Anti-liquid-dropping pressing bottle

An anti-drip and bottle body technology, applied in the field of packaging bottles, can solve the problems of dripping and poor effect of pressing the bottle, and achieve the effect of changing size and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

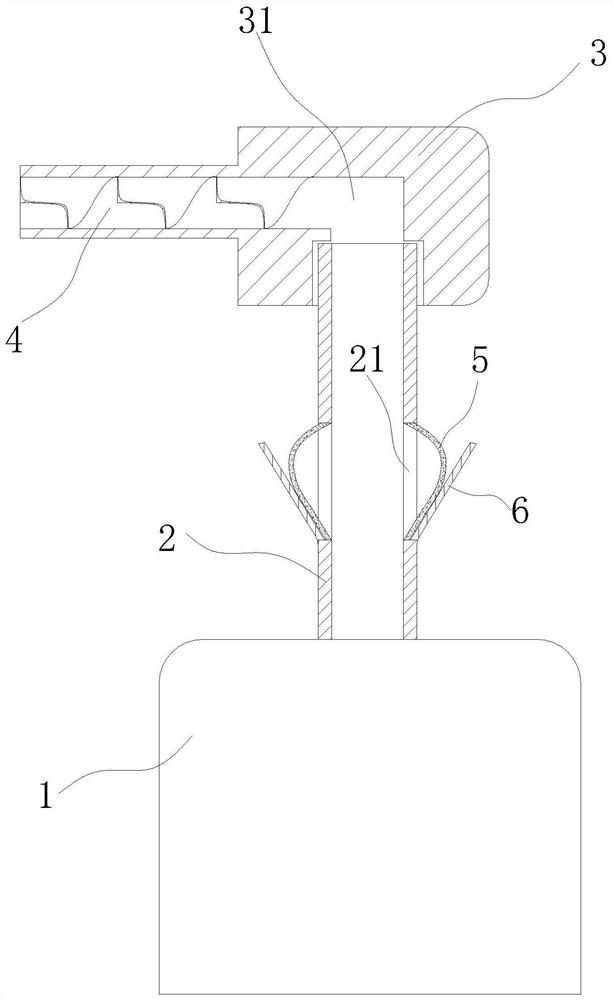

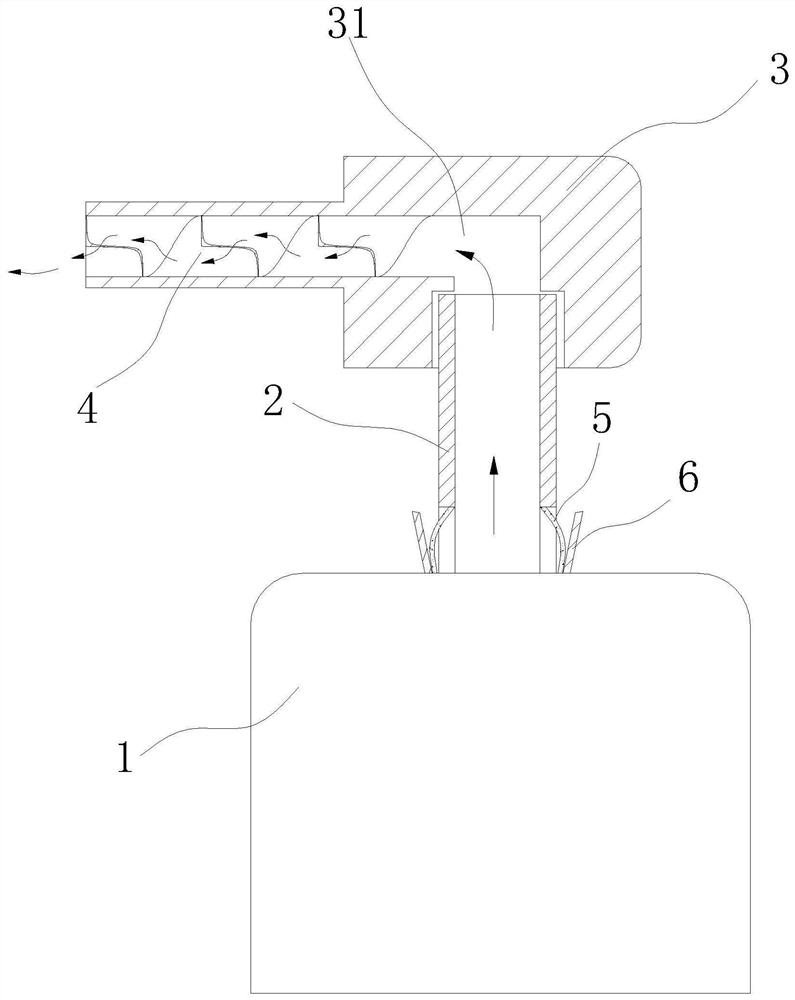

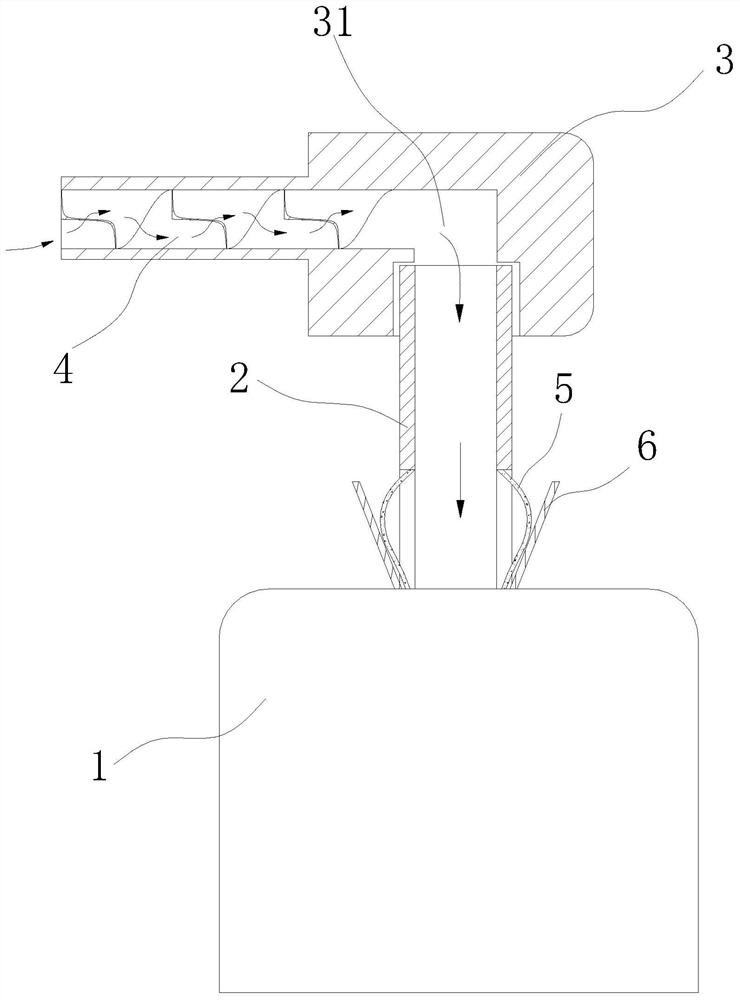

[0032] see Figure 1-3 The shown anti-drip press bottle is a kind of anti-drip press bottle that can effectively prevent dripping and is easy to operate. Specifically, an anti-drip pressing bottle includes a bottle body 1 , an upper liquid driving tube 2 , a pressing head 3 , a liquid outlet 4 , a capsule body 5 and a metal shrapnel 6 .

[0033] The bottle body 1 is provided with a pump body, and one end of the upper liquid driving tube 2 is fixedly connected with the pump body in the bottle body 1 , and the upper liquid driving tube 2 can move up and down along the joint at the upper end of the bottle body 1 .

[0034] There is an L-shaped tube 31 inside the pressing head 3, and the other end of the upper liquid driving tube 2 is detachably connected to one end of the L-shaped tube 31. The connection mode between the upper liquid driving tube 2 and the L-shaped tube 31 can be buckled or threaded. The other end of the L-shaped tube 31 is connected to the liquid outlet 4 . Th...

Embodiment 2

[0037] Embodiment 2: Another kind of anti-drip press bottle, such as Figure 4-6 As shown, the difference is that the liquid outlet part 4 is not an inner spiral tube, but a metal sheet 7 is hinged at the top of the liquid outlet of the liquid outlet part 4. When the pressing head 3 is pressed, the metal sheet 7 will rotate to the left. When the upper liquid drive tube 2 rebounds and rises, the metal sheet 7 will turn to the right, which will change the trajectory of the gas entering, so that the gas can better contact the liquid, so that the liquid can be sucked back better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com