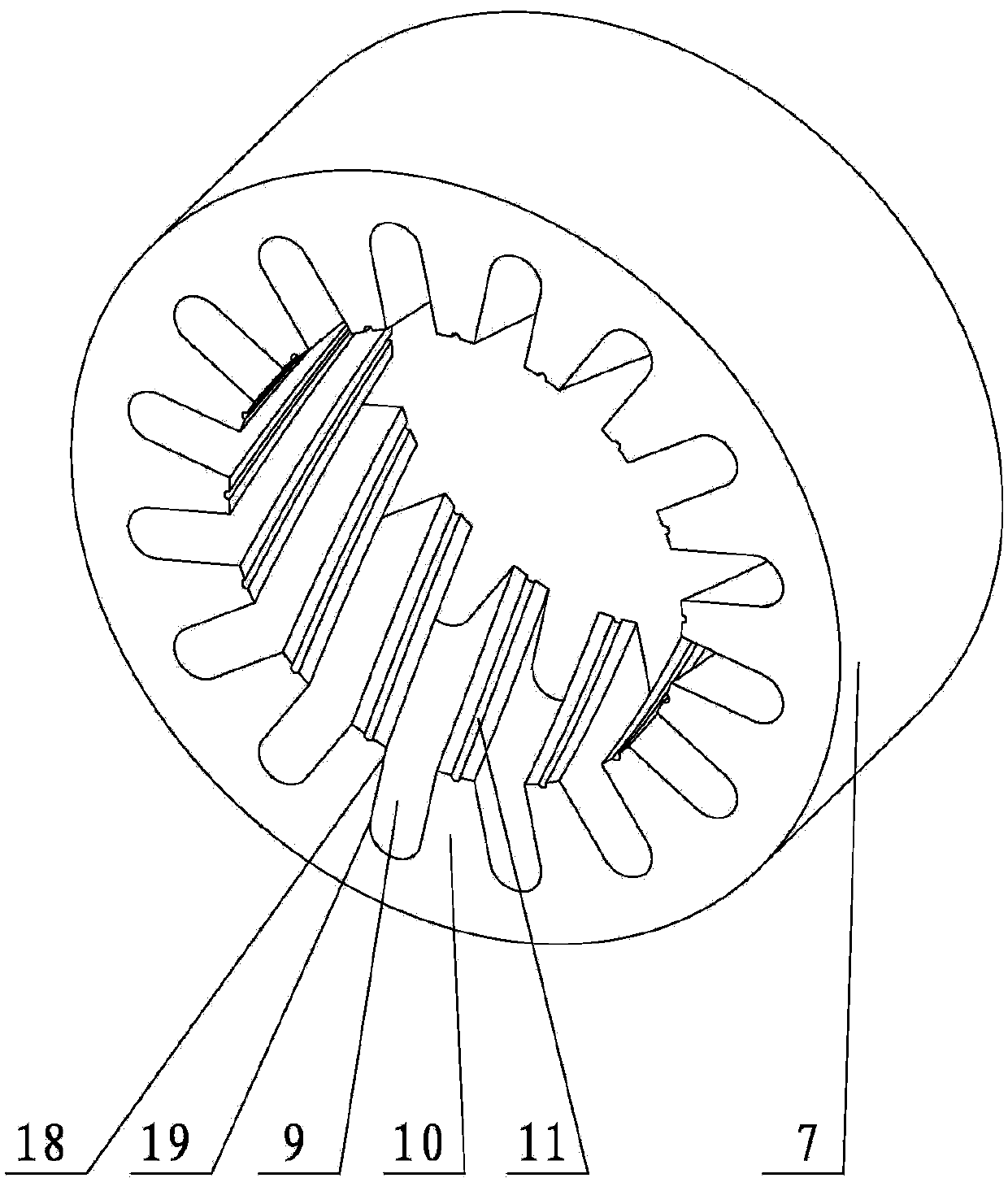

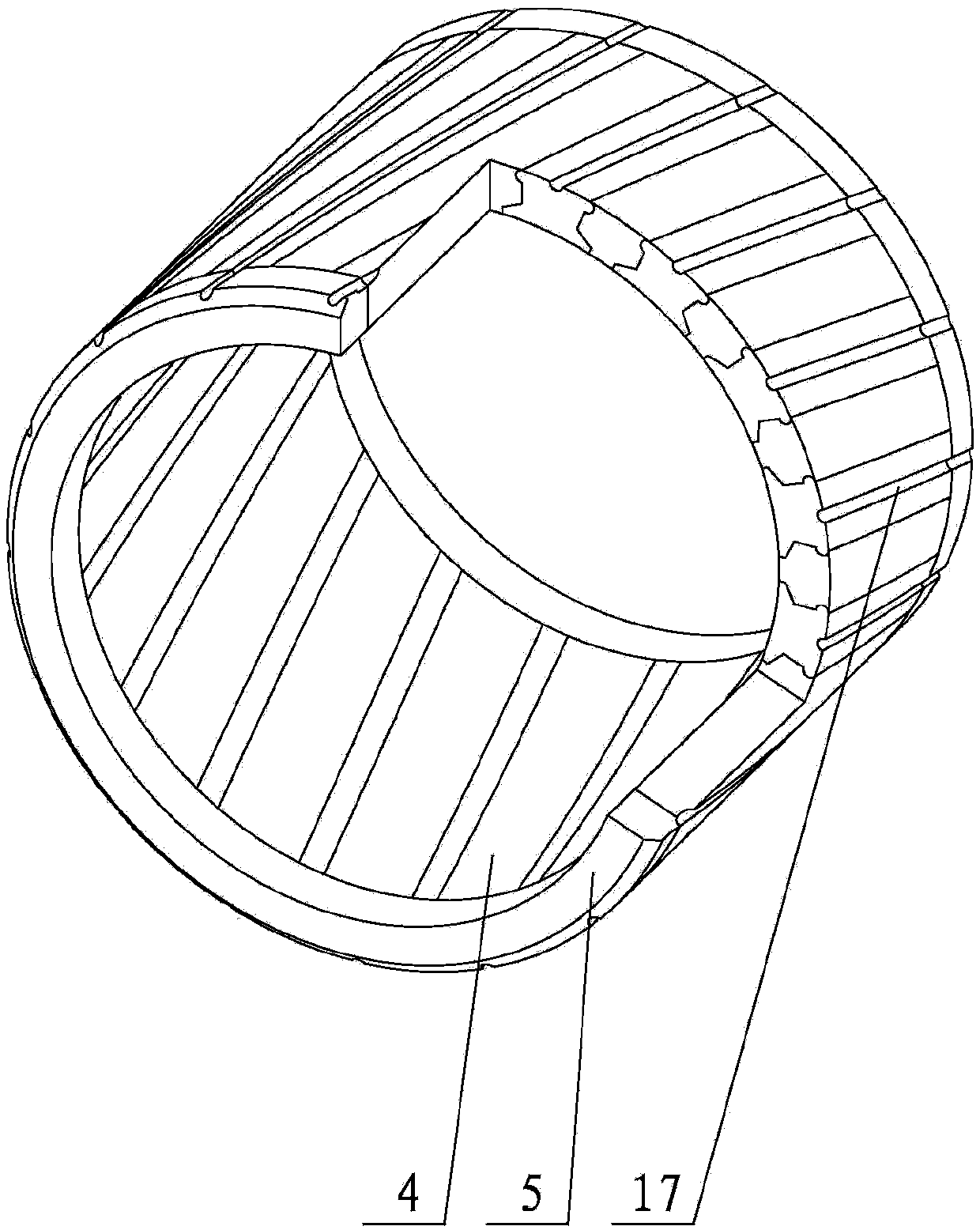

[0030] refer to figure 1 , The concentric split stator is composed of the main stator core 7, the slot insulation pad 8, the stator winding components, the notch core components, and the positioning pin 6. The stator winding components are installed in the main stator core 7, the slot insulation pad 8 is between the stator winding components and the main stator core 7, the slotted core components are installed in the main stator core 7, and the slotted core components are connected to the main stator core 7. Positioning pins 6 are used to fix the stator cores 7 .

[0031] The concentric split stator and stator winding centralized assembly method divides the hidden pole stator core into concentric main stator core 7 and slot core parts along the radial direction. When assembling the concentrically divided stator, the stator winding components are first installed by the centrali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com