Electric laundry rack

A drying rack and electric technology, applied in the field of drying racks, can solve problems such as easy failure, large space occupation, and inability to automatically limit positions, and achieve the effects of preventing mechanical failures, stable work, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

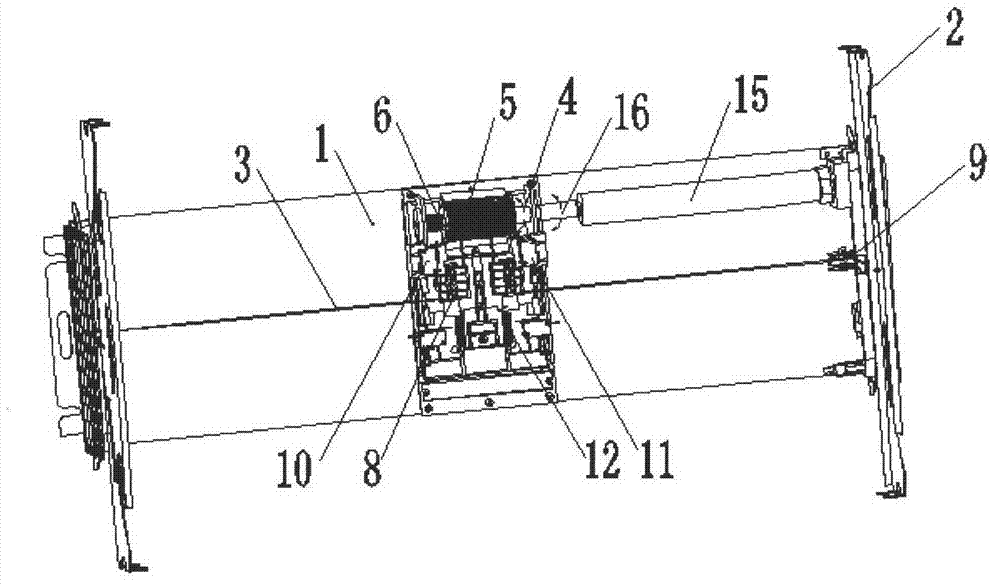

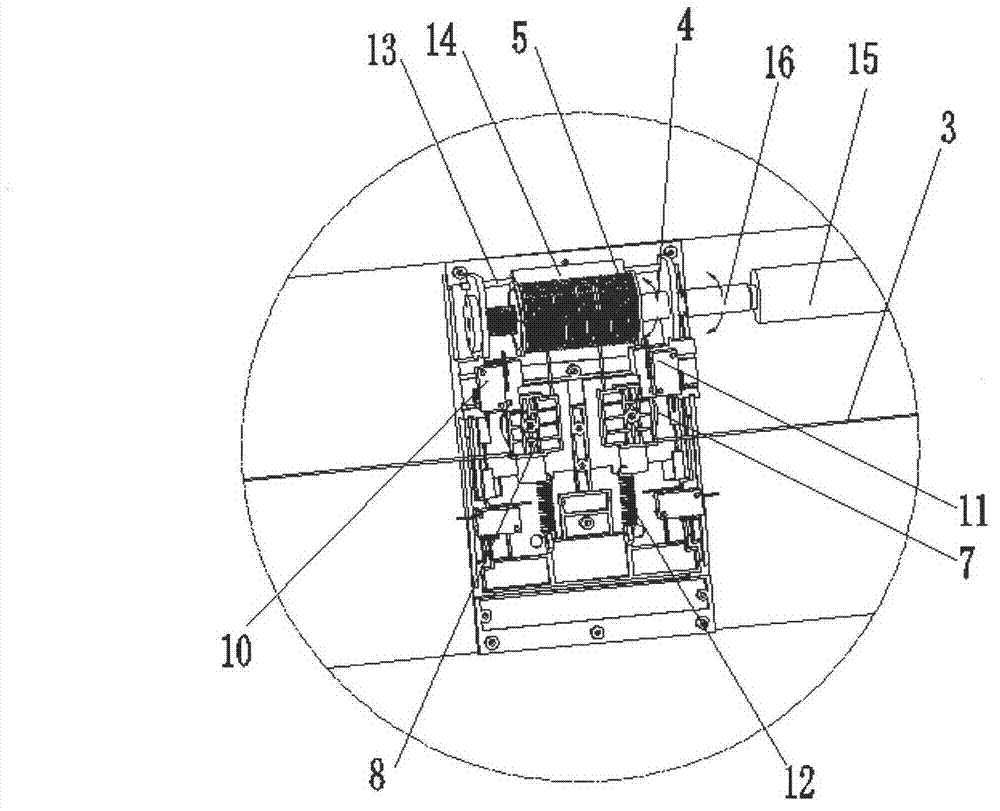

[0020] Such as figure 1 and figure 2 As shown, a kind of electric drying rack of the present invention, support 1, driving assembly, winding assembly, suspension bridge connecting rod assembly 2 and steel wire 3, driving assembly, winding assembly are arranged on the support, driving assembly and winding assembly drive connection , the suspension bridge link assembly 2 is arranged at both ends of the bracket 1; the winding assembly includes a rotating shaft 4, a winding wheel 5, a screw rod 6, a slider pulley 7, a sliding block 8 and a side wheel 9, the rotating shaft 4 is connected with the driving assembly, and the winding One end of wheel 5 is connected with rotating shaft 4, and the other end of winding wheel 5 is connected with screw rod 6, and slide block 8 is arranged on one side of winding wheel 5, and slide block pulley 7 is arranged in slide block 8, and edge wheel 9 is arranged on One side of the suspension bridge connecting rod assembly 2; one end of the steel wi...

