Coating sheet yarn winder

A coating sheet and winding machine technology, applied in the textile field, can solve the problems of not being able to adapt to the industrialization of coating sheets and yarns, different structural principles of process routes, and affecting high-speed continuous winding, etc., to achieve compact structure, small footprint, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

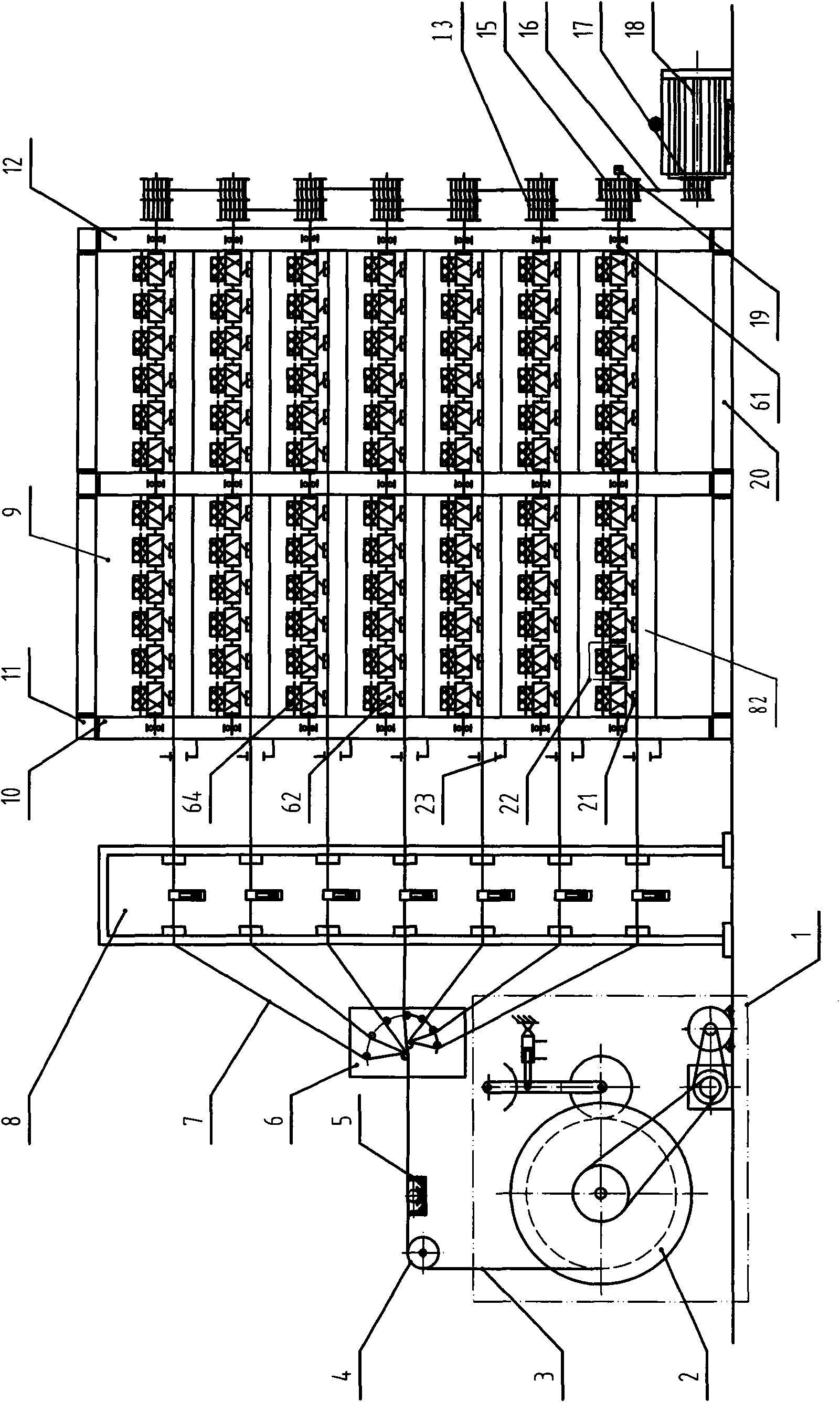

[0033] Describe the present invention in detail below in conjunction with accompanying drawing:

