Sheath injection type water-blocking factice filling equipment and production technology

A technology for water-blocking ointment and filling equipment, which is applied in the directions of light guides, optics, instruments, etc., can solve the problems of increasing equipment maintenance costs, adverse health effects, and large amount of ointment filling, and achieves good water-blocking effect. Stable product quality and low ointment consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

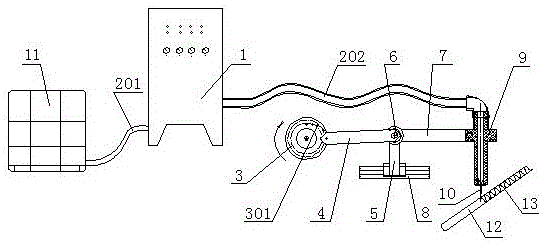

[0018] The present invention will be further described below in conjunction with the drawings as follows:

[0019] The sheathed injection type water-blocking ointment filling equipment is composed of an electrical control cabinet 1, an ointment barrel 11, an injection device and an operation control device. One side of the electrical control cabinet 1 is connected to the ointment barrel 11 through an ointment delivery pipe a201, and the electrical The other side of the control cabinet 1 is connected to the injection device through the ointment delivery pipe b202; one side of the injection device is equipped with an operation control device. The injection device is composed of an oil gun 9, an oil injection needle 10, and a fixed connecting arm 7. A through hole is made in the center of the oil gun 9, and the lower end of the through hole is equipped with an oil injection needle 10 through a fixing member; A shoulder is made on the upper part, and a fixed connecting arm 7 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com