Springback compensation device for spinning machine core mold

A springback compensation and movement technology, applied in the field of spinning forming equipment, can solve the problems of large final size and large size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

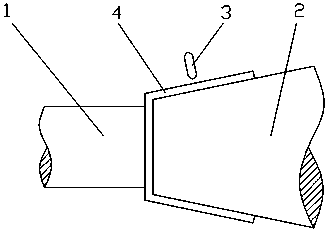

[0021] The structure of common spinning machine is as follows: figure 1 As shown, it includes ejector pin 1, mandrel 2 and rotary wheel 3. The ejector pin and mandrel clamp the billet 4 in the middle, and the three are rotated together with the main shaft of the bed, and the rotary wheel presses the billet to cause local plastic deformation. , under the joint action of the feed motion of the rotary wheel and the rotation motion of the blank, the local plastic deformation is gradually extended to the entire surface of the blank, and it is closely attached to the mandrel to complete the spinning process of the blank.

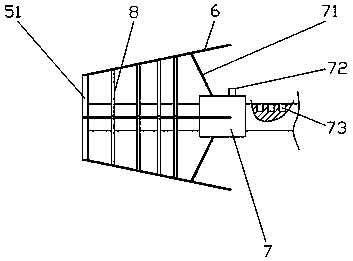

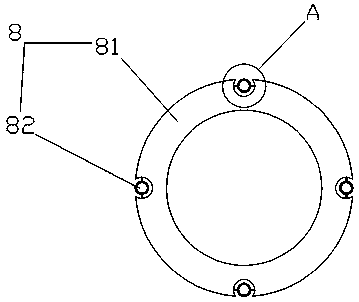

[0022] Such as Figure 2 to Figure 4 As shown in , a springback compensation device for spinning mandrel, including

[0023] The rotating shaft 5 and the skeleton, the end of the rotating shaft is provided with a working disk 51,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com