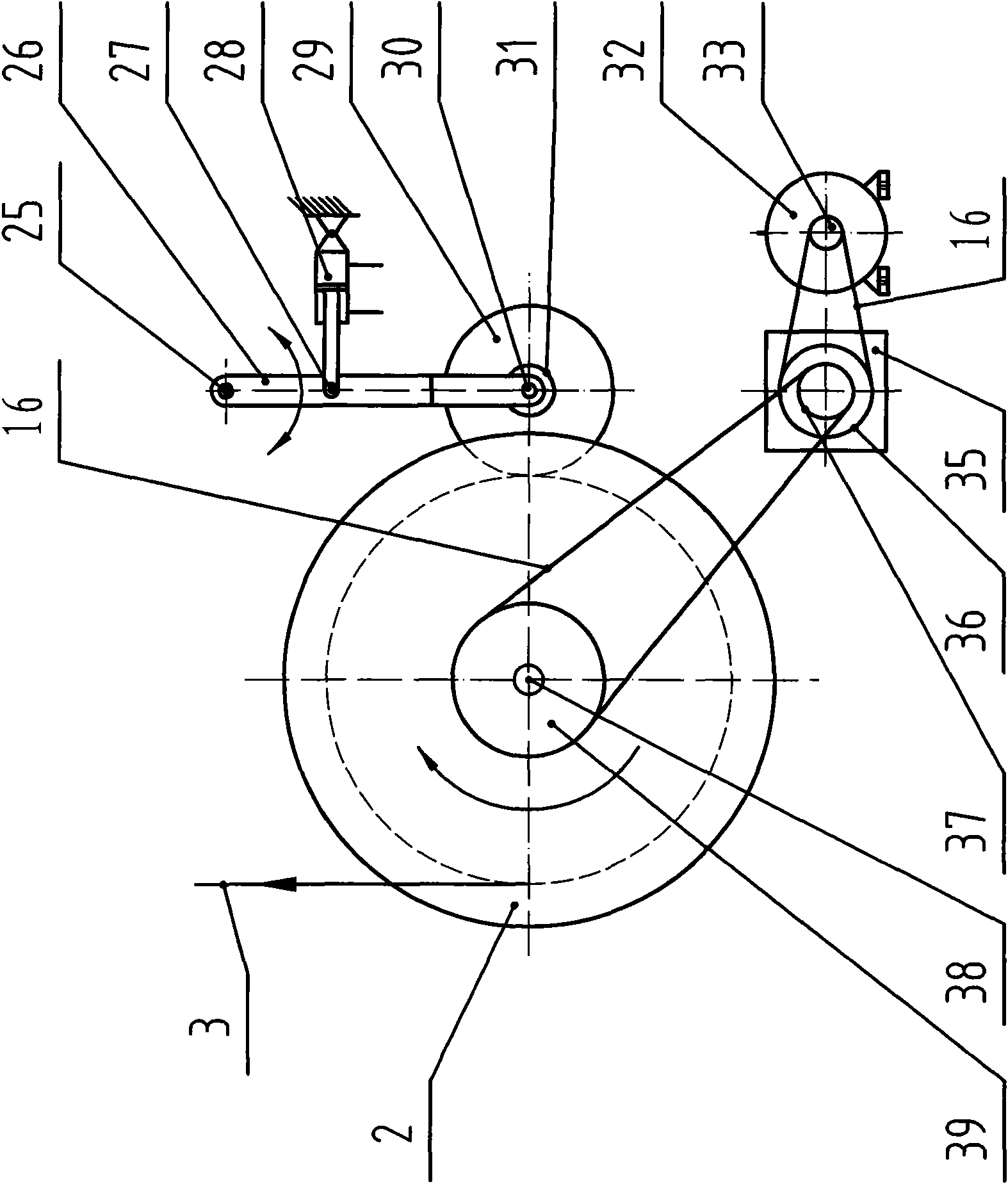

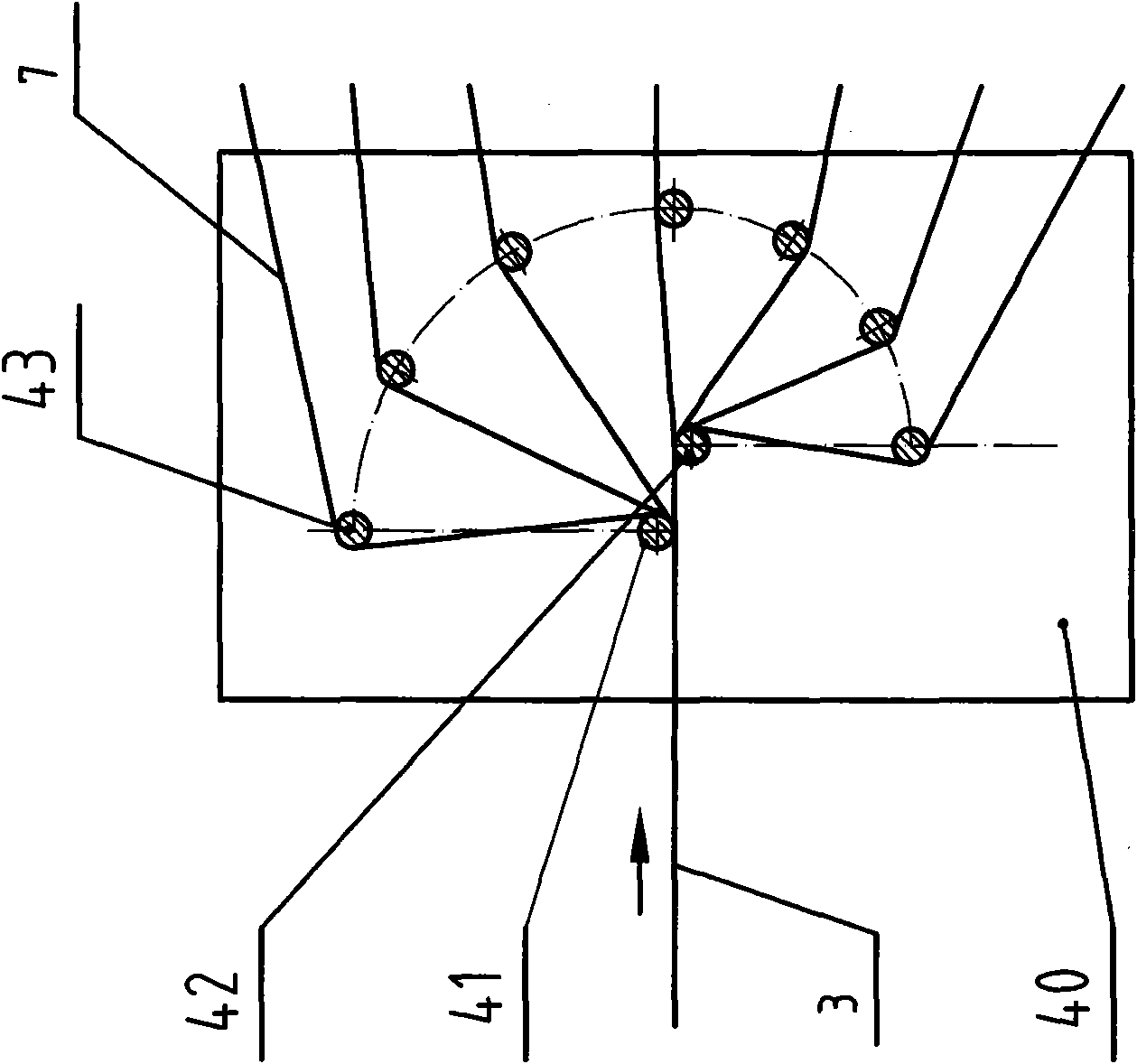

[0034] like figure 1 As shown, this machine includes a pneumatic control system and an electrical control system; the unwinding motor 32, the motor pulley 33 are connected with the input pulley 36 on the speed reducer 35 through the transmission belt 16, after the speed reducer 35 decelerates, the speed reducer 35 The output pulley 37 drives the pan head transmission shaft pulley 39 on the pan head transmission shaft 38 to rotate, so that the pan head 2 runs; the guide roller 4, the waxing and oiling device 5, the winding part 9; the winding part 9 The winder frame composed of the front wall board 10, the horizontal connecting beam 11, the upper and lower connecting beams 20, and the rear wall board 12 is equipped with several grooved cylinder drive shafts 61 on the winder frame, and on each grooved cylinder drive shaft 61 It is also equipped with several single yarn winding mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com