Wire rope automatic length specification winding equipment

A steel wire rope and sizing technology, which is used in the transportation of filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of high labor intensity, low work efficiency, and difficult to control the sizing error, and achieves low requirements for operating skills. , The effect of low labor intensity and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

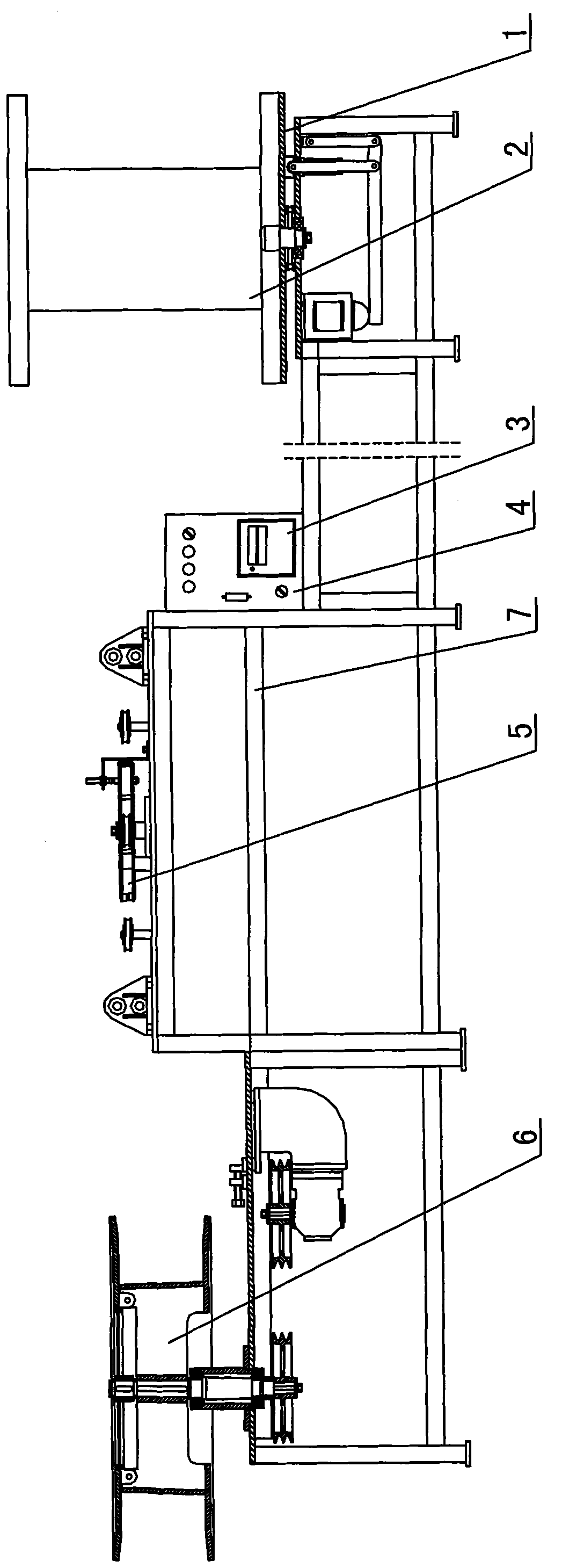

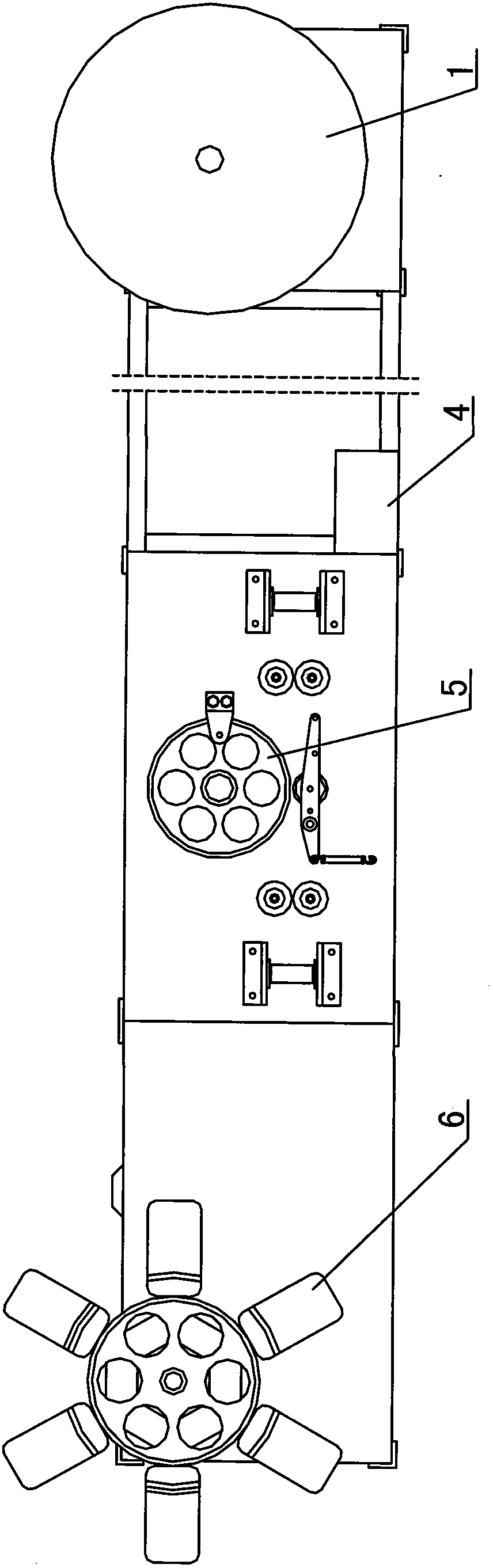

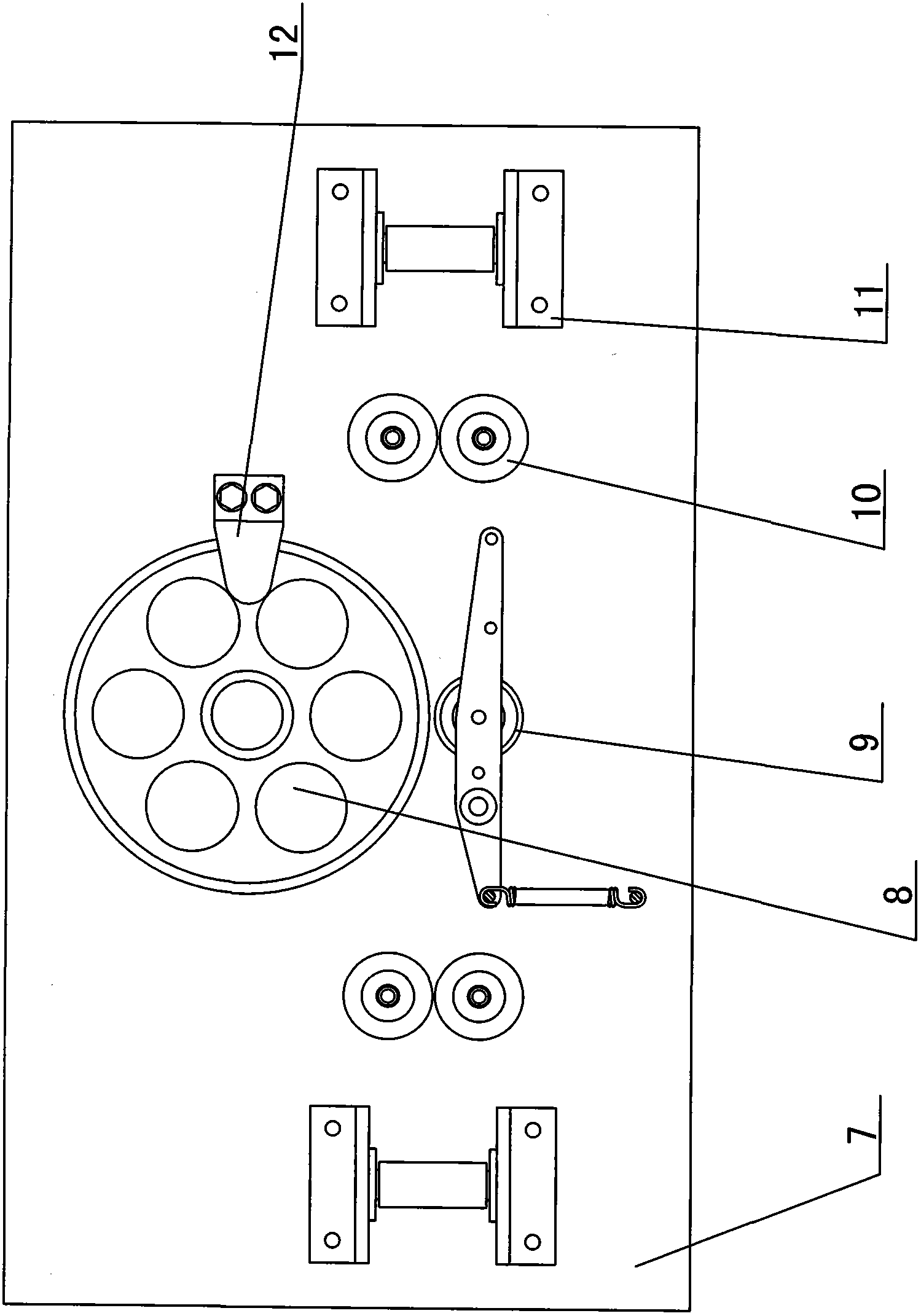

[0013] Such as Figure 1-3 As shown, the steel wire rope automatic fixed-length winding equipment according to the present invention includes a cable unwinding tray assembly 1, a fixed-length detection mechanism 5, a power winding assembly 6, and an electrical control system 4. The upper part of the cable unwinding tray assembly 1 supports Large steel wire rope reel 2, under the traction of the steel wire rope wound by power, the large reel 2 rotates on the cable unloading tray assembly 1 and releases the steel wire rope; the detection platform 7 is provided with a fixed-length detection mechanism 5 for detection The length of the steel wire rope that is coiled, the electrical control system 4 is installed on the outside of the detection stand 7 and is equipped with an electronic counter 3, and the length of the steel wire rope to be coiled by the equipment is set by the electronic counter 3. Described length detection mechanism 5 is made up of meter counting wheel group 8, pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com