A rotary oral endoscope

An intraoral, rotary technology, applied in the field of endoscopy, can solve the problems of inability to observe the oral cavity in a comprehensive and detailed manner, and inability to change the observation direction according to actual needs, and achieve the effect of convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

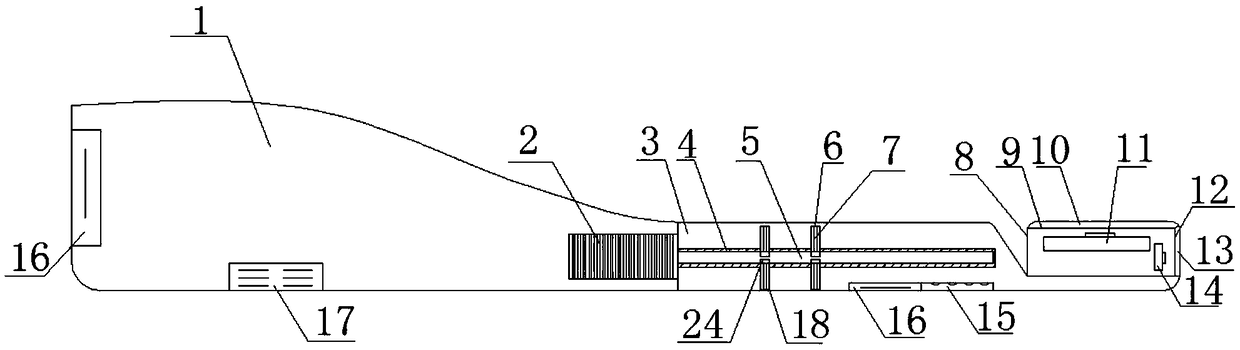

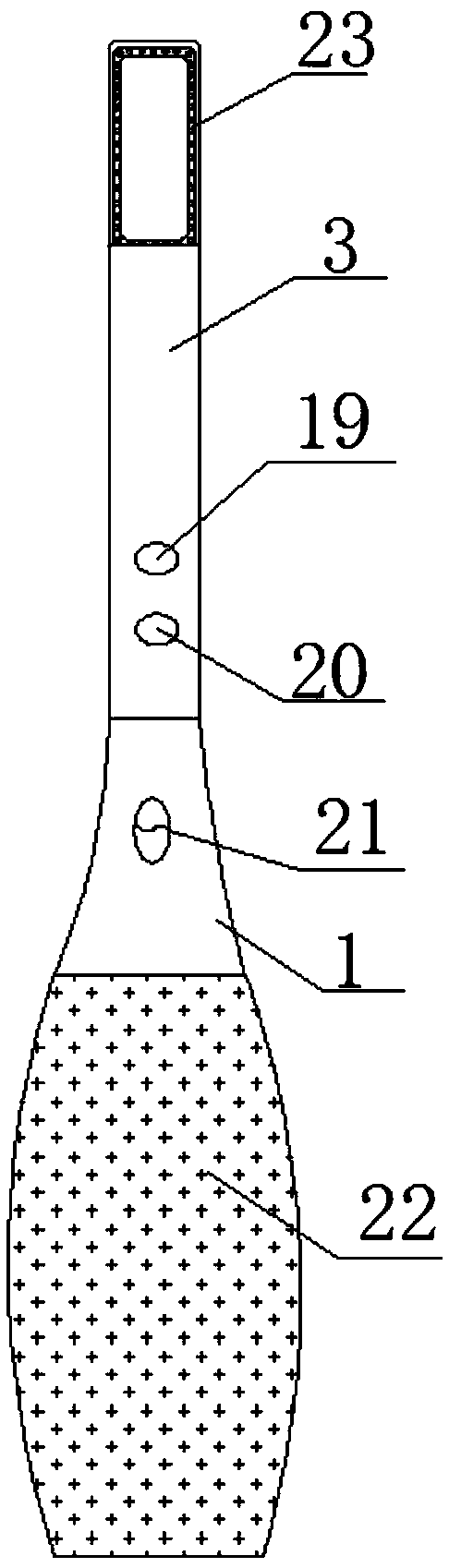

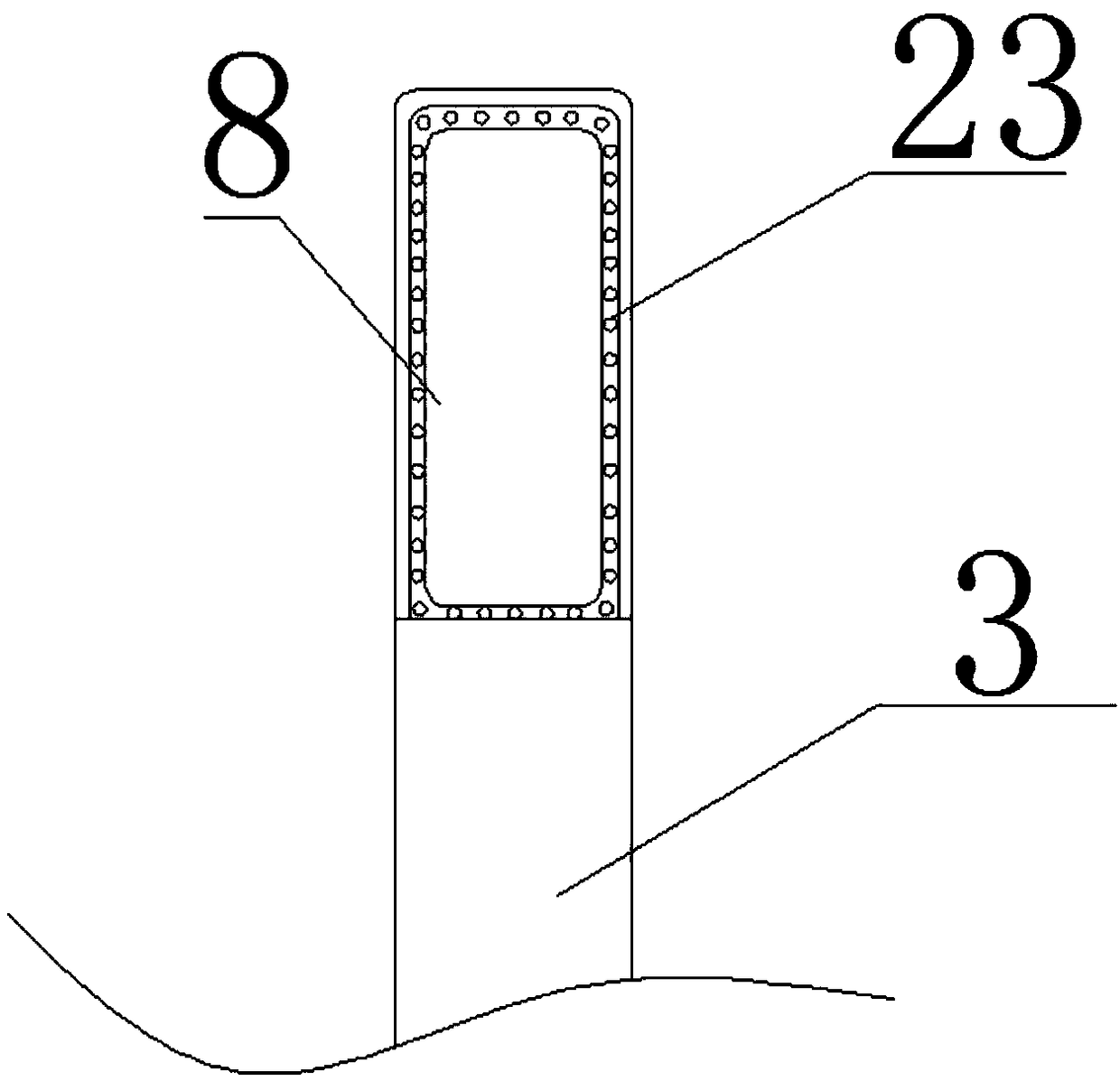

[0033] Such as figure 1 , figure 2 As shown, a rotary intraoral camera includes a handle 1 and a probe rod 3, which is characterized in that: a rotating shaft 5 is provided at the center of the top surface of the handle 1, and a rotating shaft 5 is provided at the center of the bottom surface of the probe rod 3. There is a rotating shaft groove 4 corresponding to the rotating shaft 5, the handle 1 and the probe rod 3 are detachably connected through the rotating shaft 5 and the rotating shaft groove 4, and the other end of the rotating shaft 5 extends through the top surface of the handle 1 to the handle 1 The interior is connected with the micro motor 2, and the upper end of the probe rod 3 is provided with a toothbrush head-shaped endoscope assembly 8 integrally formed with the probe rod 3, and the endoscope assembly 8 includes a plane mirror assembly 9 parallel to the probe rod 3 and A facade mirror assembly 12 perpendicular to the probe rod 3.

[0034] The working princ...

Embodiment 2

[0038] According to Example 1, such as figure 1 As shown, the plane mirror assembly 9 includes a plane eyepiece 10 and a plane camera 11 , and the elevation mirror assembly 12 includes an elevation eyepiece 13 and an elevation camera 14 . The arrangement of the plane mirror assembly 9 and the elevation mirror assembly 12 can observe and shoot the intraoral situation in different orientations simultaneously, which contributes to all-round observation.

Embodiment 3

[0040] According to Example 1, such as figure 1 As shown, the rotating shaft 5 is provided with several telescopic devices 18, the telescopic device 18 includes a telescopic slot 24 and a telescopic rod 7 fixed in the telescopic slot 24, and the telescopic device 18 in the shaft slot 4 and the rotating shaft 5 At corresponding positions, connecting grooves 6 are provided. The setting of the telescopic rod 7 can effectively prevent the handle 1 from slipping after the handle 1 is connected to the probe rod 3, and can play an auxiliary role in driving the rotation when the rotating shaft 5 drives the probe rod 3 to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com