Building roofing stainless steel rail lightning protection construction method based on attached type support

A construction method, stainless steel technology, applied in the direction of railings, buildings, roofs, etc., can solve the problems that the welding quality of down conductors and stainless steel railings is difficult to meet the requirements, affects the overall electrical conductivity of the lightning protection device, and the welding quality is difficult to meet the quality requirements. Achieve the effects of simple processing, production, installation and layout, high practical value and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

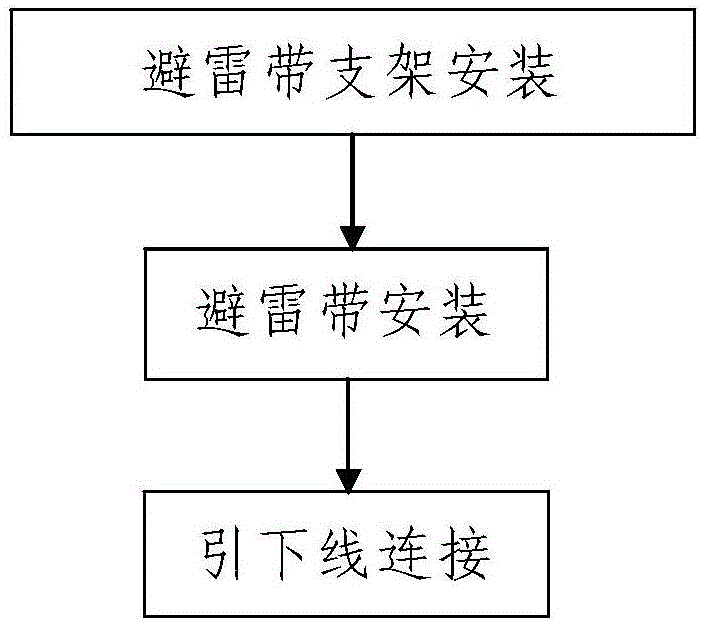

[0047] Such as figure 1 A lightning protection construction method for building roof stainless steel railings based on an attached bracket is shown, including the following steps:

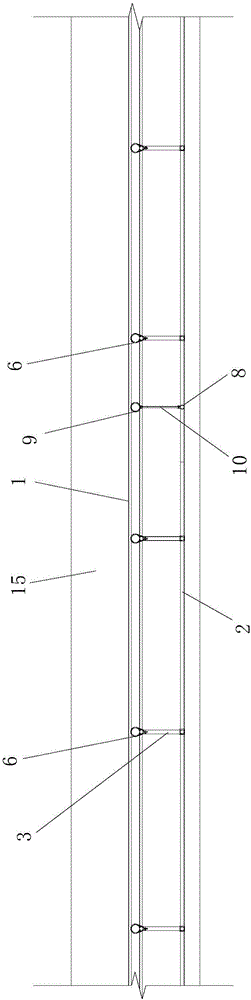

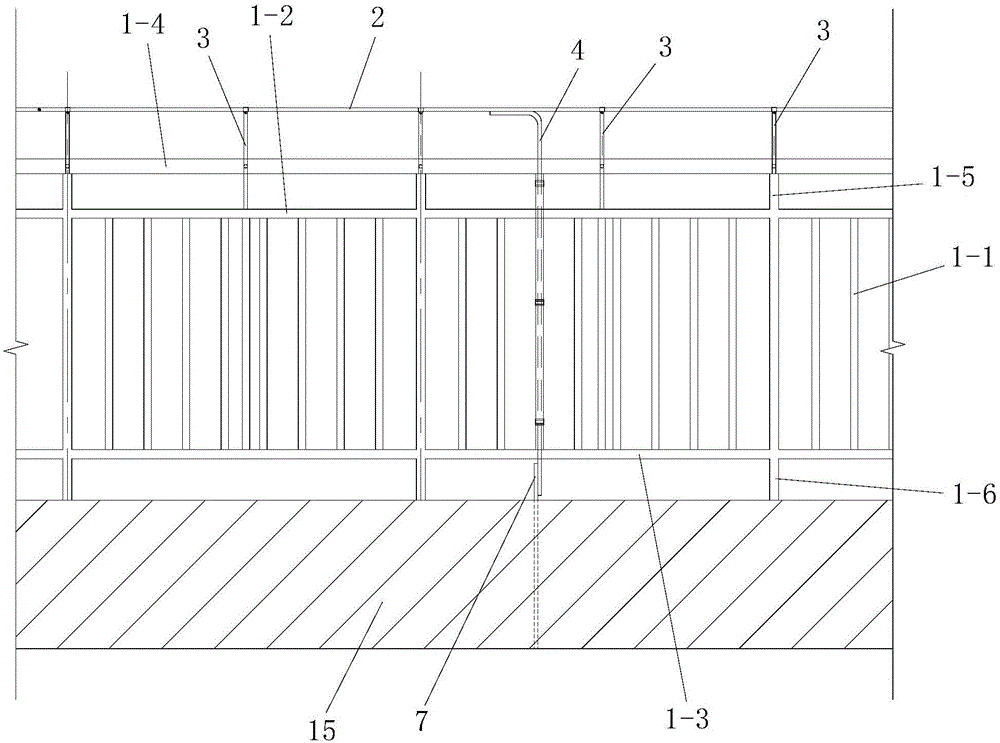

[0048] Step 1, installation of lightning protection belt support: install a plurality of lightning protection belt supports 3 on the upper outer side of the stainless steel railing 1 installed on the building roof, and the structures of a plurality of lightning protection belt brackets 3 are the same and it is arranged along the length direction of the stainless steel railing 1 by For layout from front to back, see figure 2 with diagram 2-1 ;

[0049] The stainless steel railing 1 is arranged vertically and includes a plurality of railing uprights 1-1 arranged vertically, and the plurality of railing uprights 1-1 are arranged from front to back along the length direction of the stainless steel railing 1 layout; such as Figure 5 As shown, the lightning protection belt bracket 3 is an attached...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com