Embodiment 2

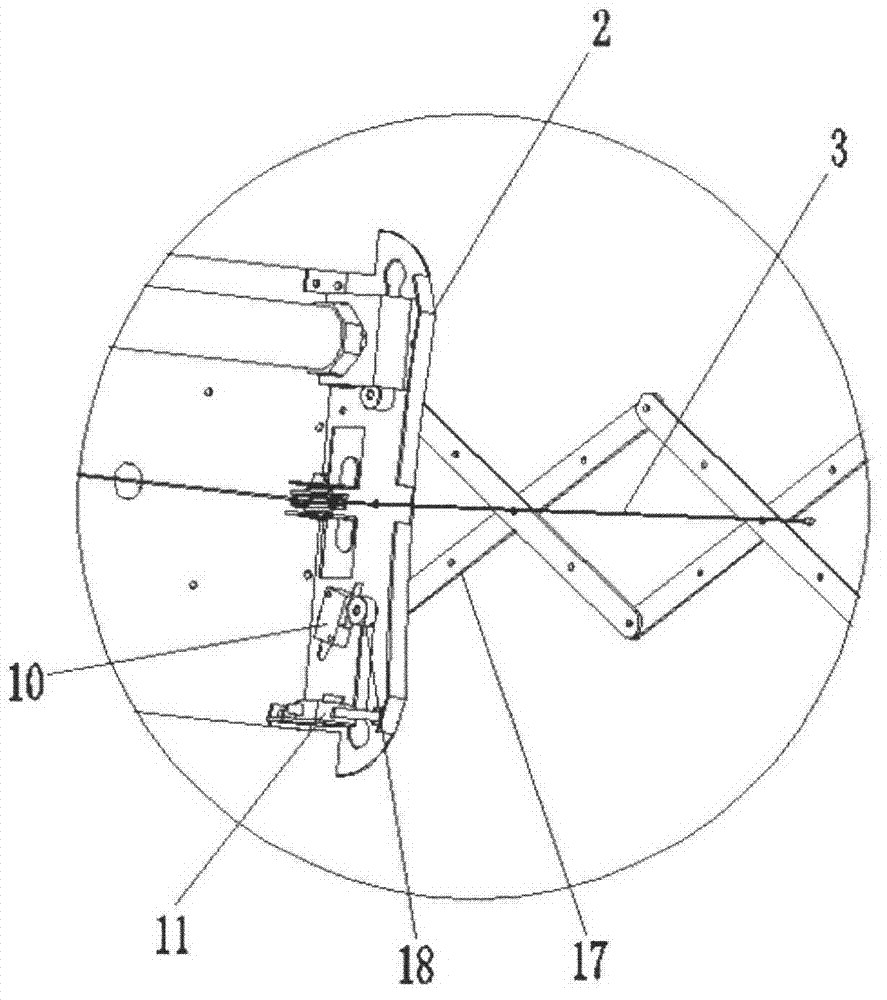

[0029] Such as image 3 and Figure 4 As shown, limit switches are also included, including an upper limit switch 10 and a lower limit switch 11. The limit switch is arranged at the connection between the bracket 1 and the suspension bridge link assembly 2, and the upper limit switch 10 is arranged below the lower limit switch 11.

[0030] When the steel wire 3 drives the suspension bridge connecting rod assembly 2 to move, the suspension bridge connecting rod assembly 2 drives the cross bracket 17 to expand and contract, and the end of the cross bracket 17 is provided with a pulley switch 18. When the cross bracket 17 is telescopic, the pulley switch 18 slides left and right in the guide groove. When touching the lower limit switch 11 on the suspension bridge link assembly 2, the cross bracket 17 stops stretching. When starting again, the cross bracket can only move upward.

[0031] When the cross bracket 17 rises to the highest point, the distance between the two adjacent c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com